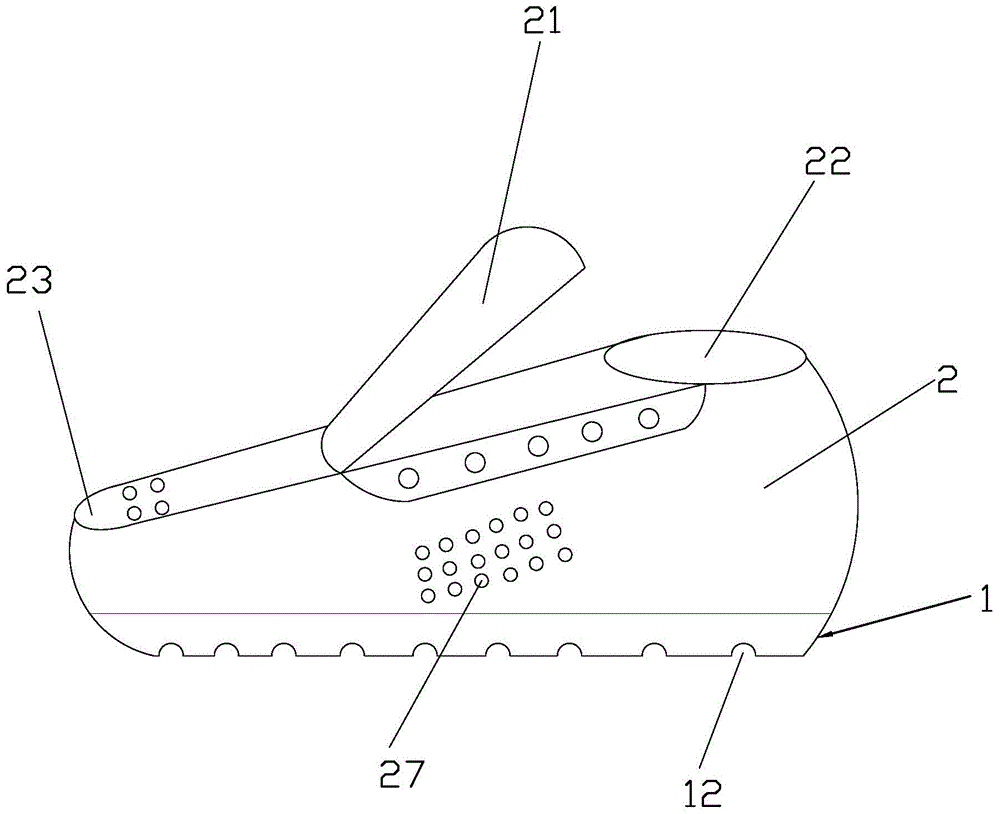

Preparation method for high-elastic rubber foamed shoe sole and application thereof to foamed shoe

A rubber foaming and high-elasticity technology, applied in the field of shoes, can solve problems such as shoe-making process troubles, stiff elastic effects, easy to pollute the environment, etc., and achieve good environmental protection effects, good wear-resistant effects, and long-lasting effects

- Summary

- Abstract

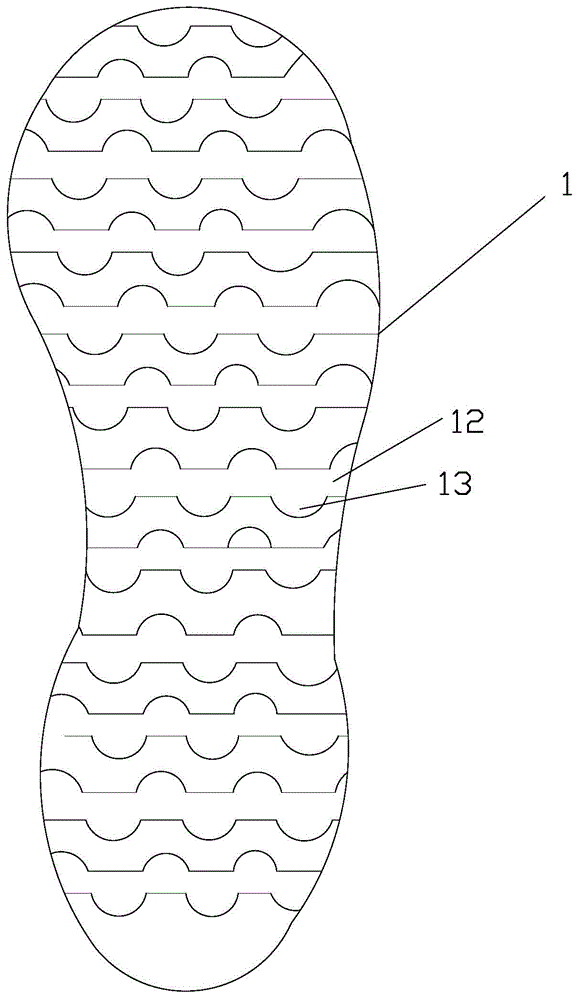

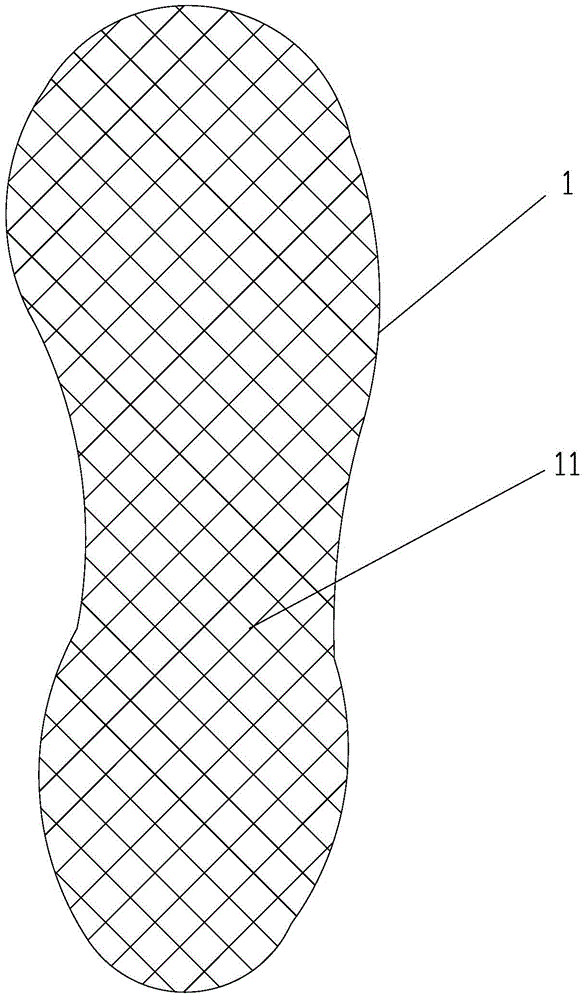

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] A preparation method for high elastic rubber foam sole, comprising the following steps:

[0030] (1) Proportioning raw materials by weight: 250-500 parts of natural rubber, 20-40 parts of talcum powder, 2-5 parts of antioxidant, 2-4 parts of rubber accelerator, 2-6 parts of zinc stearate, rubber Accelerator DM2-6 parts, zinc oxide 4-8 parts, baking soda 5-15 parts, polyethylene glycol 5-10 parts, AC foaming agent 2-6 parts;

[0031] (2) Put the raw materials into the internal mixer and stir, seal the reaction for 15-30 minutes, then start the machine to refine the raw materials into gel;

[0032] (3) cooling the jelly formed by internal mixer, the cooling time is 8-24 hours, and rubber accelerator is added in the jelly;

[0033] (4) Allocate the color of required production product, add pigment in the jelly after cooling, add sulfur and rubber vulcanization accelerator simultaneously, then put jelly into an open mill and stir evenly;

[0034] (5) Prepare a mould, intr...

Embodiment 2

[0040] A preparation method for high elastic rubber foam sole, comprising the following steps:

[0041] (1) Proportioning raw materials by weight: 350-450 parts of natural rubber, 25-35 parts of talcum powder, 3-4 parts of antioxidant, 2-4 parts of rubber accelerator, 3-5 parts of zinc stearate, rubber 3-5 parts of accelerator DM, 5-7 parts of zinc oxide, 8-12 parts of baking soda, 6-9 parts of polyethylene glycol, 3-5 parts of AC foaming agent;

[0042] (2) Put the raw materials into the internal mixer and stir, seal the reaction for 15-30 minutes, then start the machine to refine the raw materials into gel;

[0043] (3) cooling the jelly formed by internal mixer, the cooling time is 8-24 hours, and rubber accelerator is added in the jelly;

[0044] (4) Allocate the color of required production product, add pigment in the jelly after cooling, add sulfur and rubber vulcanization accelerator simultaneously, then put jelly into an open mill and stir evenly;

[0045] (5) Prepare ...

Embodiment 3

[0051] A preparation method for high elastic rubber foam sole, comprising the following steps:

[0052] (1) Raw materials are proportioned by weight: 500 parts of natural rubber, 30 parts of talcum powder, 3 parts of antioxidant, 3 parts of rubber accelerator M, 5 parts of zinc stearate, 5 parts of rubber accelerator DM, 6 parts of zinc oxide, 10 parts of baking soda, 7 parts of polyethylene glycol, 4 parts of AC foaming agent;

[0053] (2) Put the raw materials into the internal mixer and stir, seal the reaction for 20 minutes, then start the machine to knead the raw materials into gel;

[0054] (3) cooling the jelly formed by the internal mixer, the cooling time is 24 hours, and rubber accelerator is added in the jelly;

[0055] (4) Allocate the color of required production product, add pigment in the jelly after cooling, add sulfur and rubber vulcanization accelerator simultaneously, then put jelly into an open mill and stir evenly;

[0056] (5) Prepare a mould, introduce...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com