Resin compound, prepreg and laminated board prepared from resin compound

A technology of resin composition and prepreg, applied in the direction of synthetic resin layered products, chemical instruments and methods, layered products, etc., can solve the problem of reducing resin glass transition temperature, heat resistance modulus retention rate, and affecting the final cured product Heat resistance, heat and humidity resistance and water absorption, difficulty in obtaining high-performance sheets with comprehensive properties, etc., to achieve excellent high-temperature modulus, low thermal expansion coefficient, and the effect of relieving stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Synthetic example 1

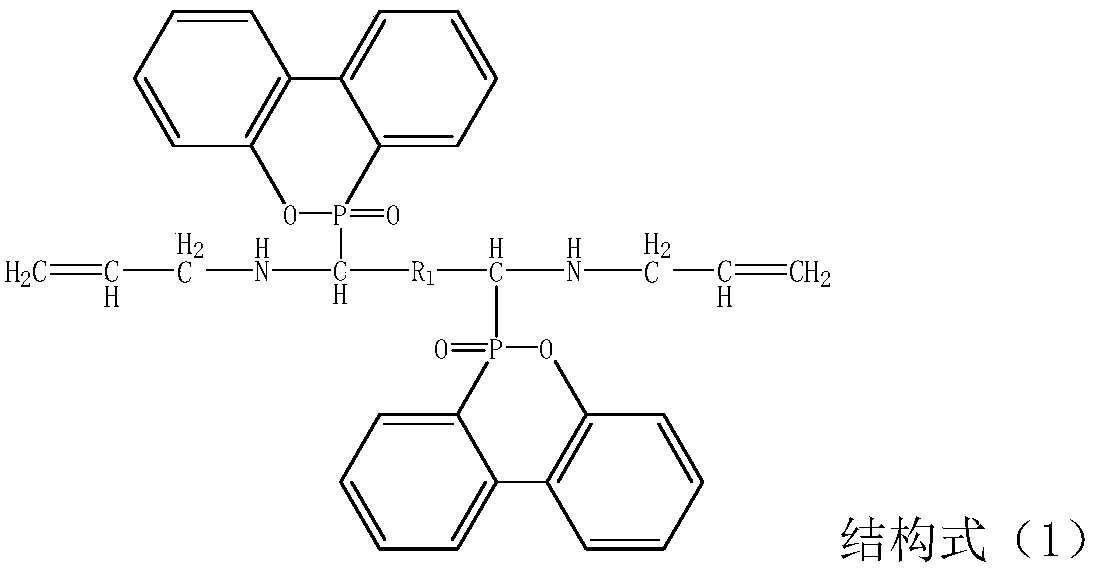

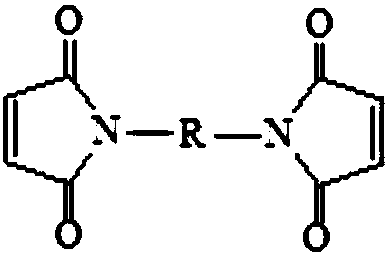

[0104] Add 100 parts of solvent N,N-dimethylformamide into a 500mL three-necked flask, and combine 4,4'-diphenylmethane bismaleimide with DOPO-containing allyl compound A-1 (straight chain group type), diallyl bisphenol A, according to the mass parts of 100:80:20, put them into a three-necked flask in turn, and continue to stir under the condition of an oil bath at 110 ° C. After the solid in the flask is completely dissolved, start timing and continue to stir for 1 hr Afterwards, the resulting product was distilled to obtain a modified bismaleimide prepolymer 1 with a solid content of 75%.

Synthetic example 2

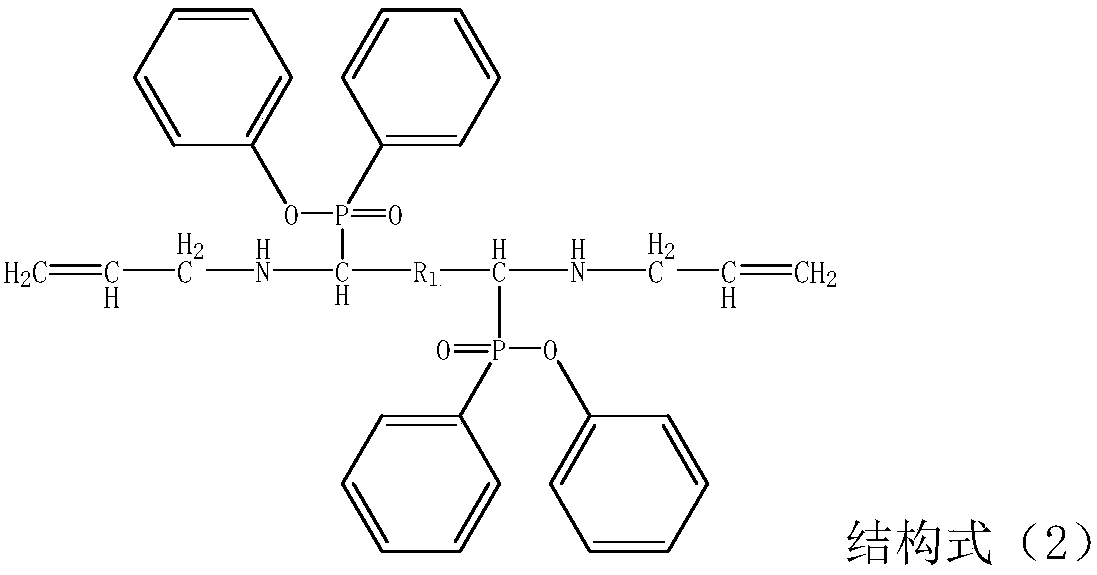

[0106] Add 100 parts of solvent N,N-dimethylformamide into a 500mL three-necked flask, and mix 4,4'-diphenylmethane bismaleimide with DOPO-containing allyl compound A-2 (aromatic group type), diallyl bisphenol A, according to the mass parts 100:60:20, put them into a three-necked flask in turn, and continue to stir under the condition of an oil bath at 110°C. After the solid in the flask is completely dissolved, start timing, and continue to stir for 1hr Afterwards, the resulting product was distilled to obtain a modified bismaleimide prepolymer 2 with a solid content of 75%.

Synthetic example 3

[0108] Add 100 parts of solvent N,N-dimethylformamide into a 500mL three-necked flask, and mix 4,4'-diphenylmethane bismaleimide with DPPO-containing allyl compound A-3 (straight chain group type), diallyl diphenyl ether, according to the mass parts 100:40:30, put them into the three-necked flask successively, keep stirring under the oil bath condition of 110 ℃, start timing after the solid in the flask is completely dissolved, and keep stirring for 1hr Afterwards, the resulting product was distilled to obtain a modified bismaleimide prepolymer 3 with a solid content of 75%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com