Blade tip trailing edge enhancing device and wind power generation blade with same

A technology for strengthening device and trailing edge, which is applied in wind power generation, wind turbines, wind turbines, etc. in the same direction as the wind, and can solve the problems of different, lightning strikes on the blade tip, and narrow bonding width.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The following descriptions of various embodiments refer to the accompanying drawings to illustrate specific embodiments in which the present invention can be implemented.

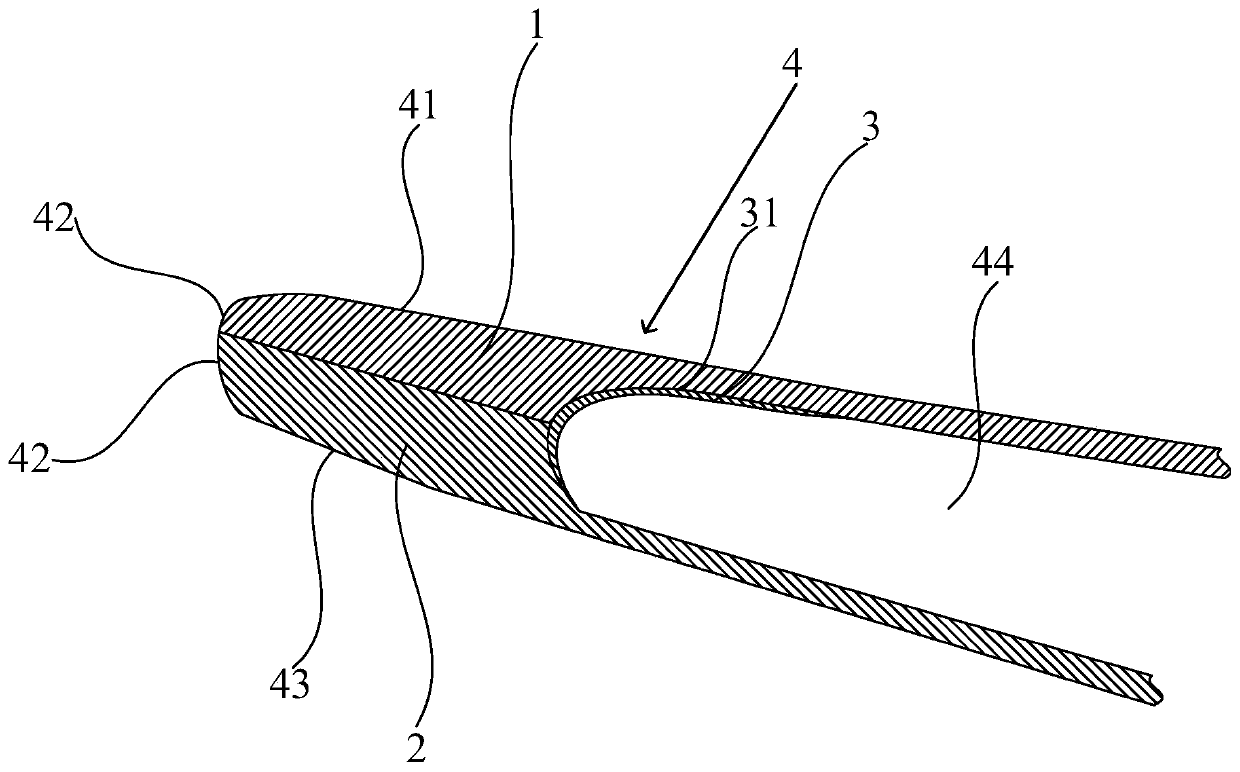

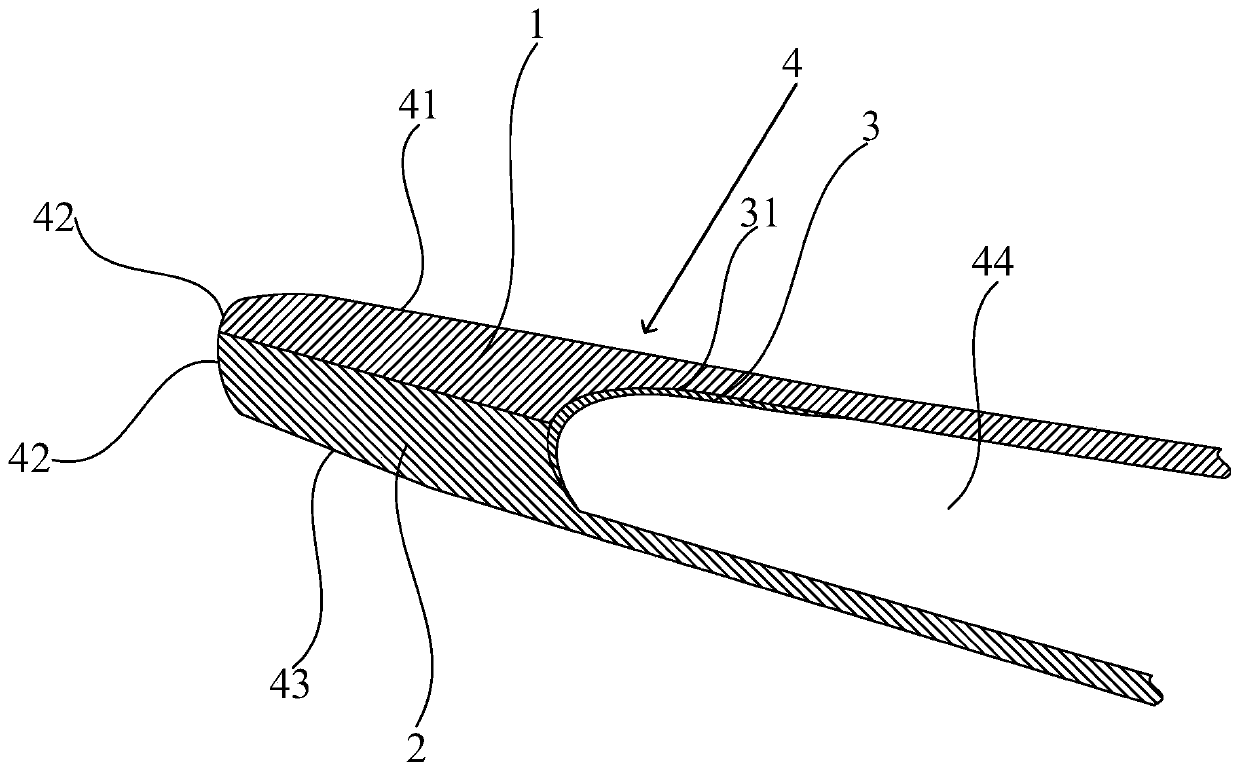

[0026] Such as figure 1 As shown, this embodiment discloses a blade tip trailing edge strengthening device, which includes a first trailing edge part 1, a second trailing edge part 2 and a reinforcing part 3, and the first trailing edge part 1 is glued Connected to the second trailing edge part 2, and a blade tip 4 is formed between the first trailing edge part 1 and the second trailing edge part 2, the outer surface of the blade tip 4 has a tip surface 42, a windward surface 41 and a leeward surface 43, The two ends of the tip surface 42 are respectively connected to the windward surface 41 and the leeward surface 43. There is a cavity 44 in the blade tip 4, and the reinforcement 3 is located in the cavity 44. The outside of the reinforcement 3 has a connection surface 31, and the connection surface...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com