Brushing method of functional environment-friendly paint

An environmentally friendly coating and functional technology, used in anti-corrosion coatings, polyester coatings, devices for coating liquids on surfaces, etc., it can solve the problems of cumbersome wall painting, rising labor costs, and no improvement, and achieve excellent thermal performance and size. Effects of stability, good compressive and anti-wear properties, excellent sealing properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

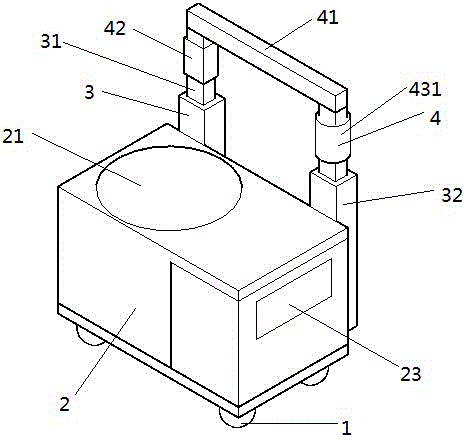

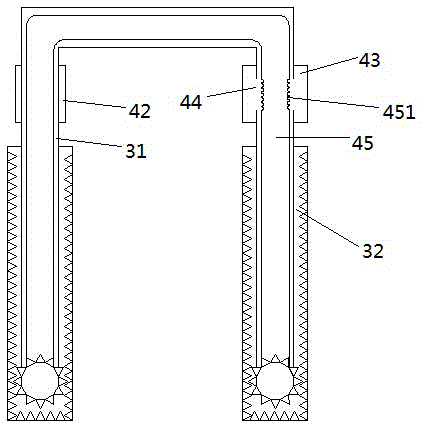

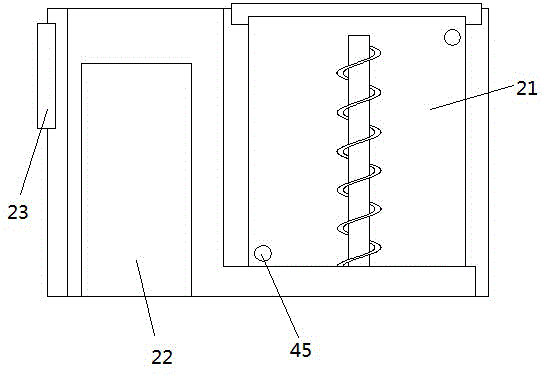

Image

Examples

Embodiment 1

[0078] Functional environment-friendly coating comprises the following component raw materials of weight part:

[0079] Glycerol: 10 parts, Pentaerythritol: 10 parts, Trimethylolpropane: 5 parts, Phthalic acid: 20 parts, Adipic acid: 3 parts, Trimellitic anhydride: 10 parts, Maleic acid: 15 parts , triethylamine: 4 parts, hydrogenated castor oil: 0.05 parts, hydroquinone: 0.05 parts, butyl glycol ether: 3 parts, styrene: 8 parts, calcium carbonate: 10 parts, titanium dioxide: 5 parts, Defoamer: 0.03 part, leveling agent: 0.01 part, dipyridyl compound: 0.5 part; 3 parts of the first solid additive; 6 parts of the second solid additive;

[0080] Add 6 parts of the first composite regulator composed of trioctylmethylammonium bromide, glycerin and polytetrafluoroethylene in a mass ratio of 1:3:2 in sequence;

[0081] 11 parts of the second composite regulator composed of diphenylamine, 2,6-di-tert-butyl and benzotriazole in a mass ratio of 1:2:3;

[0082] Sulfurized cottonseed o...

Embodiment 2

[0094] Functional environment-friendly coating comprises the following component raw materials of weight part:

[0095] Glycerol: 100 parts, Pentaerythritol: 100 parts, Trimethylolpropane: 80 parts, Phthalic acid: 200 parts, Adipic acid: 60 parts, Trimellitic anhydride: 80 parts, Maleic acid: 150 parts , triethylamine: 60 parts, hydrogenated castor oil: 2 parts, methyl hydroquinone: 2 parts, n-butanol: 70 parts, styrene: 95 parts, talcum powder: 200 parts, phthalocyanine green: 30 parts, disinfectant Foaming agent: 3 parts, leveling agent: 2 parts, novel polymeric catalyst: 6 parts; 7 parts of the first solid additive; 1.5 parts of the second solid additive;

[0096] Add 9 parts of the first composite regulator composed of trioctylmethylammonium bromide, glycerol and polytetrafluoroethylene in a mass ratio of 1: 4: 1 in sequence;

[0097] 7 parts of the second composite regulator composed of diphenylamine, 2,6-di-tert-butyl and benzotriazole in a mass ratio of 1:4:1;

[0098...

Embodiment 3

[0110] Functional environment-friendly coating comprises the following component raw materials of weight part:

[0111] Glycerol: 50 parts, Pentaerythritol: 50 parts, Trimethylolpropane: 40 parts, Phthalic acid: 100 parts, Adipic acid: 30 parts, Trimellitic anhydride: 30 parts, Maleic acid: 70 parts , triethylamine: 24 parts, hydrogenated castor oil: 1.1 parts, hydroquinone: 1.2 parts, propylene glycol methyl ether: 35 parts, styrene: 45 parts, calcium carbonate: 100 parts, phthalocyanine green: 30 parts, defoamer : 1.8 parts, leveling agent: 0.98 parts, dipyridyl compound: 4 parts; 4 parts of the first solid additive; 5 parts of the second solid additive;

[0112] Add 7 parts of the first composite regulator composed of trioctylmethylammonium bromide, glycerin and polytetrafluoroethylene in a mass ratio of 1:3:1 in sequence;

[0113] 9 parts of the second composite regulator composed of diphenylamine, 2,6-di-tert-butyl and benzotriazole in a mass ratio of 1:3:2;

[0114] Vu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com