Flame-retarding type resin prepolymer, resin composition using same, prepreg and laminated board

A flame-retardant resin and prepreg technology, which is applied in the fields of flame-retardant resin prepolymers and resin compositions prepared using them, prepregs and laminates, and can solve the problem of affecting the heat resistance of the board, reducing the glass transition temperature of the resin, Heat resistance modulus retention rate, affecting the bonding force between the board and copper foil, etc., to achieve the effects of modulus retention rate at high temperature, excellent halogen-free flame retardancy, and high glass transition temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Synthetic example 1

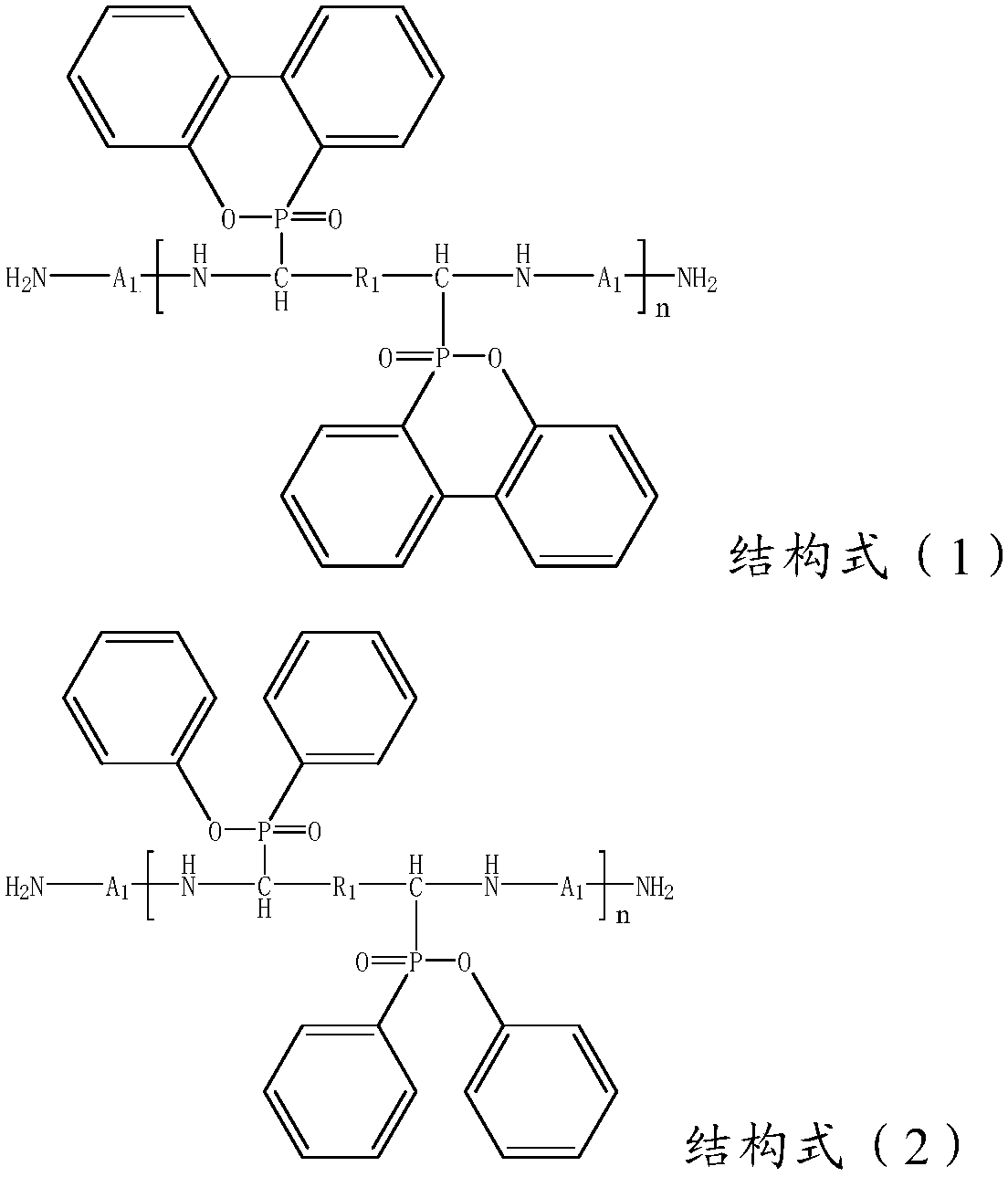

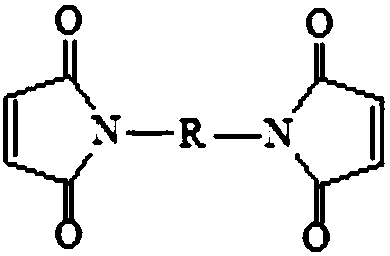

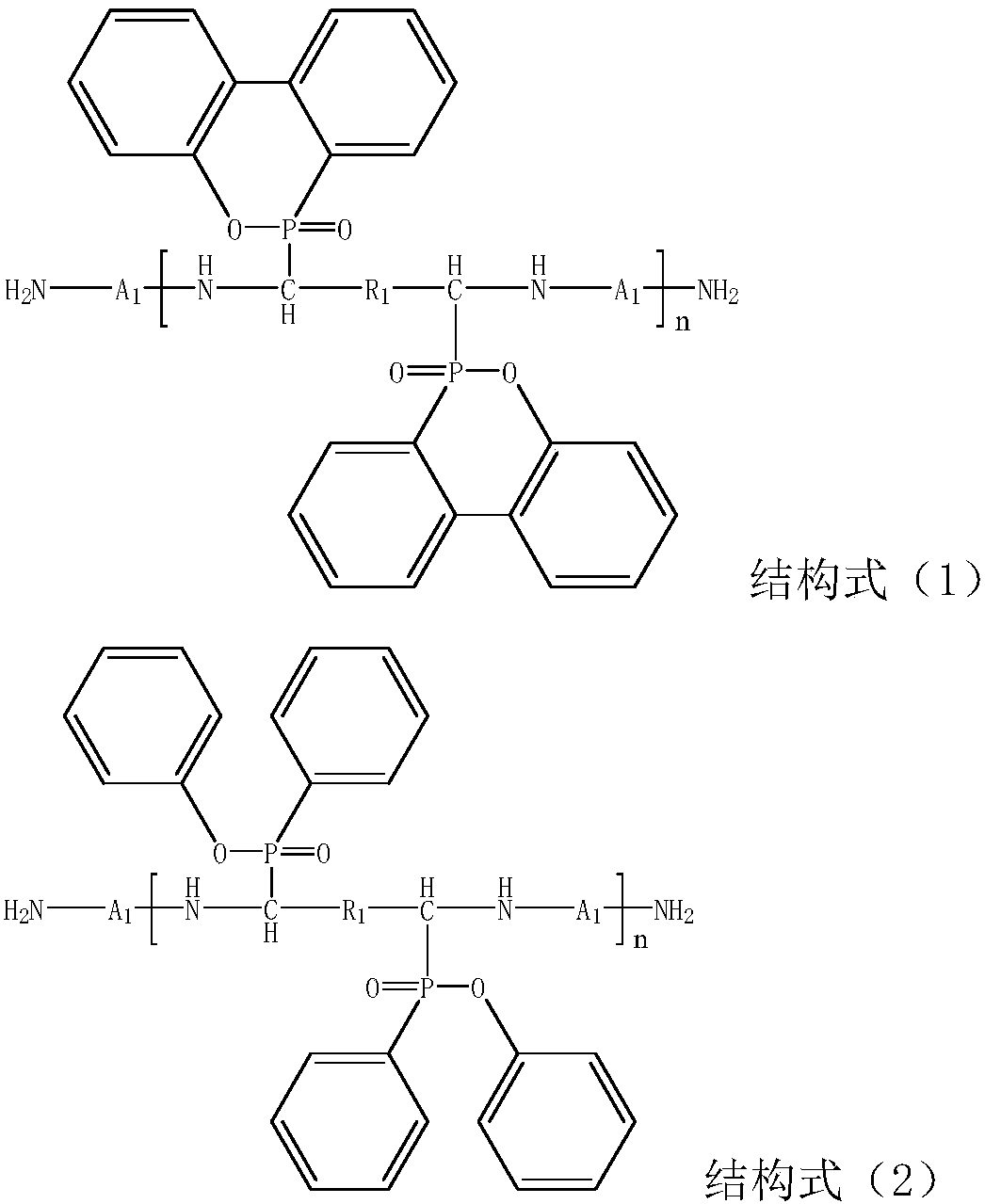

[0073] Add 100g solvent N,N-dimethylformamide into a 500mL three-necked flask, and 4,4'-diphenylmethane bismaleimide, DOPO-containing diamine compound A-1 (straight-chain base type) and diaminodiphenylmethane, according to the mass parts 100g:20g:20g were put into a three-necked flask in sequence, and kept stirring under the condition of an oil bath at 90°C. After the solid in the flask was completely dissolved, the timing was started, and after continuous stirring for 2.5hr, the The resulting product was distilled to obtain a modified bismaleimide prepolymer 1 with a solid content of 75%.

Synthetic example 2

[0075] Add 100g of solvent N,N-dimethylformamide into a 500mL three-necked flask to mix 4,4'-diphenylmethane bismaleimide, DOPO-containing diamine compound A-2 (aromatic group type) and diaminodiphenylmethane, according to the mass parts 100g: 20g: 15g were put into a three-necked flask in turn, and kept stirring under the condition of an oil bath at 90°C. After the solid in the flask was completely dissolved, the timing was started, and after 2.5 hours of continuous stirring, the The resulting product was distilled to obtain a modified bismaleimide prepolymer 2 with a solid content of 75%.

Synthetic example 3

[0077] Add 100g solvent N,N-dimethylformamide into a 500mL three-necked flask, and 4,4'-diphenylmethane bismaleimide, DPPO-containing diamine compound A-3 (straight-chain base type) and diaminodiphenyl sulfone, according to the mass parts 100g:30g:20g, put them into a three-necked flask in turn, and continue to stir under the condition of an oil bath at 90°C. After the solid in the flask is completely dissolved, start timing, and after continuing to stir for 2.5hr, put The resulting product was distilled to obtain a modified bismaleimide prepolymer 3 with a solid content of 75%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com