Patents

Literature

30results about How to "Abundant and cheap" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

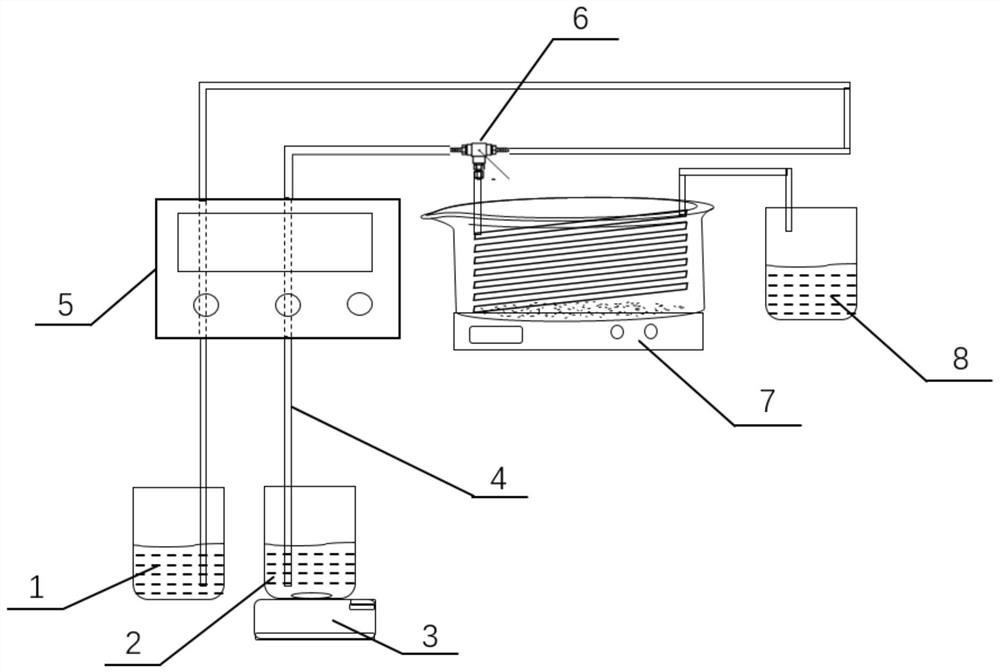

Method for preparing hydrogen through photoanode-photovoltaic battery coupled dual-illumination fully-photic-driven decomposition of water

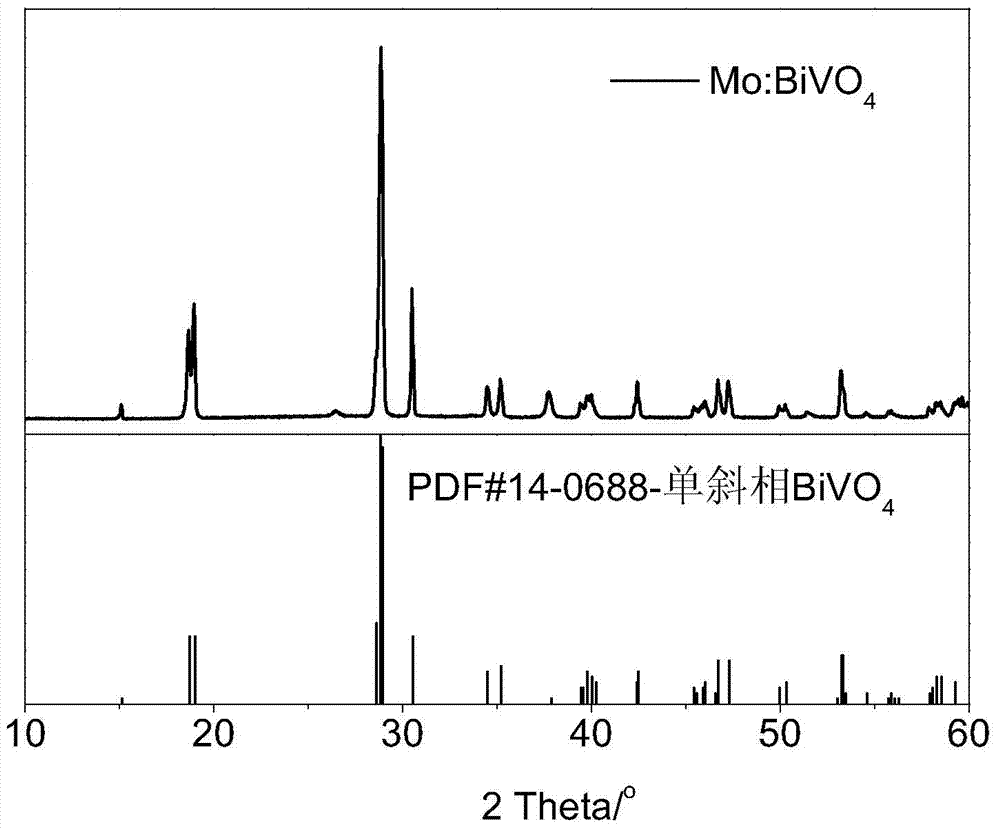

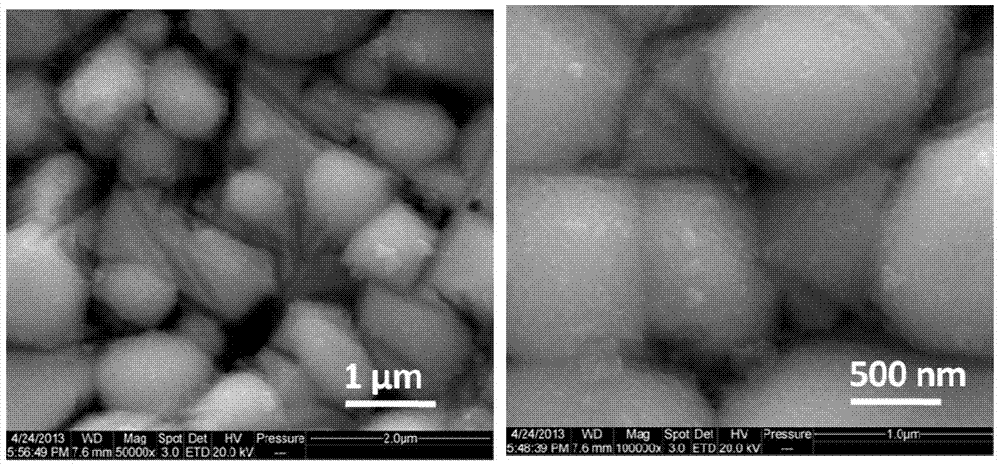

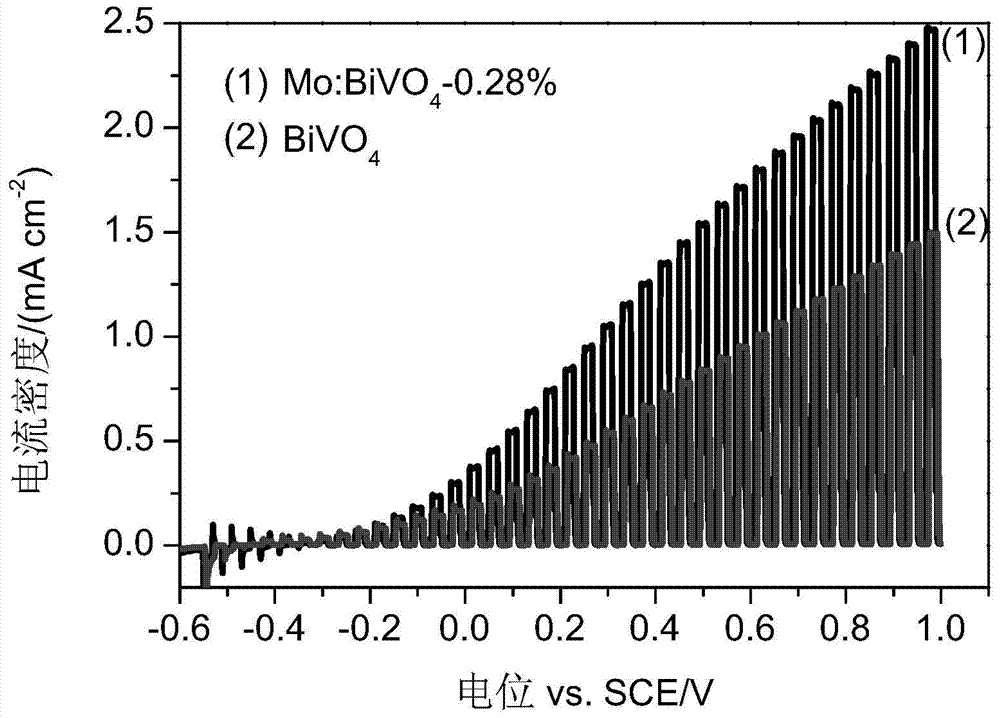

InactiveCN104711627AImprove visible light absorptionHigh catalytic activityElectrolysis componentsLight-sensitive devicesSemiconductor materialsHydrogen

The invention relates to a method for preparing hydrogen through photoanode-photovoltaic battery coupled dual-illumination fully-photic-driven decomposition of water. Efficient decomposition of water is realized under sunlight illumination conditions by using coupling of a photoelectrocatalysis technology with a photovoltaic battery technology, adopting a water oxidation cocatalsyt modified semiconductor material as a photoanode, placing a proton reduction cocatalyst modified Si battery in an electrolyte as a photocathode, directly connecting the positive electrode of the Si battery with the anode through a lead and allowing the surface of the cathode to contact with the electrolyte. The method realizes fully photic driven decomposition of water without applied bias conditions, and the solar energy utilization efficiency STH of the method reaches 2.2% or above.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

A kind of organic matter-coated slow-release fertilizer and preparation method thereof

InactiveCN102276357AExcellent physical controlled release performanceIncrease or decrease thicknessFertilizer mixturesParticulatesRelease time

The invention discloses an organic matter-coated slow-release fertilizer and a preparation method thereof. The slow-release fertilizer is prepared from the following raw materials in terms of mass percentage: 10%-70% organic matter solid powder, 2%-20% solidified binder and 10% to 88% granular fertilizer. The invention uses the organic solid powder coating material to make the organic coated slow-release fertilizer have the advantages of no solvent recovery, no drying, fast film formation, abundant and cheap sources of coating materials in the production process, and can be produced by open conventional equipment. The organic matter-coated slow-release fertilizer of the invention has excellent physical controlled-release performance, and the fertilizer effect can exceed 100 days, and the controlled-release time can be adjusted as required. At the same time, the coating material used can not only degrade in the soil but also supplement high-quality organic matter to the soil, avoiding the possible soil acidification caused by sulfur coating and the residue problems caused by resin coating, which is more friendly to the environment. It is suitable for planting fields such as agriculture and forestry.

Owner:SOUTH CHINA AGRI UNIV

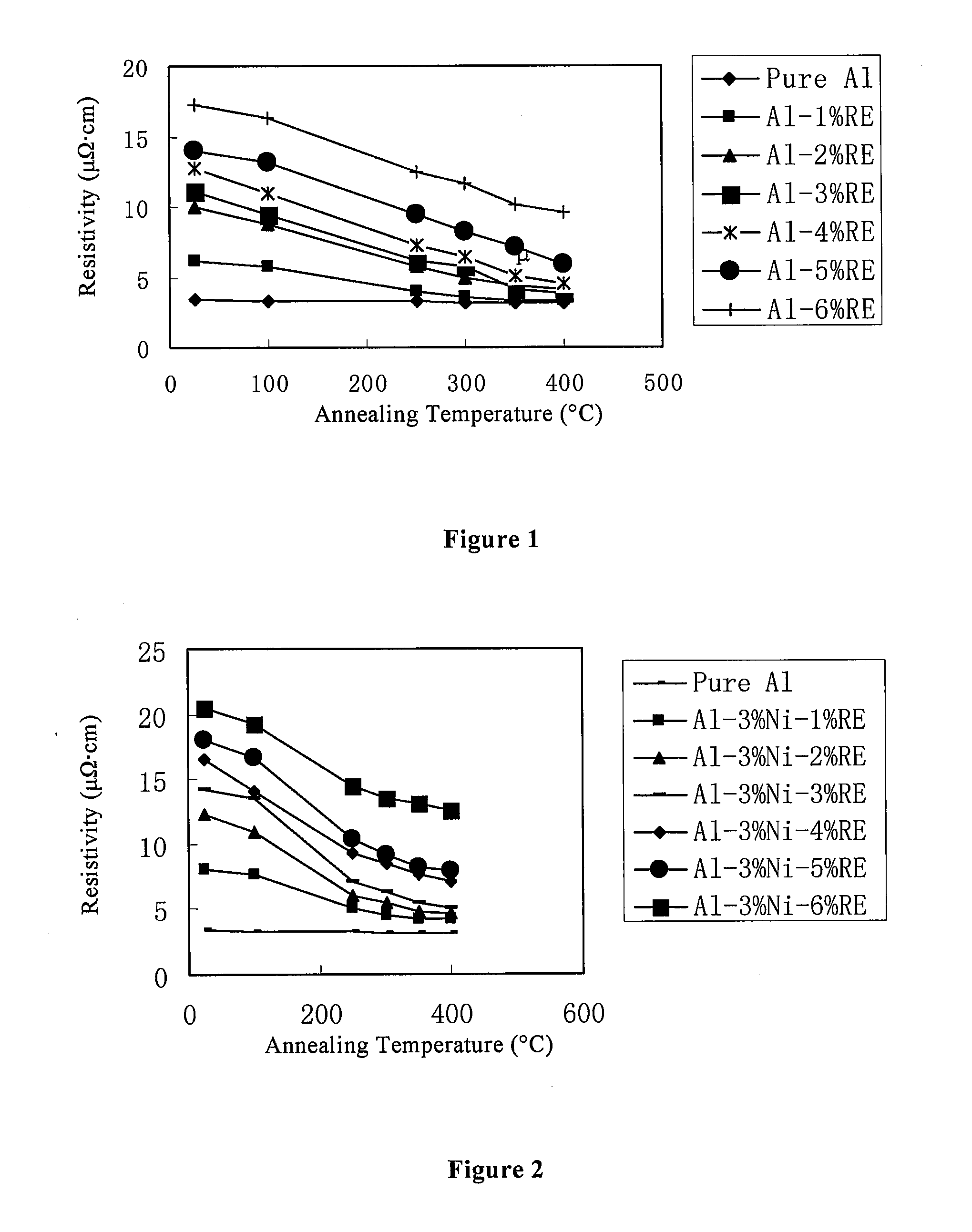

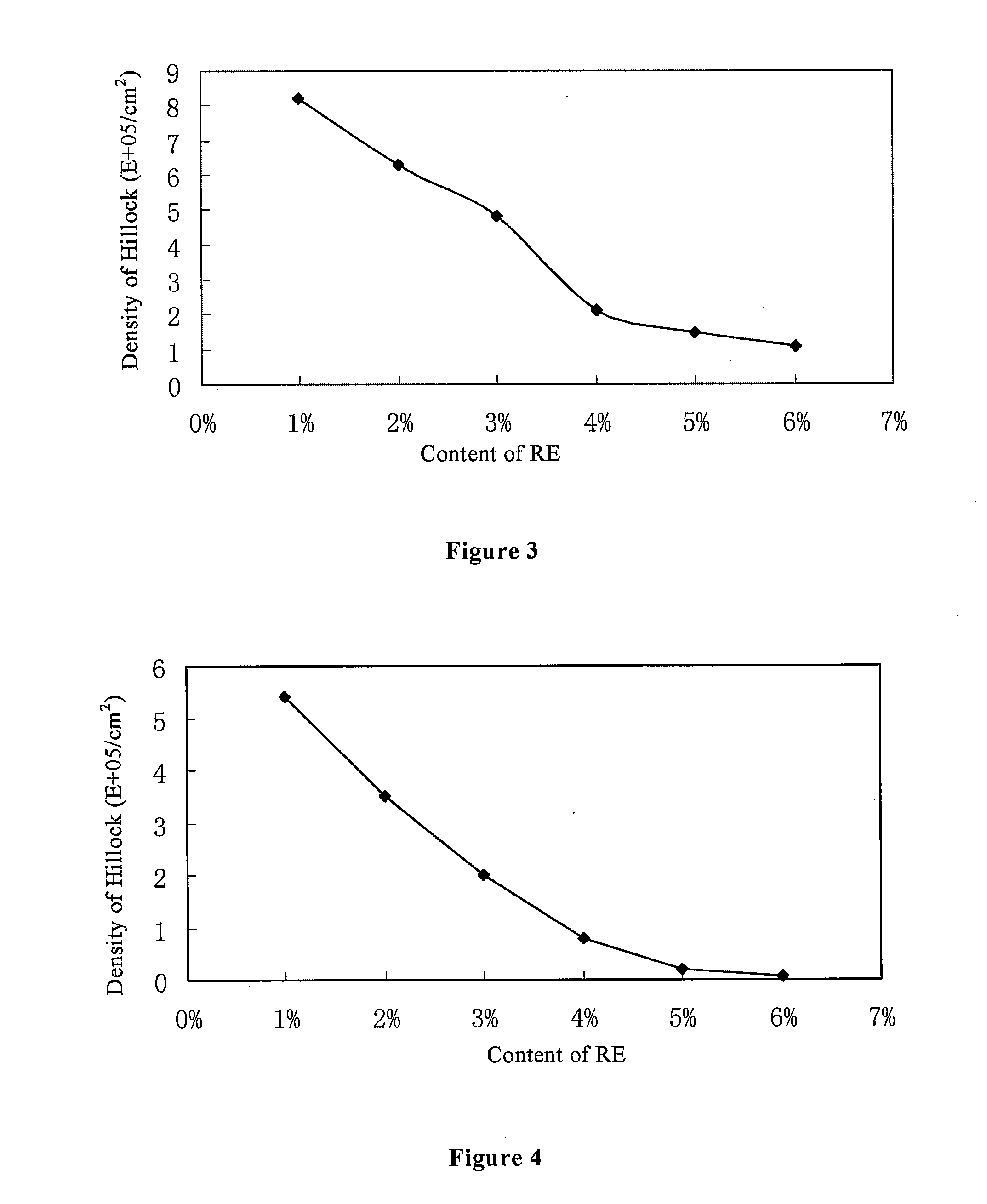

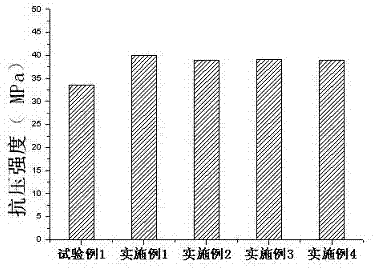

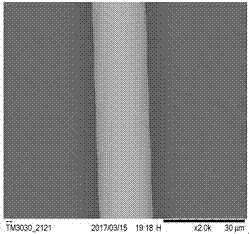

Target material for electrode film, methods of manufacturing the target material and electrode film

InactiveUS20080253925A1Cost reductionImprove resistance to corrosion and oxidationVacuum evaporation coatingSputtering coatingRare-earth elementSemiconductor

Provided are a target material for manufacturing an electrode film of a semiconductor device, methods of manufacturing the target material and manufacturing the electrode film. The target material comprises Al-RE alloy or Al—Ni-RE alloy, in which RE is a mixture of rare earth elements comprising La, Ce, Pr, and Nd.

Owner:BEIJING BOE OPTOELECTRONCIS TECH CO LTD

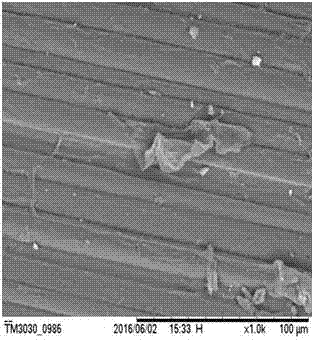

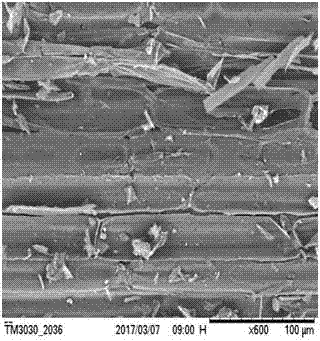

Industrial preparation method for silica carbide crystal whisker and micropowder

InactiveCN1449994AAbundant and cheapSimple structurePolycrystalline material growthSingle crystal growth detailsCarbideDiameter ratio

The industrial preparation method of silicon carbide whiskers and micrpowder is characterized by that the graphite and other industrial carbon and silicon raw materials are mixed, and placed into industrial SiC smelting furnace to make synthesis reaction, the graphite is used as conductive heating body to prepare silicon carbide whiskers and micropowder. Said preparation method is simple, the diameter of whiskers produced by said invented method is uniform, and length-diameter ratio is large and the heteromorphous crystal is less, and product quality is high.

Owner:XIAN BOER NEW MATERIAL CO LTD

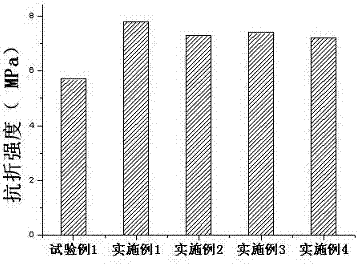

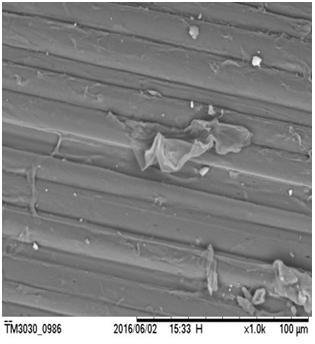

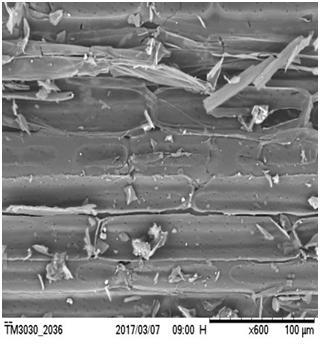

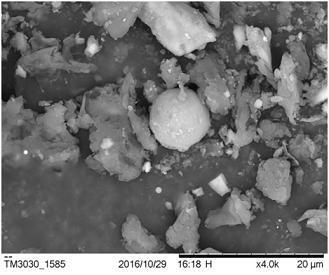

Modified basalt fiber reinforced scoria lightweight aggregate concrete and preparation method thereof

Owner:JILIN JIANZHU UNIVERSITY

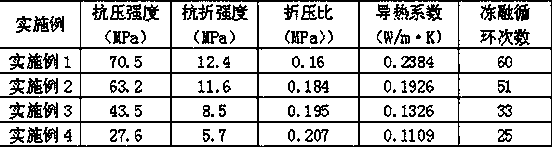

Straw compounded building material and preparation method thereof

The invention discloses a straw compounded building material and a preparation method thereof provides a novel compound building material and a preparation method thereof. The surface properties of straw can be effectively improved, and accordingly the problem that the straw and a cement base material are difficult to bond. In addition, the novel compound straw material is a green and environment-friendly resource which are rich and cheap in composition and ingredient selection, and the novel compound material having the strength properties including compression resistance, fracture resistance and freezing resistance and having very excellent thermal insulation properties can be obtained.

Owner:JILIN JIANZHU UNIVERSITY

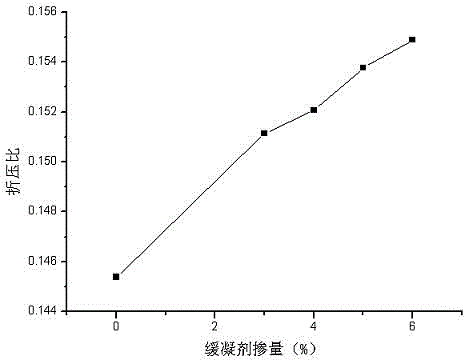

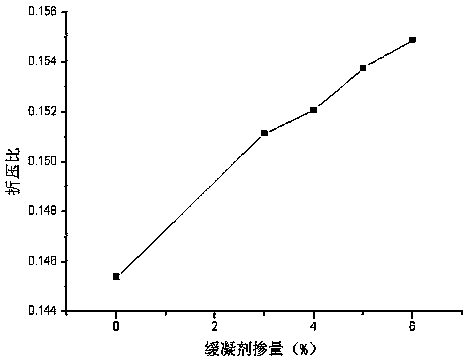

Novel alkali-activated slag and fly ash cementing material retarder and preparation method

The invention discloses a novel alkali-activated slag and fly ash cementing material retarder and a preparation method. The method comprises the steps that a straw stem and a leaf are separated and dried; the straw stem is cut into sections and roughly crushed into 1-5mm length by a ball mill; the straw stem is uniformly mixed with silicon ash; milling is performed for 10-60min in the ball mill to form 400-1000-mesh powder to obtain the retarder. The novel alkali-activated slag and fly ash cementing material retarder is prepared by taking a straw as a main raw material; a corn straw is abundant in resource and low in price; a commonly used retarder which is high in price, complicated in production technology and non-environment-friendly is replaced; a retardation effect is obvious; in addition, the straw can exert an effect of a fiber, and improves the brittleness of the retarder. The method provides a new approach for comprehensive utilization of the straw, is simple in production technology, low in cost, green and environment-friendly, and has very significant economic and social benefits.

Owner:长春昌驰环保科技有限公司

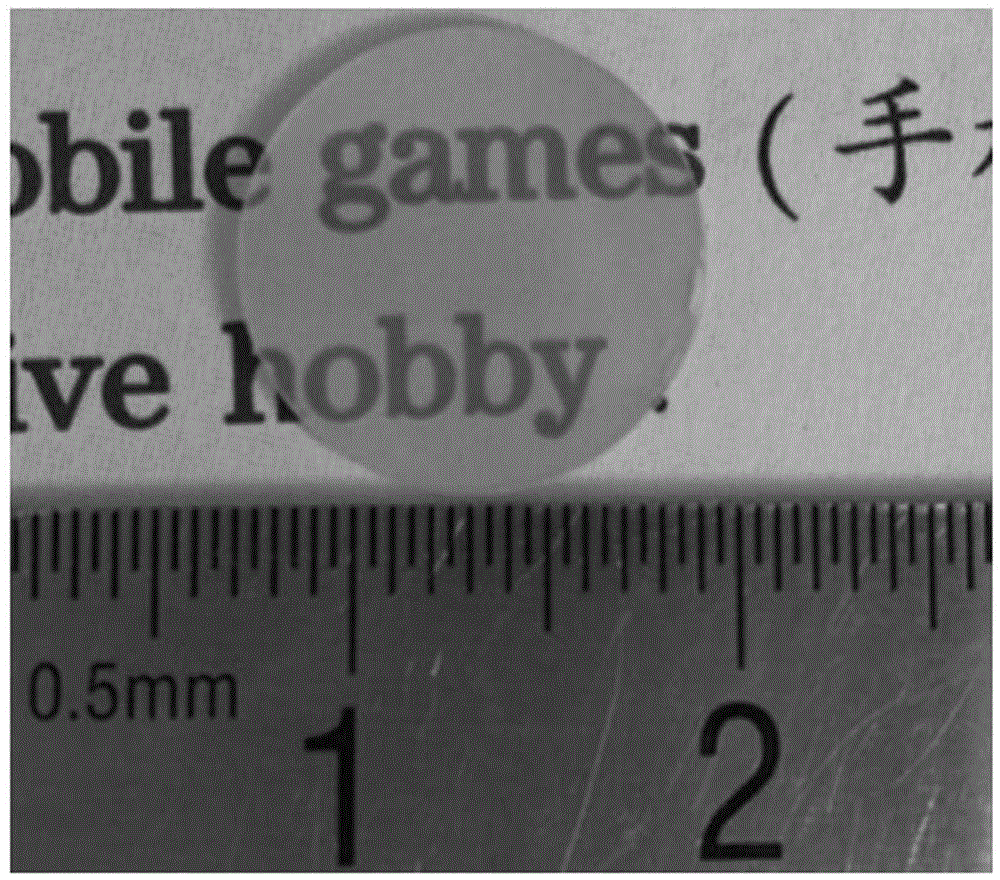

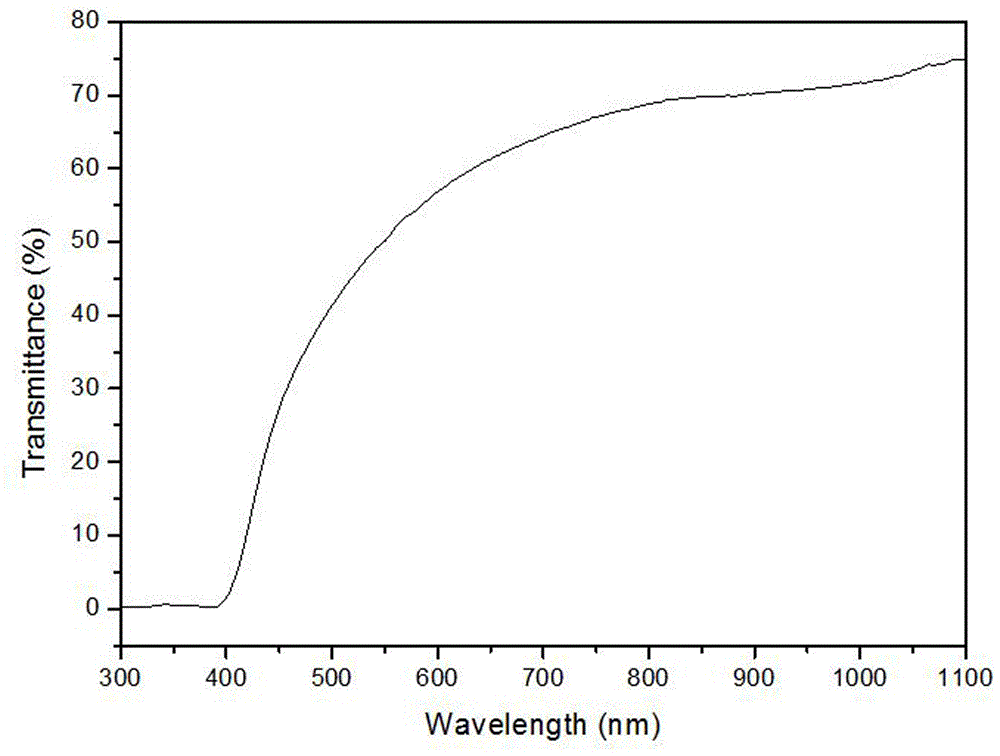

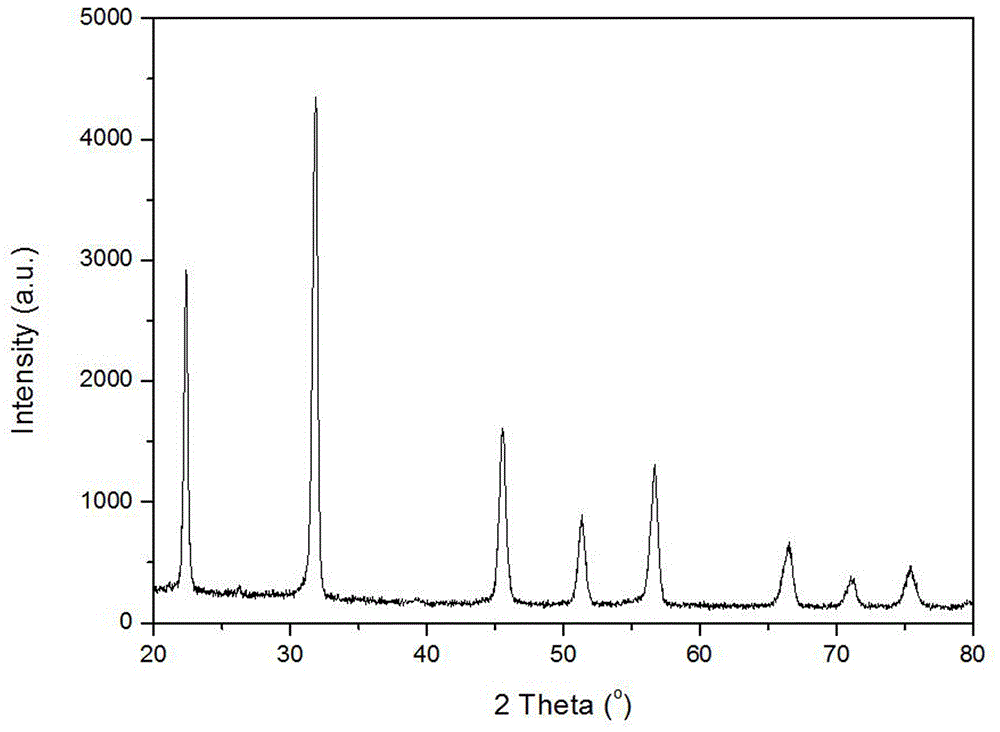

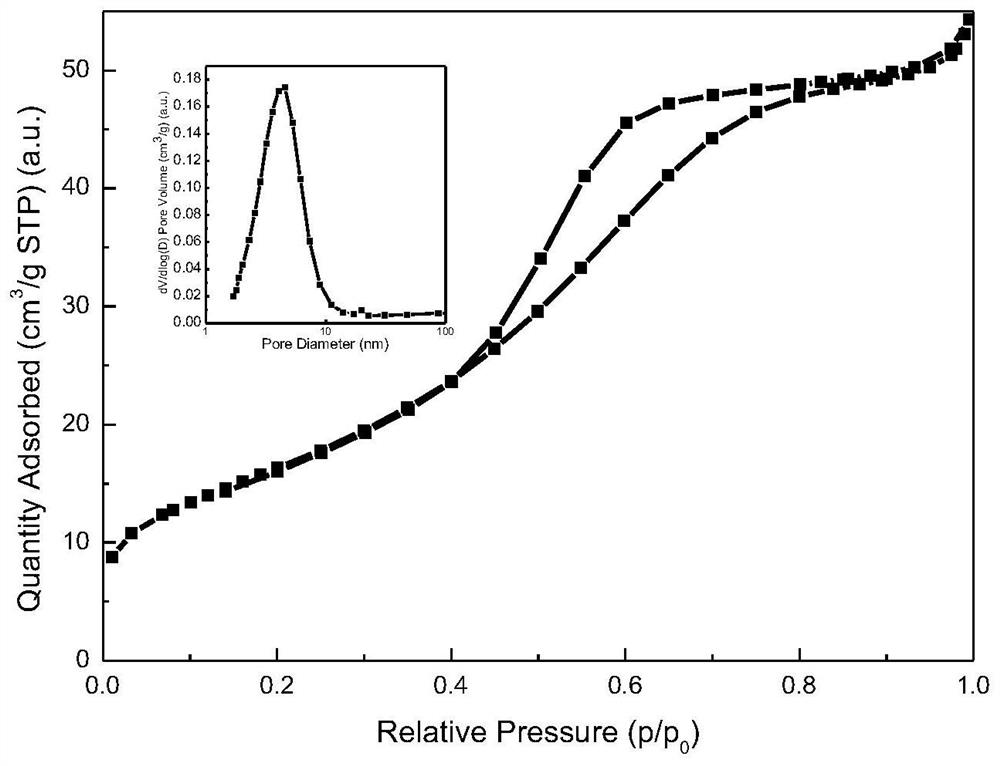

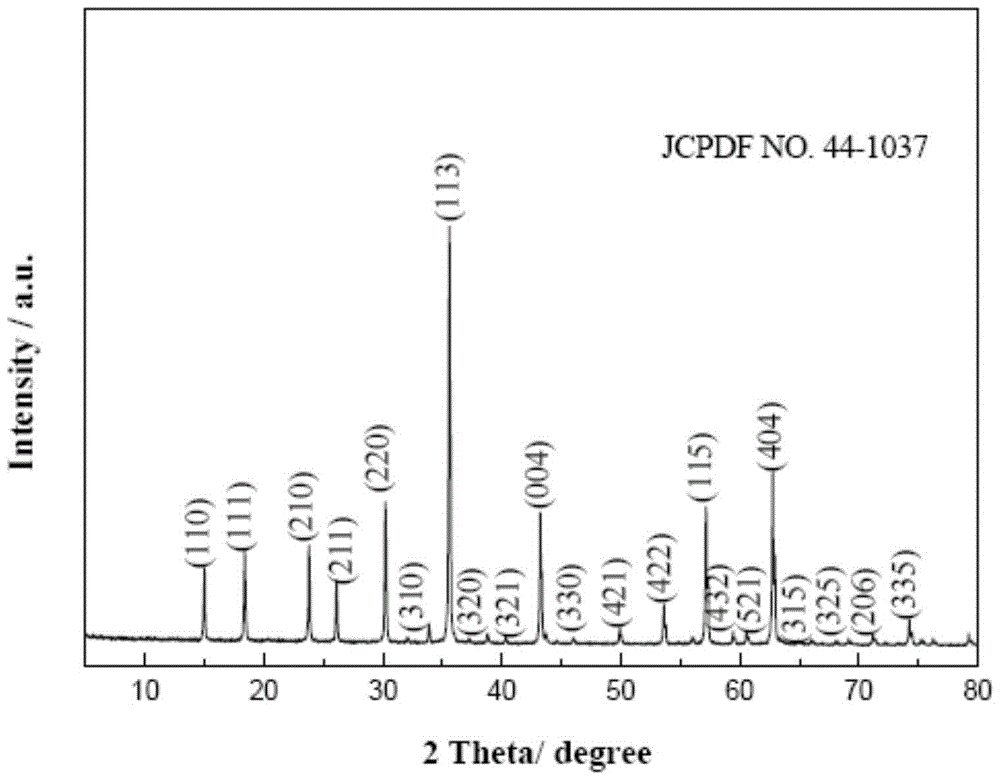

Potassium sodium niobate based transparent ceramic and preparation method thereof

The invention provides a potassium sodium niobate based transparent ceramic. Na2CO3, K2CO3, Bi2O3, BaCO3 and Nb2O5 are used as the raw materials and blended according to the chemical formula of (1-x)K0.5Na0.5NbO3-xBaBiO3, wherein in the formula, x represents the mole content in a system and is larger than 0 and no larger than 0.08. A preparation method of the potassium sodium niobate based transparent ceramic comprises the steps that (1) all the raw materials are placed in a drying oven to be dried before being weighed and blended; (2) all the raw materials are subjected to ball milling with absolute ethyl alcohol as the medium after being accurately weighed; (3) ball milling products are taken out, dried and presintered; (4) the presintered ball milling products are dried after being subjected to ball milling with absolute ethyl alcohol as the medium; (5) dried powder is pressed into a round billet after being sieved; and (6) the pressed round billet is sintered to obtain the transparent ceramic. The potassium sodium niobate based transparent ceramic has the advantages that by adjusting the doping content of the BaBiO3, the potassium sodium niobate based transparent ceramic prepared through a traditional ceramic process can reach 75% in visible light transmittance.

Owner:GUILIN UNIV OF ELECTRONIC TECH

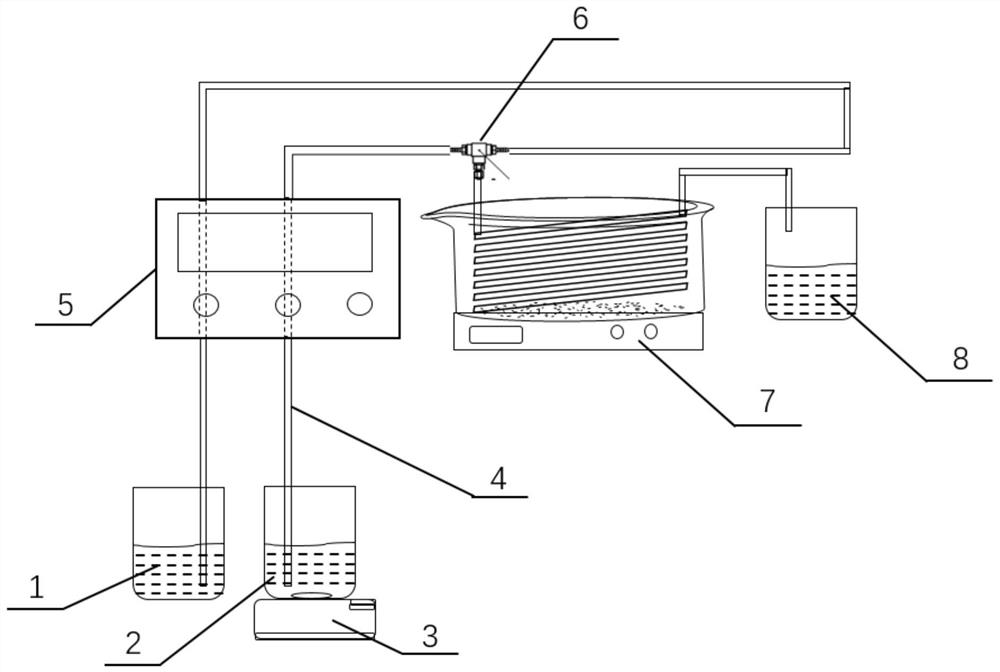

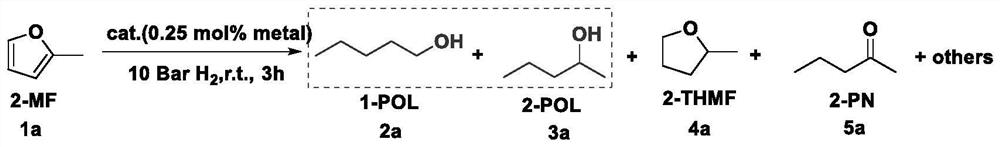

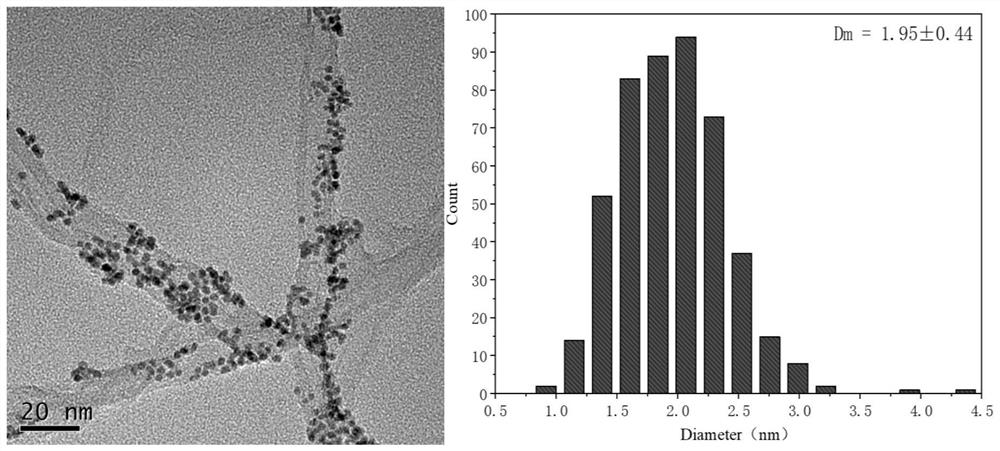

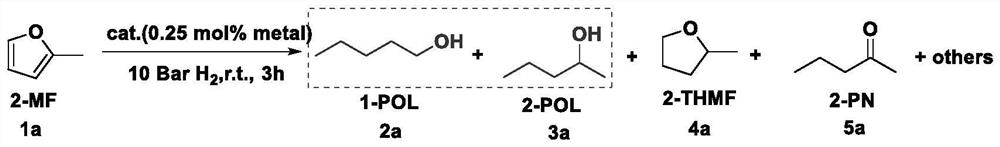

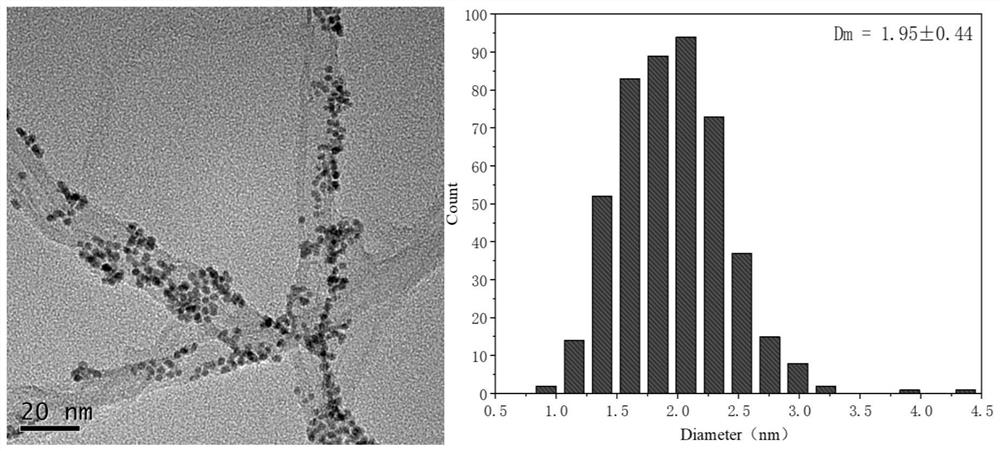

Method for preparing pentanol through hydrogenation of 2-methylfuran by using platinum-based catalyst

ActiveCN114031480ALarge specific surface areaWell mixedPreparation by oxygen reductionMetal/metal-oxides/metal-hydroxide catalystsFuranPtru catalyst

The invention provides a continuous-flow preparation method for a platinum-based catalyst. Compared with an impregnation method with the defects that time is long, selectivity is low, the manipulation of operators is depended, uneven mixing is easy to cause and the like, the continuous-flow preparation method of the platinum-based catalyst has the advantages of being simpler and more efficient and capable of realizing one-step and continuous production. According to the method, a pipe diameter of several millimeters is adopted, so the specific surface area of reaction liquid is greatly increased, mass and heat can be quickly transferred, and reaction liquid can be better mixed uniformly. Secondly, different amounts of solvents and reaction temperatures are screened, and a solvent dosage and an optimal reaction temperature are determined, so the conversion rate of pentanol prepared through hydrogenation of 2-methylfuran can reach 100% and the selectivity of pentanol is 70%, but however the selectivity of pentanol prepared through hydrogenation of 2-methylfuran by using a platinum-based catalyst prepared through the impregnation method is 53%; and the catalytic efficiency of the catalyst prepared by using the method can be improved by nearly 20% compared with the catalytic efficiency of the catalyst prepared by using the impregnation method. Mechanical operation can avoid human errors, so a result is easier to repeat, production efficiency is improved, and a new way is provided for preparing alcohol compounds by catalytic hydrogenation of furan derivatives.

Owner:NANJING UNIV OF TECH

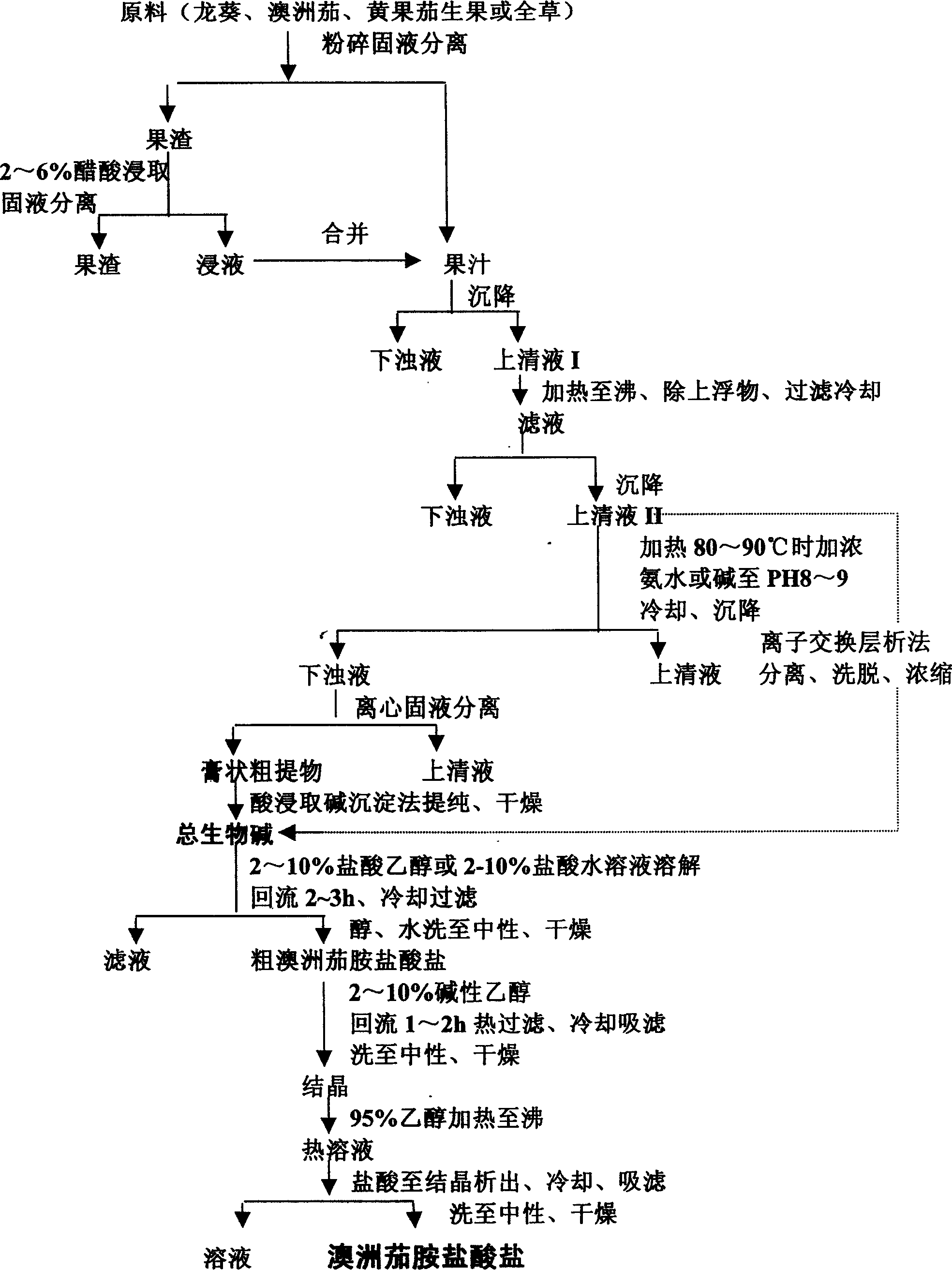

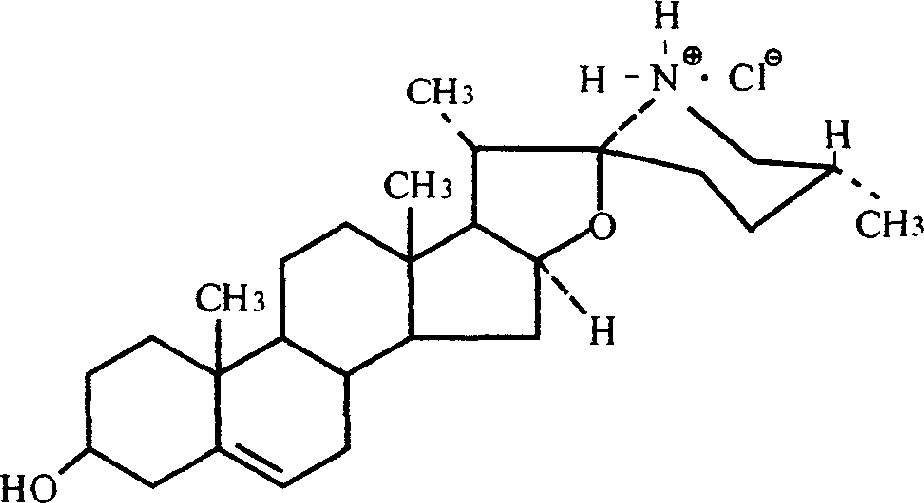

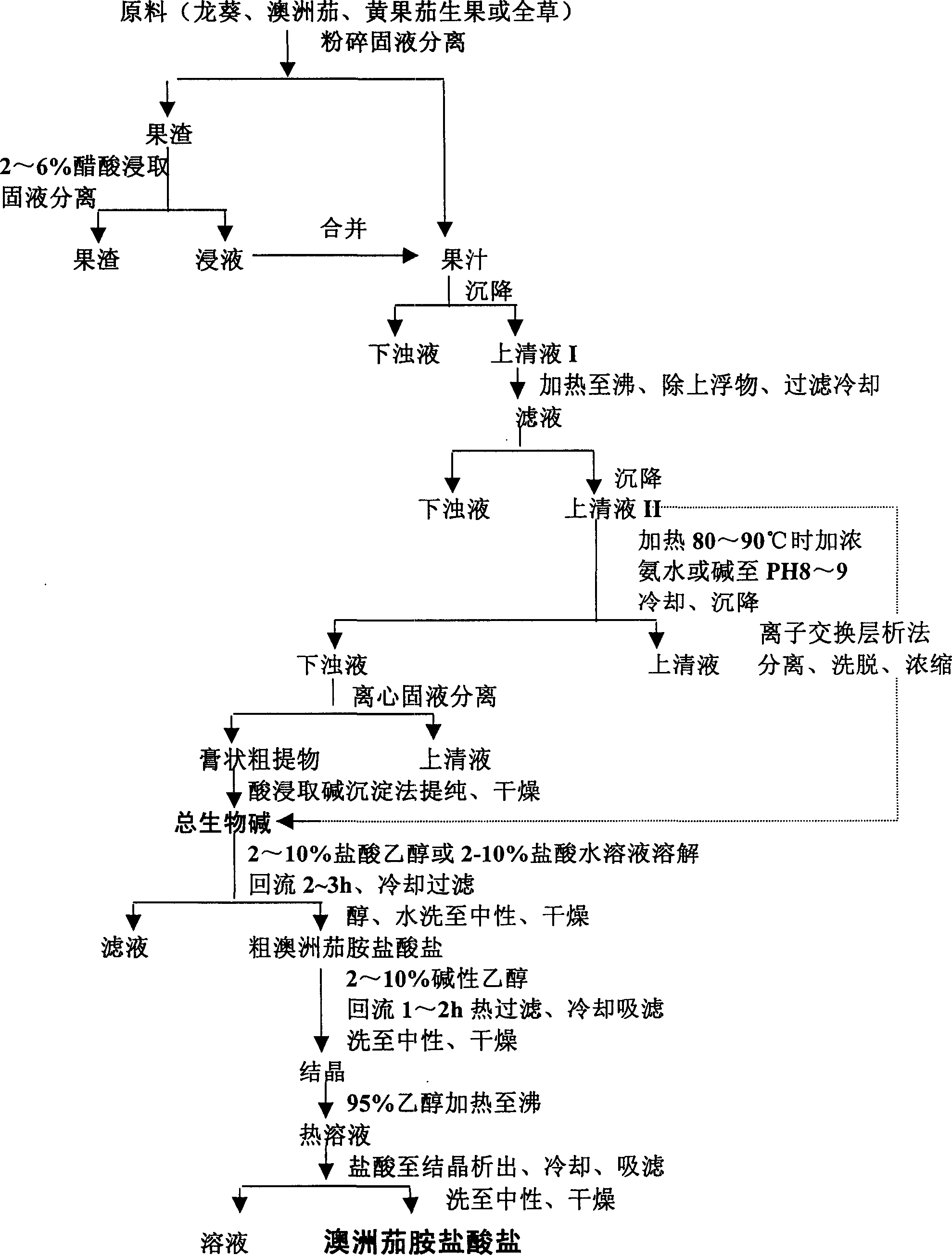

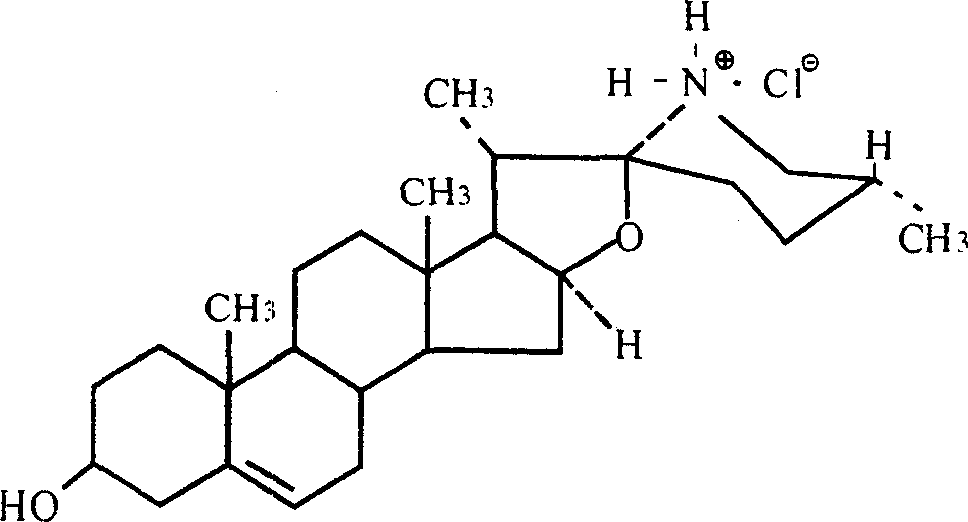

Oslasodine hydrochloride preparing process

The invention provides an Oslasodine hydrochloride preparing process for anti-cancer, asthma relieving, anti-inflammation and increasing immunity. The preparation process comprises using Solanum Nigrum L, Solanum aviculare parst and Solanum xanthocar pum Schrad, et wendl fruit or herbs as raw material, employing unique acid leaching alkali precipitation extraction method, alkaline alcohol dissolving acidic alcohol crystallization for Oslasodine hydrochloride extraction.

Owner:刘良

Slaughterhouse deodorant and preparation method thereof

InactiveCN108970388AAbundant and cheapCheap sourceGas treatmentOther chemical processesBenzoic acidBarium peroxide

The invention discloses a slaughterhouse deodorant and a preparation method thereof. The slaughterhouse deodorant is prepared from the following raw materials in parts by weight: vanadium pentoxide, aluminum ash, polyacrylamide, methanol, paraffin wax, azone, thymol, urotropin, activated charcoal, pine needle oil, mineral oil, p-chlorobenzenethiol, benzoic acid, calcium oxide, zeolite, cadmium sulfide, proteinase, cellulase, pectinase, ferroferric oxide, magnesium stearate, barium oxide and a plant extracting solution. The slaughterhouse deodorant disclosed by the invention has the advantagesof simple production technology, abundant and cheap raw material sources, cheap price, no toxicity and no odor, small corrosion, good deodorization effect and long lasting time, and has a relatively strong adsorption and decomposition capability; the slaughterhouse deodorant is applicable to reasonable decomposition and removal of odors in a slaughterhouse and volatilizes a fresh scent, and can beused for a long period.

Owner:济宁鸿润食品股份有限公司

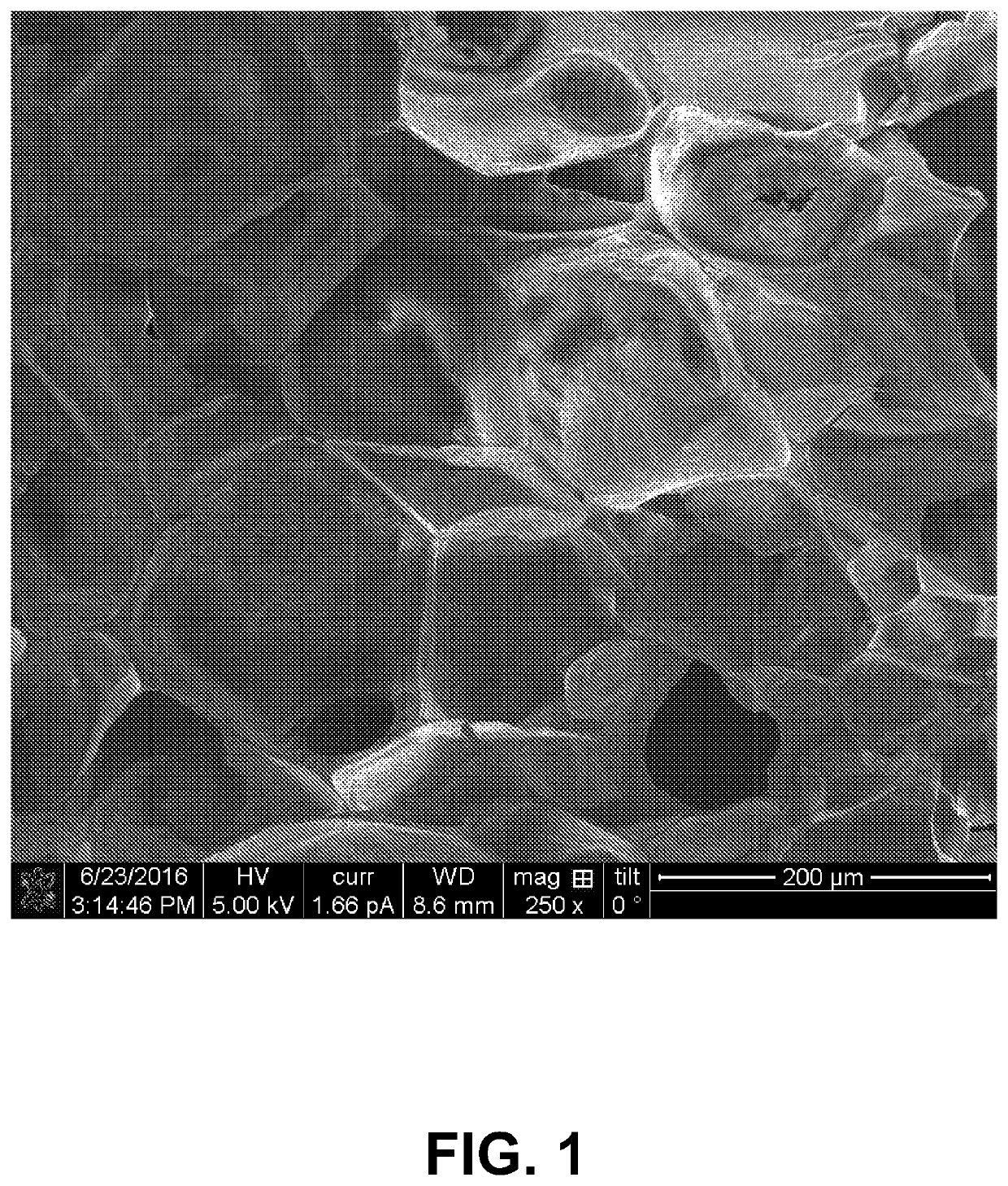

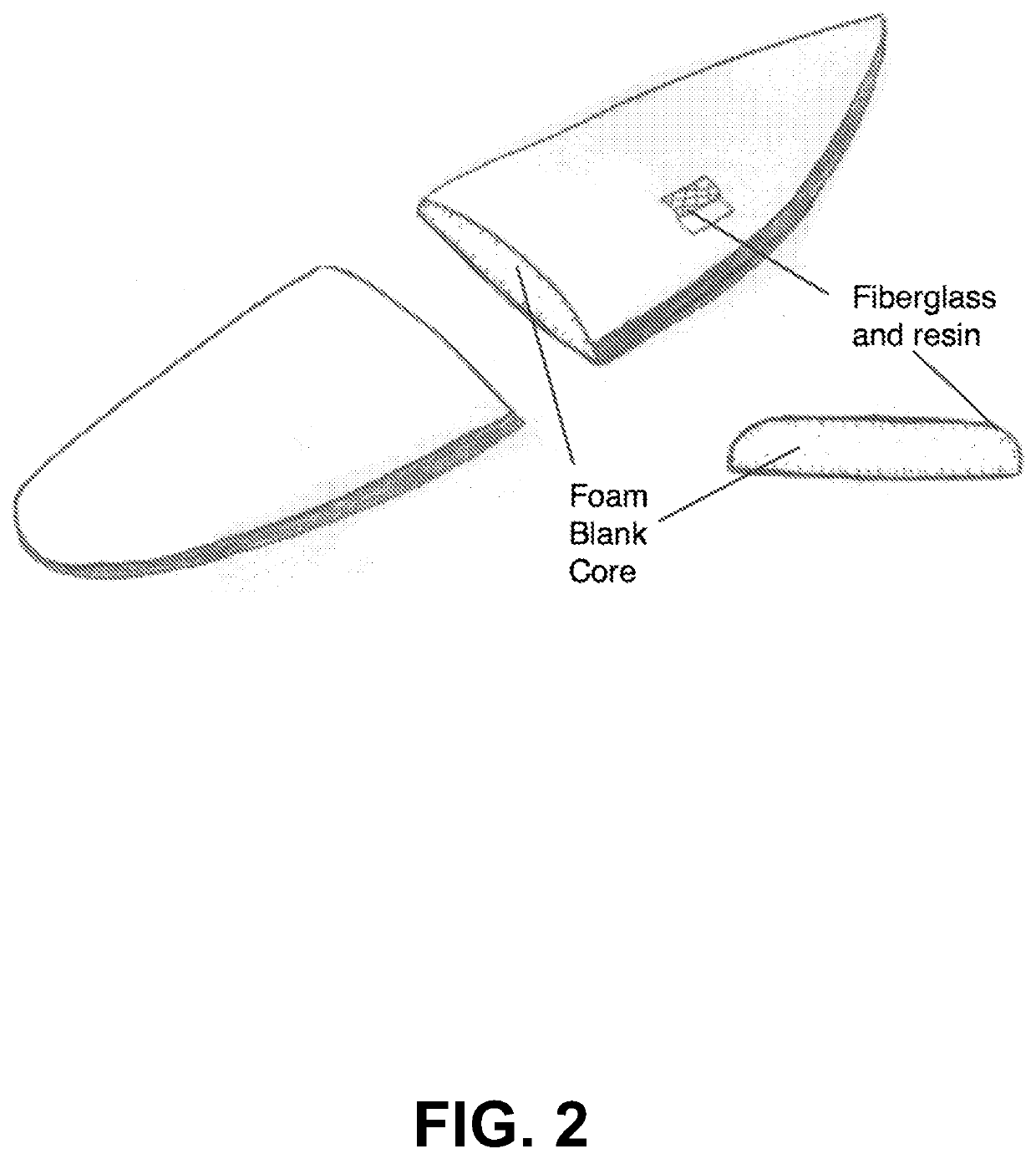

Naturally Sourced Chitin Foam

ActiveUS20200239670A1Robust mechanical propertyImprove mechanical propertiesWaterborne vesselsWater sport boardsNatural sourcePolymer science

Closed cell chitin foam is provided. The closed-cell chitin foam composition does not absorb water, is biodegradable, and is mechanically characterized by a density range of 16 to 800 kg / m3, closed-cell pore sizes ranging from 50 microns to 1 mm, an elastic modulus of 3 to 175 MPa, and a tensile strength of 0.15 to 6.5 MPa. The chitin is at least 70% acetylated. In one aspect, the foam is enclosed in a shell e.g. in the form of a surfboard. Chitin foam according to this invention is fully biodegradable. The chitin foam overcomes the current problems with foams that contain polyurethane and polystyrene, and which are manufactured from petroleum-based sources. Petroleum based foams are not renewable, have an adverse impact on our environment, and pose significant health hazards to those who manufacture them. The chitin foam with its water-based manufacturing process and naturally sourced chitin, solves these problems.

Owner:RGT UNIV OF CALIFORNIA

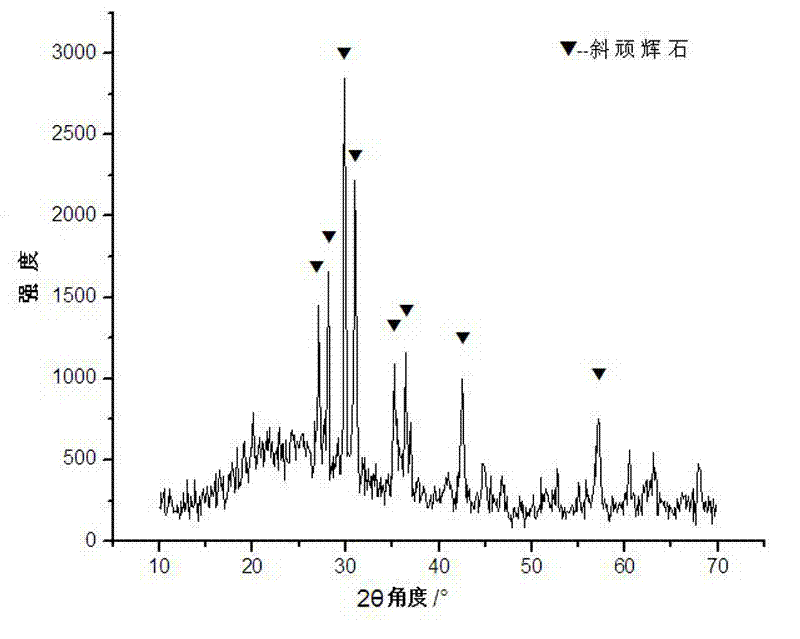

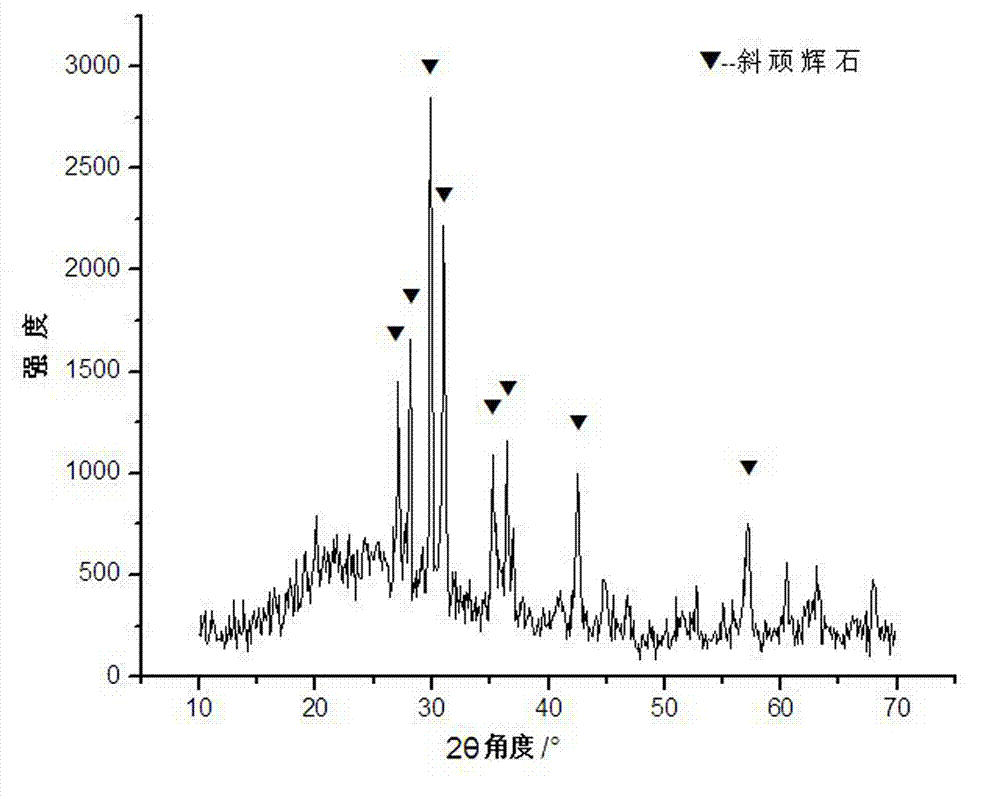

Clinoenstatite microcrystalline glass prepared by talcum and process for same

The invention relates to clinoenstatite microcrystalline glass prepared by talcum and a process for the same, wherein the process comprises the following preparation steps of: 1) weighing raw materials containing talcum, quartz, clay and sodium carbonate; 2) uniformly mixing the raw materials, heating in a silicon-molybdenum electric furnace, taking out a crucible from the electric furnace, pouring the molten glass obtained in the crucible in a pre-heated mould to mould, and then transferring into a muffle furnace, insulating for 1-2 hours at 600 DEG C, and cooling with the furnace to obtain base glass; and 3) heating the base glass obtained in the step 2) in a silicon carbide rod electric furnace with a heating speed of 5-8 DEG C / min, insulating for 1-2 hours at 950-1000 DEG C according to the thickness of a test sample, and cooling with the furnace to obtain the microcrystalline glass. The clinoenstatite microcrystalline glass prepared by talcum and the process for the same disclosed by the invention have the following advantages that: 1) the used raw materials containing talcum, quartz and clay are raw mineral materials very rich in resource and low in price; 2) preparation process is simple; and 3) crystallization for glass has no need of additional nucleating agent, and crystallization velocity is fast.

Owner:WUHAN UNIV OF TECH +1

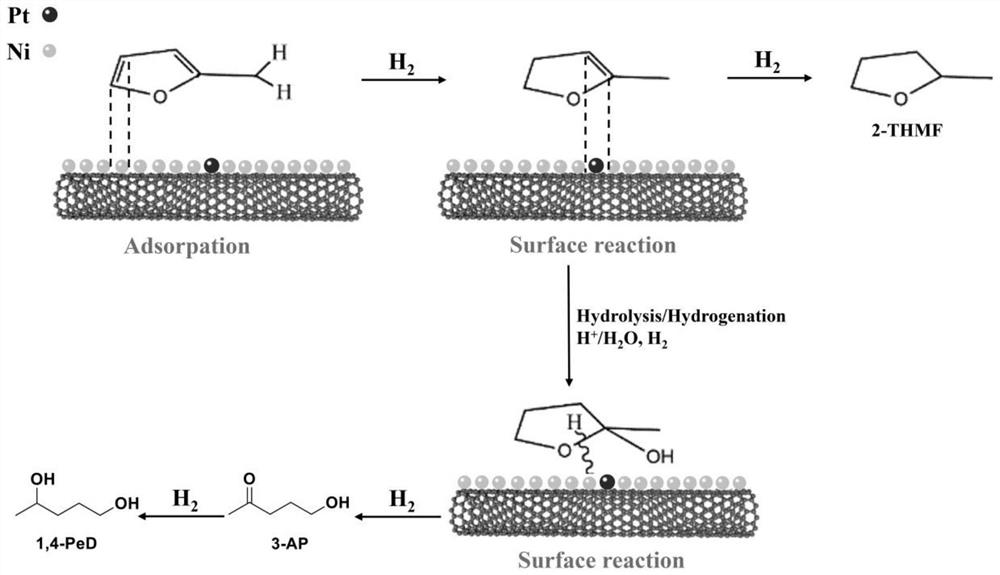

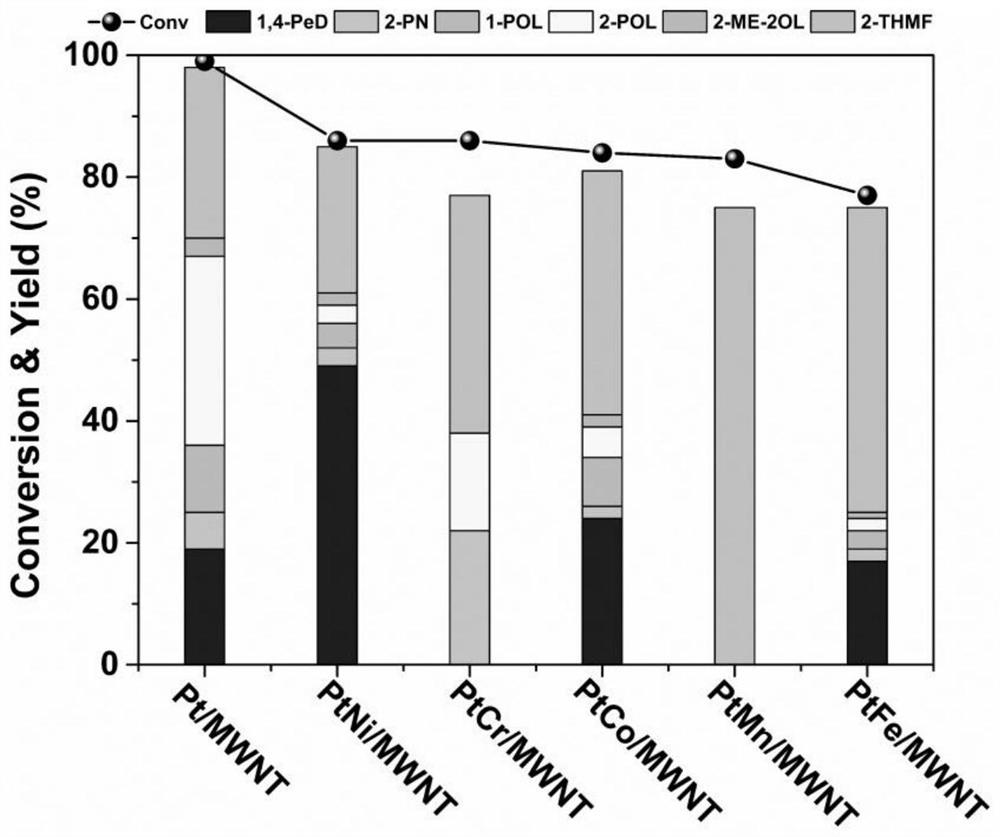

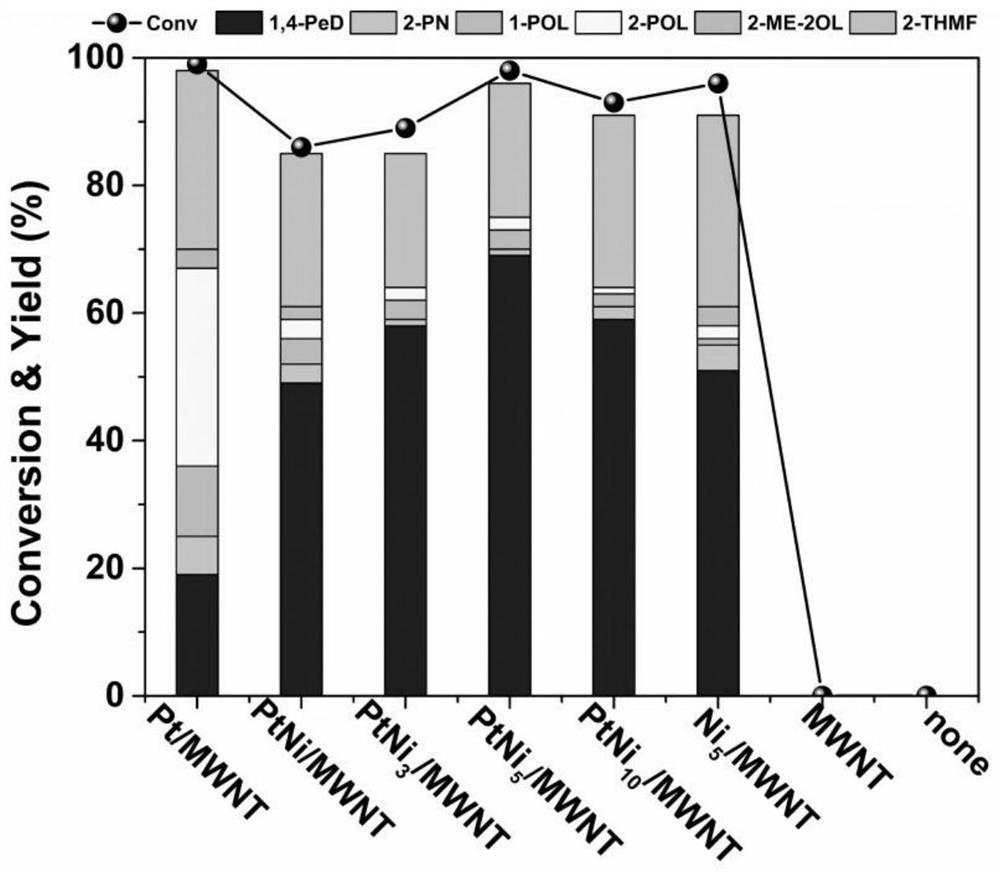

Method for catalyzing selective conversion of 2-methylfuran into 1,4-pentanediol

ActiveCN113999088AHigh activityImprove stabilityOrganic compound preparationPreparation by hydrogenationPlatinumPtru catalyst

The invention provides a method for catalyzing selective conversion of 2-methylfuran into 1,4-pentanediol. According to the application, the 2-methylfuran is used as a raw material, and a supported platinum-based bimetallic catalyst is used for catalyzing the hydro-conversion of the 2-methylfuran, wherein the PtNi5 / MWNT catalyst is used for carrying out one-pot hydrogenation on the 2-methylfuran in an ethanol / H2O (with a volume ratio of 1.5: 2.0) solvent under the conditions of 2 MPa H2 and 120 DEG C, the conversion rate of 2-methylfuran is 98%, the yield of the 1,4-pentanediol is 69%, and the yield is superior to the yield of most catalysts reported at present. The preparation method is simple in process, acid and alkaline auxiliaries do not need to be added, raw materials are renewable, the catalyst has high activity and stability, reaction conditions are milder, energy consumption is reduced to a certain extent, the catalyst is more environmentally friendly, and the energy problem which the globe faces nowadays can be partially relieved. Therefore, the method has wide application potential in industrial production.

Owner:NANJING UNIV OF TECH

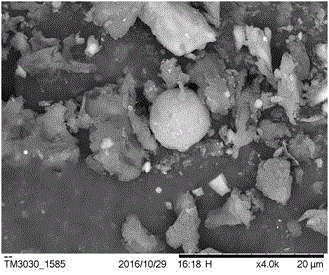

Method for recovering titanium dioxide in spent denitrification catalyst

ActiveCN104326506BLow costAbundant and cheapPhysical/chemical process catalystsTitanium dioxideSulfateRoom temperature

The invention discloses a method for recovering titanium dioxide in an invalid denitrification catalyst, which includes the following steps: (1) Grinding, grinding the invalid out-of-stock catalyst to a powder state and placing it in an open container, adding a proper amount of distilled water dropwise into the open container Prevent bottom formation; (2) Acid hydrolysis, add concentrated sulfuric acid with a mass fraction of 98% into an open container, heat the open container to dissolve the powder, keep stirring during the heating process to mix the solid and liquid evenly, when the open container Stop heating when the solution turns brown, and cool to ≤30°C to obtain titanium liquid; (3), neutralize, add a lime milk solution with a mass fraction of 50%‑80% and an active calcium content of 80% to the titanium liquid drop by drop During the process, shake well while adding dropwise, control the temperature of the titanium solution to ≤70°C, and cool to room temperature after fully reacting; (4) Concentrate and hydrolyze, concentrate the neutralized titanium solution to 195‑205g / l, add seed crystals and heat Hydrolysis; (5), filtering and rinsing; (6), drying and calcination.

Owner:安徽迪诺环保新材料科技有限公司

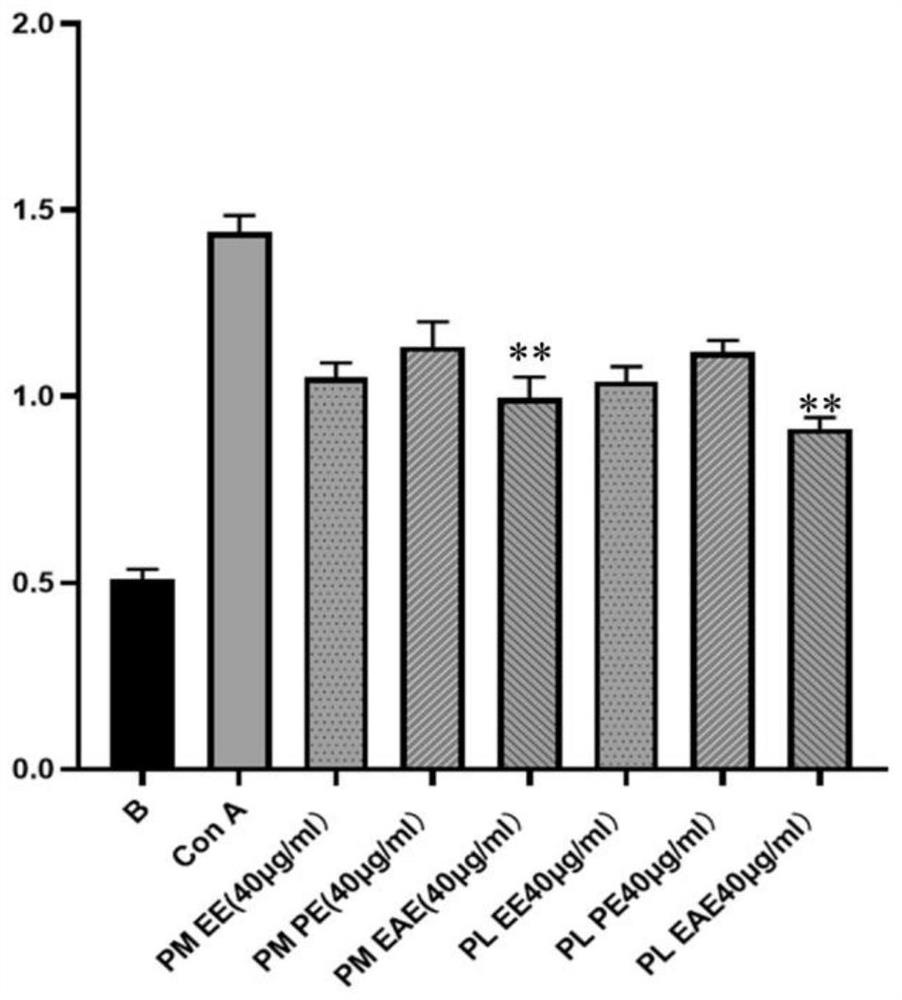

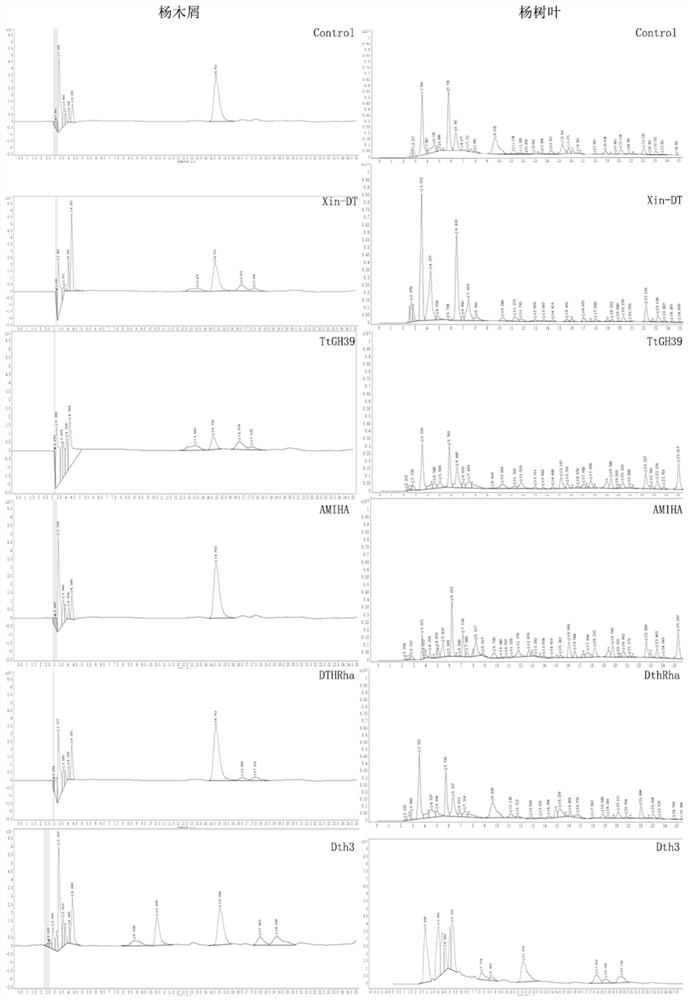

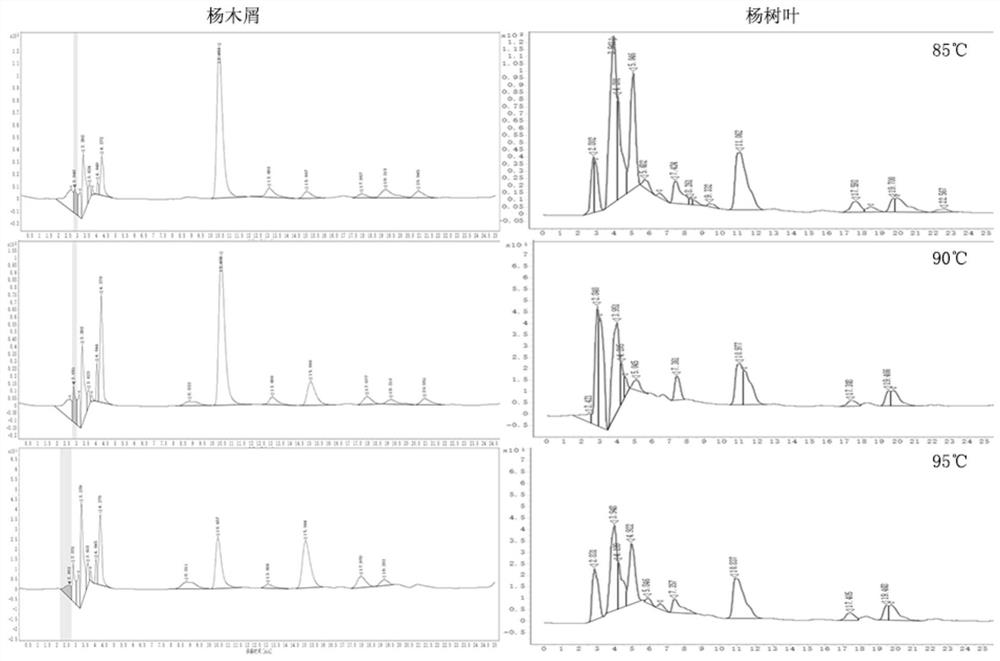

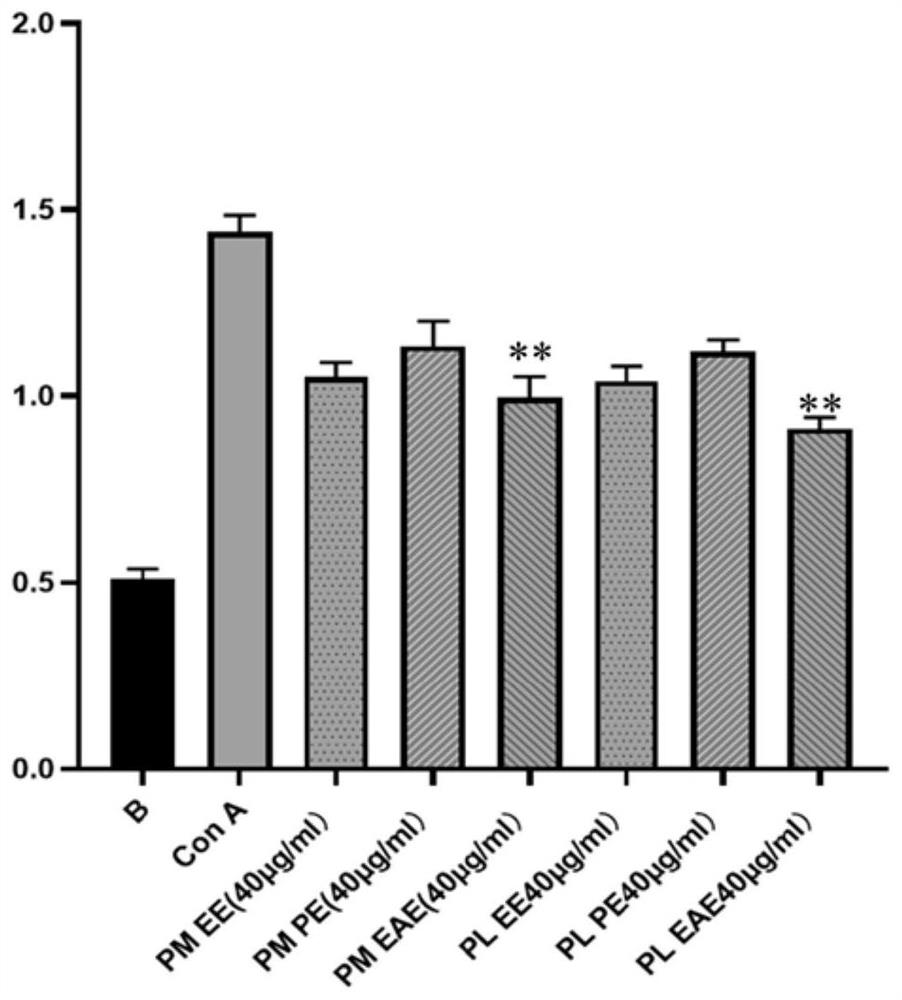

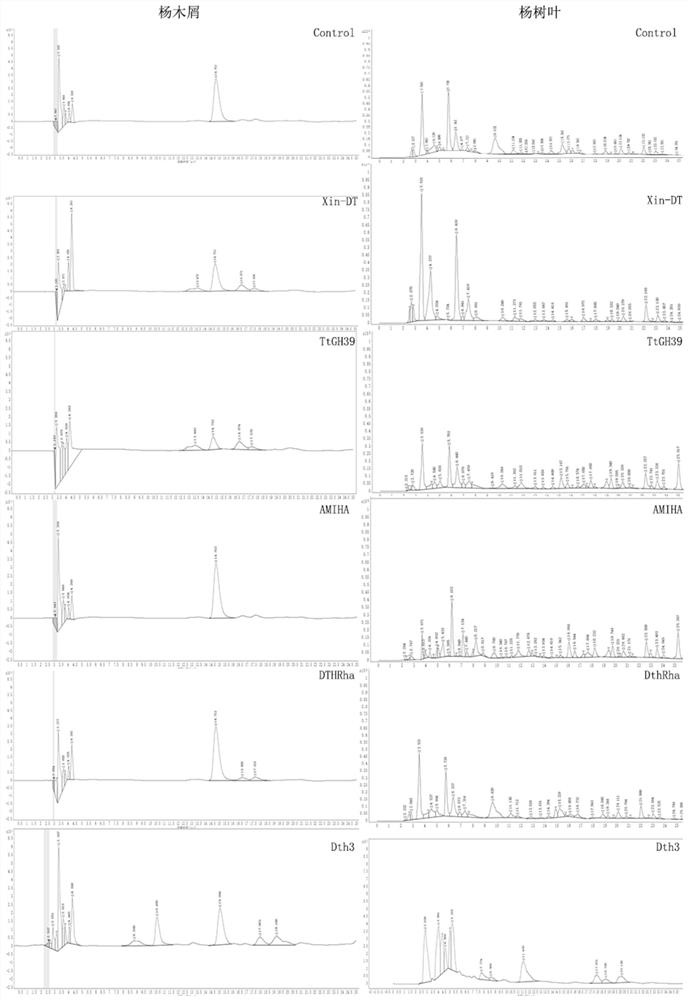

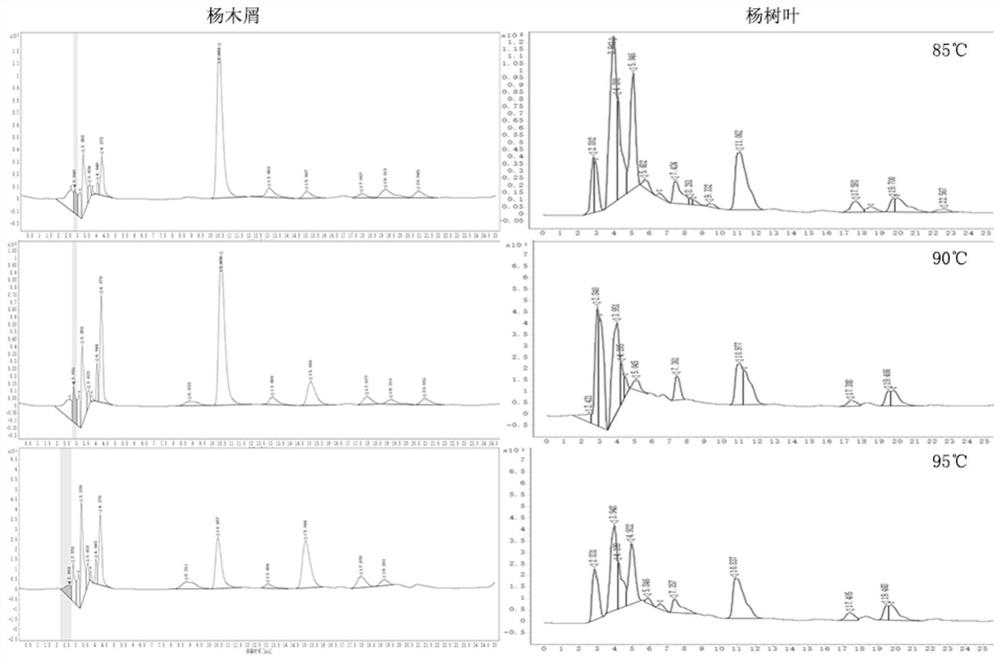

Preparation method and application of poplar transformed product for improving enteritis

InactiveCN113350413AAbundant and cheapConvenient sourceDigestive systemBiofuelsBiotechnologyAlglucerase

The invention discloses a preparation method and application of a poplar transformed product for improving enteritis. The poplar transformed product is prepared by hydrolyzing a poplar extract with beta-glucosidase. Wherein the raw material of the poplar extract is poplar sawdust and / or poplar leaves abandoned in poplar processing, and the beta-glucosidase is prepared through microbial fermentation or recombinant bacterium expression and purification. The preparation method provided by the invention has the characteristics of abundant raw material resources, low cost, simplicity, environmental protection, mild reaction, good anti-inflammatory activity of the extract and the like, and the in-vitro anti-inflammatory activity is respectively improved by 30.39% and 23.98% compared with the poplar sawdust extract and the poplar leaf extract which are obtained without enzyme hydrolysis. The extract prepared through the technology has the effect of improving animal colitis, and comprehensive utilization of poplar resources can be promoted.

Owner:NANJING FORESTRY UNIV

Oslasodine hydrochloride preparing process

The invention provides an Oslasodine hydrochloride preparing process for anti-cancer, asthma relieving, anti-inflammation and increasing immunity. The preparation process comprises using Solanum Nigrum L, Solanum aviculare parst and Solanum xanthocar pum Schrad, et wendl fruit or herbs as raw material, employing unique acid leaching alkali precipitation extraction method, alkaline alcohol dissolving acidic alcohol crystallization for Oslasodine hydrochloride extraction.

Owner:刘良

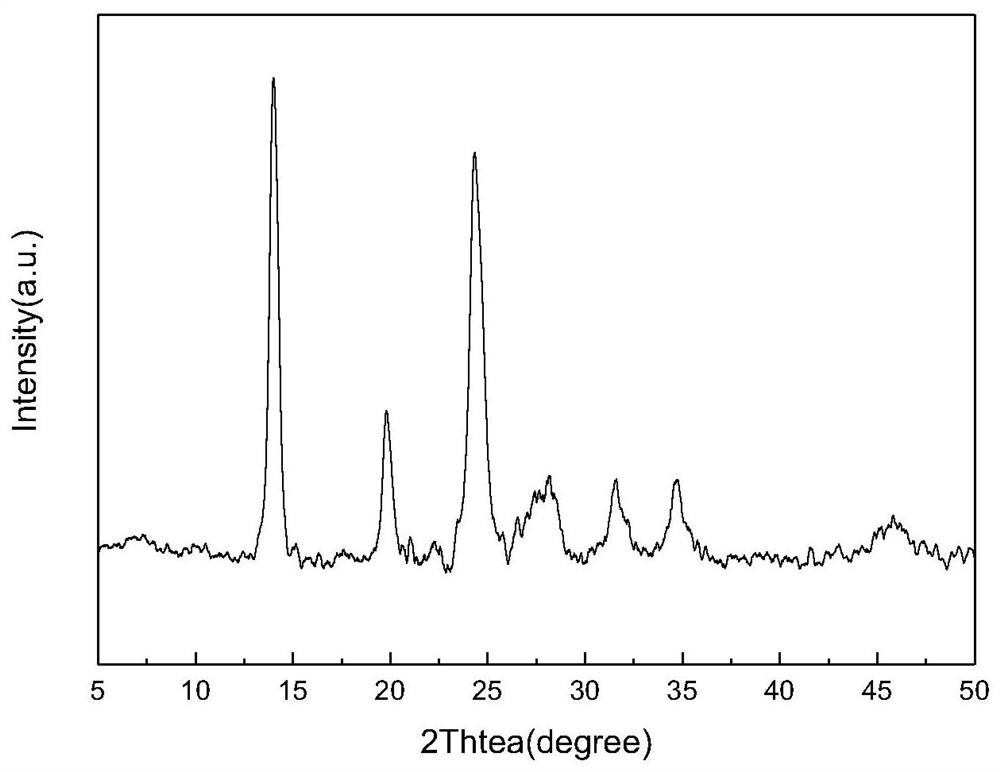

Method for preparing hierarchical pore SAPO-20 molecular sieve from illite

PendingCN112723380AReduce consumptionExpand sourceMolecular-sieve and base-exchange phosphatesMolecular-sieve silicoaluminophosphatesMolecular sieveMaterial synthesis

The invention belongs to the technical field of chemical material synthesis, and relates to a method for preparing a hierarchical pore SAPO-20 molecular sieve from illite. The method comprises the following steps: 1) calcining illite minerals and sodium carbonate to obtain activated illite; 2) mixing the activated illite with hydrochloric acid according to a mass-volume ratio of 1g to 13.5 mL, and stirring, centrifuging, washing and drying the mixture to obtain activated illite silicon slag; 3) mixing deionized water, a phosphorus source, an aluminum source, a microporous template agent, a mesoporous template agent, the acid-washed activated illite silicon slag and ethanol to obtain reactant gel, and crystallizing, centrifuging, washing, drying and calcining the reactant gel to obtain molecular sieve raw powder; and 4) calcining the molecular sieve raw powder in flowing air, and cooling the powder to obtain the hierarchical pore SAPO-20 molecular sieve. The hierarchical pore SAPO-20 molecular sieve is synthesized by taking the natural illite mineral as the raw material, so that the raw material source of the hierarchical pore SAPO-20 molecular sieve is broadened; the method has the advantages of short production process and low energy consumption, and the synthesis cost is greatly reduced.

Owner:XIAN UNIV OF SCI & TECH

A kind of straw composite building material and its preparation method

ActiveCN106966665BImprove frost resistanceImprove early strengthThermal insulationUltimate tensile strength

The invention discloses a straw compounded building material and a preparation method thereof provides a novel compound building material and a preparation method thereof. The surface properties of straw can be effectively improved, and accordingly the problem that the straw and a cement base material are difficult to bond. In addition, the novel compound straw material is a green and environment-friendly resource which are rich and cheap in composition and ingredient selection, and the novel compound material having the strength properties including compression resistance, fracture resistance and freezing resistance and having very excellent thermal insulation properties can be obtained.

Owner:JILIN JIANZHU UNIVERSITY

Industrial preparation method for silica carbide crystal whisker and micropowder

InactiveCN100415644CAbundant and cheapSimple structurePolycrystalline material growthSingle crystal growth detailsCarbideDiameter ratio

Owner:XIAN BOER NEW MATERIAL CO LTD

Catalyst for preparing low-carbon olefin through carbon dioxide hydrogenation

PendingCN112958142AFacilitated DiffusionAlkalinePhysical/chemical process catalystsLiquid hydrocarbon mixture productionPtru catalystModified carbon

The invention relates to a catalyst for preparing low-carbon olefin through carbon dioxide hydrogenation, belongs to the technical field of composite materials, and particularly relates to preparation and application of a perovskite-graphite phase carbon nitride composite material. After the composite material is subjected to surface processing, a large number of hydroxyl groups and amino groups exist on the periphery of the structure, and strong interaction can be generated between the composite material and perovskite metal. The catalyst has a unique electronic structure and good chemical stability, the olefin selectivity is improved through interaction between the surface-modified carbon nitride and perovskite iron oxide, and the surface-modified carbon nitride provides a reliable scheme for preparing olefin through hydrogenation reaction.

Owner:NINGXIA UNIVERSITY

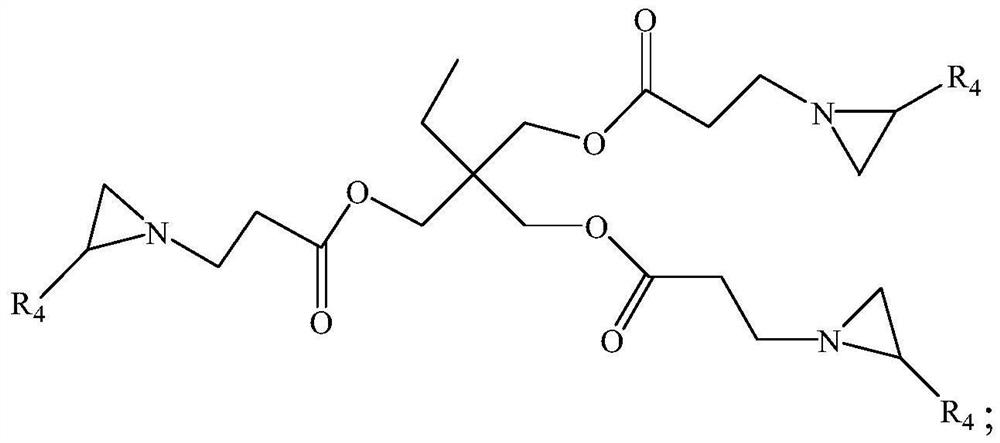

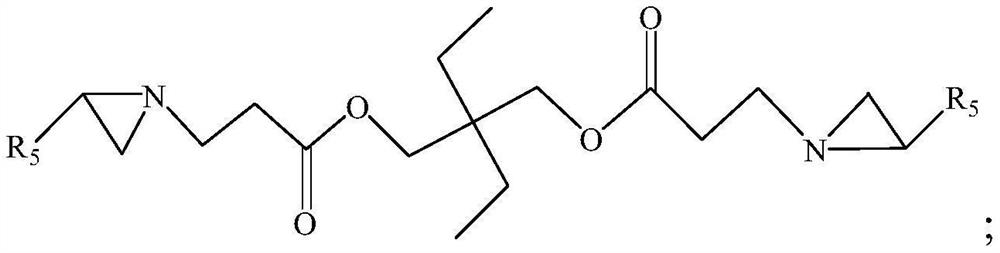

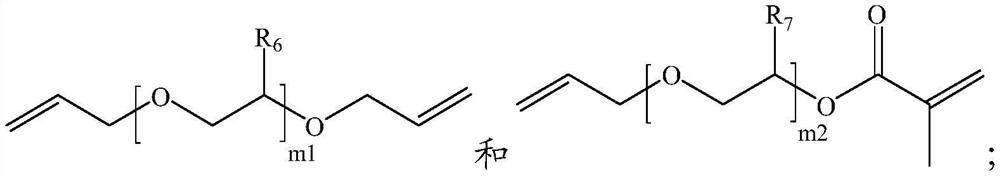

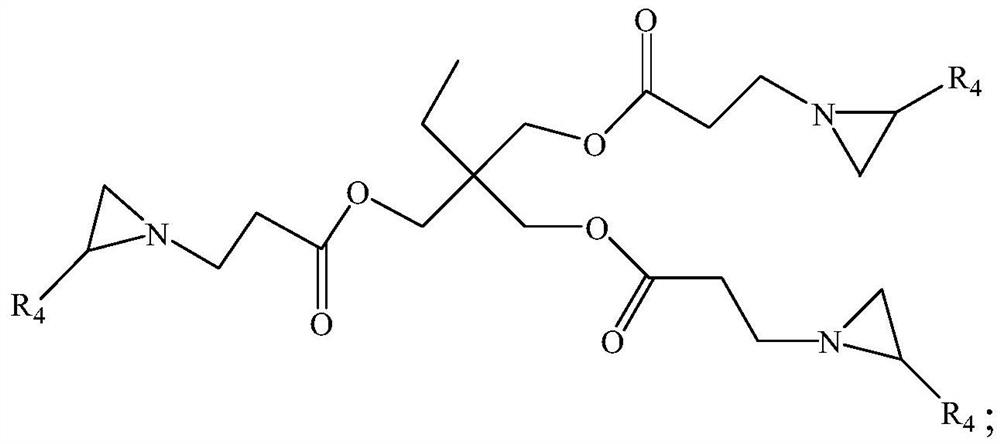

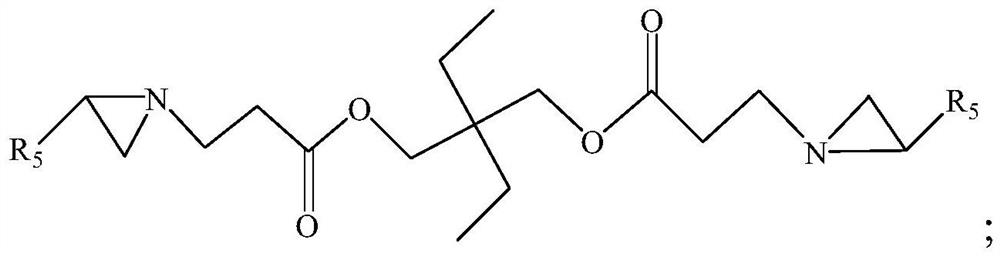

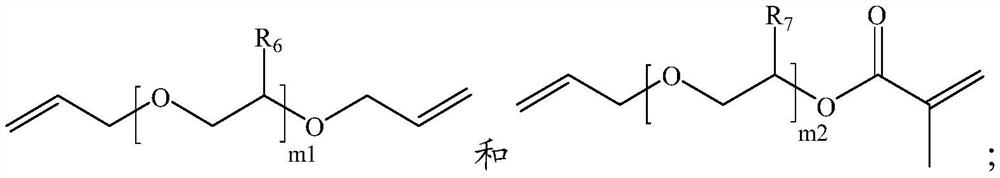

Non-isocyanate polyurethane and preparation method thereof

ActiveCN112390946AHigh molecular weightLess side effectsProductsReagentsPolymer scienceButanedioic acid

The invention discloses non-isocyanate polyurethane and a preparation method thereof, and belongs to the technical field of adhesives, and the preparation method comprises the following steps: mixinga trifunctional aziridine polymer, a double-terminal allyl compound, hydrogen type macroporous cation exchange resin containing hydrogen ions and a catalyst, and introducing CO2 for reaction under a vacuum condition; adding a difunctional aziridine polymer, a double-terminal allyl compound, 2, 3-epoxysuccinic acid and a solvent, and introducing CO2 under a vacuum condition to react; and filteringthe macroporous cation exchange resin, distilling the solvent, and adjusting the solid content to obtain the non-isocyanate polyurethane. According to the preparation method, isocyanate is not used inpolyurethane preparation, CO2 and an aziridine polymer are used as raw materials for reaction synthesis of polyurethane, CO2 is non-toxic, rich in resource and low in price, the aziridine polymer islow in volatility and friendly to operators and the environment in the production process, and the preparation method is a safe and environment-friendly production mode, the polyurethane prepared by the preparation method is excellent in performance and can replace the existing isocyanate polyurethane.

Owner:福建华夏蓝新材料科技有限公司

Catalyst for preparing low-carbon olefin through hydrogenation and preparation method thereof

PendingCN112973762AFacilitated DiffusionAlkalineHydrocarbon from carbon oxidesPhysical/chemical process catalystsPtru catalystModified carbon

The invention belongs to the technical field of composite materials, and particularly relates to preparation and application of a perovskite-graphite phase carbon nitride composite material. After the composite material is subjected to surface treatment, a large number of hydroxyl groups and amino groups exist on the periphery of the structure, and strong interaction can be generated between the composite material and perovskite metal. The catalyst has a unique electronic structure and good chemical stability, the olefin selectivity is improved through interaction between the surface-modified carbon nitride and perovskite iron oxide, and the surface-modified carbon nitride provides a reliable scheme for preparing olefin through hydrogenation reaction.

Owner:NINGXIA UNIVERSITY

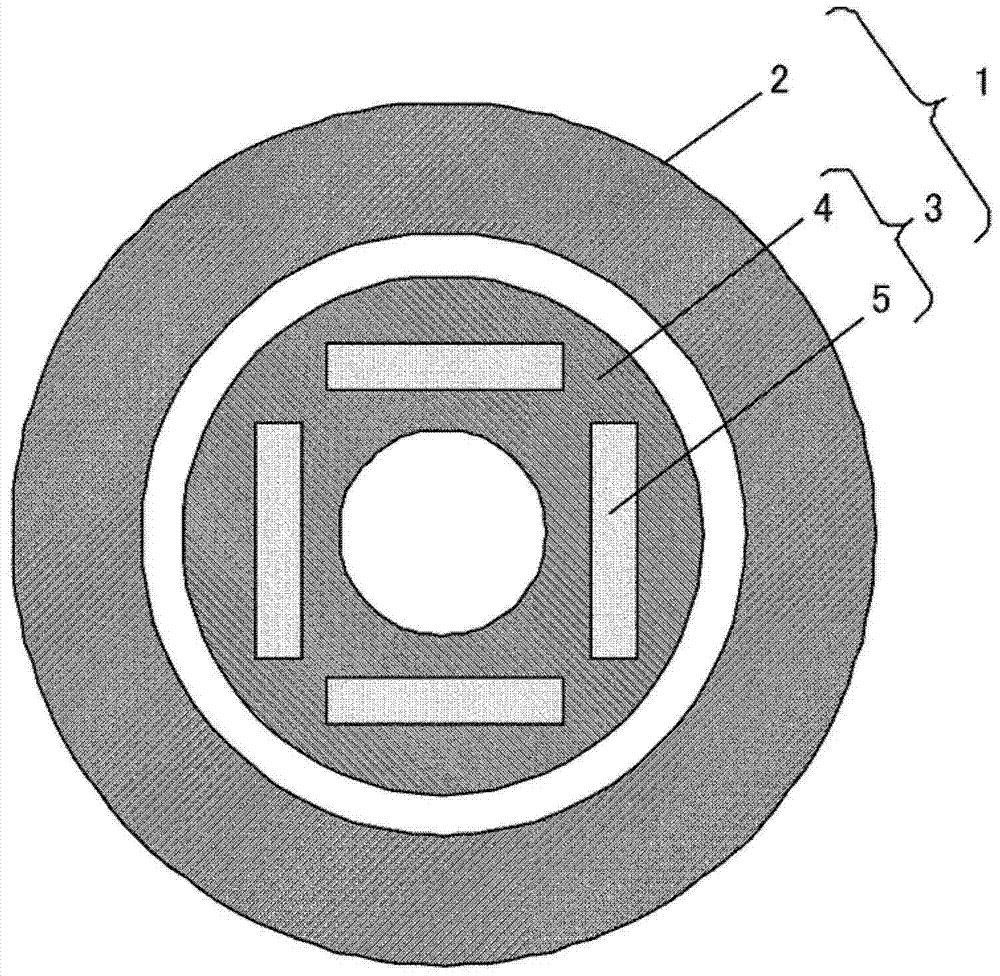

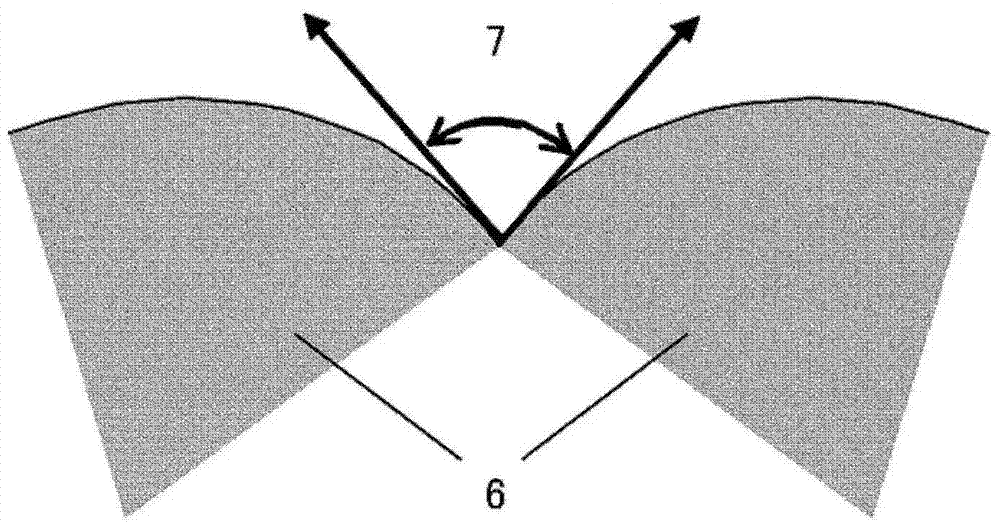

permanent magnets and electric motors

ActiveCN105047343BAbundant and cheapImprove coercive forceInorganic material magnetismMagnetic circuit characterised by magnetic materialsNatural resourceStructural phase

Owner:TDK CORPARATION

A kind of non-isocyanate polyurethane and preparation method thereof

ActiveCN112390946BHigh molecular weightLess side effectsProductsReagentsPolymer scienceButanedioic acid

The invention discloses a non-isocyanate polyurethane and a preparation method thereof, which belong to the technical field of adhesives. The preparation method combines a trifunctional aziridine polymer, a double-end allyl compound, and a hydrogen-type macroporous cation exchange resin containing hydrogen ions. Mix with catalyst and pass CO under vacuum 2 Reaction; add difunctional aziridine polymer, double-ended allyl compound, 2,3-epoxysuccinic acid and solvent, and pass CO under vacuum 2 Reaction; then filter the macroporous cation exchange resin, distill the solvent, and adjust the solid content to obtain non-isocyanate polyurethane. This preparation method does not use isocyanate in the preparation of polyurethane, with CO 2 Reacting with aziridine polymer as raw material to synthesize polyurethane, CO 2 Non-toxic, rich in resources and cheap, aziridine polymer has low volatility, and is friendly to operators and the environment during the production process. It is a safe and environmentally friendly production method. The polyurethane prepared by this preparation method has excellent performance and can replace existing There is isocyanate polyurethane.

Owner:福建华夏蓝新材料科技有限公司

A kind of alkali-activated slag-fly ash cementitious material retarder and preparation method

ActiveCN106746826BHigh activityAct as a grinding aidSolid waste managementEnvironmental resistanceSocial benefits

The invention discloses a novel alkali-activated slag and fly ash cementing material retarder and a preparation method. The method comprises the steps that a straw stem and a leaf are separated and dried; the straw stem is cut into sections and roughly crushed into 1-5mm length by a ball mill; the straw stem is uniformly mixed with silicon ash; milling is performed for 10-60min in the ball mill to form 400-1000-mesh powder to obtain the retarder. The novel alkali-activated slag and fly ash cementing material retarder is prepared by taking a straw as a main raw material; a corn straw is abundant in resource and low in price; a commonly used retarder which is high in price, complicated in production technology and non-environment-friendly is replaced; a retardation effect is obvious; in addition, the straw can exert an effect of a fiber, and improves the brittleness of the retarder. The method provides a new approach for comprehensive utilization of the straw, is simple in production technology, low in cost, green and environment-friendly, and has very significant economic and social benefits.

Owner:长春昌驰环保科技有限公司

Preparation method and application of poplar transformed product for improving enteritis

PendingCN114832046AAbundant and cheapConvenient sourceDigestive systemBiofuelsBiotechnologyAlglucerase

The invention discloses a preparation method and application of a poplar transformed product for improving enteritis. The poplar transformed product is prepared by hydrolyzing a poplar extract with beta-glucosidase. Wherein the raw material of the poplar extract is poplar sawdust and / or poplar leaves abandoned in poplar processing, and the beta-glucosidase is prepared through microbial fermentation or recombinant bacterium expression and purification. The preparation method provided by the invention has the characteristics of abundant raw material resources, low cost, simplicity, environmental protection, mild reaction, good anti-inflammatory activity of the extract and the like, and the in-vitro anti-inflammatory activity is respectively improved by 30.39% and 23.98% compared with the poplar sawdust extract and the poplar leaf extract which are obtained without enzyme hydrolysis. The extract prepared through the technology has the effect of improving animal colitis, and comprehensive utilization of poplar resources can be promoted.

Owner:NANJING FORESTRY UNIV

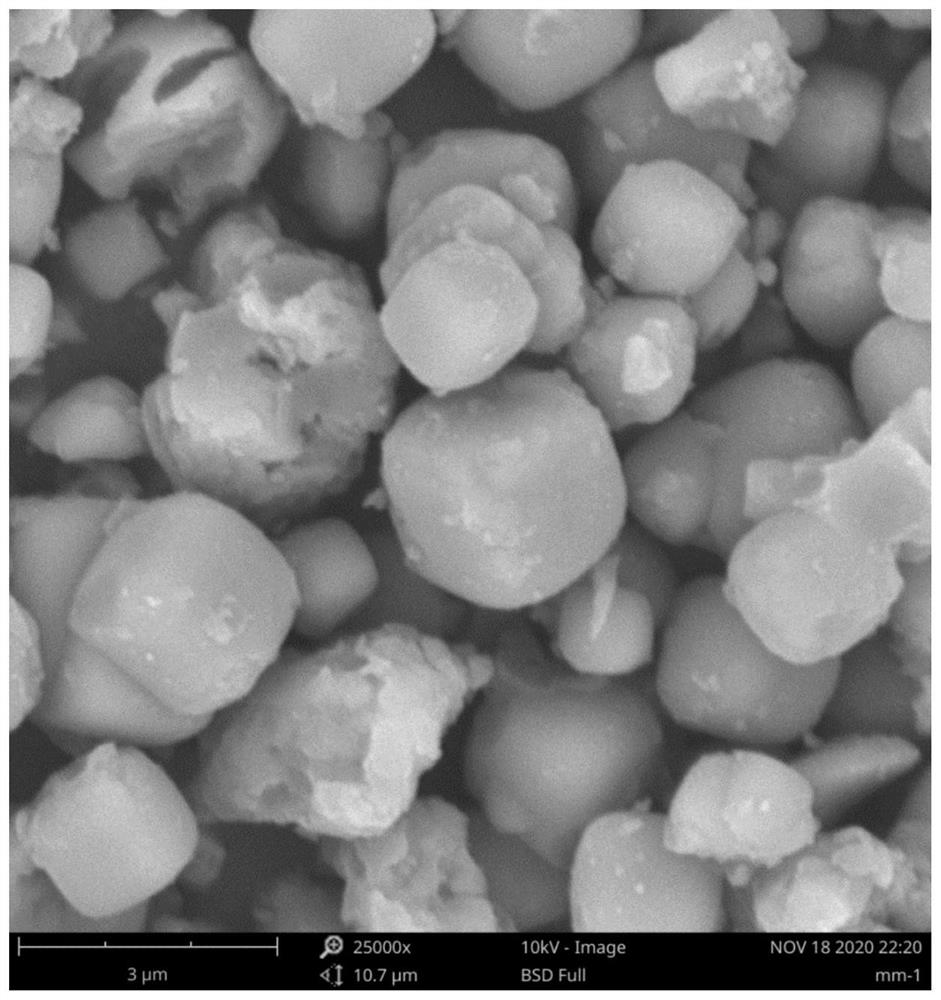

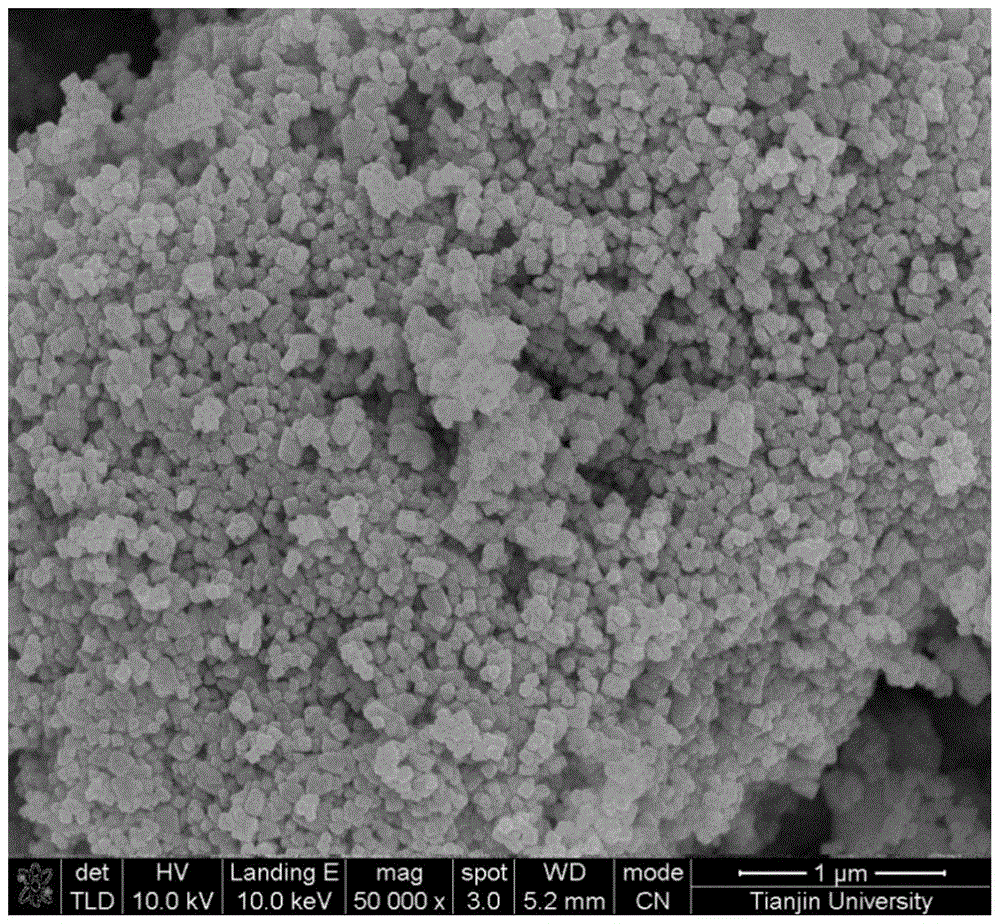

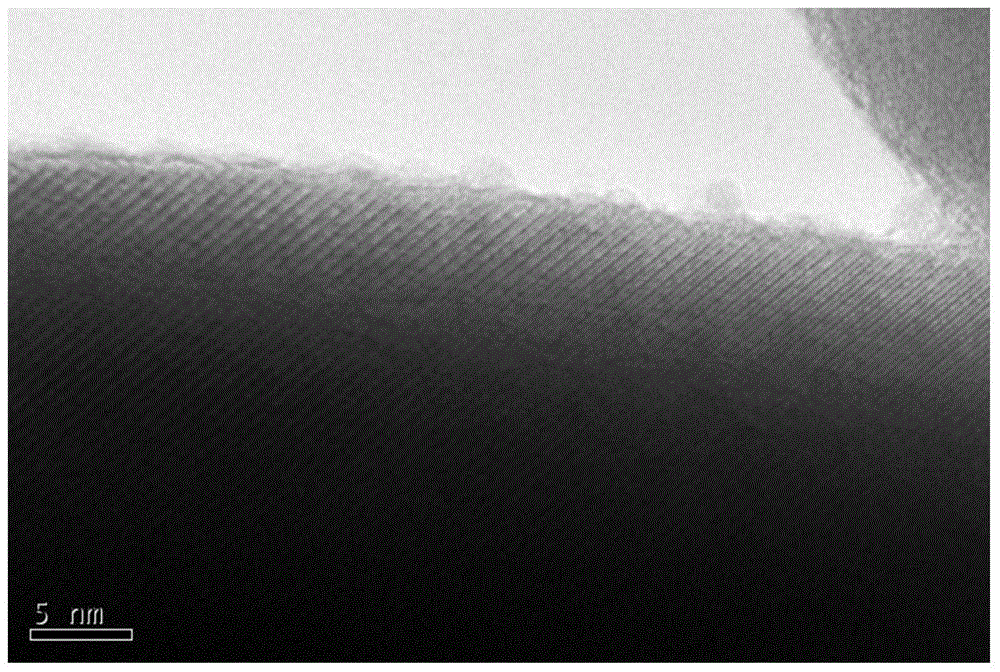

Preparation method of Li2ZnTi3O8 negative electrode material for lithium ion battery

InactiveCN104617285BReduce high temperature environmentAbundant and cheapMaterial nanotechnologyAlkali titanatesElectrical batteryLithium carbonate

The invention relates to a lithium ion battery electrode material Li2ZnTi3O8 preparation method, and aims at the defects of high temperature, longer reaction time, high organic material cost, toxicity and the like of lithium zinc titanate material preparation method in the prior art. The technical scheme is as follows: titanium dioxide (TiO2), lithium carbonate (Li2CO3) and zinc acetate (Zn (CH3COO) 2.2H2O) and mixed molten salt sodium chloride (NaCl) and potassium chloride (KCl) are mixed and stirred, in the high temperature sintering process, reactant precursors can be sufficiently contacted and reacted in liquid environment facilitating molten salts, prepared nanoscale particular material is uniform in size and free of obvious agglomeration, accumulation holes are among particles, and the structural features is conducive to play the electrochemical properties of the material.

Owner:TIANJIN UNIV

Clinoenstatite microcrystalline glass prepared by talcum and process for same

The invention relates to clinoenstatite microcrystalline glass prepared by talcum and a process for the same, wherein the process comprises the following preparation steps of: 1) weighing raw materials containing talcum, quartz, clay and sodium carbonate; 2) uniformly mixing the raw materials, heating in a silicon-molybdenum electric furnace, taking out a crucible from the electric furnace, pouring the molten glass obtained in the crucible in a pre-heated mould to mould, and then transferring into a muffle furnace, insulating for 1-2 hours at 600 DEG C, and cooling with the furnace to obtain base glass; and 3) heating the base glass obtained in the step 2) in a silicon carbide rod electric furnace with a heating speed of 5-8 DEG C / min, insulating for 1-2 hours at 950-1000 DEG C according to the thickness of a test sample, and cooling with the furnace to obtain the microcrystalline glass. The clinoenstatite microcrystalline glass prepared by talcum and the process for the same disclosed by the invention have the following advantages that: 1) the used raw materials containing talcum, quartz and clay are raw mineral materials very rich in resource and low in price; 2) preparation process is simple; and 3) crystallization for glass has no need of additional nucleating agent, and crystallization velocity is fast.

Owner:WUHAN UNIV OF TECH +1

A kind of method that utilizes platinum-based catalyst to be used for the hydrogenation of 2-methylfuran to prepare pentanol

ActiveCN114031480BLarge specific surface areaWell mixedMetal/metal-oxides/metal-hydroxide catalystsPreparation by oxygen reductionFuranPtru catalyst

The invention provides a continuous flow preparation method of a platinum-based catalyst. Compared with the impregnation method, the time is long, the selectivity is low, and it depends on the operator's technique and the problems of easy mixing and unevenness. The method is simpler and more efficient, and can be produced in one step and continuously . The method adopts a pipe diameter of several millimeters, which greatly increases the specific surface area of the reaction liquid, and can quickly transfer heat and mass, and the reaction liquid can be better mixed evenly. Secondly, this method has screened different amounts of solvents and reaction temperatures, determined the amount of solvent and the optimal reaction temperature, and can make 2-methylfuran hydrogenation to prepare amyl alcohol conversion rate can reach 100%, and the selectivity of amyl alcohol is 70%. %, while the platinum-based catalyst prepared by the impregnation method has a selectivity of 53% for the hydrogenation of 2-methylfuran to pentanol, and the catalytic efficiency can be improved by nearly 20% compared with the impregnation method. The mechanized operation can avoid human error, make the results more repeatable, improve the production efficiency, and provide a new way for the catalytic hydrogenation of furan derivatives to prepare alcohols.

Owner:NANJING TECH UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com