Patents

Literature

80results about How to "Low process conditions" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Preparation method of porous silicon-based tungsten trioxide nanorod composite-structure gas sensor element

InactiveCN103424435ASimple methodLow process conditionsMaterial analysis by electric/magnetic meansGas detectorElectrochemical corrosion

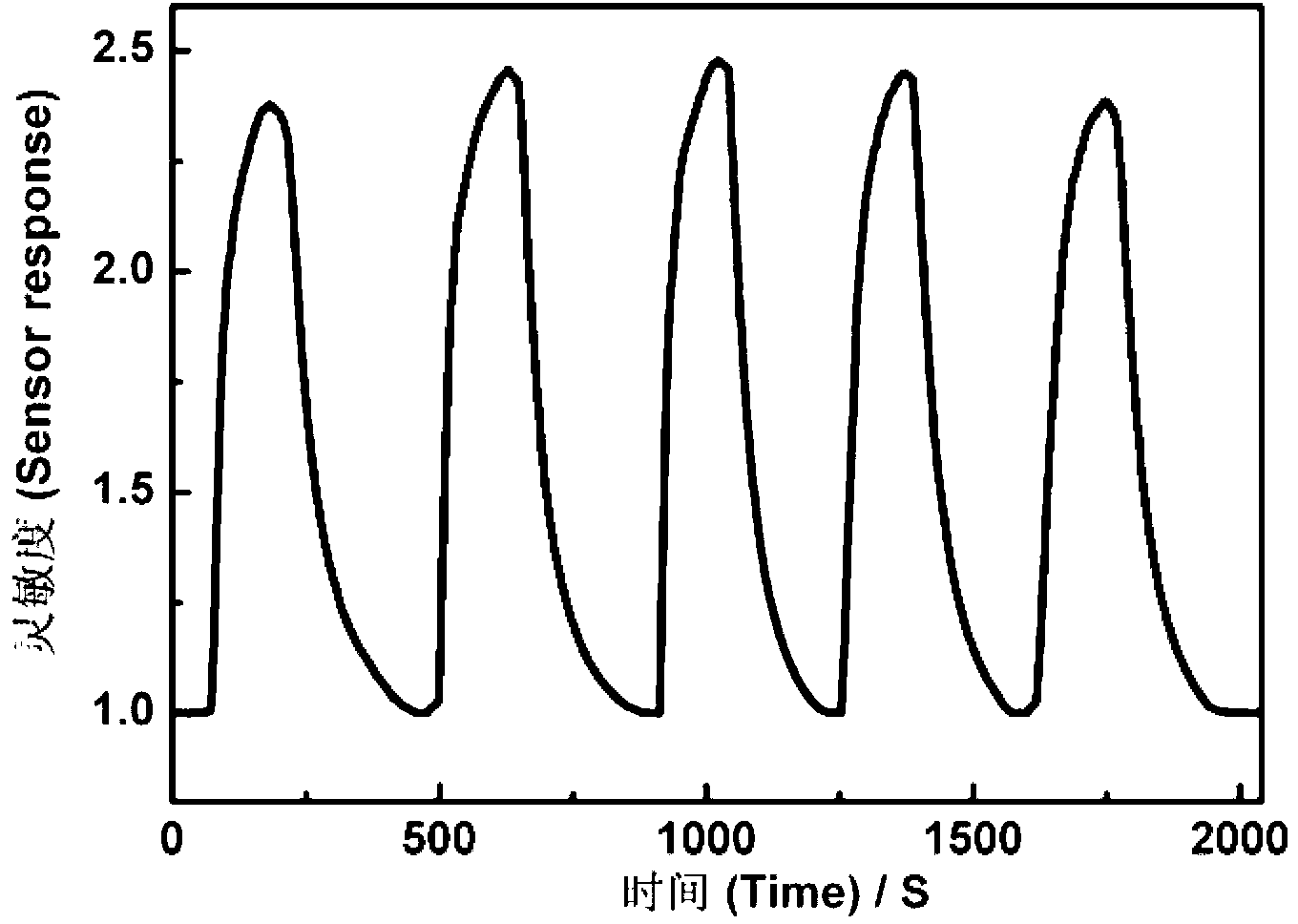

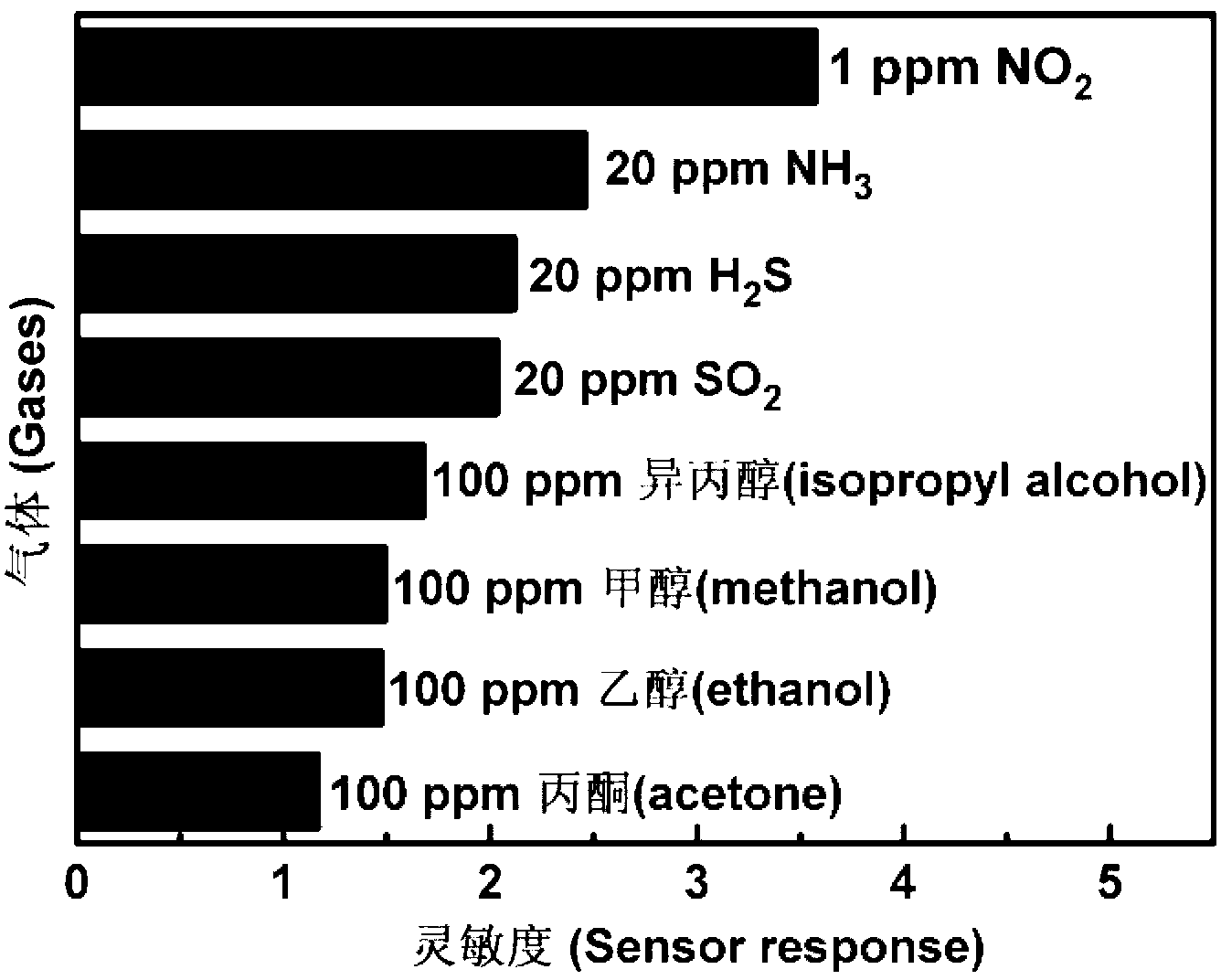

The invention discloses a preparation method of a porous silicon-based tungsten trioxide nanorod composite-structure gas sensor element. A porous silicon layer is prepared on a polished surface of a P-type single-side-polished monocrystalline wafer by double-channel electrochemical corrosion; tungsten oxide nanorods are grown in situ on porous silicon by hydrothermal process, so that composite-structure porous silicon-based tungsten trioxide nanorods are obtained; two platinum electrodes are deposited on the surface of the wafer by magnetron sputtering. The novel porous silicon-based tungsten trioxide nanorod composite-structure gas sensor element which has excellent gas-sensitiveness features, such as simplicity in preparation process, ease of control, capability of detecting nitride oxide gas at the room temperature and high flexibility, is provided.

Owner:TIANJIN UNIV

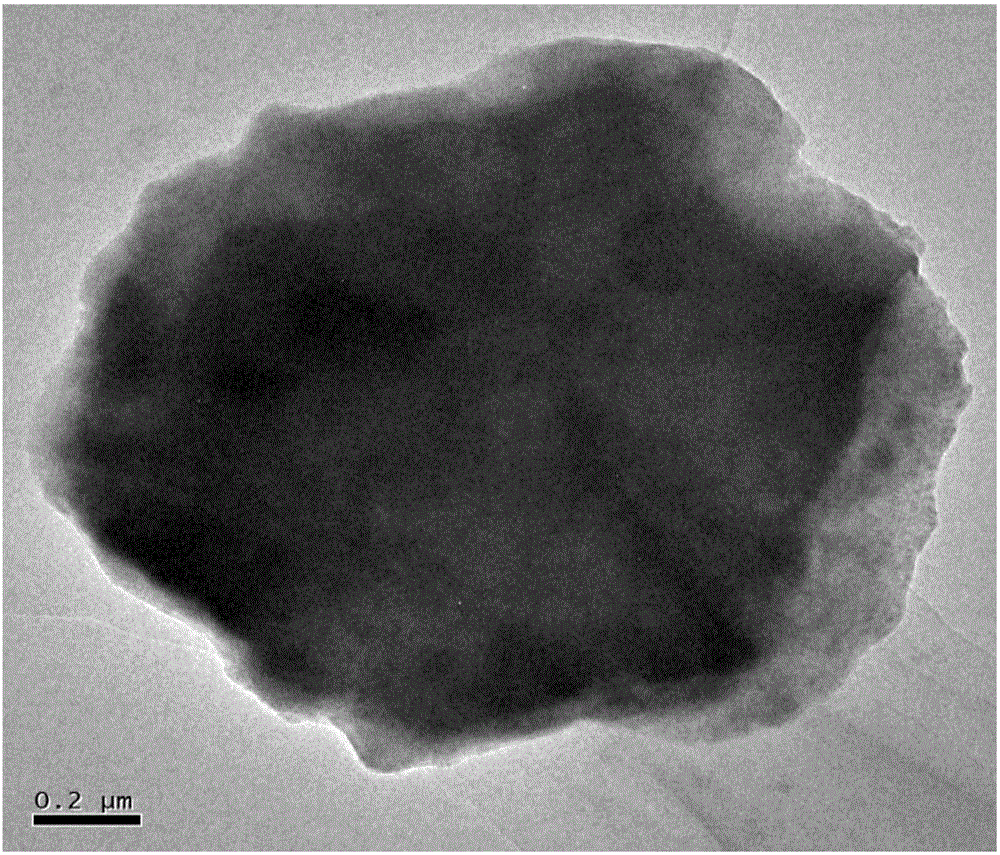

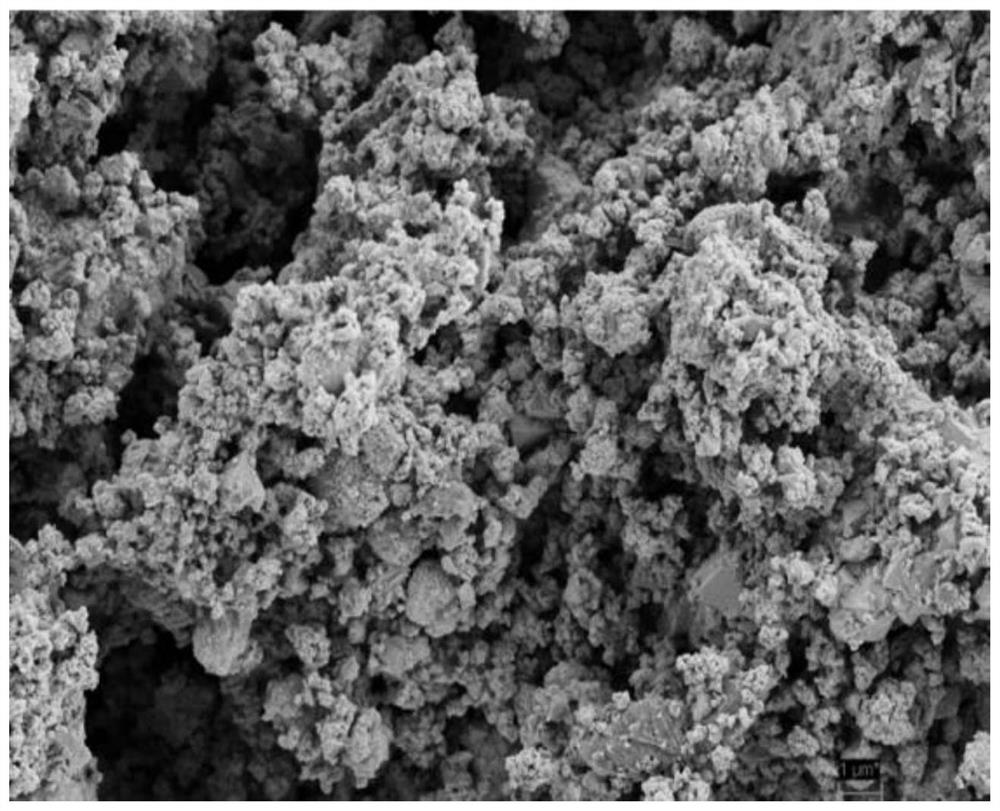

Lithium-enriched manganese-based material precursor as well as preparation method, lithium-enriched manganese-based anode material and preparation method thereof, lithium battery

ActiveCN108557905AEnough grain boundary fusionActive enoughCell electrodesSecondary cellsChemistryVoltage

The invention relates to a lithium-enriched manganese-based material precursor which is a lithium-enriched manganese-based carbonate precursor of a lamellar morphology, the particle size of the precursor is 1-7mu m, and the specific surface area of the precursor is 8-50m<2> / g. By adopting the lithium-enriched manganese-based carbonate precursor of the lamellar morphology, a lithium-enriched manganese-based anode material of a high single crystallization degree can be easily prepared. The invention further relates to a preparation method of the lithium-enriched manganese-based carbonate precursor of the lamellar morphology, and a preparation method and the application of the lithium-enriched manganese-based anode material of a single crystal morphology. Therefore, the mechanical strength, the stability, the compaction density, the capacity and the first efficiency of the micro structure of the anode material can be improved, and the voltage attenuation of the material can be inhibited.

Owner:桑德新能源技术开发有限公司 +1

Inner coating for improving glazing property of turned carbon-containing fireproof material and coating method thereof

The invention provides an inner coating for improving glazing property of turned carbon-containing fireproof material. The coating is prepared by uniformly mixing the following components in percentage by weight: 10-40% of bonder, 1-15% of dispersant, 10-80% of filler made of fireproof material and 10-30% of water. The components of the filler made of fireproof material are consistent to the components of the fireproof material to be turned. The coating provided by the invention mainly has the beneficial effects that the filler made of fireproof material in the using process has the effect of repairing surface pits of the carbon-containing fireproof material so as to further improve the coating of the outer antioxidant coating, so that the glazing and glaze burning condition as well as later burning effect are improved.

Owner:维苏威高级陶瓷(鞍山)有限公司

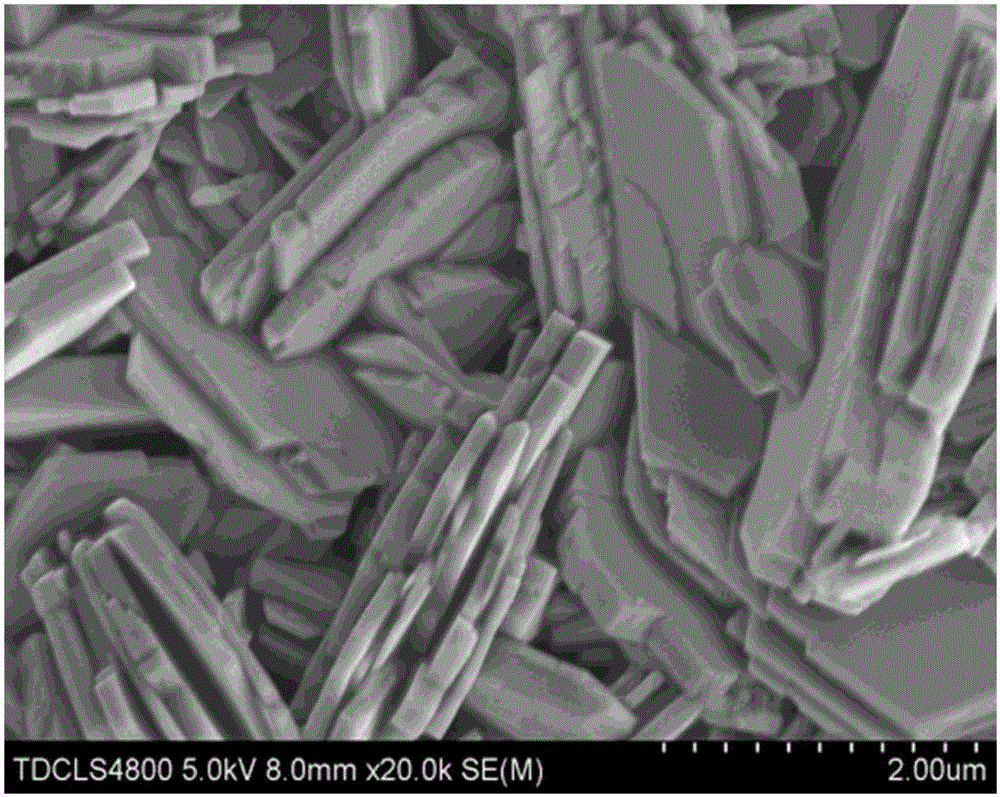

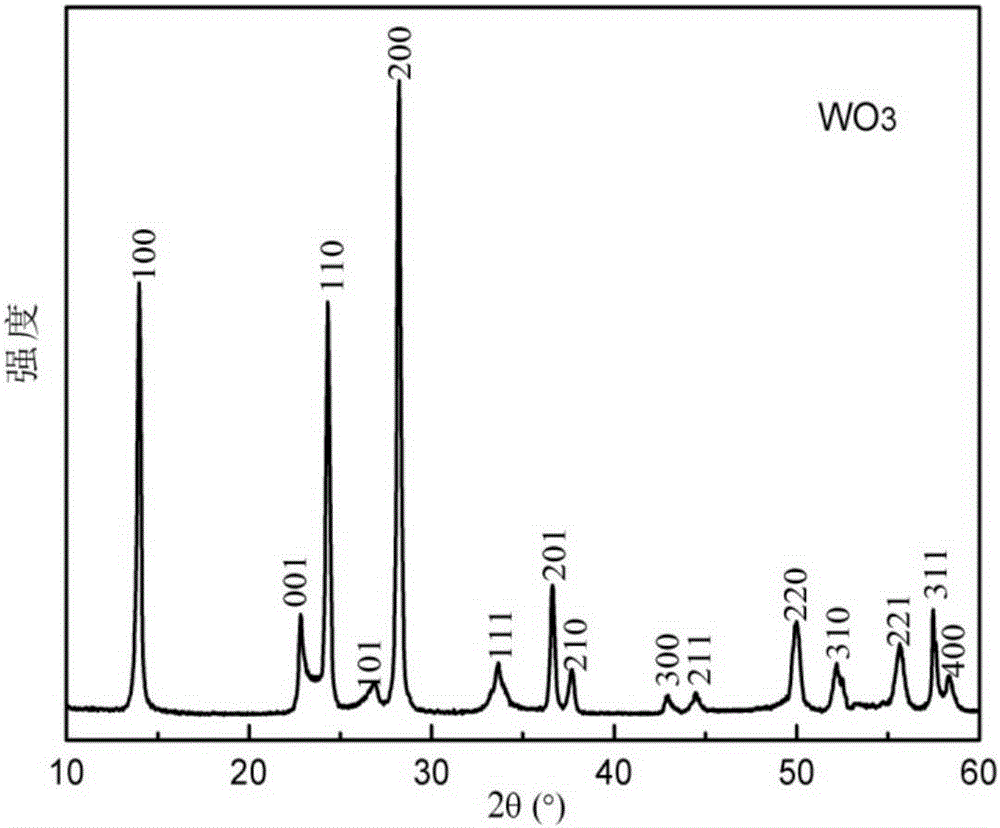

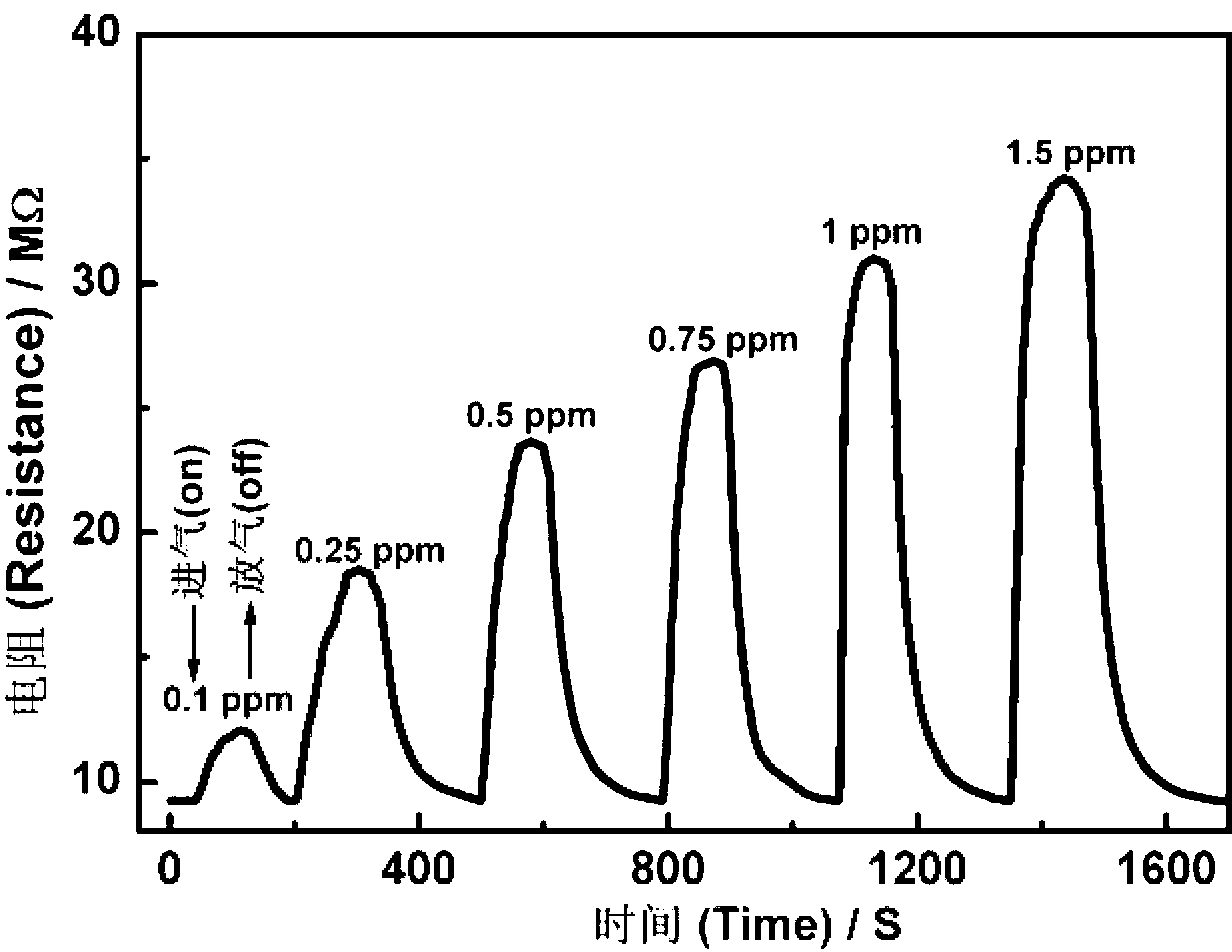

Preparation method for tungsten-oxide-nanosheet-structured gas sensor working at room temperature

InactiveCN105301063AEasy to operateNo pollution in the processMaterial nanotechnologyMaterial resistanceSolventSolvothermal reaction

The invention discloses a preparation method for a tungsten-oxide-nanosheet-structured gas sensor working at room temperature. The preparation method comprises the steps that a ceramic wafer substrate is cleaned, a platinic interdigital electrode is prepared on the ceramic wafer substrate, a solvothermal reaction solution is prepared, a tungsten-oxide-nanorod-structured gas sensor is prepared through a solvothermal method, an aluminum oxide substrate after a solvothermal reaction is cleaned, and thermal treatment is performed on elements of the tungsten-oxide-nanorod-structured gas sensor. According to the preparation method, the tungsten-oxide-nanosheet-structured gas sensor can be prepared at low cost. According to the solvothermal method, operation is easier, the technological conditions needing to be controlled are few, and no pollution to the environment is generated. The preparation method for the tungsten-oxide-nanosheet-structured gas sensor which can detect nitrogen oxide gas with the extremely low concentration (can reach 0.1 ppm) and is high in sensitivity and rapid to respond / recover is supplied, and the important practice and research significances are achieved.

Owner:TIANJIN UNIV

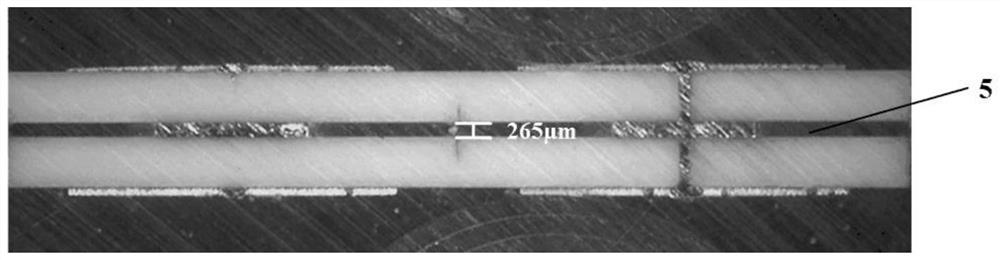

Production method of nitric oxide gas sensor element

InactiveCN102998337ALow process conditionsEasy to controlMaterial analysis by electric/magnetic meansCorrosionPower flow

The invention discloses a production method of a nitric oxide gas sensor element, which comprises the steps of 1, cleaning an n type single-face polished monocrystalline silicon piece; 2, producing silicon substrate hole-order porous silicon with hole size of 50-200nm on the polished surface of the silicon piece by adopting a double-groove electrochemical corrosion method, wherein a corrosion solution is a hydrofluoric acid water solution with concentration of 6-8 percent, the density of the applied corrosion current is 115-135mA / cm<2>, and the corrosion time is 5-25min; and 3, placing the porous silicon in a vacuum chamber of an ultrahigh vacuum facing-target magnetron sputtering device, and producing the nitric oxide gas sensor element based on the silicon substrate hole-order porous silicon. The production method has the advantages of simpleness, flexibility, adjustability, less process conditions and easiness in control; and the nitric oxide gas sensor element has the advantages of high sensitivity, high selectivity, quick response / recovery characteristic and good repeatability under the conditions of room temperature and extreme low concentration (0.1ppm).

Owner:TIANJIN UNIV

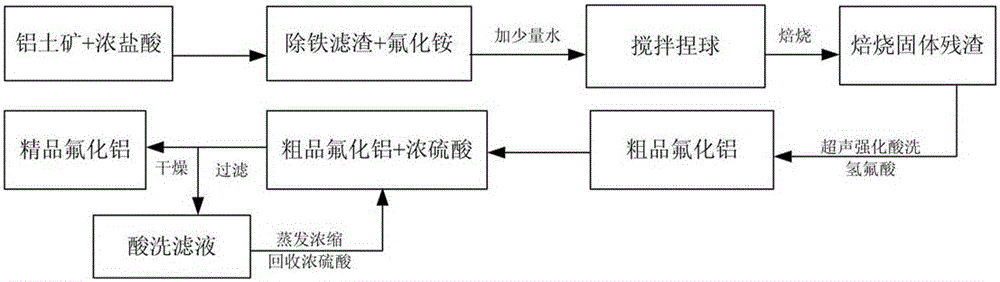

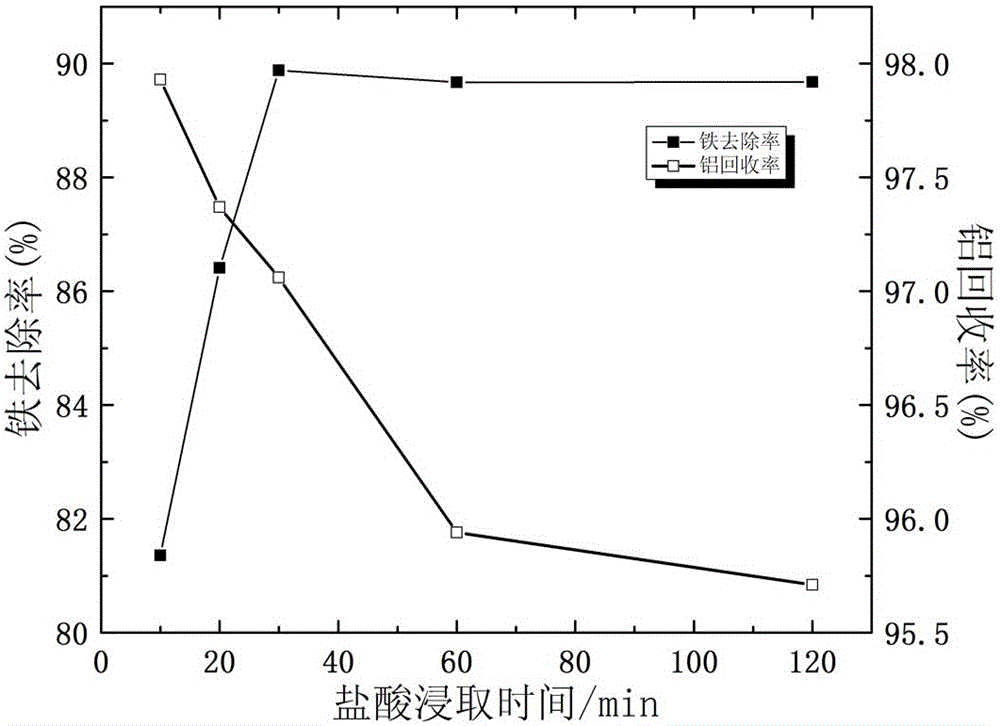

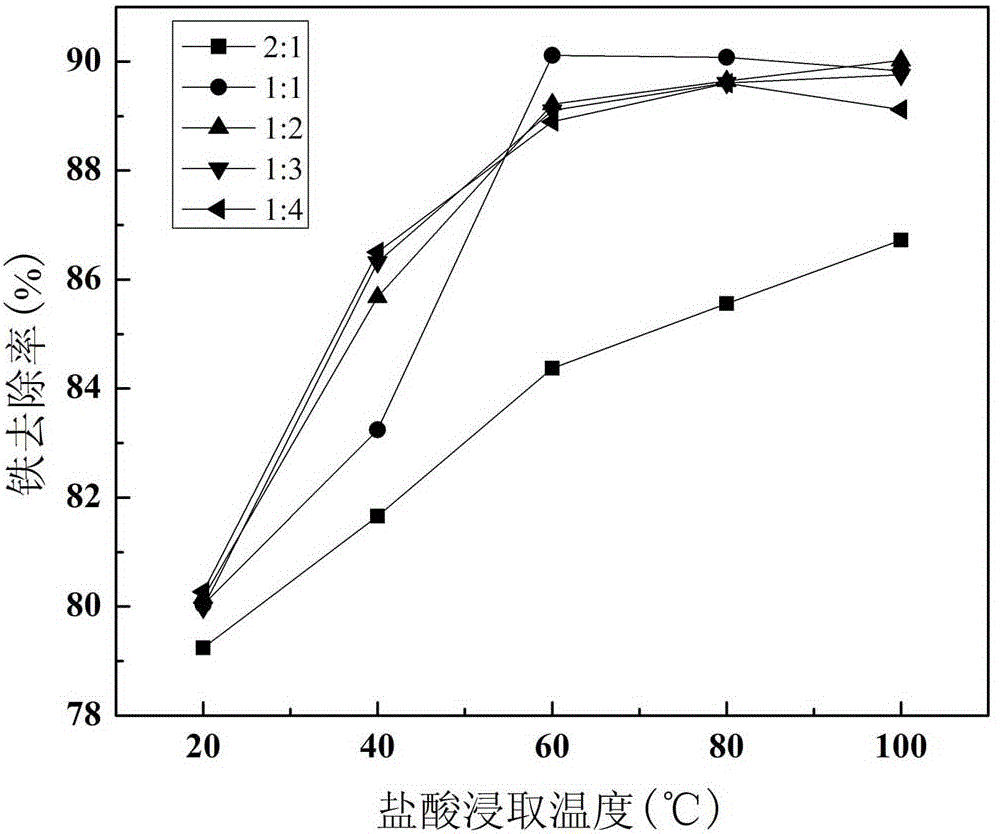

Method for preparing aluminium fluoride by utilizing low grade bauxite

The invention provides a method for preparing aluminium fluoride by utilizing low grade bauxite. The method mainly comprises the following steps: hydrochloric acid leaching to remove iron, stirring and ball kneading, high-temperature roasting to remove silicon, ultrasonic hydrofluoric acid washing and concentrated sulfuric acid washing to remove titanium. The method has the beneficial effects that the problem of how to effectively remove the impurities in the low grade bauxite, such as iron, silicon and titanium, to prepare fine aluminium fluoride is solved through the steps, so that the active ingredients in the low grade bauxite are fully utilized, thus improving the product quality and reducing the resource waste; and the method provided by the invention dispenses with pretreatment of the low grade bauxite, is mild in process conditions and is suitable for large-scale production.

Owner:洛阳国兴矿业有限公司

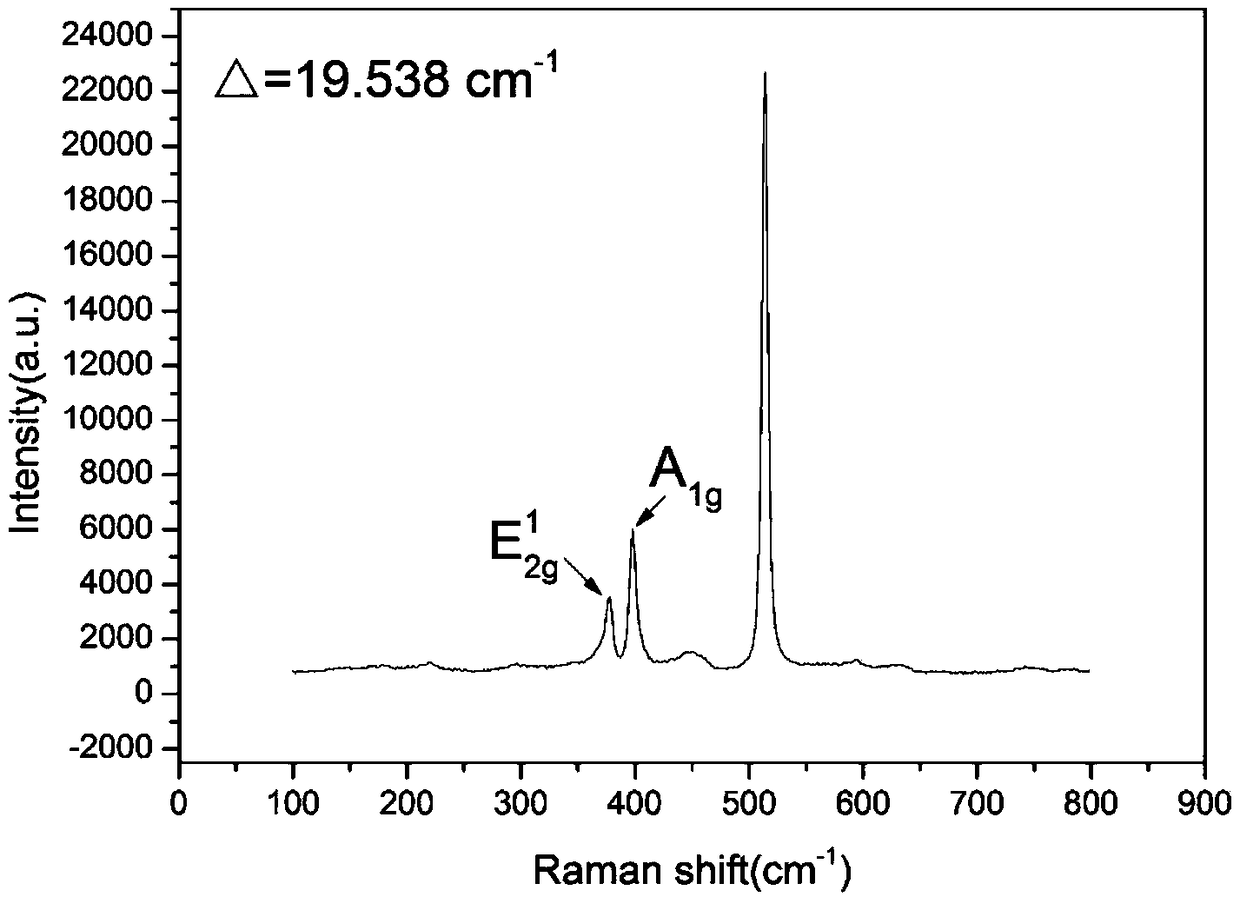

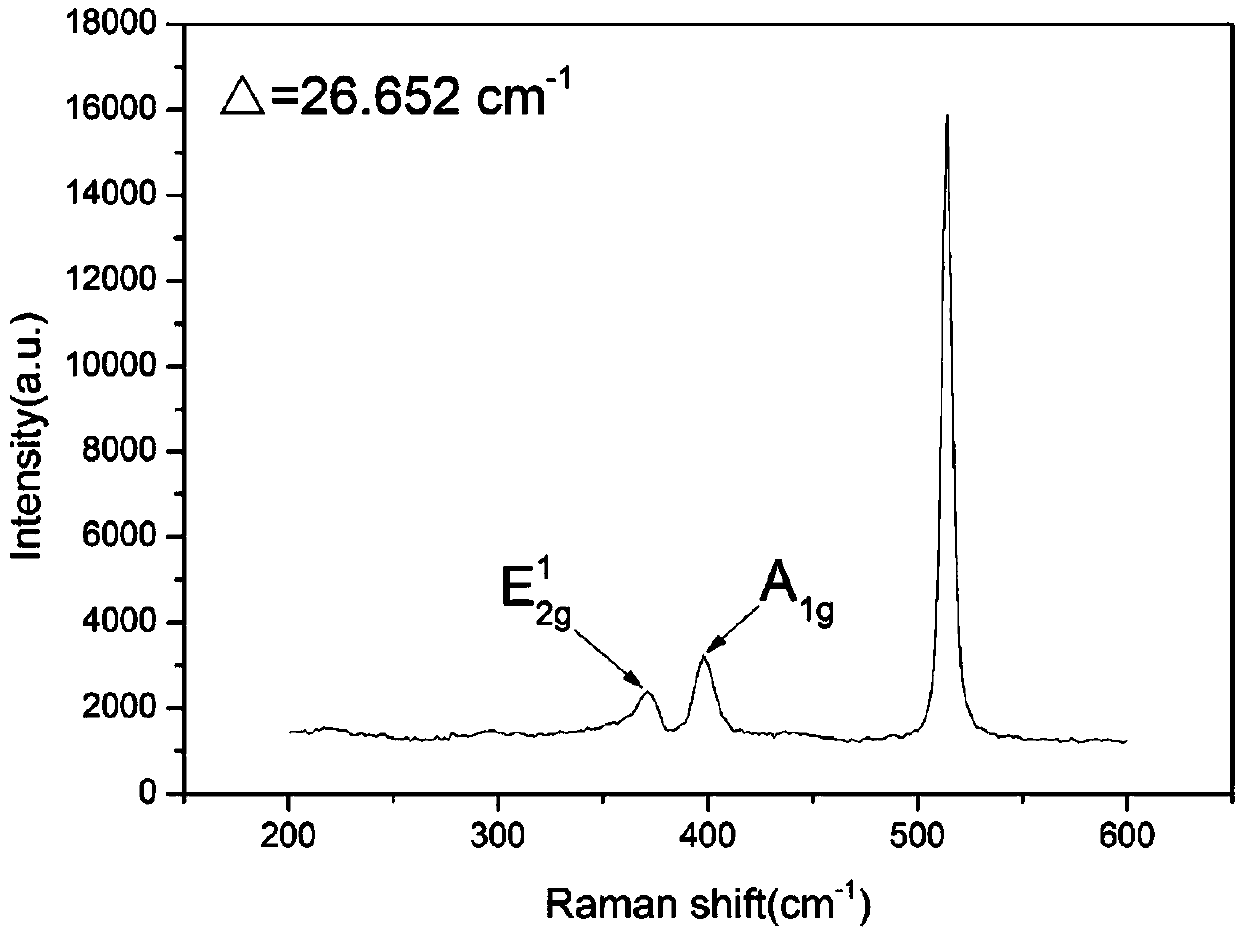

Synthetic method of single-layer porous molybdenum disulfide

InactiveCN108588674ASimple methodLow process conditionsChemical vapor deposition coatingGas phaseRotational temperature

The invention discloses a synthetic method of single-layer porous molybdenum disulfide. In an inert atmosphere, common sulfur powder and MoO3 are adopted to serve as raw materials, the single-layer porous MoS2 grows by the use of a chemical vapor deposition method in the single-temperature region, and the pore diameter is in a nanometer scale; the temperature in the deposition process is controlled to be 650 DEG C at the room temperature, the temperature rising rate cannot be excessively high, the optimal temperature rising rate is 10 DEG C / min, the deposition time is controlled to range from5 minutes to 15 minutes, and preparation of the single-layer porous MoS2 can be accomplished; and strict control over the single-layer porous MoS2 is achieved through ultrasonic cleaning treatment ofa substrate and optimization of preparation parameters such as the sulfur group elemental powder consumption amount, the growth temperature and the growth time.

Owner:KUNMING UNIV OF SCI & TECH

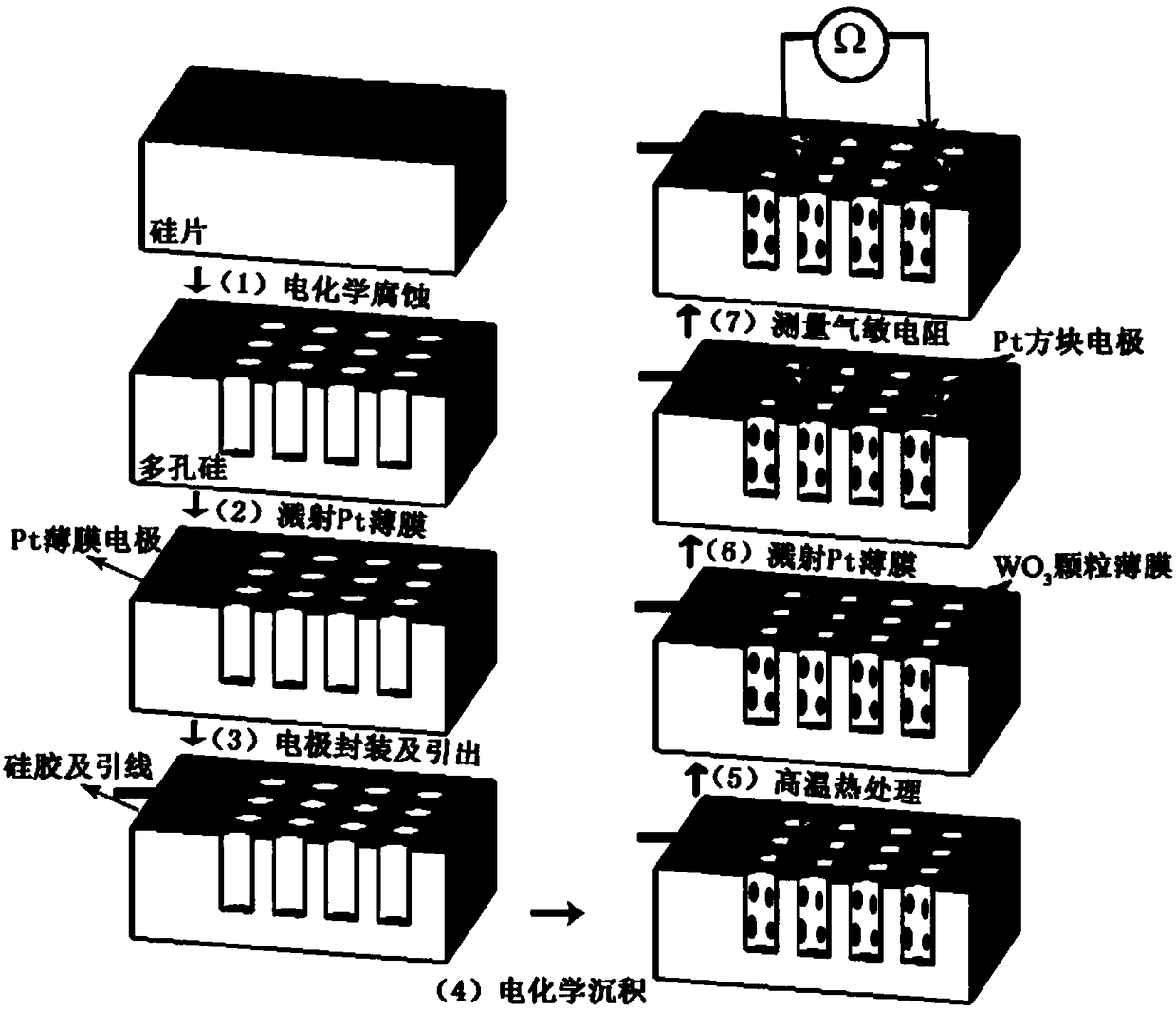

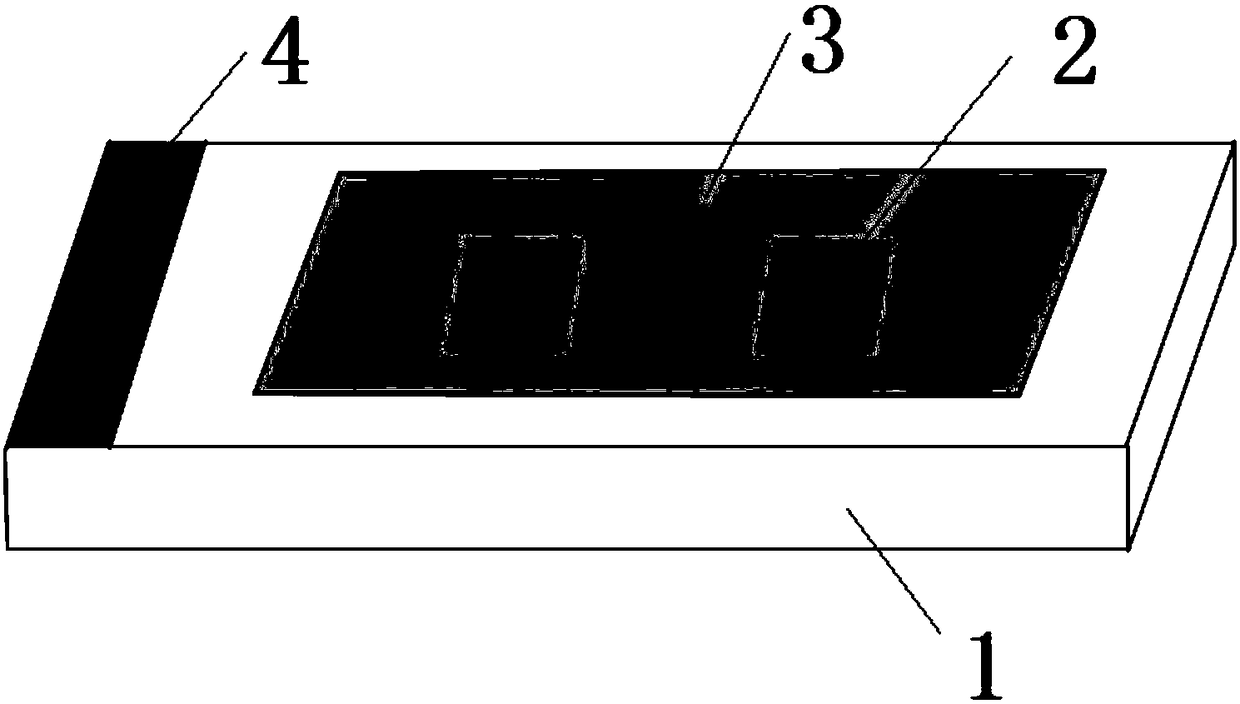

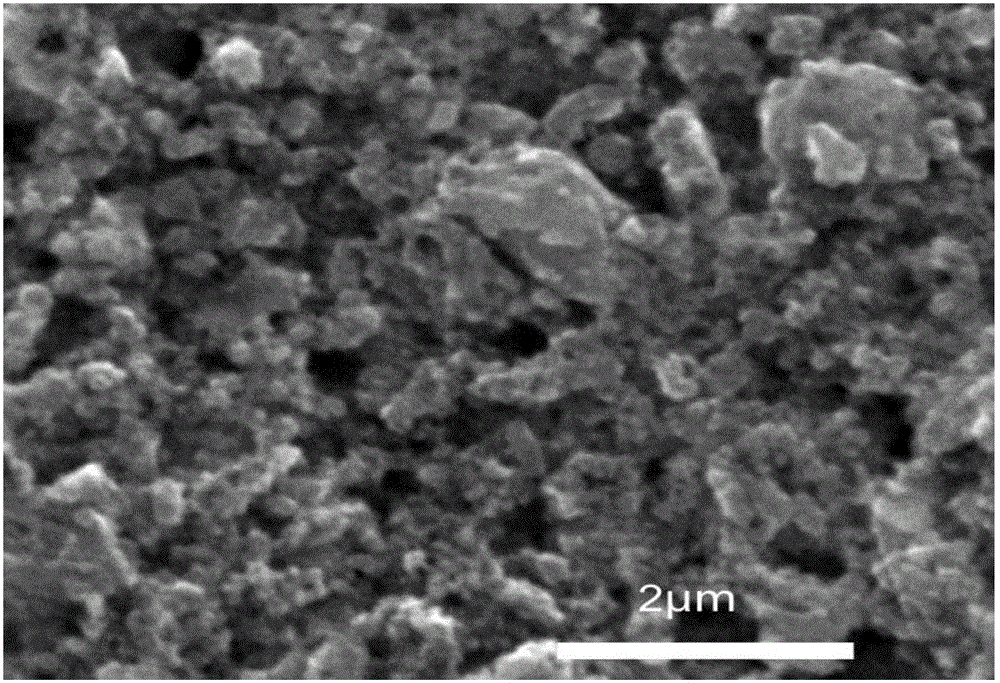

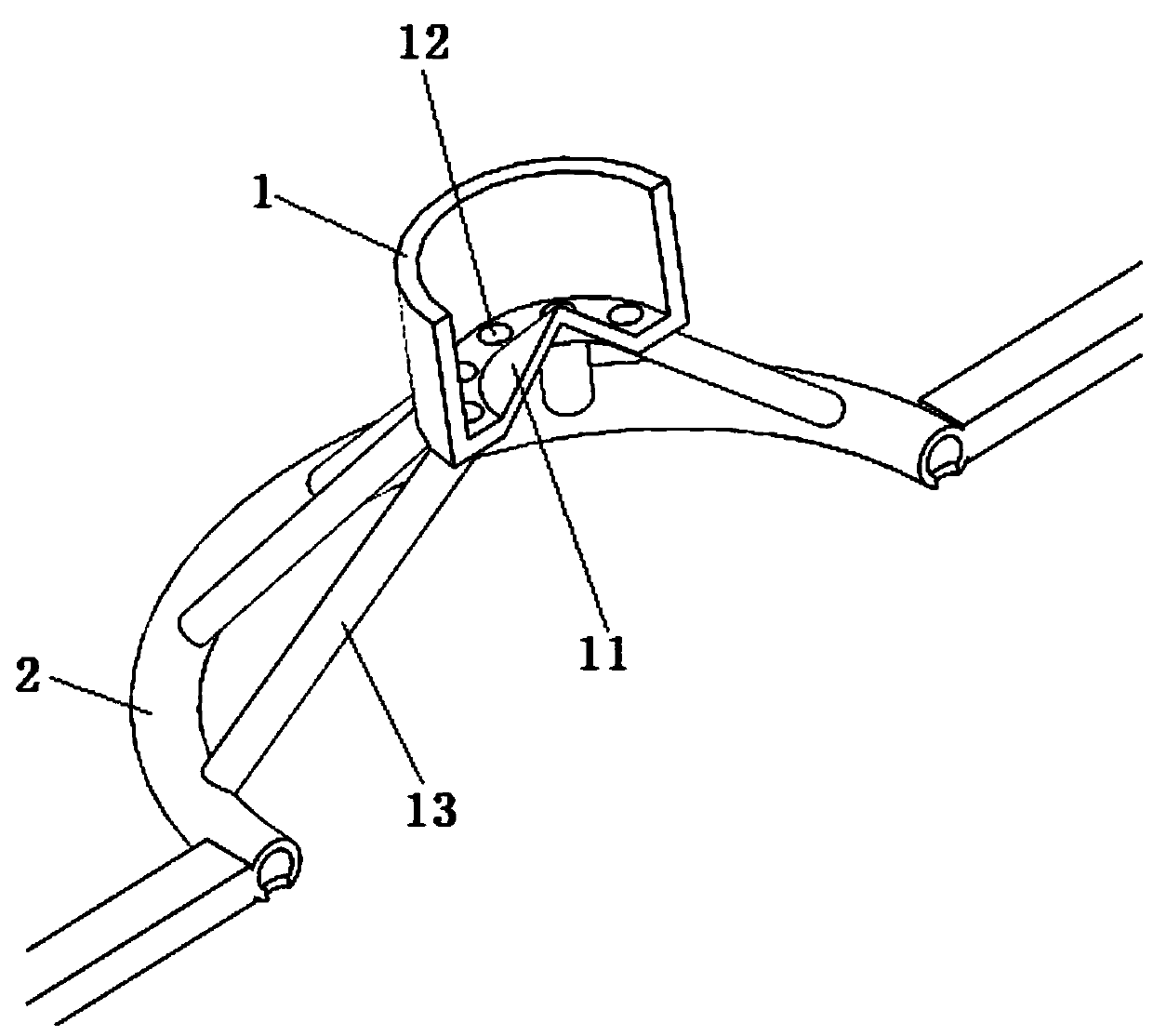

Porous silicon-based tungsten oxide film composite material gas sensitive sensor and preparation method and application thereof

The invention discloses a porous silicon-based tungsten oxide film composite material gas sensitive sensor and a preparation method and an application thereof. The porous silicon-based tungsten oxidefilm composite material gas sensitive sensor is composed of a porous silicon substrate, a Pt film electrode, a porous silicon-based tungsten oxide sensitive layer and a Pt electrode formed thereon. The porous silicon-based tungsten oxide sensitive layer is composed of a porous silicon layer and a tungsten oxide (WO3) film deposited thereon by constant potential electrodeposition. By preparing a ohmic contact electrode on the porous silicon substrate and growing WO3 particle film in situ on porous silicon by means of an electrochemical method, the method is relatively simple, the needed controlprocess conditions are relatively few, and the cost is low; the prepared porous silicon-based tungsten oxide film composite material gas sensitive sensor can detect low concentration nitrogen dioxidegas at room temperature and has the characteristics of being relatively high in sensitivity, relatively good in responding / recovering property and good in selectivity and repeatability.

Owner:TIANJIN NORMAL UNIVERSITY

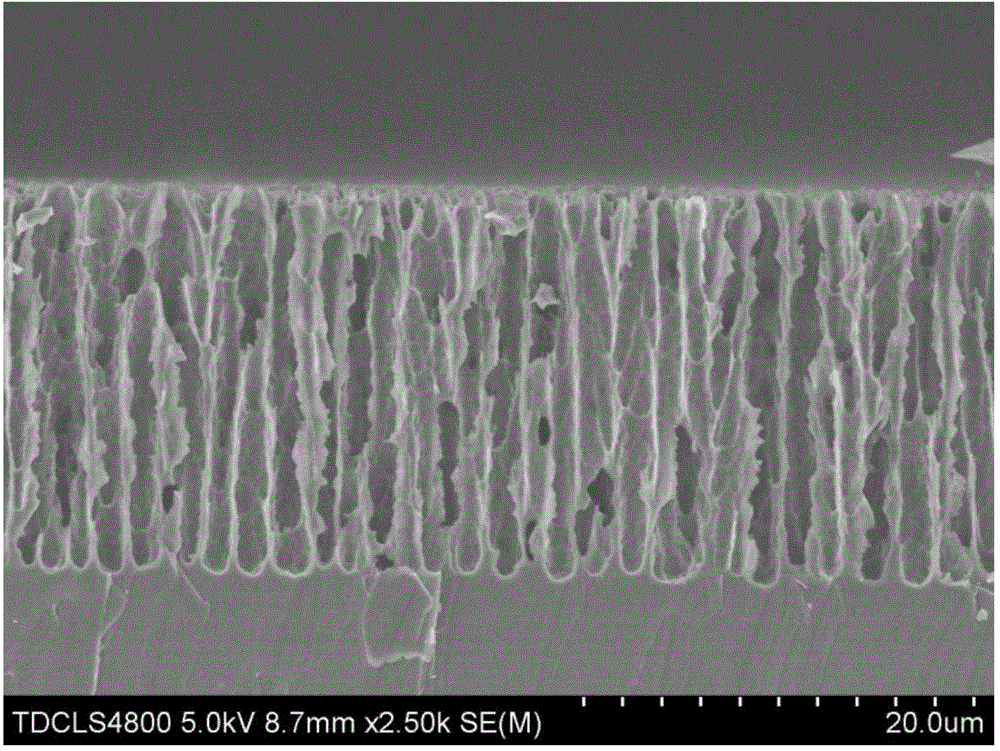

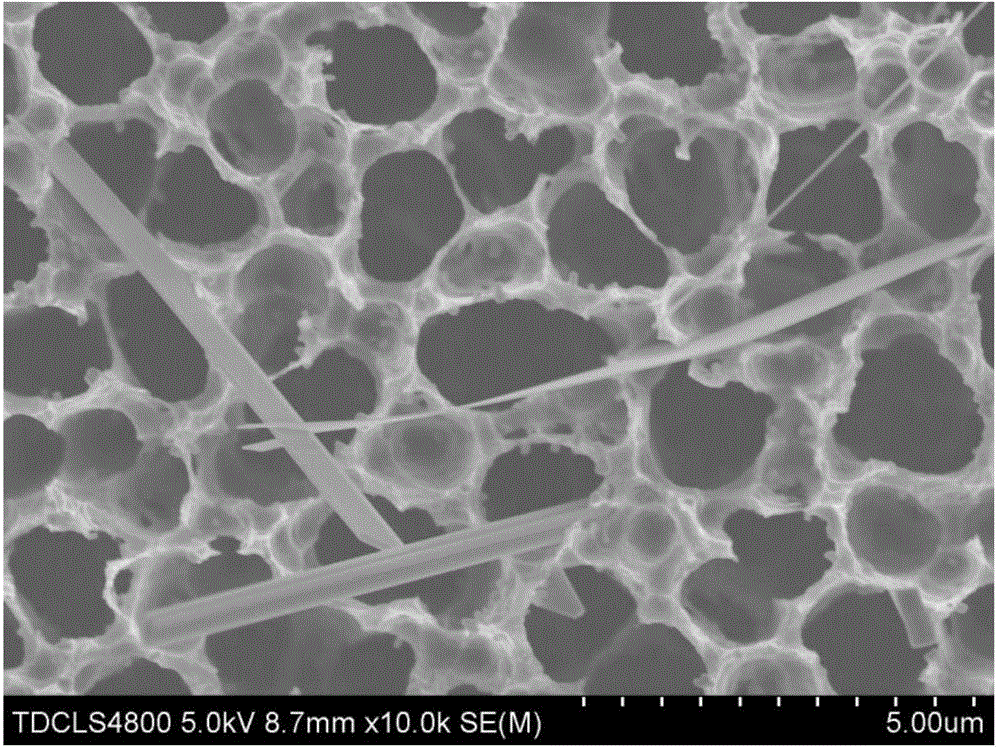

Preparation method of porous-silicon-based and multi-dimensional tungsten-oxide composite structure

InactiveCN104634935AEasy to operateLow process conditionsMaterial analysisFree diffusionComposite structure

The invention discloses a preparation method of a porous-silicon-based and multi-dimensional tungsten-oxide composite structure, which adopts a hydrothermal method to grow a multi-dimensional nano structure of tungsten oxide on ordered porous silicon and provides the novel porous-silicon-based and multi-dimensional tungsten-oxide composite structure simple in manufacturing process and controllable in morphology. The hydrothermal method is simpler in operation and fewer in process conditions needing to be controlled and has no pollution to the environment. In addition, the prepared porous-silicon-based and multi-dimensional tungsten-oxide composite structure has higher specific surface area; simultaneously, the ordered tungsten-oxide nano-rod array is more beneficial to absorption and free diffusion of gas; and the porous-silicon-based and multi-dimensional tungsten-oxide composite structure has important practice and research values in the aspects of reducing the working temperature of a gas-sensitive sensor and improving the sensitivity and the selectivity of the sensor.

Owner:TIANJIN UNIV

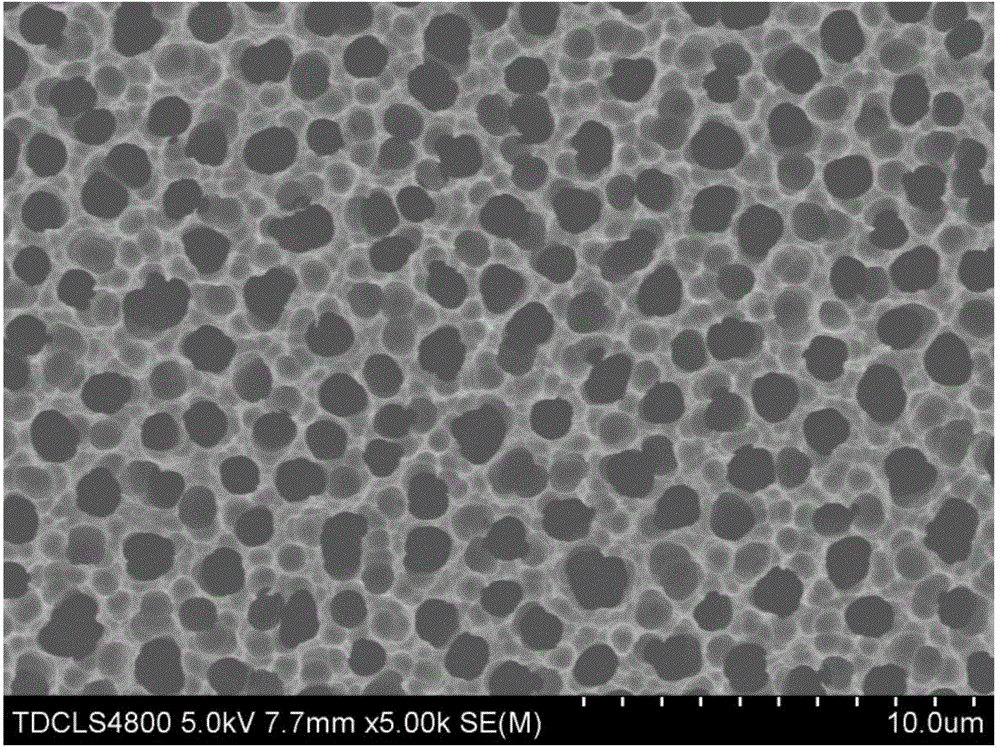

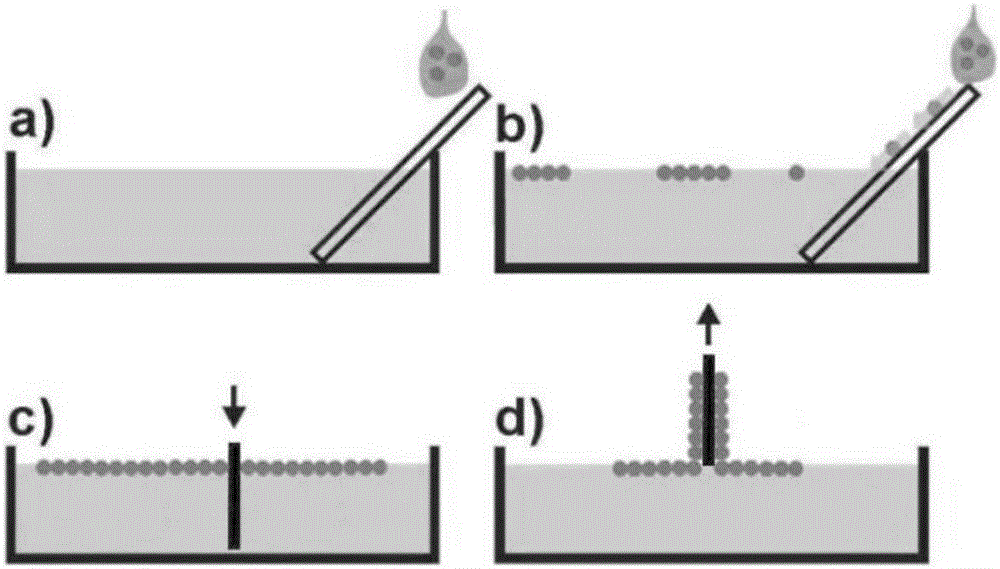

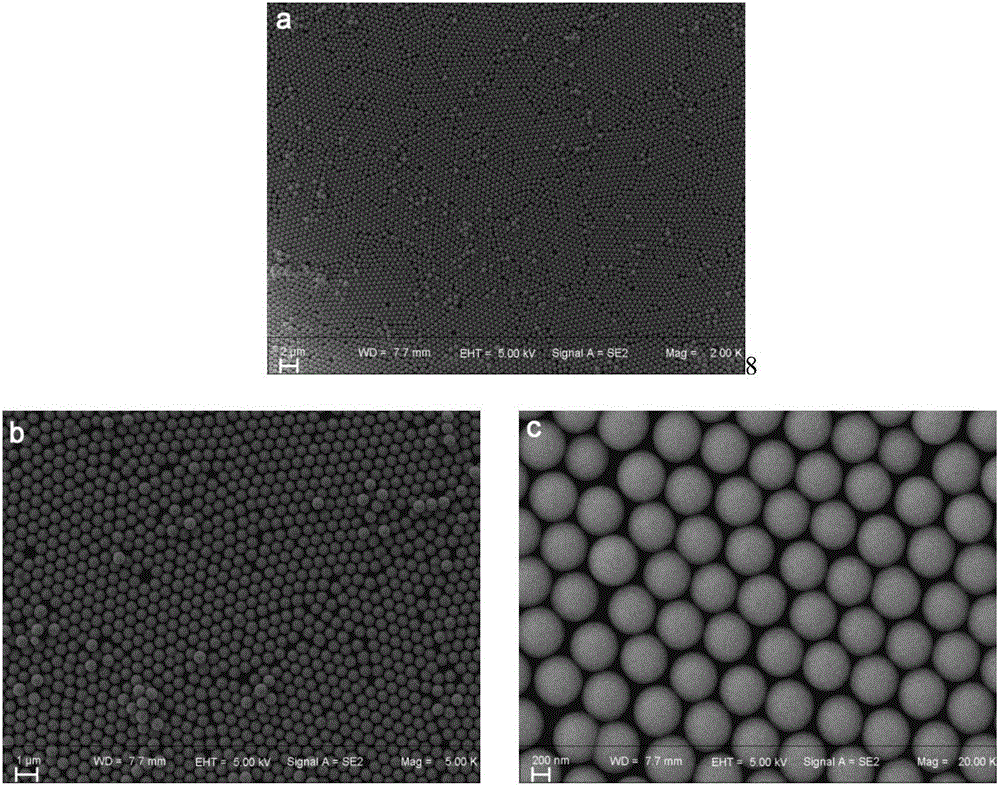

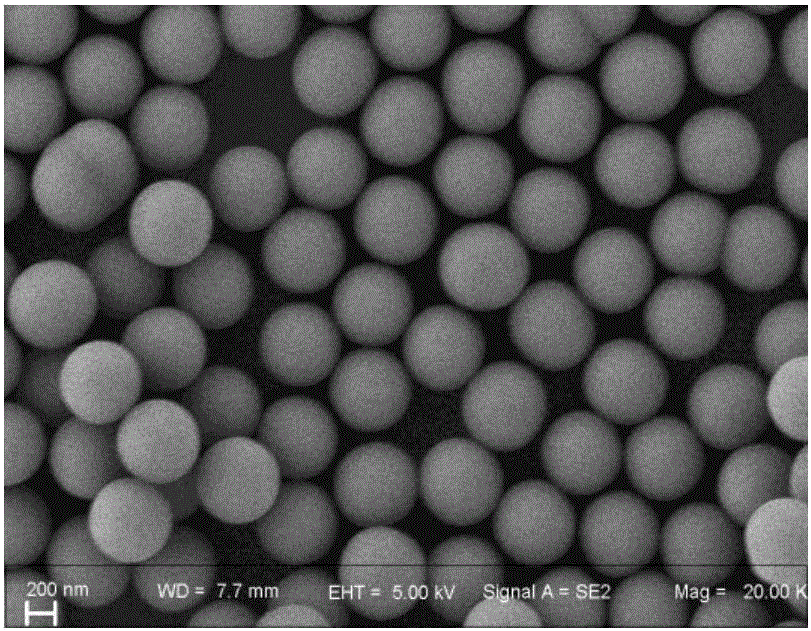

Preparation method of single-layer ordered silicon dioxide nanosphere array

InactiveCN106220237AMonolayer ordered SiO

<sub>2</sub>

The nanosphere method is simpleLow process conditionsAlcoholNanoparticle

The invention discloses a preparation method of a single-layer ordered silicon dioxide nanosphere array. The preparation method comprises the following steps of sapphire substrate cleaning; drainage sheet cleaning; single-layer SiO2 nanosphere preparing, wherein a drainage sheet is taken out and obliquely inserted into a certain amount of deionized water, a newly-prepared SiO2-absolute ethyl alcohol solution is dropwise added to the drainage sheet to form a single-layer SiO2 array, then a lifting solution is prepared, after standing is conducted till the liquid level is stable, a Al2O3 substrate is lifted through a coating lifting machine, standing is conducted till the Al2O3 substrate is dried, and then the single-layer SiO2 nanosphere array is formed on the Al2O3 substrate. According to the method, the single-layer ordered silicon dioxide nanosphere array is prepared through a draining, dispersing and lifting method at room temperature, and the prepared SiO2 nanosphere array is single in layer and compact in arrangement, can serve as a mask plate for the following process to prepare the large-area periodic and ordered nanoparticle array and prepare and research biological chips, optical devices and nanometer devices and is short in needed cycle and low in cost.

Owner:TIANJIN UNIV

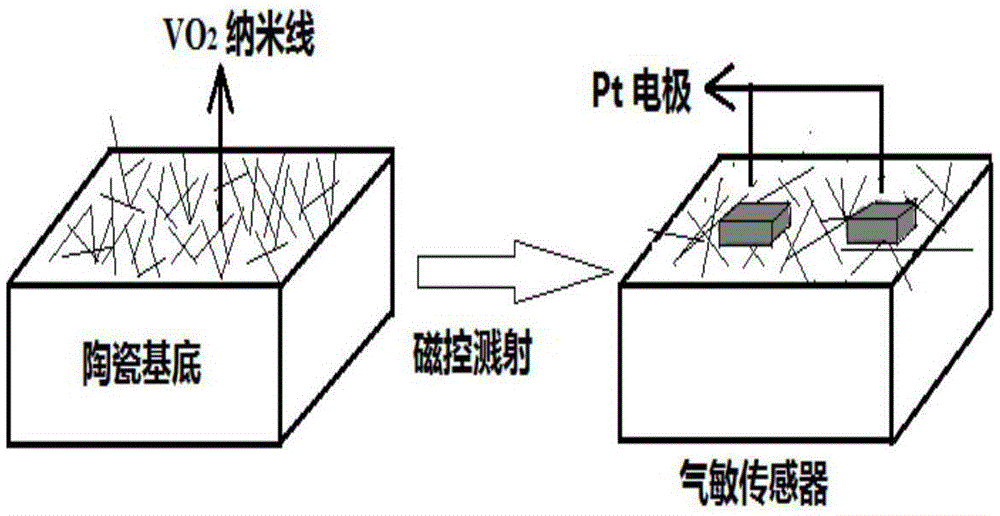

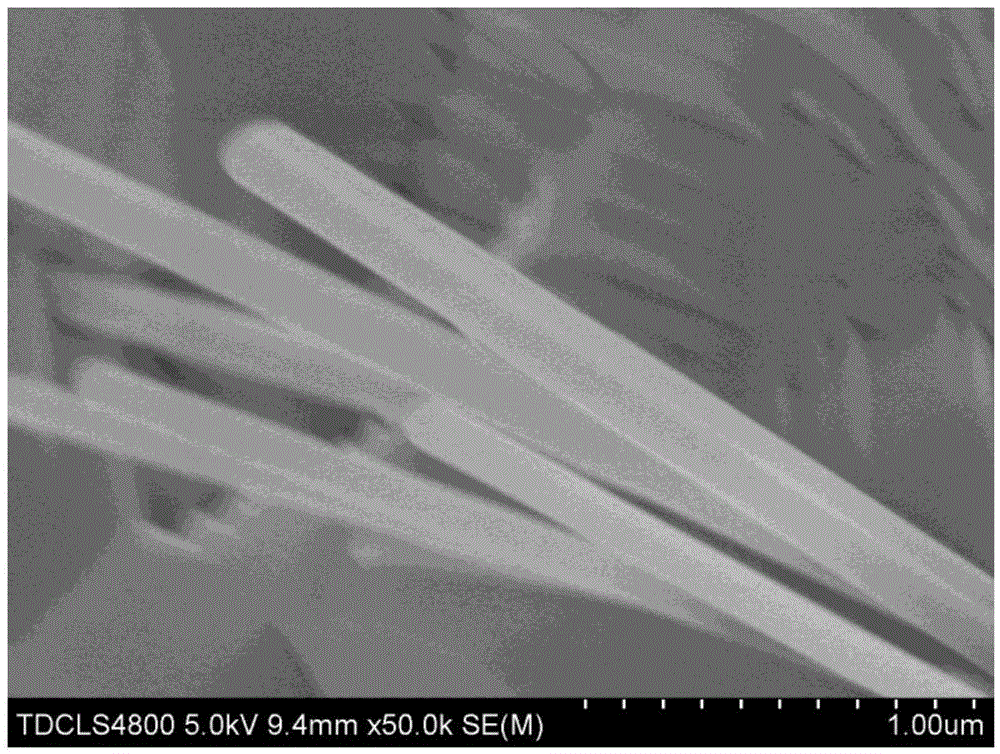

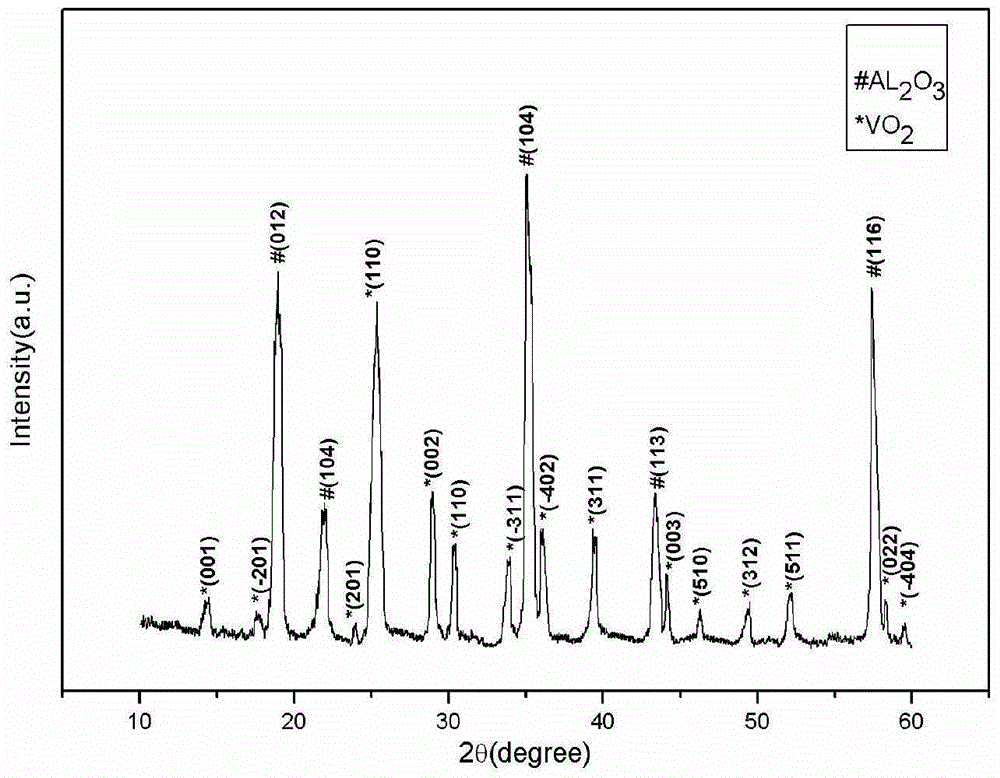

Preparation method for room temperature NO2 sensor with ceramic-based vanadium oxide nanorod structure

InactiveCN105486723AIncrease the areaHigh sensitivityMaterial resistanceGas detectorRoom temperature

The invention discloses a preparation method for a room temperature NO2 sensor with a ceramic-based vanadium oxide nanorod structure. The preparation method comprises the following steps: cleaning of a ceramic substrate; weighing of V2O5 powder; preparation of a ceramic-based vanadium oxide nanorod by using a single vapor transport method; and preparation of a ceramic-based vanadium oxide nanorod gas-sensitive sensor element. The ceramic substrate used in the invention has a rough bottom surface, is low in cost and can easily realize large-area preparation of the vanadium oxide nanorod. The ceramic-based vanadium oxide nanorod gas-sensitive sensor element is simple in structure, low in preparation cost, easy in operation and time-saving and can work at room temperature. Thus, the prepared gas-sensitive sensor element can detect NO2 gas at room temperature and has the advantages of high sensitivity, rapid response, short recovery time and repeatable detection.

Owner:TIANJIN UNIV

Water resistant carton adhesive

InactiveCN104293238ASimple structureImprove liquidityNon-macromolecular adhesive additivesStarch adhesivesAdhesiveWater quality

The invention discloses a water resistant carton adhesive which is prepared from the following raw materials in parts by weight: 65-75 parts of water, 28-34 parts of sweet potato powder, 12-16 parts of calcium carbonate, 1-2 parts of sodium hydroxide, 2-3 parts of keto-aldehyde polyvinyl alcohol compound, 3-4 parts of sepiolite powder, 1.2-1.6 parts of bridging agent, 0.15-0.18 part of sodium carboxymethyl cellulose, 0.10-0.12 part of water quality stabilizer and 0.26-0.36 parts of borax; the water resistant carton adhesive is prepared according to the following steps: pouring water into a container, regulating the temperature of the water to 33-45 DEG C, adding sodium hydroxide and uniformly stirring; then adding the sweet potato powder, and continuously stirring to be sticky; adding calcium carbonate and borax and stirring for 13-20 min; adding the water quality stabilizer and stirring for 5-10min; adding the sepiolite powder, the keto-aldehyde polyvinyl alcohol compound, the bridging agent and sodium carboxymethyl cellulose, uniformly stirring, standing and cooling. The water resistant carton adhesive disclosed by the invention has strong adhesive ability and good waterproof performance.

Owner:HEFEI DONGCAI PRINTING TECH

Method for preparing taurine

InactiveCN109485586ALow process conditionsReduce generationSulfonic acids salts preparationSulfonic acid preparationHydrogenEthylene oxide

The invention provides a method for preparing taurine. The method comprises the following steps: carrying out an addition reaction on ethylene oxide and sodium hydrogen sulfite in the presence of a heterogeneous catalyst so as to obtain sodium hydroxyethyl sulfonate at high selectivity; carrying out an ammonolysis reaction on the synthesized sodium hydroxyethyl sulfonate under catalysis of a homogeneous catalyst; and neutralizing, crystallizing, separating and the like, thereby obtaining the finished taurine. Compared with the traditional production process, the process disclosed by the invention has the advantages that by-products in the addition reaction process can be obviously reduced, the temperature and pressure of the ammonolysis reaction are reduced, the reaction time is shortened,and industrial production is easily realized.

Owner:WANHUA CHEM GRP CO LTD

Ammonium molybdate modified catalyst as well as preparation method and application thereof

ActiveCN113318756AHigh catalytic efficiencyChange surface structurePhysical/chemical process catalystsWater treatment compoundsPtru catalystPhysical chemistry

The invention belongs to the technical field of catalysts. The invention provides an ammonium molybdate modified catalyst. The ammonium molybdate modified catalyst comprises ammonium molybdate modified ferrous disulfide and molybdenum disulfide in a mass ratio of (9.5-10.5) : (1.5-2.5). Molybdenum disulfide is added into the catalyst, sulfur defects are easily formed in a hydrogen peroxide solution, sulfur defects and Fe < 2 + > double active sites promote decomposition of hydrogen peroxide to oxidize and decompose organic pollutants, ammonium molybdate increases the number of active sites of ferrous disulfide, and the catalytic efficiency is improved; meanwhile, on the basis of self-repairing, Fe < 3 + > on the surface of the catalyst is promoted to be converted into Fe < 2 + > due to existence of sulfur defects, so that the purpose of circulation is achieved, and secondary pollution cannot be caused in the whole sewage treatment process. The invention further provides a preparation method of the catalyst, ammonium molybdate modified ferrous disulfide and molybdenum disulfide are combined by adopting a ball milling process, the process is simple, the technology is mature, and the catalyst is suitable for large-scale popularization.

Owner:GUANGXI UNIV FOR NATITIES

Process for preparing poly n-butyl cyan acrylate nanometer particle

InactiveCN1733313AProtection from vandalismHigh in vitro gene transfer efficiencyPowder deliveryGenetic material ingredientsAqueous solutionMonomer

Owner:张阳德

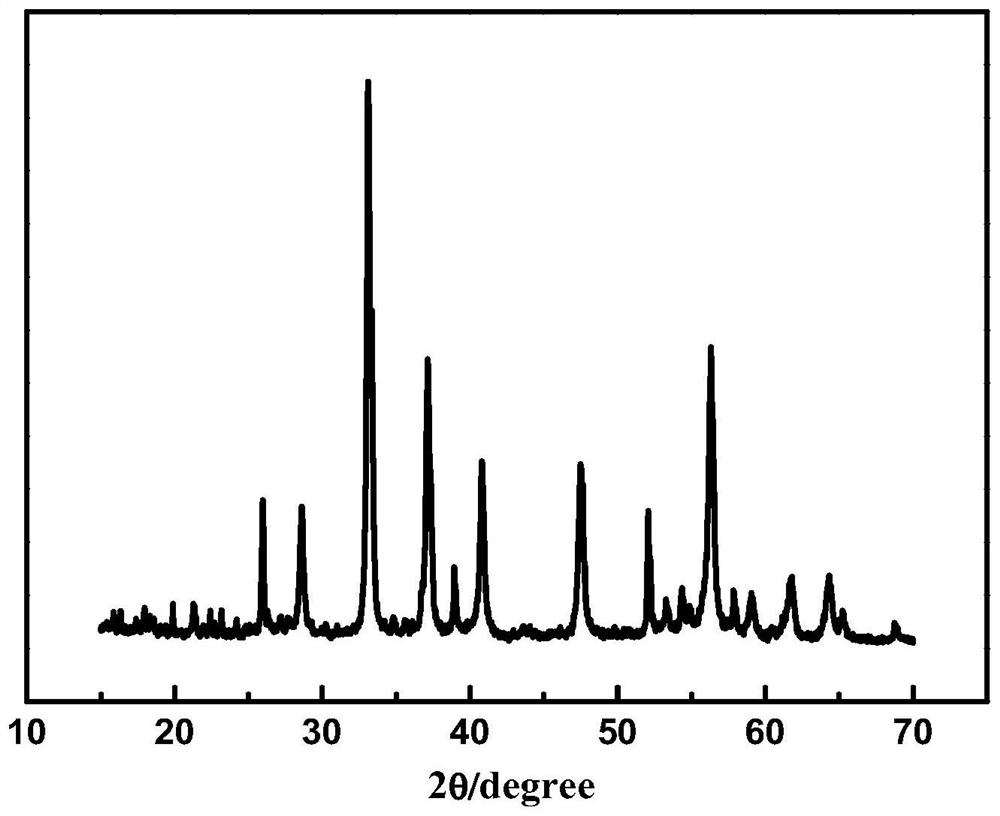

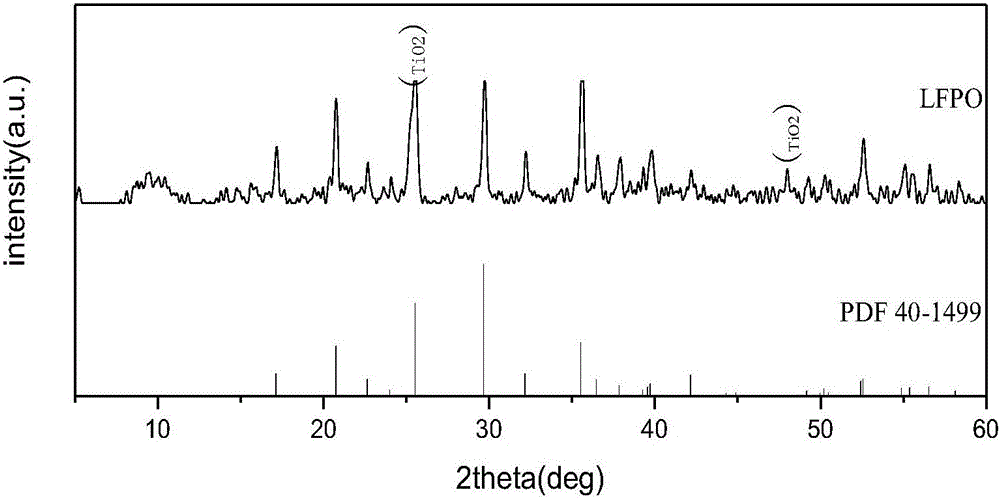

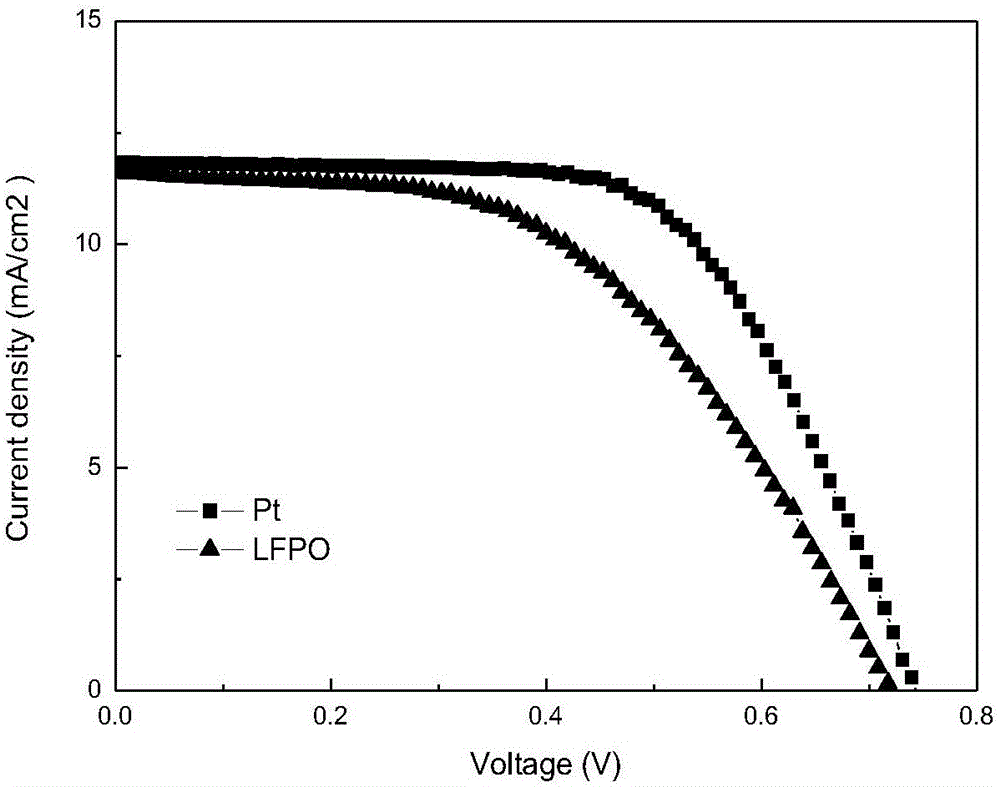

Counter electrode for dye-sensitized solar cell and preparation method thereof

ActiveCN106024396AImprove catalytic performanceImprove adhesionLight-sensitive devicesFinal product manufactureCatalytic effectSolar cell

The invention discloses a counter electrode for a dye-sensitized solar cell and a preparation method thereof. The counter electrode is composed of a conductive substrate and a LiFePO4 catalytic activity layer attached to the conductive substrate. The preparation method comprises steps: 1) a LiFePO4-based counter electrode paste is prepared: LiFePO4, nano-TiO2, an ethyl cellulose ethanol solution and terpineol are mixed and milled for 1 to 2 hours via a high-speed ball mill, and the LiFePO4-based counter electrode paste is obtained; 2) the counter electrode is prepared: uniform scrape coating or spin coating of the counter electrode paste is carried out on the conductive substrate, low temperature preheating at a temperature of 60 to 80 DEG C is firstly carried out, the conductive substrate is placed in a tubular furnace with a protective gas after the coating is dried, the temperature rises to 450 to 500 DEG C in a temperature-programmed method, heat preservation for 30 to 60 min is carried out, the LiFePO4 catalytic activity layer is formed, natural cooling to the room temperature is carried out, and inlet of the protective gas is stopped. The electrode has good catalytic effects on an iodine electrolyte, and can obtain approximate short circuit current density and open circuit voltage as a platinum electrode. The process of the preparation method is simple, the operation and the control are easy and safe.

Owner:WUHAN INST OF PHYSICS & MATHEMATICS CHINESE ACADEMY OF SCI

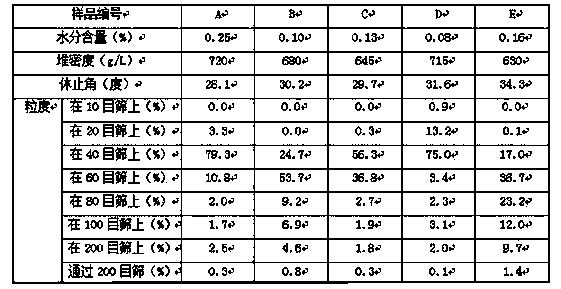

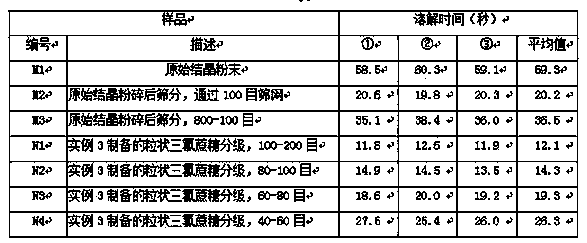

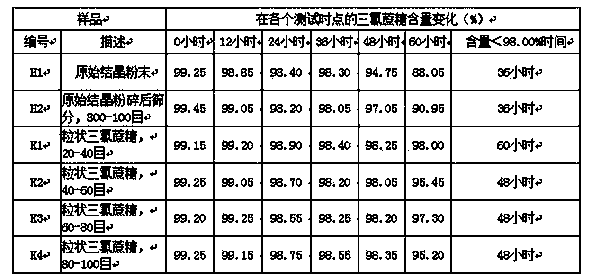

Preparation method of granular sucralose

InactiveCN104026549AImprove thermal stabilityImprove liquidityFood ingredientsFood preparationSucroseProcess engineering

The invention discloses a preparation method of granular sucralose. The preparation method comprises the following steps: (1) mixing sucralose with a binder to form a mixture; (2) granulating the mixture; (3) drying wet granules to obtain granular sucralose; (4) classifying the dried granules to obtain granular sucralose in one or more granularity ranges; (5) circulating and feeding one part or all classified granules in the one or more granularity ranges to the step (1). The prepared granular sucralose disclosed by the invention has the granularity range within 400 meshes, and is relatively excellent in properties such as thermal stability, fluidity, dissolving performance and caking resistance. The preparation method disclosed by the invention is small in number of process conditions, easy to operate, low in equipment requirement, and applicable to production and amplification.

Owner:WENGYUAN GUANGYE QINGYI FOOD TECH

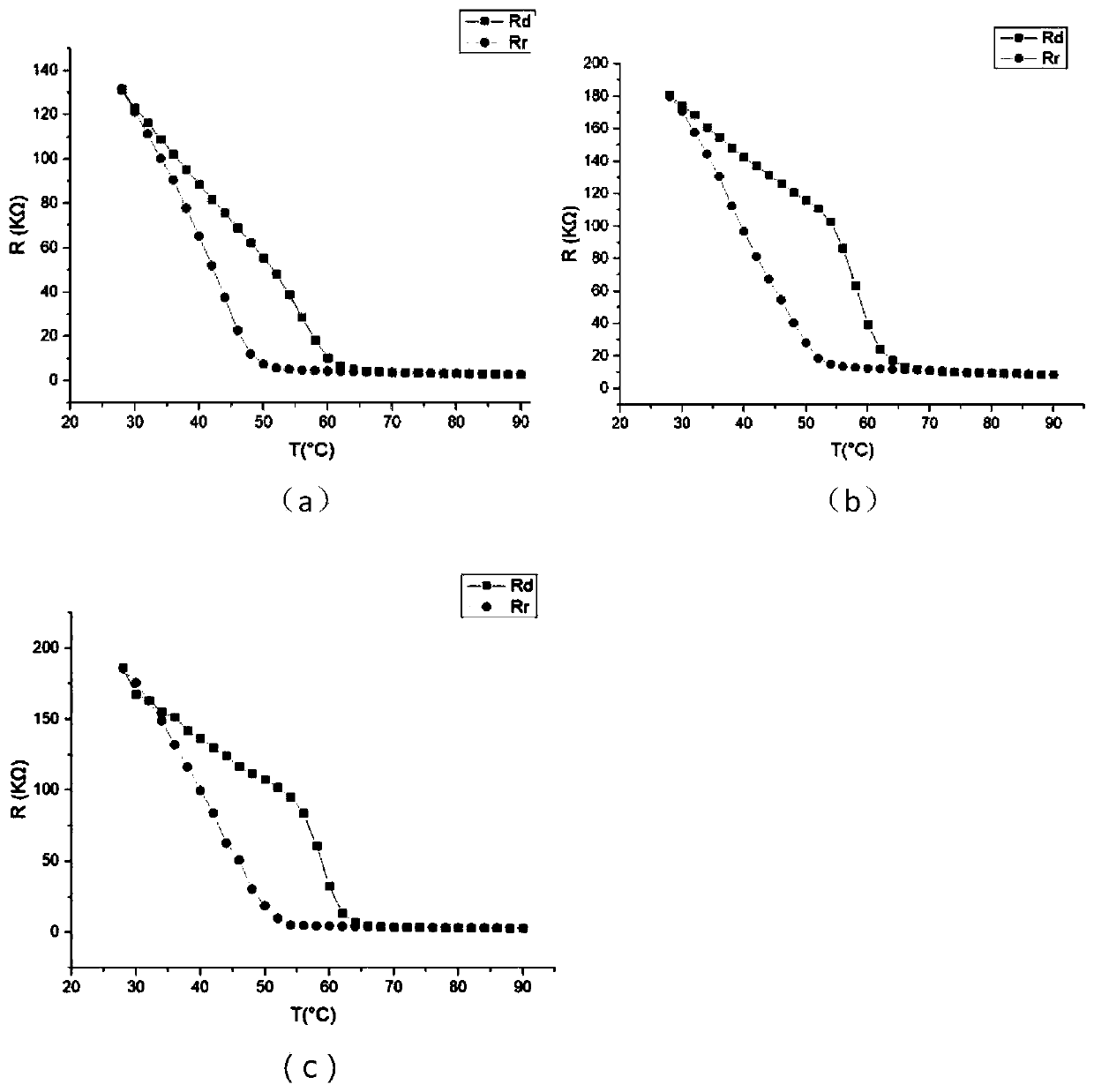

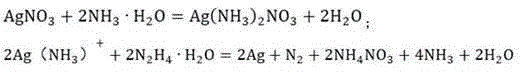

Vanadium dioxide-graphene composite film structure, and preparation method and application thereof

InactiveCN110627055AHigh visible light transmittanceSimple methodCarbon compoundsVanadium oxidesVanadium dioxideComposite film

The invention discloses a vanadium dioxide-graphene composite film structure, and a preparation method and application thereof. A sapphire substrate is spin coated with reduced graphene oxide; then, avanadium film is sputtered in a magnetron sputtering mode; rapid oxidation annealing is carried out in a rapid annealing furnace; and finally acid corrosion is carried out to form a graphene-VO2 nanoparticle composite film structure. According to the method disclosed by the invention, optical performance of VO2 intelligent windows is improved by overcoming defects in traditional surface modification anti-reflection film; a mode of compounding VO2 and graphene is adopted to load the VO2 film by graphene; the graphene is crimped during film formation, and then negative surface strain is applied to the VO2 film, so that the phase change temperature of VO2 is reduced; and meanwhile, the size of VO2 particles is changed, and the phase change amplitude is improved.

Owner:TIANJIN UNIV

High-strength corrugated case binder and production method thereof

InactiveCN109852341AHigh strengthHigh bonding strengthNon-macromolecular adhesive additivesProtein adhesivesCardboardMaterials science

The invention discloses a high-strength corrugated case binder. The high-strength corrugated case binder is produced from the following raw materials of, in parts by weight, 30-40 parts of soybean protein isolate, 10-15 parts of modified phenolic resin, 6-8 parts of modified lignin, 150-200 parts of NaOH aqueous solution and 9-11 parts of citric acid. The invention furthermore discloses a production method of the high-strength corrugated case binder. According to the binder, the soybean protein isolate is adopted as a binder main body, the modified phenolic resin is adopted as a cross-linkingagent of the soybean protein isolate, and degraded soybean protein is linked, so that higher binding strength and better water resistance are obtained; by adding the modified lignin, the contents of free formaldehyde and free cresol in the phenolic resin are reduced; and the produced binder is high in binding strength and good in binding performance, the phenomenon of water and binder separation is not liable to happen, the production method is simple, technology conditions are low, a bound board is high in compressive resistance and high in puncture resistance, and the quality of a produced corrugated case can be guaranteed.

Owner:CHUZHOU CIGARETTE MATERIALS FACTORY

Composite salt-resistant thickening agent, and preparation method and application thereof

The invention discloses a composite salt-resistant thickening agent, which belongs to the field of daily chemicals. The composite salt-resistant thickening agent consists of xanthan gum, guar gum and sodium alginate, wherein the weight ratio of the xanthan gum to the guar gum to the sodium alginate is (5-8):(2-5):(1-3); and the composite salt-resistant thickening agent is prepared by the following steps of: dissolving the xanthan gum, the guar gum and the sodium alginate into water in turn; stirring and uniformly mixing; adjusting to the concentration for use by using water; and adjusting pH value to be 6 to 8; and heating at the temperature of between 50 and 80 DEG C for 10 to 60 minutes. The amount of the used thickening agent is 0.01 to 1.0 percent of the weight of the salt-containing daily chemical. The composite salt-resistant thickening agent has acid and alkali resistance, high temperature resistance, anti-freezing effect and does not have toxic or side effect, is excellently matched with a common surfactant (such as sodium alcohol ether sulfate AES, sodium ammonium dodecyl sulfate K12A and the like) in the daily chemical and has the advantages of simple manufacturing process, low technological condition and low comprehensive cost.

Owner:自贡市轻工业设计研究院有限责任公司 +1

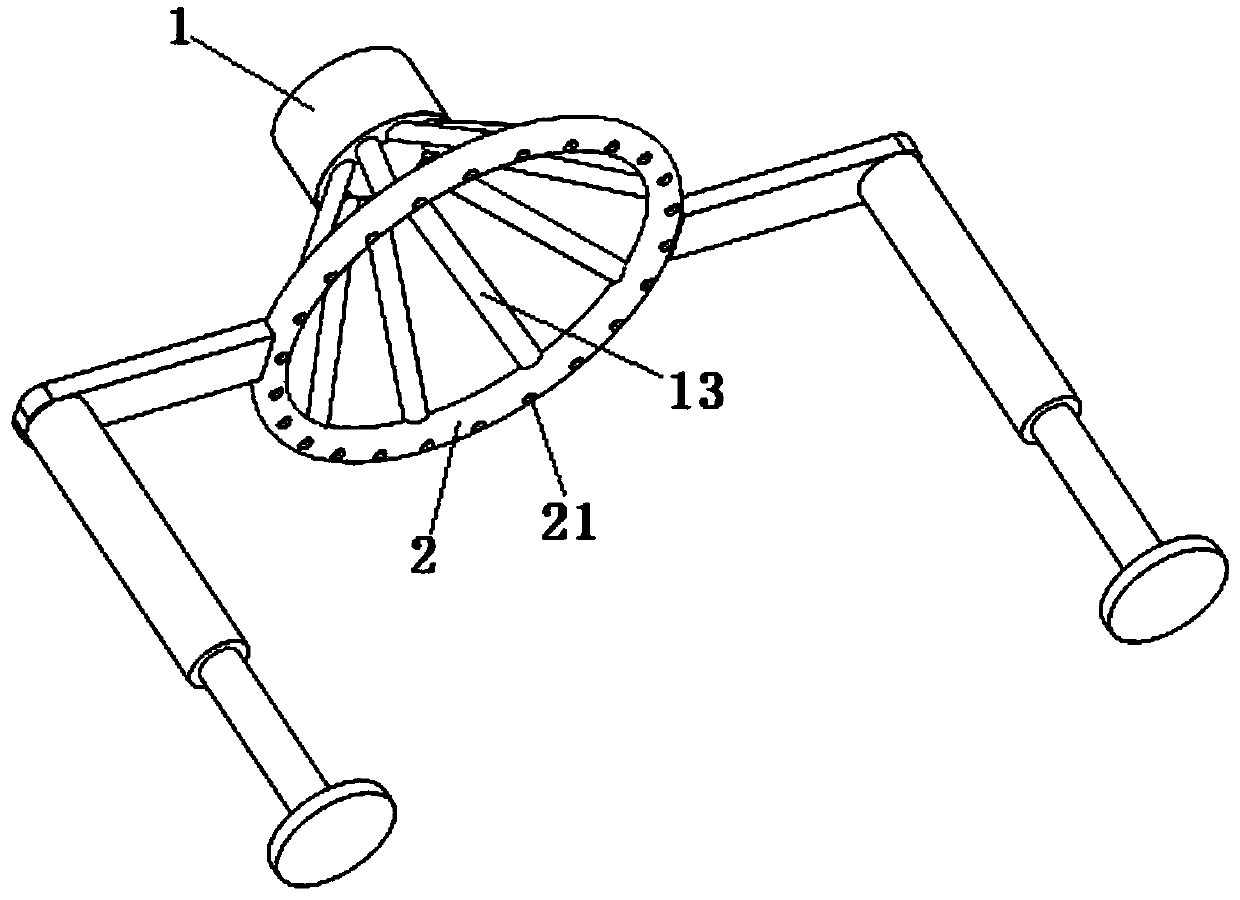

Nano Ag powder preparation method

The invention relates to the technical field of powder metallurgy, in particular to a nano Ag powder preparation method. The method includes preparation; mixed solution preparation, reduction solution preparation, oxidation reduction reaction, centrifugal separation and high pressure drying. The method is simple to operate, the required process condition is simple, the nano silver produced by the method has high purity, even granularity distribution, high collection rate and low impurity content, and grains are not prone to gathering.

Owner:侯善敬

Anti-mildew carton adhesive

InactiveCN104277738AHigh bonding strengthStrong puncture resistanceNon-macromolecular adhesive additivesStarch adhesivesEpoxyCellulose

The invention discloses an anti-mildew carton adhesive, which is prepared from the following raw materials in parts by weight: 65-75 parts of water, 9-12 parts of rice starch, 22-30 parts of sticky rice starch, 12-16 parts of calcium carbonate, 1-2 parts of sodium hydroxide, 3-4 parts of epoxy resin, 0.12-0.16 part of a naphthalene sulfonate formaldehyde condensation compound, 1.5-1.8 parts of carboxymethyl cellulose, 0.3-0.5 part of borax, and 1.5-1.7 parts of a preservative. A preparation method comprises the following steps: pouring water into a container, and regulating the temperature of water to be 50-70DEG C; adding rice starch into water, then evenly stirring and adding sticky rice starch, and stirring to be thick, to obtain an emulsion A; adding calcium carbonate into the emulsion A, and stirring to obtain an emulsion B, wherein the stirring time lasts 10-20min; adding sodium hydroxide, epoxy resin, naphthalene sulfonate formaldehyde condensation compound, carboxymethyl cellulose, borax and preservatives into the emulsion B, evenly stirring, and then standing and cooling. The anti-mildew carton adhesive is strong in adhesion power and difficultly generates mildew.

Owner:HEFEI DONGCAI PRINTING TECH

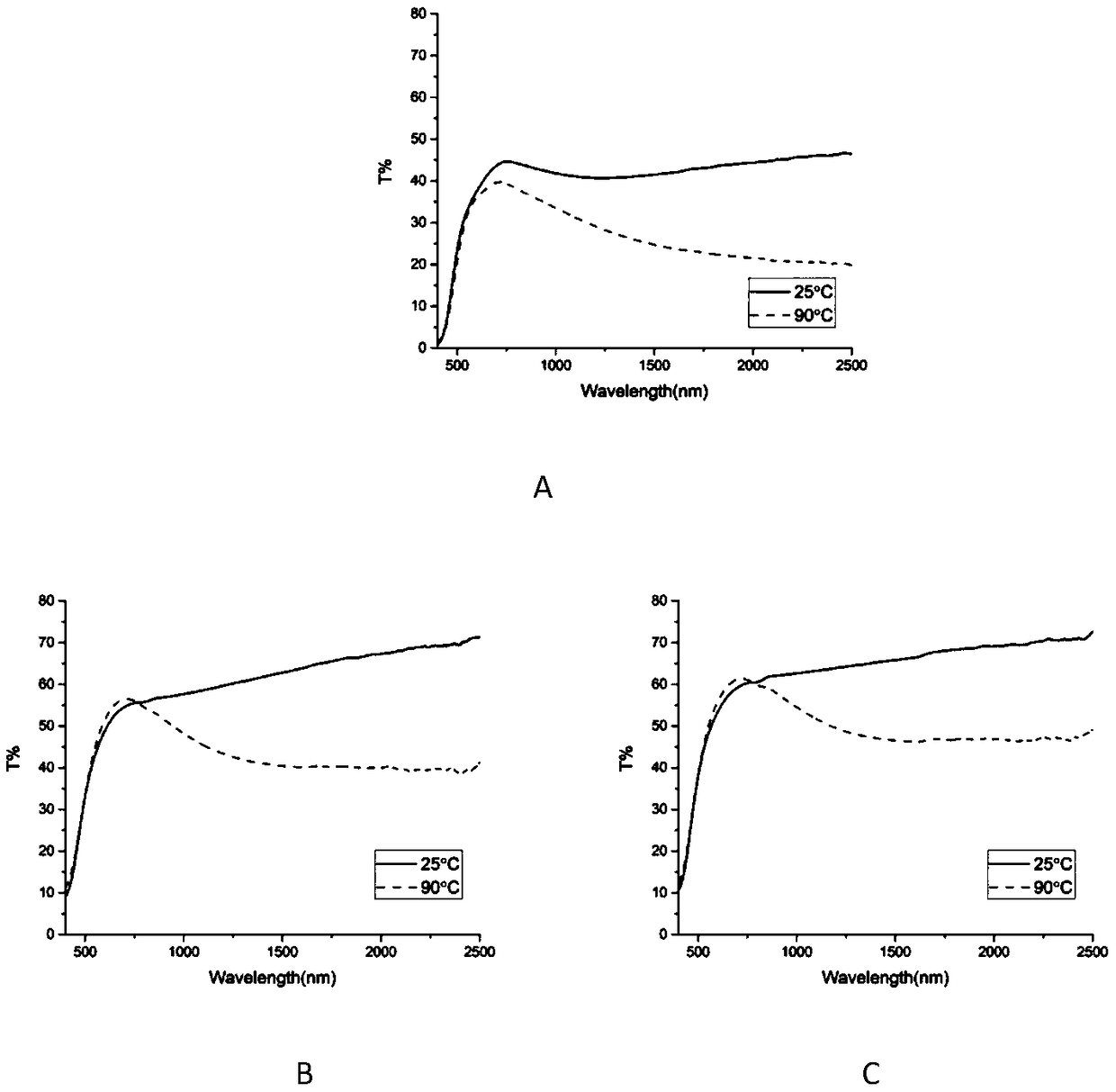

Method for improving visible light transmittance of vanadium dioxide film by using dilute sulfuric acid etching

InactiveCN109402581AHigh porosityLow process conditionsVacuum evaporation coatingSputtering coatingTransmittanceVanadium dioxide

The invention discloses a method for improving visible light transmittance of a vanadium dioxide film by using dilute sulfuric acid etching. A vanadium dioxide film, prepared through combining magnetron sputtering and rapid annealing, is etched by adopting a dilute sulfuric acid treatment mode, and the continuous planar vanadium dioxide film is etched into separate particles in an acid treatment manner in a whole preparation process, so that the porosity of the film is improved. According to the method disclosed by the invention, required process conditions are low and are easily controlled, and the visible light transmittance of VO2 can be effectively improved. A vanadium metal film is sputtered firstly, then, thermal annealing oxidation is carried out, and finally, soaking etching is carried out by using dilute sulfuric acid, so that the manufacturing cost is low, and the method is applicable to large-batch industrial production.

Owner:TIANJIN UNIV

Easy-to-coat carton adhesive

InactiveCN104277736AHigh bonding strengthStrong puncture resistanceNon-macromolecular adhesive additivesStarch adhesivesSodium bicarbonatePolyvinyl alcohol

The invention discloses an easy-to-coat carton adhesive. The easy-to-coat carton adhesive is prepared from the following raw materials in parts by weight: 100-120 parts of water, 20-30 parts of corn starch, 10-15 parts of calcium carbonate, 2-3 parts of alum, 2-3 parts of light magnesium oxide, 0.42-0.46 part of aluminum sulfate, 0.36-0.38 part of polyvinyl alcohol, 1-2 parts of sodium bicarbonate, 0.7-0.8 part of potassium permanganate and 0.6-0.8 part of borax. The easy-to-coat carton adhesive is prepared according to the following steps: pouring water into a container and adjusting water temperature to 56-64 DEG C; pouring corn starch into the water, continuously stirring to a viscous state, then adding calcium carbonate and potassium permanganate, and stirring for 15-18min to obtain an emulsion A; and adding alum and light magnesium oxide into the emulsion A, stirring for 6-8min, then adding aluminum sulfate, polyvinyl alcohol and sodium bicarbonate, uniformly stirring, then adding borax, stirring for 20-25min, standing and cooling. The easy-to-coat carton adhesive disclosed by the invention is strong in adhesive capacity and easy to coat, and can improve the compressive strength and flexural strength of carbons.

Owner:HEFEI DONGCAI PRINTING TECH

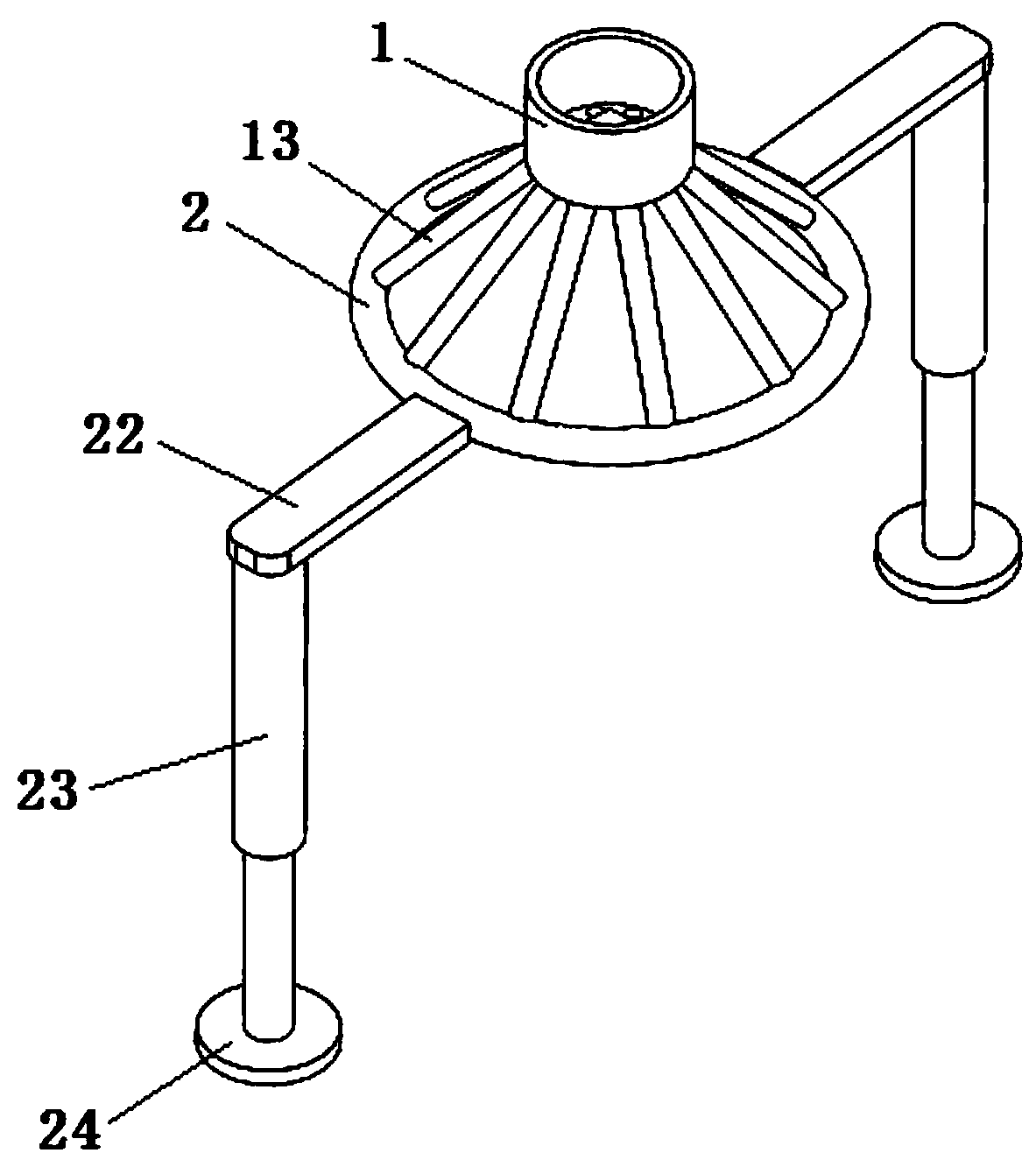

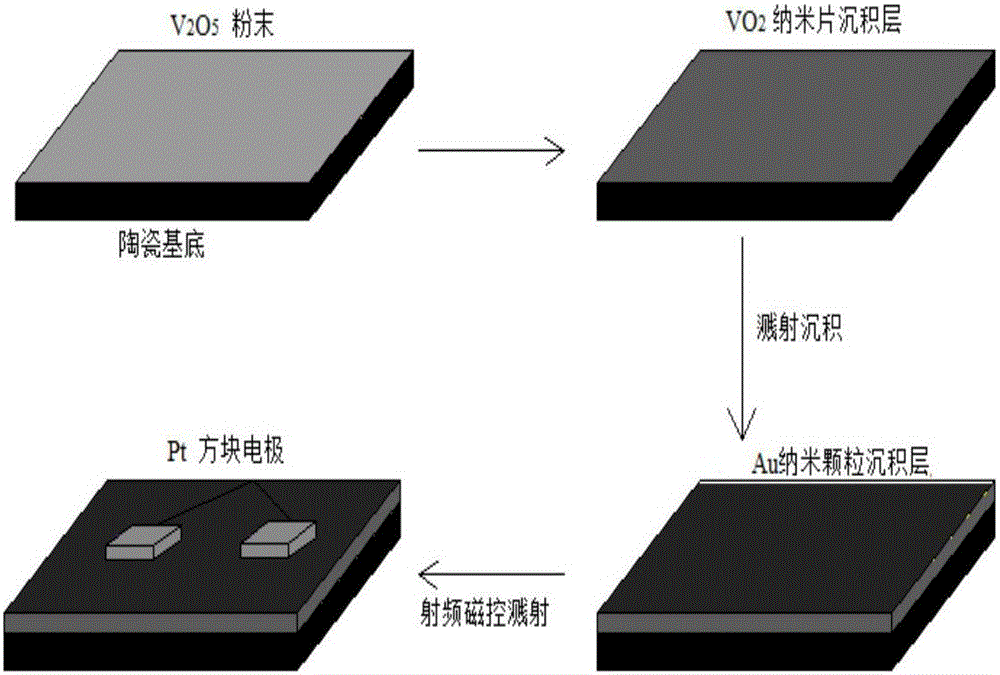

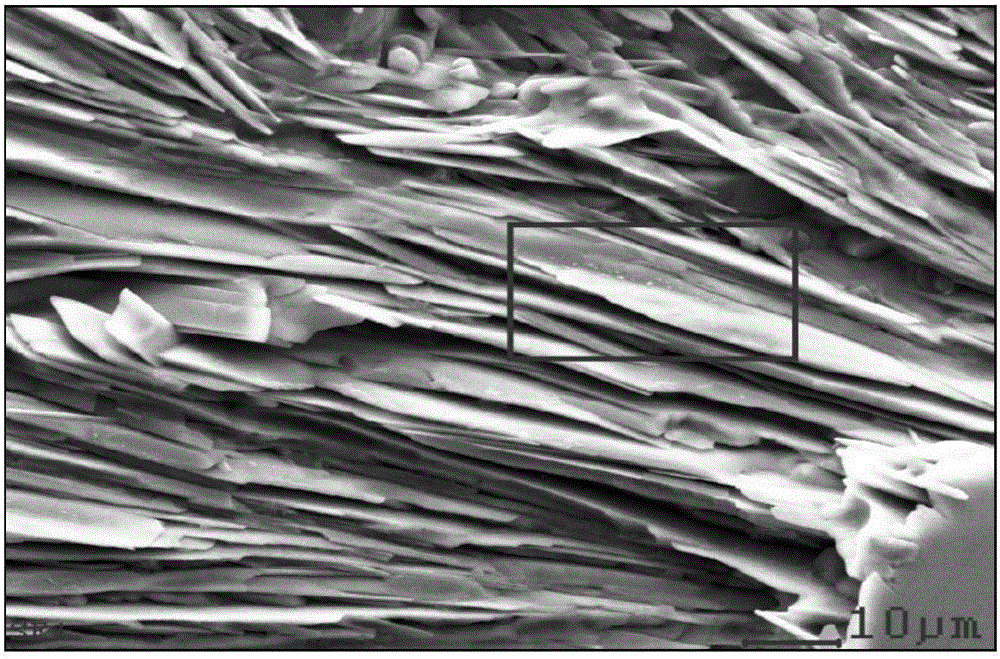

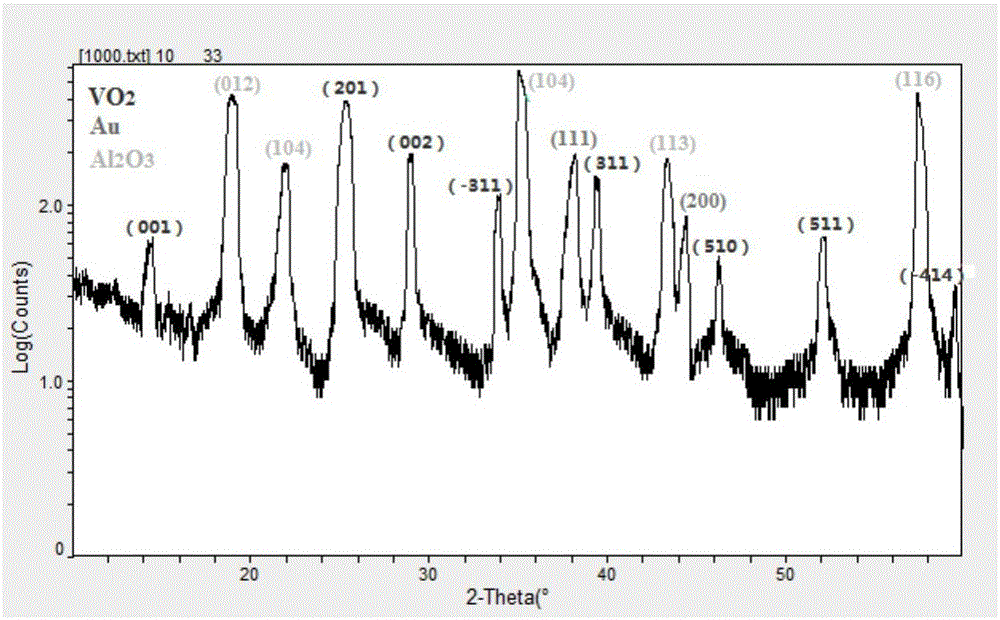

Production method of gold-doped vanadium dioxide nanosheet structured room temperature CH4 gas-sensitive sensor

InactiveCN106248743ANo pollution in the processImprove adsorption capacityMaterial resistanceVanadium dioxideGas detector

The invention discloses a production method of a gold-doped vanadium dioxide nanosheet structured room temperature CH4 gas-sensitive sensor. The method comprises the following steps: cleaning a ceramic substrate; weighing V2O5 powder; preparing vanadium dioxide nanosheets through a single vapor transportation technology; doping the surfaces of the vanadium dioxide nanosheets with gold; and producing the gold-doped vanadium dioxide nanosheet gas-sensitive sensor element. The method provided by the invention has the advantages of simplicity in operation, realization of low-cost preparation of the gold-doped vanadium dioxide nano-sheets, few control technology conditions needed by the single vapor transportation technology, and no pollution to environment. The gold-doped vanadium dioxide nano-sheets have large specific surface area and large gas diffusion channel, and are in favor of adsorbing and diffusing gases. The gold-doped vanadium dioxide nanosheet structured room temperature CH4 gas-sensitive sensor produced in the invention has the advantages of high sensitivity and short response recovery time in the detection of low-concentration CH4 gas at room temperature. The study of a gold-doped vanadium dioxide composite material in reduction of the temperature of the gas sensor and improvement of the sensitivity of the gas sensor still has great research potential.

Owner:TIANJIN UNIV

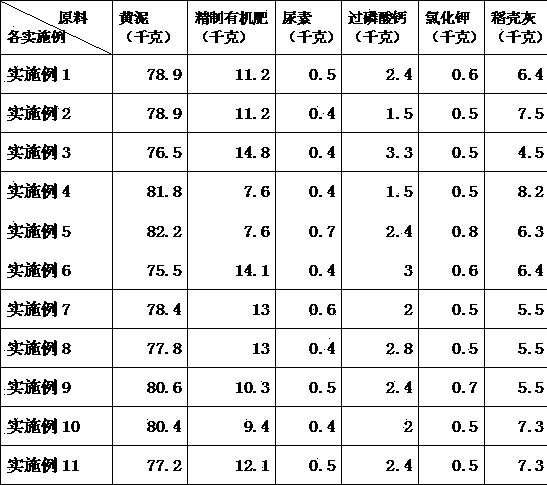

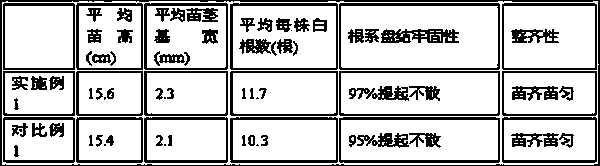

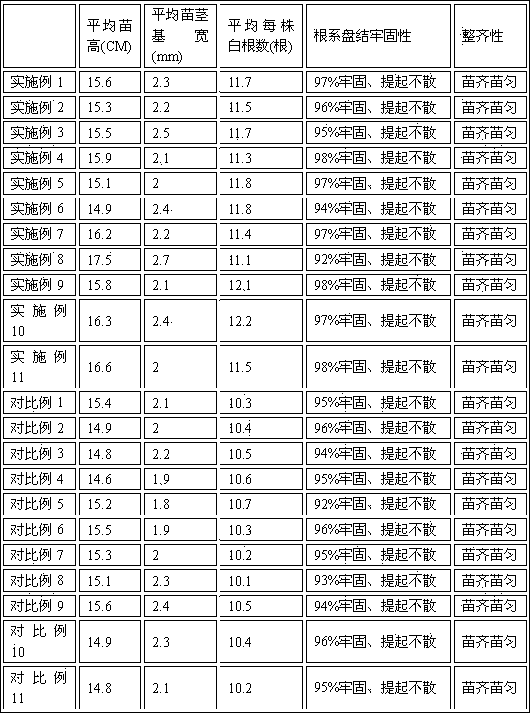

Matrix for machine-transplanted rice seedlings and preparation method thereof

The invention discloses a matrix for machine-transplanted rice seedlings and a preparation method thereof. The preparation method comprises steps of firstly, preparing the following raw materials: 75.5-82.2 parts of yellow mud, 7.6-14.8 parts of refined organic fertilizer, 0.4-0.7 part of urea, 1.5-3.3 parts of calcium superphosphate, 0.5-0.8 part of potassium chloride and 4.5-8.2 parts of rice hull ash; secondly, smashing the yellow mud, sieving by a sieve with pore diameter of 4-8mm; thirdly, uniformly mixing and stirring the raw materials; fourthly, piling up the uniformly mixed material for 15-40 days so as to obtain the matrix for the machine-transplanted rice seedlings; fifthly, 6-8 days before seeding, spraying dexon solution onto the matrix for the machine-transplanted rice seedlings to disinfect the matrix. The raw materials are abundant and cheap, and the machine-transplanted rice seedlings cultivated by the matrix are strong and have firmly coiled root systems.

Owner:湖南省安邦农业研究院

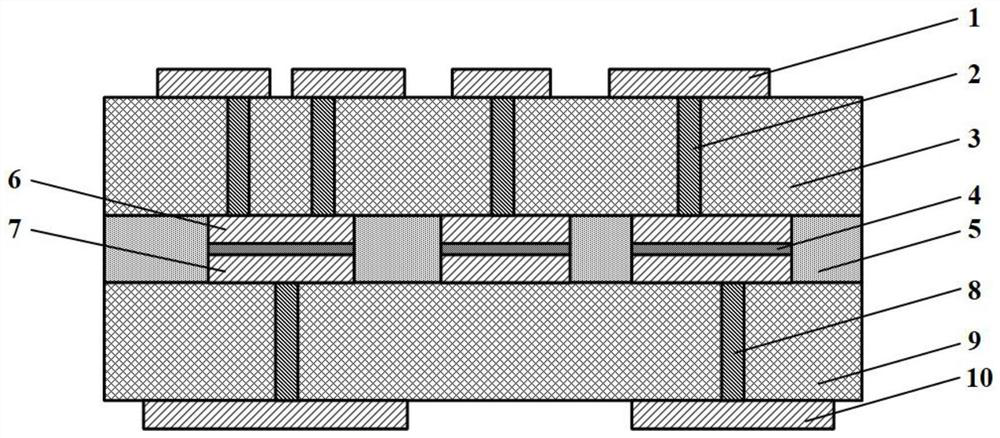

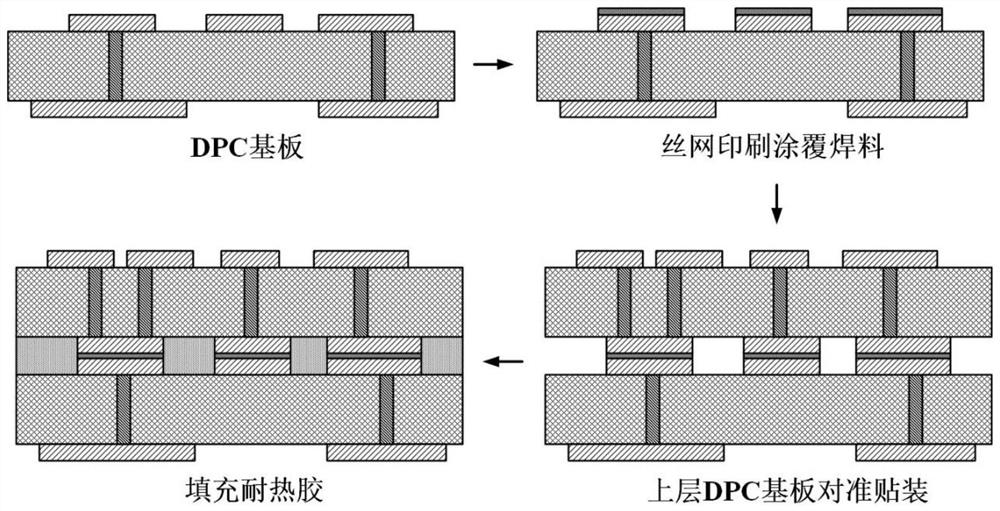

Preparation method of multilayer ceramic circuit board

PendingCN114501857AEasy to processImprove connection strengthSemiconductor/solid-state device detailsSolid-state devicesHeat resistanceMiniaturization

The invention discloses a preparation method of a multilayer ceramic circuit board. The multilayer ceramic circuit board is formed by stacking and bonding a plurality of electroplated ceramic substrates (DPC). The method comprises the following steps: firstly, preparing a DPC ceramic substrate containing a surface circuit layer and vertical interconnection metal columns through a pattern electroplating process; then preparing a metal solder on the circuit layer of the DPC ceramic substrate, stacking and aligning a plurality of DPC ceramic substrates, and then bonding to realize mechanical stable connection and electric interconnection between the DPC ceramic substrates; and finally, filling high-temperature-resistant insulating glue between the DPC substrates, and curing to obtain the multi-layer ceramic circuit board. By utilizing the characteristics of good heat conduction / heat resistance, high pattern precision, vertical interconnection and the like of the DPC ceramic substrates, mechanical connection and electric interconnection between the DPC substrates are realized through metal bonding, the multilayer ceramic circuit board with high reliability and high precision is prepared, and the requirements of miniaturization and integrated packaging of power devices are met.

Owner:武汉利之达科技股份有限公司 +1

Method for preparing multilayer molybdenum disulfide in one step

InactiveCN108677162ASimple methodLow process conditionsChemical vapor deposition coatingGas phaseSulfur

The invention discloses a method for preparing multilayer molybdenum disulfide in one step. In an inert atmosphere, common sulfur powder and MoO3 are used as raw materials, multilayer MoS2 is grown incontrol by using chemical vapor deposition method in a single temperature zone, and the number of layers is 3 to 7; the temperature during deposition is controlled at 650 DEG C to 750 DEG C and the deposition time is controlled at 5 to 30 minutes to complete the preparation of multilayer MoS2; and strict control of multilayer MoS2 is realized by optimization of the preparation parameters such asultrasonic cleaning treatment of the substrate, amount of sulfur powder, growth temperature and growth time.

Owner:KUNMING UNIV OF SCI & TECH

Nanometer waterproof liquid and waterproof method for electronic products

The invention provides nanometer waterproof liquid for electronic products. The nanometer waterproof liquid comprises, by weight, 1%-5% of liquid silicone rubber, 94%-98% of No.70 alkane solvent oil, 0.2%-0.6% of tween 60 and 0.2%-0.6% of polyethylene glycol. The liquid silicone rubber is used as a waterproof agent, the No.70 alkane solvent oil is used as a solvent, the tween 60 is used as a surfactant A, and the polyethylene glycol is used as a surfactant B. The invention further provides a waterproof method for the electronic products. The waterproof method is implemented by the aid of the nanometer waterproof liquid for the electronic products. The waterproof method includes steps of 1, arranging the electronic products in sealing bins of special nanometer waterproof coating machines for mobile phones; 2, striking the nanometer waterproof liquid for the electronic products by the aid of high-pressure gas, atomizing the nanometer waterproof liquid, ejecting the nanometer waterproof liquid, filling the sealing bins with the nanometer waterproof liquid and converting the nanometer waterproof liquid in a liquid state into waterproof liquid in a nanometer-scale gas state; 3, carrying out vacuum suction, forming a layer of waterproof films from the waterproof liquid in the nanometer-scale gas state and attaching each layer of waterproof films on the surface of each electronic products; 4, volatilizing the solvent, then enabling the nanometer-scale waterproof agent to be in contact with water molecules in air, naturally solidifying the nanometer-scale waterproof agent and ultimately forming the waterproof films.

Owner:云台科技(深圳)有限公司

High-temperature-resistant high-load self-lubricating bearing surface structure and manufacturing method thereof

InactiveCN104149417AImprove carrying capacitySmall wear scar widthLamination ancillary operationsLaminationBearing surfaceWear resistance

The invention discloses a high-temperature-resistant high-load self-lubricating bearing surface structure and a manufacturing method thereof. The bearing surface structure is a laminated structure, is formed by overlapping a bottom layer, a middle layer and a surface layer from bottom to top, wherein the bottom layer is a 08F cold-rolled steel plate which is 1.5-2.5 millimeters in thickness; the middle layer is made of tin bronze powder, and is 0.15-0.28 millimeter in thickness; and the surface layer is a modified polytetrafluoroethylene material layer which is 0.02-0.05 millimeter in thickness. Through the method, pure polytetrafluoroethylene is turned into modified polytetrafluoroethylene, the bearing surface structure can meet the requirement of a dry friction condition, the working temperature can be up to 300 DEG C, the friction coefficient is 0.2, and the grinding width is less than 4 millimeters; compared with the pure polytetrafluoroethylene, the modified polytetrafluoroethylene has the advantages that the pressure resistance is improved by 5-10 times, the wear resistance is improved by 1,000 times, the linear expansion coefficient is lowered by 80 percent, and the heat conductivity is increased by 5 times; and the high-temperature-resistant high-load self-lubricating bearing surface structure can be widely applied to the field of bearings.

Owner:WUJIANG MINGYANG NEW MATERIALS TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com