Preparation method of visible-light response tungsten trioxide-bismuth vanadate heterojunction thin film electrode

A thin-film electrode and heterojunction technology, applied in the field of nanomaterials, can solve the problems of low cost-effectiveness, slow generation, decreased electrode charge transport performance, etc., and achieve high photoelectric efficiency and good effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

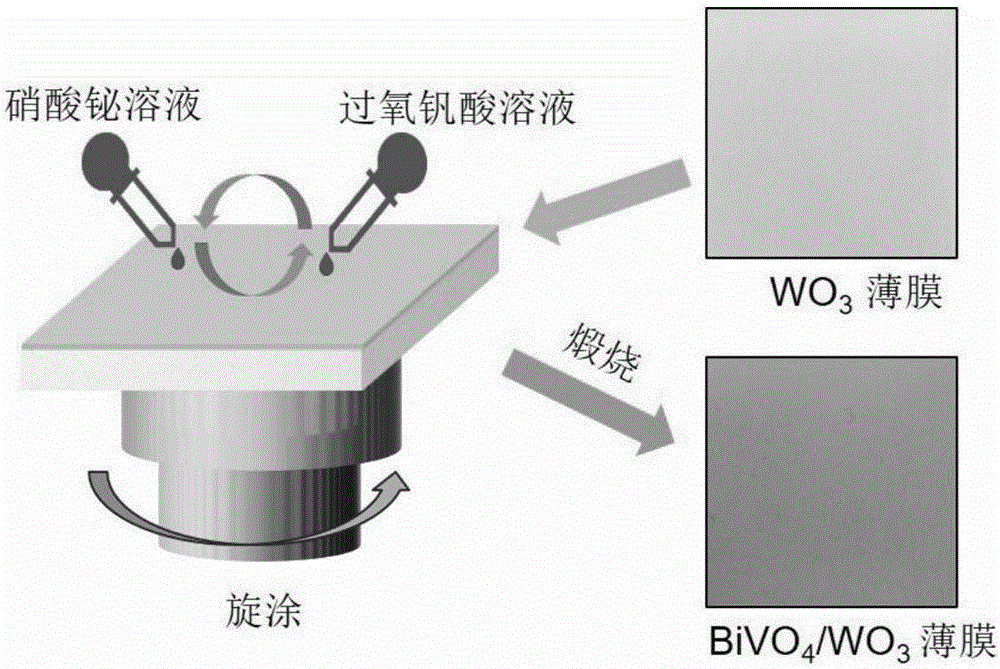

[0032] see first figure 1 ,figure 1 is the visible light responsive WO described in the present invention 3 / BiVO 4 Schematic diagram of the preparation process of the heterojunction thin film electrode, the visible light responsive WO of the present invention 3 / BiVO 4 The preparation method of the heterojunction thin film electrode is through the WO 3 The surface of the film was alternately spin-coated with bismuth nitrate solution and peroxovanadate solution, using bismuth nitrate and peroxovanadate solution in WO 3 The surface of the film is directly reacted to obtain bismuth peroxovanadate, and finally the film is sintered at one time to obtain the WO 3 / BiVO 4 Heterojunction thin film electrodes. Specifically include the following steps:

[0033] 1~3g Bi(NO 3 ) 3 ·5H 2 O is dissolved in 100 mL of 2 mol / L acetic acid aqueous solution to obtain a bismuth nitrate solution, and 0.2-1 g of NH 4 VO 3 Dissolved in 100mL of 50~200mmol / L H 2 O 2 The peroxovanadate s...

Embodiment 1

[0037] WO was first prepared by chemical bath method in the prior art 3 Nanosheet films (Zhou Baoxue et al., a WO 3 Preparation method and application of nanosheet array thin film, Chinese patent application number: 201510724443.X): containing 0.4gNa 2 WO 4 ·2H 2 O, 0.15g ammonium oxalate, 9mL 37% hydrochloric acid, 8mL 37% H 2 O 2 and 30 mL of ethanol in 30 mL of deionized aqueous solution, the tungstic acid film was obtained on a conductive glass substrate in a water bath at 85 °C for 200 min, and then heat-treated at 500 °C for 2 h after WO 3 Nanosheet films.

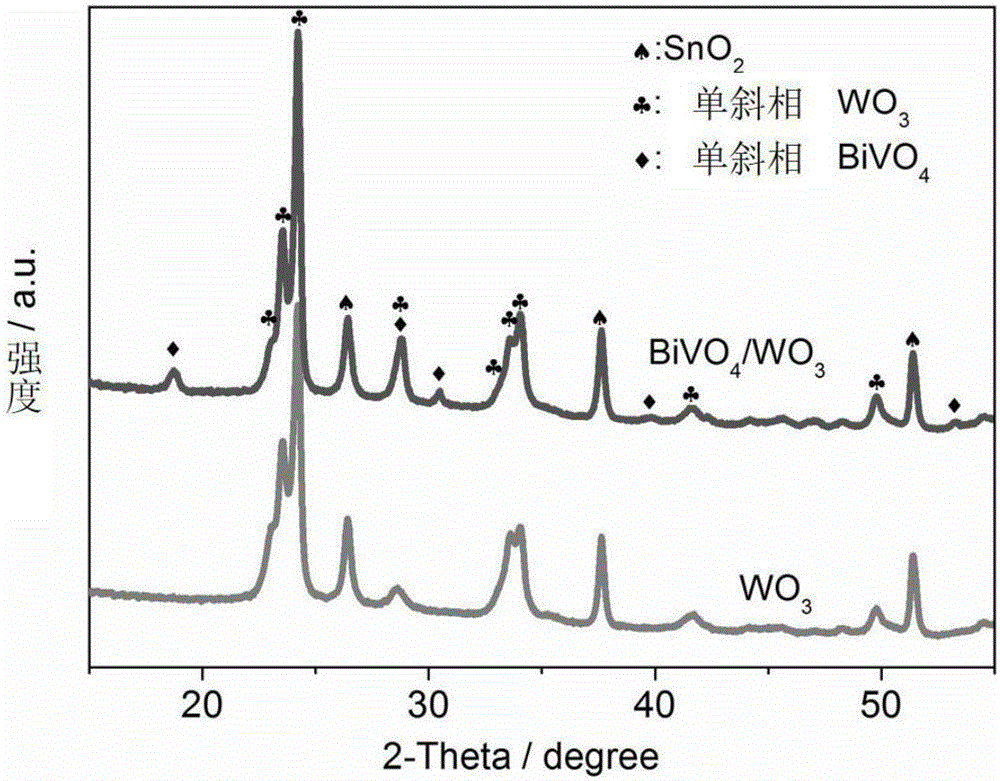

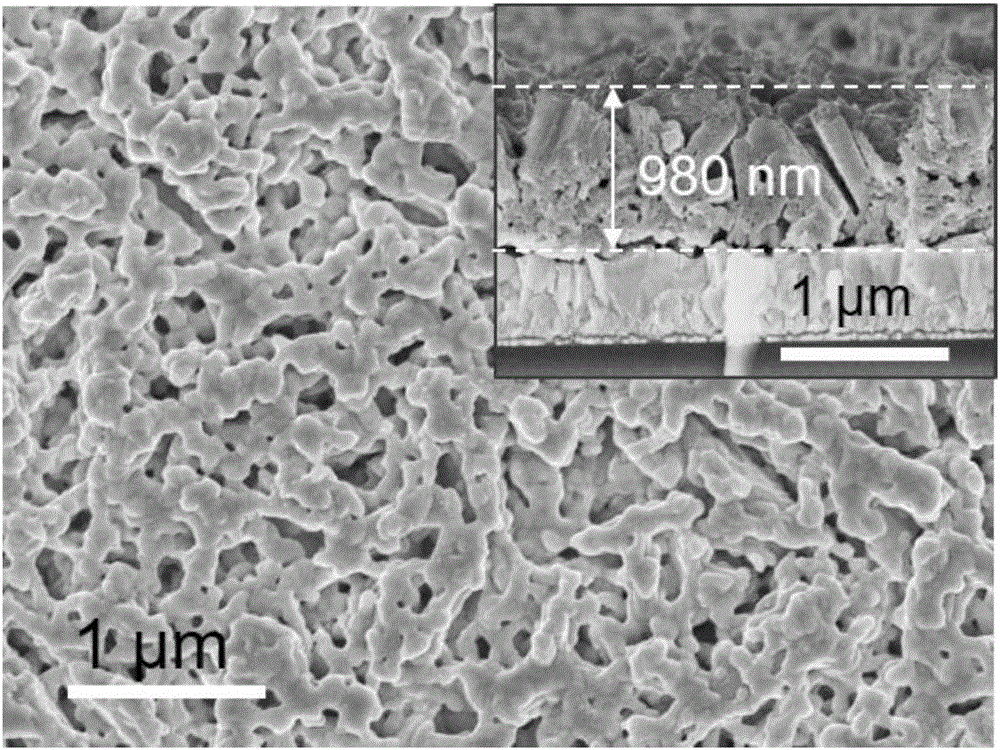

[0038] 2.4gBi (NO 3 ) 3 ·5H 2 O was dissolved in 100 mL of 2 mol / L acetic acid aqueous solution to obtain a bismuth nitrate solution, and 0.58 g of NH 4 VO 3 Dissolved in 100mL of 100mmol / L H 2 O 2 The peroxovanadate solution is obtained in the aqueous solution, and then the bismuth nitrate solution is spin-coated on the above-mentioned WO 3 The surface of the nanosheet film, and then spin-coated the per...

Embodiment 2

[0044] First use the prior art anodizing method to prepare WO 3 Nanoporous film (J.Solid State Electrochem. 2014, 18, 157-161): In an aqueous solution containing 0.1 M sodium sulfate and 0.5% HF, at 35 °C, the tungsten sheet was anodized at a voltage of 50 V for 30 min. WO was obtained after heat treatment at 500 °C for 2 h 3 Nanoporous films.

[0045] 1g Bi (NO 3 ) 3 ·5H 2 O was dissolved in 100 mL of 2 mol / L acetic acid aqueous solution to obtain a bismuth nitrate solution, and 0.2 g of NH 4 VO 3 Dissolved in 100mL of 50mmol / L H 2 O 2 The peroxovanadate solution is obtained in the aqueous solution, and then the bismuth nitrate solution is spin-coated on the obtained WO 3 The surface of the nanoporous film, and then spin-coated peroxovanadate solution on the obtained WO 3 On the surface of the nanoporous film, after repeating the spin coating process 20 times, the obtained film was heat-treated at 400 °C for 6 hours at a time, and then naturally cooled to obtain WO ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com