Silicon rubber cable joint

A cable joint and silicone rubber technology, applied in the field of silicone rubber cable joints, can solve the problems of easy foaming, delamination and tear resistance, easy aging of cable joints, etc., and achieve the effects of excellent electrical performance, high strength and effective insulation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

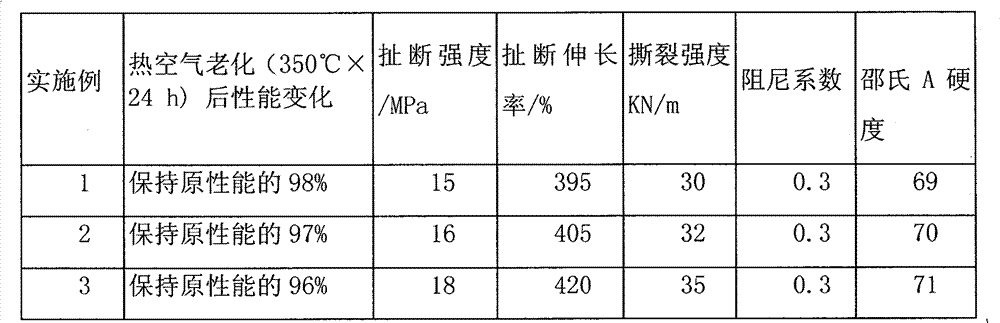

Examples

Embodiment 1

[0021] Example 1, unit: g.

[0022] Vinyl silicone rubber 35 parts,

[0023] 25 parts of white carbon black,

[0024] 26 parts of acetylene carbon black,

[0025] Antiaging agent 4010NA 1.5 parts,

[0026] Accelerator TMTD 0.3 part,

[0027] 3 parts of benzoyl peroxide,

[0028] 2.4 parts of magnesium oxide,

[0029] 1.4 parts of stearic acid,

[0030] 3.5 parts of antimony trioxide,

[0031] Rosin 1.5 parts.

Embodiment 2

[0032] Embodiment 2, unit: g.

[0033] Vinyl silicone rubber 40 parts,

[0034] 28 parts of white carbon black,

[0035] 31 parts of acetylene carbon black,

[0036] Antiaging agent 4010NA 1.5 parts,

[0037] Accelerator TETD 0.3 parts,

[0038] 3 parts of benzoyl peroxide,

[0039] 2.4 parts of magnesium oxide,

[0040] 1.4 parts of stearic acid,

[0041] 5 parts of antimony trioxide,

[0042] Rosin 2.4 parts,

[0043] 2 parts of Kemlok adhesive.

Embodiment 3

[0044] Embodiment 3, unit: g.

[0045] Vinyl silicone rubber 37.5 parts,

[0046] 26.5 parts of white carbon black,

[0047] Acetylene carbon black 28.5 parts,

[0048] Antiaging agent 4010NA 1.5 parts,

[0049] Accelerator TMTM 0.3 part,

[0050] 3 parts of benzoyl peroxide,

[0051] 2.4 parts of magnesium oxide,

[0052] 1.4 parts of stearic acid,

[0053] 4.25 parts of antimony trioxide,

[0054] Rosin 1.9 parts,

[0055] 2.4 parts of ferric oxide.

[0056] The manufacture method of a kind of silicone rubber cable joint of the present invention is as follows:

[0057] 1. First mix the above-mentioned raw materials according to the specified weight parts, and put them into the open mixer in order for mixing. The mixed rubber is parked at room temperature for 1 day, and then re-mixed and released;

[0058] 2. Forming: the film is pasted with adhesive film on the forming machine, and then transferred into the mold. In order to prevent mold sticking, polytetrafluoroe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength at break | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com