Cyanate ester resin modified by phosphoric hybridization and preparation method of cyanate ester resin

A cyanate ester resin and cyanate ester technology, which is applied in the field of phosphorus-containing hybrid graphene oxide modified cyanate resin and its preparation, can solve the problem of modified CE resin with low phosphorus content and low dielectric constant of deviated CE resin , Dielectric constant and loss increase, to achieve the effect of low phosphorus content, excellent carbon forming ability, and outstanding heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

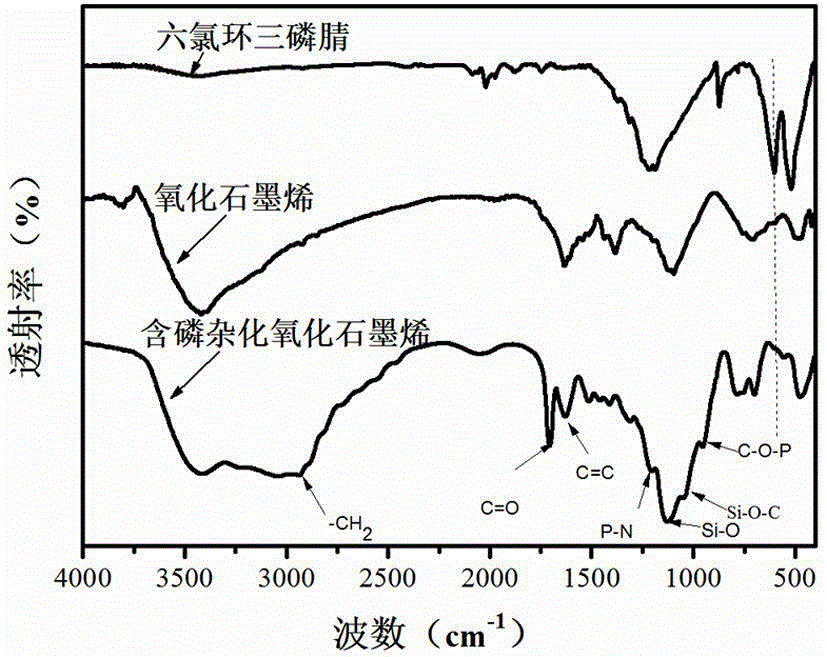

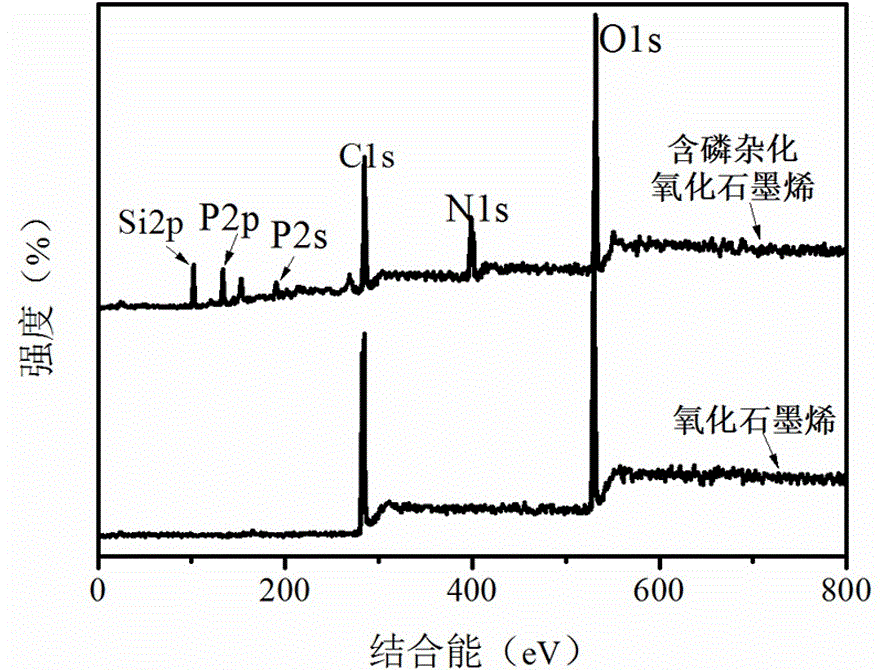

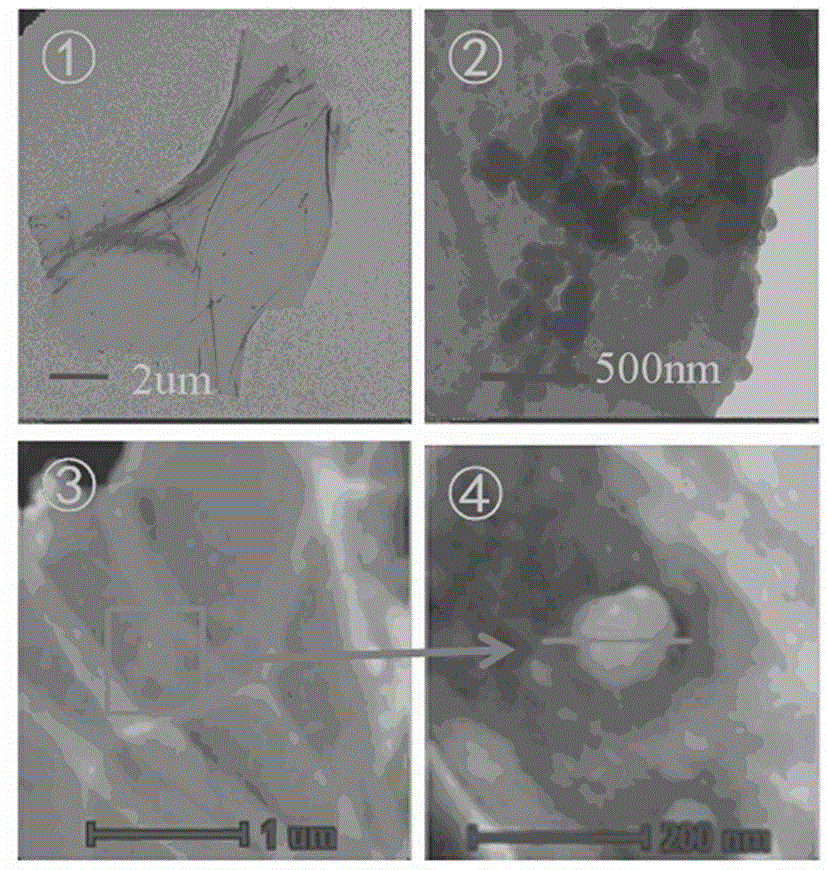

[0038] 1. Preparation of phosphorus-containing hybrid graphene oxide flame retardant

[0039] Add 0.1g of graphene oxide to 100g of tetrahydrofuran, and ultrasonically disperse for 1 hour to obtain a fully mixed system A; under the condition of nitrogen protection and stirring, add 5g of triethylamine to system A, and react at 0°C for 1 hour to obtain system B ; Dissolve 1g of phosphazene in 20g of tetrahydrofuran to obtain system C; add system C dropwise to system B, and react at 3°C for 2h; then raise the temperature to 60°C and react for 3h to obtain system D; 3.8g3 -Aminopropyltriethoxysilane was dissolved in 20g tetrahydrofuran to obtain system E; system E was added dropwise to system D, and reacted at 60°C for 3 hours to obtain system F; 0.4g water was added dropwise to In system F, react at 60°C for 3h; then react at 20°C for 10h. After the reaction, filter, wash with tetrahydrofuran and ethanol for 5 times, and dry in a vacuum oven at 60°C for 10 hours to obtain pho...

Embodiment 2

[0065] Add 0.25g of phosphorus-containing hybrid graphene oxide flame retardant prepared in Step 1 of Example 1 and 49.75g of 4,4'-dicyanato-diphenylpropane (bisphenol A cyanate) into the beaker , ultrasonically stirred at 85°C for 15min, and then mechanically stirred at 190°C for 6h to obtain a prepolymer; pour the prepolymer into a mold preheated at 190°C, and then defoam under vacuum at 190°C for 0.5h Put it in an oven, perform curing and post-treatment according to the processes of 200°C / 2h+220°C / 2h and 240°C / 4h, and naturally cool to room temperature to obtain a phosphorus-containing hybrid graphene oxide modified cyanate resin, which contains Phosphorus content is 0.055wt%, Tdi is 434.5℃, PHRR is 243.0kW / m 2 , the TTI is 85s, the LOI is 28.1, and the dielectric constant and loss at 1Hz are 3.6 and 0.007, respectively. Compared with CE resin, Tdi is slightly increased, PHRR is reduced by 20.5%, TTI is extended by 14s, and the dielectric properties are close to CE resin. ...

Embodiment 3

[0067] 1. Preparation of phosphorus-containing hybrid graphene oxide flame retardant

[0068] Add 0.1g of graphene oxide to 50g of tetrahydrofuran, and stir mechanically for 50 minutes to obtain a fully mixed system A; under argon protection and stirring conditions, add 1g of triethylamine to system A and react at 0°C for 0.5h to obtain System B; Dissolve 0.1g of phosphazene in 10g of tetrahydrofuran to obtain system C; add system C dropwise to system B and react at 4°C for 1h; then raise the temperature to 40°C and react for 2h to obtain system D; 2gγ -Aminopropyltrimethoxysilane was dissolved in 10g tetrahydrofuran to obtain system E; system E was added dropwise to system D, and reacted at 45°C for 2 hours to obtain system F; 0.4g water was added dropwise to In system F, react at 60°C for 2h; then react at 15°C for 10h. After the reaction, after filtering, washing with tetrahydrofuran and ethanol five times respectively, and drying in a vacuum oven at 60°C for 10 h, a phosp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal decomposition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com