Tungsten-nitrogen binary co-doped nanometer TiO2 photocatalyst and preparation method thereof

A photocatalyst and co-doping technology, which is applied in chemical instruments and methods, physical/chemical process catalysts, nanotechnology, etc., can solve the problems of low photocatalytic efficiency and achieve improved photocatalytic activity, effective absorption, and bandgap width Reduced effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

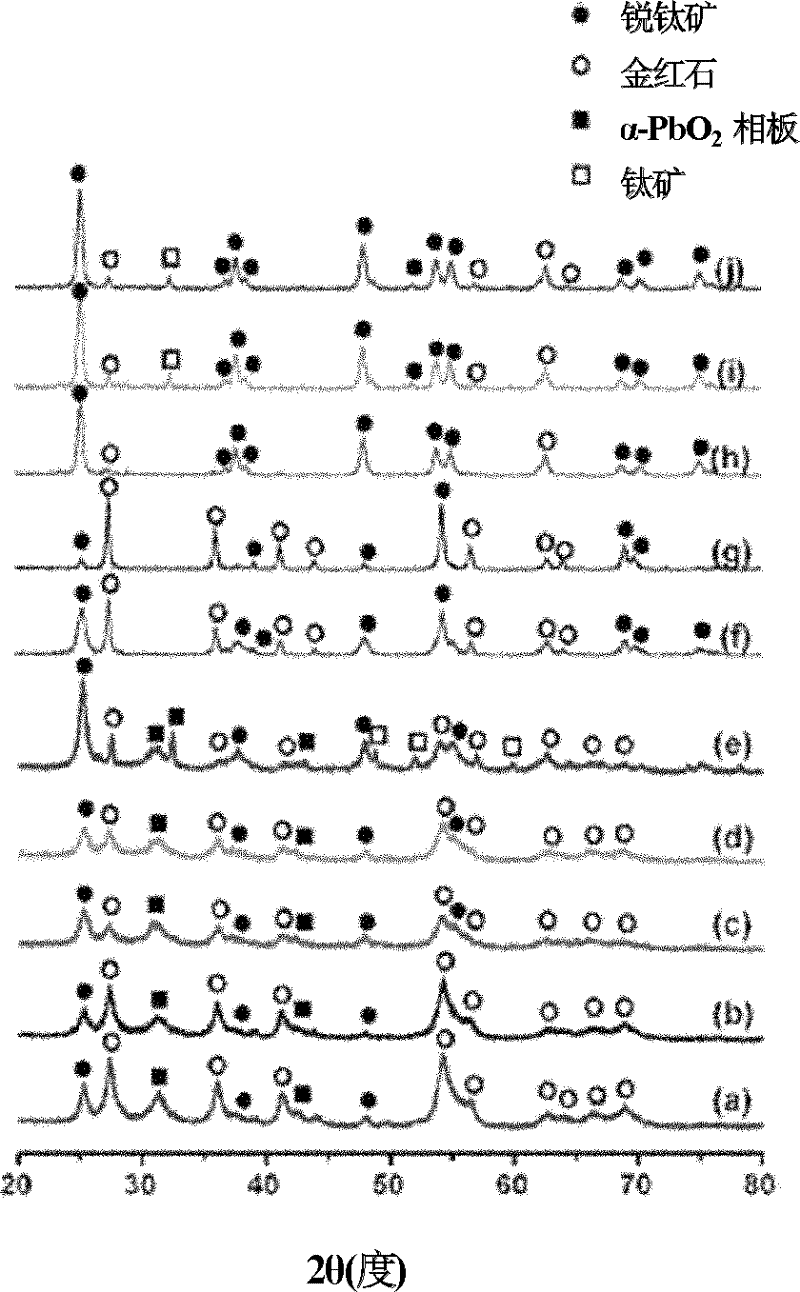

[0029] In this example, tungsten and nitrogen binary co-doped nano-TiO 2 The preparation method of the photocatalyst adopts the two-step method of sol-gel method and high-energy ball milling method to dope tungsten element and nitrogen element. In the first step, W-doped nano-TiO was prepared by sol-gel method 2 Photocatalyst; the second step, using mechanical alloying method (high-energy ball milling method) to incorporate nitrogen into W-doped nano-TiO 2 (W, N) binary co-doped nano-TiO in photocatalyst 2 Photocatalyst, and finally remove the incompletely reacted organic matter by heat treatment, and further treat TiO 2The photocatalyst is crystallized. details as follows:

[0030] In the first step, W-doped nano-TiO was prepared by sol-gel method 2 Photocatalyst, the specific operation steps are:

[0031] (1) First add 34mL tetrabutyl titanate into 88mL ethanol and stir for 30 minutes until the mixture is uniform;

[0032] (2) adding 1.4mL of concentrated nitric acid ...

Embodiment 2

[0043] The difference from Example 1 is that it is as follows:

[0044] In the first step, W-doped nano-TiO was prepared by sol-gel method 2 Photocatalyst, the specific operation steps are:

[0045] (1) First add 17mL tetrabutyl titanate into 44mL ethanol and stir for 30 minutes until the mixture is uniform;

[0046] (2) adding 0.7mL concentrated nitric acid with a concentration of 70wt% to adjust the pH value to 1.5 to obtain a uniform solution A;

[0047] (3) 3.6mL concentration of 5wt% Na 2 WO 3 The aqueous solution was added dropwise to Solution A under vigorous stirring to form a sol. Wherein, the amount of the tungsten inorganic salt solution is 0.5-10wt% based on the doping amount of tungsten element, which is 5wt% in this embodiment;

[0048] (4) After gelling the obtained sol at room temperature for 36 hours, drying at 70° C. for 36 hours to obtain a xerogel;

[0049] (5) Baking the xerogel in air at 500°C for 2 hours to obtain W-doped TiO 2 catalyst of light; ...

Embodiment 3

[0053] The difference from Example 1 is that it is as follows:

[0054] In the first step, W-doped nano-TiO was prepared by sol-gel method 2 Photocatalyst, the specific operation steps are:

[0055] (1) First add 51mL tetrabutyl titanate into 132mL ethanol and stir for 30 minutes until the mixture is uniform;

[0056] (2) Add 2.1mL of concentrated nitric acid with a concentration of 70wt% to adjust the pH value to 1.8 to obtain a uniform solution A;

[0057] (3) 10.8mL concentration of 3wt% Na 2 WO 3 The aqueous solution was added dropwise to Solution A under vigorous stirring to form a sol. Wherein, the dosage of the tungsten inorganic salt solution is 0.5-10wt% based on the doping amount of tungsten element, which is 3wt% in this embodiment;

[0058] (4) After gelling the obtained sol at room temperature for 24 hours, drying at 80°C for 48 hours to obtain a xerogel;

[0059] (5) Baking the xerogel in air at 400°C for 2 hours to obtain W-doped TiO 2 catalyst of light; ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com