Method for preparing hydrogen through photoanode-photovoltaic battery coupled dual-illumination fully-photic-driven decomposition of water

A photovoltaic cell and photoanode technology, applied in the direction of electrolysis process, electrolysis components, photosensitive equipment, etc., can solve the problems of narrow light absorption range, difficulty in realization, limitation, etc., achieve a wide range of material selection, improve water oxidation activity, and material preparation easy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

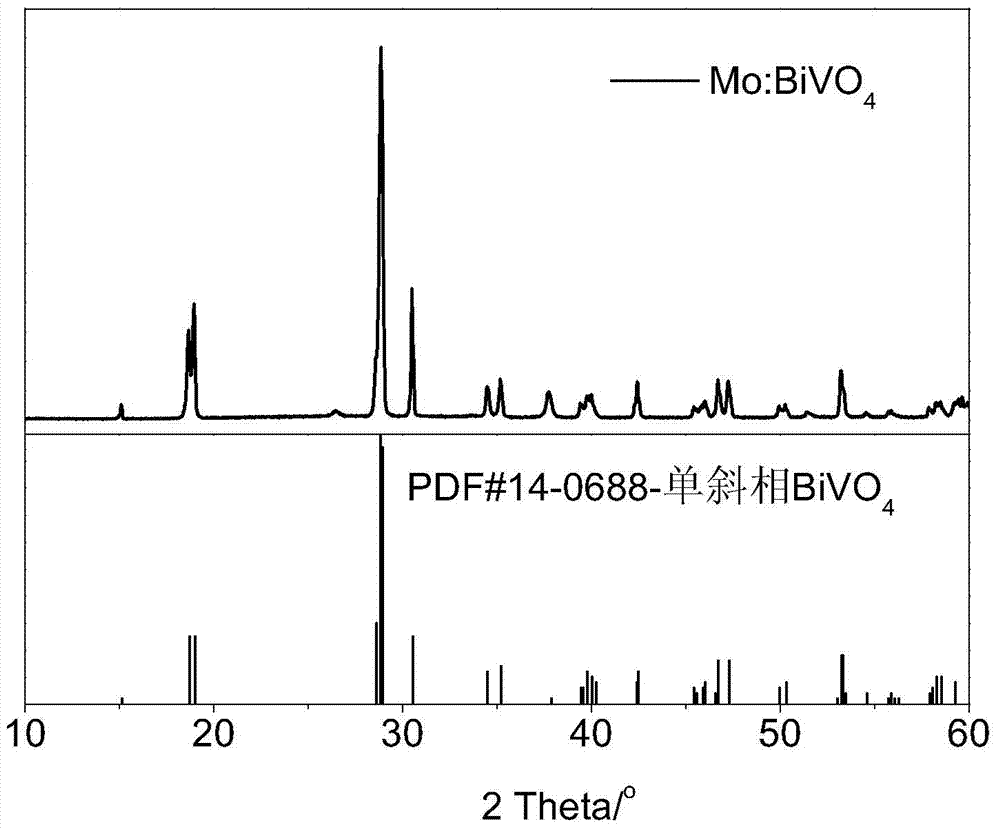

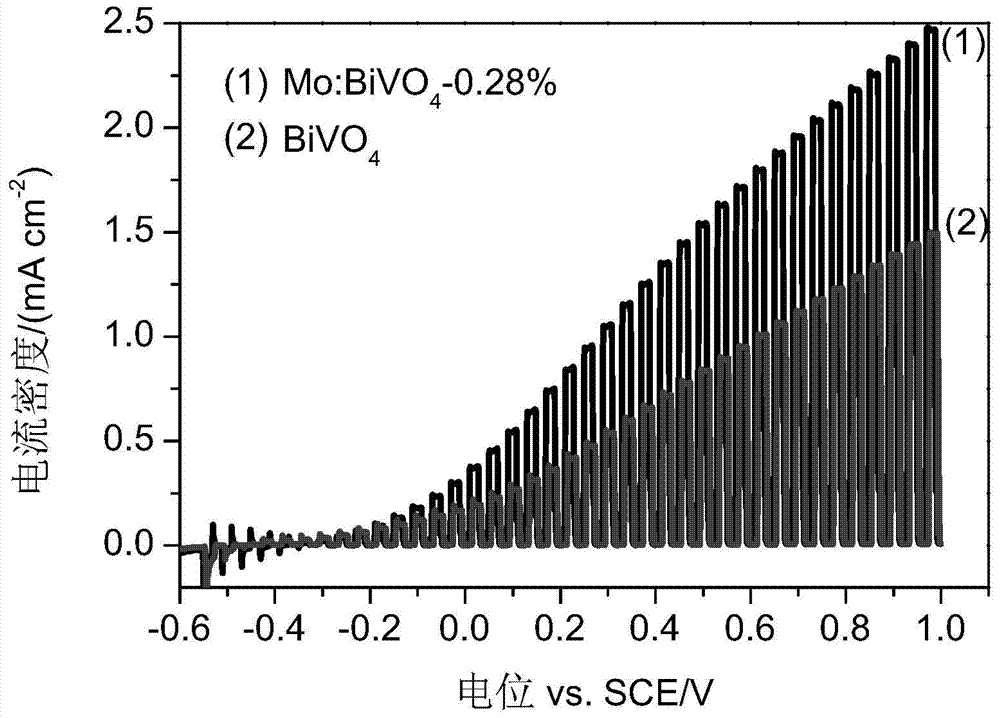

[0067] 0.3% Mo-doped BiVO 4 Preparation and photoelectric characterization of the photoanode:

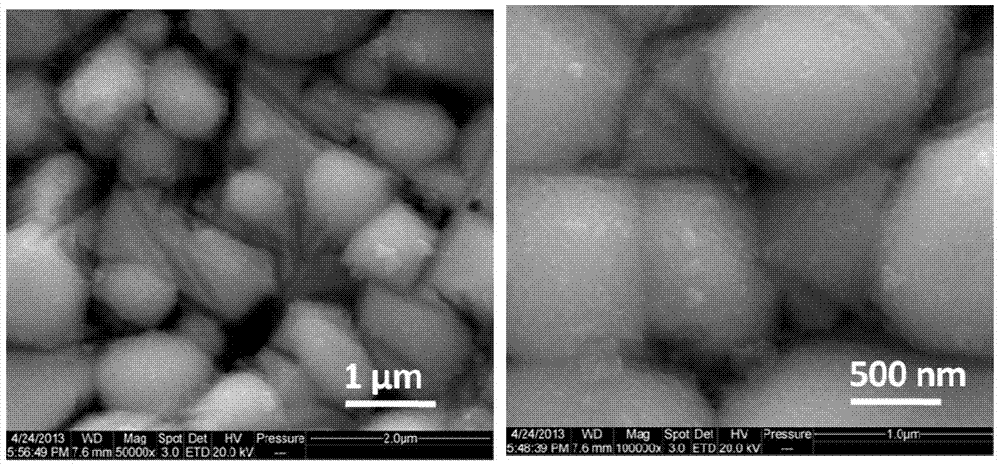

[0068] 202mL water plus 11mL concentrated HNO 3 , weighing 8.75mmol VOSO 4 .xH 2 O was dissolved in the above solution, and 1.2133g Bi(NO 3 ) 3 .5H 2 O, add 0.02625mmol MoCl after dissolving 3 or MoCl 5 , 52g of anhydrous sodium acetate to adjust the pH to about 5.1, and then add nitric acid to adjust the pH to 4.7. The above solution was used as electrolyte, Pt sheet was used as counter electrode, FTO was used as working electrode, and saturated calomel electrode SCE was used as reference electrode. Under the condition of constant temperature in 70°C water bath, CHI760D electrochemical workstation was used to control the potential of 1.855Vvs. Take it out for cleaning after 50 minutes, bake it in the air at 500°C, the heating rate is 2°C / min, and finally soak it in 1M KOH for 15 minutes to remove V 2 o 5 Impurities. Mo:BiVO 4 The results of the XRD spectrum of the photo...

Embodiment 2

[0071] Mo:BiVO 4 Loading of Surface Promoter FeOOH

[0072] Take 35mL of secondary water and pass it through Ar for 30min to remove the dissolved air, and then use it to prepare 0.1M FeCl 2 Solution, adjust pH to 4.1 with ammonia water, select current step deposition, current density 10μA / cm 2 Deposition 3s, 1μA / cm 2 Deposition 2s, light source Xe lamp (light intensity to 2mW / cm 2 ), the deposition voltage will first decrease and then increase with the increase of the deposition amount. 4 SEM of the photoanode as image 3 .

Embodiment 3

[0074] Mo:BiVO 4 Surface Promoter CoB i load

[0075] Configured with 30μM Co(NO 3 ) 2 0.1M sodium borate buffer solution (pH9), with 300W Xe lamp (λ>420nm) as the light source, with Mo:BiVO 4 is the photoanode, the Pt sheet is the counter electrode, the saturated calomel electrode SCE is the reference electrode, and the deposition is carried out at a constant potential of 0Vvs.SCE, and the deposition time is 10s.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com