Substrate used for diamond synthesis and having coating layer as well as diamond synthesis system

A coating and diamond technology, applied in the field of diamond synthesis devices, can solve problems such as the surface roughness of the coating, and achieve the effect of improving product quality and achieving batch stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

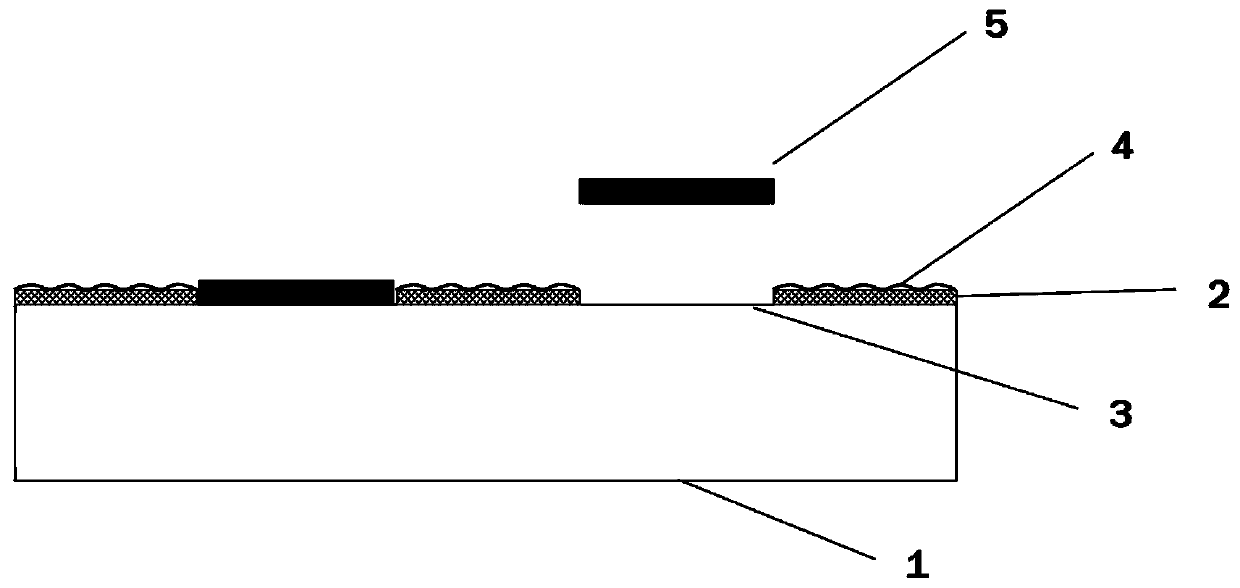

[0073] figure 1 It is a structural schematic diagram of a substrate for diamond synthesis with a coating layer in an embodiment of the present invention.

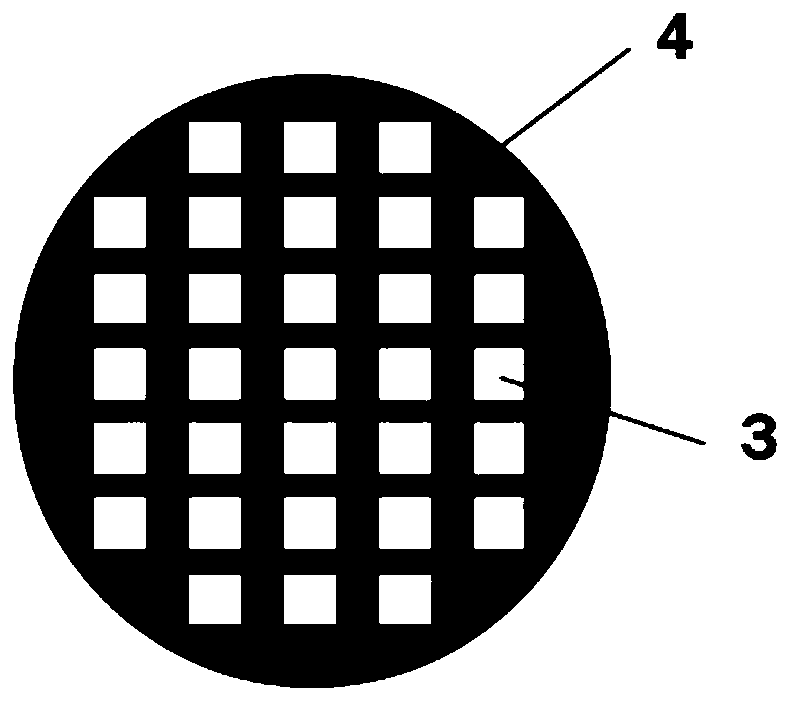

[0074] Such as figure 1 As shown, the substrate for diamond synthesis with a coating layer includes a substrate base 1 , a coating layer 2 ; a first surface 3 not covered by the coating layer, and a coating layer surface 4 .

[0075] The substrate base 1 is located in the reaction chamber 8, and the upper surface of the substrate base is a sample mounting surface. The coating layer 2 covers part of the sample mounting surface.

[0076] Since the working environment of the substrate is as high as 900°C, the coating layer is made of a material that can withstand a high temperature of at least 900°C without detaching from the contact surface and warping. The material of the coating layer is preferably W alloy. At the same time, considering the requirements of the working environment, other metals such as Mo can also be se...

Embodiment 2

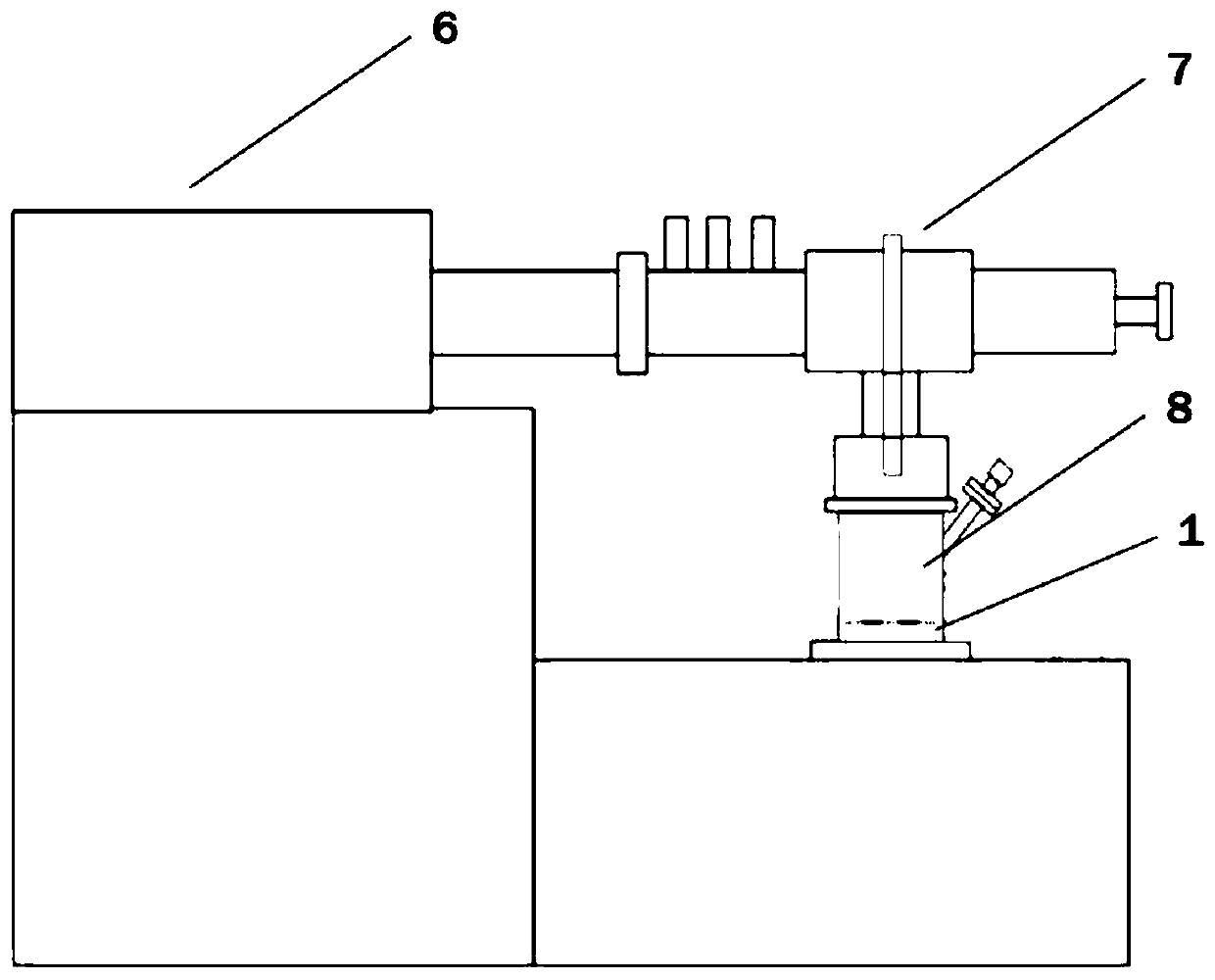

[0082] This embodiment provides a diamond synthesis system including the above-mentioned substrate. The system includes a microwave source 6 and a microwave coupling system 7 . The microwave coupling system guides microwaves generated by the microwave source 6 into the reaction chamber 8 . Generally speaking, the microwave coupling system includes components such as waveguide, three-pin, mode converter, and short-circuit piston. Further, a circulator and a water load may be included to protect the microwave generating device and absorb reflected microwaves. The reaction chamber is connected with a reaction chamber of an air inlet system and an air outlet system. The air intake system introduces the reaction gas into the reaction chamber. After the microwave coupling system introduces the microwave into the reaction chamber, the microwave excites the dissociated reaction gas in the reaction chamber to form plasma, and deposits diamond on the seed crystal. The gas outlet syste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com