Nano carbon dioxide-phenolic resin composite foam material and preparation method thereof

A technology of nano-silica and phenolic resin, which is applied in the field of composite foam materials and preparation, can solve the problems of mechanical properties, compressive and bending resistance, unsatisfactory slag drop, high application cost, easy slag drop and damage, etc. Achieve the effects of improving mechanical properties and thermal stability, high mechanical properties and thermal stability, and simple preparation methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

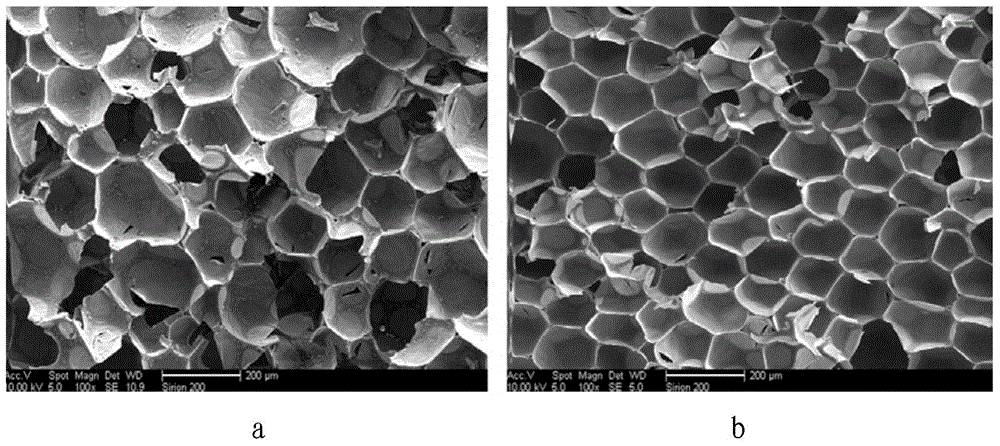

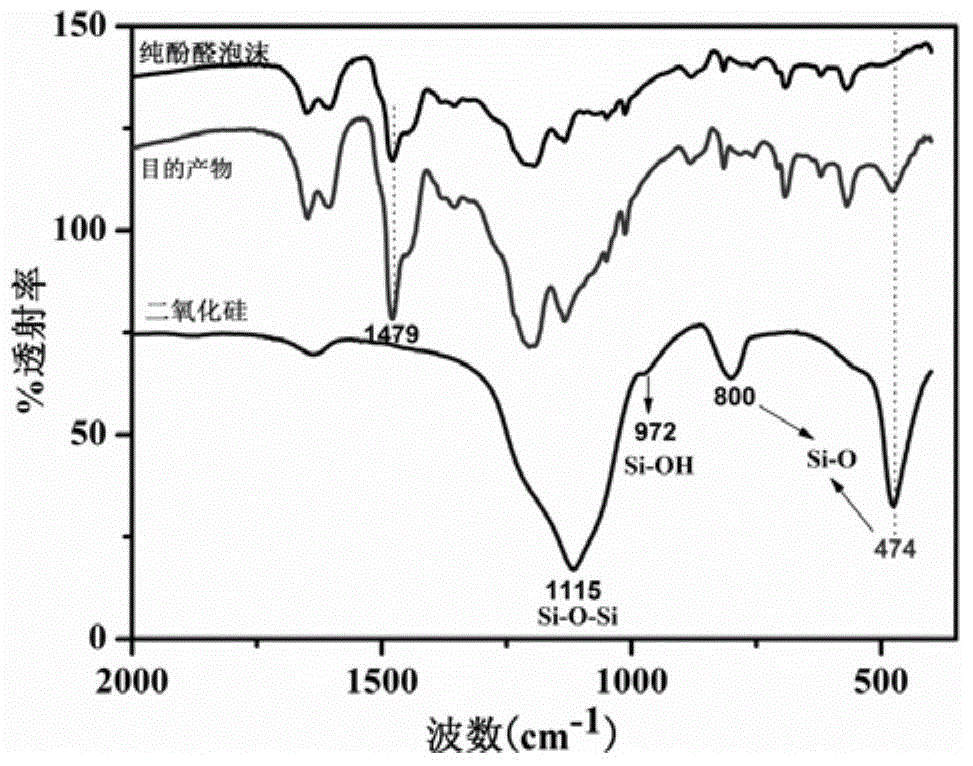

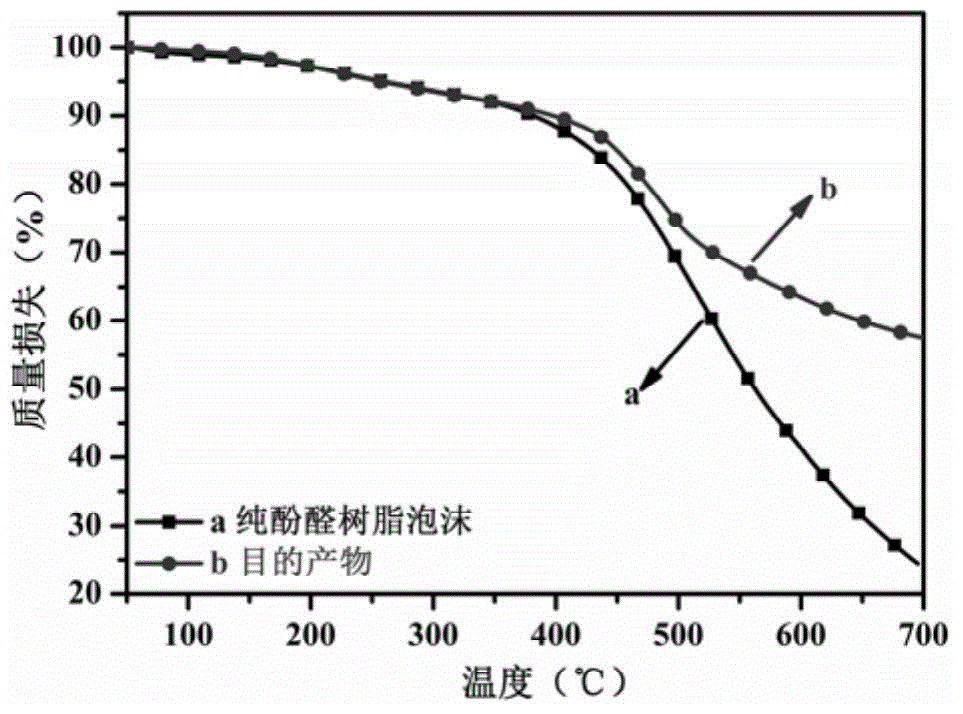

Embodiment 1

[0046] The specific steps of preparation are:

[0047] Step 1. First, the SiO with a weight percentage of 20wt% and a particle size of 10nm 2 The sol is ultrasonically dispersed into the formaldehyde solution (or the mixed solution of the formaldehyde solution and the paraformaldehyde) in a weight ratio of 1:3 to obtain a mixed solution. After mixing the mixed solution, phenol, and alkaline solution with a concentration of 15% by weight, they are placed for polymerization reaction at 70°C for 4.5 hours; among them, the formaldehyde solution (or the mixed solution of formaldehyde solution and paraformaldehyde) in the mixed solution, phenol and The weight ratio of the alkaline solution is 1.3:1:0.7, and the alkaline solution is a sodium hydroxide solution to obtain a resol phenolic resin in which silica nanoparticles are uniformly dispersed.

[0048] Step 2. Perform acid neutralization and vacuum distillation treatment on the resole phenolic resin in which silica nanoparticles are un...

Embodiment 2

[0051] The specific steps of preparation are:

[0052] Step 1. First, the SiO with a weight percentage of 25wt% and a particle size of 20nm 2 The sol is ultrasonically dispersed into the formaldehyde solution (or the mixed solution of the formaldehyde solution and the paraformaldehyde) in a weight ratio of 1:3.5 to obtain a mixed solution. After mixing the mixed solution, phenol and an alkaline solution with a concentration of 18% by weight, they were placed for polymerization at 75°C for 4.3 hours; among them, the formaldehyde solution (or the mixed solution of formaldehyde solution and paraformaldehyde), phenol and The weight ratio of the alkaline solution is 1.4:1:0.6, and the alkaline solution is a sodium hydroxide solution to obtain a resole phenolic resin in which silica nanoparticles are uniformly dispersed.

[0053] Step 2. Perform acid neutralization and vacuum distillation treatment on the resole phenolic resin in which silica nanoparticles are uniformly dispersed under s...

Embodiment 3

[0056] The specific steps of preparation are:

[0057] Step 1. Firstly, SiO with a weight percentage of 30wt% and a particle size of 30nm 2 The sol is ultrasonically dispersed into a formaldehyde solution (or a mixed solution of formaldehyde solution and paraformaldehyde) in a weight ratio of 1:4 to obtain a mixed solution. Then mix the mixed solution, phenol and alkaline solution with a concentration of 20wt%, and place them at 80°C for 4h polymerization reaction; among them, the formaldehyde solution (or the mixed solution of formaldehyde solution and paraformaldehyde), phenol and alkali in the mixed solution The weight ratio of the aqueous solution is 1.5:1:0.5, and the alkaline solution is a sodium hydroxide solution to obtain a resole phenolic resin in which silica nanoparticles are uniformly dispersed.

[0058] Step 2. Perform acid neutralization and vacuum distillation treatment on the resole phenolic resin in which silica nanoparticles are uniformly dispersed under stirring...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com