A kind of method that utilizes platinum-based catalyst to be used for the hydrogenation of 2-methylfuran to prepare pentanol

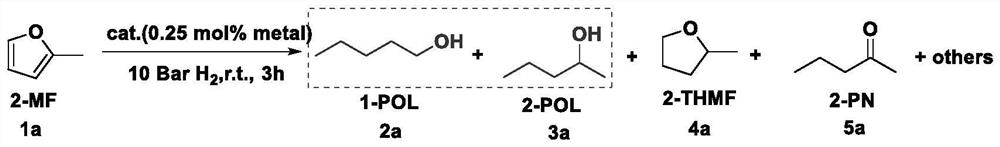

A technology of methyl furan and catalyst, which is applied in the field of hydrogenation of 2-methylfuran to prepare amyl alcohol using platinum-based catalysts, which can solve the problems of easy inactivation of enzymes, high cost, and difficulty in separating amyl alcohol, and improve production Efficiency, avoidance of human error, effect of catalytic efficiency improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

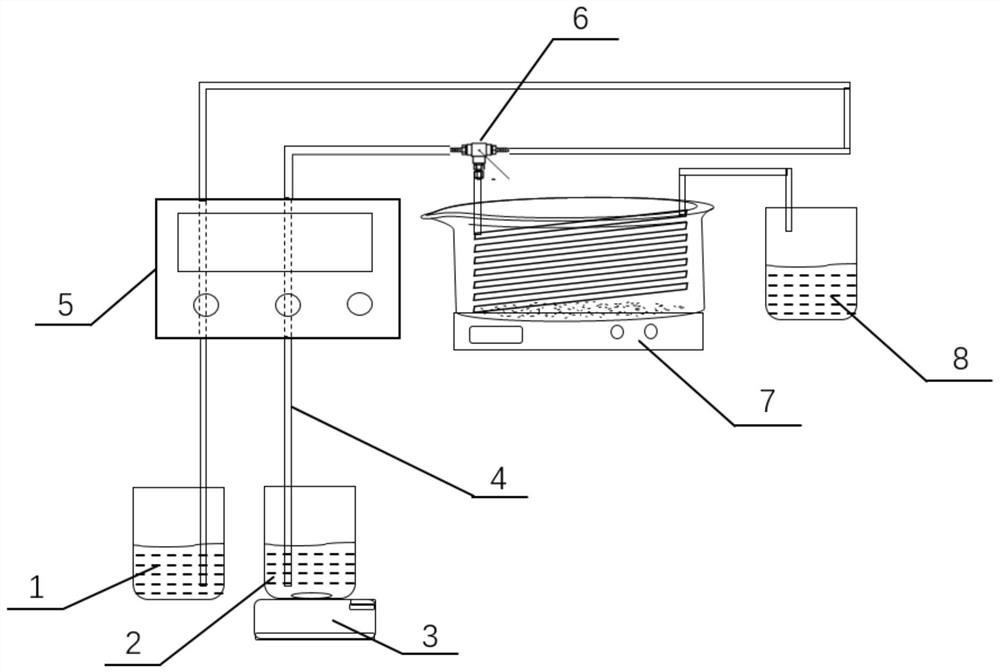

[0040] (1) The continuous flow device is composed of two peristaltic pumps, a magnetic stirrer, a PP tee, a Teflon pipeline, an oil bath and a collecting device; In a container, the outlet pipes of the two peristaltic pumps are connected to the two ends of the tee made of PP material, and the lower interface of the tee is connected to a length of Teflon pipe, and this section of Teflon pipe is fixed on In the oil bath, the outlet end of the last Teflon pipeline is fixed above the collection device;

[0041] (2) Add 3 g of multi-walled carbon nanotubes and 300 mL of nitric acid into the round bottom flask, install the round bottom flask in an oil bath, stir at 120° C., condense and reflux for 4 hours. After the purification, quickly add deionized water to cool down and dilute the acid concentration, repeatedly wash and filter the carbon nanotubes until the final filtrate pH=7, and then dry in an oven at 80°C for 12 hours. Take out the dried carbon nanotubes, put them into a mo...

Embodiment 2

[0076] (1) Add 3 g of multi-walled carbon nanotubes and 300 mL of nitric acid into a round bottom flask, install the round bottom flask in an oil bath, stir at 120° C., condense and reflux for 4 hours. After the purification, quickly add deionized water to cool down and dilute the acid concentration, repeatedly wash and filter the carbon nanotubes until the final filtrate pH=7, and then dry in an oven at 80°C for 12 hours. Take out the dried carbon nanotubes, put them into a mortar for grinding, and sieve through a 100-mesh standard sieve to make a carbon nanotube carrier;

[0077] (2) Dissolve 1 g of chloroplatinic acid in 50 mL of ultrapure water, and make it into a platinum precursor solution (Pt: 7.5 mg / mL) for later use;

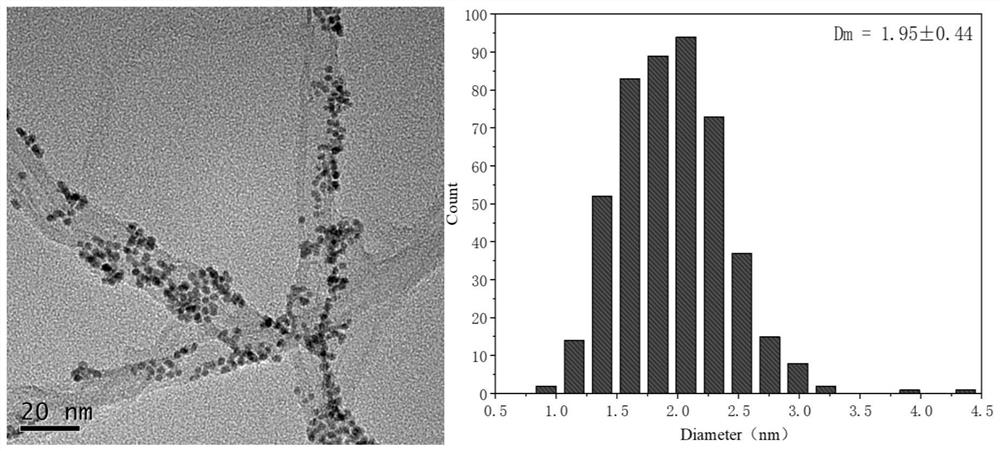

[0078] (3) Weigh 190 mg of multi-walled carbon nanotube carrier, add it to a beaker, measure 200 ml of ethylene glycol for ultrasonic dispersion, put it on a magnetic stirrer and stir for later use, take 1330 μl of HPtCl 4 ·xH 2 O aqueous solution was...

Embodiment 3

[0079] Embodiment 3 Catalyst ICP test

[0080] The platinum-based catalysts prepared in Example 1 and Comparative Examples 1-1, 1-2, and 1-3 were weighed, dissolved in aqua regia, diluted to constant volume, and passed through an Inductively Coupled Plasma Optical Emission Spectrometer (ICP- OES) test, the results are shown in Table 1.

[0081] Table 1 Catalyst ICP test results

[0082]

[0083] According to the above results, the prepared catalysts of Example 1 and Example 2 have a loading rate greater than 95%, while the catalysts of Comparative Examples 1-1, 1-2, 1-3, 1-4, 1-5, and 1-6 The loading rate is all in 60%~90%, and the loading effect is not good, in order to be better with impregnation method (specific method reference document Selective hydroconversion of 2-methylfuran to pentanolson MWNT-supported Pt catalyst at ambient temperature prepared catalyst ( ICP: 4.9%)) Contrast, available embodiment 1 and embodiment 2 are used for the hydrogenation of 2-methylfur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com