Chromium target manufacturing method

A manufacturing method and technology for chromium targets, which are applied in the field of chromium target manufacturing, can solve the problems of high manufacturing cost of chromium targets, high requirements for manufacturing equipment, harsh process conditions, etc. Density effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

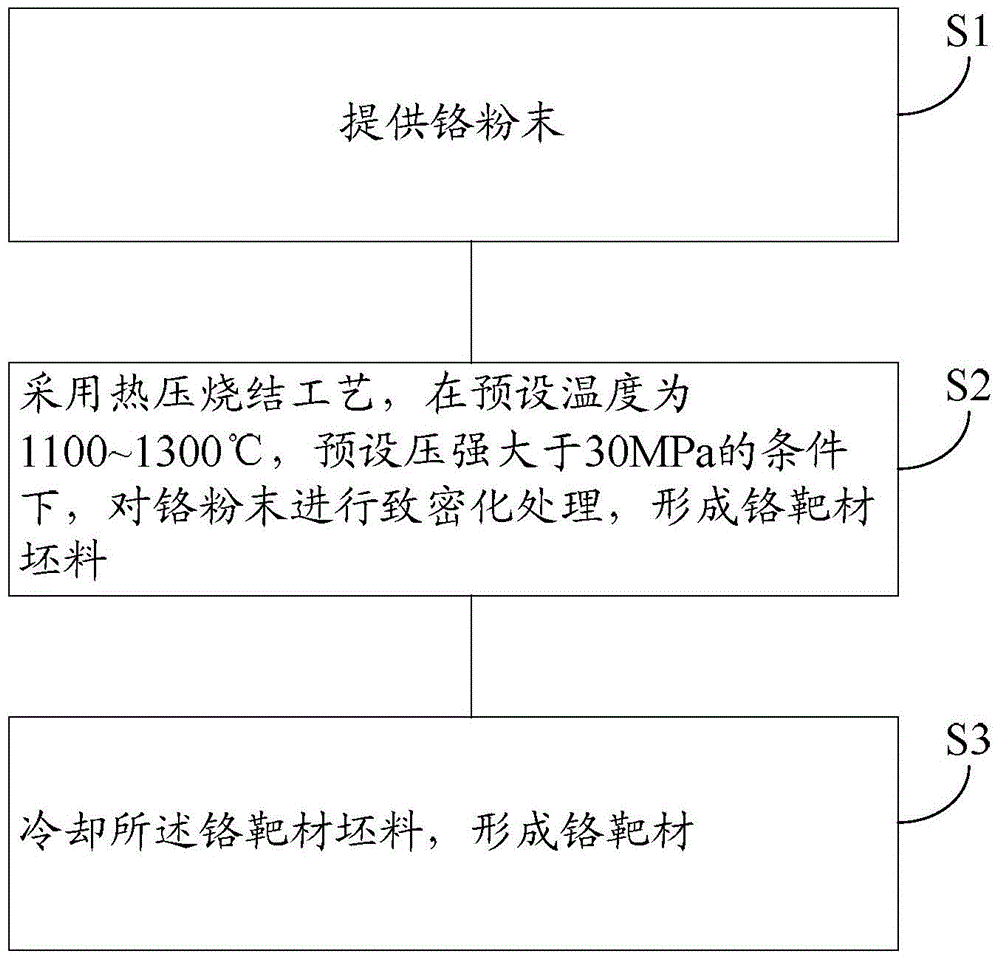

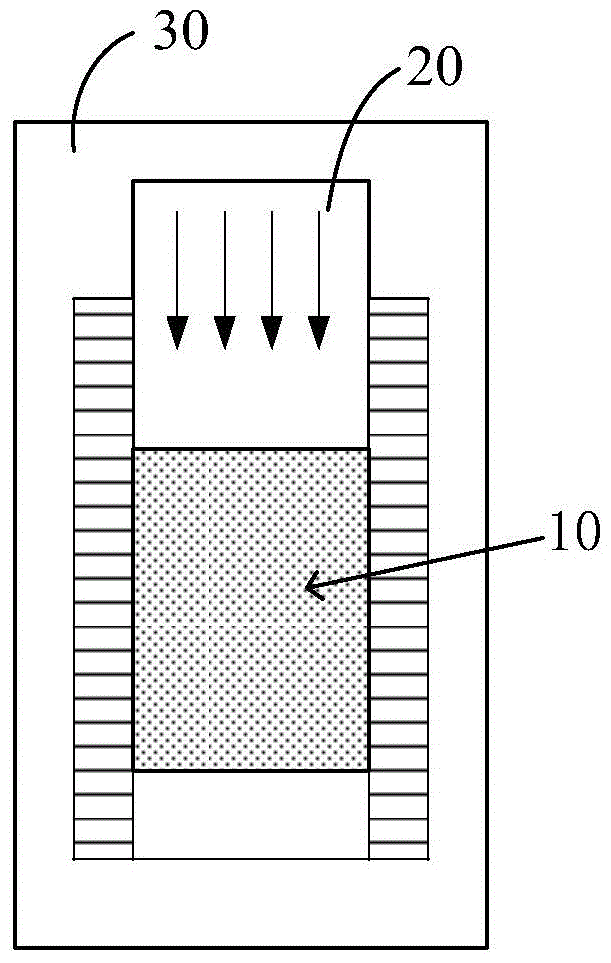

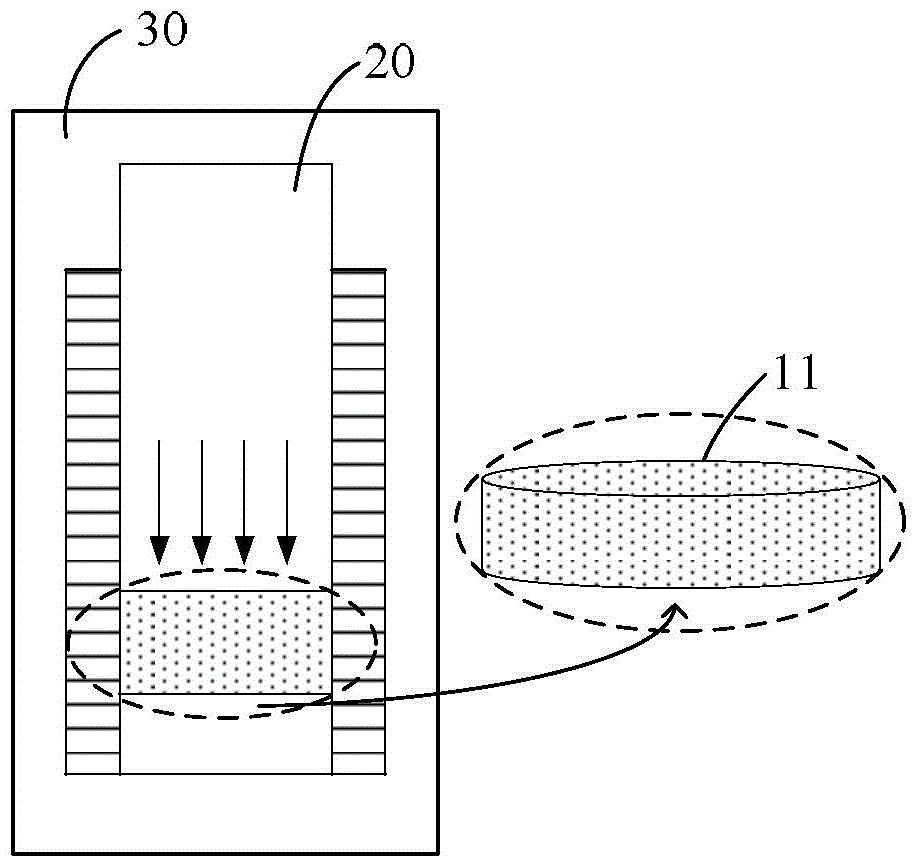

[0029] As mentioned in the background art, the existing manufacturing methods of chromium targets have high requirements on process equipment and harsh manufacturing process conditions, resulting in high manufacturing costs and low yields of chromium targets. For this reason, the present invention provides a new method for manufacturing a chromium target. The method for manufacturing a chromium target adopts a hot pressing sintering process, and cooperates with specific temperature, pressure control and other process settings to obtain a density greater than 99.5 %, the grain size is less than 50μm, and the high-quality chromium target with uniform internal structure meets the requirements of the sputtering coating process for the chromium target. In addition, compared with the existing chromium target manufacturing process, the chromium target manufacturing method provided by the present invention requires less process equipment, and the process conditions are easy to control,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| crystal size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com