Fire retardant glass fiber reinforced nylon composite material, and preparation method thereof

A nylon composite material and glass fiber technology, applied in the field of glass fiber reinforced nylon composite material and its preparation, can solve the problems of corroded products, release of harmful substances, product performance degradation, etc. The effect of improving impact performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

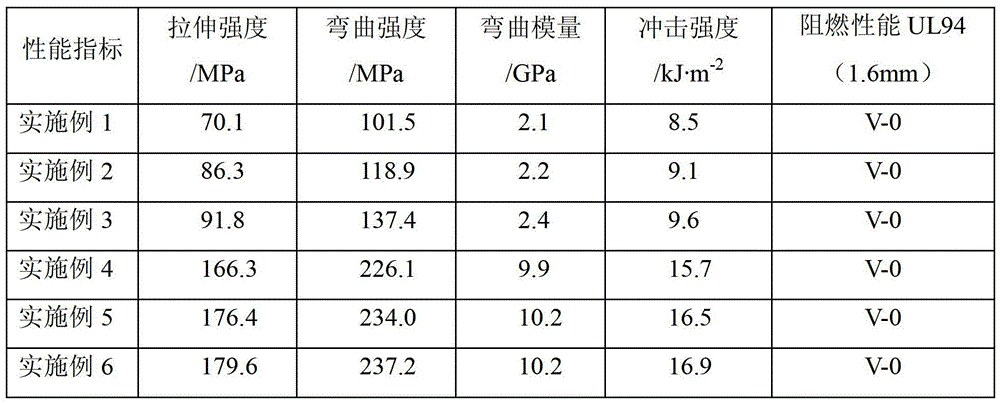

Examples

Embodiment 1

[0041] (1) First dry nylon 6 in an oven at 90°C for 10 hours, take 100 parts of dried nylon 6, 50 parts of flame retardant melamine polyphosphate (of which P 2 o 5 content of 38%, N content of 45%), 10 parts of char-forming agent thermoplastic phenolic resin, 0.1 part of antioxidant 1010 and 0.2 parts of lubricant silicone powder, mixed in a high-speed mixer for 3 minutes;

[0042] (2) Dissolve 0.2 parts of coupling agent 3-aminopropyltriethoxysilane (KH550) in absolute ethanol to prepare a coupling agent-ethanol solution with a concentration of 0.5%, and spray the solution by spraying method On 40 pieces of chopped glass fiber (length 3.0mm), and dry the glass fiber sprayed with coupling agent solution in an oven at 120°C for 30min;

[0043] (3) Send the mixture in (1) above into the twin-screw extruder through the upstream feeding port, and at the same time, feed 40 parts of glass fibers in the above (2) into the twin-screw extruder through the downstream feeding port for m...

Embodiment 2

[0046] (1) First dry nylon 6 in an oven at 100°C for 8 hours, take 100 parts of dried nylon 6, 46.2 parts of flame retardant melamine polyphosphate (of which P 2 o 5 content of 34%, N content of 40%), 13.4 parts of carbon forming agent pentaerythritol phosphate, 0.2 parts of antioxidant 168 and 0.4 parts of lubricant TAF (modified ethylene bis fatty acid amide, Suzhou Xingtai Photochemical Auxiliary Co., Ltd.) mixed in a high-speed mixer for 4 minutes;

[0047](2) Dissolve 0.4 parts of the coupling agent 3-glycidyl etheroxypropyltrimethoxysilane (KH560) in absolute ethanol to prepare a coupling agent-ethanol solution with a concentration of 1.0%, and spray the Spray the solution on 53.3 parts of chopped glass fiber (length 4.5mm), and dry the glass fiber sprayed with the coupling agent solution in an oven at 110°C for 45 minutes;

[0048] (3) Send the mixture in the above (1) into the twin-screw extruder through the upstream feeding port, and at the same time, send 53.3 part...

Embodiment 3

[0051] (1) First dry nylon 6 in an oven at 110°C for 6 hours, take 100 parts of dried nylon 6, 44.5 parts of flame retardant melamine polyphosphate (of which P 2 o 5 content is 33%, N content is 39%), 11.1 parts of carbon forming agent pentaerythritol, 0.25 parts of antioxidant 1076 and 0.6 parts of lubricant RH-313A (Dongguan Jianxing Plastic Products Co., Ltd.) are mixed in a high-speed mixer 5min;

[0052] (2) Dissolve 0.6 parts of coupling agent 3-(methacryloyloxy)propyltrimethoxysilane (KH570) in absolute ethanol to prepare a coupling agent-ethanol solution with a concentration of 1.25%, and use the spray method Spray the solution on 70.0 parts of chopped glass fibers (6.0 mm in length), and dry the glass fibers sprayed with the coupling agent solution in an oven at 100°C for 60 minutes;

[0053] (3) Send the mixture in the above (1) into the twin-screw extruder through the upstream feeding port, and at the same time, send 66.7 parts of glass fibers in the above (2) int...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com