Potassium sodium niobate based transparent ceramic and preparation method thereof

A potassium-sodium niobate-based, transparent ceramic technology, which is applied in the field of photoelectric transparent ceramic materials, and can solve problems such as the need to improve light transmittance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

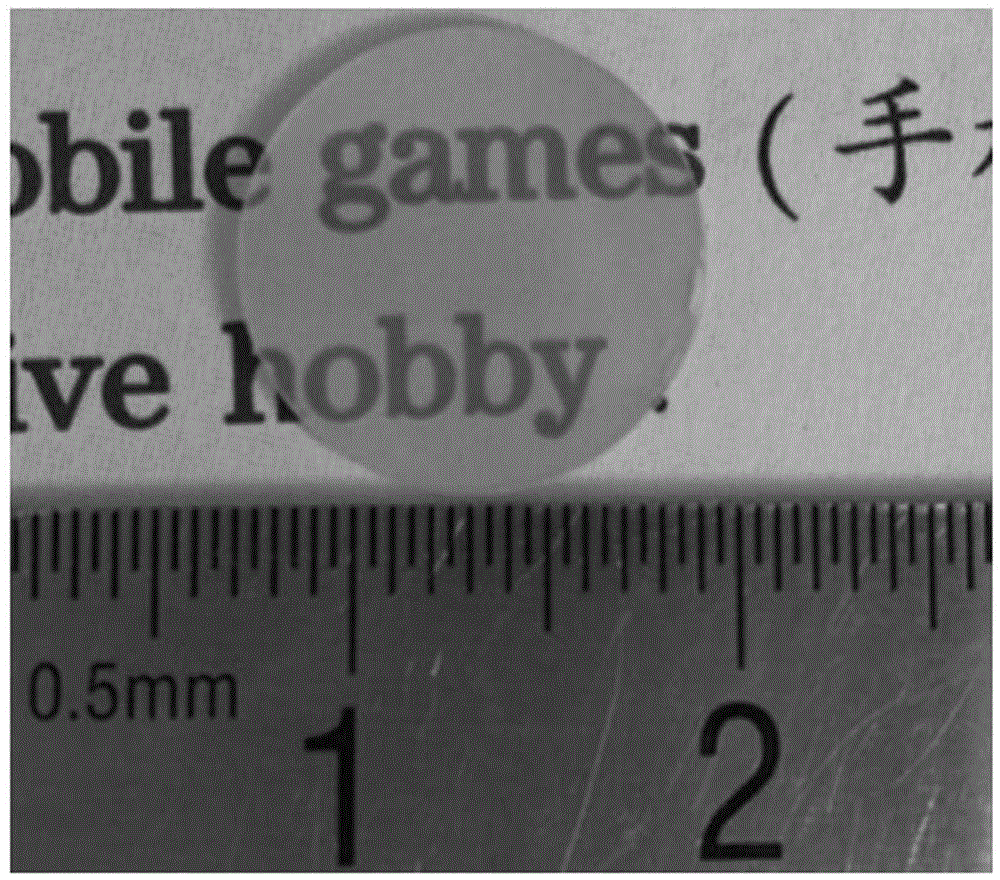

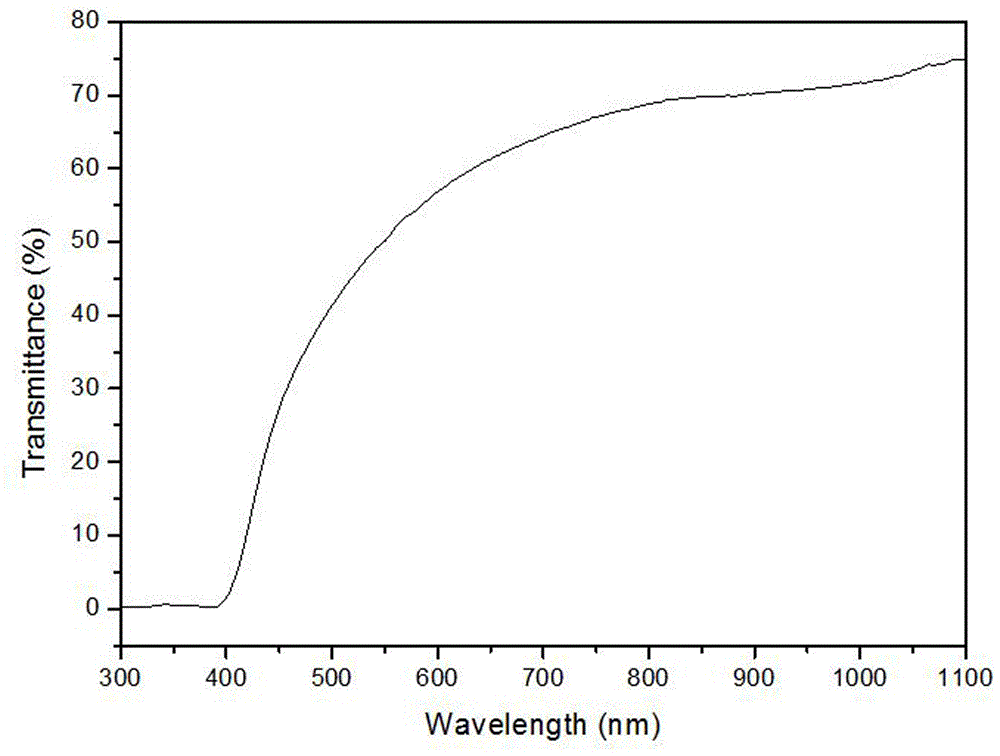

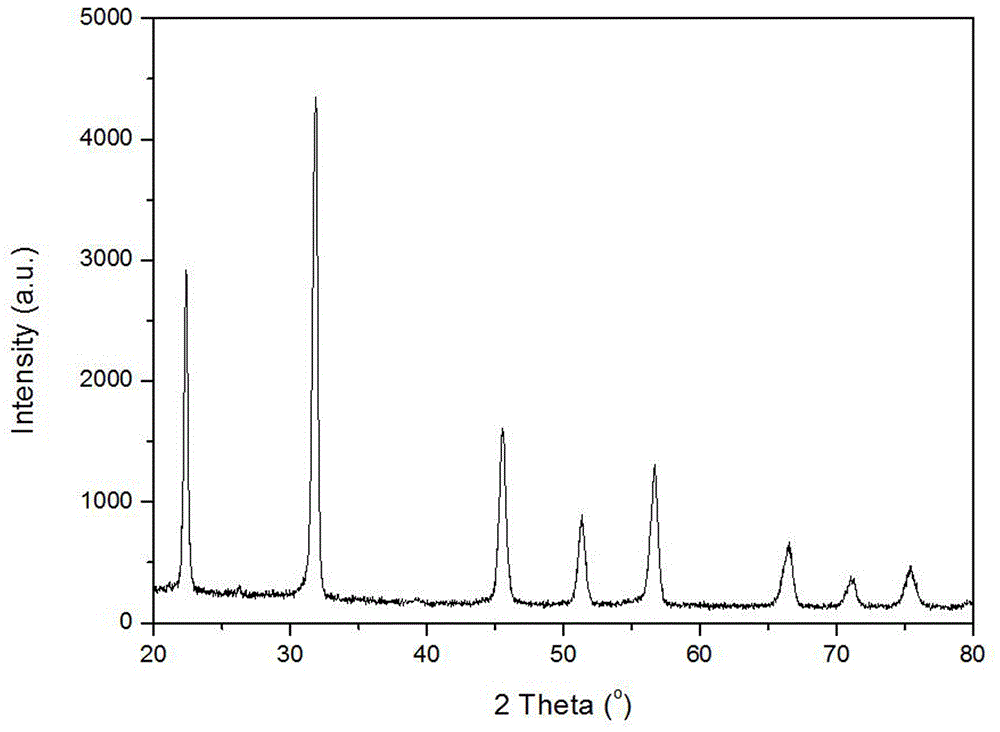

[0019] Take Na 2 CO 3 、K 2 CO 3 、 Bi 2 o 3 、BaCO 3 , Nb 2 o 5 As raw material, according to chemical formula (1-x) K 0.5 Na 0.5 NbO 3 -xBaBiO 3 (x=0.08), carry out batching, and prepare potassium sodium niobate-based transparent ceramics by traditional ceramic preparation technology. All raw materials were dried in an oven at 120 °C for 5-7 h before weighing and batching. After accurate weighing, use absolute ethanol as the medium for ball milling for 24 h, and after drying, pre-calcine the obtained powder at 750 °C for 6 h at a heating rate of 1 °C / min, and then use absolute ethanol as the medium for ball milling for 16-24 h. Then dry. Pass the dried powder through a 100-mesh sieve, press it into a round billet with a diameter of 14 mm and a thickness of 0.5 mm under a pressure of 100 MPa, and sinter at 1140 ° C for 18 hours to obtain a transparent ceramic such as figure 1 shown. The measured light transmittance-frequency curve of potassium sodium niobate-based...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com