Composite bismuth ferrite photocatalyst and preparation method and application thereof

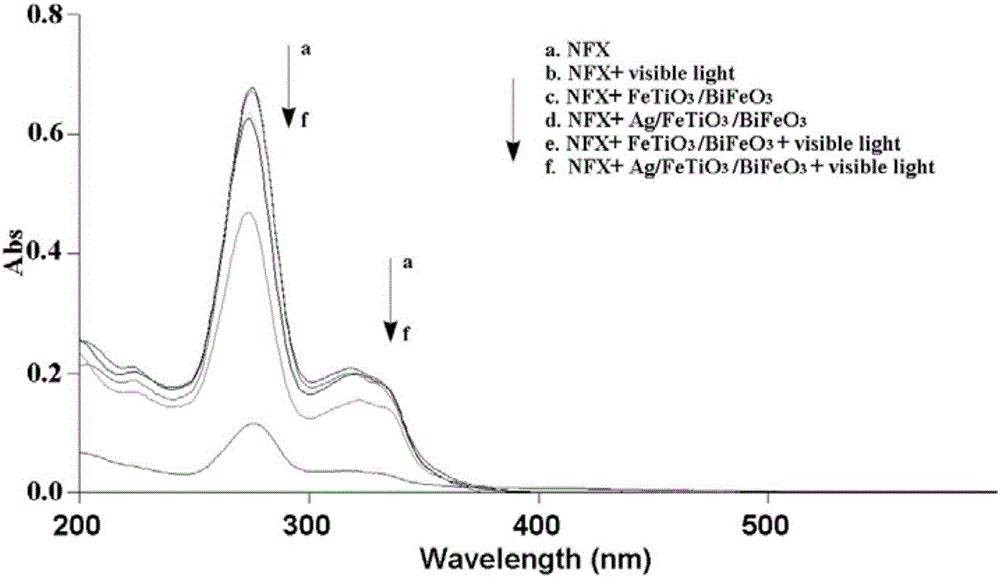

A photocatalyst, bismuth ferrite technology, applied in chemical instruments and methods, heterogeneous catalyst chemical elements, physical/chemical process catalysts, etc., can solve the problems of reducing the photocatalytic efficiency of catalysts and low utilization of sunlight, etc. The effect of improving the utilization rate of visible light, broadening the light response range, and improving the catalytic activity of visible light

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0015] A kind of composite bismuth ferrite photocatalyst, preparation method comprises the steps:

[0016] 1) Synthesis of FeTiO by sol-gel method 3 Nanoparticles: drop the ferric nitrate solution into the ethanol solution of tetrabutyl titanate, stir magnetically, add sodium hydroxide solution until a dark brown precipitate is produced, wash with deionized water, dry, and calcinate in a muffle furnace at 400°C for 4h , to get FeTiO 3 nanoparticles.

[0017] 2) Synthesis of BiFeO by sol-gel method 3 Nanoparticles: Dissolve bismuth nitrate pentahydrate and iron nitrate nonahydrate in ethylene glycol, and stir the mixture magnetically for 30 minutes at room temperature to form a sol. After the sol is dried in an oven at 90°C, it is calcined in a muffle furnace at 450°C for 30 minutes. , after cooling, wash with distilled water and absolute ethanol, and dry to obtain BiFeO 3 nanoparticles.

[0018] 3) FeTiO 3 Place in deionized water, stir to obtain a suspension, add AgNO t...

Embodiment 1

[0020] 1) Synthesis of BiFeO by sol-gel method 3 Nanoparticles: Accurately weigh 7.7611g of bismuth nitrate pentahydrate and 6.4640g of ferric nitrate nonahydrate, and dissolve them in 36mL of ethylene glycol. At room temperature, the mixture was magnetically stirred for 30 min to form a sol. The sol was oven-dried at 90°C and calcined in a muffle furnace at 450°C for 30 min. After cooling, wash with distilled water and absolute ethanol several times, and dry to obtain BiFeO 3 nanoparticles.

[0021] 2) Synthesis of FeTiO by sol-gel method 3 Nanoparticles: drop 10mL of 1mol / L ferric nitrate solution into 10mL of 1mol / L tetrabutyl titanate ethanol solution, and stir magnetically for 3h. Add 1mol / L sodium hydroxide solution until a dark brown precipitate is produced, wash with deionized water, and dry. Calcined in a muffle furnace at 400°C for 4h to obtain FeTiO 3 nanoparticles.

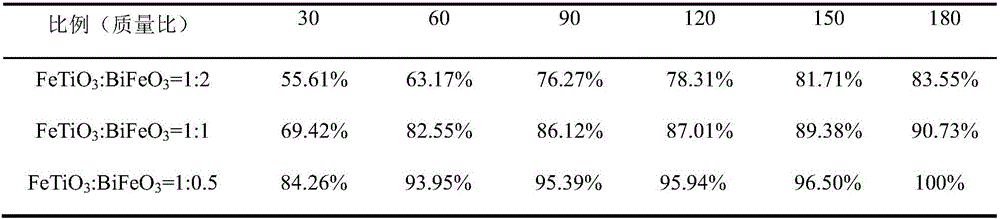

[0022] 3) Take 1.0g of FeTiO prepared above 3 The powder was placed in 20mL deionized water...

Embodiment 2

[0024] 1) Synthesis of BiFeO by sol-gel method 3 Nanoparticles: the same as in Example 1.

[0025] 2) Synthesis of FeTiO by sol-gel method 3 Nanoparticles: the same as in Example 1.

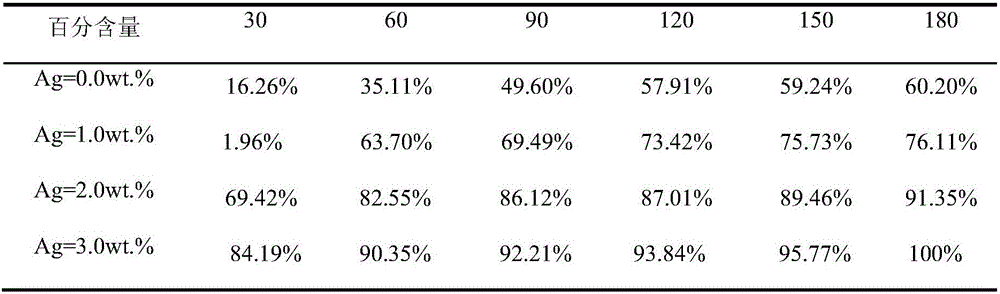

[0026] 3) Take 1.0g of FeTiO prepared above 3 Put the powder in 20mL deionized water, stir to get a suspension, add 0.02g, 0.04g, 0.06g of AgNO 3 , avoid light and stir for 20min. Then, stir for 10 min under the irradiation of UV lamp, then add 1.0 g of BiFeO 3 Powder, ultrasonic 5min. After centrifugation, the resulting precipitate was washed with deionized water and dried. Finally, calcined in a muffle furnace at 400 °C for 30 min to obtain FeTiO 3 and BiFeO 3 Composite bismuth ferrite photocatalysts with a mass ratio of 1:1 and different Ag loadings (1%, 2%, 3%).

PUM

| Property | Measurement | Unit |

|---|---|---|

| clearance rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com