Clinoenstatite microcrystalline glass prepared by talcum and process for same

A technology of glass-ceramic and enstatite, which is applied in the field of glass-ceramic and enstatite glass-ceramics and its technology, can solve the problems of unavailable glass products, limited application, and inability to realize the production of special-shaped products, etc., to achieve easy automatic molding, The effect of wide application range and fast crystallization speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Quartz, talcum powder, clay, anhydrous sodium carbonate are pulverized, cross 45 mesh sieves, obtain powder, take by weighing 25 grams of quartz, 40 grams of talcum powder, 24.0 grams of clay, 20 grams of anhydrous sodium carbonate, put into mixing Mix in the feeder for 30 minutes.

[0026] Put the mixture into a 100ml corundum crucible, heat and melt it in a silicon-molybdenum electric furnace at a heating rate of 5°C / min, keep it at 1500°C for 3 hours, take out the crucible from the electric furnace, and melt the molten glass in the crucible Pour it on a preheated iron plate, hydraulically press the glass into a glass plate with the iron plate, quickly transfer the glass plate to a muffle furnace heated to 600°C in advance, anneal for 1 hour, and cool down with the furnace to obtain the basic glass.

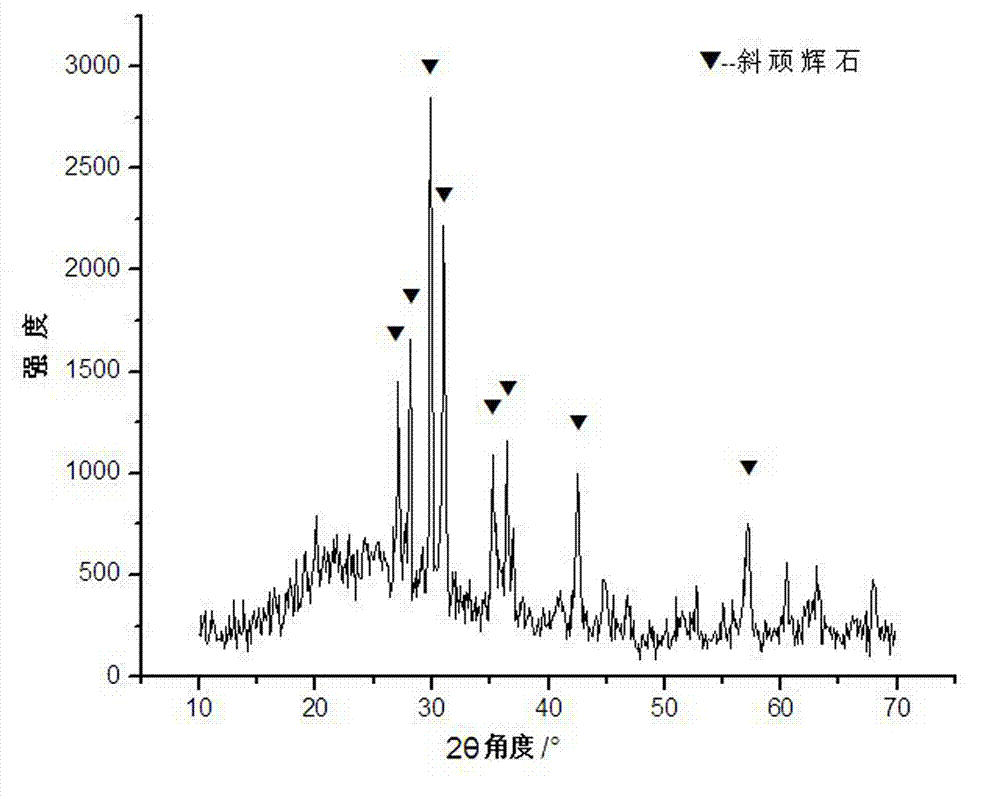

[0027] After the glass plate is cooled, it is taken out and placed in a silicon carbide rod furnace for heat treatment, from room temperature to 980°C at a heating rate ...

Embodiment 2

[0032] Raw material type and raw material processing are the same as embodiment 1, take respectively by weighing 22 grams of quartz, 46 grams of talcum powder, 26 grams of clay, and 17 grams of anhydrous sodium carbonate. The raw material mixing procedure, melting system and annealing system are the same as in Example 1. The heat treatment system is as follows: from room temperature to 1000 ° C, the heating rate is 5 ° C / min, at 1000 ° C for 2.0 hours, and cooling with the furnace, the mineral phase composition of the glass-ceramics is obtained as cleropyne.

Embodiment 3

[0034] Raw material type and raw material processing are the same as embodiment 1, take by weighing 19 grams of quartz, 53 grams of talcum powder, 20 grams of clay, and 17 grams of anhydrous sodium carbonate. The raw material mixing procedure, melting system and annealing system are the same as in Example 1. The heat treatment system is as follows: from room temperature to 1000°C, the heating rate is 5°C / min, at 1000°C for 1.5h, and cooled with the furnace to obtain the mineral phase composition of glass-ceramics as clinopside.

PUM

| Property | Measurement | Unit |

|---|---|---|

| whiteness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com