A kind of alkali-activated slag-fly ash cementitious material retarder and preparation method

A technology for cementitious material and fly ash, which is applied in the fields of alkali-excited slag-fly ash cementitious material retarder, alkali-excited slag-fly ash cementitious material modifier, and can solve the problem of alkali-excited slag-fly ash cementitious material. Coal ash cementitious material flash setting and other problems, to achieve the effect of significant economic and social benefits, simple production process and cheap resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

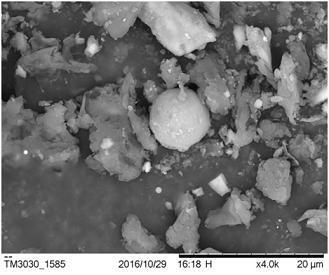

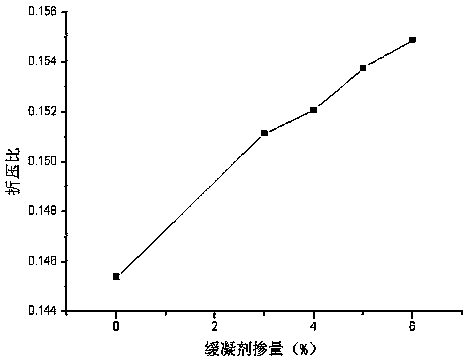

Image

Examples

Embodiment 1

[0022] 1. Separation and crushing of corn stalks: the stems and leaves of the corn stalks are separated and dried, and the stalks of the corn stalks are cut into segments and roughly crushed into lengths of 1-5 mm by a ball mill for use.

[0023] 2. Weigh 0.95 kg of corn stalks and 0.05 kg of silica fume grinding aid and mix them with corn stalks evenly, stir for 2-3 minutes, after mixing, put them into a ball mill for grinding for 30 minutes, and sieve them with a 0.02 mm (700 mesh) sieve, that is An alkali-activated slag-fly ash cementitious material retarder is prepared.

Embodiment 2

[0025] 1. Separation and crushing of corn stalks: the stems and leaves of the corn stalks are separated and dried, and the stalks of the corn stalks are cut into segments and roughly crushed into lengths of 1-5 mm by a ball mill for use.

[0026] 2. Weigh 0.8kg of corn stalks and 0.2kg of silica fume grinding aid and mix them with corn stalks evenly, stir for 2-3 minutes, after mixing, put them into a ball mill for grinding for 30 minutes, and sieve them with a 0.02 mm (700 mesh) sieve to make the When the fineness reaches below 700 mesh, an alkali-activated slag-fly ash cementitious material retarder is prepared.

Embodiment 3

[0028] 1. Separation and crushing of corn stalks: the stems and leaves of the corn stalks are separated and dried, and the stalks of the corn stalks are cut into segments and roughly crushed into lengths of 1-5 mm by a ball mill for use.

[0029] 2. Weigh 0.7kg of corn stalks and 0.3kg of silica fume grinding aid and mix them with corn stalks evenly, stir for 2-3 minutes, after mixing, put them into a ball mill for grinding for 30 minutes, and sieve them with a 0.02 mm (700 mesh) sieve to make the When the fineness reaches below 700 mesh, an alkali-activated slag-fly ash cementitious material retarder is prepared.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com