Patents

Literature

96results about How to "Increase or decrease thickness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

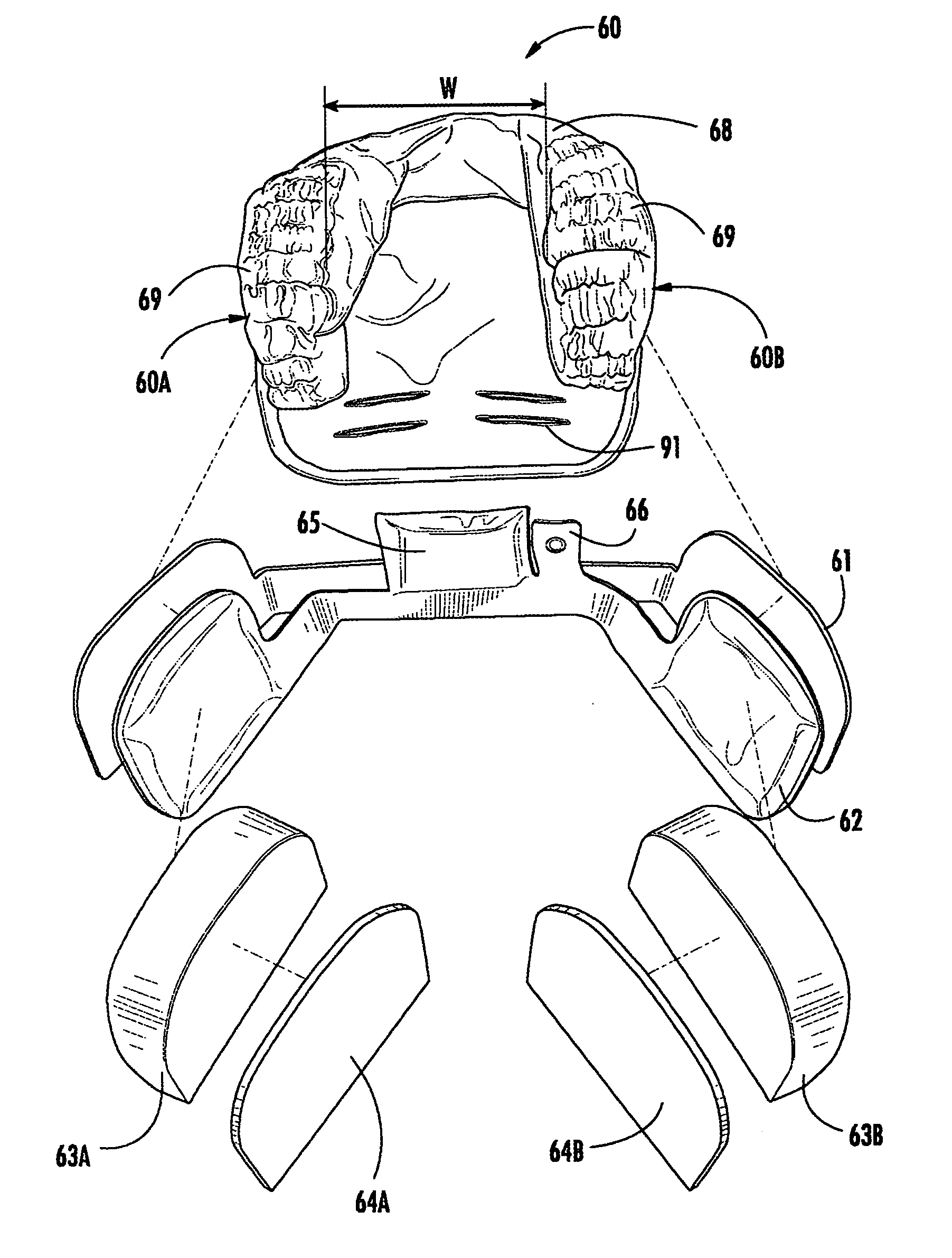

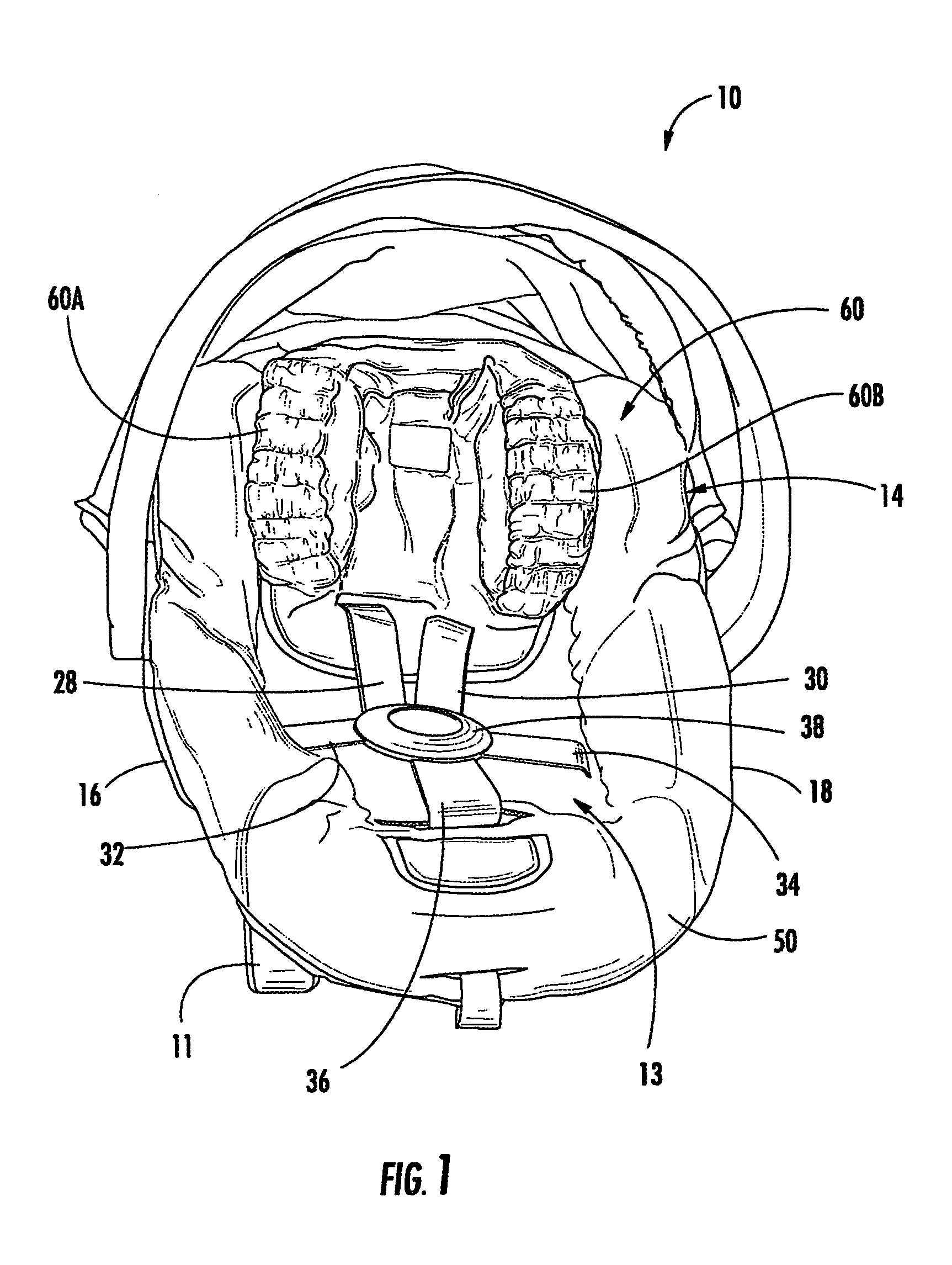

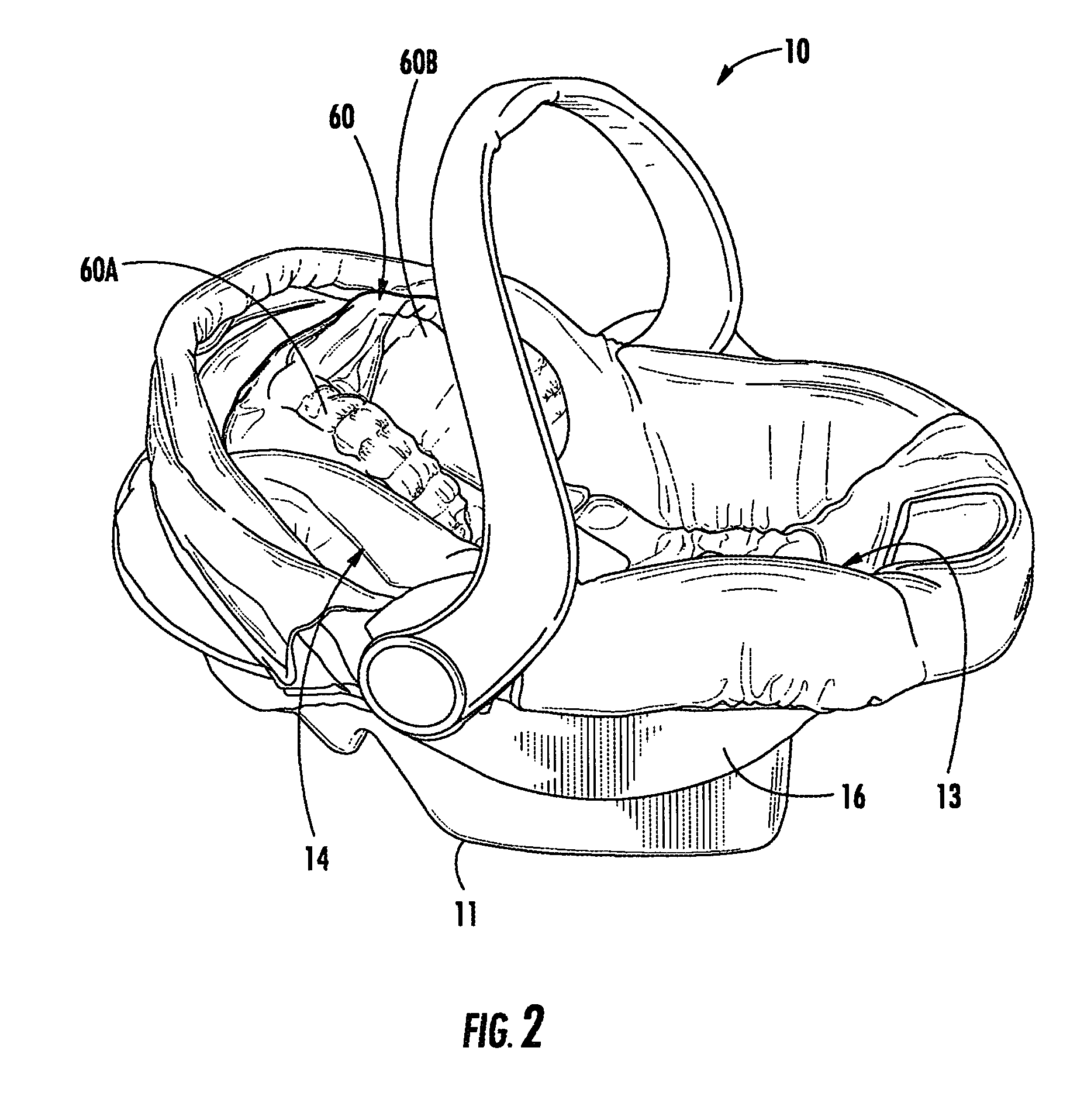

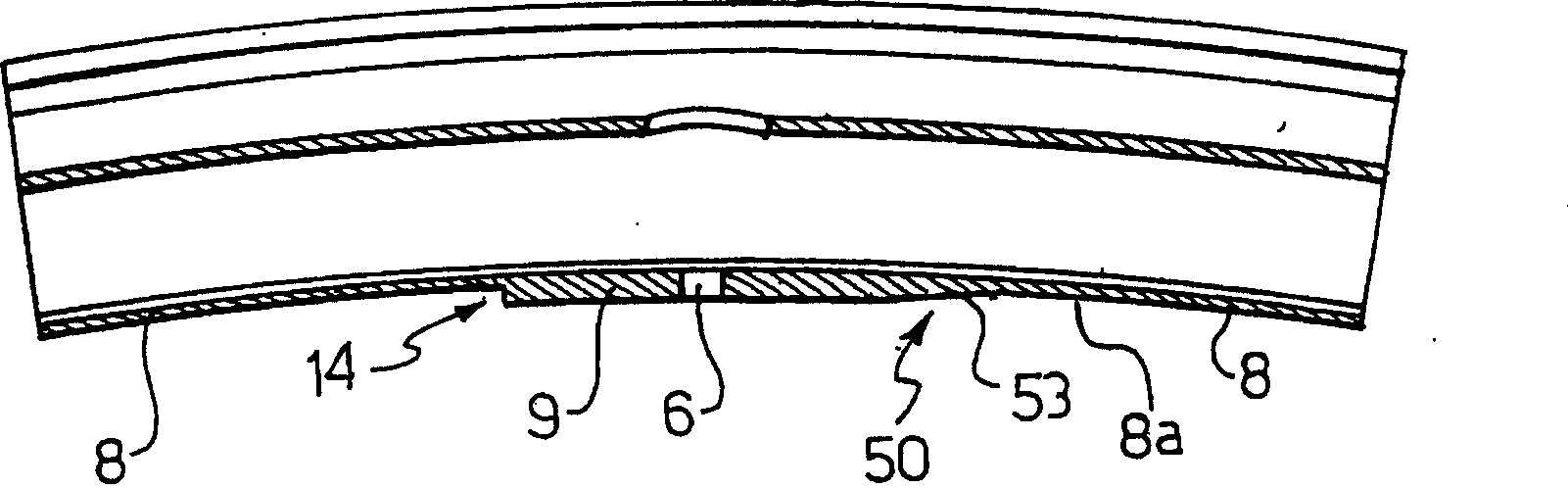

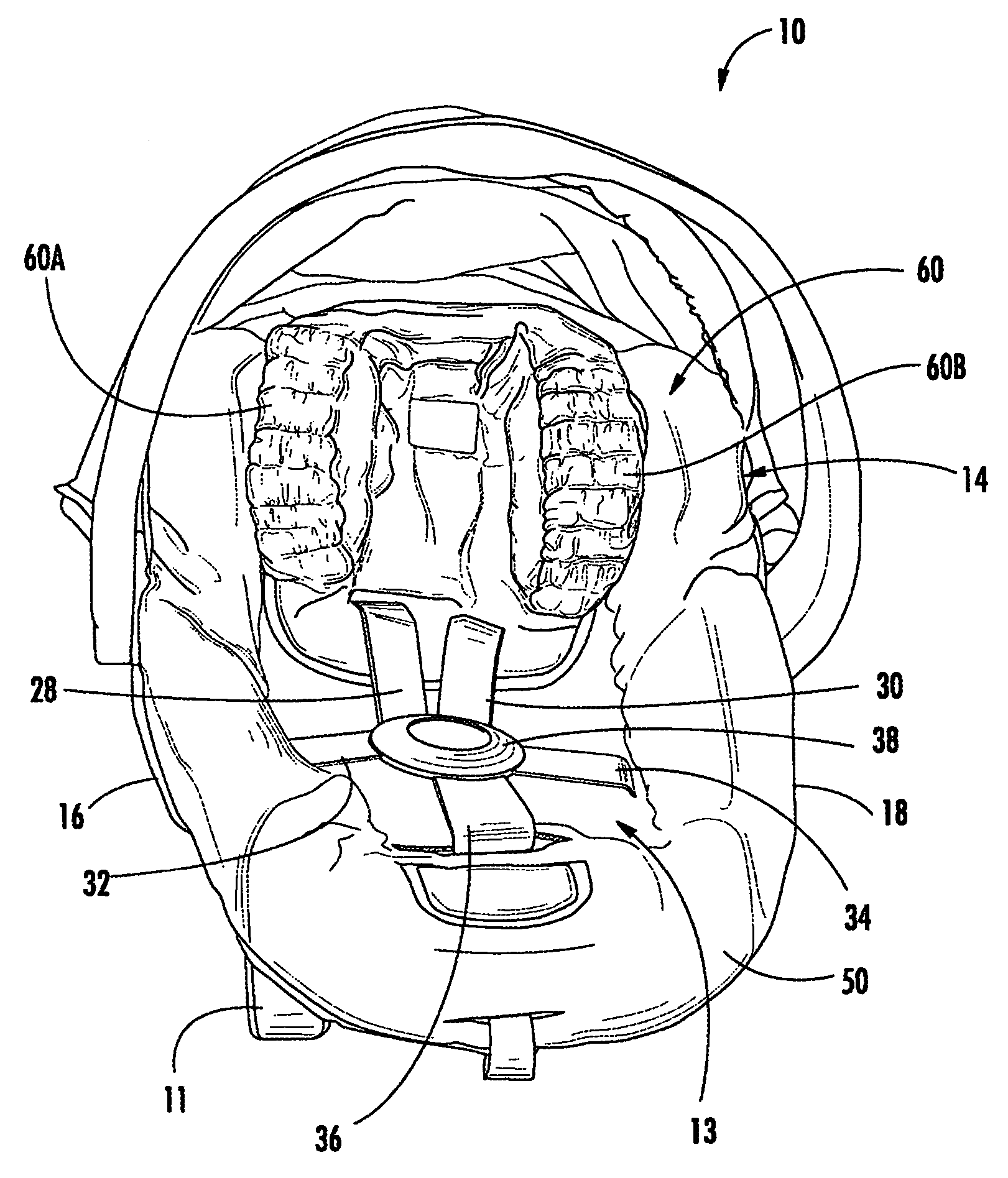

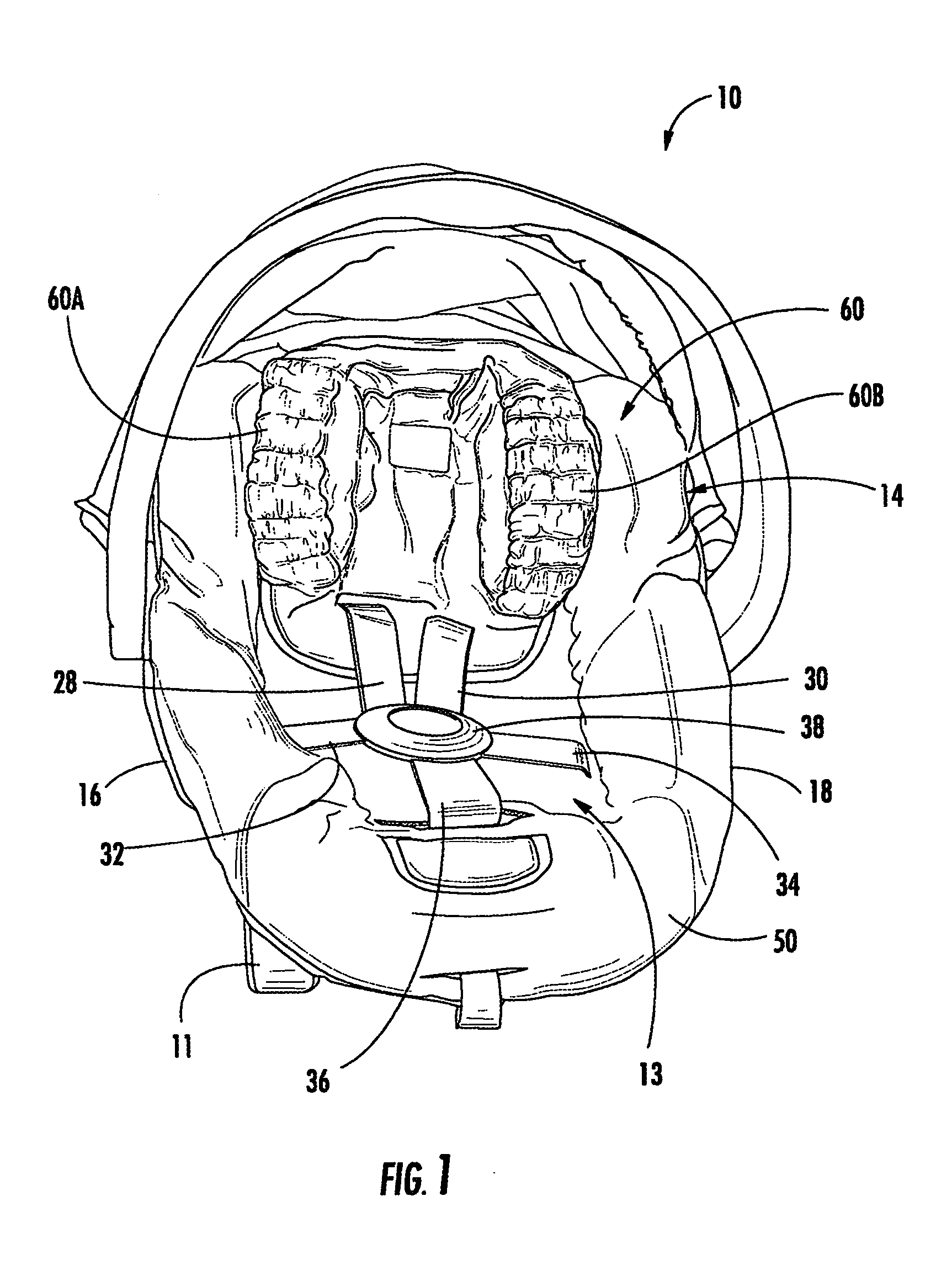

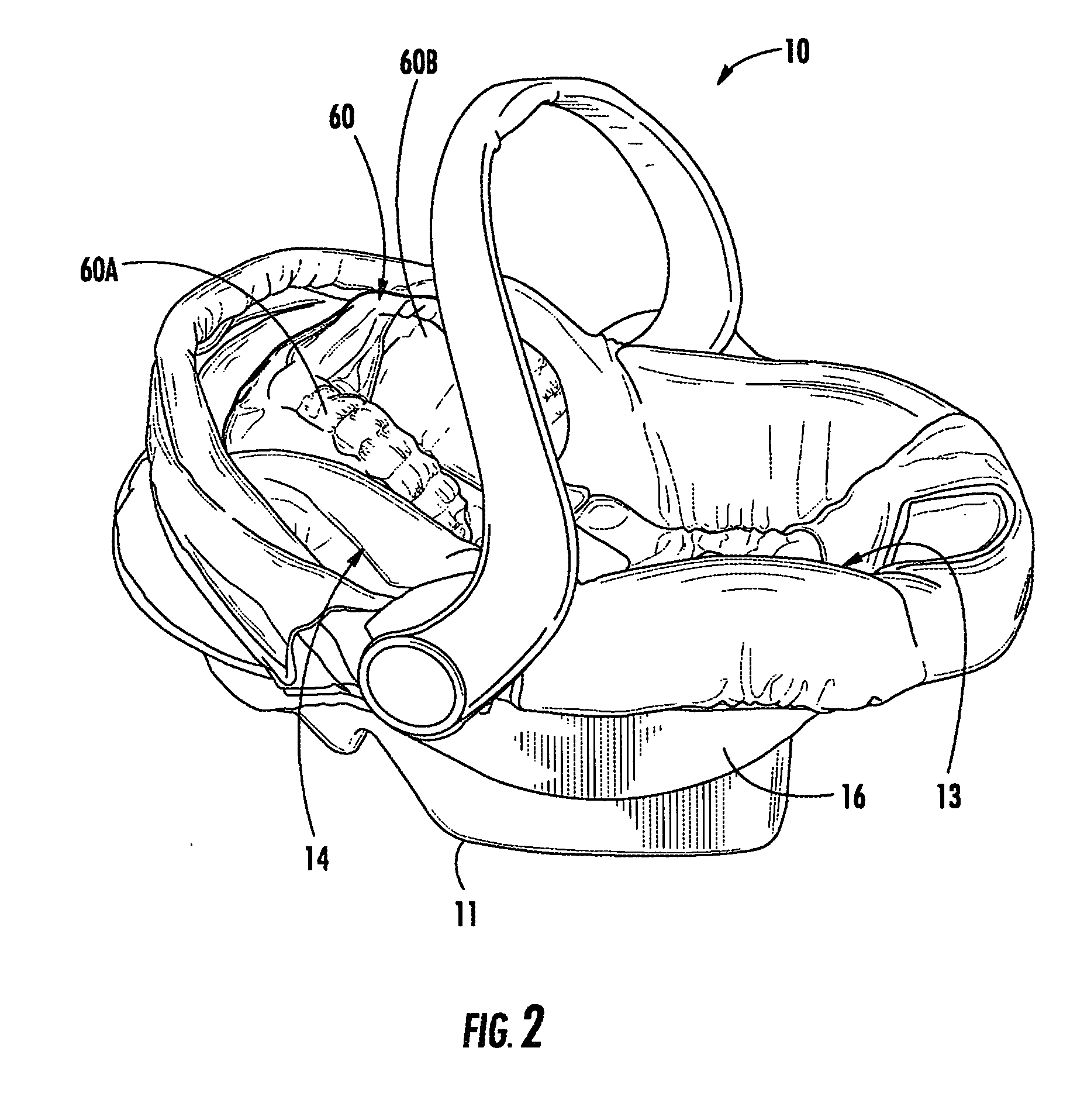

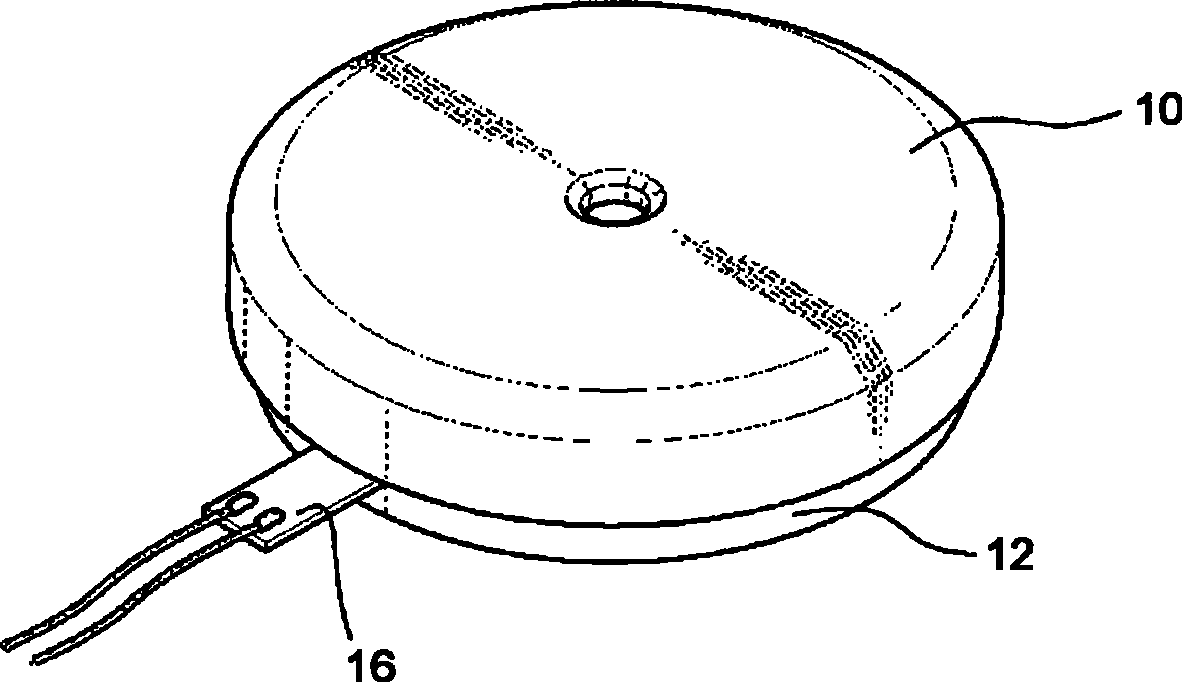

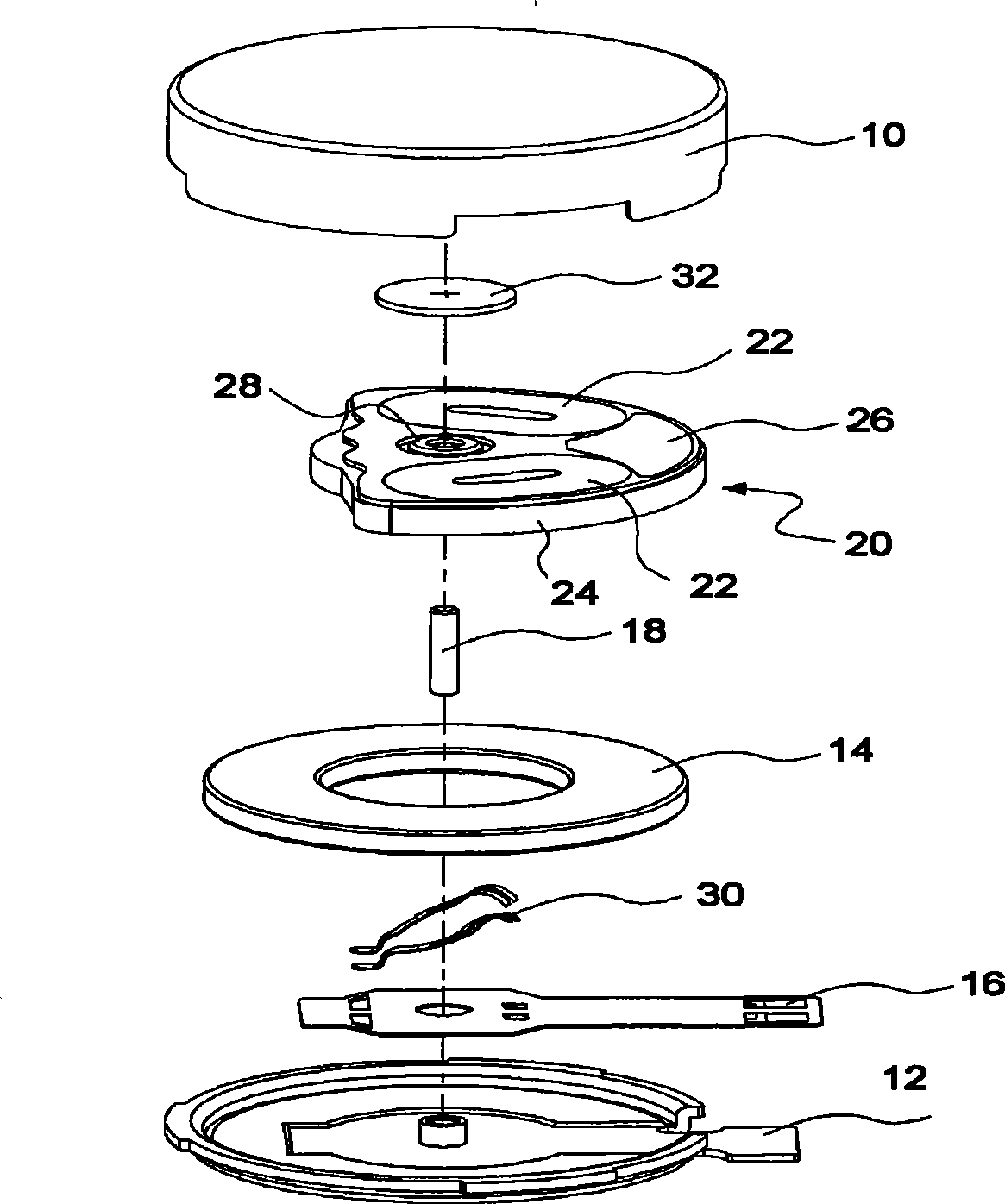

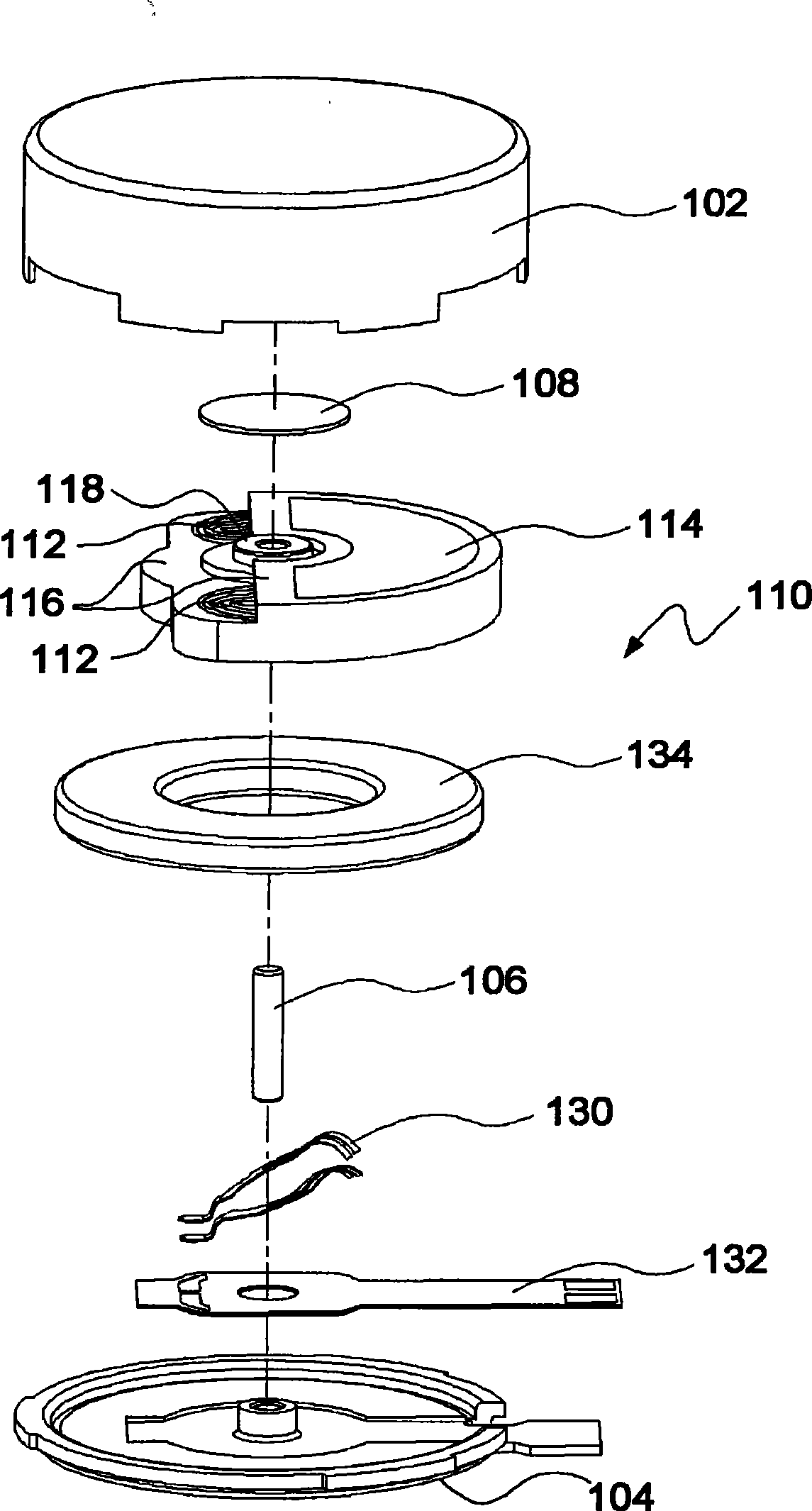

Child safety seat with adjustable head restraint

ActiveUS7234771B2Improve protectionIncrease or decrease thicknessOperating chairsSofasEnergy absorptionEngineering

A side-protective head restraint pad, pad assembly and safety seat. The restraint pad includes an air bladder with a pump for selectively inflating the air bladder and a release valve for selectively deflating the air bladder, an energy-absorbing component and a comfort component. A flexible enclosure is provided within which the air bladder, energy-absorbing component and comfort component are positioned in overlaid configuration to define a unit. The head restraint pad is adapted for being placed in a seat in lateral alignment with one side of the head of an occupant and inflatable or deflatable as appropriate to restrain the head against injurious lateral movement caused by a side impact relative to the seat.

Owner:BRITAX CHILD SAFETY

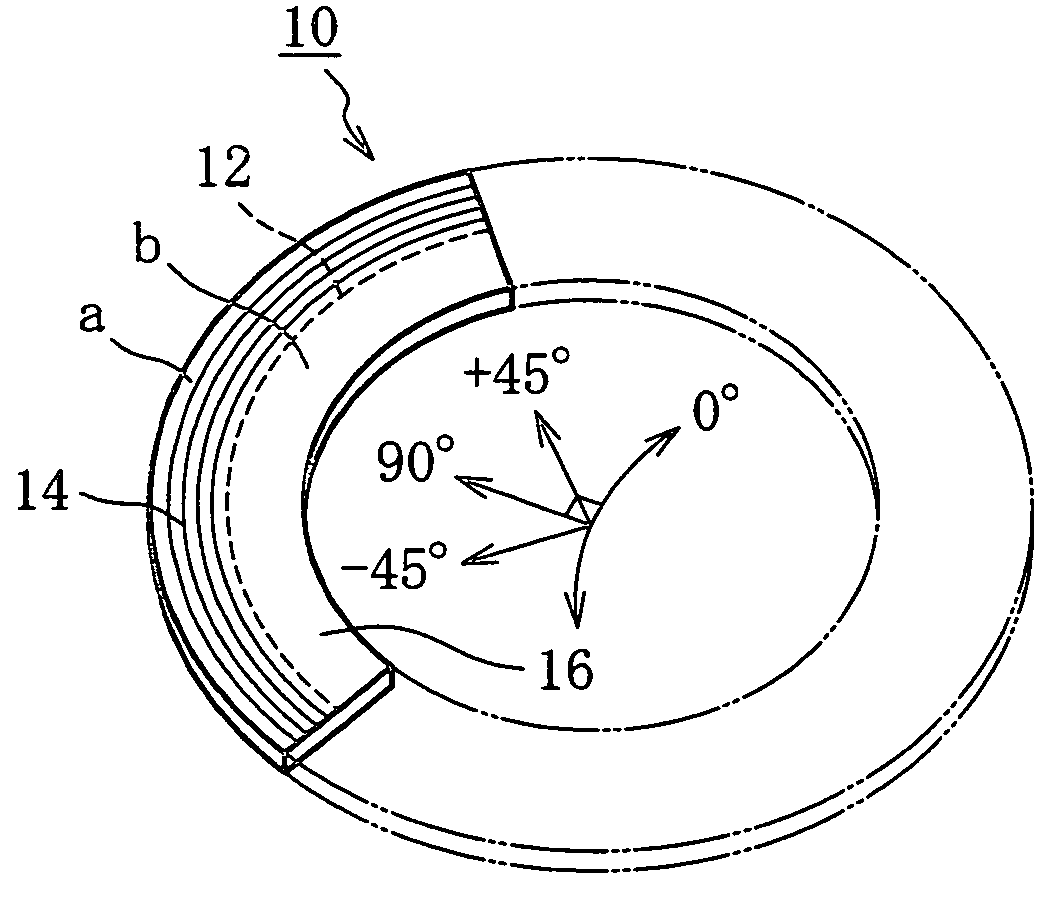

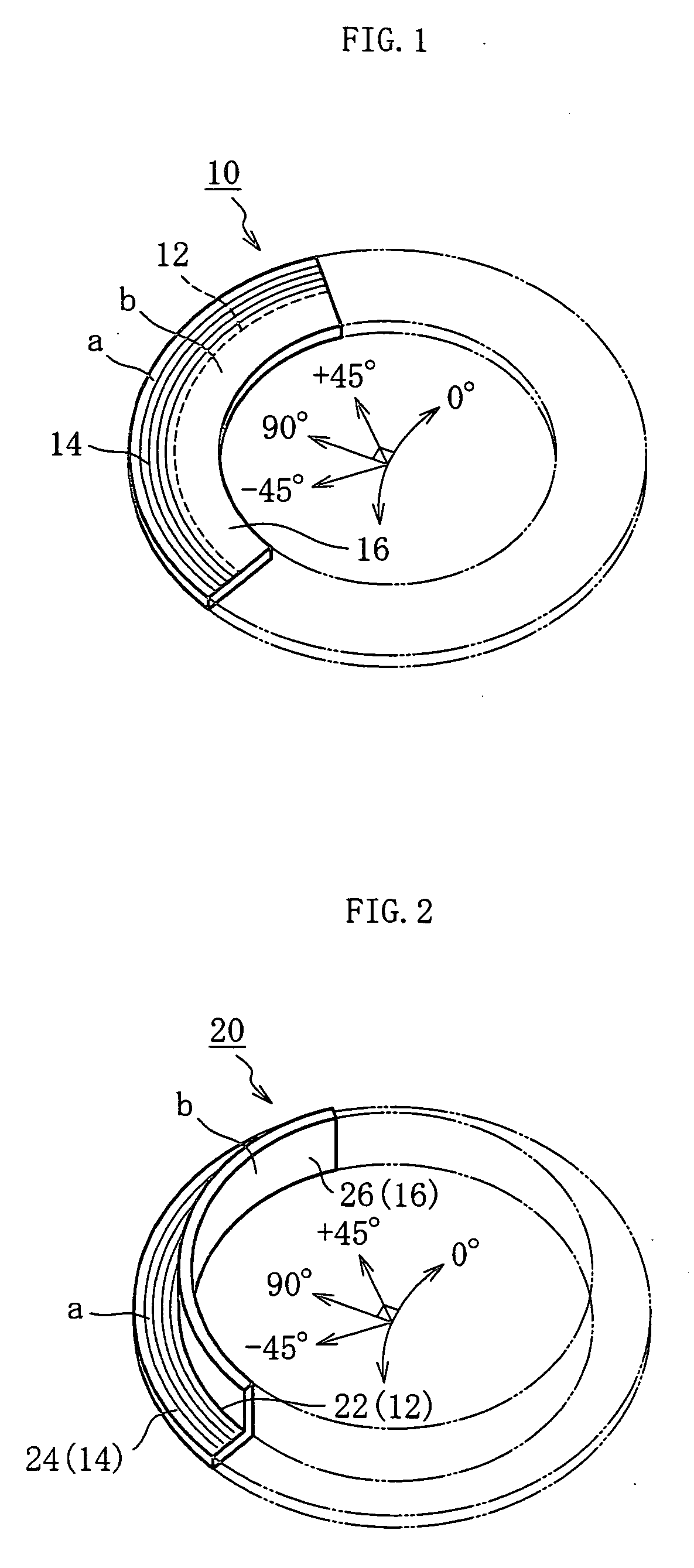

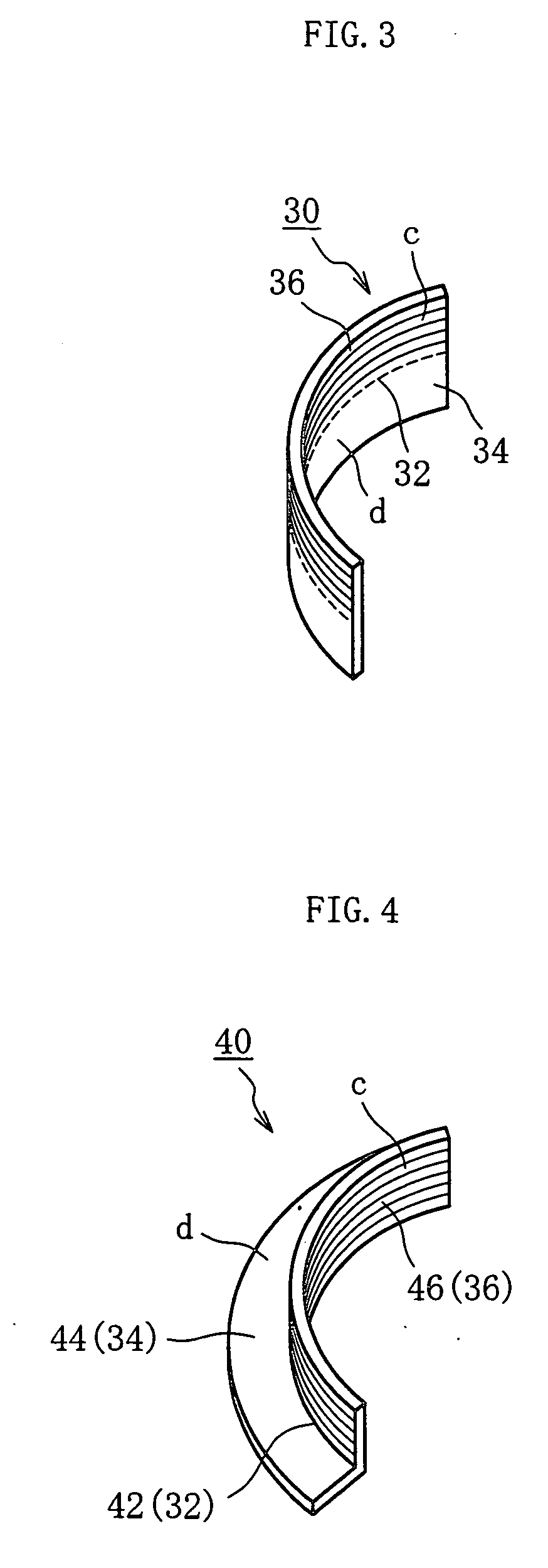

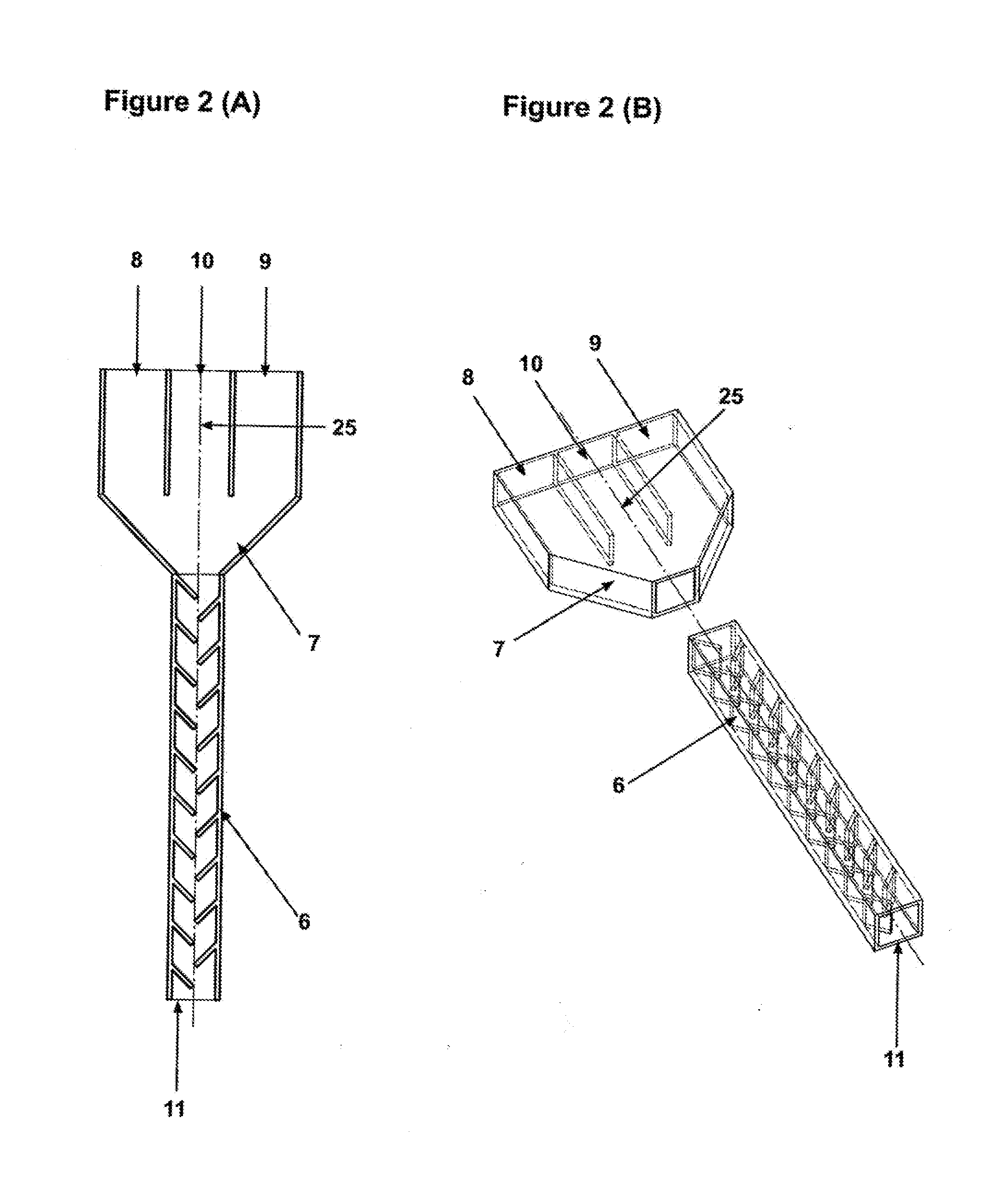

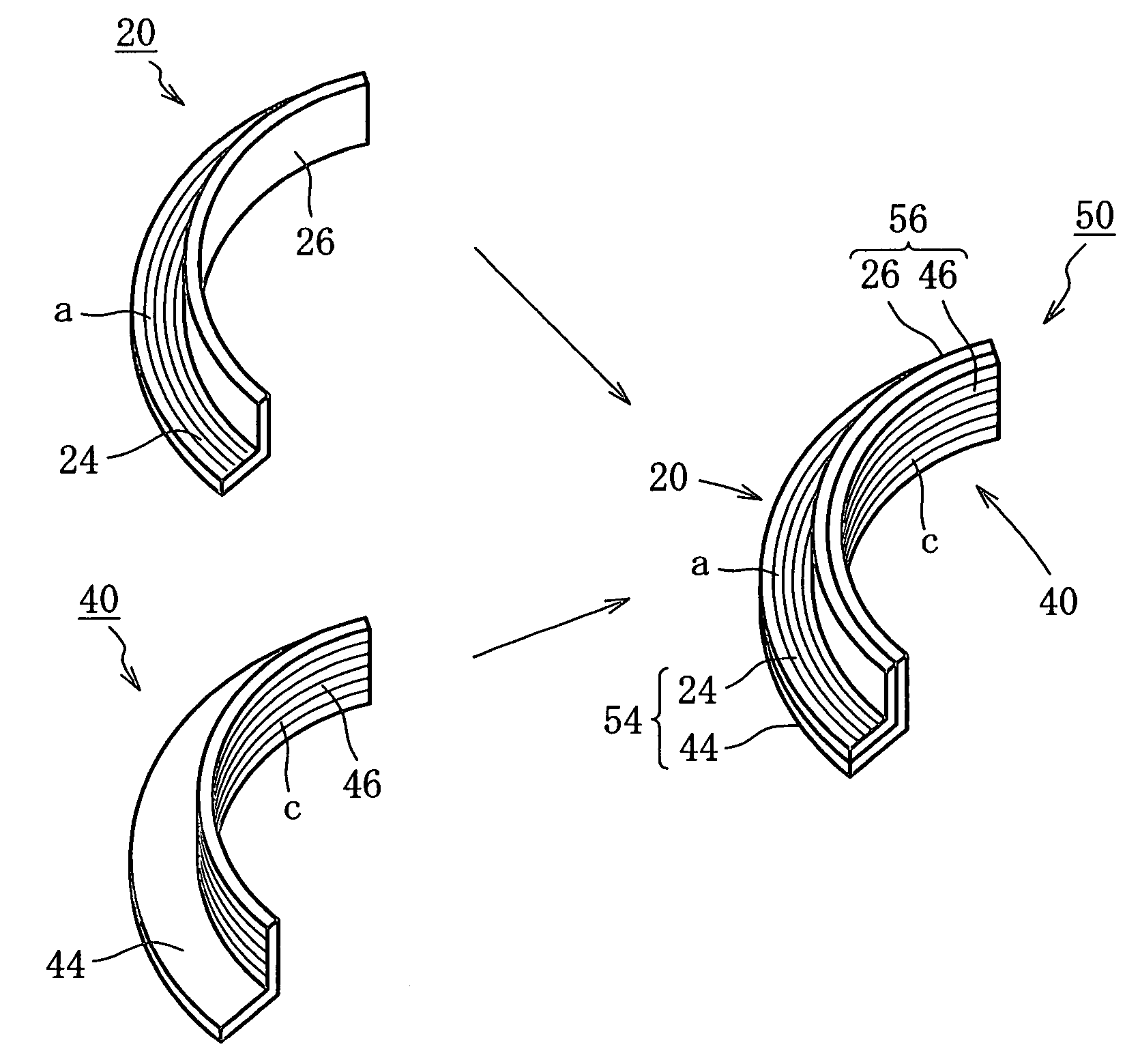

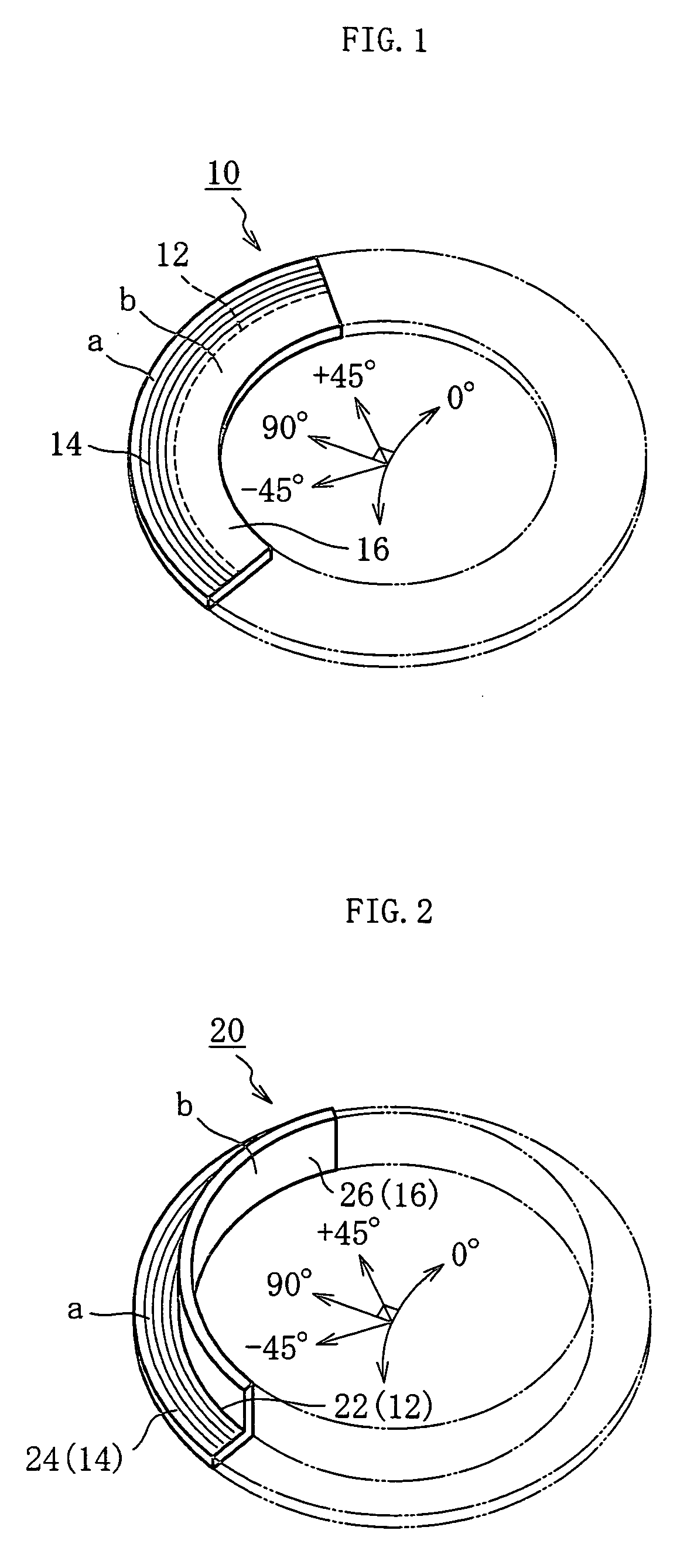

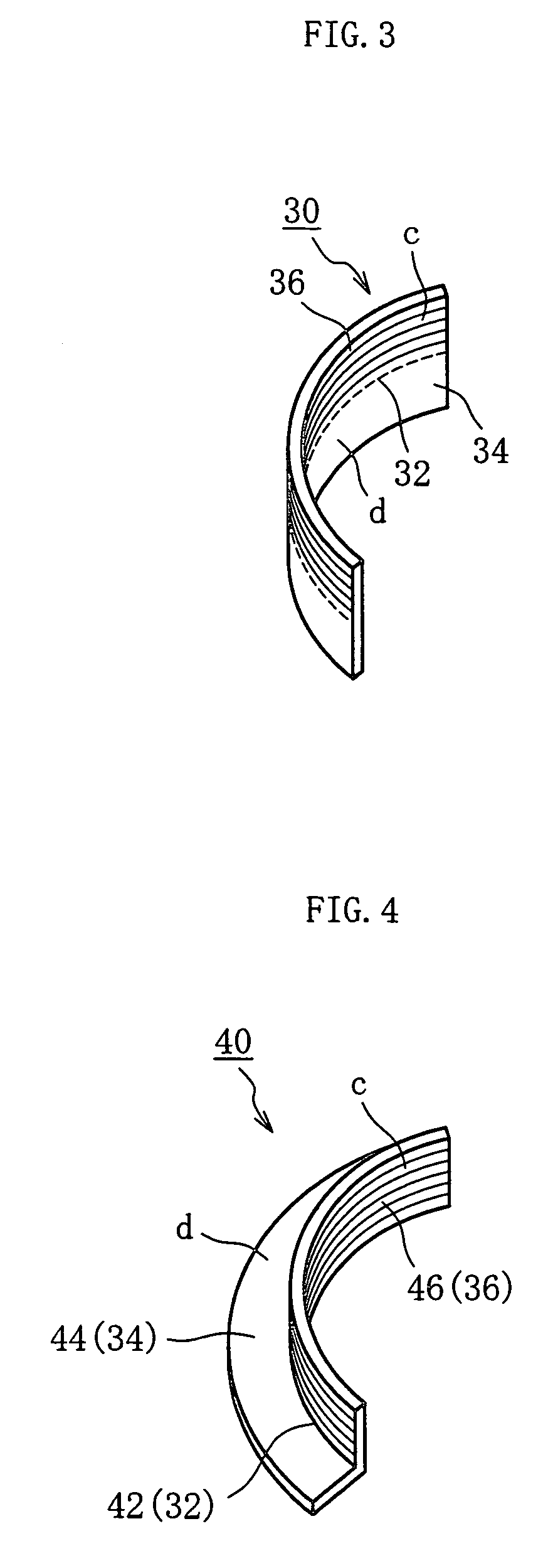

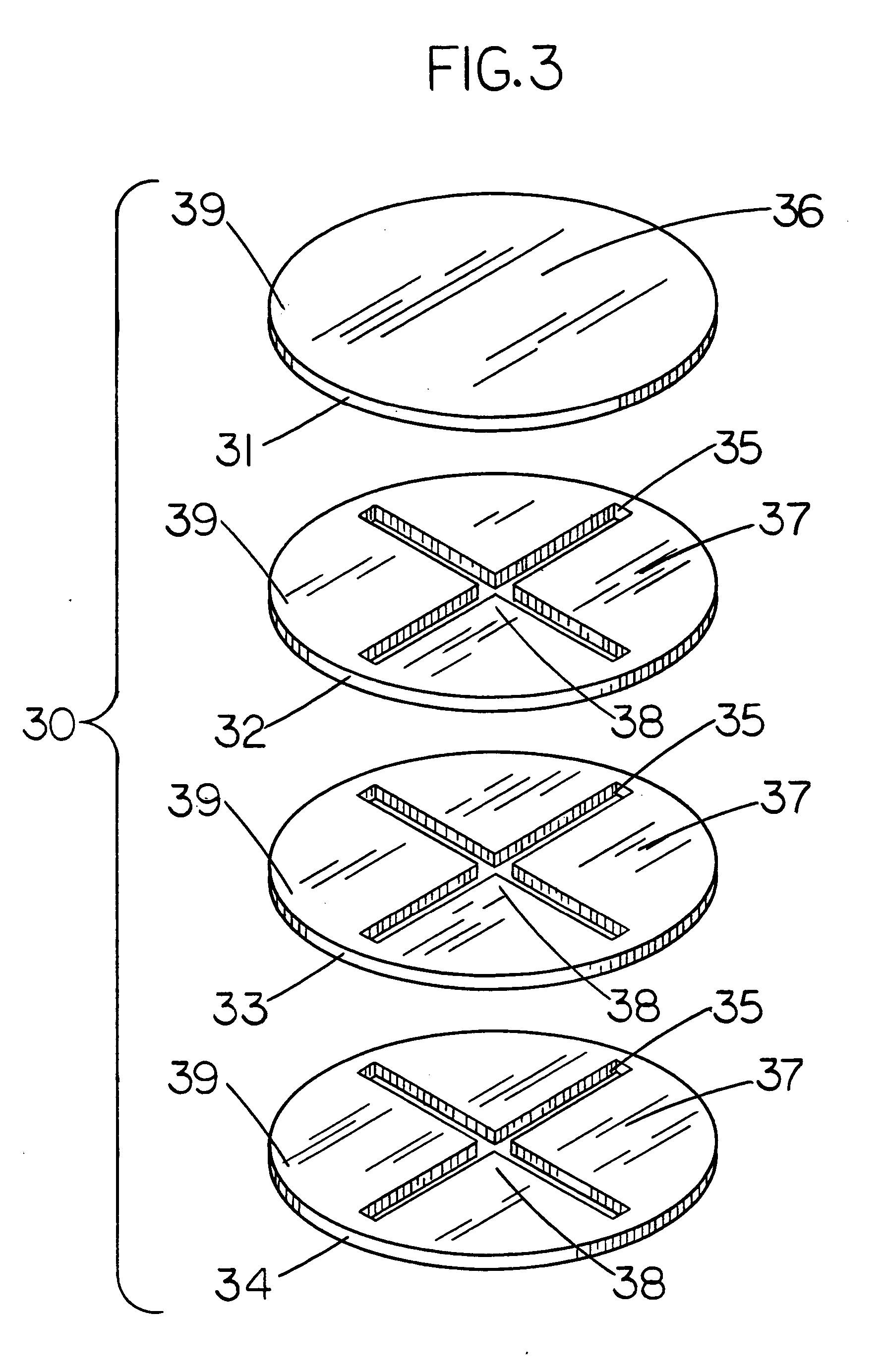

Preform precursor for fiber-reinforced composite material, preform for fiber-reinforced composite material, and method of manufacturing the precursor and the preform

InactiveUS20050042410A1Simple to executeEasy to bendEngine sealsLayered productsFiber-reinforced compositeMaterials science

Technical Field of the Invention: A structural member required to have a prescribed strength in an aircraft, an automobile, a vessel or a constructed structure, etc., especially in a circular bore portion or a curved portion such as a wing or a body of an aircraft. Technical Problem: A preform for a fiber-reinforced composite material to be used as a structural member of a fiber-reinforced composite material having a curved portion is to be manufactured through a low-cost mass production. Means of Solving the Problem A preform for a fiber-reinforced composite material (20) including a bent portion (22) along a curved line for bending (12), a flange portion (24) corresponding to an outer circumferential portion (14) and a semi-cylindrical portion (26) formed by bending an inner circumferential portion (16), based on a precursor of a preform for a fiber-reinforced composite material (10) provided with the curved line for bending (12) located in a flat plane or a curved plane region having a predetermined extension; the outer circumferential portion (14) corresponding to a region (a) where a plurality of reinforced fibers is partly disposed in parallel along the curved line for bending (12), and the inner circumferential portion (16) corresponding to the section (b) constituted solely of another plurality of reinforced fibers disposed throughout the entire area, so as to intersect the former plurality of reinforced fibers at a predetermined angle in the region (a). Principal Use: An aircraft, an automobile, a vessel, a constructed structure, etc. Especially a window frame or a fuel inlet of an aircraft.

Owner:SHIKIBO LTD

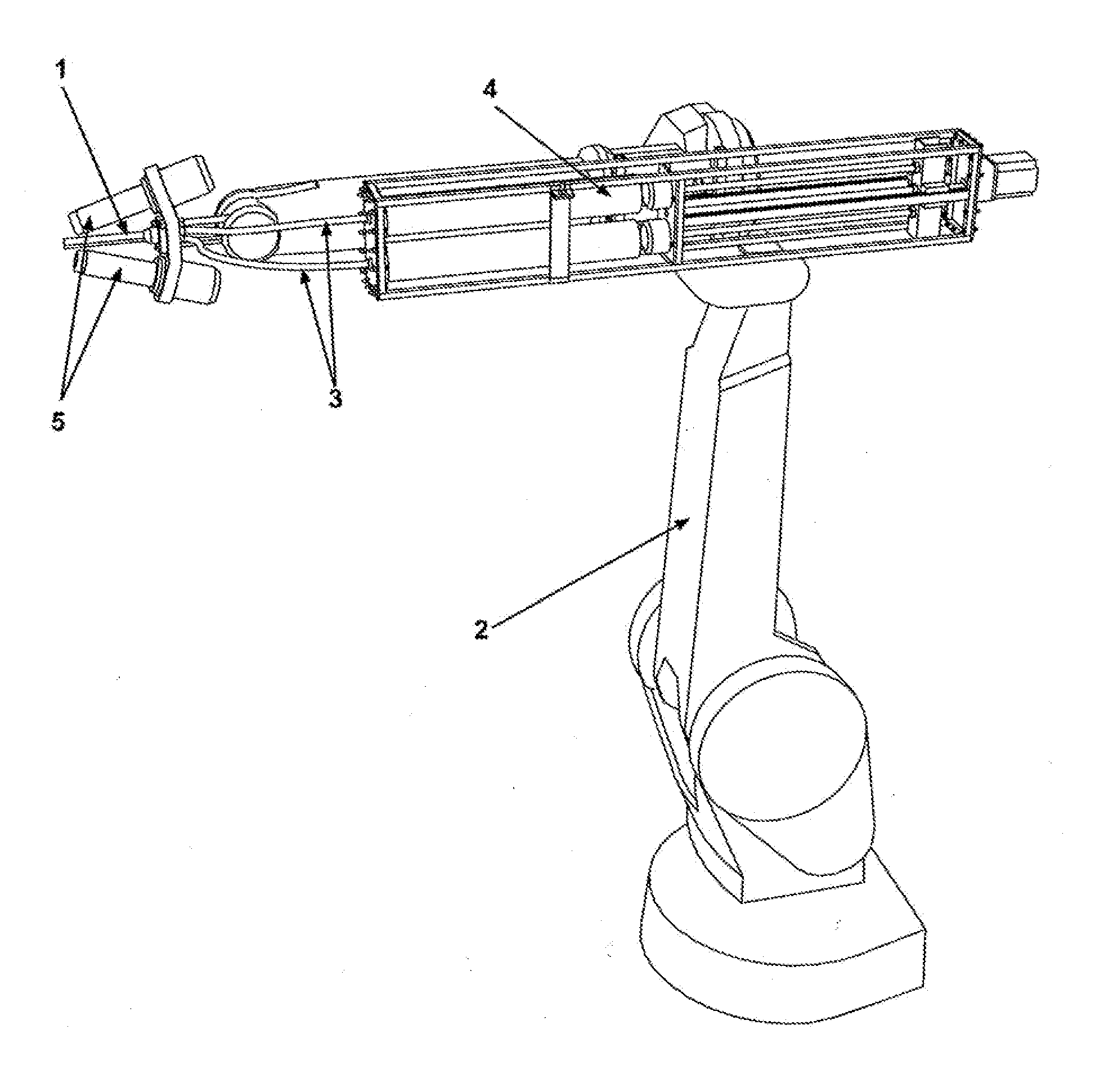

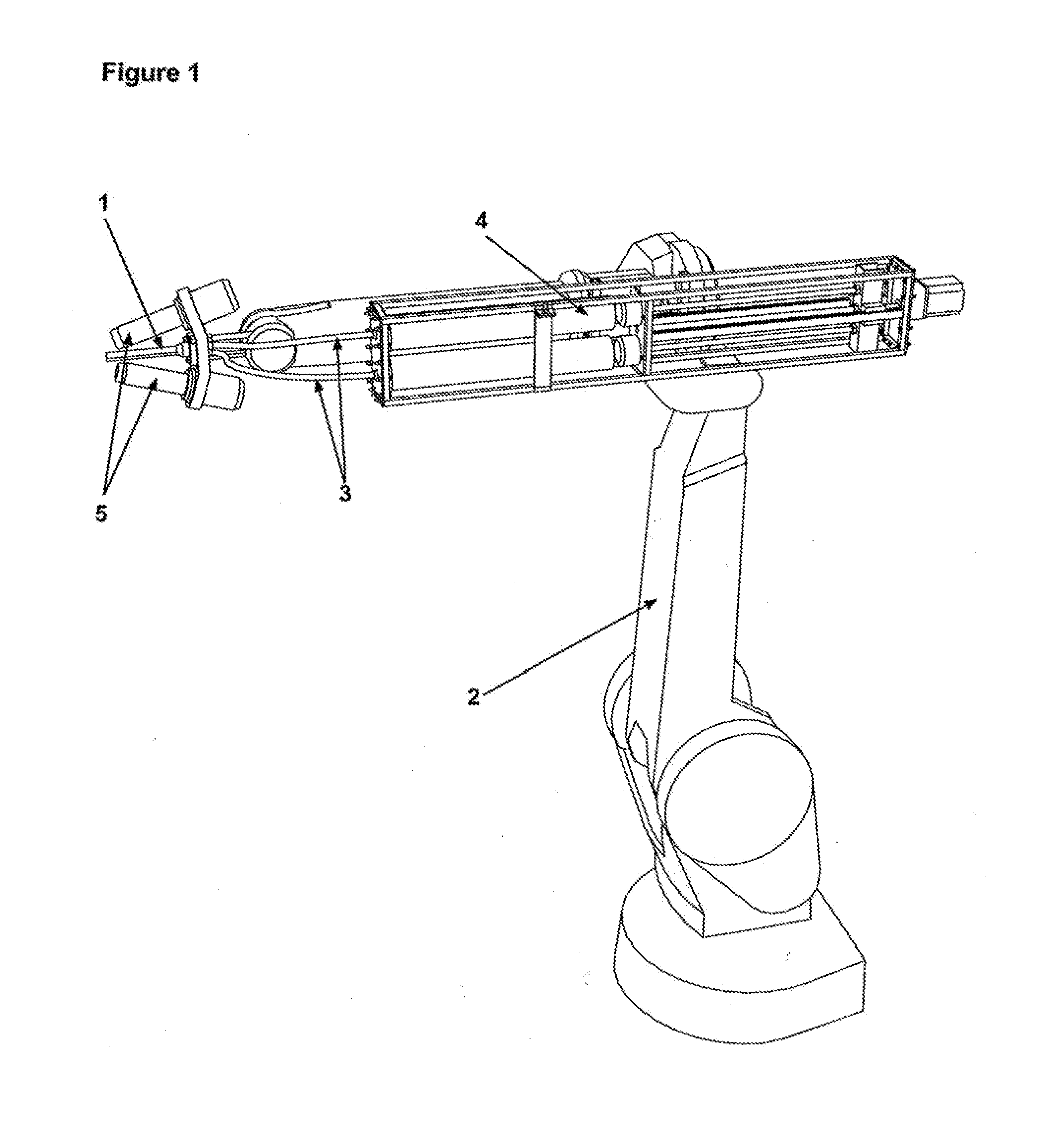

System and Method for Manufacturing a Three-Dimensional Object from Freely Formed Three-Dimensional Curves

InactiveUS20140284832A1Increase or decrease the speed of the extrusion of the source componentsIncrease or decrease thicknessAuxillary shaping apparatusAdditive manufacturing with liquidsEngineeringSurface geometry

A three-dimensional object is manufactured by forming a series of three-dimensional formed curves of extruded material that together comprise the geometry of the surface of the object. The material is extruded from a nozzle that is positioned by a robotic arm under the control of a robotic controller. A computer that has a definition of the geometric surface generates commands to the robotic controller to cause it to sequentially form the series of formed curves that the computer calculates comprise the surface geometry.

Owner:NOVIKOV PETR +1

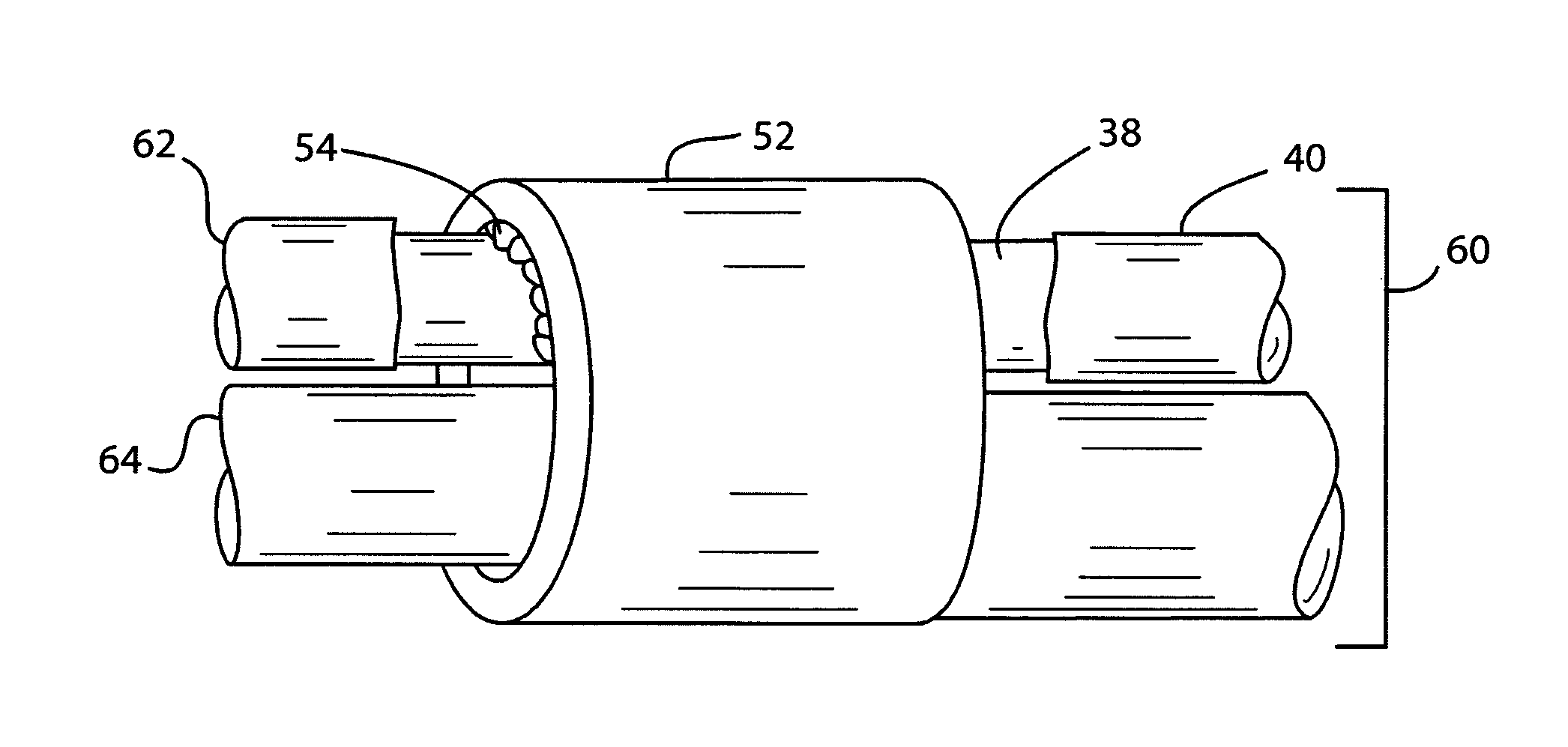

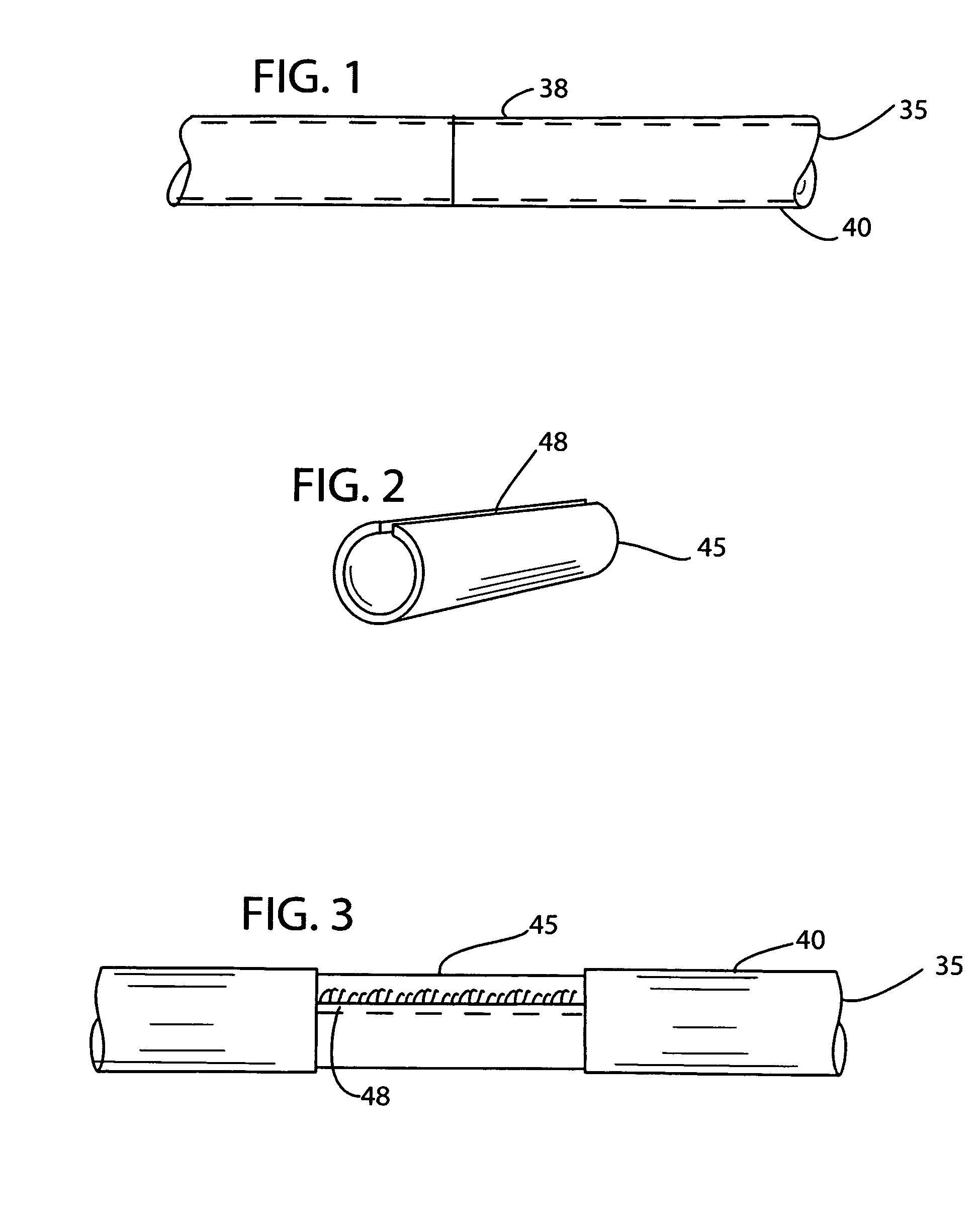

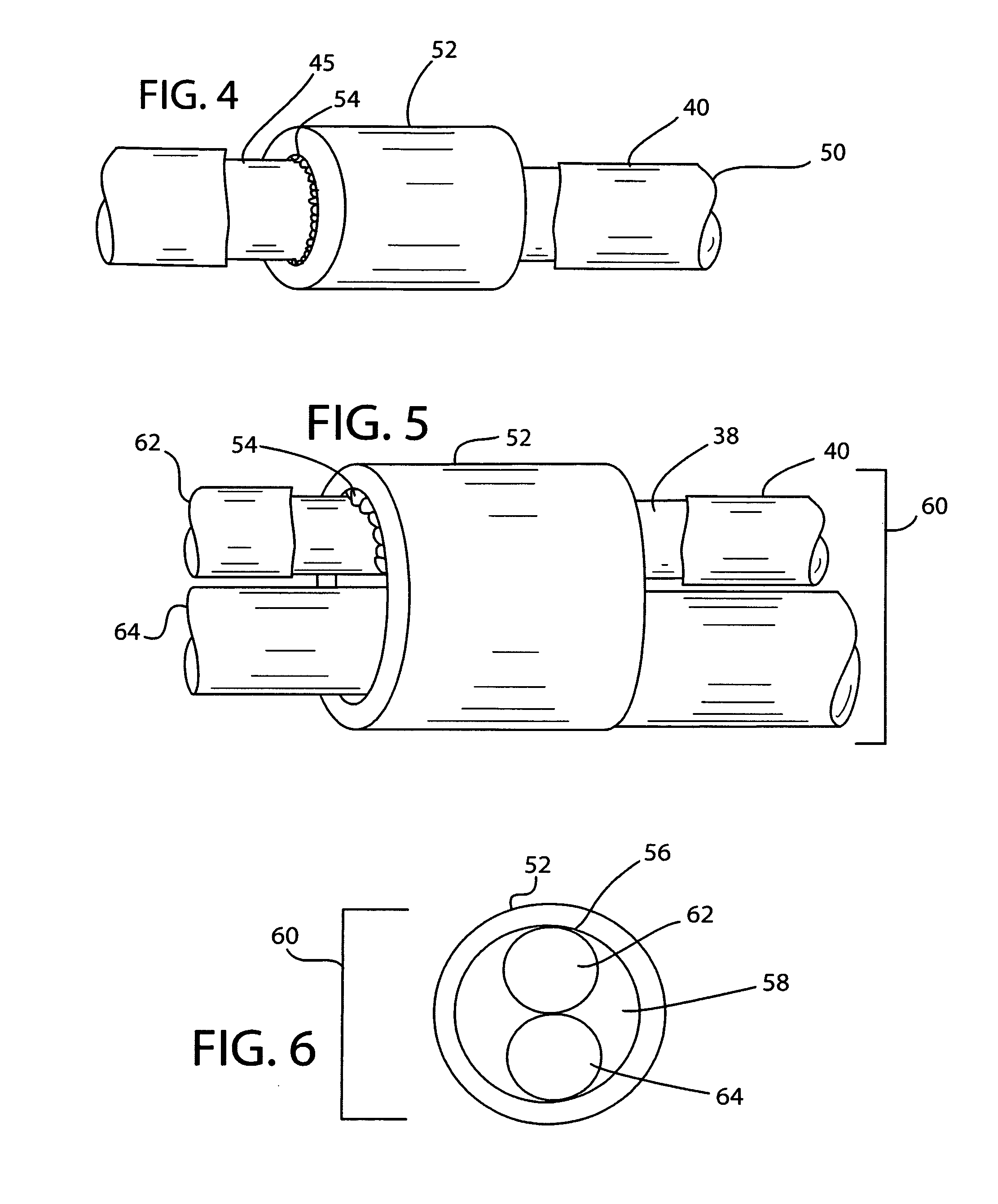

Electrode and connector attachments for a cylindrical glass fiber wire lead

InactiveUS20110220408A1Improve conductivityLow electrical resistanceSpinal electrodesLine/current collector detailsFine lineElectrical conductor

A cardiac pacemaker or other CRT device has one or more fine wire leads to the heart. Formed of a glass, silica, sapphire or crystalline quartz fiber with a metal coating, a unipolar lead can have an outer diameter as small as about 300 microns or even smaller. The metal buffer coating may be deposited directly on the glass / silica fiber, or upon an intermediate layer between the glass / silica fiber and metal, consisting of carbon and / or polymer. The resulting metallized glass / silica fibers are extremely durable, can be bent through small radii and will not fatigue even from millions of iterations of flexing. Bipolar fine wire leads can include several insulated metallized glass / silica fibers residing side by side, or can be coaxial with two or more insulated metal conductive paths. An outer protective sheath of a flexible polymer material can be included. The fine wire lead incorporates a thin metal conductor, which poses unique challenges for attachment to standardized connectors, as well as stimulation electrodes. The present invention describes means and materials for creating robust and durable electrically conductive connections between the fine wire lead body and a proximal standardized connector and distal ring and tip electrodes.

Owner:CARDIA ACCESS

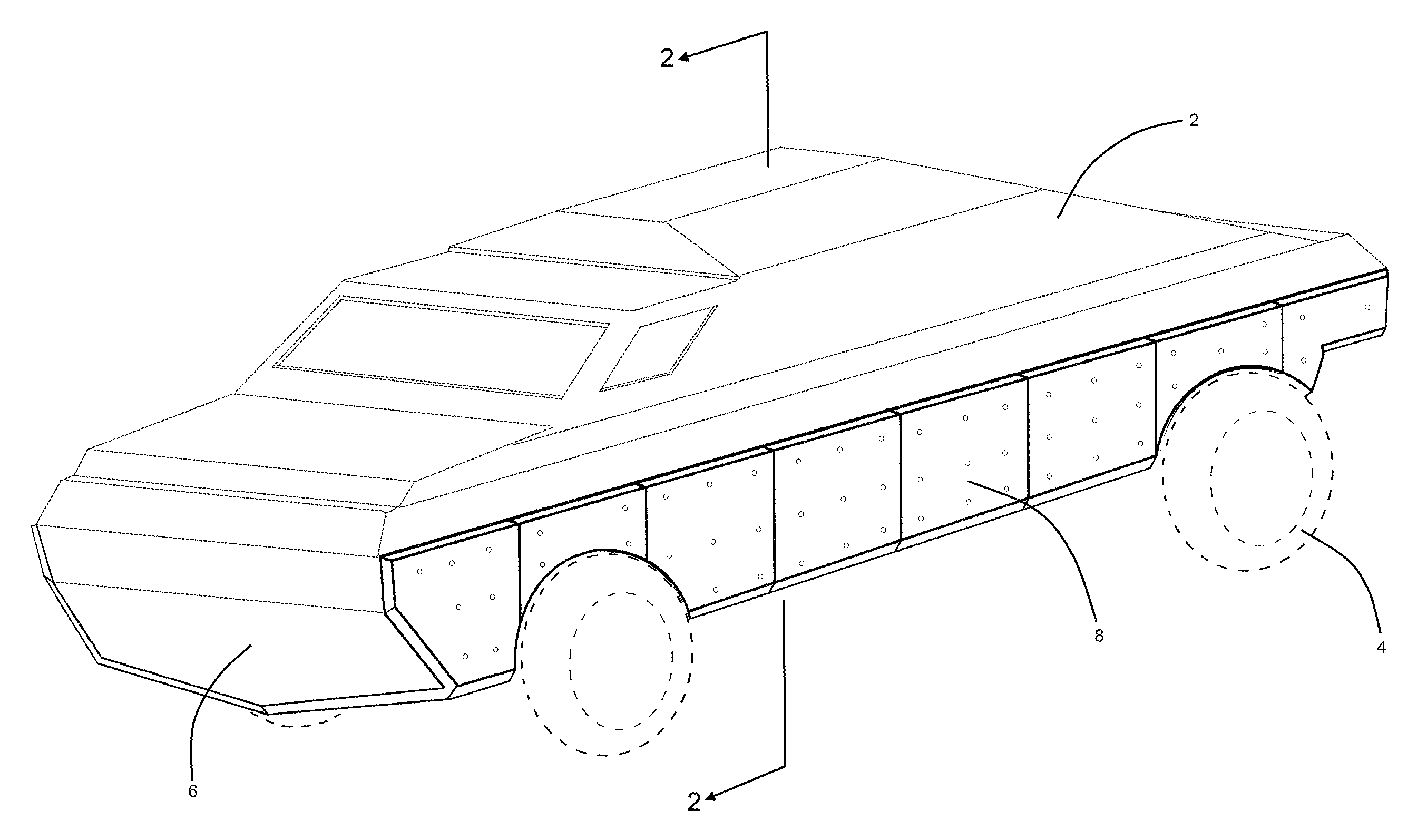

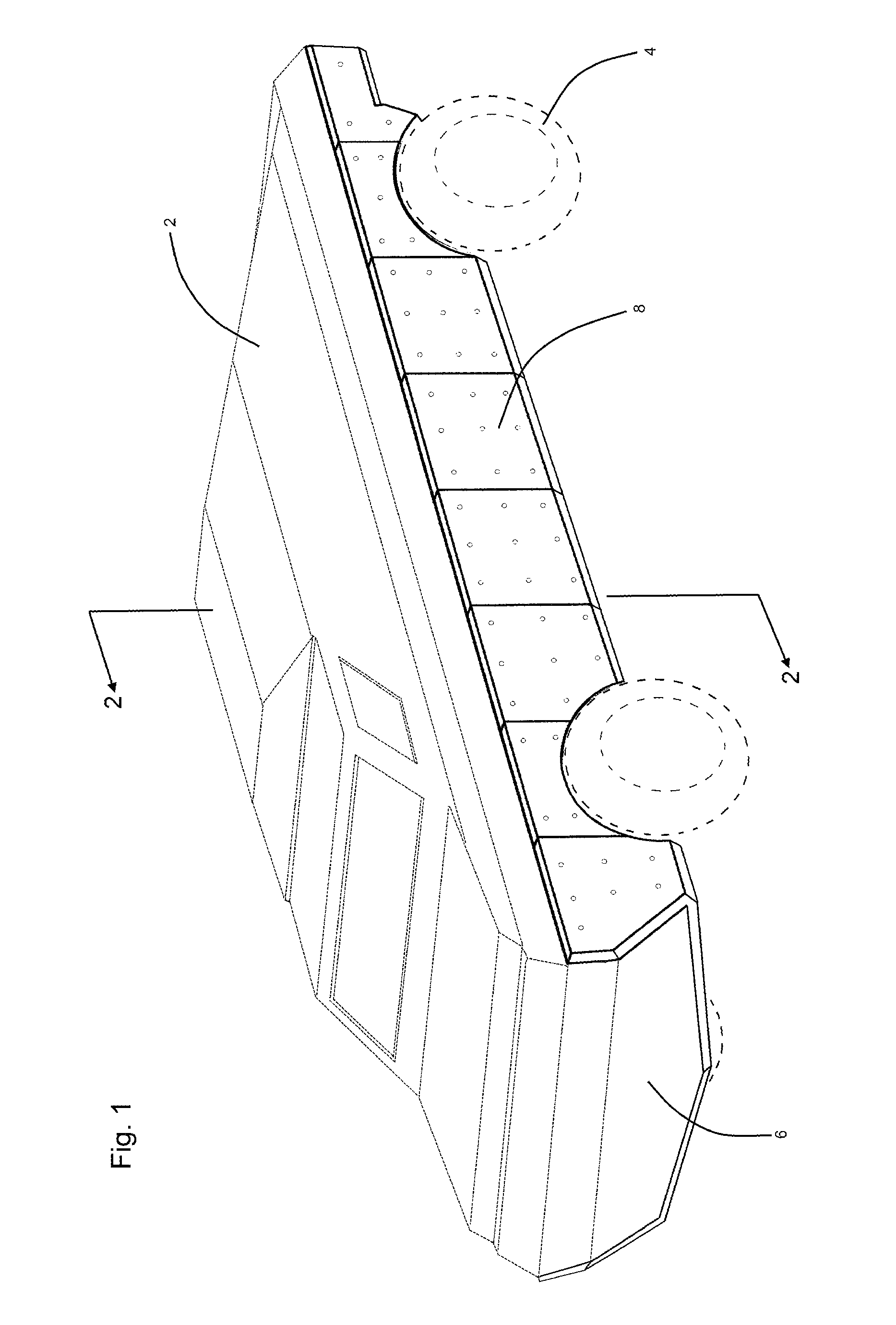

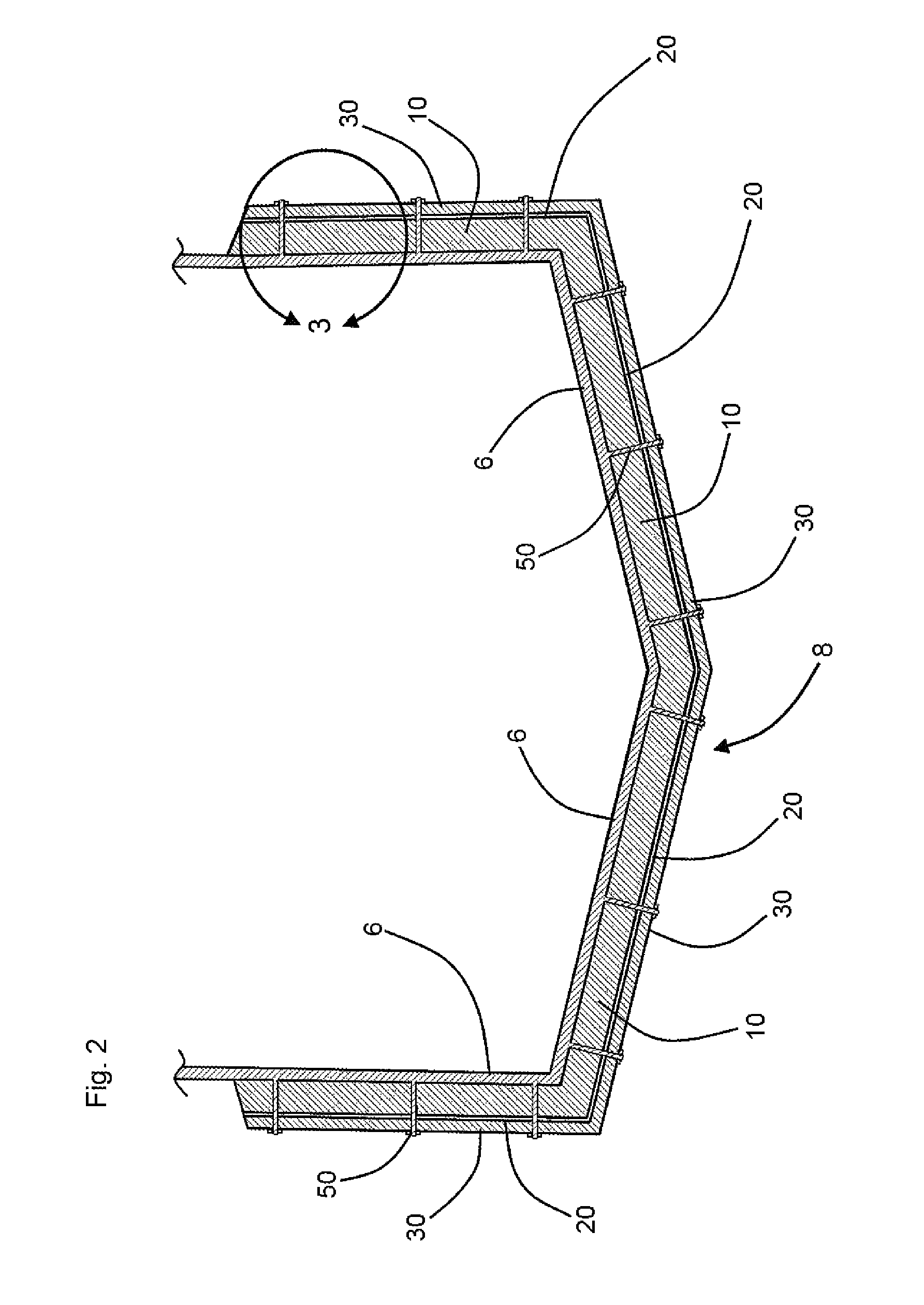

Assembly for armoring an amphibious vehicle against projectile penetrations

ActiveUS8596183B2Improve abilitiesMaximizing buoyancyAmphibious vehiclesDefensive equipmentEngineeringLow density

An assembly for armoring an amphibious vehicle against projectile penetrations, the amphibious vehicle having a hull, the assembly including a rigid spall generating sheet, the rigid spall generating sheet having a thickness and an outer surface; a buoyant sheet fixedly attached to and extending inwardly from the rigid spall generating sheet; and a multiplicity of fasteners interconnecting the rigid and buoyant sheets with the amphibious vehicle's hull, the buoyant sheet incorporating a low density, nonabsorbent hardened foam material; the buoyant sheet functioning for vehicle buoyancy enhancement and for defining a spall dispersal space overlying the hull and underlying the rigid spall generating sheet.

Owner:LEADING TECH COMPOSITES

Preform precursor for fiber-reinforced composite material, preform for fiber-reinforced composite material, and method of manufacturing the precursor and the preform

InactiveUS7138167B2Easy to bendSimple compositionEngine sealsLayered productsFiber-reinforced compositeMaterials science

A preform for a fiber-reinforced composite material including a bent portion along a curved line for bending, a flange portion corresponding to an outer circumferential portion, and a semi-cylindrical portion formed by bending an inner circumferential portion along the curved line for bending located in a flat plane or a curved plane region. The preform is formed from a precursor having a predetermined extension. The outer circumferential portion corresponds to a first region where a first plurality of reinforced fibers is partially disposed in parallel along the curved line for bending. The inner circumferential portion corresponds to a second region constituted solely of a second plurality of reinforced fibers disposed throughout the entire area, so as to intersect the first plurality of reinforced fibers at a predetermined angle in the first region.

Owner:SHIKIBO LTD

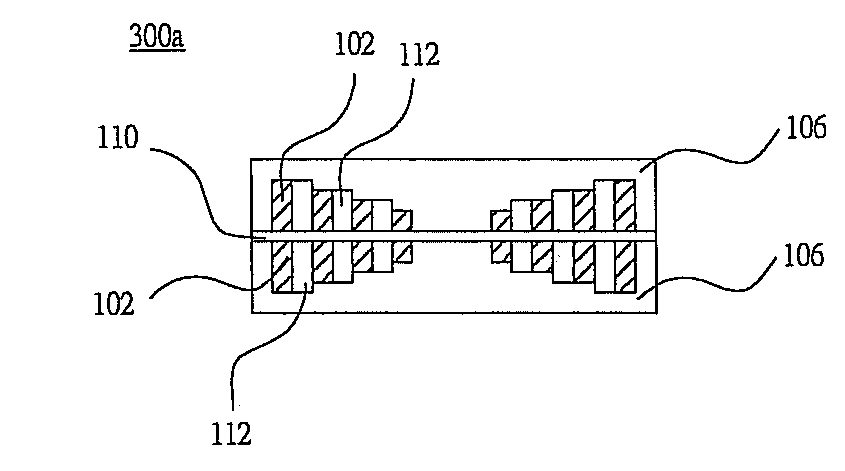

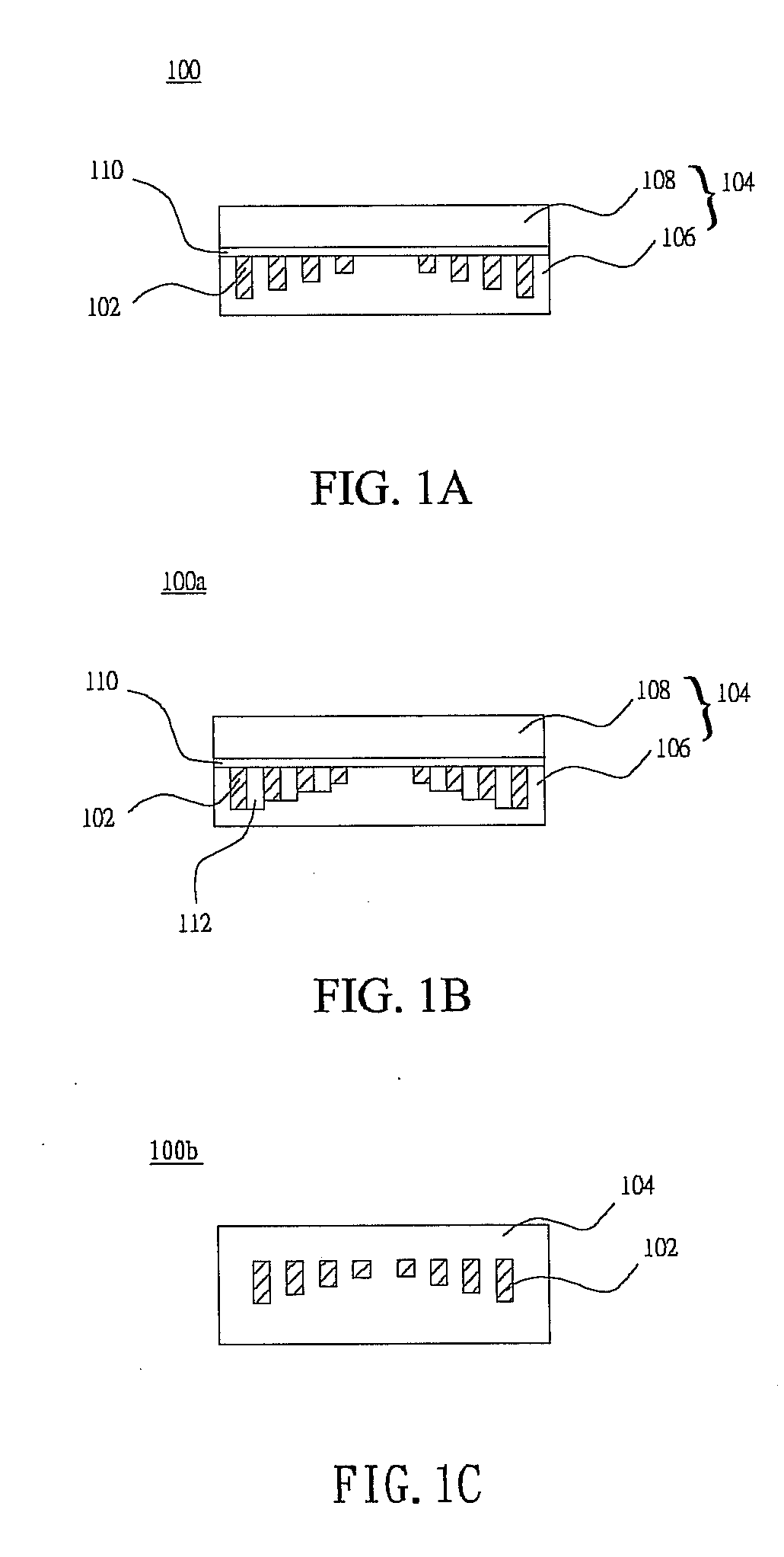

Magnetic component

InactiveUS20090322458A1High-quality factorImprove performanceTransformers/inductances detailsInductances/transformers/magnets manufactureElectrical and Electronics engineeringMagnetic components

Owner:DELTA ELECTRONICS INC

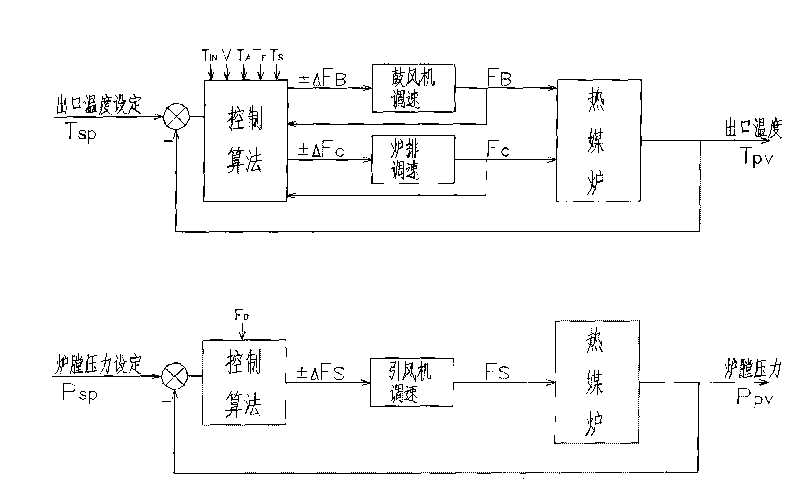

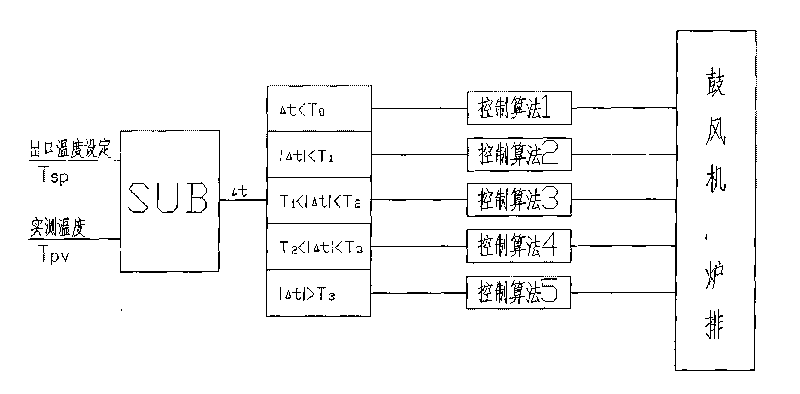

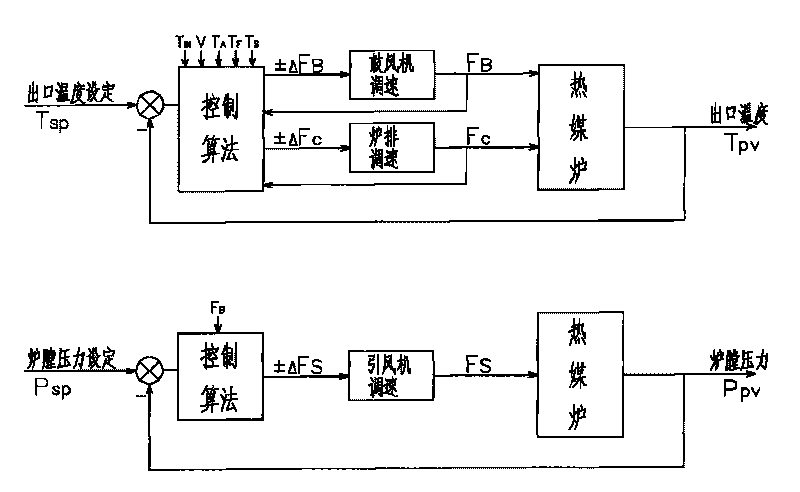

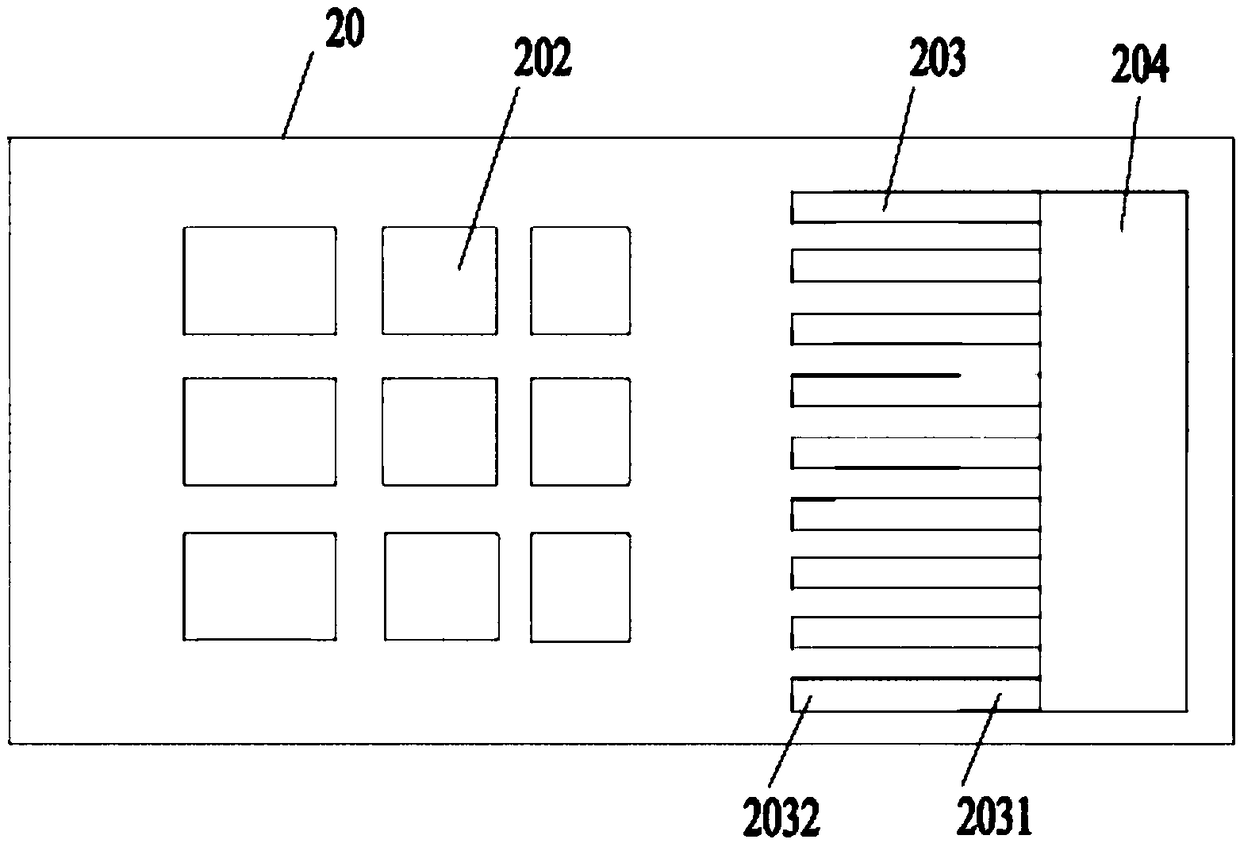

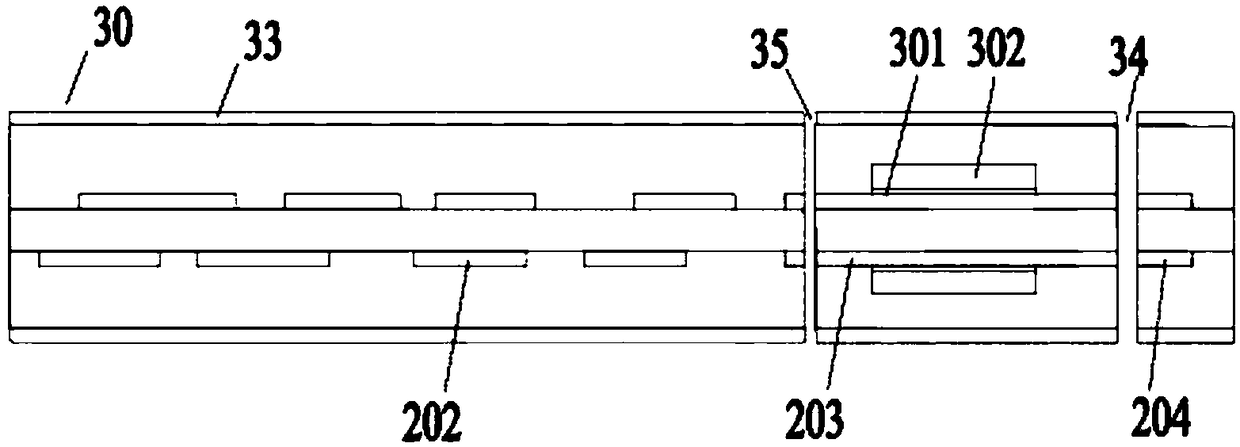

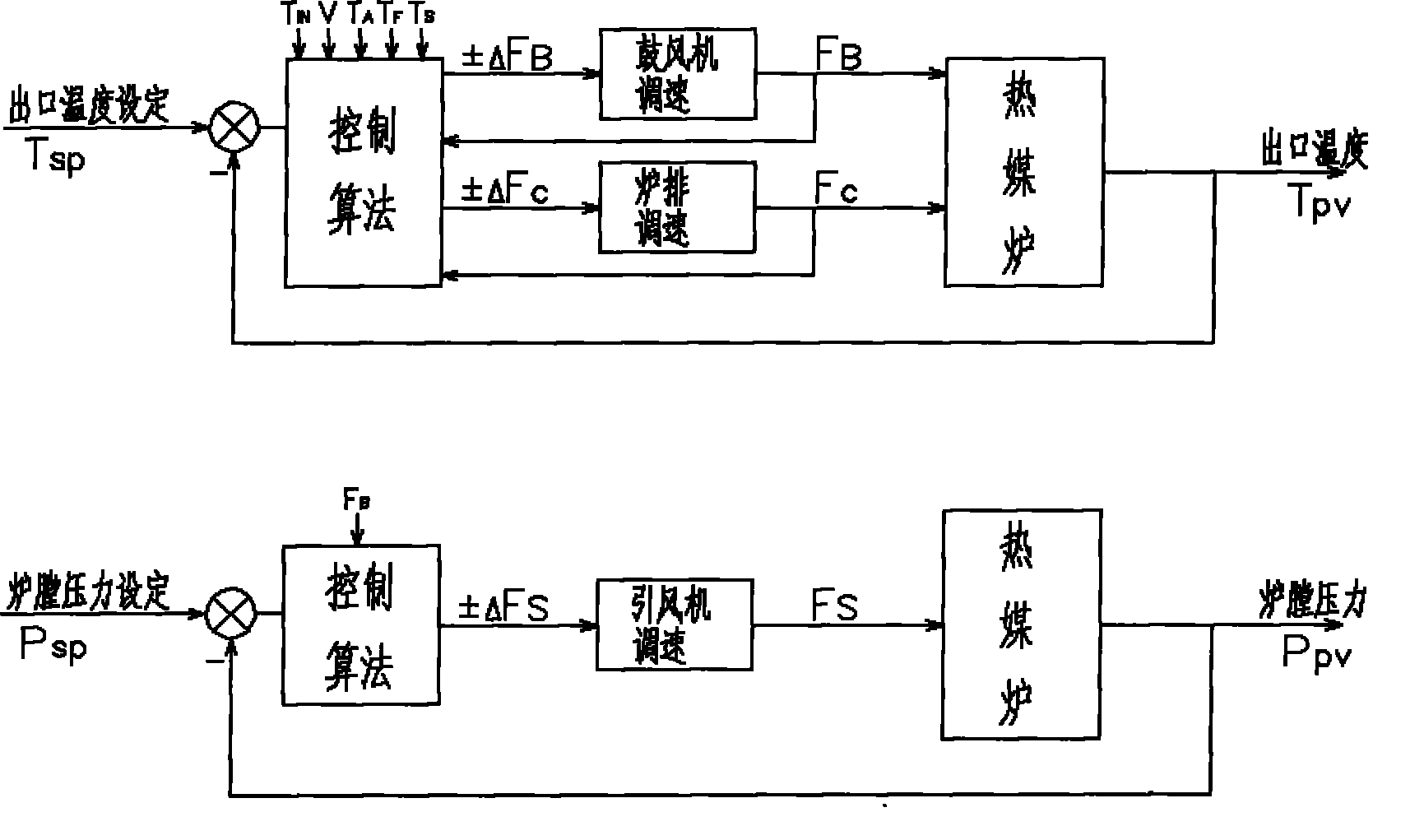

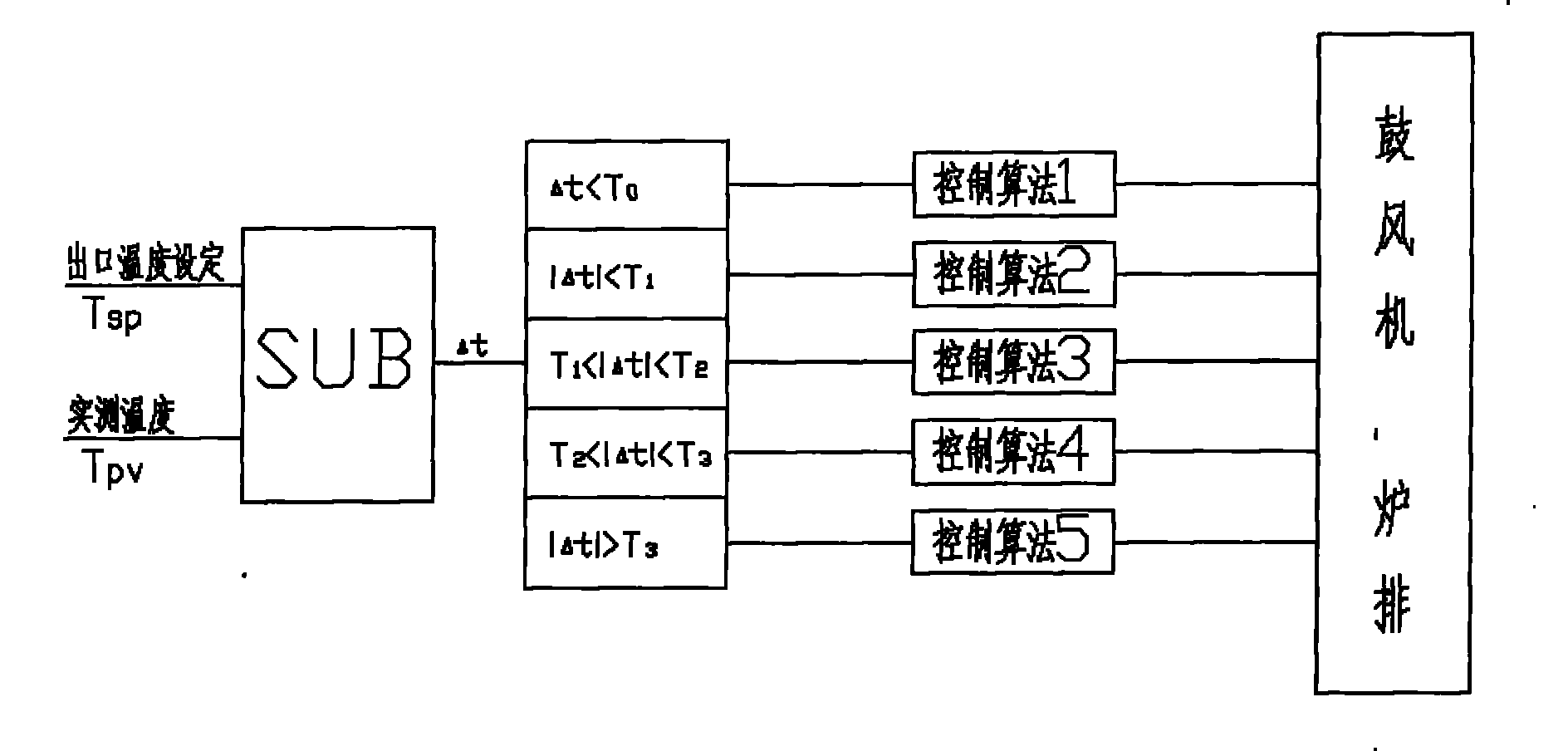

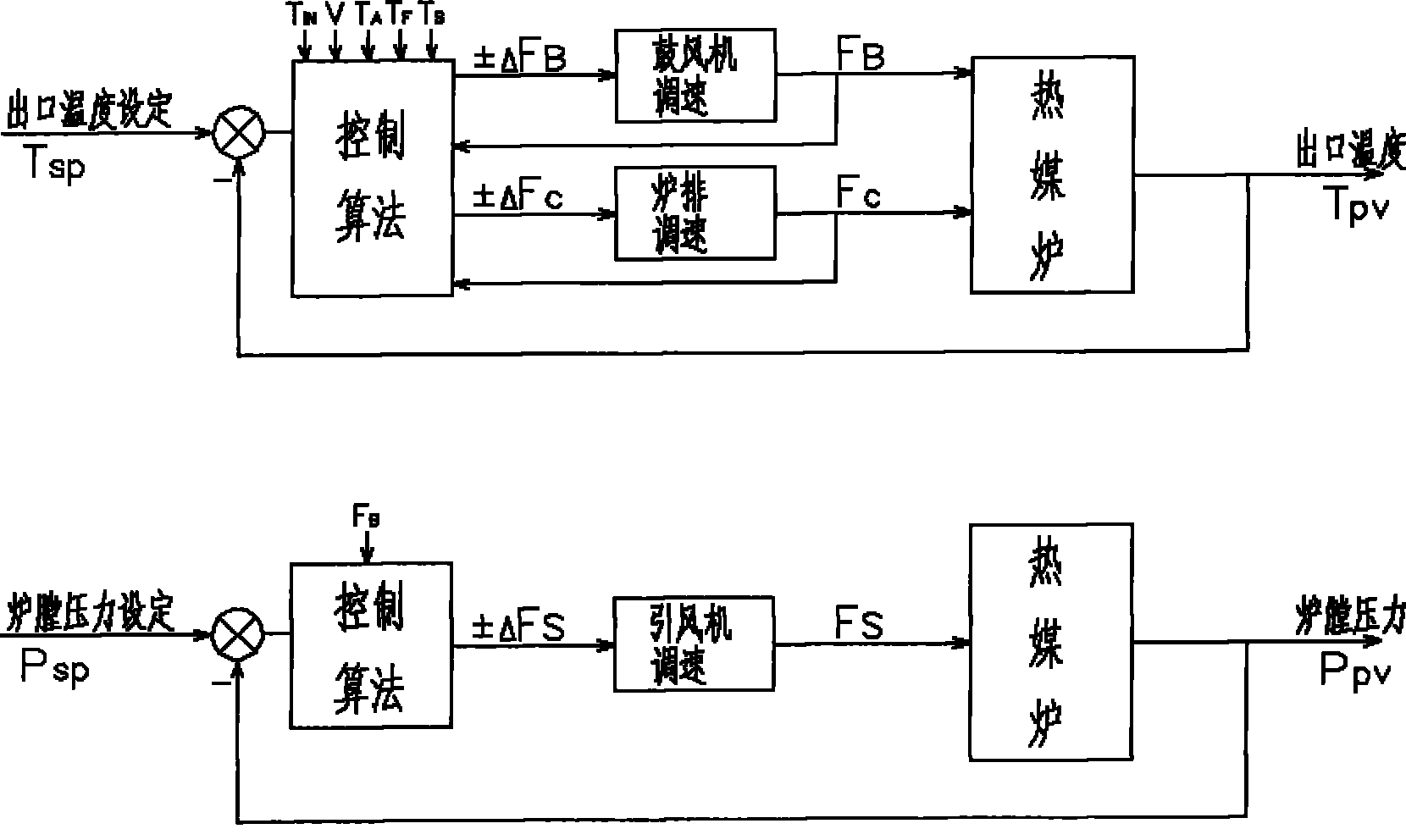

Coal burning heat medium furnace high-precision temperature regulation and combustion control method

ActiveCN101749730AHelp with troubleshootingImprove combustion efficiencyFuel supply regulationAutomatic controlEngineering

The invention provides a coal burning heat medium furnace high-precision temperature regulation and combustion control method and relates to the technical field of DCS industrial control systems, in particular to large-scale chain coal bed burning heat medium furnace (heat medium furnace for short) high-precision temperature regulation and combustion control. As is generally known, the temperature control of the coal burning heat medium furnace depends on the combustion control of the coal burning heat medium furnace. Therefore, a suitable sensor and a suitable transmitter are used to obtain parameters which influence the combustion and the heat medium outlet temperature in the burning process; the factors which influence the combustion and the heat medium outlet temperature are treated differentially and destroyed by adopting multi-circuit regulation when grasping main problems, thus avoiding interaction among the steps; the control algorithm adopts sectional control, feed-forward control and self-adaptive control on the basis of normal PID. According to the scheme, the influence of nonlinearity, much interference, large lag and the like can be overcome, thus realizing automatic control in the heating process and automatic regulation in normal heating, and the actual control precision of the heat medium outlet temperature can achieve plus or minus 0.7DEG C.

Owner:CHINA SHIPPING NETWORK TECH

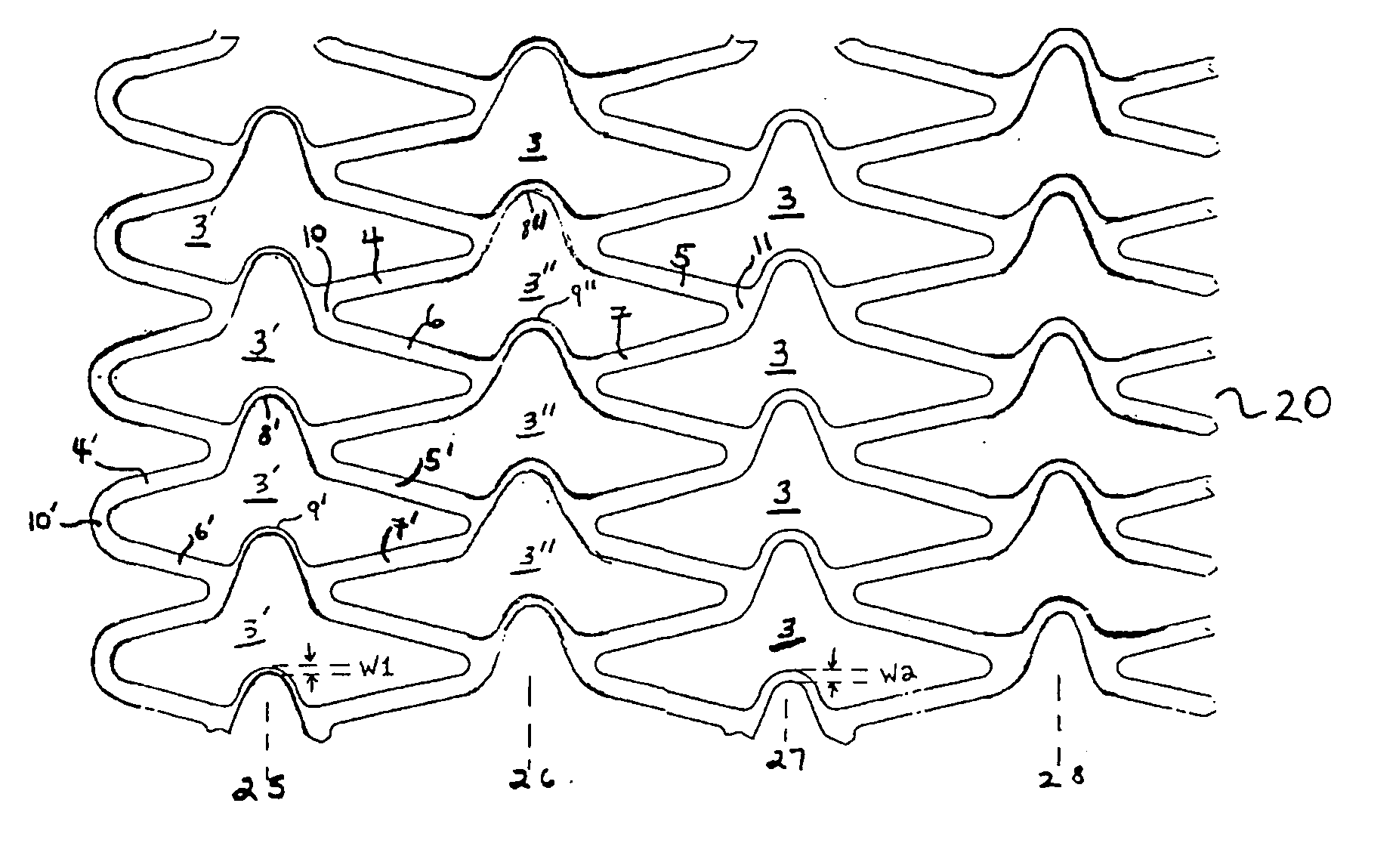

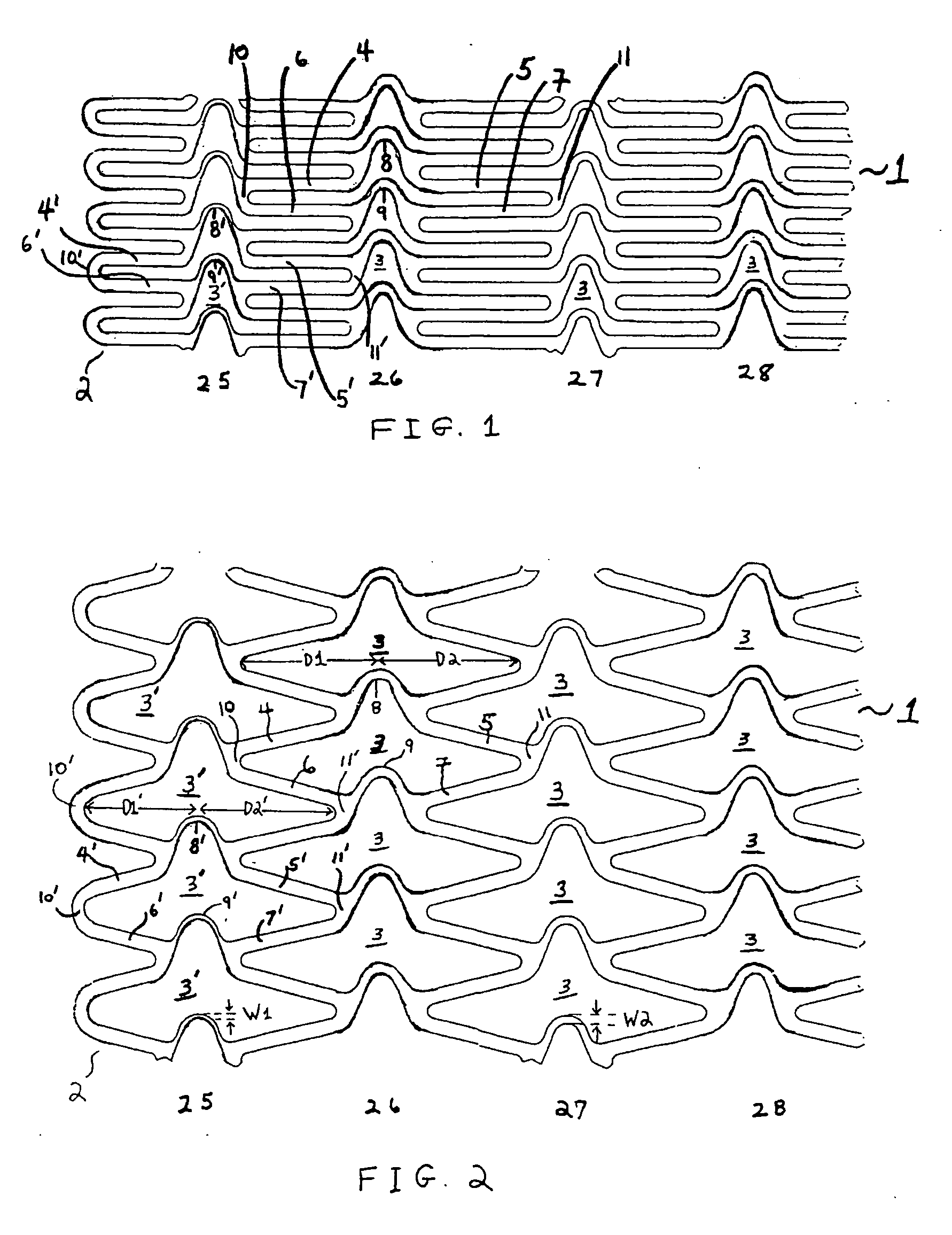

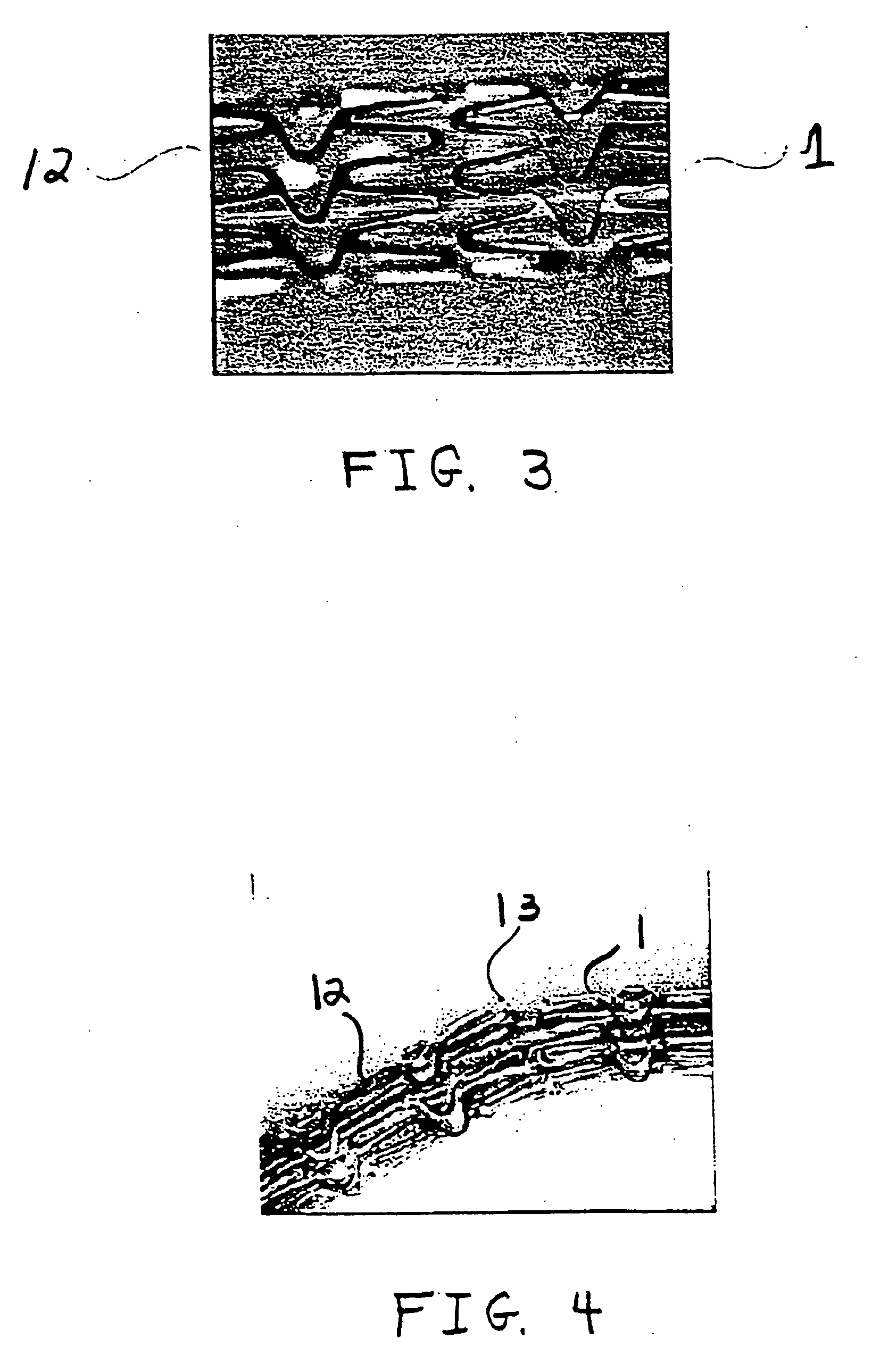

Stent with variable features to optimize support and method of making such stent

InactiveUS20060173531A1Improve final performanceIncrease or decrease thicknessStentsSurgeryVariable featuresInsertion stent

An intravascular stent especially suited for implanting in lumens having variable characteristics such as curvatures, changing diameters as found in ostial regions or variable wall compliance during systolic cycles. The stent can include an end region which is fabricated to have a greater radial strength than the remaining axial length of the stent. Such a stent is particularly suited for use in ostial regions, which require greater support near the end of the stent. The stent alternatively can include sections adjacent the end of the stent with greater bending flexibility than the remaining axial length of the stent. Such a stent is particularly suited for use in curved arteries. The stent can be constructed with an end that has greater radial strength and sections adjacent the end with greater bending flexibility. Such a stent prevents flaring of the stent end during insertion. The stent can also be constructed to have increased longitudinal flexibility when expanded such that it flexes with the vessel wall during systolic cycles.

Owner:MEDINOL LTD

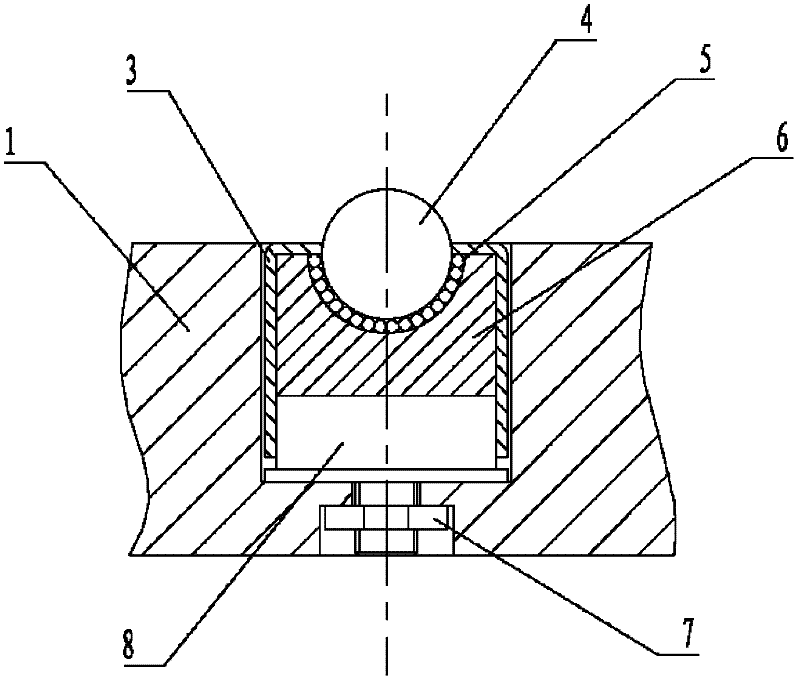

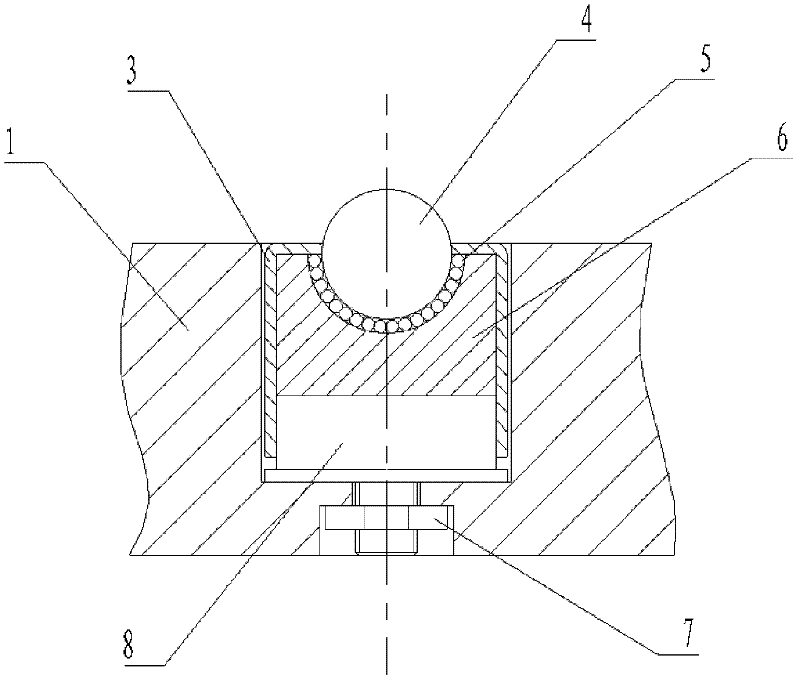

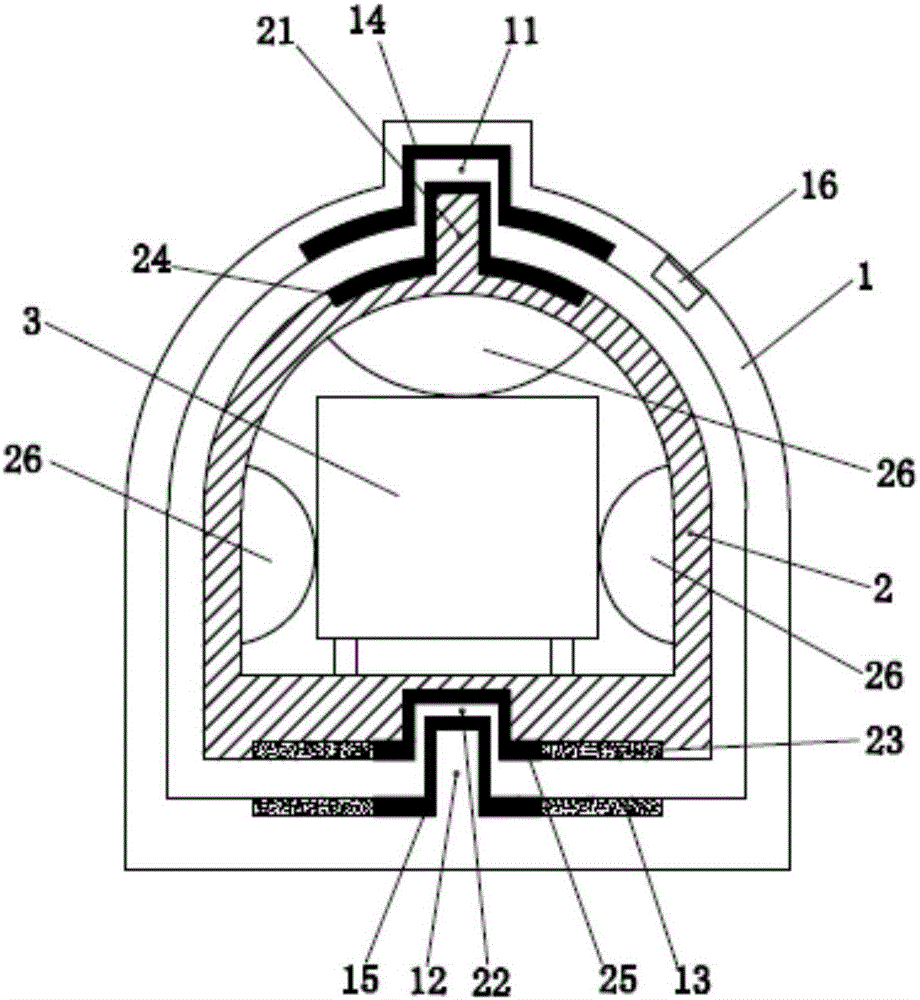

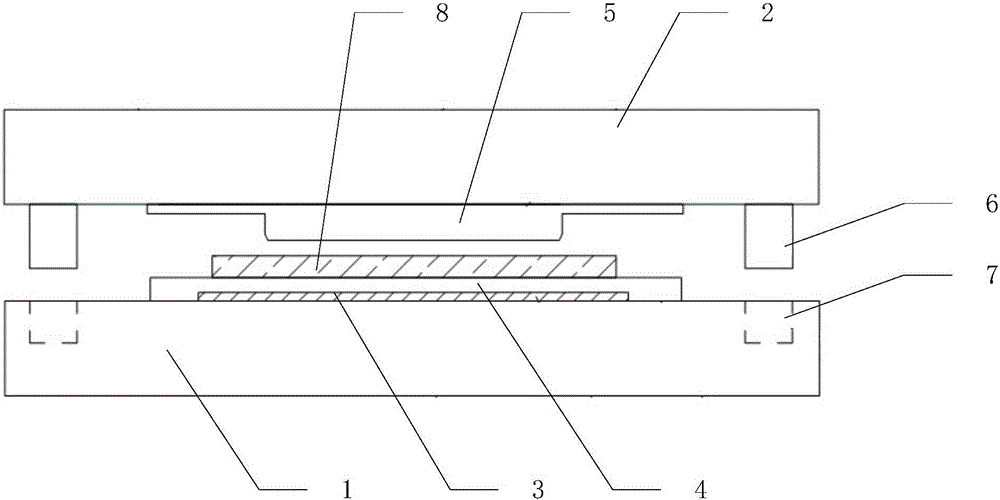

Dynamic grounding pressure test device

ActiveCN102445300AIncrease or decrease thicknessAdjust exposed volumeInflated body pressure measurementInterference fitData acquisition

The invention provides a dynamic grounding pressure test device for a tyre. The dynamic grounding pressure mainly comprises a test platform, piezoelectric pressure sensors, a data acquiring and processing system and universal ball seats. A certain amount of stepped holes are formed on the upper surface of the test platform and are arranged in an array manner, the piezoelectric pressure sensors are arranged in the stepped holes, a universal ball seat is arranged on the upper part of a shell of each of the pressure sensors and consists of a universal ball, a ball, a fixed sleeve and a base, a flat plate is arranged at the upper end of each fixed sleeve, a round hole is formed at the center of each flat plate, the diameter of each round hole is smaller than that of each universal ball, and an extension part at the lower end of each fixed sleeve is in interference fit with the shell of the corresponding pressure sensor to make the corresponding universal ball seat fixed on the correspoding pressure sensor. The dynamic grounding pressure test device for the tyre can be used for measuring static or dynamic grounding pressure distribution of the tyre, does not limit the rotational speed and a rolling plane of the tyre, and makes a simulation environment more authentic and measuring data more accurate.

Owner:BEIJING UNIV OF CHEM TECH

A kind of organic matter-coated slow-release fertilizer and preparation method thereof

InactiveCN102276357AExcellent physical controlled release performanceIncrease or decrease thicknessFertilizer mixturesParticulatesRelease time

The invention discloses an organic matter-coated slow-release fertilizer and a preparation method thereof. The slow-release fertilizer is prepared from the following raw materials in terms of mass percentage: 10%-70% organic matter solid powder, 2%-20% solidified binder and 10% to 88% granular fertilizer. The invention uses the organic solid powder coating material to make the organic coated slow-release fertilizer have the advantages of no solvent recovery, no drying, fast film formation, abundant and cheap sources of coating materials in the production process, and can be produced by open conventional equipment. The organic matter-coated slow-release fertilizer of the invention has excellent physical controlled-release performance, and the fertilizer effect can exceed 100 days, and the controlled-release time can be adjusted as required. At the same time, the coating material used can not only degrade in the soil but also supplement high-quality organic matter to the soil, avoiding the possible soil acidification caused by sulfur coating and the residue problems caused by resin coating, which is more friendly to the environment. It is suitable for planting fields such as agriculture and forestry.

Owner:SOUTH CHINA AGRI UNIV

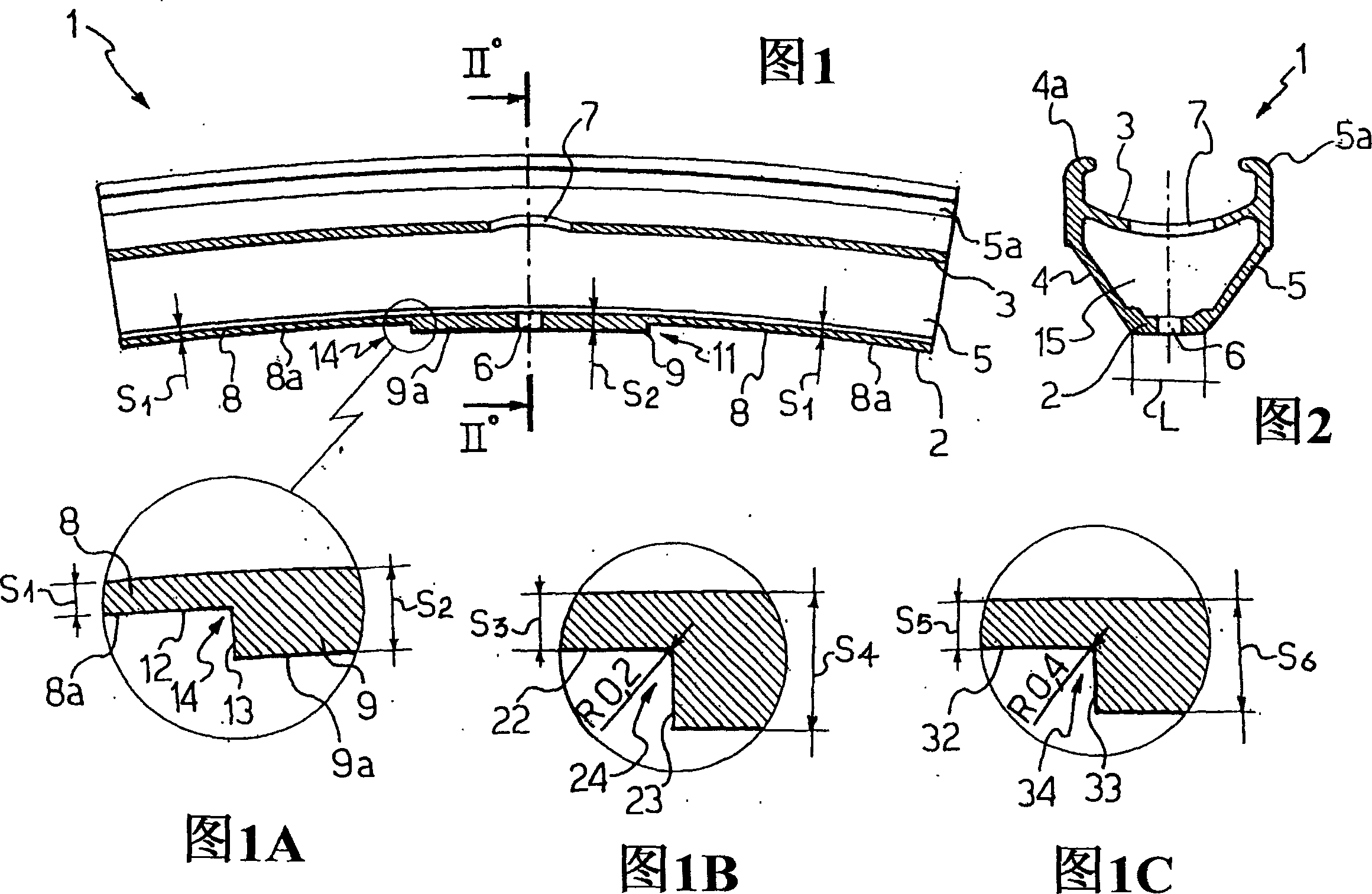

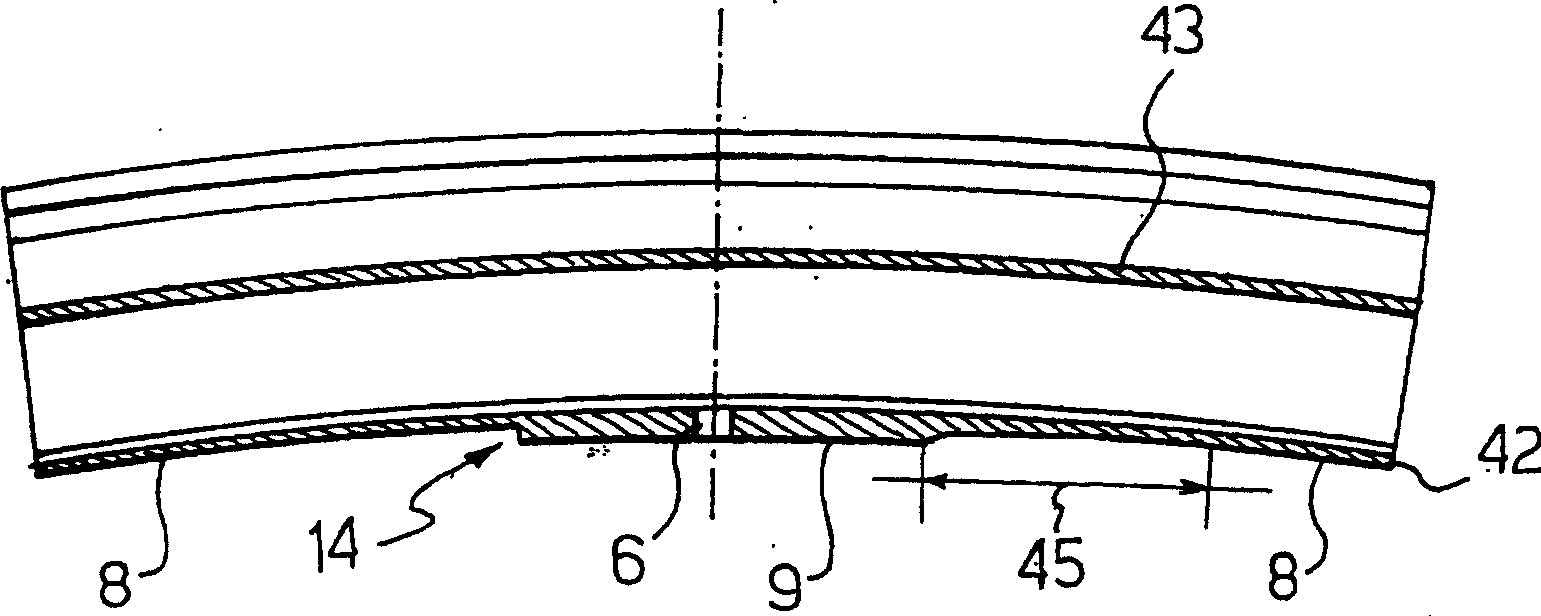

Lightened rim for a bicycle wheel and method for manufacturing such a rim

The rim has a lower bridge (2) and side walls with spoke attachment zones (9) having a predetermined thickness. Infra-spoke zones (8) are placed between the spoke attachment zones. The increase in thickness between an infra-spoke zone (8) and the adjacent spoke attachment zone (9) or the decrease in thickness between the zone (9) and the zone (8) has a very sharp progression and a sharp corner (14, 11). Independent claims are also included for the following: (a) a bicycle wheel comprising a rim (b) a method for forming zones of reduced thickness in the lower bridge or in the side walls of a rim of a bicycle wheel.

Owner:CAMPAGNOLO SRL

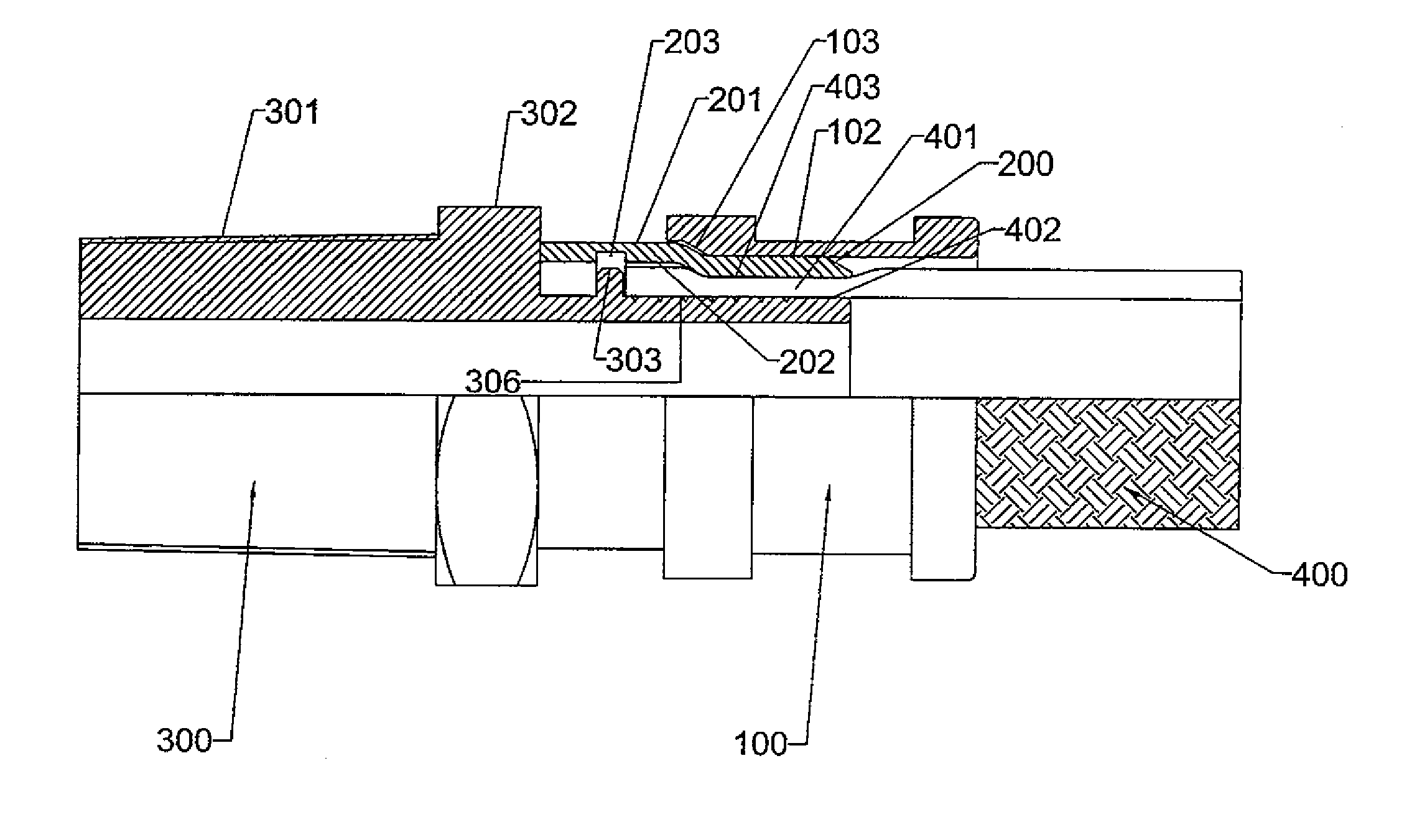

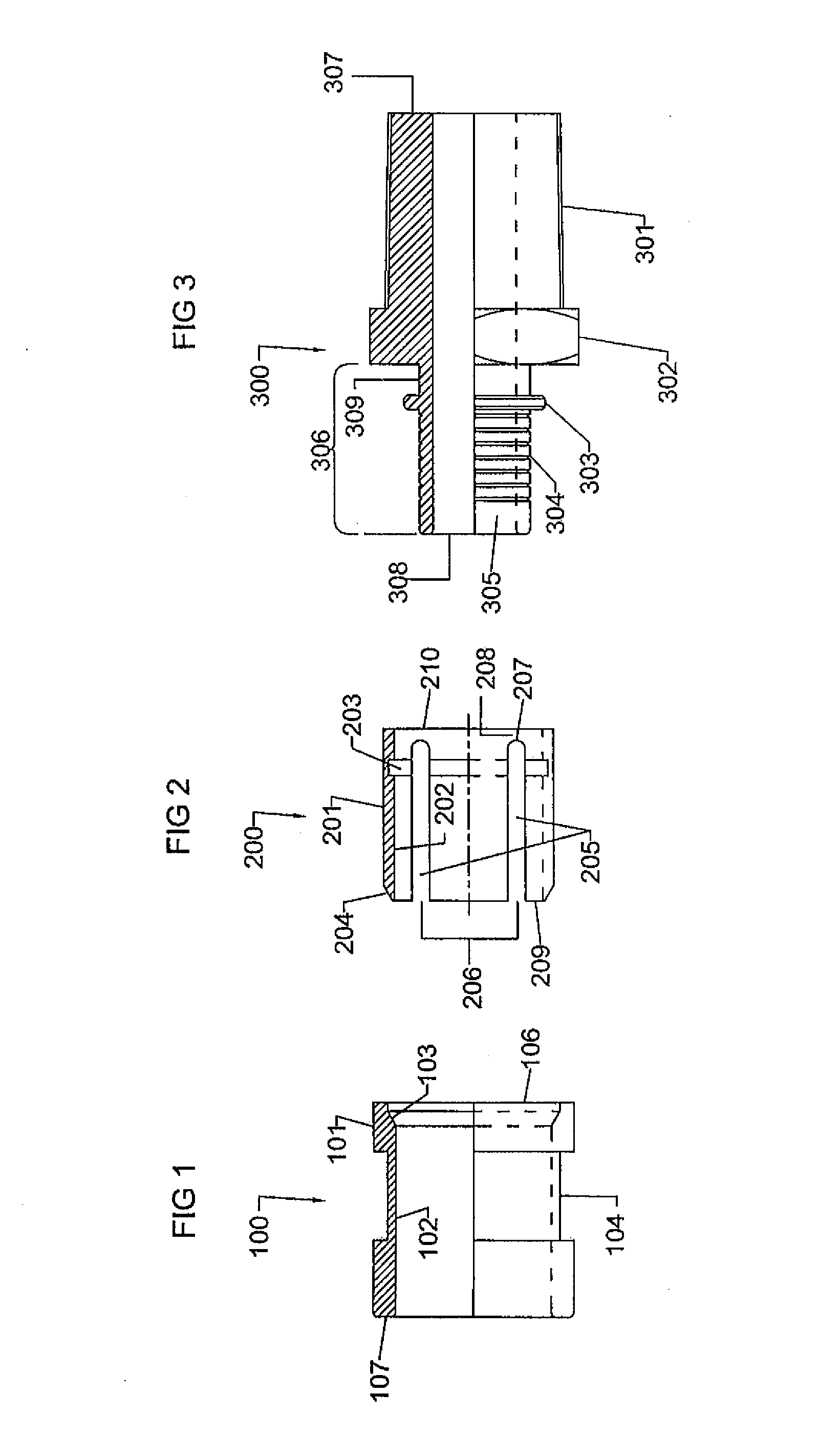

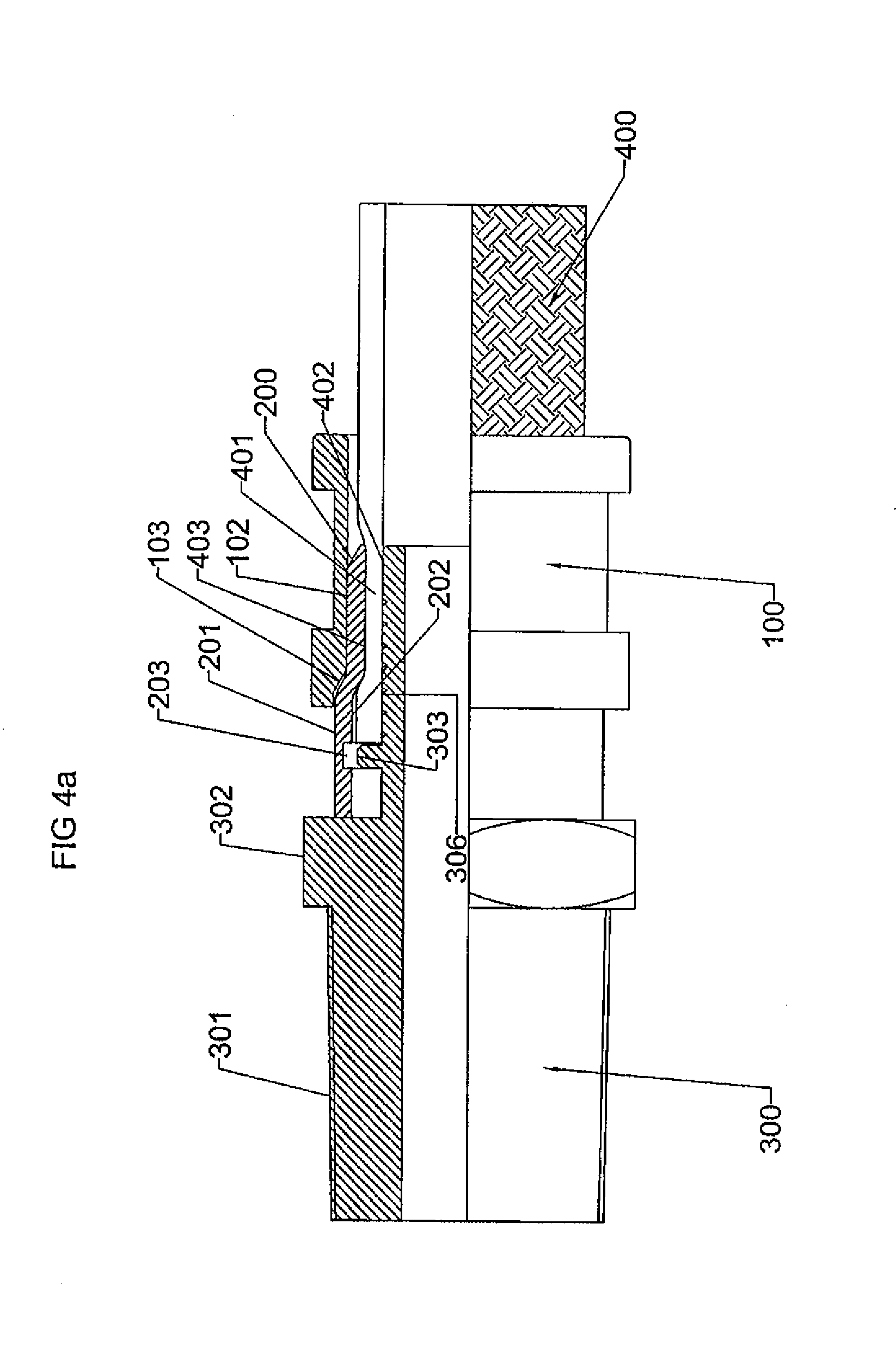

Hose fitting

InactiveUS20100025986A1Reduce frictionAvoid longitudinal displacementHose connectionsPipe connection arrangementsEngineering

A hose end fitting in which a connection body (300) is secured to a hose end (401) by an inner sleeve (200) and an outer collar (100). A radius of an outer surface (201) of the inner sleeve (200) is greater than a radius of an inner surface (102) of the outer collar (100) such that when the outer collar (100) is forced over the inner sleeve (200), the inner sleeve is radially compressed onto the hose end. The outer collar (100) and inner sleeve (200) are locked in position by the radial expansion force of the compressed hose (401) and the inner sleeve (200).

Owner:AFLEX HOSE

Child safety seat with adjustable head restraint

ActiveUS20050099044A1Improve protectionIncrease or decrease thicknessOperating chairsSofasEnergy absorptionEngineering

A side-protective head restraint pad, pad assembly and safety seat. The restraint pad includes an air bladder with a pump for selectively inflating the air bladder and a release valve for selectively deflating the air bladder, an energy-absorbing component and a comfort component. A flexible enclosure is provided within which the air bladder, energy-absorbing component and comfort component are positioned in overlaid configuration to define a unit. The head restraint pad is adapted for being placed in a seat in lateral alignment with one side of the head of an occupant and inflatable or deflatable as appropriate to restrain the head against injurious lateral movement caused by a side impact relative to the seat.

Owner:BRITAX CHILD SAFETY

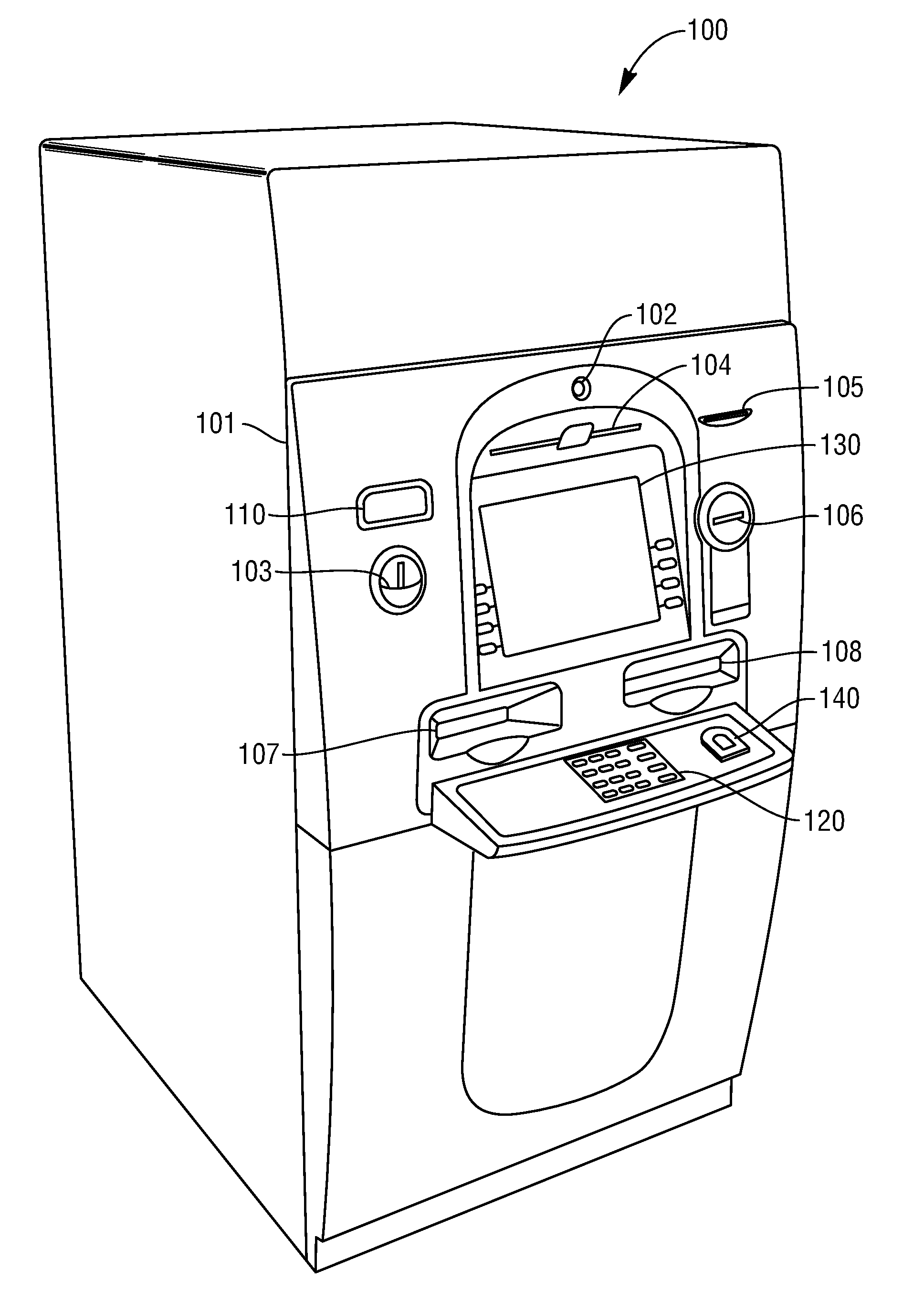

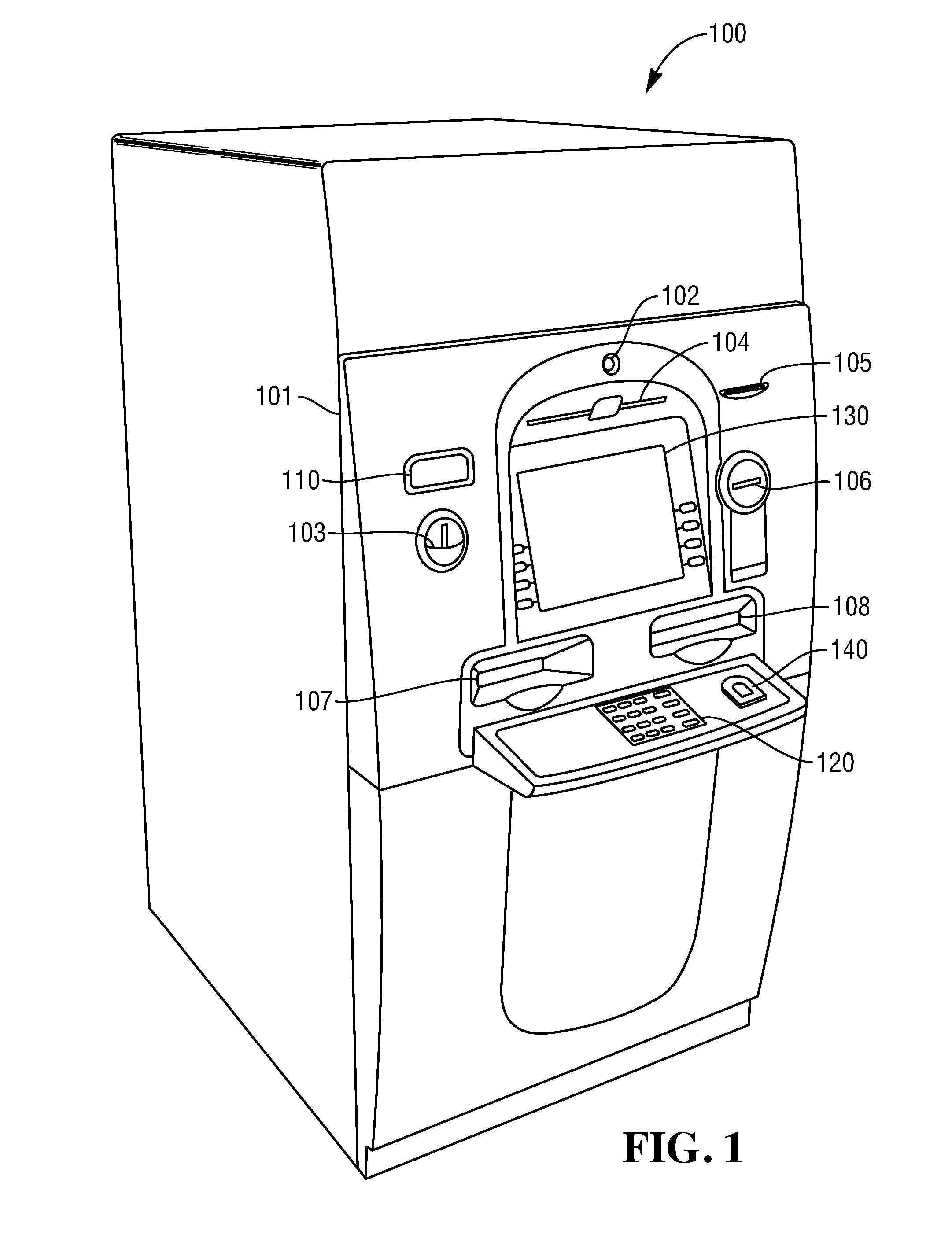

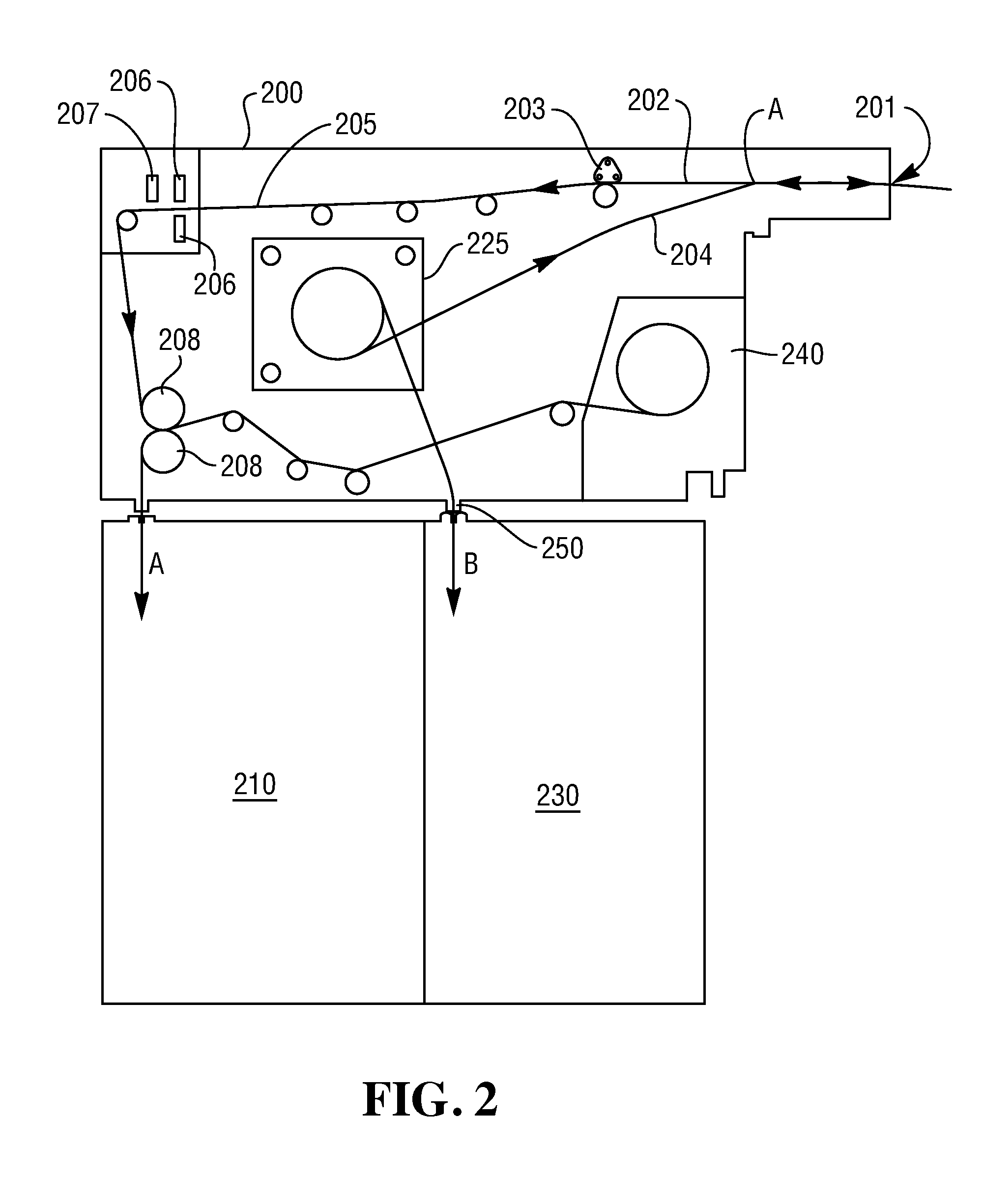

Clamping of media items

ActiveUS20150034457A1Reduce decreaseIncrease or decrease thicknessConveyorsFunction indicatorsEngineeringSupport surface

The present invention provides a method and apparatus for transporting items of media along a transport path. The apparatus comprises at least one clamp member to apply a clamp force to a bunch of media items located between a support surface and said clamp member, wherein said clamp member is selectively moveable towards or away from said support surface to apply a predetermined clamp force to the bunch of media items.

Owner:NCR CORP

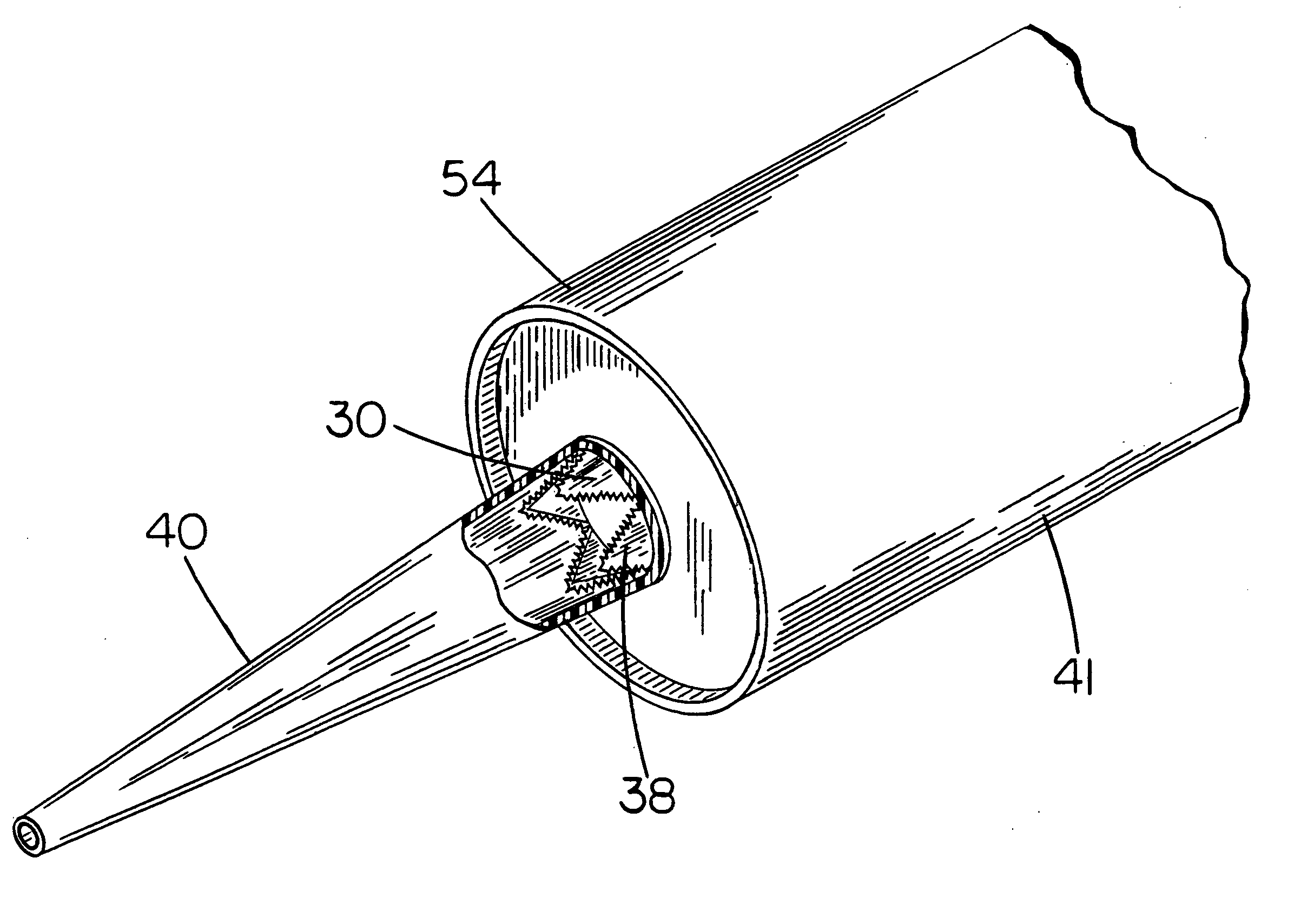

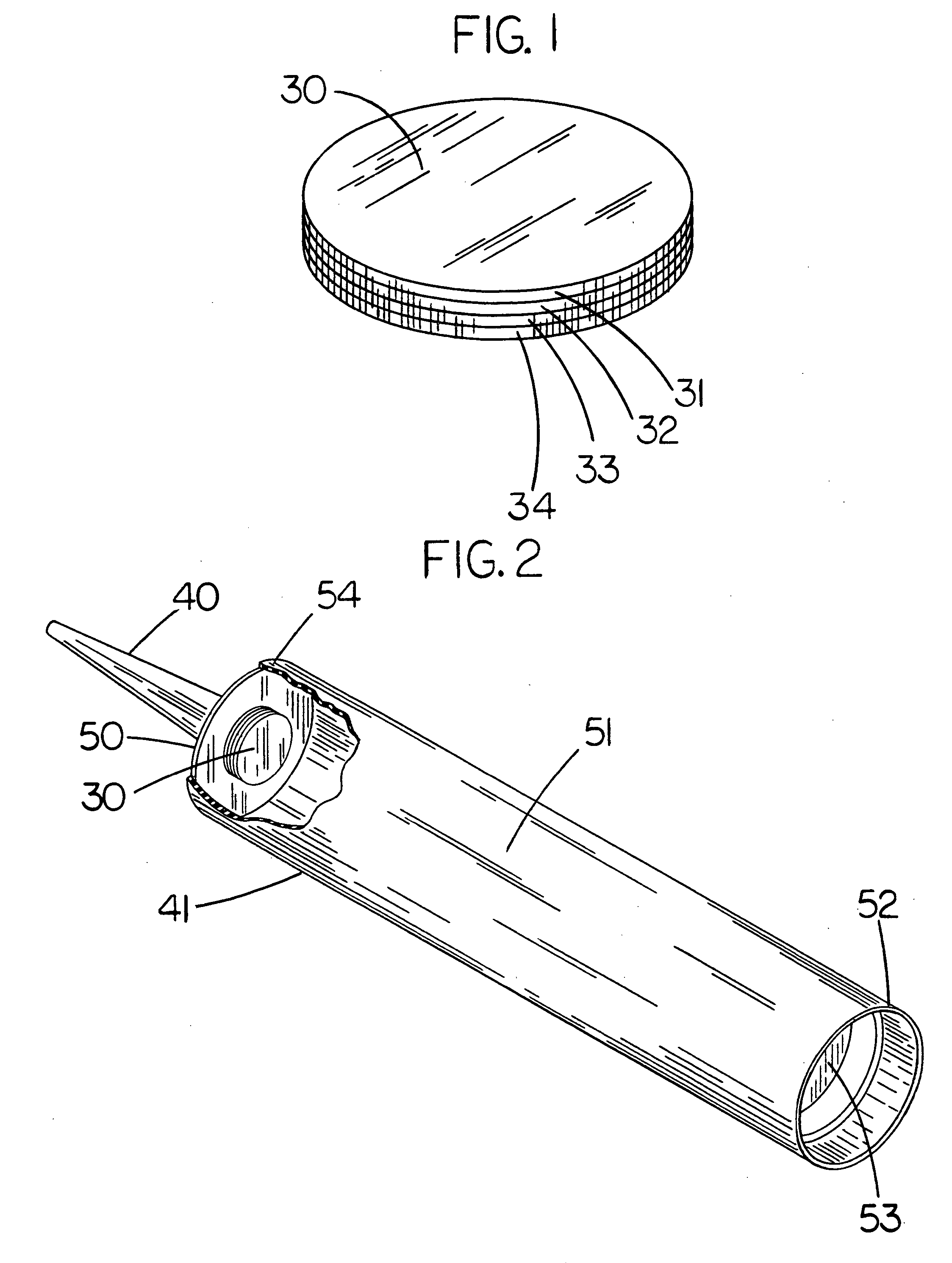

Cartridge nozzle seal opened by internal cartridge pressure

InactiveUS20050087570A1Low production costIncrease or decrease thicknessLiquid surface applicatorsClosuresCombined useEngineering

An improved multi layered frangible seal is bonded over the interior opening of the dispensing nozzle of a cartridge container of the type used in combination with an application gun providing a leak proof closure that automatically breaks open in a defined configuration when sufficient internal cartridge pressure is brought to bear against the seal. The seal invention is constructed of a first layer of leak proof frangible material that is bonded to an additional layer of material. The additional layer of material contains one or more cut through and / or cut out void configurations that forms a breaking pattern that turns the additional layer into a break and tear template layer. Bonding the template layer to the frangible layer strengthens the surface area of the frangible layer every where except in the area of the breaking pattern by leaving only the frangible layer covering over the cut through and / or cut out void configuration of the template layer. This leaves a weakness in the multi layered seal only in the area of the breaking pattern which forces the seal to automatically break open and tear only in the weaker single frangible layered area of the breaking pattern when bonded over the interior opening of the cartridge nozzle and sufficient pressure is brought to bear against the seal when the cartridge is pressurized by the application gun. The use of a separate layer of material to form the frangible area of the seal provides the ability to control the thickness of the seal material that must break open with the precision necessary to allow the burst pressure of the seal to be precisely regulated. This multi layered construction method produces a closure seal that is strong enough to remain intact when subjected to the pressure created during the filling operation of the cartridge and yet weak enough to automatically break open and dispense the contents at a variable burst pressure that can be precisely set. An uncut area of the breaking pattern keeps the broken open portion of the seal attached to the nozzle preventing any contamination of the dispensed product when the seal breaks open.

Owner:JACKMAN BRIAN F

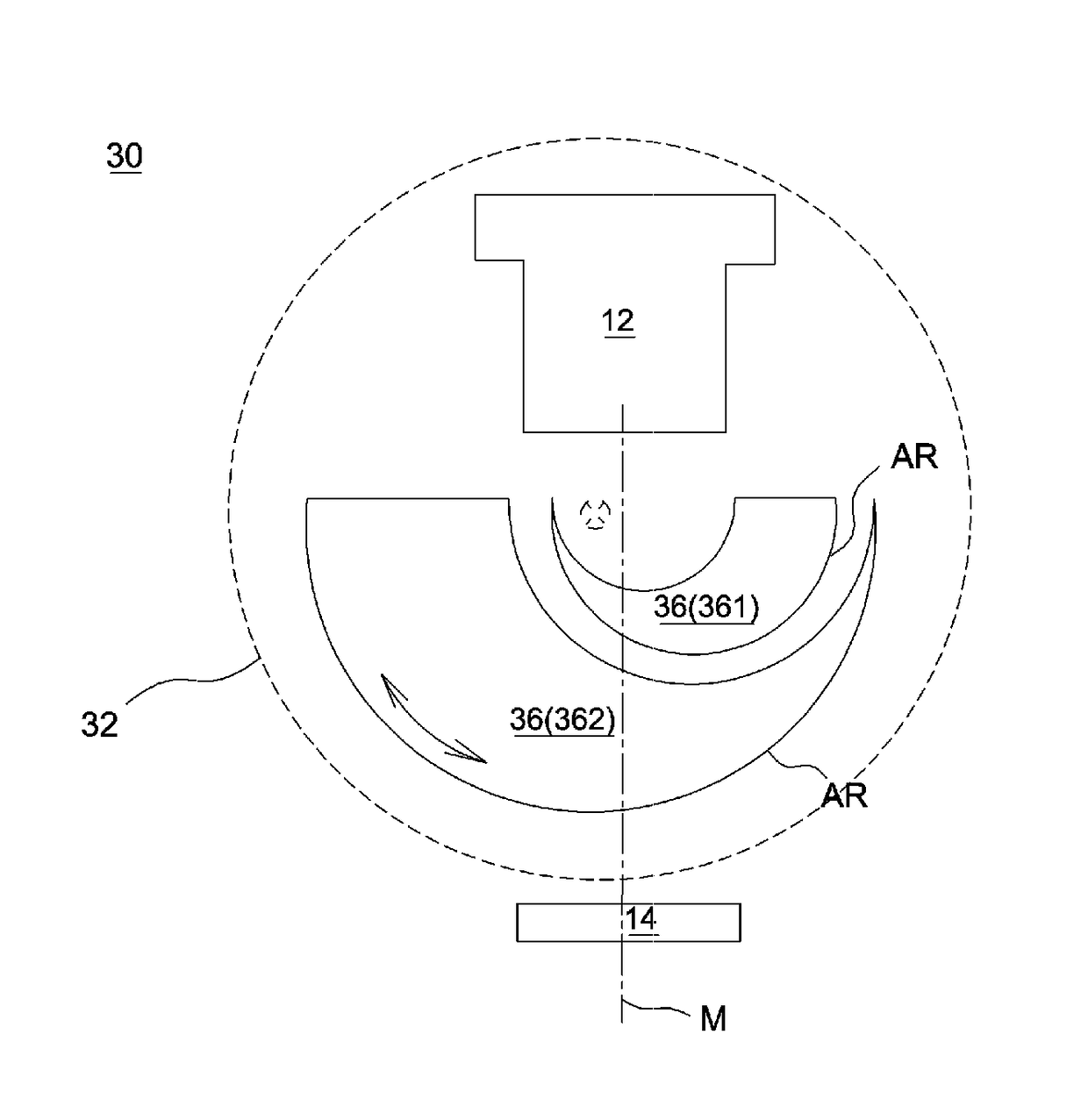

Flat oscillating motor

InactiveCN101459368ANot easily deformedPrevent coil deformationMagnetic circuit rotating partsDC commutatorSpecific gravityHollow core

The invention discloses a flat type vibrating motor for electronic products which are mobile phones and pagers and the like, wherein the center portion of an upper shell and a lower shell which provide round space in the mutually butted inner portions is perpendicularly fixed with a rotating shaft, the rotating shaft supports a rotor to rotate, the rotor is a flat structure which is integrally formed by two coils and a vibrator with high specific gravity, the two coils are fixed with generation magnetic fields on a printed circuit board which is matched with commutators, the vibrator with high specific gravity is fixed on the upper portion of the coil, the vibrator is tungsten alloy powder with high specific gravity and less quantitative nickel, a circular arc body of the vibrator is subject to a rotating center, more than half of the upper surface of the coil is covered not exceeding the range of 180 degrees, and the lower portion of the rotor is orderly equipped with a permanent magnet and a soft printed winding board, a circular circle of the permanent magnet is equipped with an N pole and an S pole crossways, and the soft printed winding board is connected with an external power supply. One side of an electric brush is fixed on the soft printed circuit board, the other surface contacts with the commutators, the rotor is an integrated structure of resin and metal vibrator with high specific gravity, the resin is used for the upper portion of the coil, a wire casing is formed on the periphery of a bearing, the outer edge of the vibrator is formed into a step shape, the structure of firmly binding with resin injection objects is increased, a hollow core of the coil is also injected by the resin, thereby reducing the coil to deform because of plastic pressure in maximal degree.

Owner:WENDENG YONGBAI MICRO MOTOR CO LTD +1

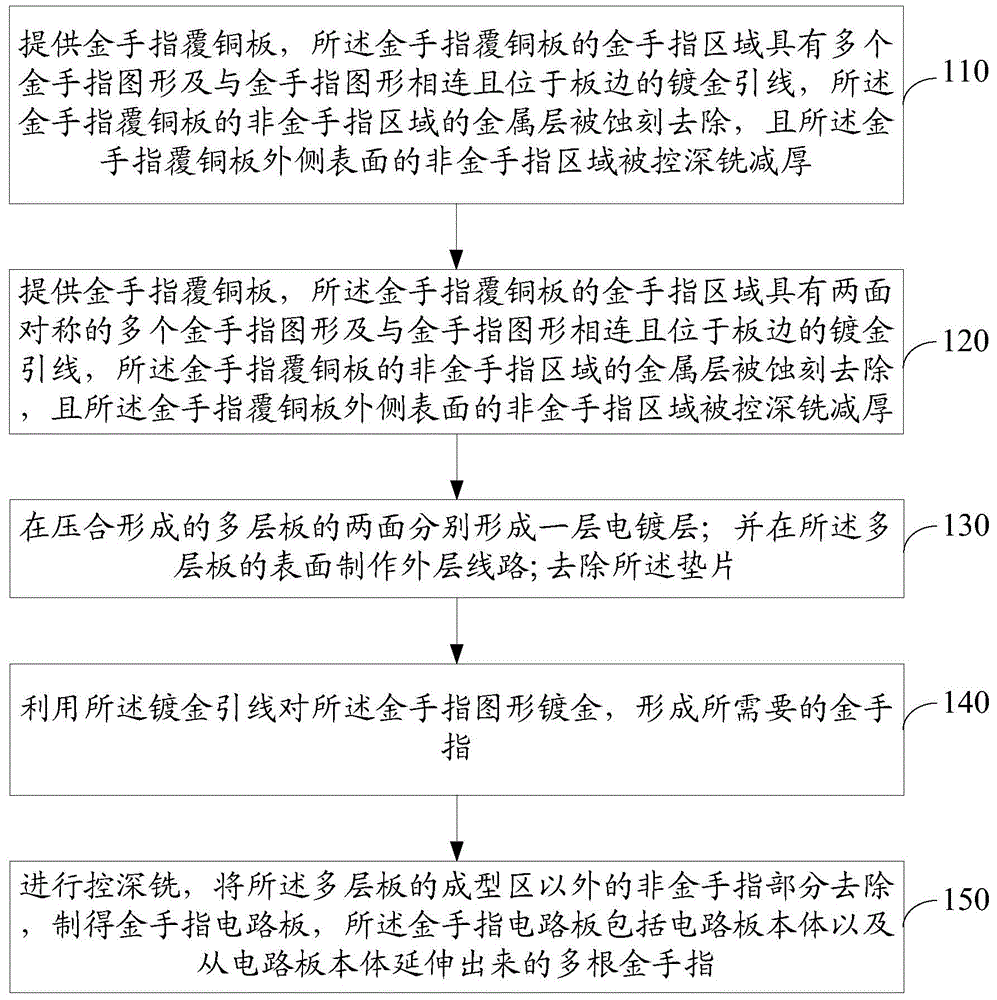

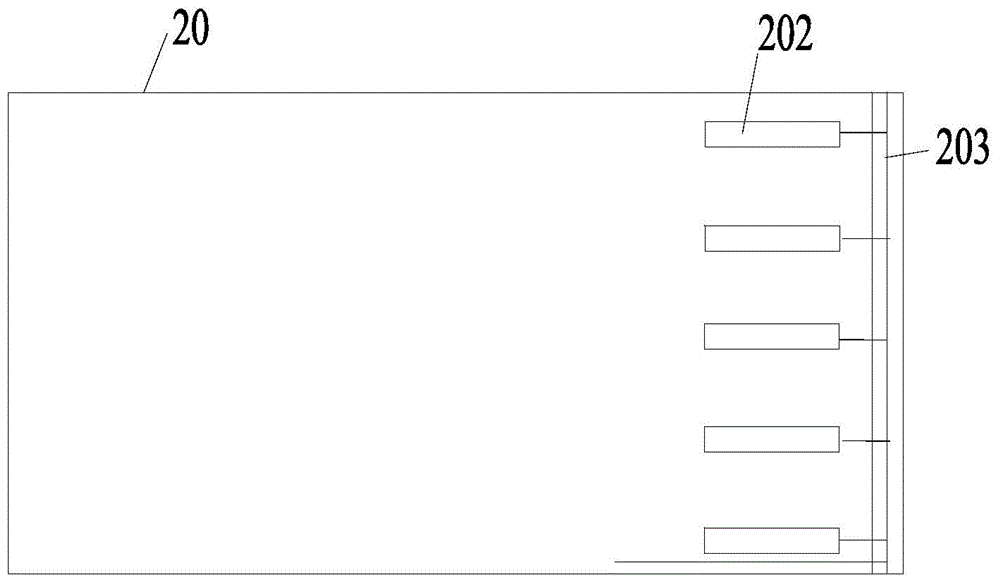

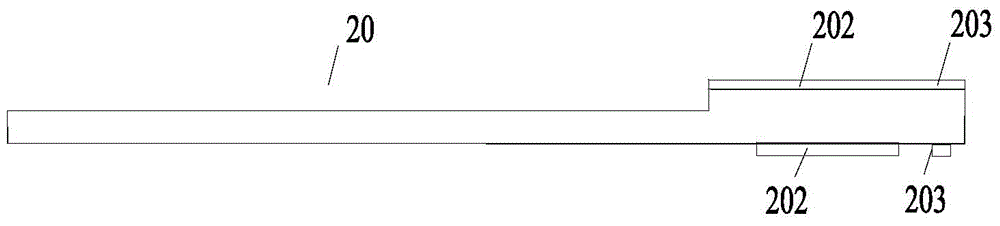

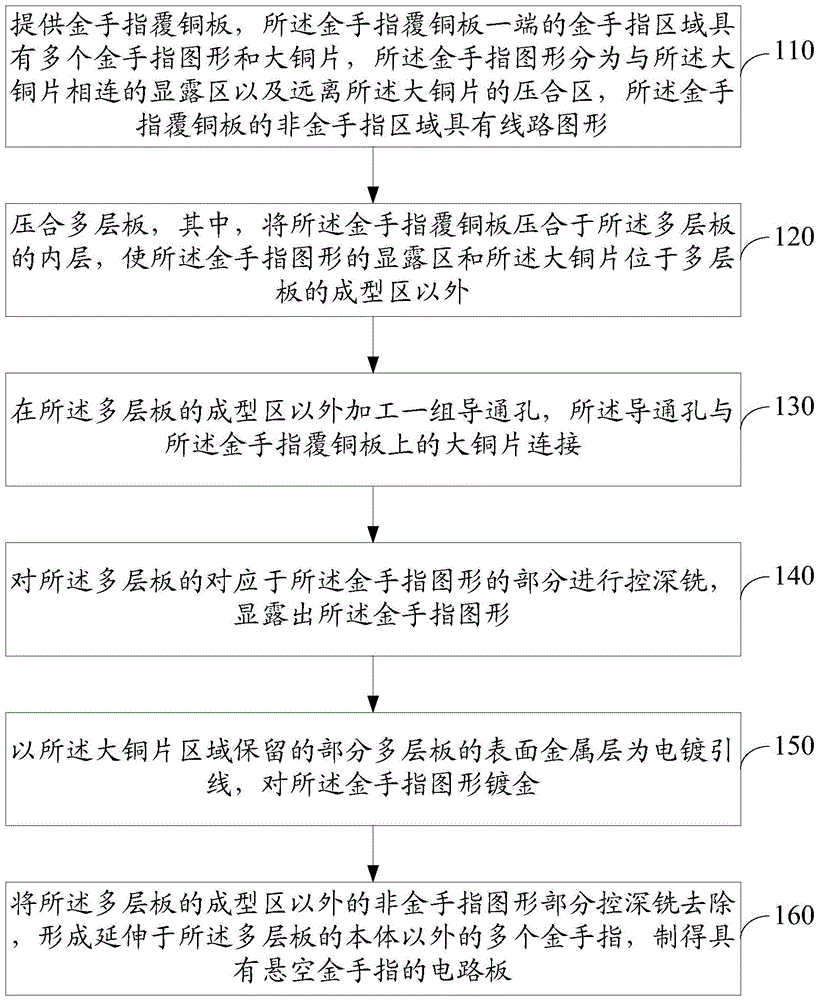

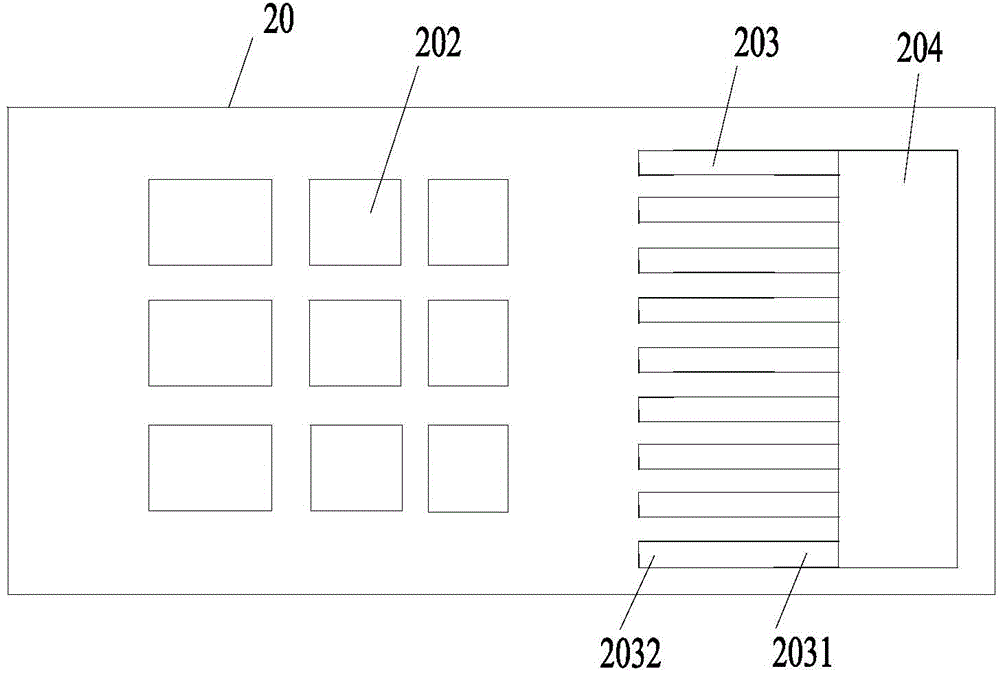

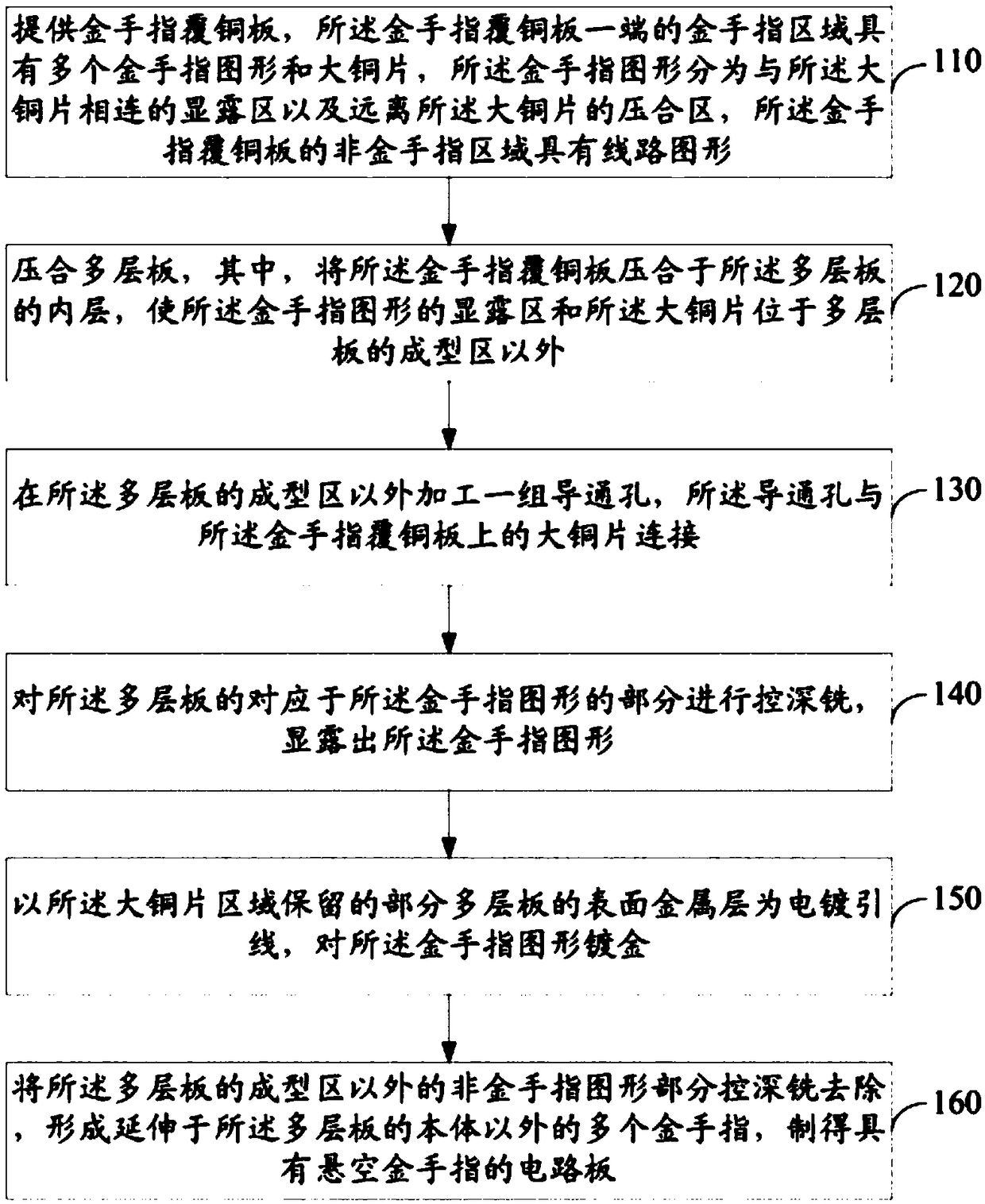

Processing method of circuit board gold finger, and gold finger circuit board

ActiveCN104981113AMeet plugging needsIncrease costElectrical connection printed elementsMultilayer circuit manufactureEngineeringCopper

The invention discloses a processing method of a circuit board gold finger, and a gold finger circuit board, for solving the technical problems of quite high restrictions, very poor versatility and high proneness to waste of resources and increase of the cost existing in a conventional gold finger circuit board. The method comprises the following steps: providing gold finger copper-clad boards with gold finger patterns and gilded lead wires, non gold finger areas at the surfaces of outer sides being subjected to controlled depth milling and thickness reduction; laminating an external-layer dielectric layer and an external-layer metal layer at controlled depth milling and thickness reduction areas; laminating an internal-layer line layer and an internal-layer dielectric layer between the non gold finger areas of the two gold finger copper-clad boards; arranging pads between the gold finger areas of the two gold finger copper-clad boards; then, pressing to form a multilayer board; manufacturing an external-layer line; gilding the gold finger patterns to form gold fingers; performing the controlled depth milling and thickness reduction to remove a non gold finger portion apart from a formation area of the multilayer board so as to prepare the gold finger circuit board, wherein the gold finger circuit board comprises a circuit board main body and the multiple extending gold fingers.

Owner:SHENNAN CIRCUITS

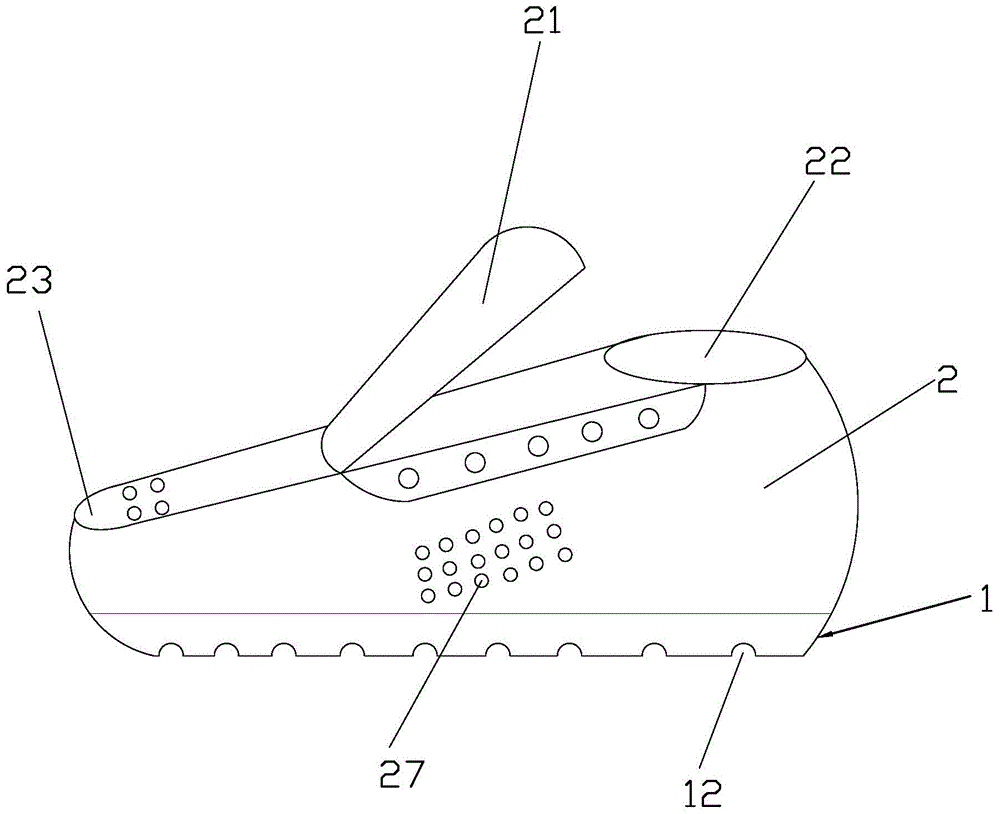

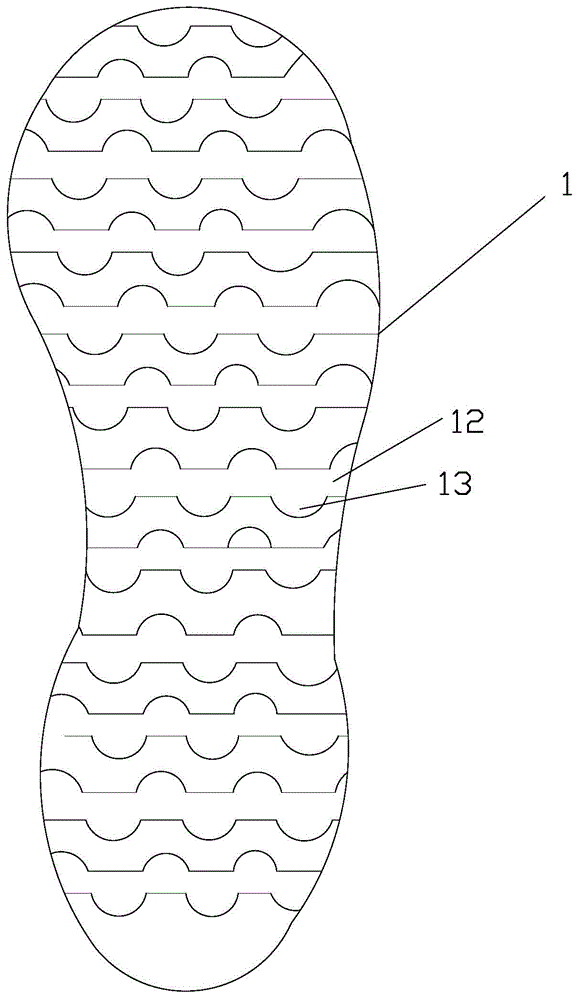

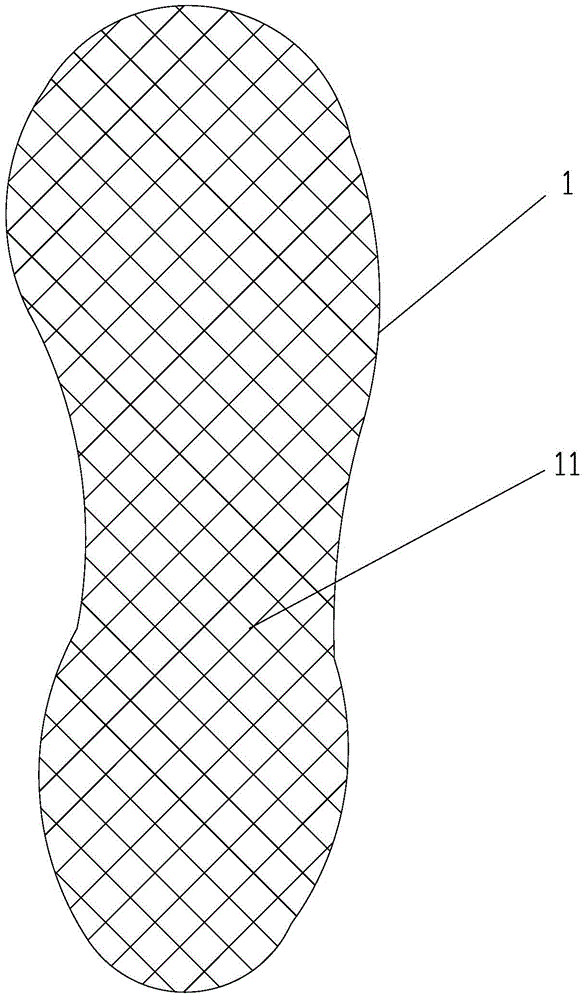

Preparation method for high-elastic rubber foamed shoe sole and application thereof to foamed shoe

The invention provides a preparation method for a high-elastic rubber foamed shoe sole. The raw materials comprises, in parts by weight, 250-500 parts of natural rubber, 20-40 parts of talcum powder, 2-5 parts of an anti-ageing agent, 2-4 parts of a rubber promoter M, 2-6 parts of zinc stearate, 2-6 parts of a rubber promoter DM, 4-8 parts of zinc oxide, 5-15 parts of sodium bicarbonate, 5-10 parts of polyethylene glycol, and 2-6 parts of AC foaming agent. Also, the shoe sole is applied to prepare a rubber foamed shoe, and the rubber foamed shoe comprises the sole and a vamp which are in adhesive connection. The thickness of the sole is 0.2-1.2 cm, the top surface of the sole is provided with an antiskid thread, the bottom surface of the sole is provided with water-discharging grooves which are distributed at equal intervals and run through the left and right ends of the sol, the distance of adjacent water-discharging grooves is 0.1-0.5 cm, and the wall of the water-discharging groove is provided with a groove gradually oblique from the top to the bottom of the water-discharging groove. The sole possesses good elastic effect, is resistant to wear and is not easy to deform. The shoe prepared by using the sole is comfortable to wear, and the preparation technology is simple.

Owner:NANAN FANKE BEARING DETECTION TECH CO LTD

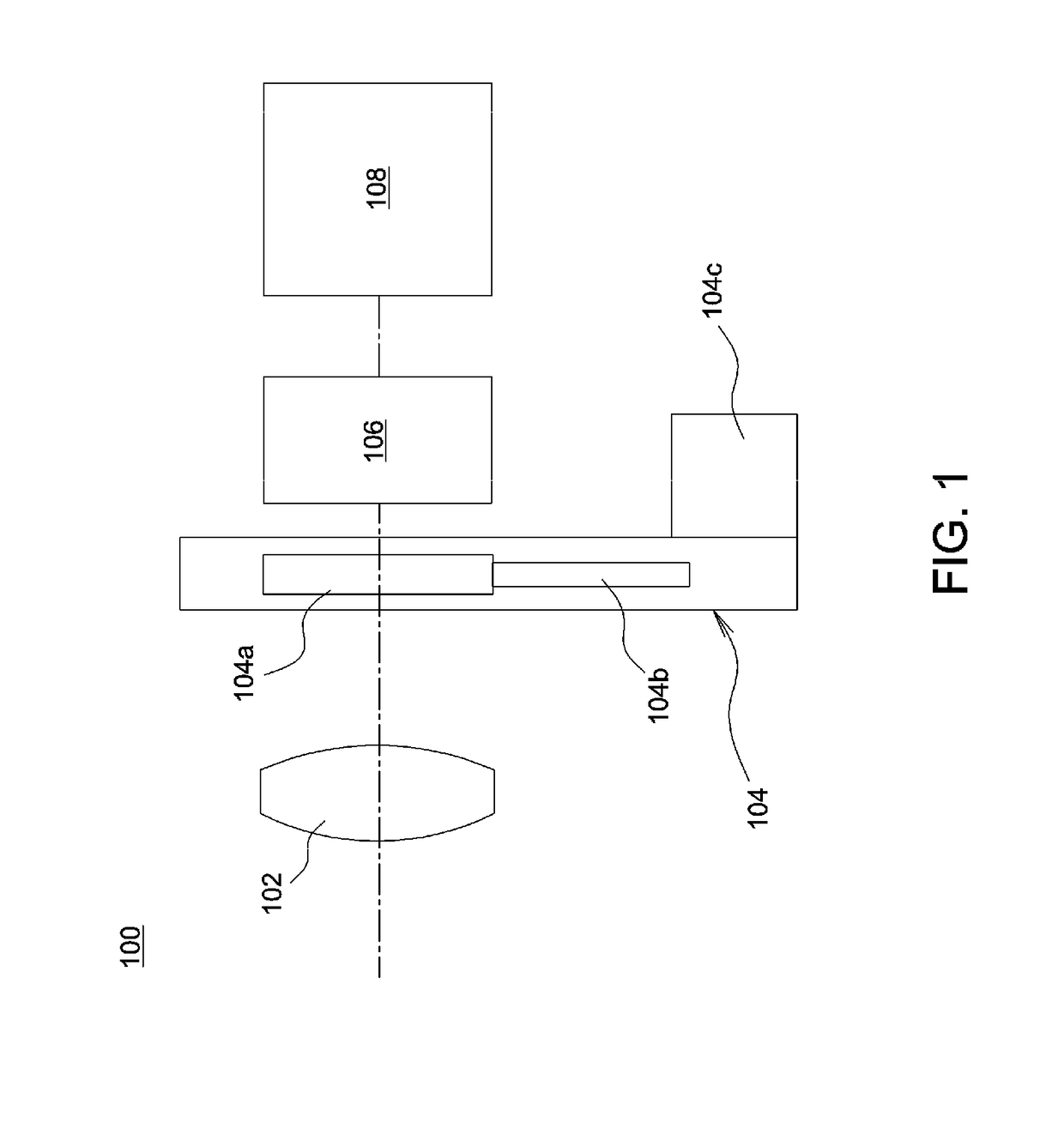

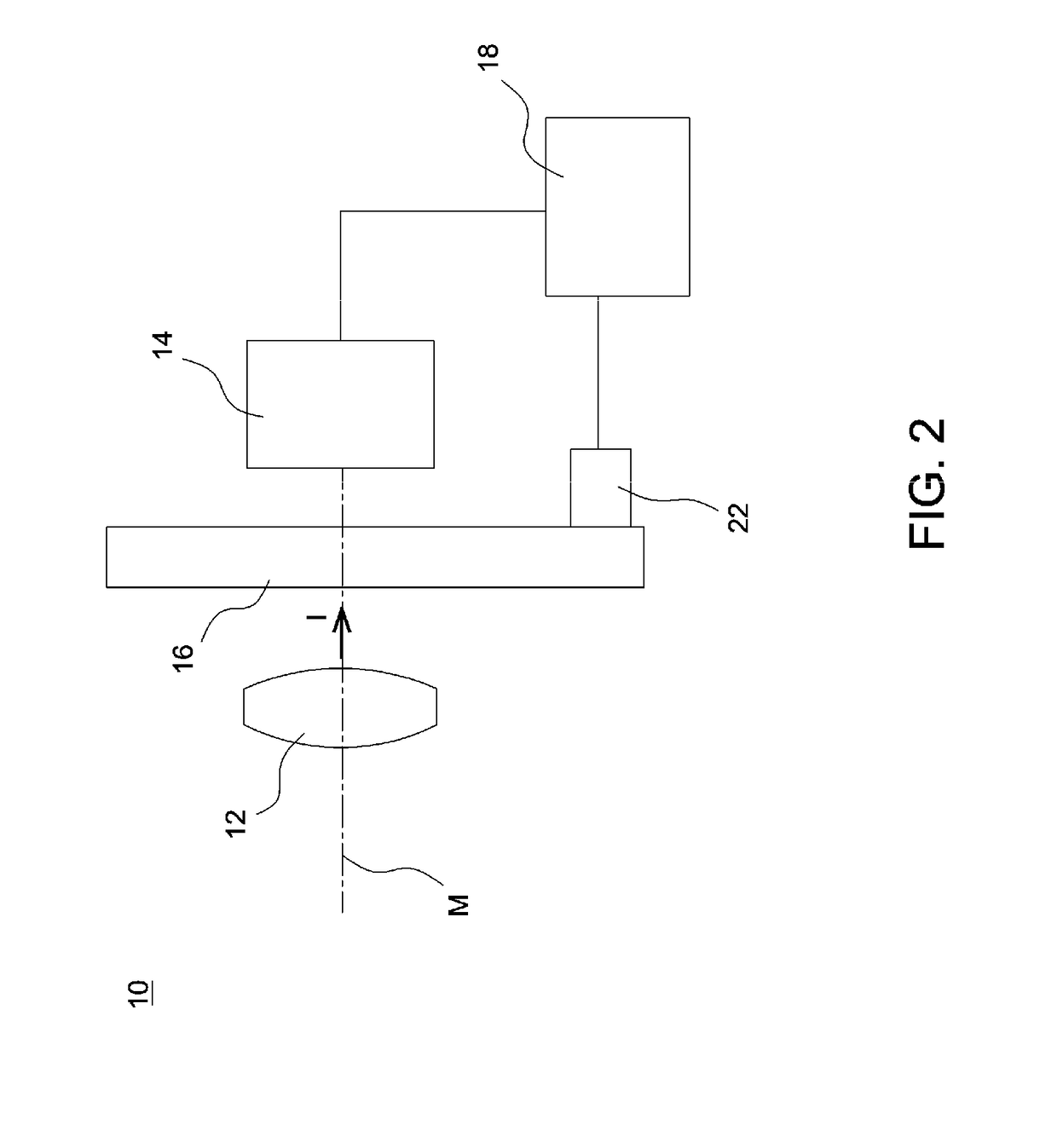

Image pickup apparatus

ActiveUS9774774B2Improve accuracyReduce aberrationTelevision system detailsColor television detailsLight beamRefractive index

An image pickup apparatus includes a lens, an image sensor, an optical filter, and a driving device. The lens focuses light beams from at least one subject to form an optical image, and the image sensor receives the optical image and converts the optical image into at least one electric signal. The optical filter includes a first plate and a second plate, the first plate is disposed between the lens and the image sensor, and the second plate is disposed between the first plate and the image sensor. The driving device moves the second plate. The second plate has substantially the same index of refraction as the first plate, and a thickness of the second plate is continuously decreased or increased across the second plate.

Owner:YOUNG OPTICS

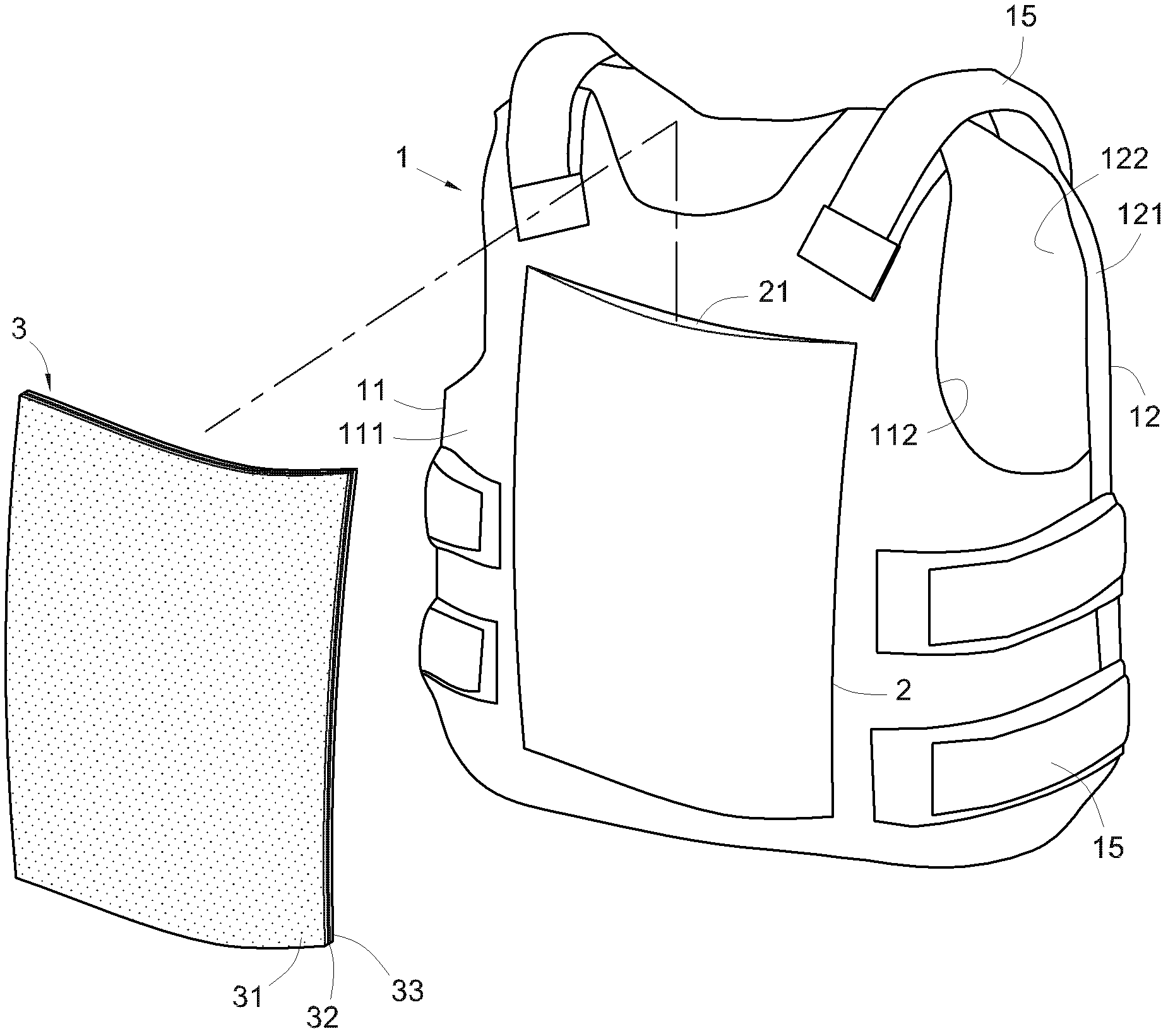

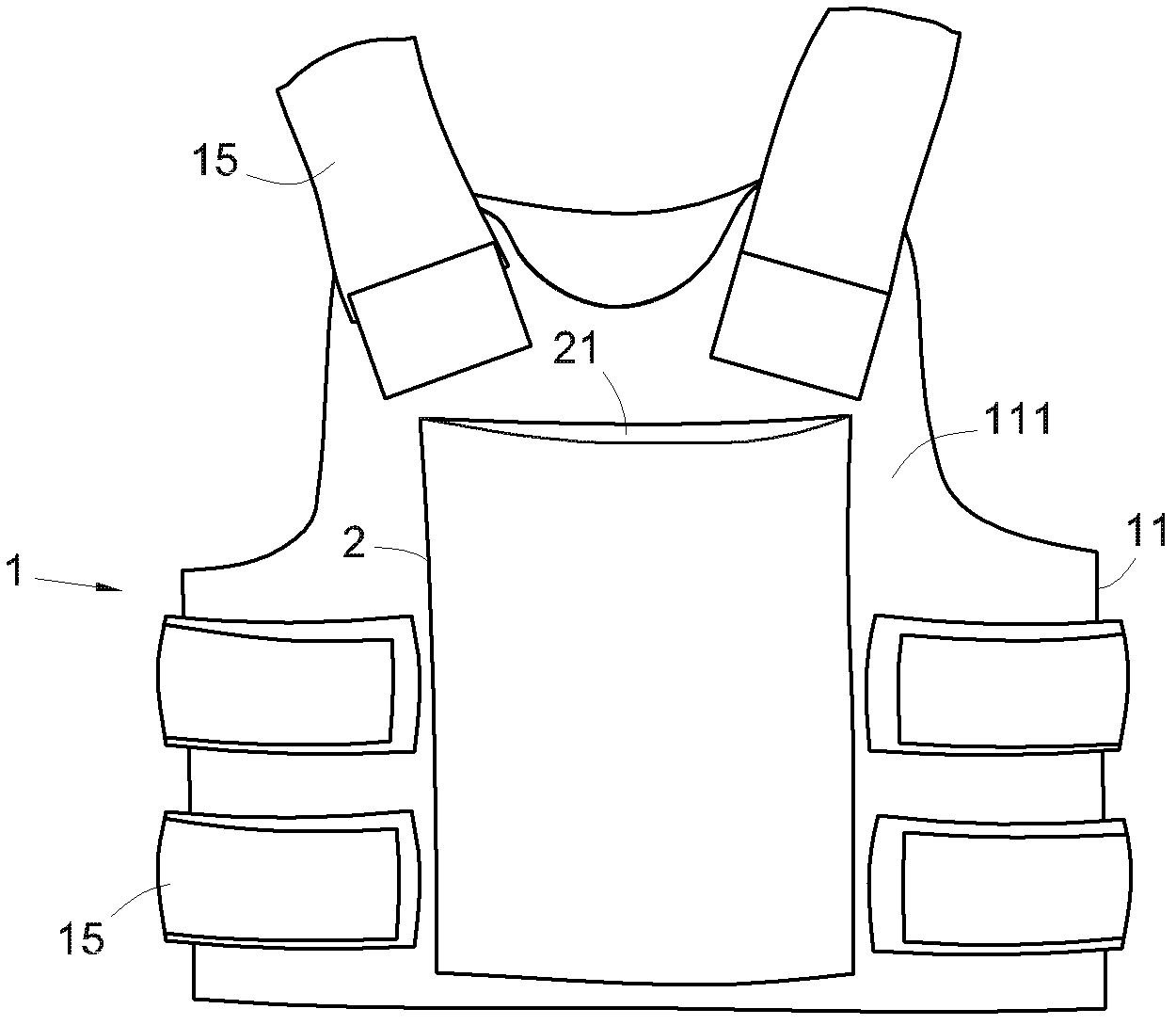

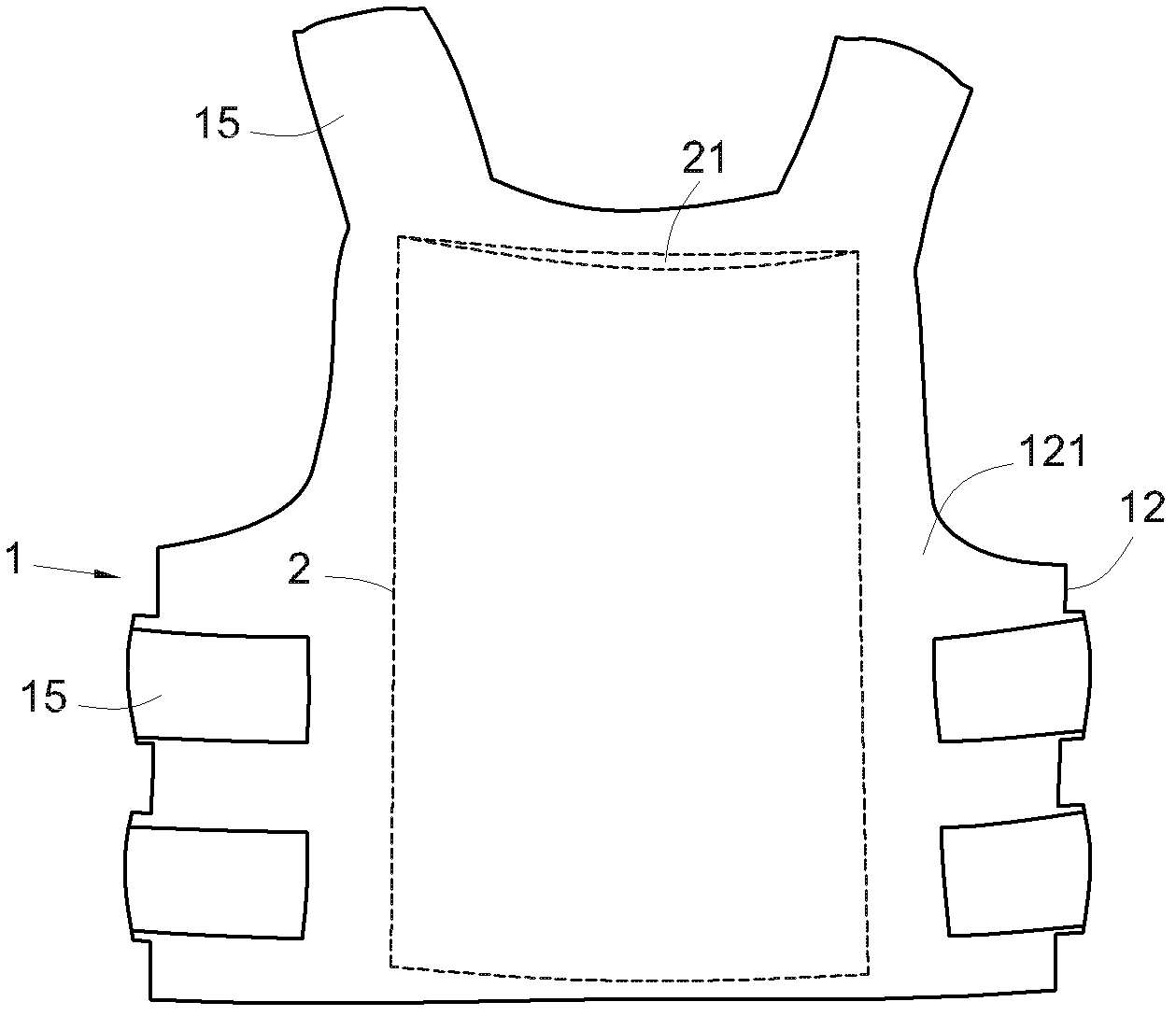

Detachable type health care and protection multifunctional casual clothes

InactiveCN103126126AIncrease or decrease thicknessReduce weightPersonal protection gearProtective garmentEngineeringPolycarbonate

The invention relates to detachable type health care and protection multifunctional casual clothes which comprise a casual clothes body and a plurality of containing pockets. The casual clothes body comprises a front part and a back part. The plurality of containing pockets are arranged on the casual clothes body. A pocket opening of each containing pocket is formed in the surface of the casual clothes body. A protective plate which can be pulled and replaced through each pocket opening is contained in each containing pocket. Each protective plate is formed by combining of an abrasion resistant layer with flexibility, a polycarbonate layer and a buffer layer in sequence in a stacking mode, wherein the thickness of the polycarbonate layer can be increased or decreased according to changing of safety levels, and the buffer layer can be attached to a body of a wearer and has flexibility. According to the detachable type health care and protection multifunctional casual clothes, the protective plates which are different from the thickness of the polycarbonate layer can be freely pulled and replaced according to the safety levels, and accordingly external force attacking such as thumping, cutting, puncturing or flipping can be withstood, weight can be greatly lowered, using convenience can be improved, and meanwhile production cost is saved.

Owner:周季良

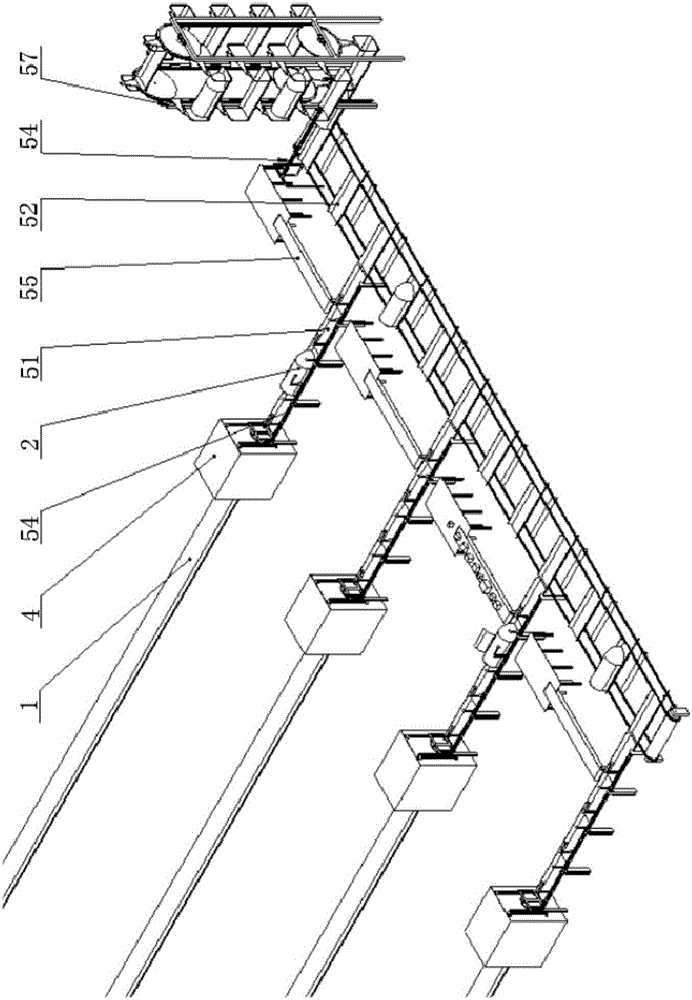

Magnetic suspension vacuum pipeline transmission system for freight transport

The invention discloses a magnetic suspension vacuum pipeline transmission system for freight transport. The magnetic suspension vacuum pipeline transmission system for the freight transport comprises at least two point-to-point vacuum transporting pipelines, and also comprises freight carrying cabin bodies used for moving in the vacuum transporting pipelines; adaptive concave-convex structures are arranged between the freight carrying cabin bodies and the vacuum transporting pipelines; concentrated transporting box bodies are mounted in the freight carrying cabin bodies; the tail ends of the vacuum transporting pipelines are provided with a freight transport cabin body transmission line used for loading and unloading the concentrated transporting box bodies and moving the freight carrying cabin bodies to another vacuum transporting pipeline; isolation cabins are connected between the freight transport cabin body transmission line and the vacuum transporting pipelines. The magnetic suspension vacuum pipeline transmission system for the freight transport, which is provided by the invention, is quick in speed, low in energy consumption, low in pollution and further lower in the input cost and the operation cost of a project; the freight carrying cabin bodies are good in running stability in the vacuum transporting pipelines.

Owner:林援及

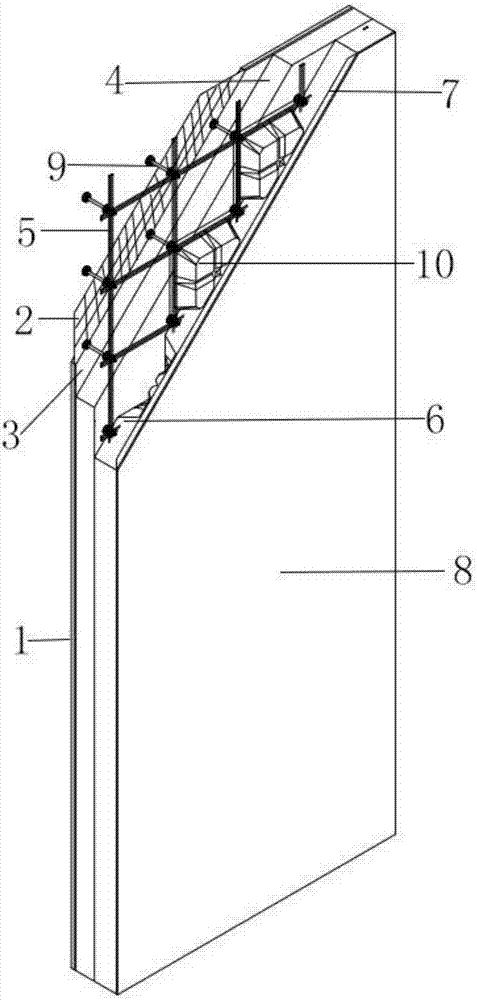

Modular assembled wall body and assembling method thereof

InactiveCN107143058ASimple structureSave human effortWallsCeramic shaping apparatusFiberglass meshWire gauze

The invention discloses a modular assembled wall body which comprises a cement protecting layer, a steel wire gauze, a first cement layer, an insulating layer, at least one bar-mat reinforcement, a second cement layer, a glass fiber net and an inner decorative layer successively arranged, wherein the steel wire gauze and the bar-mat reinforcements are connected through a plurality of connecting rod members to form an internal bracket supporting a wall body; the netty structure of the bar-mat reinforcement is rectangular lattices, each of which is fixedly provided with a module shell; the insulating layer is clamped between the steel wire gauze and the bar-mat reinforcement through the plurality of connecting rod members; the first cement layer is arranged between he insulating layer and the cement protecting layer; and the second cement layer is arranged between the insulating layer and the internal decorative layer. The wall body can be industrially produced in an assembly line, so that the wall body is relatively fast to produce, convenient to construct, easy to transport and storable, and is relatively good in sound-isolating and insulating effects.

Owner:任于亮

Mold cutting device of mold cutting machine and method for adjusting mold cutting depth of mold cutting machine

ActiveCN105666581AMaterials are readily availableReduce processing difficultyMetal working apparatusPunchingMachining

The invention discloses a mold cutting device of a mold cutting machine. The mold cutting device comprises an upper template, a lower template and a cutter mold arranged on the upper template; a machined material is arranged between the lower template and the cutter mold; a layer of buffer pad for adjusting a mold cutting depth is arranged below the machined material, and is low in machining difficulty to reduce the production cost; meanwhile, the invention further provides a method for adjusting the mold cutting depth of the mold cutting machine; and the method comprises the steps of: 1) starting the mold cutting device of the mold cutting machine to perform trail punching for the machined material; 2) repeatedly adjusting the trail punching through adjusting a mold cutting height to finish rough positioning of the mold cutting depth; omitting a step 3) if the mold cutting depth reaches the machining requirement; and otherwise, continuing the step 3); and 3) adjusting the thickness of the buffer pad after the step 2), and combining the adjustment of the mold cutting height to repeatedly adjust the trial punching so as to finish precise positioning of the mold cutting depth. The method realizes quick positioning of the mold cutting depth through comprehensively adjusting the thickness of the buffer pad and the mold cutting height, and reduces the production cost when guaranteeing the quality of a mold cutting product.

Owner:SUZHOU JINHE NEW MATERIAL

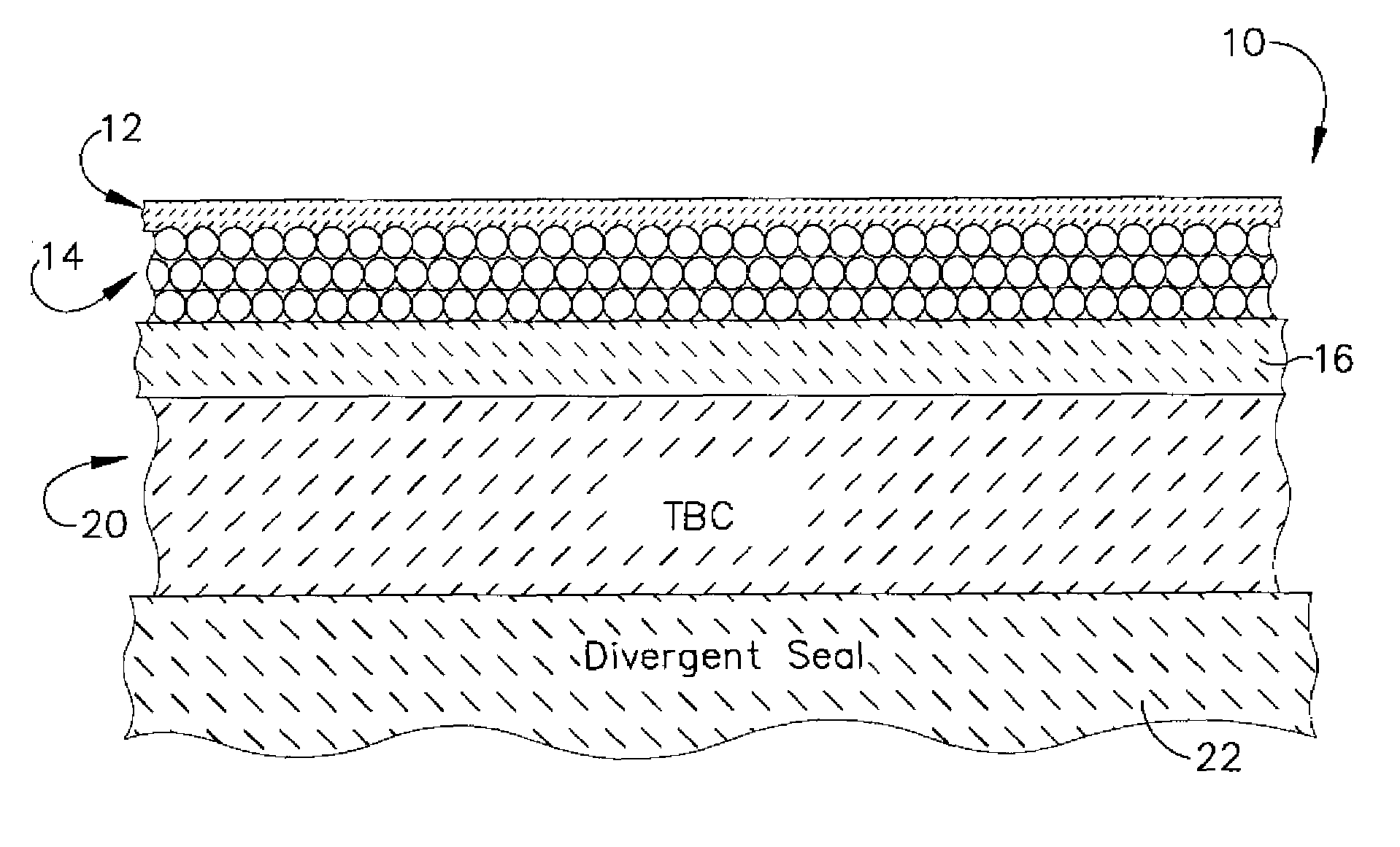

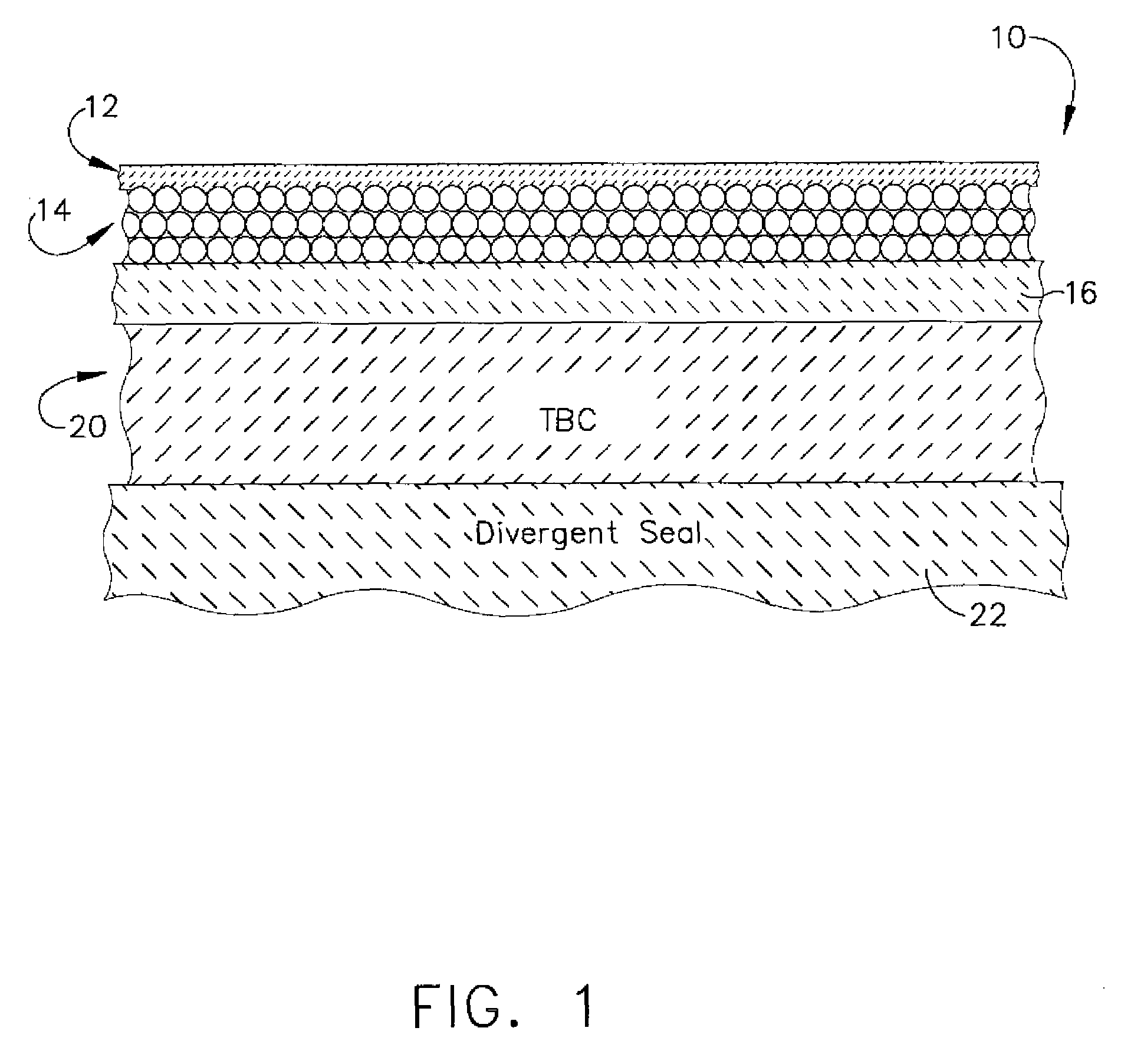

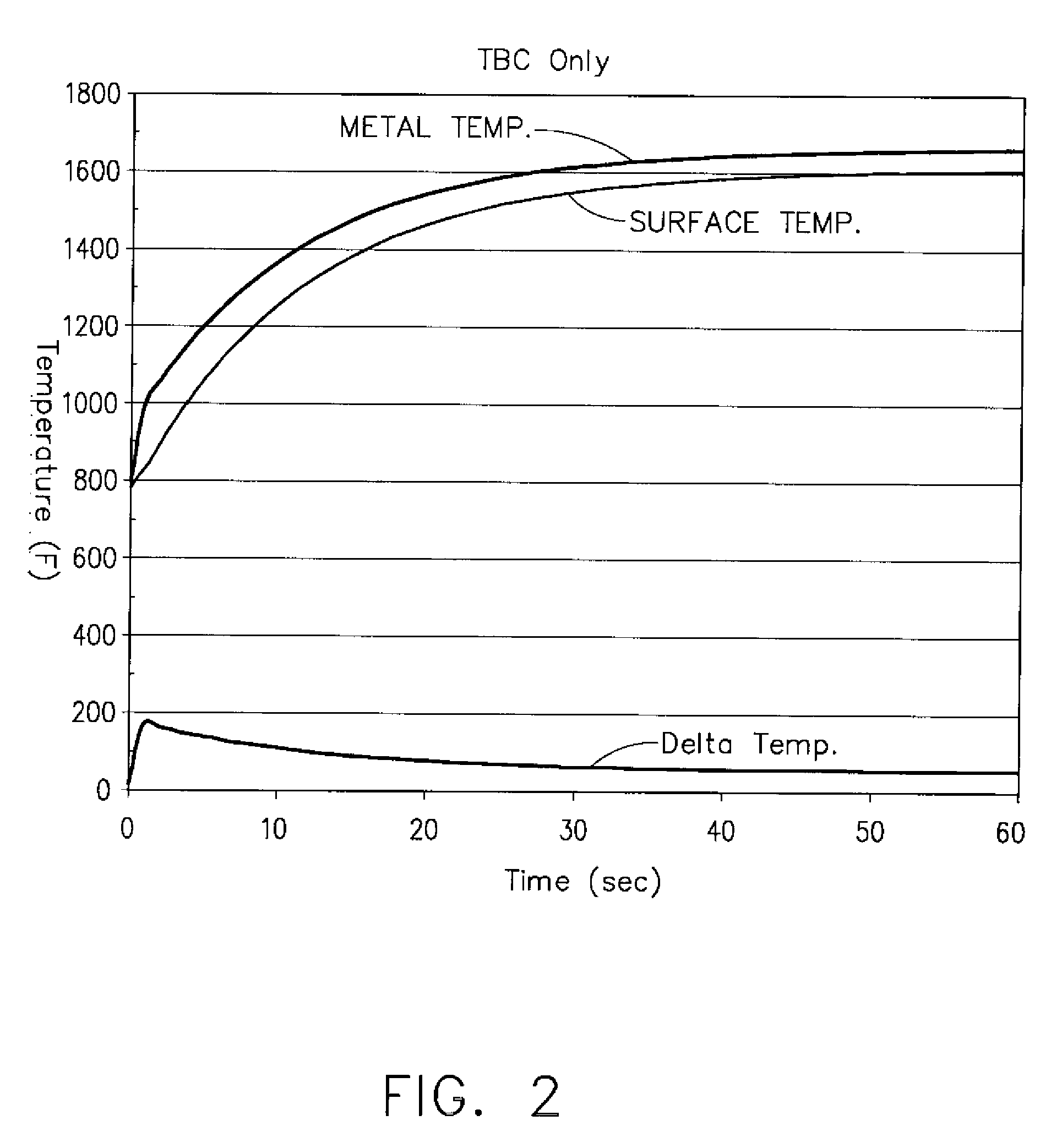

Low thermal and radiation conductivity coating

ActiveUS20090169898A1Increase or decrease thicknessReduce conductionEfficient propulsion technologiesGlass/slag layered productsCoating systemEngineering

A coating system that includes a plurality of portions, each portion comprising one or more layers. The coating system includes an outer portion, which is an infrared radiation (IR) interaction portion, that dissipates incident (IR). Underlying this outer portion is a performance portion. The performance portion comprises at least one layer that includes microspheres. Between the substrate and performance portion is a compliance portion. The compliance portion comprises at least one layer of high temperature material that has a coefficient of thermal expansion (CTE) intermediate the performance layer and the substrate. The compliance portion thus reduces any high temperature thermal mismatch between the substrate and the performance portion.

Owner:GENERAL ELECTRIC CO

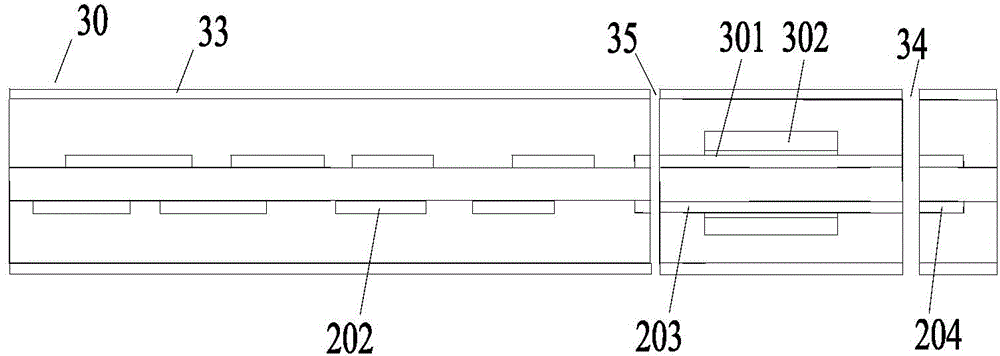

Processing method for dangling gold fingers and circuit board

ActiveCN104981114AMeet plugging needsSmall limitationsElectrical connection printed elementsPrinted element electric connection formationEngineeringCopper

The present invention discloses a processing method for dangling gold fingers and a circuit board so as to solve the technical problems of existing gold finger circuit boards that limitation is strong, versatility is poor, waste of resources is likely to be incurred and the cost is increased. The method comprises: pressing a gold finger copper clad laminate with a gold finger pattern to an inner layer of a multilayer board; processing a set of via holes outside a formed region of the multilayer board, wherein the via holes are connected with the gold finger pattern by a large copper sheet on the gold finger copper clad laminate; exposing the gold finger pattern by depth control milling; plating the gold finger pattern with gold; and removing non-gold finger patterns outside the formed region of the multilayer board by the depth control milling to form the gold fingers and obtain a circuit board with the dangling gold fingers.

Owner:SHENNAN CIRCUITS

Processing method for suspended gold finger, and circuit board

InactiveCN109379840AMeet plugging needsSmall limitationsLaminating printed circuit boardsElectrical connection printed elementsEngineeringCopper

The invention discloses a processing method for a suspended gold finger and a circuit board, which can solve the technical problem that the existing gold finger circuit boards have high limitation, are poor in versatility, and cause resource waste and cost increase. The method includes: pressing a gold finger copper clad plate having a gold finger pattern to an inner layer of a multi-layer board;processing a set of via holes outside a forming area of the multi-layer board, wherein the via holes are connected to the gold finger pattern through a large copper piece on the gold finger copper clad plate; performing deep-cut milling to reveal the gold finger pattern; performing gold plating on the gold finger pattern; performing deep-cut milling to remove the non-gold finger pattern part outside the forming area of the multi-layer board, forming a gold finger, and obtaining a circuit board having a suspended structure gold finger.

Owner:湖北金禄科技有限公司

Coal burning heat medium furnace high-precision temperature regulation and combustion control method

ActiveCN101749730BIncrease or decrease thicknessImprove combustion efficiencyFuel supply regulationTemperature controlAutomatic control

The invention provides a coal burning heat medium furnace high-precision temperature regulation and combustion control method and relates to the technical field of DCS industrial control systems, in particular to large-scale chain coal bed burning heat medium furnace (heat medium furnace for short) high-precision temperature regulation and combustion control. As is generally known, the temperature control of the coal burning heat medium furnace depends on the combustion control of the coal burning heat medium furnace. Therefore, a suitable sensor and a suitable transmitter are used to obtain parameters which influence the combustion and the heat medium outlet temperature in the burning process; the factors which influence the combustion and the heat medium outlet temperature are treated differentially and destroyed by adopting multi-circuit regulation when grasping main problems, thus avoiding interaction among the steps; the control algorithm adopts sectional control, feed-forward control and self-adaptive control on the basis of normal PID. According to the scheme, the influence of nonlinearity, much interference, large lag and the like can be overcome, thus realizing automatic control in the heating process and automatic regulation in normal heating, and the actual control precision of the heat medium outlet temperature can achieve plus or minus 0.7DEG C.

Owner:COSCO SHIPPING TECH CO LTD

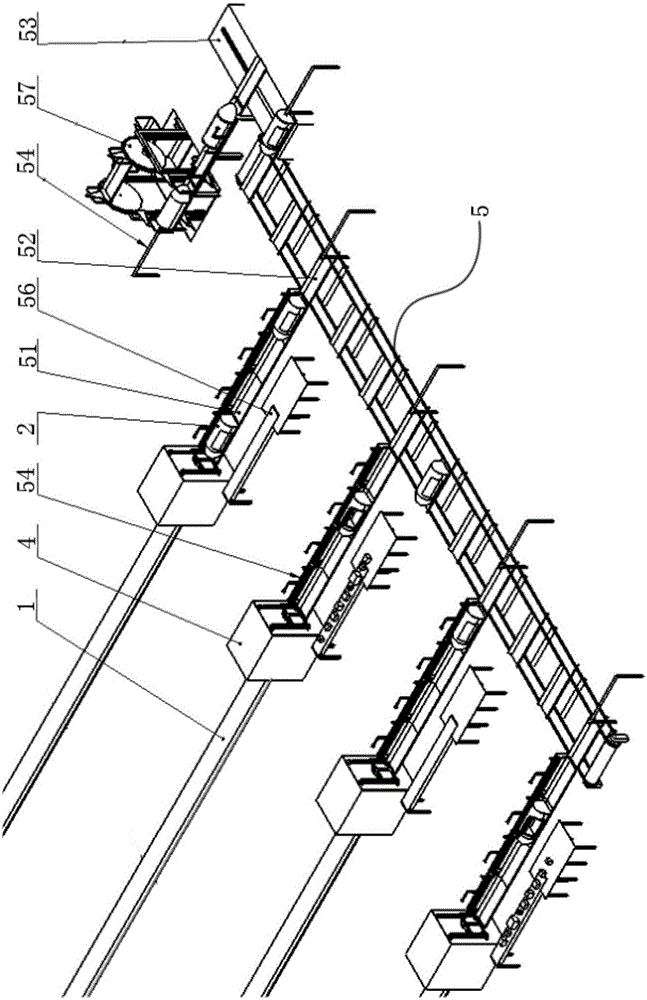

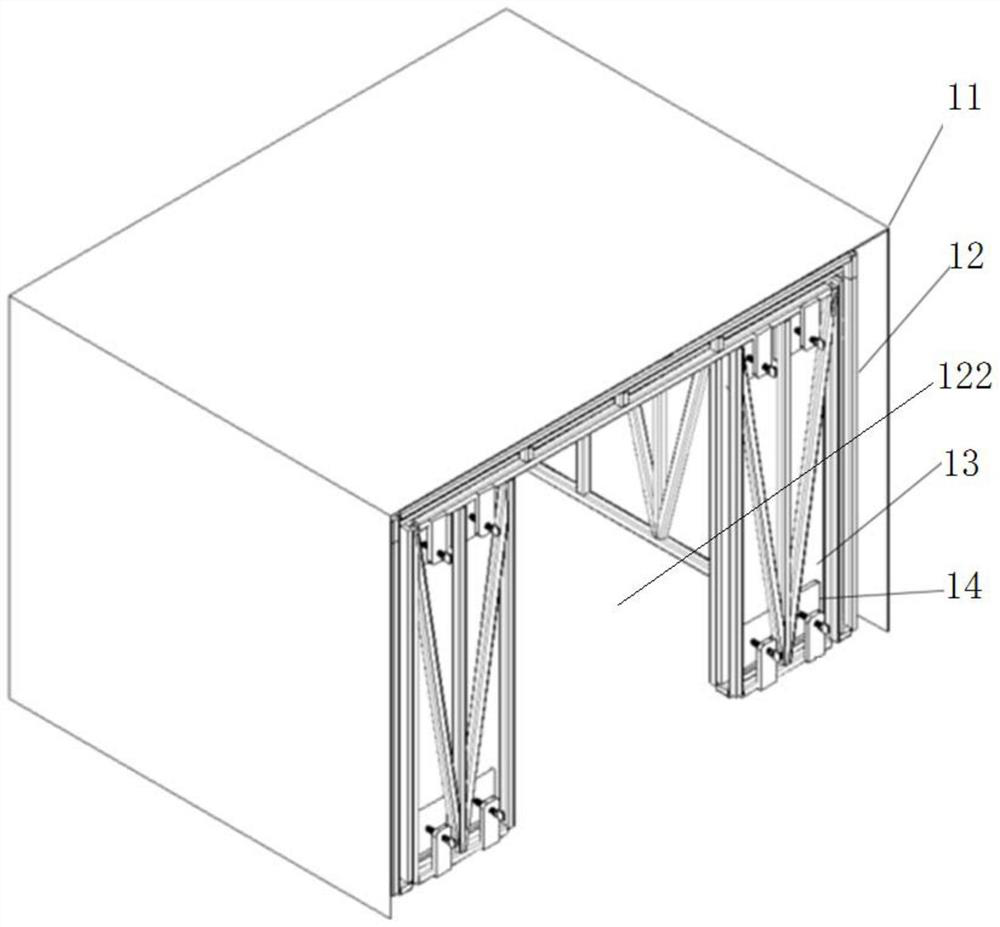

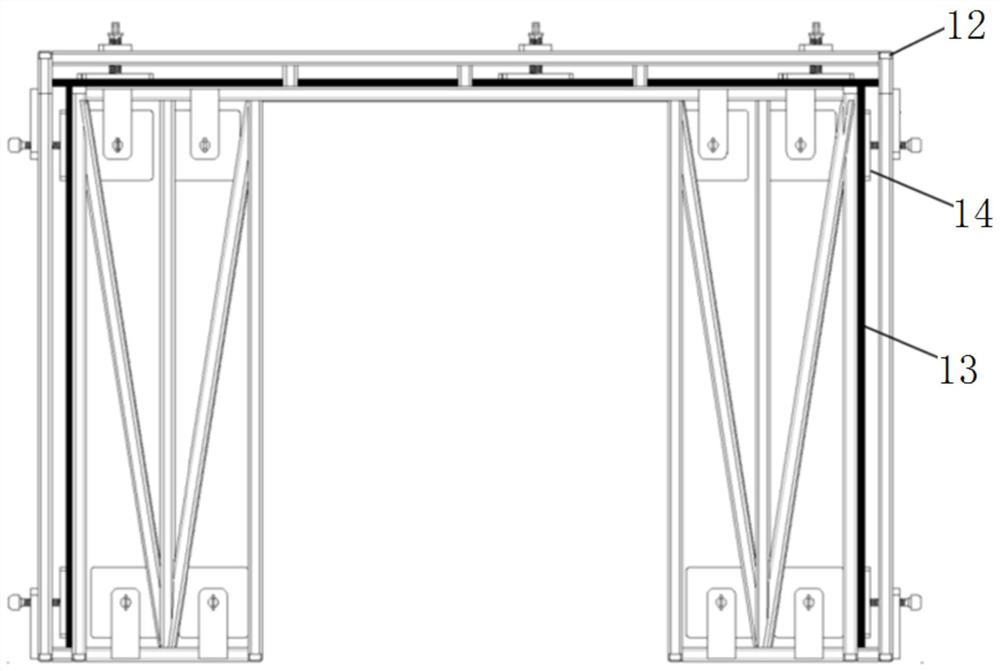

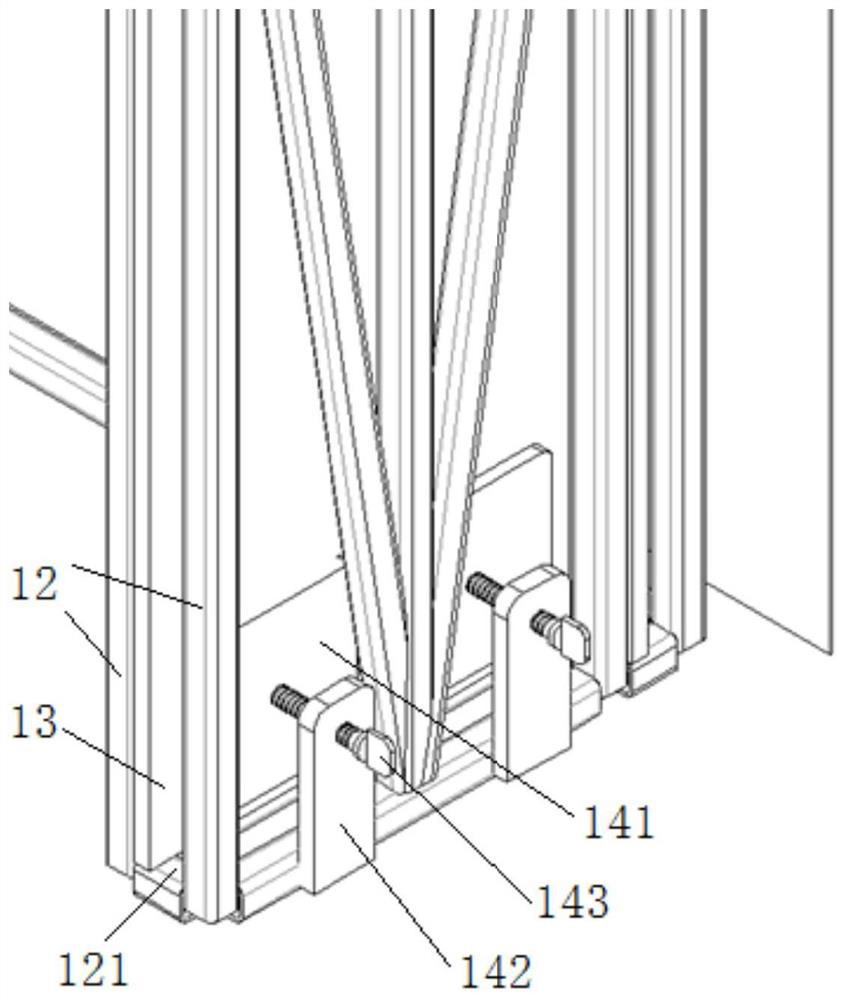

Industrial online CT radiation shielding device and CT detection equipment

PendingCN112666193ARealize online testing requirementsMeet testing needsMaterial analysis using wave/particle radiationRadiation leakageStructural engineering

The invention provides an industrial on-line CT radiation shielding device and CT detection equipment, and aims to break through the limitation that a traditional industrial CT self-shielding device is small in size of a detectable part, not suitable for on-line detection and incapable of changing the shielding amount. The shielding device can realize flexible adjustment of the radiation safety requirement and the shielding thickness in the industrial CT on-line detection process, meanwhile, the detection requirement of a large-size detection piece can be met. The device comprises a skin, a main body frame, N shielding layers and a shielding layer adjusting assembly, the main body frame is provided with multiple layers, the multiple layers of main body frames are sequentially nested from inside to outside, and the main body frame is provided with a mounting rail; the N shielding layers are installed in the installation rails of the main body frame, and the shielding layers are fixed to the main body frame through the shielding layer adjusting assemblies. The skins are arranged on the inner side and the outer side of the main body frame and used for wrapping the main body frame, openings are formed in the two sides of the main body frame and the skins, and lead rubber is arranged at the openings to prevent radiation leakage.

Owner:NAT INST CORP OF ADDITIVE MFG XIAN

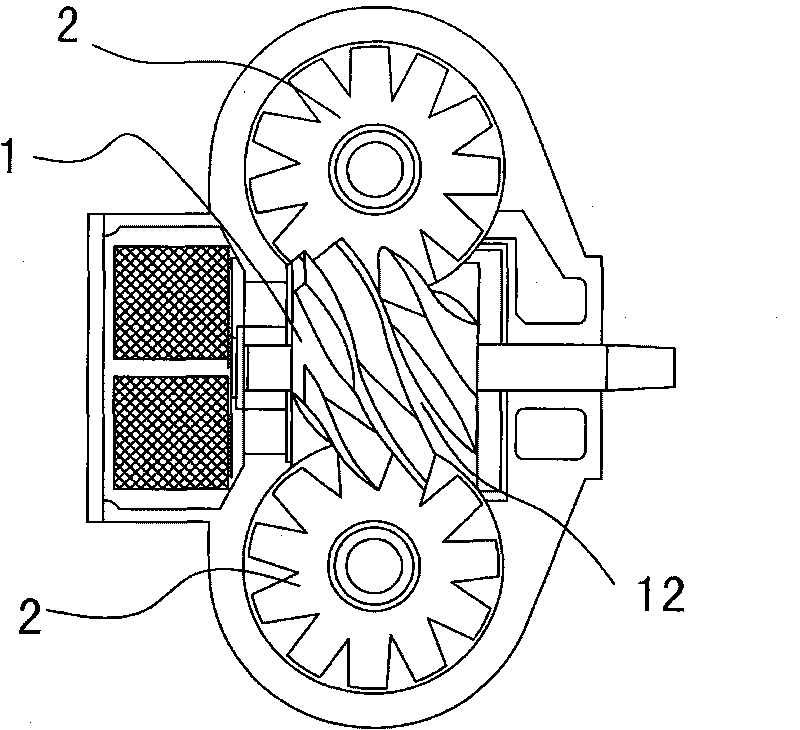

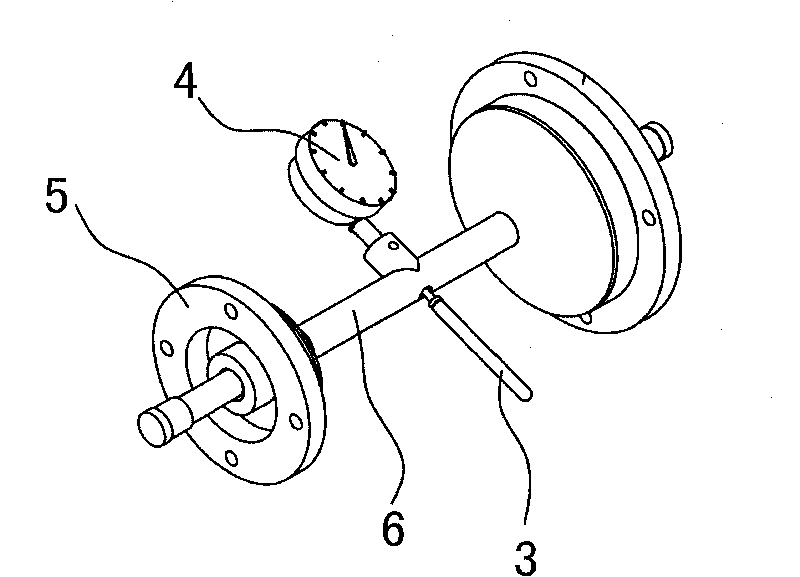

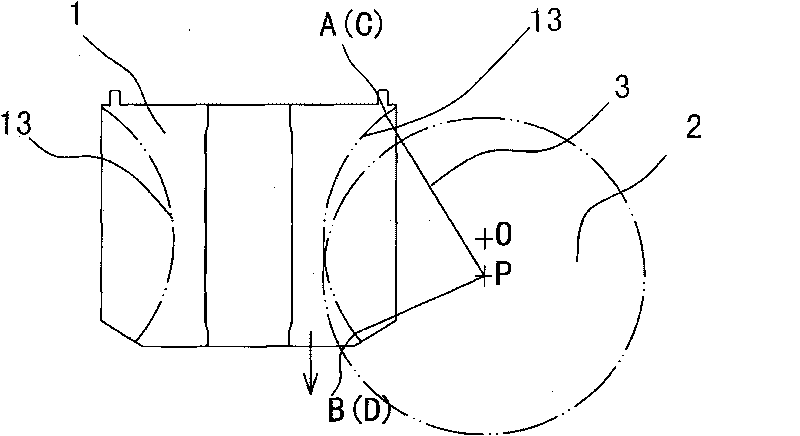

Method for adjusting star wheel-rotor engagement accuracy of single screw rod type refrigerating compressor

ActiveCN101725530AIncrease or decrease thicknessAvoid wear and tearRotary piston pumpsRotary piston liquid enginesRefrigeration compressorEngineering

The invention relates to a method for adjusting star wheel-rotor engagement accuracy of a single screw rod type refrigerating compressor. The method has the following steps that: (1) a main shaft is arranged in a machine casing, and a circular gasket is prearranged; (2) a centering tooling is arranged in the machine casing position in which a star wheel is arranged; (3) a screw rod rotor rotates, the end of a centering needle is adjusted to one end of a rotor groove, and a reading of a dialgage at the time is recorded as a; the screw rod rotor reversely rotates, the end of the centering needle is adjusted to the other end of the rotor groove, and a reading of the dialgage at the time is recorded as b; the tolerance range is set to be 0+ / -delta, and the difference between b and a is compared with 0+ / -delta; (4) if the difference between b and a exceeds the tolerance range, the thickness of the circular gasket between the fixed mating surfaces is increased or decreased, and the step (3) is repeated, until the difference between b and a is controlled within the tolerance range. The invention solves the problems that the traditional star wheel-rotor engagement has complicated debugging process, the assembly efficiency of the products is low, and the assembled star wheel-rotor engagement is still low.

Owner:MCQUAY AIR CONDITIONING & REFRIGERATION SUZHOU

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com