Novel flame-retardant door and window profile and preparation method thereof

A door and window profile, a new technology, applied in the field of doors and windows, can solve the problems of poor flame retardancy, achieve excellent halogen-free flame retardancy, broad application prospects, and good mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

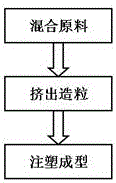

[0016] figure 1 It is a process step chart of the preparation method of the new flame-retardant door and window profile in the embodiment of the present invention; the raw material components contained in the door and window profile include polycarbonate, ABS resin, MBS resin, composite flame retardant, and composite auxiliary agent. The preparation method The method includes the following steps: a) mixing raw materials, b) extrusion granulation, and c) injection molding.

[0017] The new flame-retardant door and window profiles mentioned in the present invention use polycarbonate / ABS resin composite plastic as the base material, and are prepared by adding composite flame retardant, compatibilizing and toughening agent and composite auxiliary agent, and adopting the method of melt blending and extrusion. become. Among them, the composite flame retardant is composed of bisphenol A bis(diphenyl phosphate) and potassium perfluorobutane sulfonate at a mass ratio of 120:1; the com...

Embodiment 1

[0019] The specific preparation method is as follows:

[0020] a) Mix raw materials, first weigh 78% polycarbonate, 10% ABS resin, 3% MBS resin, 8% composite flame retardant, 1% composite auxiliary agent by weight percentage; then put the above raw materials into Put it into a high-speed stirring container and mix evenly, wherein, the stirring speed is 500r / min, and the stirring time is 10min.

[0021] b) Extrusion granulation, put the mixed material prepared in step a) into a twin-screw extruder, and melt and extrude according to the extruder process conditions to obtain pellets; wherein, the extruder process conditions are: extruder The rotation speed is 40r / min, and the temperature of each section of the extruder is 200°C, 210°C, 220°C, and 210°C from the feed port to the die head.

[0022] c) Injection molding, first preheat the pellets prepared in step b) at 80°C for 2 hours, and then use the injection molding machine to inject the pellets according to the injection mold...

Embodiment 2

[0024] The specific preparation method is as follows:

[0025] a) Mix raw materials, first weigh 85% polycarbonate, 3% ABS resin, 3% MBS resin, 8% composite flame retardant, 1% composite auxiliary agent by weight percentage; then put the above raw materials into Put it into a high-speed stirring container and mix evenly, wherein, the stirring speed is 500r / min, and the stirring time is 10min.

[0026] b) Extrusion granulation, put the mixed material prepared in step a) into a twin-screw extruder, and melt and extrude according to the extruder process conditions to obtain pellets; wherein, the extruder process conditions are: extruder The rotation speed is 40r / min, and the temperature of each section of the extruder is 200°C, 210°C, 220°C, and 210°C from the feed port to the die head.

[0027] c) Injection molding, first preheat the pellets prepared in step b) at 80°C for 2 hours, and then use the injection molding machine to inject the pellets according to the injection moldi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com