Anti-bending halogen-free flame-retardant sheath material for elevator flat cable as well as preparation method and application of bending-resistant halogen-free flame-retardant sheath material

A flame-retardant sheath and anti-bending technology, applied in the field of elevator flat cables, can solve problems such as poor safety, increased processing procedures, and prone to defective products, and achieve excellent high and low temperature resistance, improve product quality, The effect of excellent wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

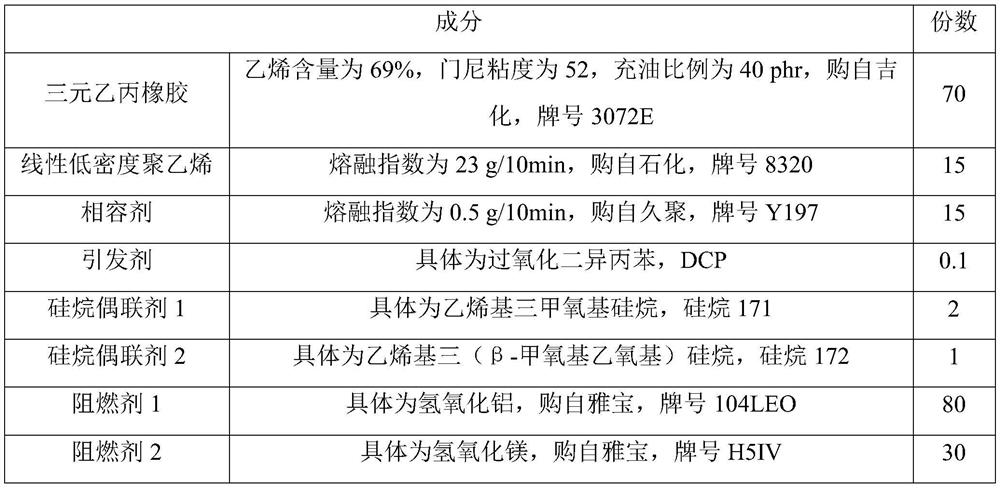

[0033] This embodiment provides a bending-resistant, halogen-free, flame-retardant sheathing material for an elevator flat cable. The raw material formula of the bending-resistant, halogen-free, flame-retardant sheathing material for an elevator flat cable is shown in Table 1 below.

[0034] Table 1

[0035]

[0036]

[0037] The preparation method of the bending-resistant halogen-free flame-retardant sheathing material for elevator flat cables includes the following steps: weighing each raw material according to the formula, first putting in a flame retardant, and then adding vinyl tris(β-methoxyethoxy) Silane, mixing and kneading; then put in EPDM rubber, linear low density polyethylene, lubricant, and antioxidant in turn; finally put in the mixed solution of initiator and vinyltrimethoxysilane during the stirring process, and put in after kneading evenly Mixed in an internal mixer, and then extruded and granulated by twin-screw; wherein, during the mixing process, linea...

Embodiment 2

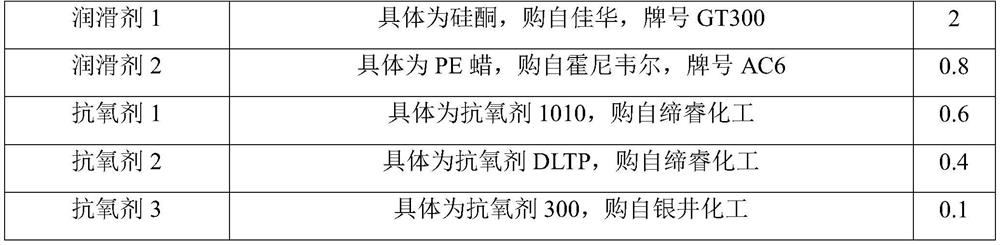

[0039] This embodiment provides a bending-resistant, halogen-free, flame-retardant sheathing material for an elevator flat cable. The raw material formula of the bending-resistant, halogen-free, flame-retardant sheathing material for an elevator flat cable is shown in Table 2 below.

[0040] Table 2

[0041]

[0042]

[0043] The preparation method is the same as in Example 1.

Embodiment 3

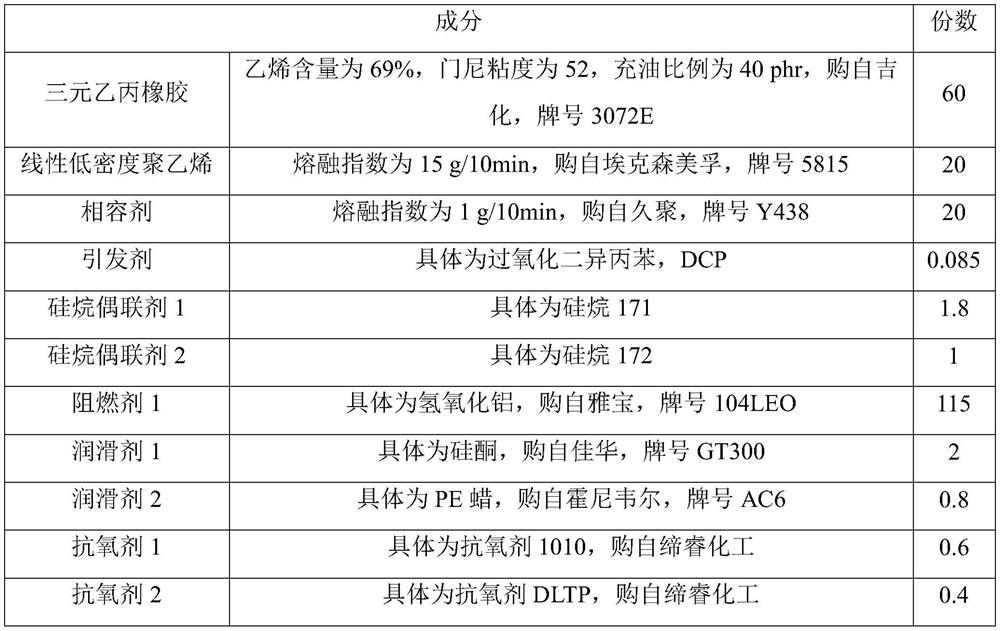

[0045] This embodiment provides a bending-resistant, halogen-free, flame-retardant sheathing material for an elevator flat cable. The raw material formula of the bending-resistant, halogen-free, flame-retardant sheathing material for an elevator flat cable is shown in Table 3 below.

[0046] table 3

[0047]

[0048] The preparation method is the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com