High-performance flame-retardant PLA (polylactic acid)/graphene nano-sheet composite material and preparation method thereof

A technology of graphene nanosheets and composite materials, applied in the field of high-performance flame-retardant PLA/graphene nanosheet composite materials and their preparation, to achieve good compatibility

Inactive Publication Date: 2014-05-07

JIANGSU YUEDA NEW MATERIALS TECH

View PDF4 Cites 18 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, the PLA material itself is brittle, has no flame retardancy and poor heat resistance, which greatly limits its application

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

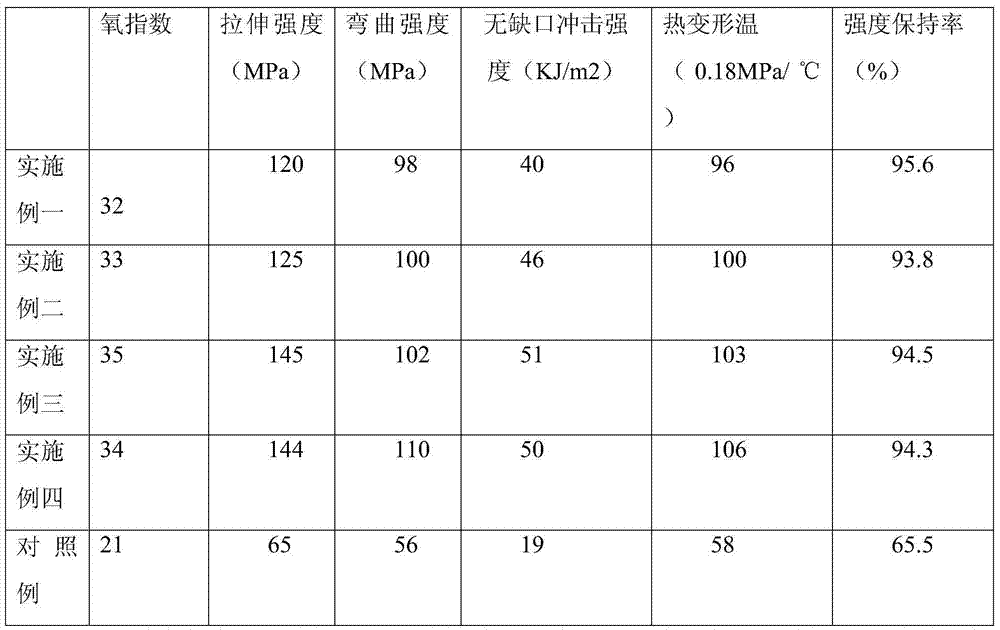

Effect test

Embodiment 1

[0022] Example 2:

Embodiment 2

[0024] Example 3:

Embodiment 3

[0026] Example 4:

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Login to View More

Abstract

The invention discloses a method for preparing a high-performance flame-retardant PLA (polylactic acid) / graphene nano-sheet composite material. The composite material comprises the following components in parts by weight: 30-100 parts of PLA, 10-30 parts of flame retardant, 5-10 parts of a flame retardant synergist, 1-5 parts of a nucleation accelerant, 2-6 parts of a flexibilizer, 1-6 parts of a graphene nano-sheet, 5-15 parts of carbon fibers, 10-20 parts of glass fiber, and 5-25 parts of talc powder. According to the preparation method, the mechanical performance of PLC can be improved by adopting the graphene nano-sheet which is subjected to surface treatment by a silane coupling agent. The composite material has the advantages that the compatibility of the graphene nano-sheet and PLA can be improved, the graphene nano-sheet can be well dispersed in matrix resin to play the effect of synergetic flame retardance.

Description

technical field [0001] The invention relates to a PLA / graphene nanosheet composite material, in particular to a high-performance flame-retardant PLA / graphene nanosheet composite material and a preparation method thereof. Background technique [0002] PLA (polylactic acid) is a thermoplastic aliphatic polyester. The lactic acid and lactide required for the production of polylactic acid can be fermented, dehydrated, and purified from renewable resources. The obtained polylactic acid generally has good mechanical and processing properties. performance, while polylactic acid products can be quickly degraded in various ways after being discarded, and it is a kind of green plastic with good performance. However, the PLA material itself is brittle, has no flame retardancy and poor heat resistance, which greatly limits its application. [0003] Graphene nanosheets, referred to as GNSs (Graphene nanosheets) or GNFs (Graphene Nano Flakes), also known as carbon nanosheets CNFs (Carbo...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C08L67/04C08K13/06C08K9/06C08K3/04C08K7/06C08K7/14C08K3/34C08K3/32C08K5/3492B29B9/06B29C47/92B29C48/92

CPCB29B7/46B29B7/72B29B7/7461B29B7/90B29B9/06B29B9/14B29B2009/125B29C48/04B29C48/40B29C48/911B29C48/92B29C2948/92552B29C2948/92704B29C2948/92885C08K3/042C08K5/0066C08K7/06C08K7/14C08L67/04C08L77/00C09K21/00

Inventor 虞小波杨玉晴蔡铜祥

Owner JIANGSU YUEDA NEW MATERIALS TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com