Patents

Literature

33results about How to "Long synthesis time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Lithium-enriched manganese-based material precursor as well as preparation method, lithium-enriched manganese-based anode material and preparation method thereof, lithium battery

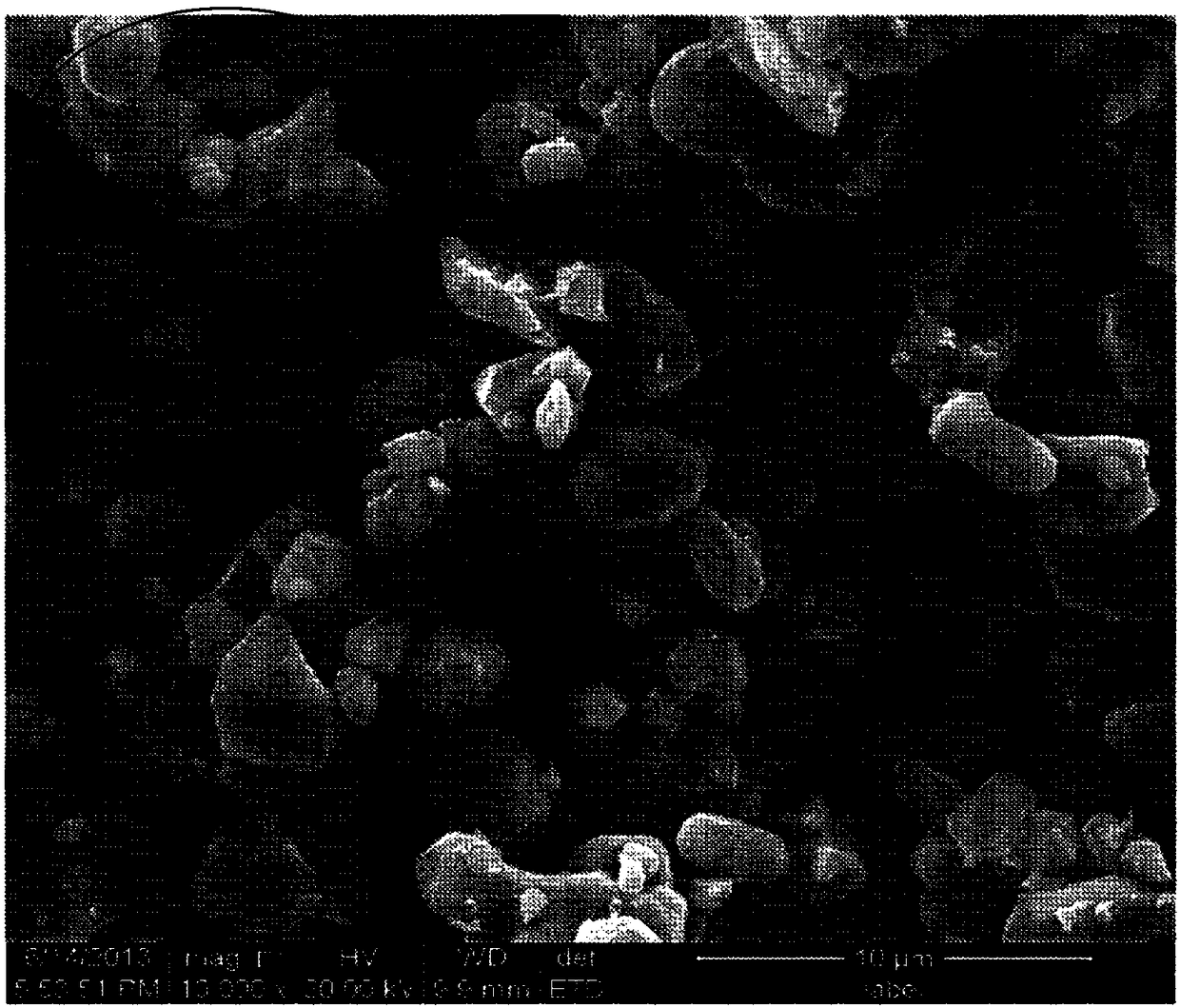

ActiveCN108557905AEnough grain boundary fusionActive enoughCell electrodesSecondary cellsChemistryVoltage

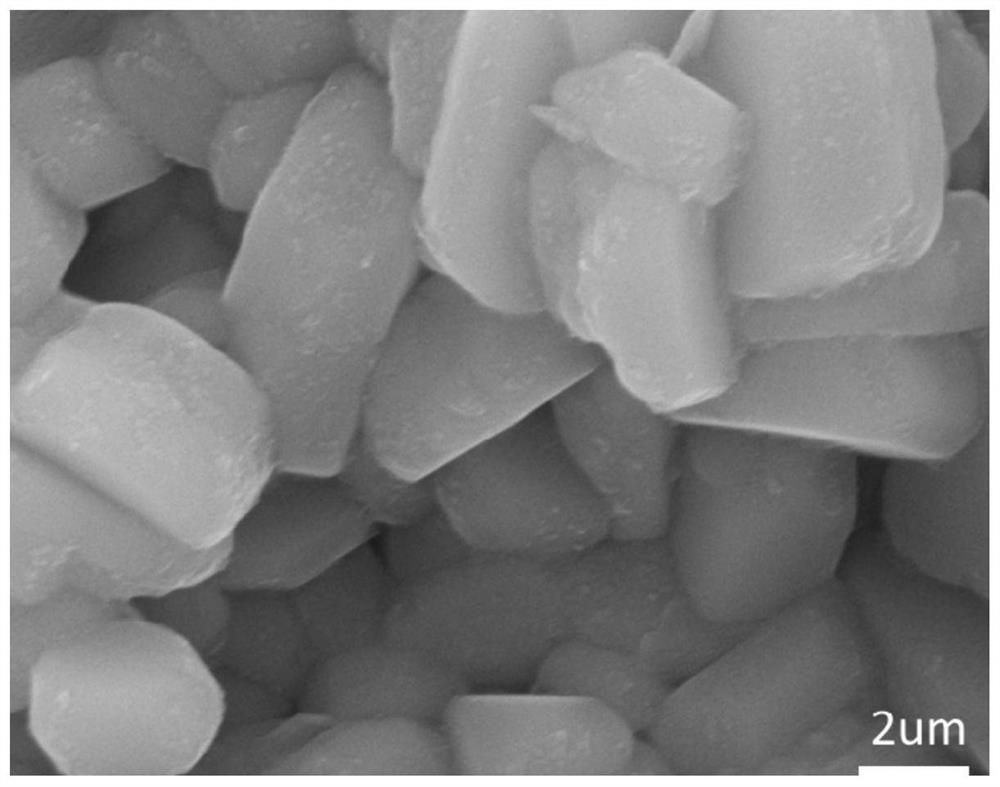

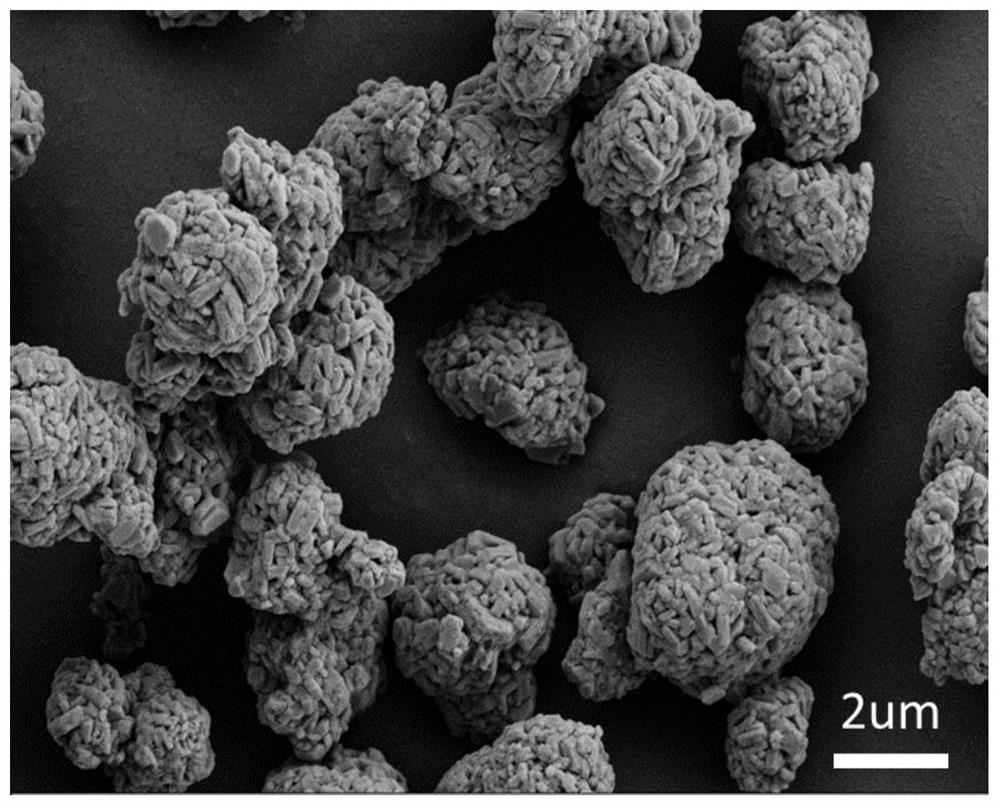

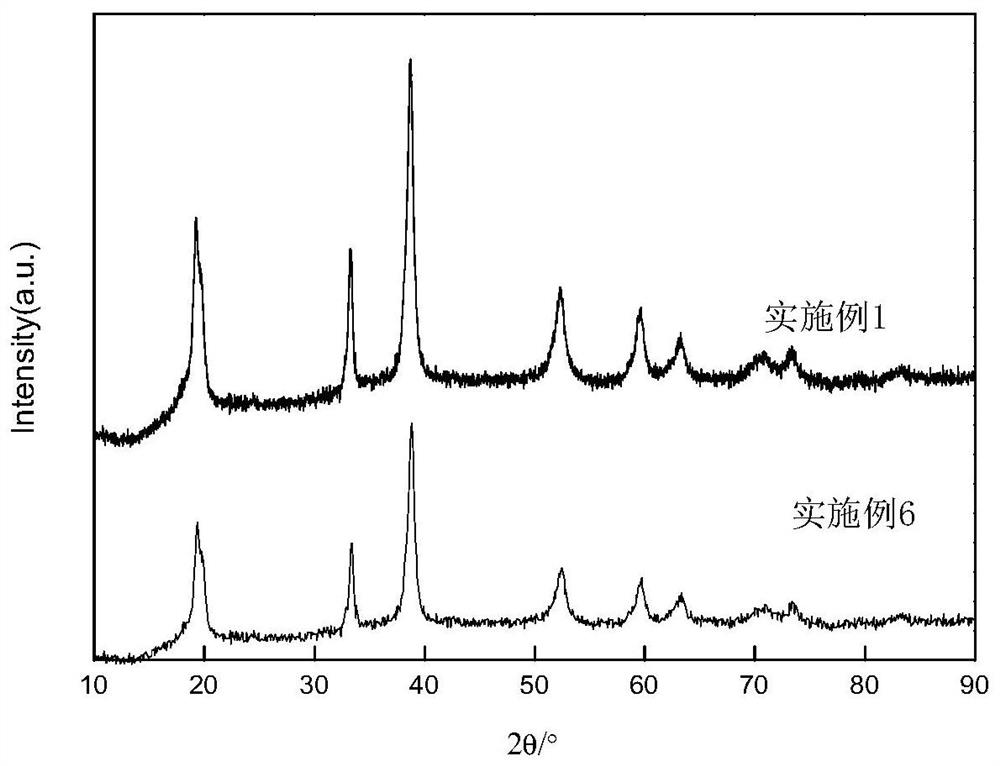

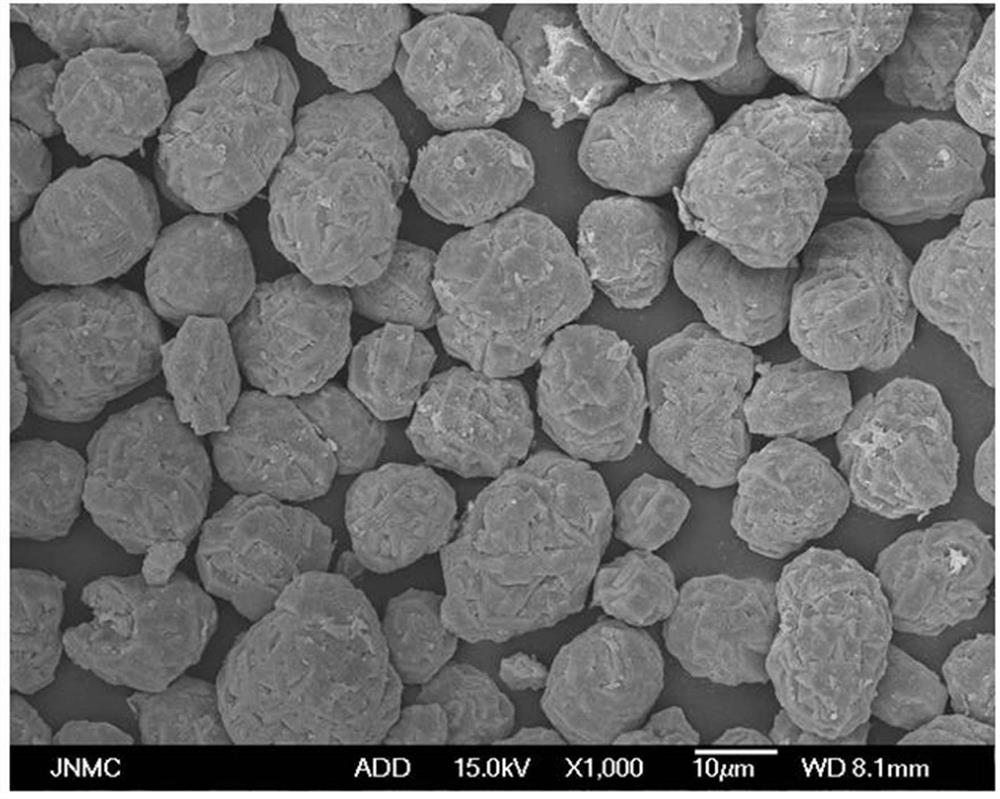

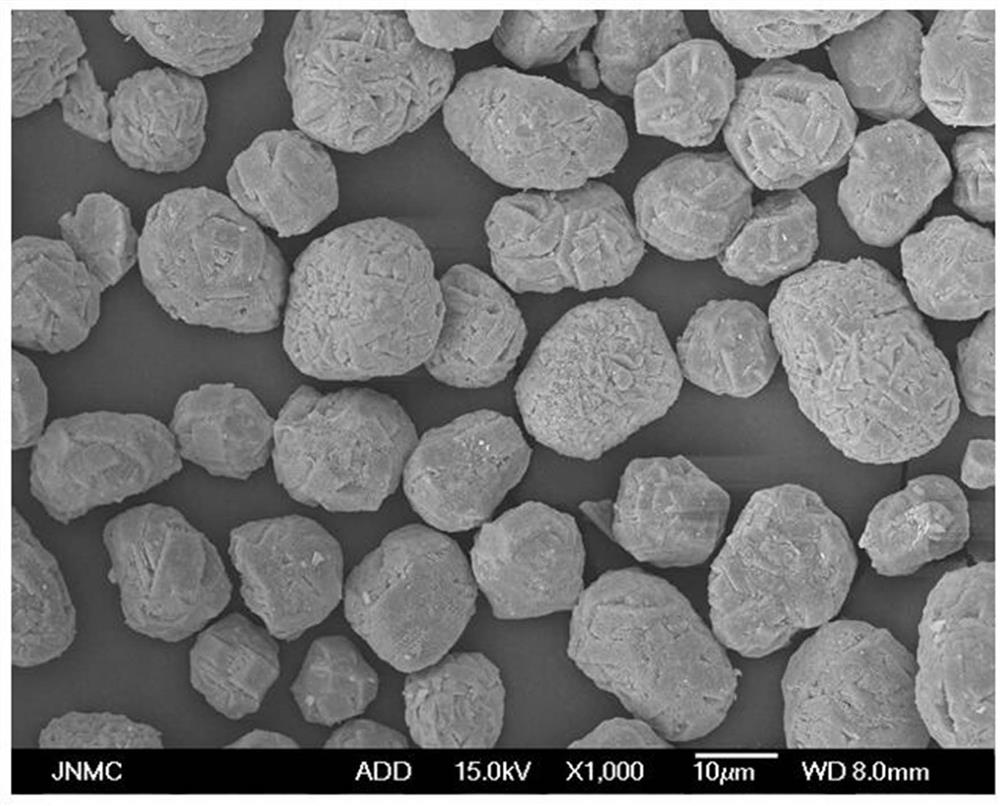

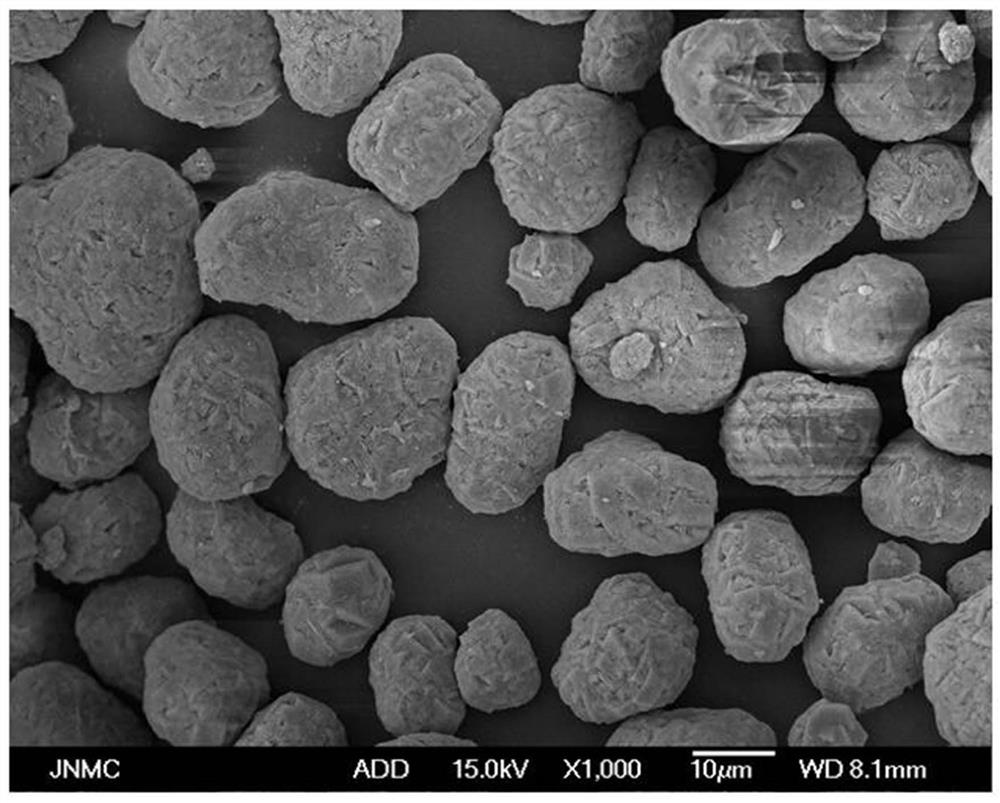

The invention relates to a lithium-enriched manganese-based material precursor which is a lithium-enriched manganese-based carbonate precursor of a lamellar morphology, the particle size of the precursor is 1-7mu m, and the specific surface area of the precursor is 8-50m<2> / g. By adopting the lithium-enriched manganese-based carbonate precursor of the lamellar morphology, a lithium-enriched manganese-based anode material of a high single crystallization degree can be easily prepared. The invention further relates to a preparation method of the lithium-enriched manganese-based carbonate precursor of the lamellar morphology, and a preparation method and the application of the lithium-enriched manganese-based anode material of a single crystal morphology. Therefore, the mechanical strength, the stability, the compaction density, the capacity and the first efficiency of the micro structure of the anode material can be improved, and the voltage attenuation of the material can be inhibited.

Owner:桑德新能源技术开发有限公司 +1

Preparation method of branched polyethyleneimine and shale intercalation inhibitor

ActiveCN107722953AReliable technologyHigh yieldDrilling compositionEthylenediaminePolyamine Compound

The invention discloses a preparation method of branched polyethyleneimine and a shale intercalation inhibitor prepared from the branched polyethyleneimine. The branched polyethyleneimine is preparedby the following steps: S1. synthesizing aziridine; S2. with a polyamine compound and the aziridine as raw materials, preparing the branched polyethyleneimine by a stepwise synthesis process or a one-pot synthesis process, wherein the polyamine compound is polyethylene polyamine or alkylamine; the polyethylene polyamine is one of diethylenetriamine, triethylene tetramine, tetraethylenepentamine and pentaethylenehexamine; the alkylamine is one of ethylenediamine, propane diamine, butanediamine, pentamethylene diamine, nonamethylene diamine and decamethylene diamine. The shale intercalation inhibitor is prepared by proportionally mixing the branched polyethyleneimine with water. The branched polyethyleneimine synthesis method provided by the invention has the advantages of high yield and cheap raw materials and is suitable for large-scale industrial production; the shale intercalation inhibitor prepared from the branched polyethyleneimine can effectively alleviate the problem of unstableborehole wall caused by the hydration dispersion of shale.

Owner:SOUTHWEST PETROLEUM UNIV

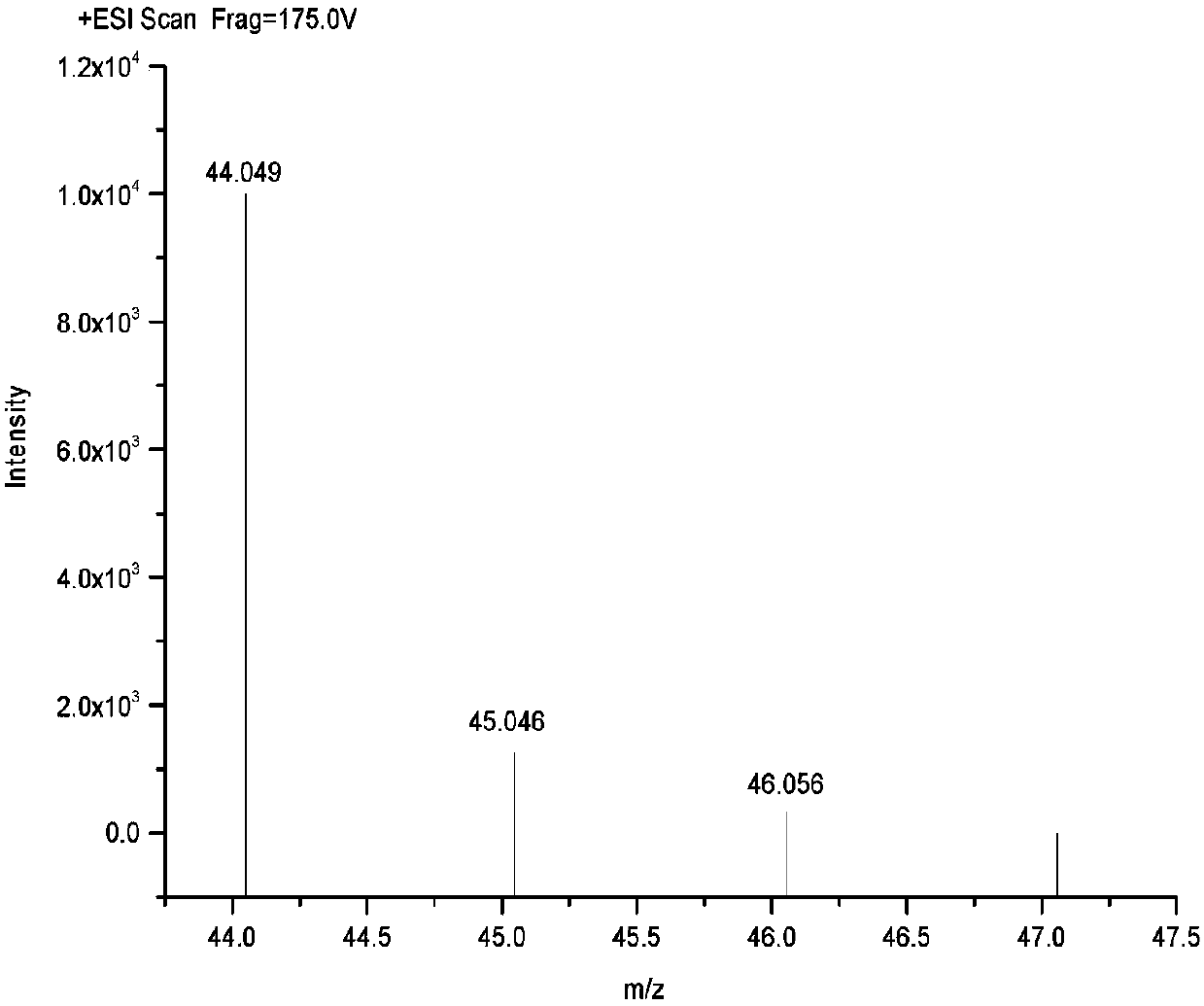

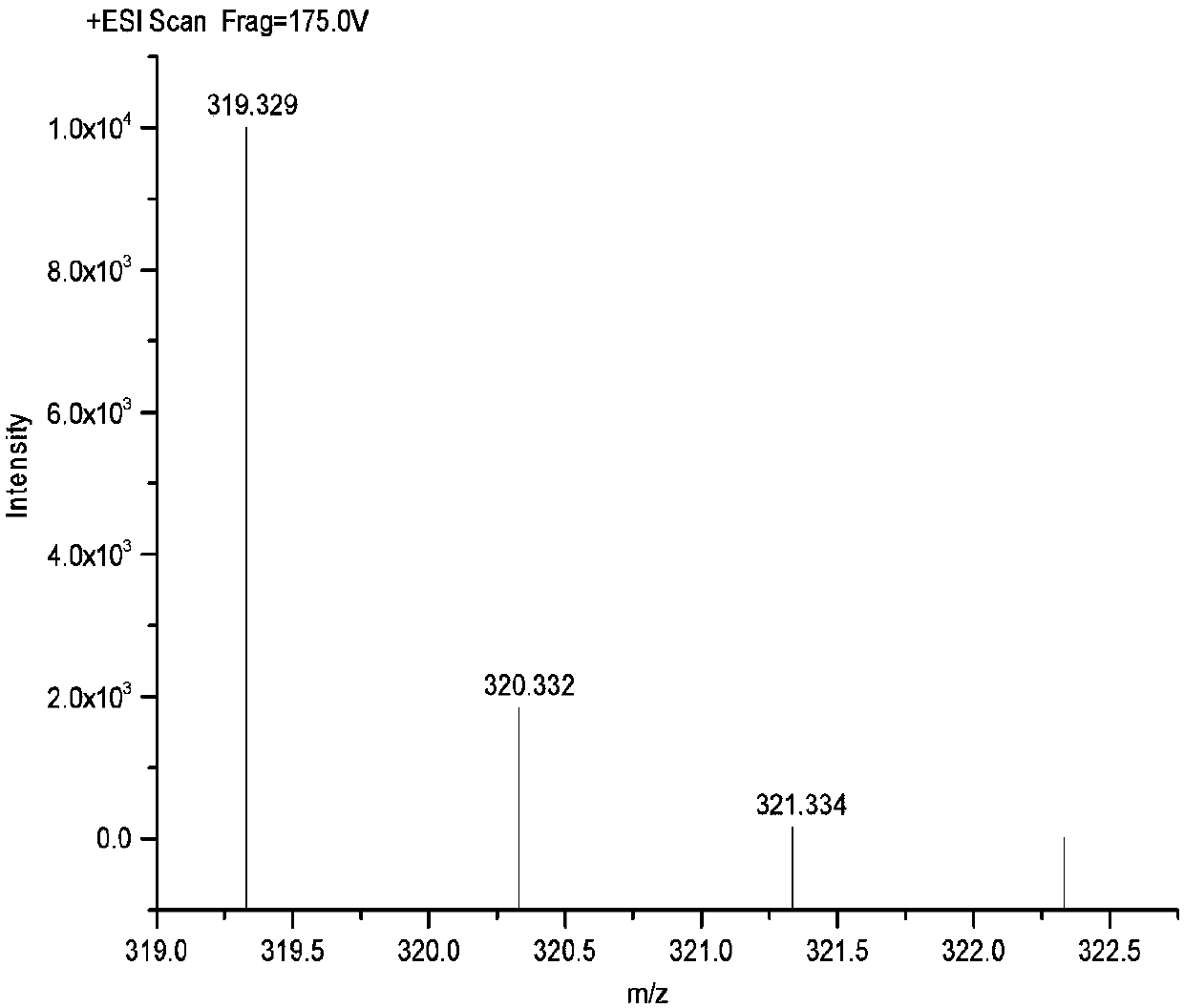

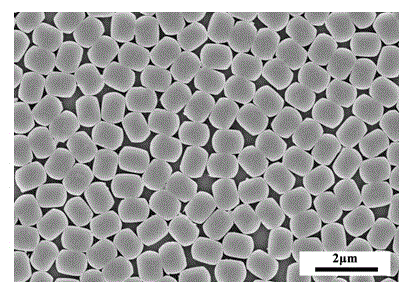

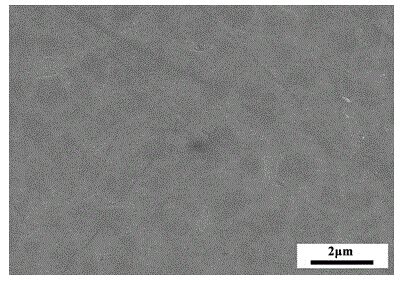

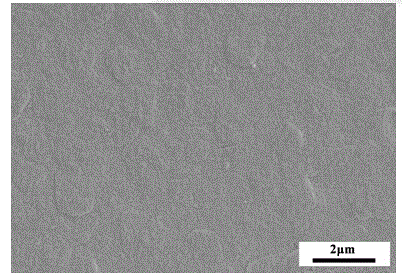

Method for preparing highly-oriented MFI-type molecular sieve membrane by secondary growth process

InactiveCN104891519ASuppress generationGood orientationCrystalline aluminosilicate zeolitesMolecular sieveSilicic acid

The invention discloses a method for preparing a highly-oriented MFI-type molecular sieve membrane by a secondary growth process, which comprises the following steps: 1) preparation of a secondary growth synthesis liquid: mixing certain amounts of ethyl orthosilicate, tetrapropyl ammonium hydroxide and water, stirring at room temperature for 3-5 hours, adding an ammonium salt water solution with a certain concentration into the clear synthesis liquid, and continuing stirring for 1-3 hours to obtain the final synthesis liquid, wherein the synthesis liquid is composed of the following components in parts by mole: 1 part of ethyl orthosilicate, 0.1-0.4 part of tetrapropyl ammonium hydroxide, 100-500 parts of water and 0.075-0.3 part of water; 2) putting a carrier coated with a b-axis-oriented crystal seed layer into a high-pressure synthesis kettle, pouring the synthesis liquid, and sealing; crystallizing at 120-180 DEG C for 3-12 hours; and 3) cooling the synthesis kettle, taking out the carrier, washing and drying to obtain the oriented MFI-type molecular sieve membrane on the carrier. The ammonium salt added into the traditional synthesis liquid can effectively inhibit the twin crystal from generation in the secondary growth process. The method is simple to operate, and has the advantages of wide application range, no special requirements for the carrier and low preparation cost.

Owner:ZHEJIANG UNIV

Industrial preparation method for silica carbide crystal whisker and micropowder

InactiveCN1449994AAbundant and cheapSimple structurePolycrystalline material growthSingle crystal growth detailsCarbideDiameter ratio

The industrial preparation method of silicon carbide whiskers and micrpowder is characterized by that the graphite and other industrial carbon and silicon raw materials are mixed, and placed into industrial SiC smelting furnace to make synthesis reaction, the graphite is used as conductive heating body to prepare silicon carbide whiskers and micropowder. Said preparation method is simple, the diameter of whiskers produced by said invented method is uniform, and length-diameter ratio is large and the heteromorphous crystal is less, and product quality is high.

Owner:XIAN BOER NEW MATERIAL CO LTD

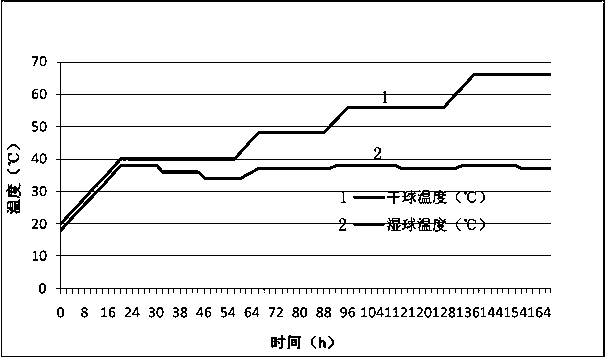

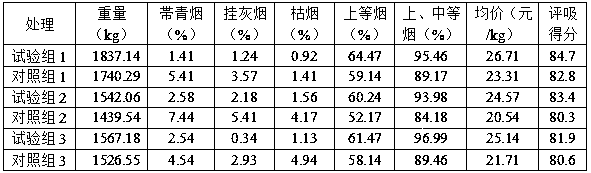

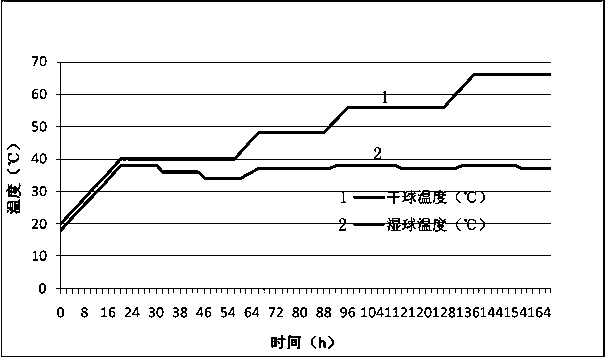

Temperature stabilizing and humidity reducing dense flue-cured tobacco curing method

ActiveCN107594607AImprove qualityIntensive baking method is simpleTobacco preparationEngineeringWet-bulb temperature

The invention discloses a temperature stabilizing and humidity reducing dense flue-cured tobacco curing method. The dense flue-cured tobacco curing method comprises a temperature stabilizing and humidity reducing yellowing stage, a temperature stabilizing and humidity reducing color fixing stage and a temperature stabilizing and humidity reducing killing-out stage. The method disclosed by the invention can reduce a wet bulb temperature step by step by stabilizing tobacco leaf yellowing, color fixing and killing-out appropriate temperatures, so that a curing target of mutual coordination between tobacco leaf yellowing and water loss, between color fixing and aroma enhancement and between killing-out and aroma maintenance is achieved in a curing process; a yellow flue-cured tobacco rate is improved to a greater extent, and tobacco leaf quality is improved. The method disclosed by the invention has the advantages of simpleness and easiness in operation control.

Owner:YUNNAN ACAD OF TOBACCO AGRI SCI

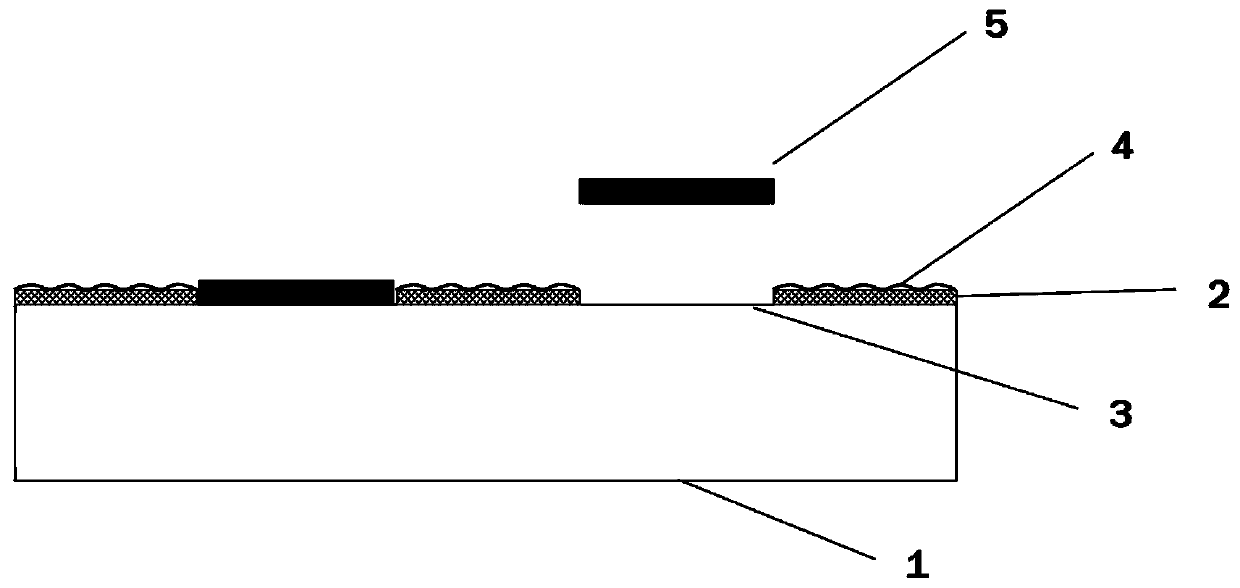

Substrate used for diamond synthesis and having coating layer as well as diamond synthesis system

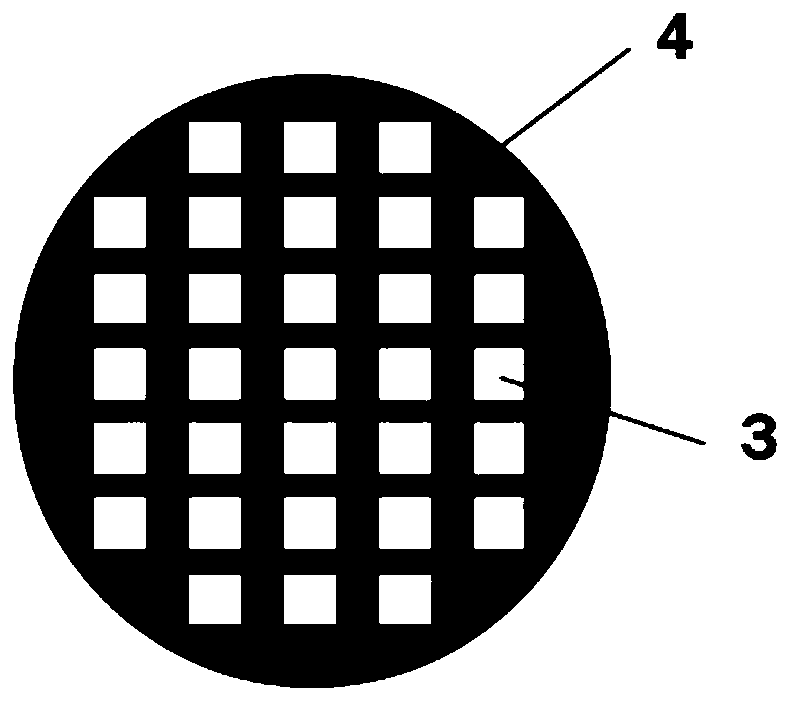

InactiveCN109913947ABatch Stability AchievedImprove product qualityPolycrystalline material growthFrom chemically reactive gasesSeed crystalCoupling system

The invention provides an underlayment used for diamond synthesis and having a coating layer as well as a diamond synthesis system. The substrate is used to place seed crystals for diamond synthesis and at least comprises one sample mounting surface, a plurality of seed crystal mounting grooves are formed in each sample mounting surface, the roughness of each sample mounting surface is larger thanthat of the bottom surfaces of the seed crystal mounting grooves. aiming at the problems of diamond fixation and polycrystalline growth in diamond mass production in the prior art, a film is uniformly plated on the surface of the substrate to roughen the plating surface, so that purposes of fixation of diamond seed crystals, batch fixation and inhabitation of polycrystalline growth can be achieved. The invention also provides a diamond synthesis system which comprises a microwave source, a microwave coupling system, a reaction chamber with an air inlet system and an air outlet system, a vacuum system connected to the reaction chamber, a substrate located in the reaction chamber, wherein the substrate at least comprises one sample mounting surface, the plurality of seed crystal mounting grooves are formed in the surface of each sample mounting surface, and the roughness of each sample mounting surface is larger than that of the bottom surfaces of the seed crystal mounting grooves.

Owner:CHANGSHA ADVANCED MATERIALS IND RES INST CO LTD

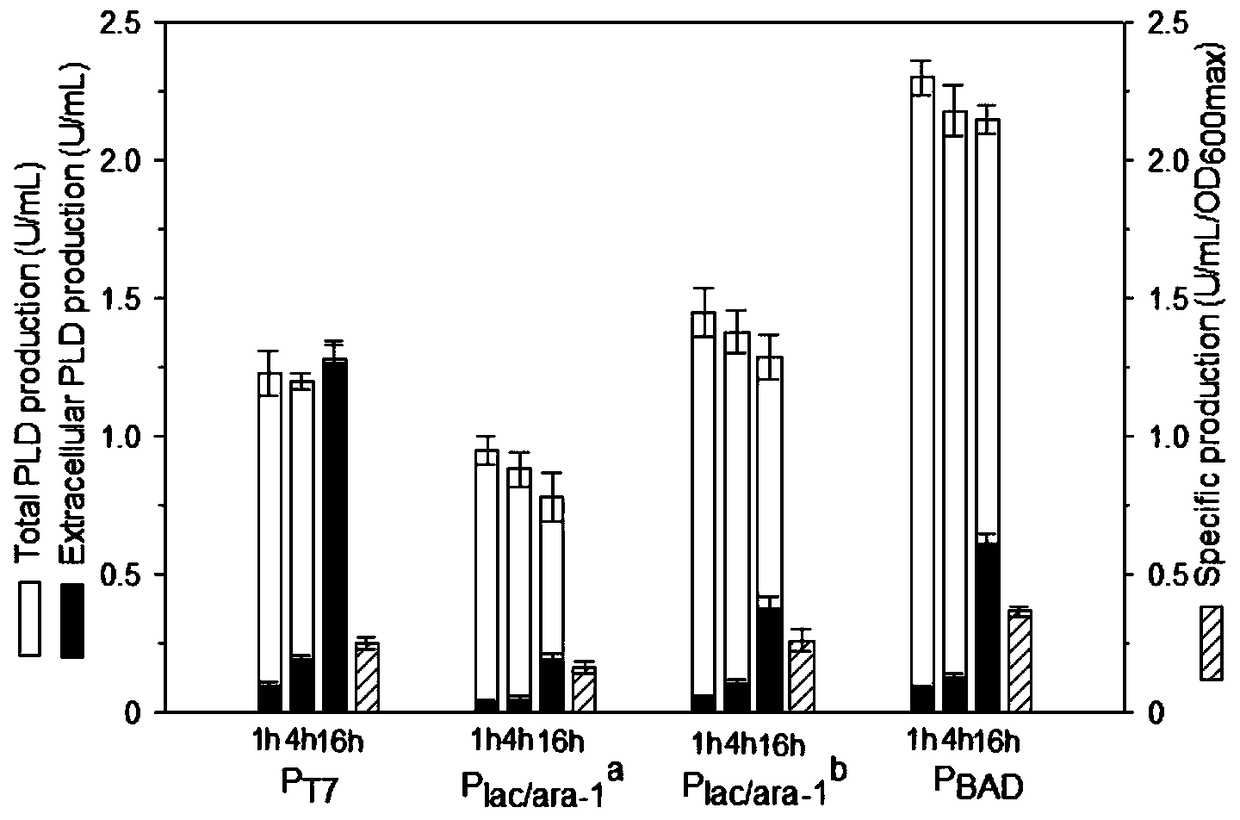

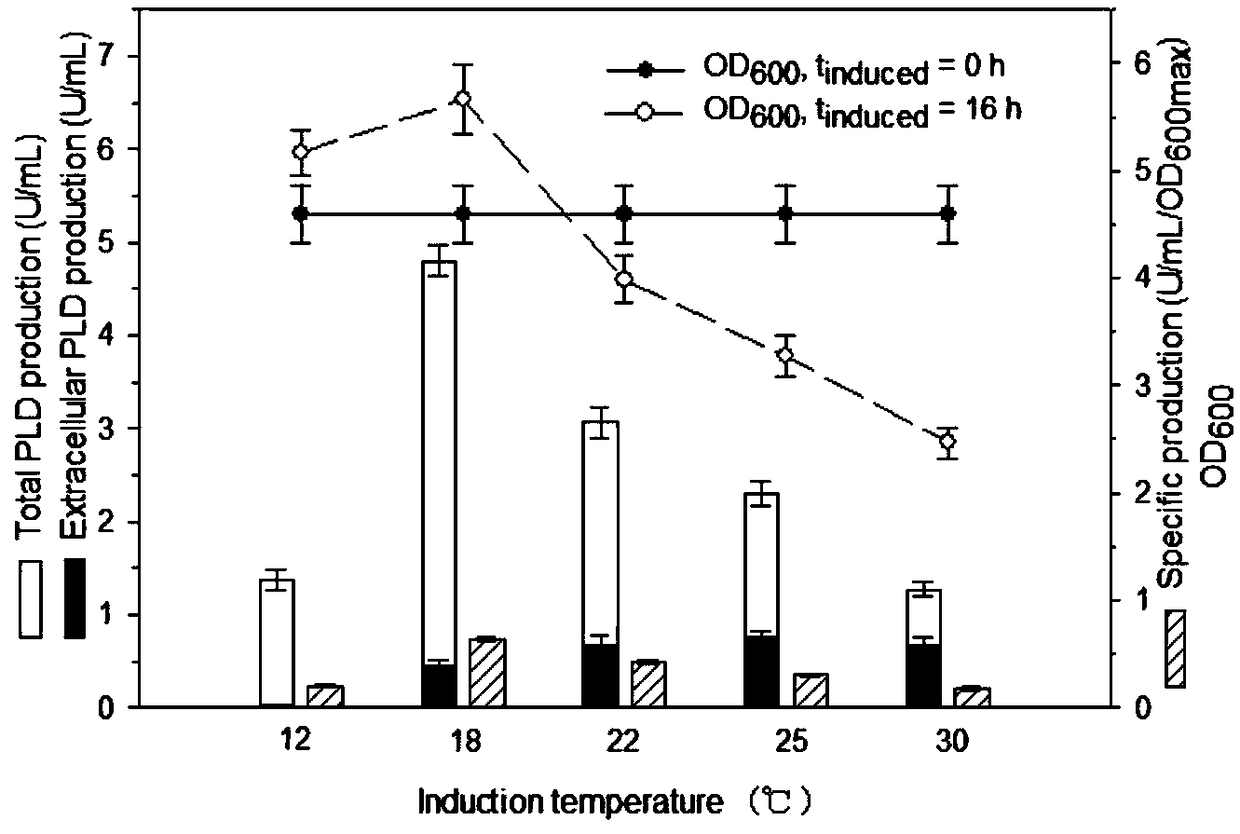

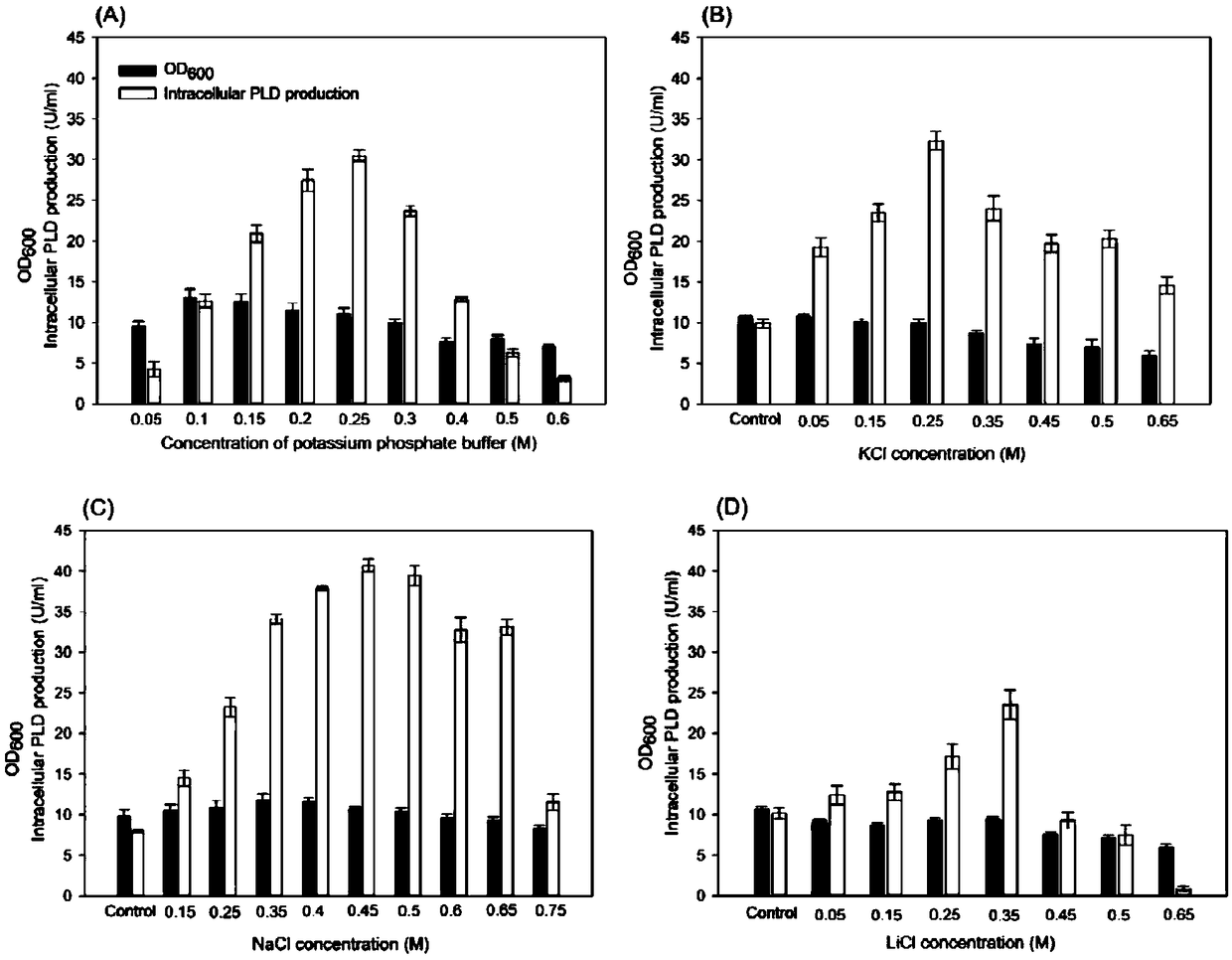

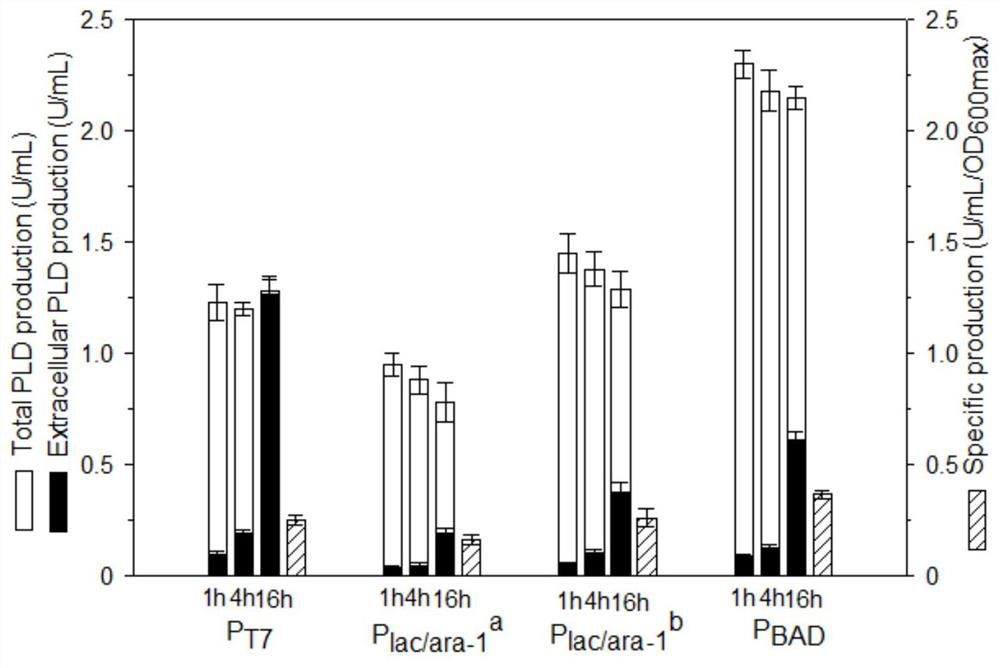

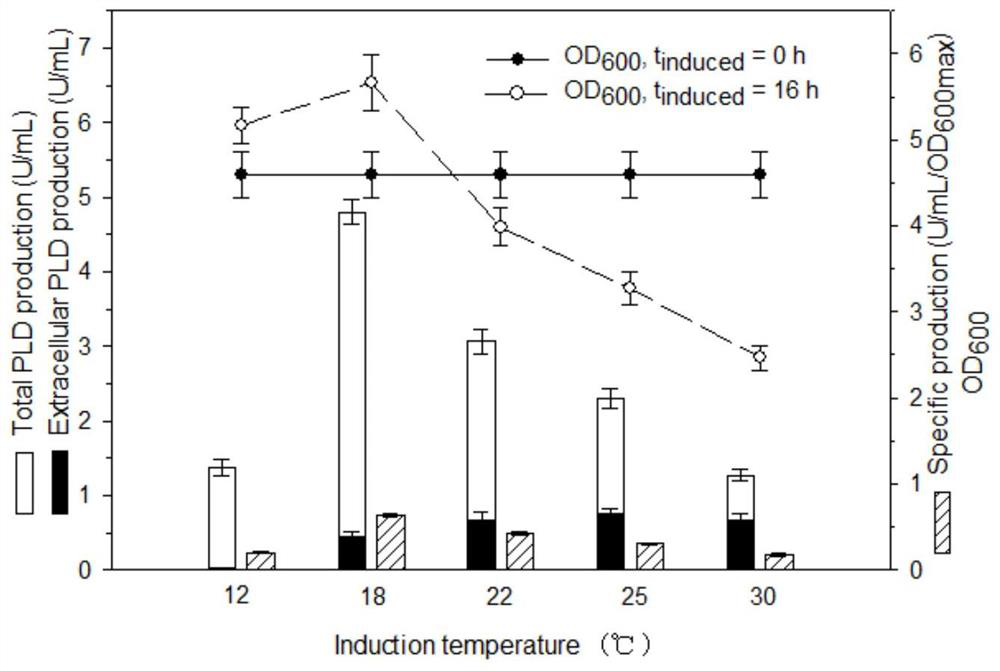

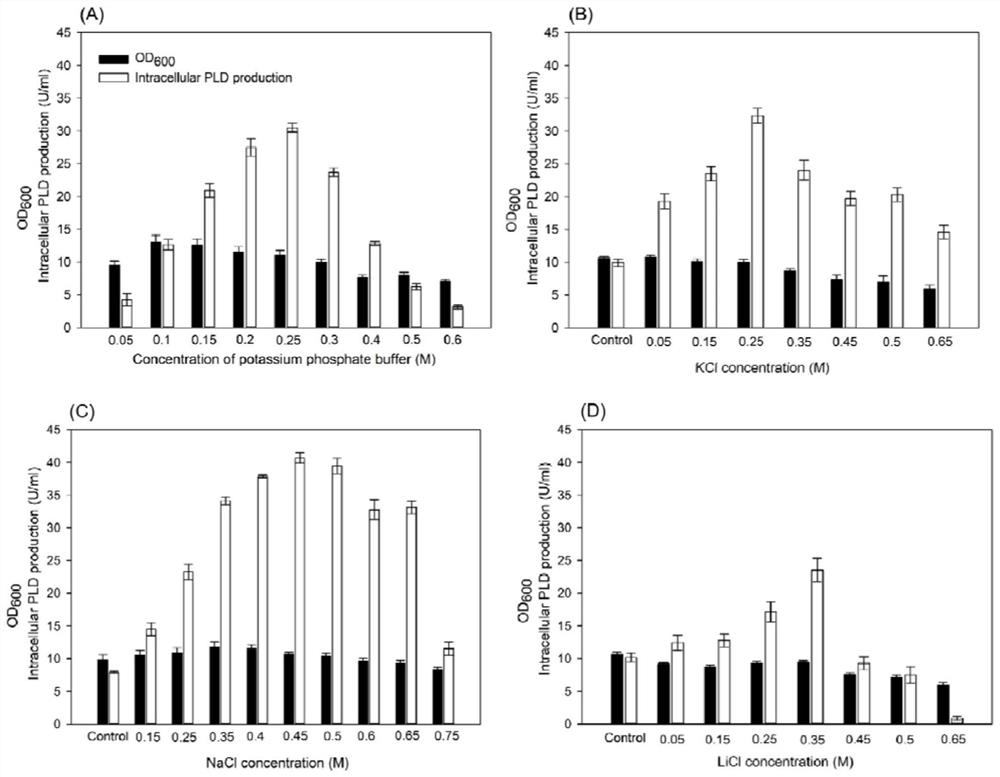

Method for producing phospholipase D through recombinant escherichia coli

ActiveCN109136207AInhibition of lysisOptimal physiological stateBacteriaHydrolasesEscherichia coliHigh density

The invention discloses a method for producing phospholipase D through recombinant escherichia coli. According to the method, a phospholipase D gene is in preciseness-type starting sub control, a pararea of pSC101 is inserted in an expression plasmid, an escherichia coli mutant strain recA is used for keeping the genetic stability of the plasmid, cells containing the plasmid at the growth periodare cultured to high density, and saturation induction is conducted at the induction period; meanwhile, the temperature is decreased, alkali metal salt stress is applied, the cytotoxicity of PLD to ahost is reduced, cell lysis is inhibited, the synthesis time of PLD is prolonged, and accordingly PLD expression is improved.

Owner:XIAMEN UNIV

Preparing method for precursor of lithium ionic cell positive material

InactiveCN101284683AGood physical appearanceEvenly distributedCell electrodesManganese oxides/hydroxidesChemical measurementMetal

A method for preparing the precursor of the anode material for a lithium battery is characterized in that the preparation process comprises the steps of preparing a metal salt solution with the total metal ion concentration of 0.1 to 3mol / L according to the stoichiometric proportion of corresponding metal salts and the prepared precursor composite hydroxid; adding a sodium hydroxide solution with the concentration of 0.1 to 5mol / L to the metal salt solution; and reacting under the condition of inert gases to obtain the precursor composite hydroxid. The protection by the inert gases effectively prevents the oxidation of Mn and the generation of Alpha type hydrous hydroxide, so as to prepare the pure phase composite hydroxid precursor with the Beta-Ni(OH)2 type structure. The precursor has evenly distributed elements, good electrochemical activity and is favorable for preparing high-performance anode materials.

Owner:JINCHUAN GROUP LIMITED

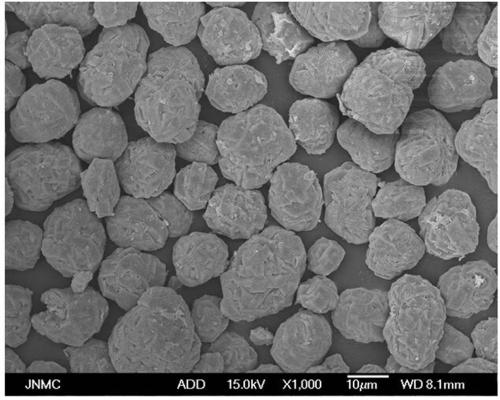

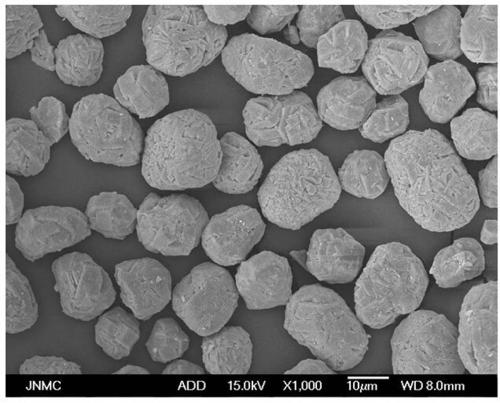

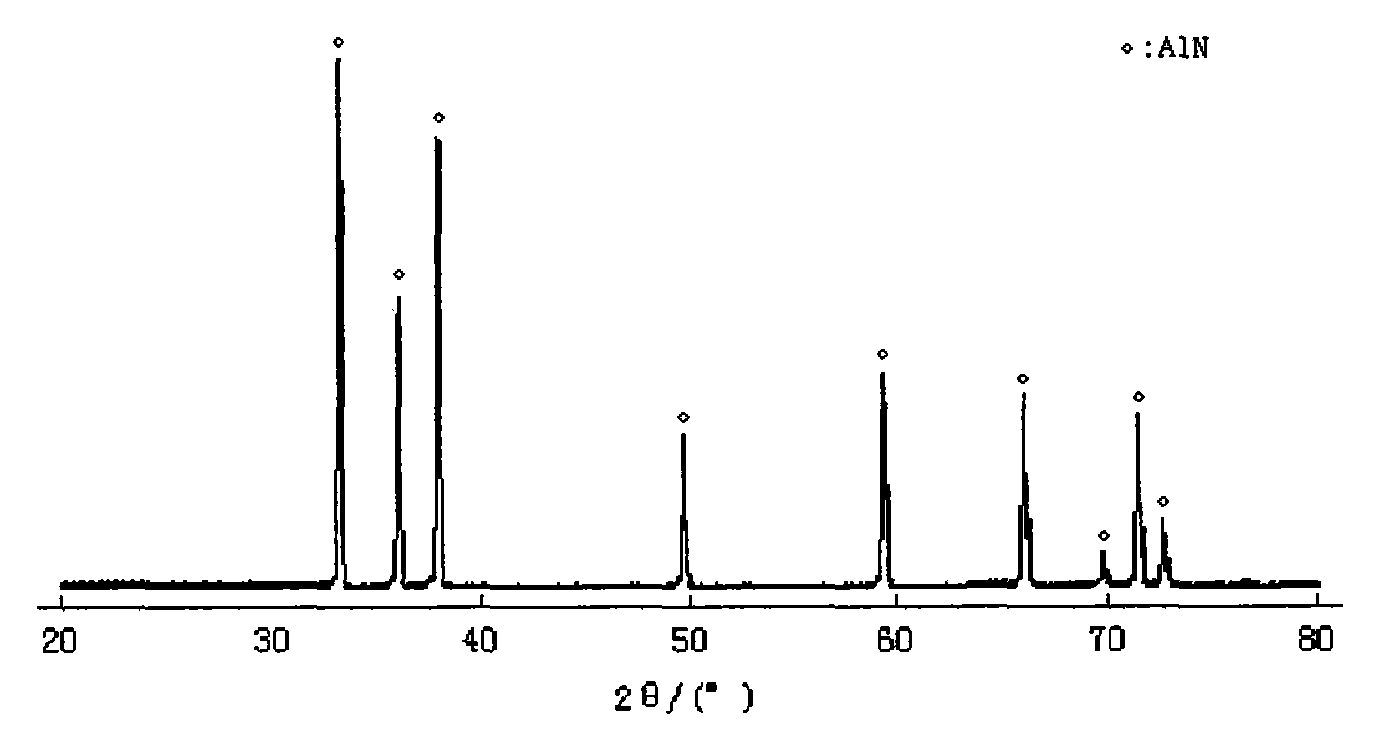

Method for synthesizing ferro-silicon nitride by microwave

InactiveCN1775662ASimple structureEasy maintenanceNitrogen-metal/silicon/boron binary compoundsGranularityFerrosilicon

The invention provides silicon iron nitride microwave-synthesizing method, using silicon iron as raw material for microwave synthesis, grinding silicon iron ore into powder with particle size smaller than 0.5mm, placing the silicon iron powder into a microwave synthesis reaction cavity, adding ammonium-containing additive by 5% of the raw material, uniformly mixing, where microwave frequency is 300MHz-300GHz, pressure is 0.1-0.12MPa and synthesis temperature is 800-1800 deg.C, inputting nitrogen gas for microwave synthesis for 0.5-3 hours, and cooling the synthetic to obtain the finished product silicon iron nitride. The invention couples special wave band of the microwave with basic structure of the material to produce heat to heat in a mode of heating the material by its medium loss, and has the advantages of low synthesis temperature, short synthesis time, low energy consumption, etc.

Owner:长沙隆泰科技有限公司

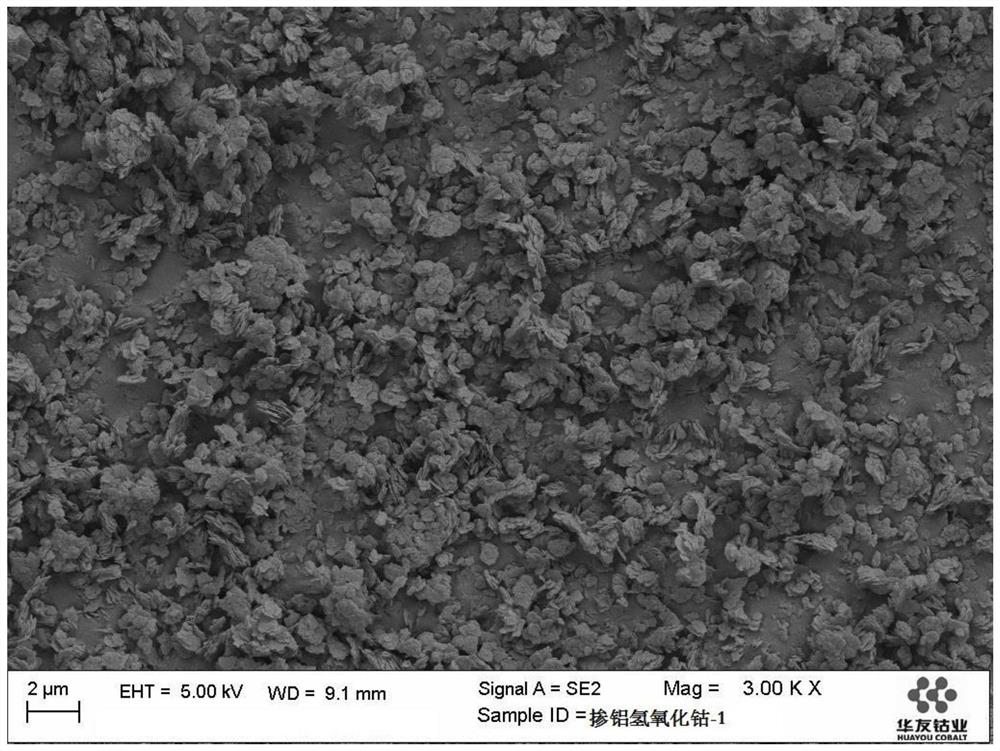

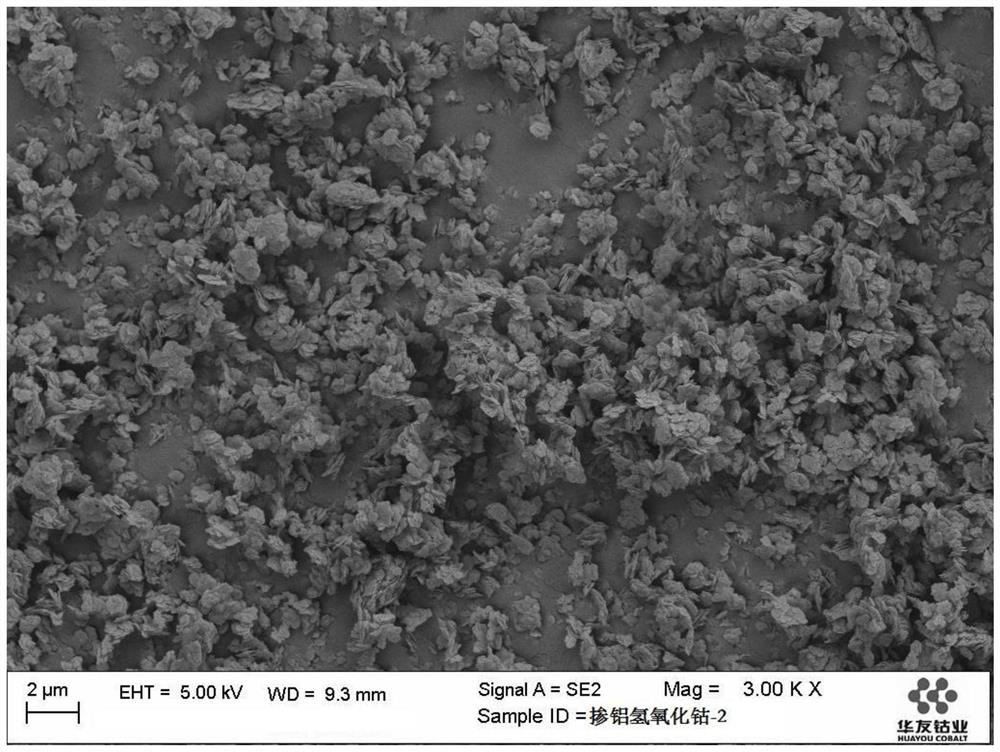

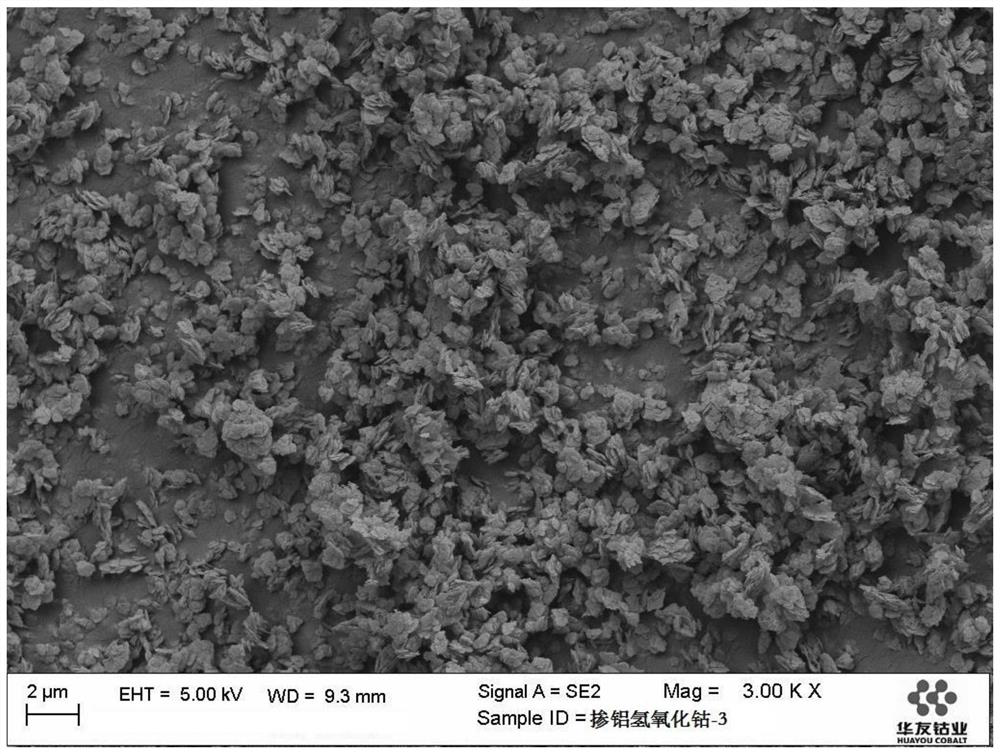

Preparation method of aluminum-doped cobalt hydroxide for high-voltage LCO coating material

ActiveCN110642299ALow solid contentReduce the probability of collisionPositive electrodesLi-accumulatorsSlurryAnti oxidant

The invention belongs to the technical field of preparation of lithium battery positive electrode materials, particularly relates to a cobalt hydroxide preparation method, and provides a preparation method of aluminum-doped cobalt hydroxide for a high-voltage LCO coating material, wherein the method comprises: carrying out wet co-precipitation reaction on a cobalt-aluminum mixed solution and a liquid alkali, adding an antioxidant during the process to protect the divalent cobalt from being oxidized into the trivalent cobalt, and improving the dispersity of the particles by controlling the reaction rate and the crystal nucleus growth rate; and carrying out filter pressing on the synthesized slurry, washing, carrying out low-temperature drying, and breaking by adopting a jet mill to finallyobtain an agglomeration-free aluminum-doped cobalt hydroxide finished product with D50 of less than 1 [mu]m. According to the invention, the aluminum-doped cobalt hydroxide prepared by the method is wide in aluminum doping range, wherein the aluminum doping range can reach 0.1-1%.

Owner:취저우화여우코발트뉴머터리얼컴퍼니리미티드 +1

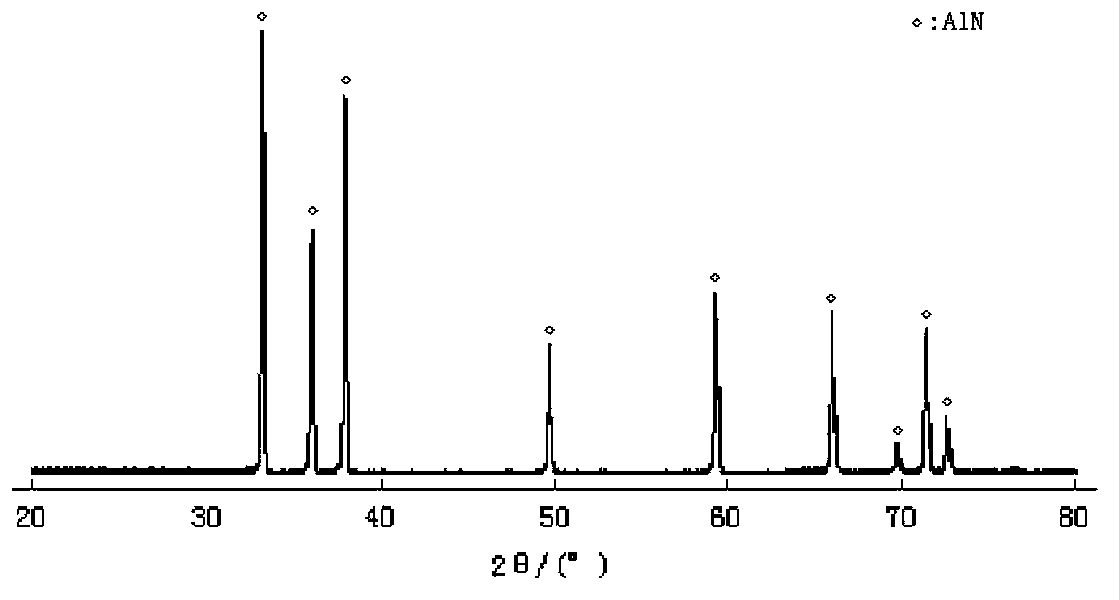

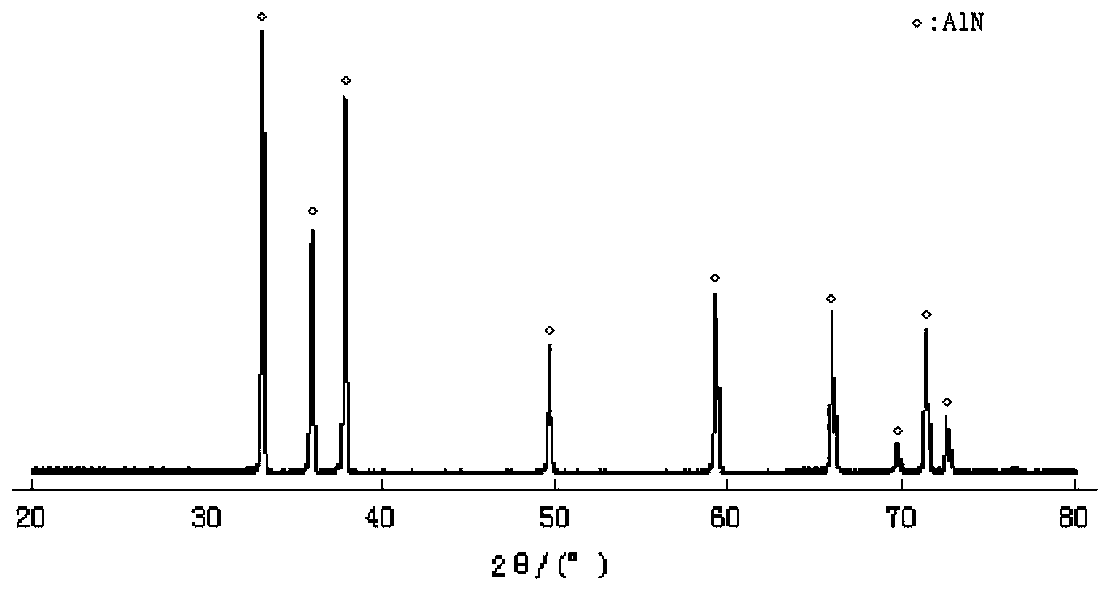

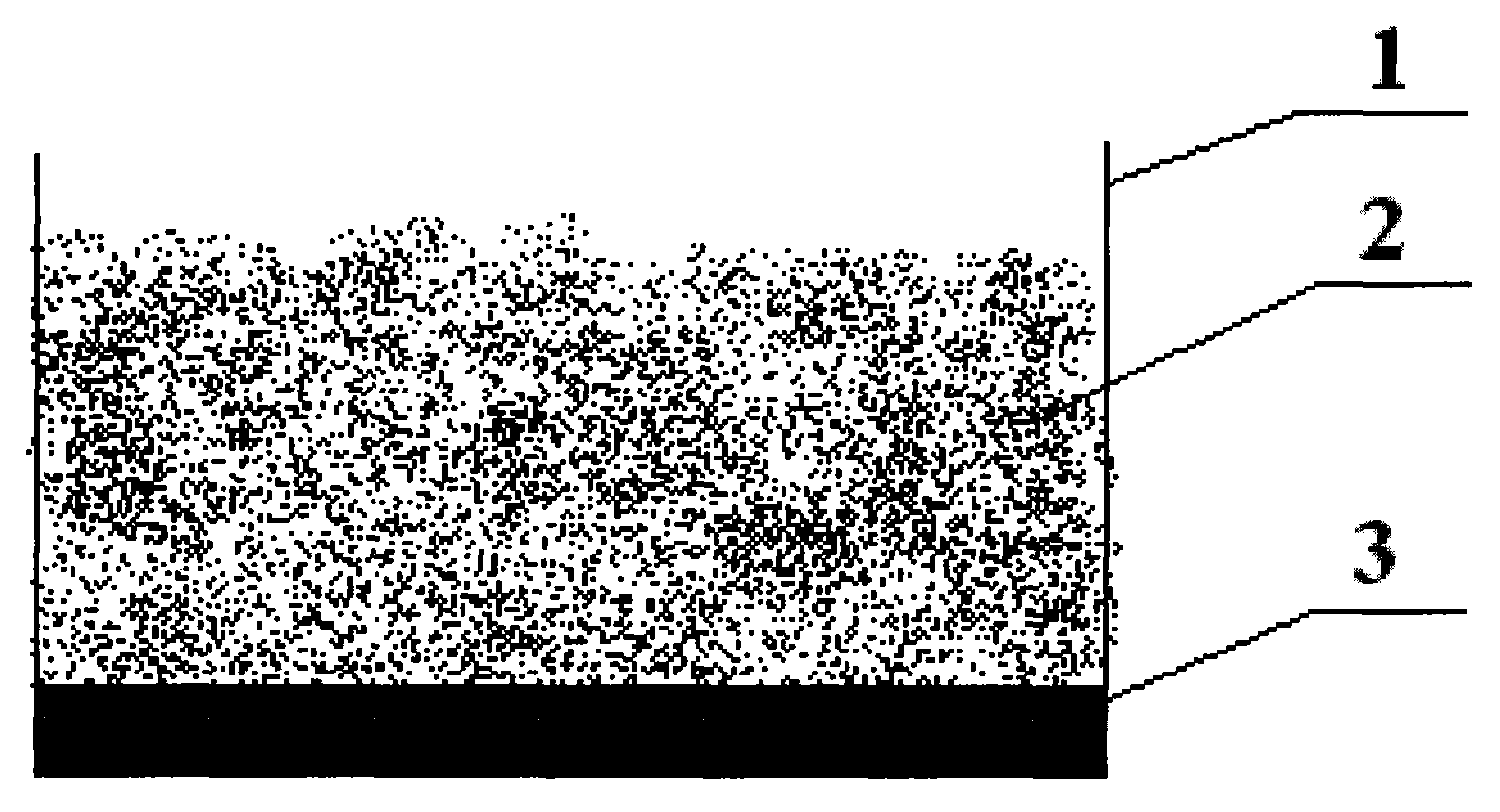

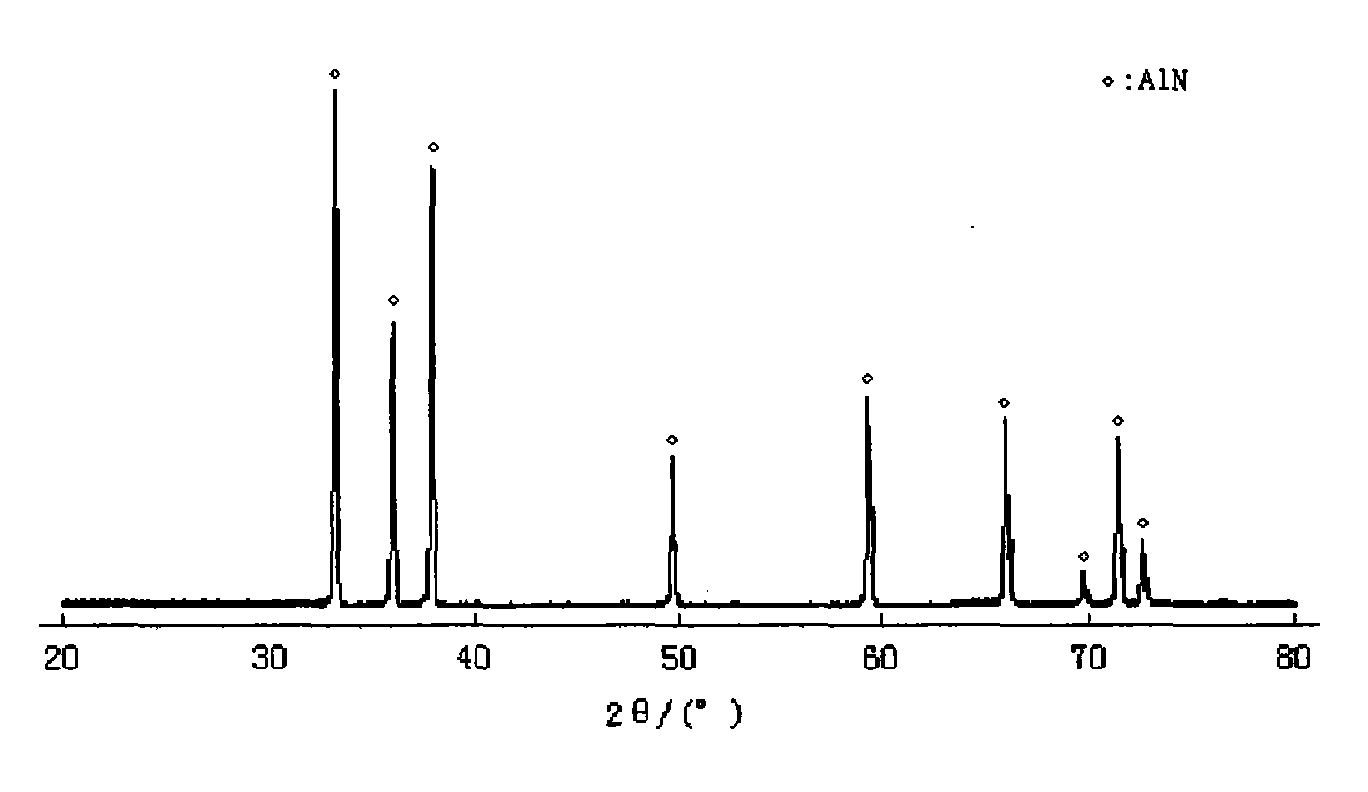

Microwave preparation method of high-quality aluminum nitride powder

InactiveCN103387214ASimple structureEasy maintenanceNitrogen compoundsThermal insulationNitrogen gas

The invention discloses a microwave preparation method of high-quality aluminum nitride powder. The microwave preparation method comprises the following steps of: mixing an aluminum source with a carbon source in a C / AL molar ratio of (3-6):1; adding calcium carbonate with an Al / Ca molar ratio of 100:(1-5) for uniformly mixing; carrying out microwave synthesis in a microwave reaction device under a nitrogen-containing atmosphere, wherein the heating rate for the microwave synthesis is 3 DEG C / min-20 DEG C / min, the temperature is 1200 DEG C-1600 DEG C, and the thermal insulation time is 0-10 hours; and cooling the obtained product to obtain the high-quality finished product aluminum nitride powder. Different from a conventional heating way by convection, conduction or radiation, the microwave preparation method is used for generating heat by coupling a special wave band of the microwave with a base structure of the material, and used for heating in an integral material heating way by virtue of medium loss of the material; moreover, the microwave preparation method of the high-quality aluminum nitride powder has the advantages of good synthesis quality, low synthesis temperature, short synthesis time, low synthesis energy consumption and the like.

Owner:HENGYANG KAIXIN SPECIAL MATERIAL TECH CO LTD

Preparation method of rare earth element-doped cobaltosic oxide

ActiveCN110002514ACrystal denseEvenly dispersedCobalt oxides/hydroxidesRare-earth elementLiquid ratio

The invention discloses a preparation method of rare earth element-doped cobaltosic oxide. The method comprises the following steps: rear earth element is added into a cobalt solution; with the extension of synthetic time, concentration gradient of the cobalt solution added to a reaction kettle increases or decreases; simultaneously, solid-to-liquid ratio of slurry in the reaction kettle is adjusted, and cobalt hydroxide with uniform doping is synthesized by a wet method; after the synthesis, the synthetic product is washed, dried and calcined to obtain a large granular or small granular rareearth element-doped cobaltosic oxide product.

Owner:JINCHUAN GROUP LIMITED +1

A method for producing phospholipase D by recombinant Escherichia coli

ActiveCN109136207BInhibition of lysisOptimal physiological stateBacteriaHydrolasesEscherichia coliPhospholipase

Owner:XIAMEN UNIV

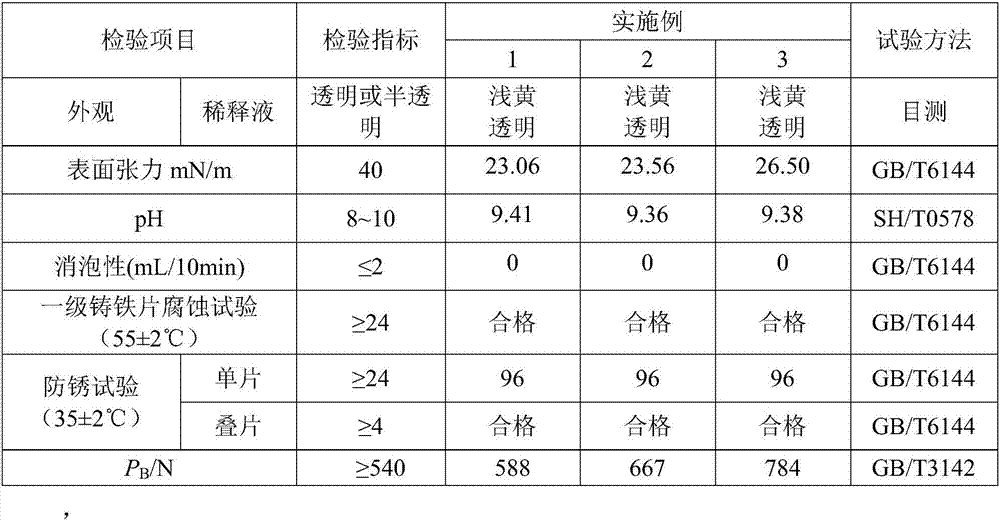

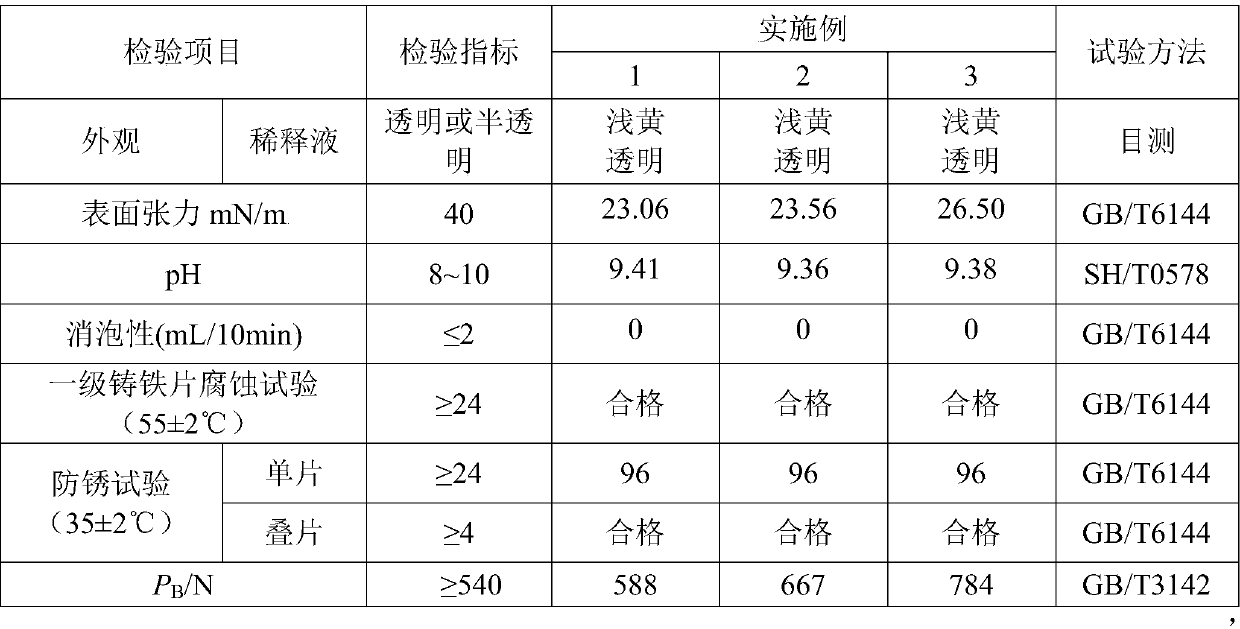

Fully synthetic cutting fluid with high abrasion resistance and high antirust performance and method for preparing fully synthetic cutting fluid

ActiveCN107955697AStrong extreme pressureImprove the lubrication effectLubricant compositionLow speedPolyethylene glycol

The invention discloses fully synthetic cutting fluid with high abrasion resistance and high antirust performance and a method for preparing the fully synthetic cutting fluid, and belongs to the technical field of technological lubrication. By the aid of the fully synthetic cutting fluid and the method, the problems of poor universality, short user cycles, vulnerability to decaying and deterioration and severe pollution of the traditional cutting fluid mainly can be solved. The fully synthetic cutting fluid comprises, by weight, 0.50%-1.00% of disodium tetraborate decahydrate, 1.00%-2.00% of extreme-pressure agents, 0.02%-0.10% of defoaming agents, 0.08%-0.15% of 1, 2, 3-benzotriazole, 0.50%-1.50% of polyethylene glycol, 1.00%-2.00% of synthetic additive components A and the balance deionized water. The synthetic additive components A in the fully synthetic cutting fluid are multi-effect additives, and oleic acid and triethanolamine are synthesized according to a mass ratio of 1.8-2.0under the condition of constant temperatures ranging from 60 DEG C to 80 DEG C for 3-6 h to obtain the multi-effect additives. The fully synthetic cutting fluid and the method have the advantage thatthe fully synthetic cutting fluid not only is applicable to common cutters, but also is applicable to hard aluminum alloy cutters, can be used for machining diversified materials at high and low speeds and particularly can be used for machining cast iron, carbon steel, stainless steel and the like at high and low speeds.

Owner:UNIV OF SCI & TECH BEIJING

Microwave synthesis method for aluminum nitride powder

InactiveCN101885478AImprove performanceSimple structureNitrogen compoundsSynthesis methodsNitrogen gas

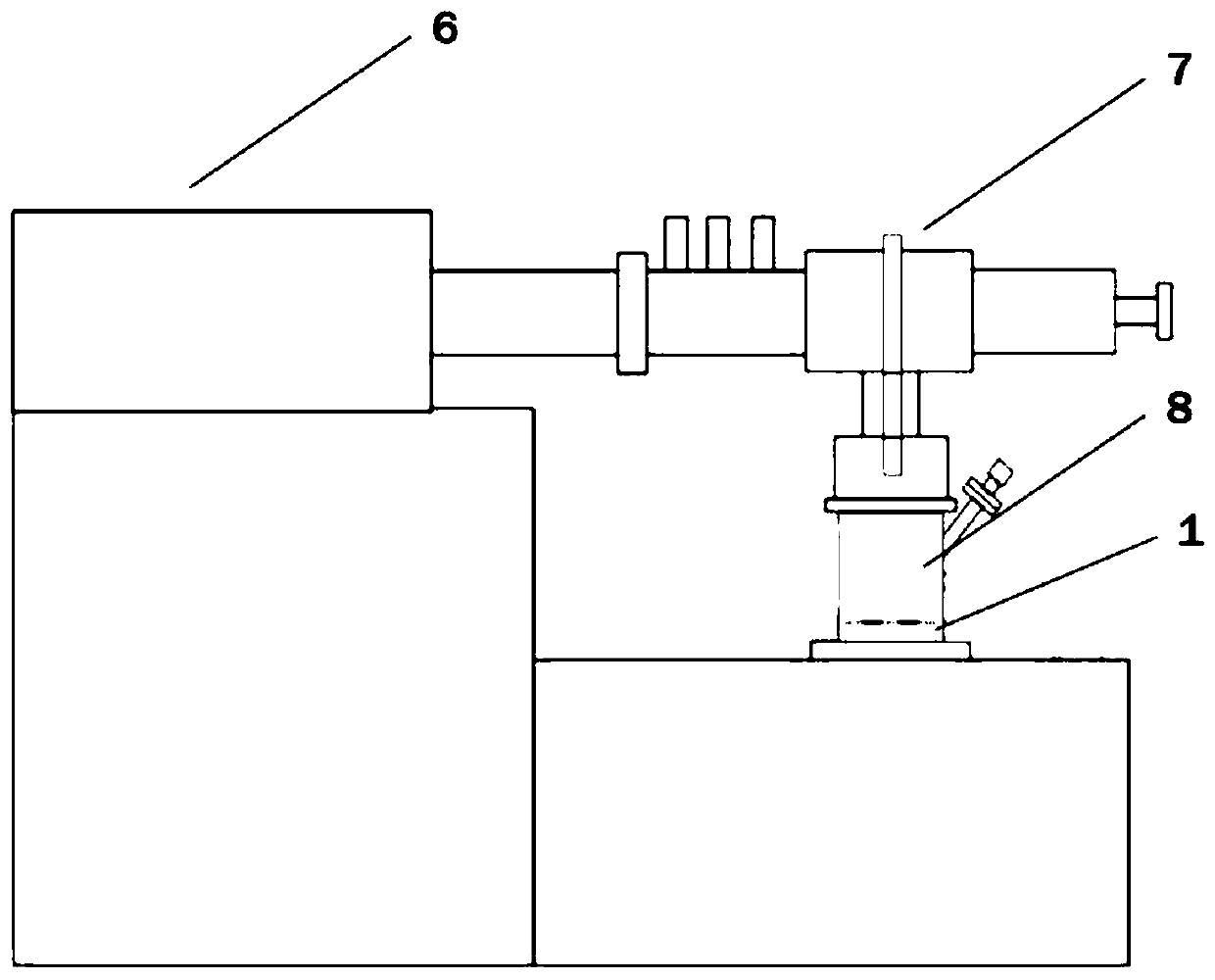

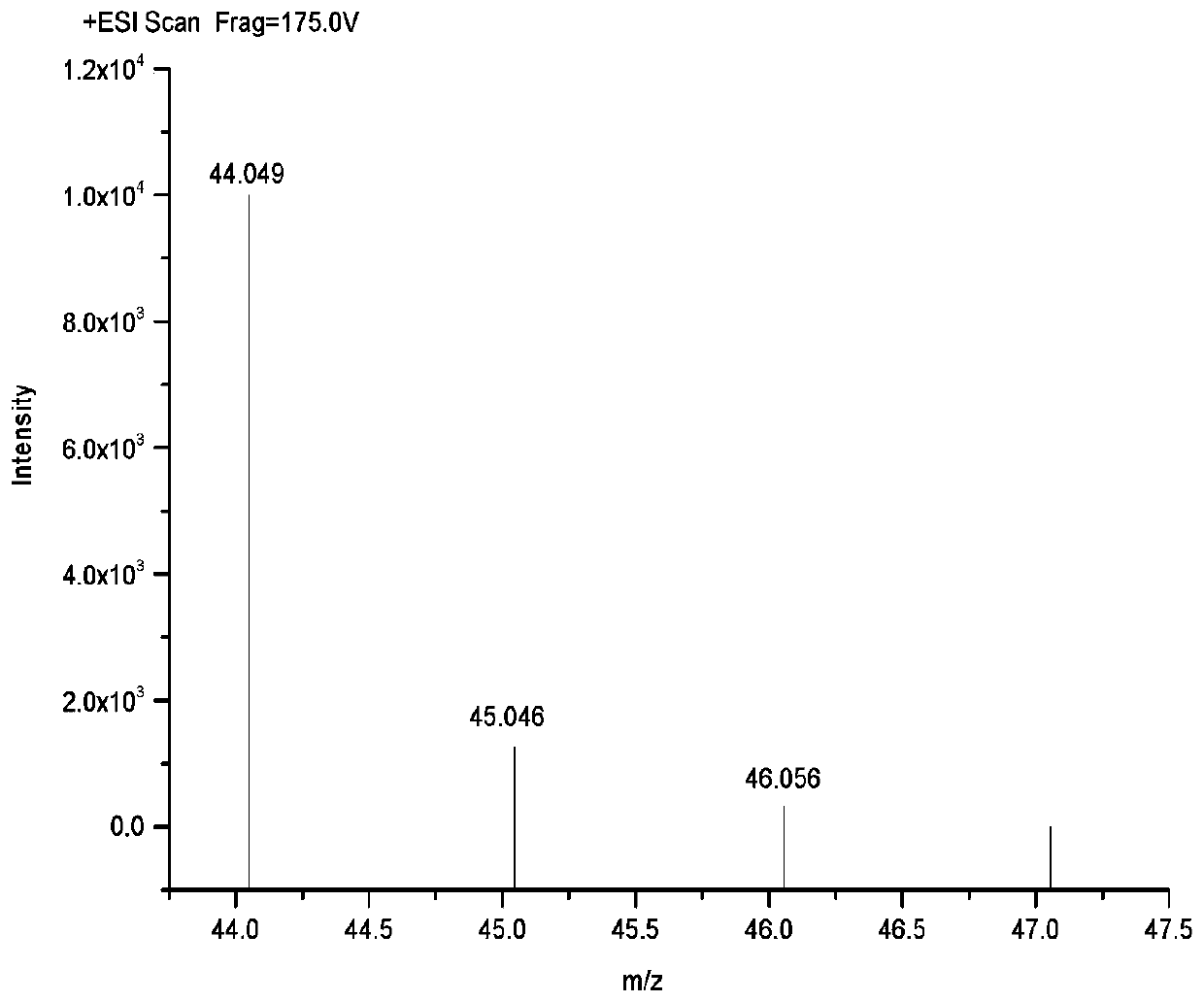

The invention relates to a microwave synthesis method for aluminum nitride powder. In the method, microwave synthesis is performed by using aluminum powder as a raw material and comprises the following steps of: thoroughly and uniformly mixing the aluminum powder with particle size smaller than 0.5 millimeters and ammonium salt according to a proportion; placing the mixture according to a figure 1 and putting the mixture into a microwave synthesis reaction cavity, wherein the microwave frequency is 2, 450 MHz, the pressure is the normal pressure and the synthesis temperature is between 600 DEG C and 1,300 DEG C; introducing nitrogen-containing atmosphere for microwave synthesis; keeping the temperature for 0 to 5 hours; and cooling the synthesized product to obtain the finished product of the aluminum nitride powder. In the microwave synthesis method, heat is generated by coupling a special wave band of the microwave and a basic structure of the material and the dielectric loss of the material makes the material heated in an integral heating way which is different from the conventional heating way through convection, conduction or radiation; and the method has the advantages of low synthesis temperature, short synthesis time, low energy consumption of synthesis, high yield, high product performance, simple process and the like and can realize large-scale industrial production.

Owner:HUNAN UNIV

Full synthetic cutting fluid

InactiveCN109536264AImprove the lubrication effectDistributedLubricant compositionEngineeringShort terms

The invention relates to the field of metal cutting additives, in particular to a full synthetic cutting fluid. According to a technical scheme adopted by the invention, the full synthetic cutting fluid is composed of the following components by weight percentage: 5-10% of a water-soluble extreme pressure additive, 3-5% of a surfactant, 5-15% of a rust inhibitor, 4-8% of a lubricant, 5-20% of a cosolvent, 5-10% of a triazole corrosion inhibitor, 0.2-1% of a bactericide, 0.1-1% of a defoamer, 1-2% of a synthetic additive, and the balance deionized water. The full synthetic cutting fluid provided by the invention has the advantages of: strong anti-rust ability, good ability for preventing workpieces from oxidizing and rusting, a maximum three-month (indoor) short-term rust protection effectaccording to different storage conditions, and strong hard water adaptability and physicochemical stability at the same time.

Owner:上海加美实业有限公司

A kind of preparation method of aluminum-doped cobalt hydroxide applied to high-voltage ICO coating material

ActiveCN110642299BLow solid contentReduce the probability of collisionPositive electrodesLi-accumulatorsSlurryAnti oxidant

The invention belongs to the technical field of preparation of cathode materials for lithium batteries, and in particular relates to a preparation method of cobalt hydroxide. The invention provides a method for preparing aluminum-doped cobalt hydroxide applied to high-voltage LCO coating materials. In the method, a cobalt-aluminum mixed solution and liquid caustic soda are subjected to a wet co-precipitation reaction, and an antioxidant is added during the process to protect divalent cobalt from It is oxidized to trivalent, and improves particle dispersion by controlling the reaction rate and crystal nucleus growth rate. The synthesized slurry is press-filtered, washed, dried at low temperature, and crushed by a jet mill to finally obtain a finished product of aluminum-doped cobalt hydroxide with D50<1 μm without agglomeration. The aluminum-doped cobalt hydroxide prepared by the method has a wide range of doping aluminum, which can reach 0.1-1%.

Owner:취저우화여우코발트뉴머터리얼컴퍼니리미티드 +1

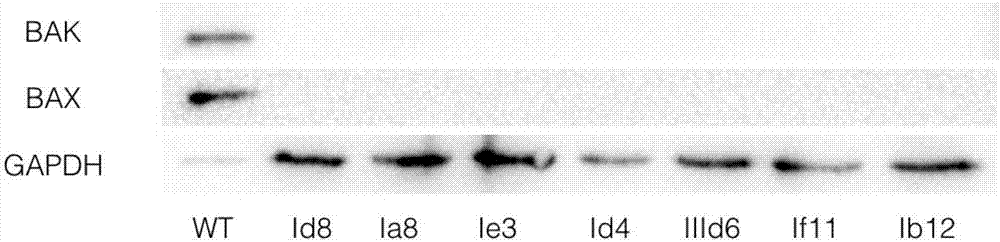

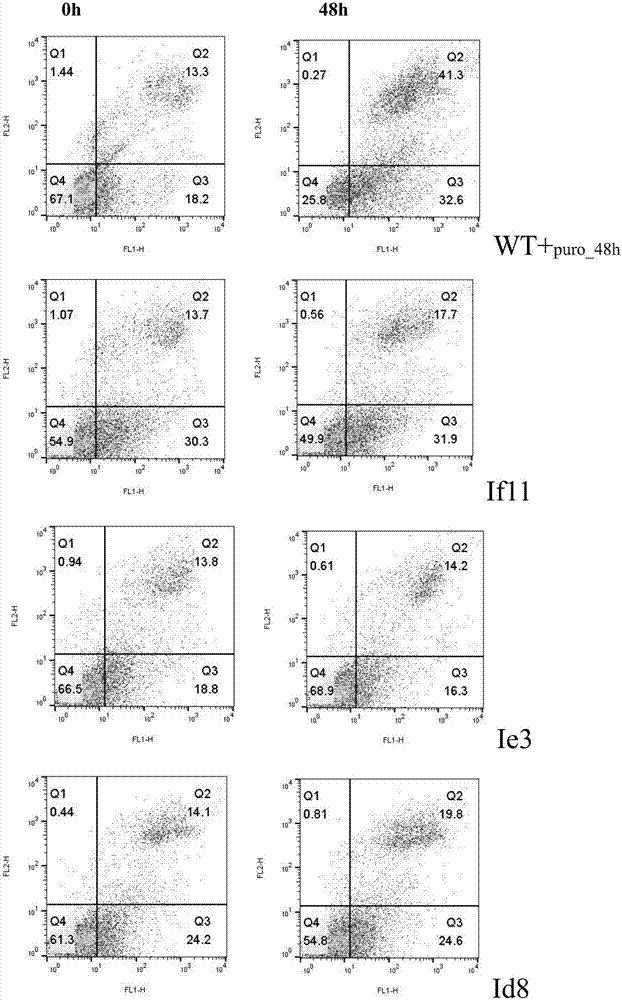

Construction method of anti-apoptosis CHO-K1 cell line capable of improving expression level by combining with valproic acid

InactiveCN107384924AImprove expression levelLong synthesis timeVector-based foreign material introductionDNA/RNA fragmentationFunctional identificationValproic Acid

The invention discloses a construction method of an anti-apoptosis CHO-K1 cell line capable of improving expression level by combining with valproic acid. The construction method comprises the following steps: firstly, respectively designing out corresponding sgRNA sequences on exons of BAK and a BAX genes; secondly, preparing PSK-sgRNA-BAK and PSK-sgRNA-BAX plasmids; thirdly, transfecting the plasmids into CHO-K1 cells and then screening and selecting monoclone to obtain different cell lines; fourthly, carrying out Western Blot detection; fifthly, carrying out functional identification and verification; sixthly, jointly using an exogenous protein expression cell line constructed by knockout cell lines and the valproic acid to further improve the expression level of the exogenous protein. According to the stable cell line prepared by the method disclosed by the invention, synthetic time of recombinant protein of the stable cell line can be prolonged and more recombinant proteins are obtained.

Owner:JIANGNAN UNIV

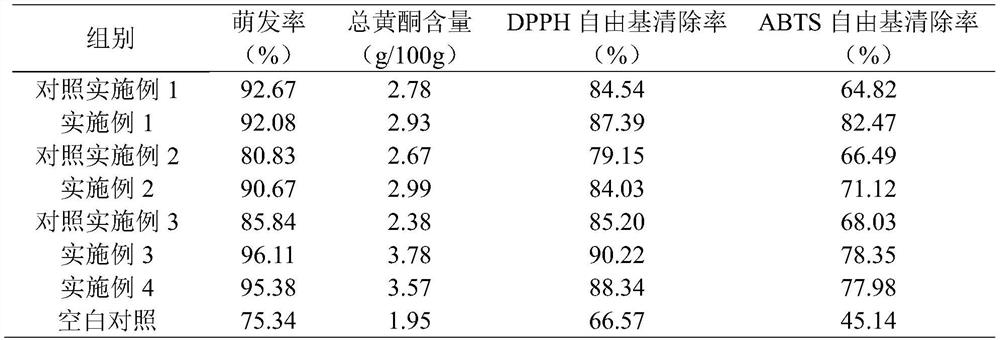

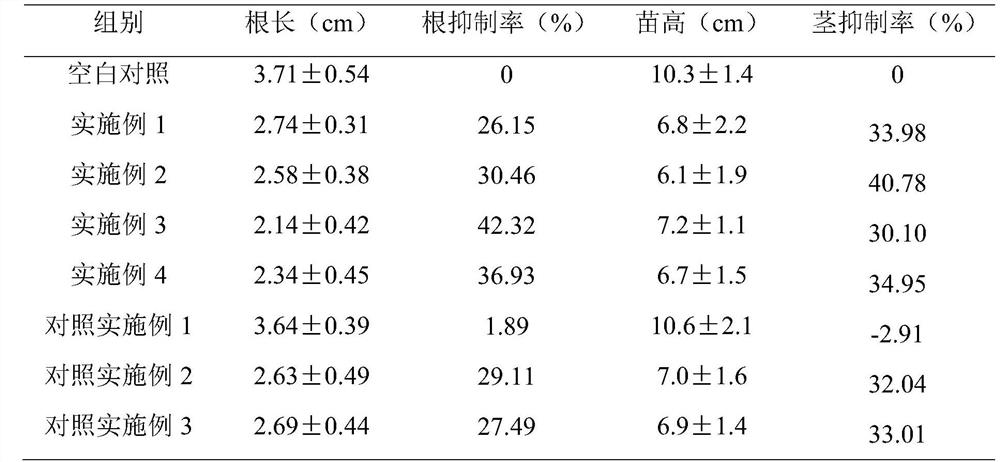

A kind of production method of tartary buckwheat sprouts

ActiveCN110199610BPromote germinationHigh activityBiocidePlant growth regulatorsBiotechnologyAntioxidant capacity

Owner:ANHUI POLYTECHNIC UNIV

Industrial preparation method for silica carbide crystal whisker and micropowder

InactiveCN100415644CAbundant and cheapSimple structurePolycrystalline material growthSingle crystal growth detailsCarbideDiameter ratio

Owner:XIAN BOER NEW MATERIAL CO LTD

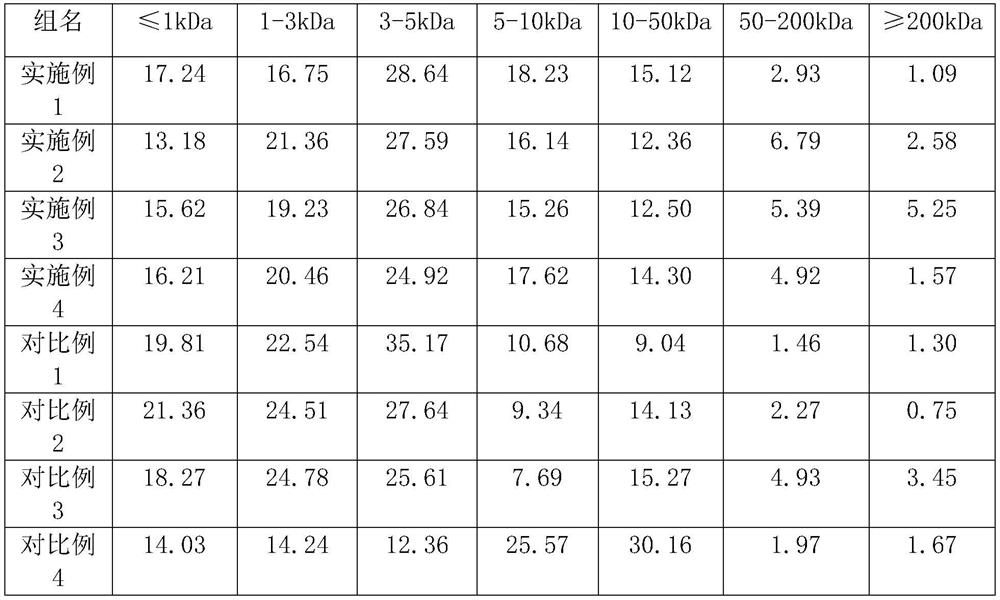

Special peptone for producing inosine through fermentation as well as preparation method and application of peptone

PendingCN114058666AReasonable molecular weight distributionPromote growth and reproductionFermentationInosine synthesisMass propagation

The invention discloses special peptone for producing inosine through fermentation as well as a preparation method and application of the peptone, belonging to the field of peptone preparation. The preparation method for special peptone used for producing inosine through fermentation comprises the following steps: (1) adding various enzymes into fishbone soup to obtain a concentrated fishbone peptone solution; (2) adding various enzymes into a bovine bone soup to obtain a concentrated bovine bone peptone solution; (3) adding various enzymes into a soybean meal filtrate to obtain a concentrated soybean meal peptone solution; and (4) mixing the above three concentrated solutions in proportion, and conducting drying into powder to obtain the special peptone for fermentation production of inosine. The peptone prepared by the method is reasonable in molecular weight distribution, effectively controls a strain fermentation metabolism speed while promoting mass propagation and growth of strains, prolongs inosine synthesis time, increases inosine yield, and lays an important foundation for large-scale inosine fermentation production.

Owner:淄博锦源生物科技股份有限公司

A method for intensive curing of flue-cured tobacco with stable temperature and low humidity

ActiveCN107594607BImprove qualityIntensive baking method is simpleTobacco preparationCooking & bakingEngineering

The invention discloses a temperature stabilizing and humidity reducing dense flue-cured tobacco curing method. The dense flue-cured tobacco curing method comprises a temperature stabilizing and humidity reducing yellowing stage, a temperature stabilizing and humidity reducing color fixing stage and a temperature stabilizing and humidity reducing killing-out stage. The method disclosed by the invention can reduce a wet bulb temperature step by step by stabilizing tobacco leaf yellowing, color fixing and killing-out appropriate temperatures, so that a curing target of mutual coordination between tobacco leaf yellowing and water loss, between color fixing and aroma enhancement and between killing-out and aroma maintenance is achieved in a curing process; a yellow flue-cured tobacco rate is improved to a greater extent, and tobacco leaf quality is improved. The method disclosed by the invention has the advantages of simpleness and easiness in operation control.

Owner:YUNNAN ACAD OF TOBACCO AGRI SCI

Method for synthesizing ferro-silicon nitride by microwave

InactiveCN100358799CSimple structureEasy maintenanceNitrogen-metal/silicon/boron binary compoundsGranularityFerrosilicon

The invention provides silicon iron nitride microwave-synthesizing method, using silicon iron as raw material for microwave synthesis, grinding silicon iron ore into powder with particle size smaller than 0.5mm, placing the silicon iron powder into a microwave synthesis reaction cavity, adding ammonium-containing additive by 5% of the raw material, uniformly mixing, where microwave frequency is 300MHz-300GHz, pressure is 0.1-0.12MPa and synthesis temperature is 800-1800 deg.C, inputting nitrogen gas for microwave synthesis for 0.5-3 hours, and cooling the synthetic to obtain the finished product silicon iron nitride. The invention couples special wave band of the microwave with basic structure of the material to produce heat to heat in a mode of heating the material by its medium loss, and has the advantages of low synthesis temperature, short synthesis time, low energy consumption, etc.

Owner:长沙隆泰科技有限公司

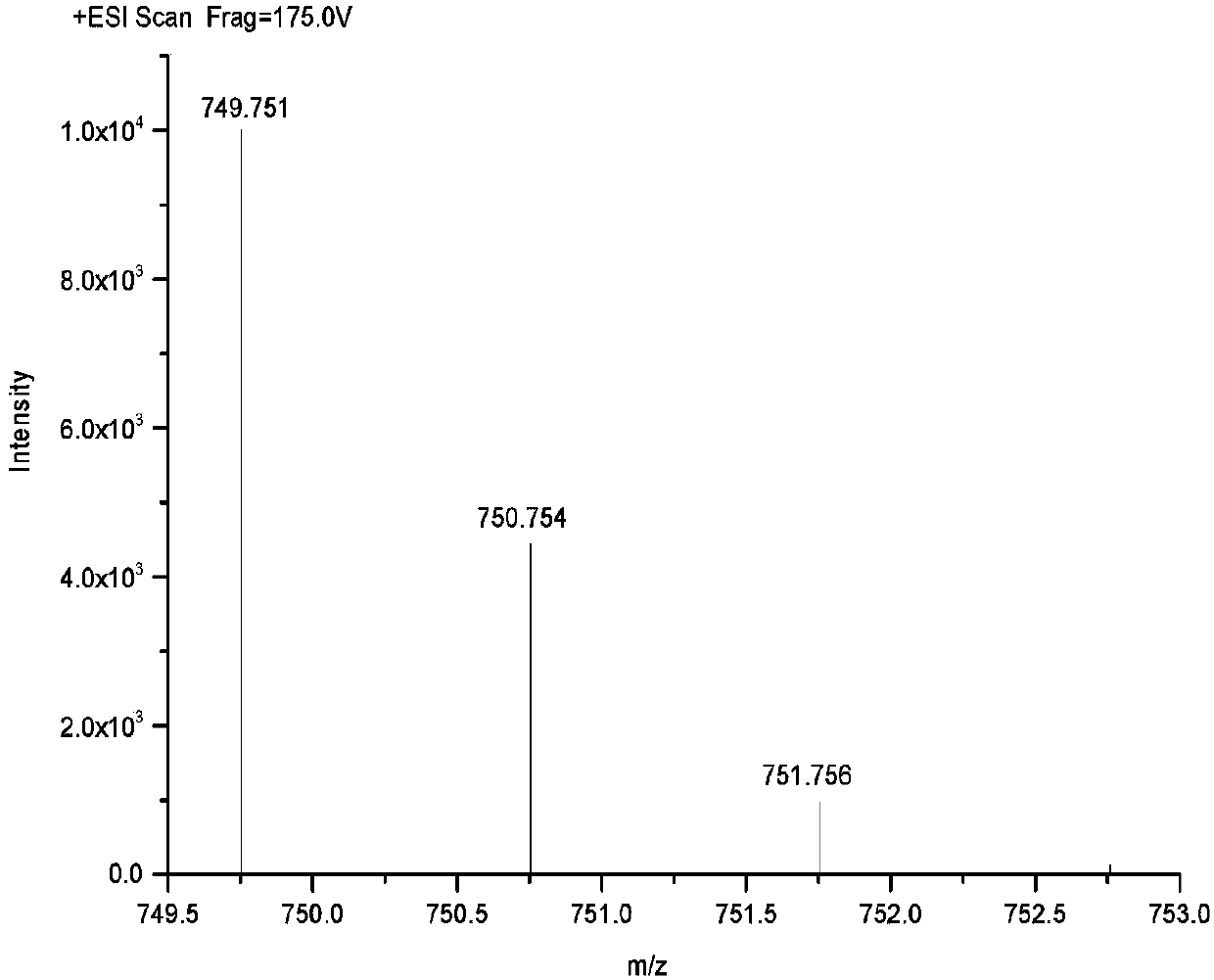

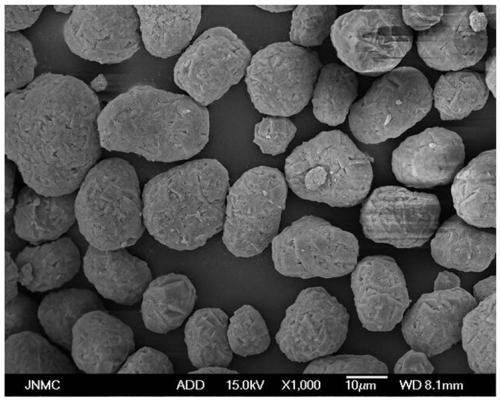

A kind of single crystal nickel cobalt lithium manganate precursor and its preparation method and application

ActiveCN109346718BAvoid corrosionGood dispersionCell electrodesSecondary cellsNickel saltActive agent

The invention provides a single crystal nickel cobalt lithium manganate precursor and a preparation method and application thereof. The preparation method comprises the following steps: dissolving soluble nickel salt, cobalt slat, manganese salt and / or salt doped with metal ions M in deionized water to obtain a mixed salt solution; mixing the salt solution with a carbonate solution and feeding thesolutions in parallel to a reaction kettle where a surfactant is dispersed to be stirred and reacted; and then carrying out centrifugalization, washing and drying to obtain the single crystal nickelcobalt lithium manganate precursor. The chemical formula of the single crystal nickel cobalt lithium manganate precursor is NixCoyMnzM(1-x-y-z)CO3, wherein M is the doped metal ions, x is greater than0 but less than 0.8, y is greater than 0 but less than 0.4, z is greater than 0 but less than 0.4 and (1-x-y-z) is greater than or equal to 0 but less than or equal to 0.1. The preparation process issimple to operate, free of an inert atmosphere or an additive, continuous to prepare and easy to implement industrial production.

Owner:ENERGY RES INST OF SHANDONG ACAD OF SCI

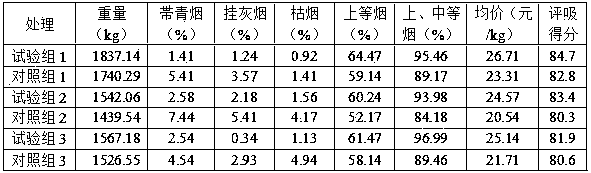

A harvesting and curing process of upper part tobacco for growing special flue-cured tobacco

The invention relates to an upper tobacco harvesting and curing process for growing special flue-cured tobacco. The process includes that if color is fixed before 42 DEG C, tobacco leaves are less prone to browning reaction and free of 'black bad tobacco', so that yellow tobacco rate after curing is high; the tobacco leaves after being cured contain a lot of aromatic substances and are large in aroma amount. The yellowing period of the flue-cured tobacco is high in yellowing temperature, high in humidity and long in time, and aromatic premise substances decomposed by the tobacco leaves are large in amount; when dry balls are at 52 DEG C in a color fixing period, synthesis time of the aromatic substances is prolonged; highest temperature is lower than that of conventional curing processes by about 3 DEG C in a stem drying period, and few aromatic substances are evaporated, so that the tobacco leaves after being cured contain a lot of aromatic substances and are large in aroma amount; usability of upper tobacco of the flue-cured tobacco is improved. Upper leaves start to be harvested when the upper leaves are about 60 days old, at the time, leaves inserted on tobacco plants are still large in amount, and nutrition of the tobacco plants do not concentrate on the upper leaves, so that big, deep and thick phenomena of the upper leaves are avoided, and regional characteristics of the flue-cured tobacco are ensured.

Owner:平顶山市烟草公司汝州市分公司 +1

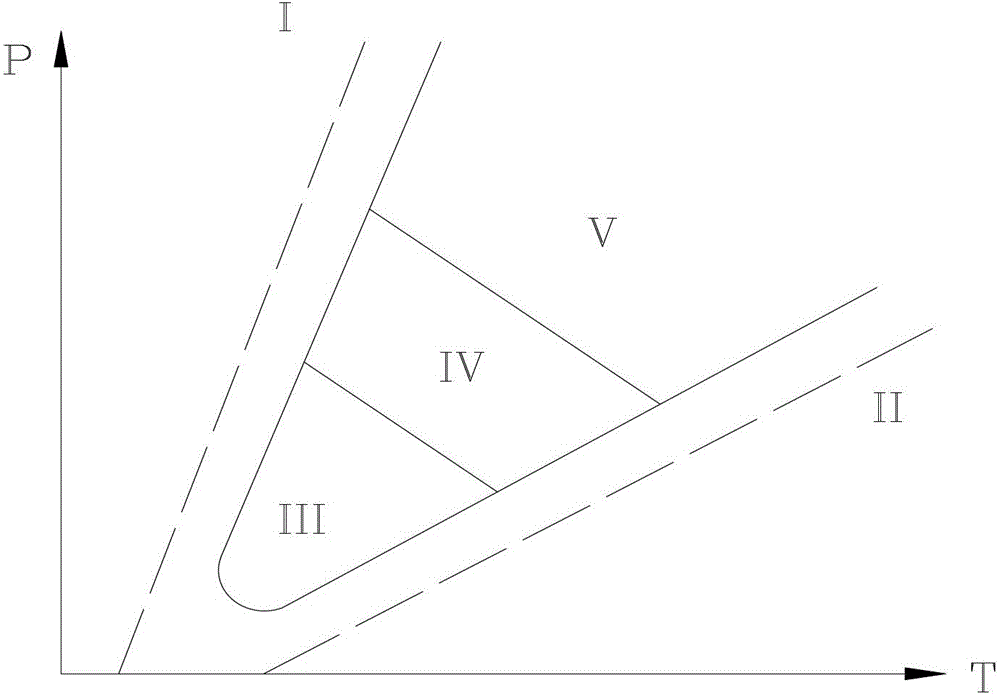

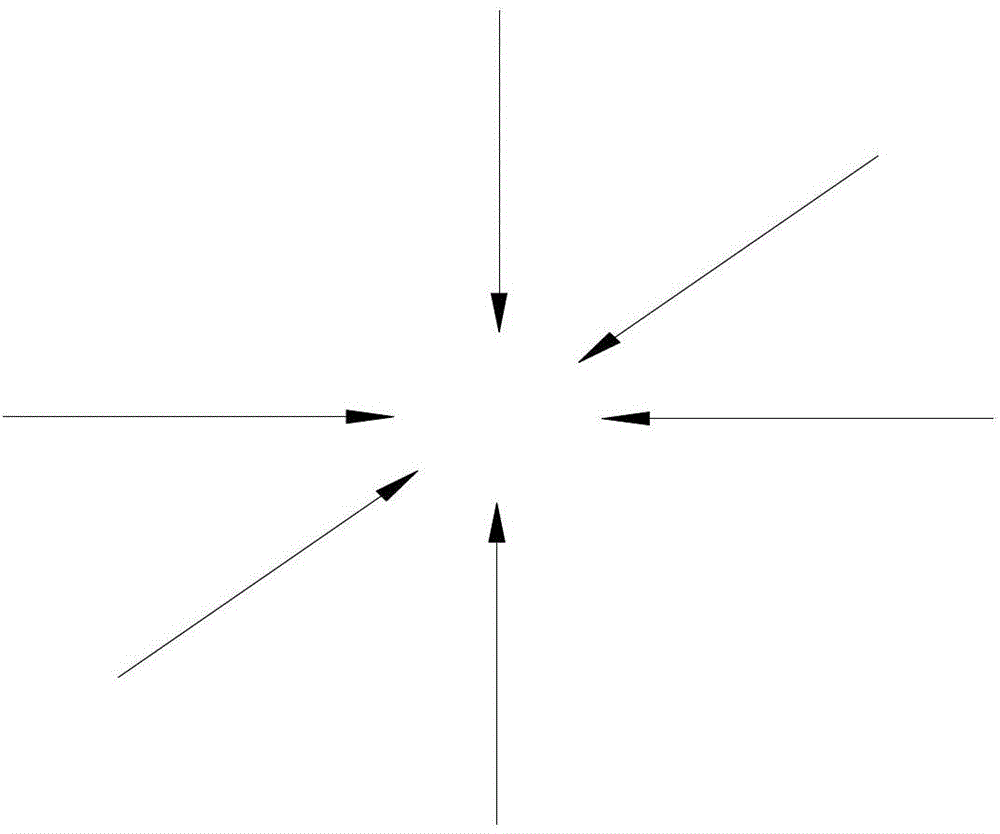

Synthesis process of a highly wear-resistant artificial diamond flake catalyst

InactiveCN102921350BHigh transparencyGranularity increaseUltra-high pressure processesMagnetic susceptibilityGranularity

The invention discloses a synthesis process of disc-shaped contact agent for high-abrasion-resistance artificial diamond. The synthesis process comprises two heating hammers (1) of which chambers axially correspond and four non-heating hammers (2) which radially correspond, wherein the alpha angles of the two heating hammers (1) is 42 degrees; A-A surfaces of the four non-heating hammers are 40 degrees 30 minutes; the B-B surfaces of the four non-heating hammers are 41 degrees 30 minutes; namely, the four non-heating hammers (2) are adjacent in 41 degrees 30 minutes; and the two heating hammers (1) and the four non-heating hammers (2) are adjacent in 42 degrees to 40 degrees 30 minutes. The invention discloses the synthesis process of the disc-shaped contact agent for the high-abrasion-resistance artificial diamond which is coarse in granularity, high in transparence, sharp in edge, and low in magnetic susceptibility.

Owner:湖南宁乡金鑫超硬材料厂

A kind of preparation method of branched polyethyleneimine and shale intercalation inhibitor

ActiveCN107722953BReliable technologyHigh yieldDrilling compositionPolyamine CompoundPolymer science

The invention discloses a preparation method of branched polyethyleneimine and a shale intercalation inhibitor prepared from the branched polyethyleneimine. The branched polyethyleneimine is preparedby the following steps: S1. synthesizing aziridine; S2. with a polyamine compound and the aziridine as raw materials, preparing the branched polyethyleneimine by a stepwise synthesis process or a one-pot synthesis process, wherein the polyamine compound is polyethylene polyamine or alkylamine; the polyethylene polyamine is one of diethylenetriamine, triethylene tetramine, tetraethylenepentamine and pentaethylenehexamine; the alkylamine is one of ethylenediamine, propane diamine, butanediamine, pentamethylene diamine, nonamethylene diamine and decamethylene diamine. The shale intercalation inhibitor is prepared by proportionally mixing the branched polyethyleneimine with water. The branched polyethyleneimine synthesis method provided by the invention has the advantages of high yield and cheap raw materials and is suitable for large-scale industrial production; the shale intercalation inhibitor prepared from the branched polyethyleneimine can effectively alleviate the problem of unstableborehole wall caused by the hydration dispersion of shale.

Owner:SOUTHWEST PETROLEUM UNIV

A kind of fully synthetic cutting fluid with high anti-wear and anti-rust performance and preparation method thereof

ActiveCN107955697BStrong extreme pressureImprove the lubrication effectLubricant compositionLow speedMass ratio

Owner:UNIV OF SCI & TECH BEIJING

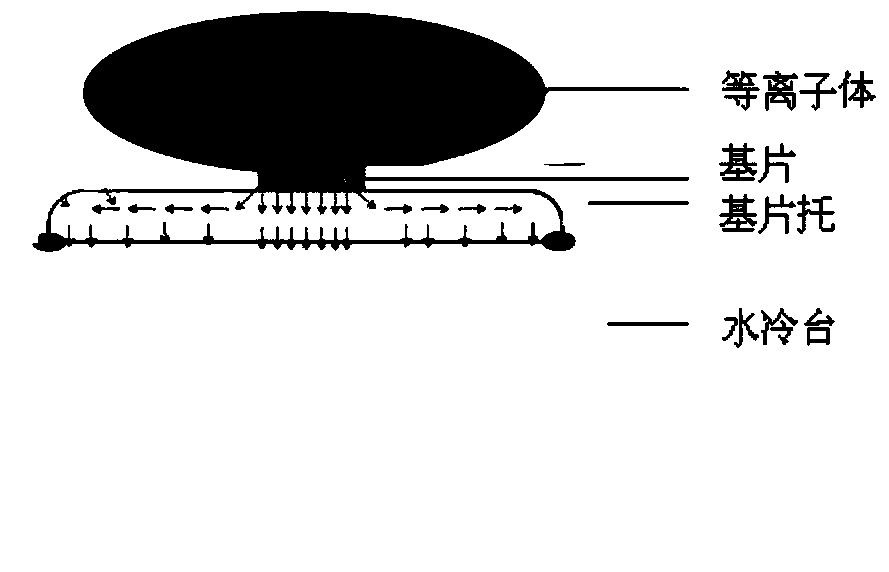

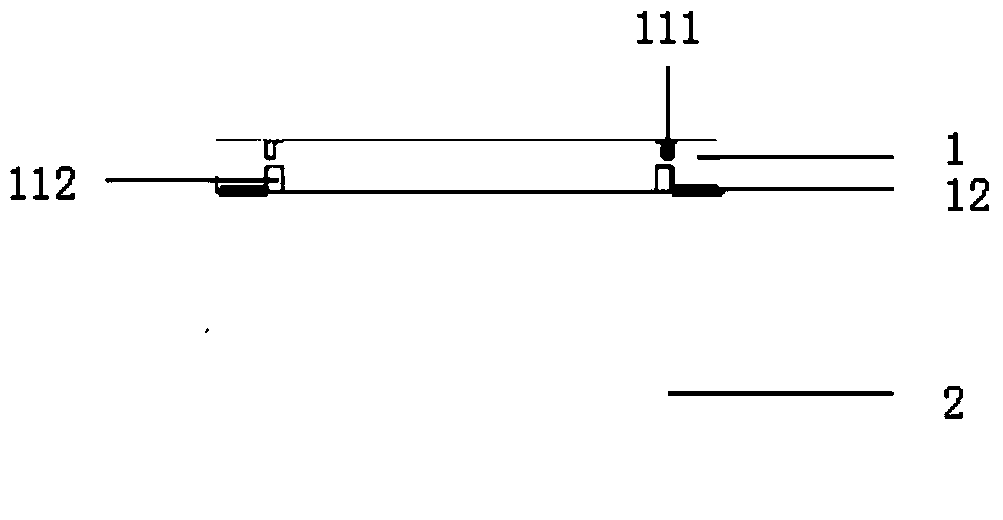

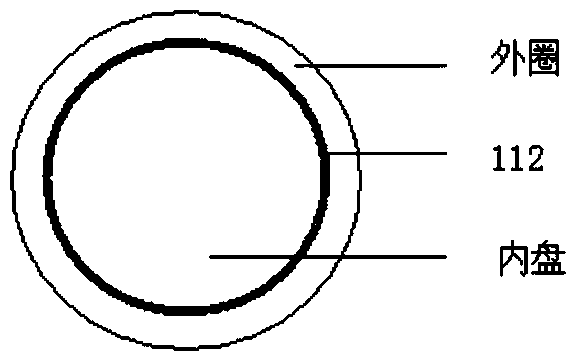

A kind of abutment assembly for preparing diamond

ActiveCN106811737BStable growthStable generationChemical vapor deposition coatingThermal bridgeHeat conducting

The invention belongs to the technical field of diamond synthesis, and provides a pedestal assembly for preparing diamond. The pedestal assembly comprises a water cooling table and a substrate support arranged on the water cooling table. The water cooling table is tightly connected with the substrate support. Annular grooves are formed in the upper and lower surfaces of the portion, close to the outer edge, of the substrate support, and an upper thermal bridge and a lower thermal bridge are formed correspondingly. A heat conducting gasket is arranged between the water cooling table and the substrate support and located on the outer ring part of the portion, with the lower thermal bridge as the boundary, of the lower surface of the substrate support.

Owner:徐州景澜新材料科技有限公司

A preparation method for doping rare earth element tricobalt tetroxide

ActiveCN110002514BCrystal denseEvenly dispersedCobalt oxides/hydroxidesRare-earth elementCobalt(II,III) oxide

The invention discloses a method for preparing cobalt tetroxide doped with a rare earth element. In the method, the rare earth element is mixed into a cobalt solution, and as the synthesis time prolongs, the concentration of the cobalt solution added to the reactor increases or decreases in a gradient manner. At the same time, the solid-to-liquid ratio of the slurry in the reactor is adjusted, and evenly doped cobalt hydroxide is synthesized by wet method. After the synthesis is finished, the synthesized product is washed, dried, and calcined to obtain a product doped with rare earth element tricobalt tetroxide with large particle size or small particle size. Using this process, it is possible to prepare cobalt tetroxide products doped with La, Ce, Y, doping amount uniformly distributed, and spherical or quasi-spherical in shape.

Owner:JINCHUAN GROUP LIMITED +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com