Patents

Literature

121 results about "Rebound effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The rebound effect, or rebound phenomenon, is the emergence or re-emergence of symptoms that were either absent or controlled while taking a medication, but appear when that same medication is discontinued, or reduced in dosage. In the case of re-emergence, the severity of the symptoms is often worse than pretreatment levels.

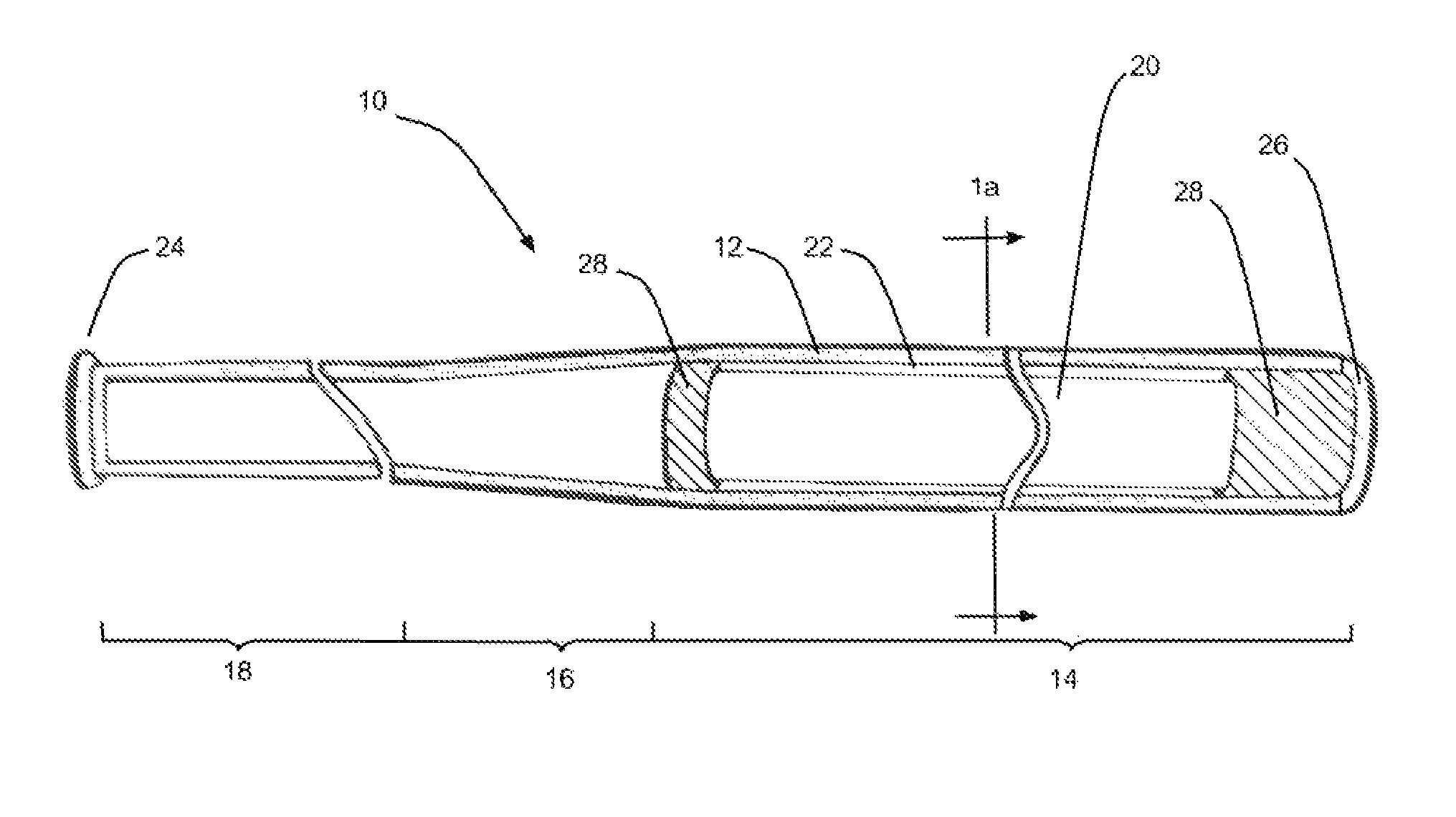

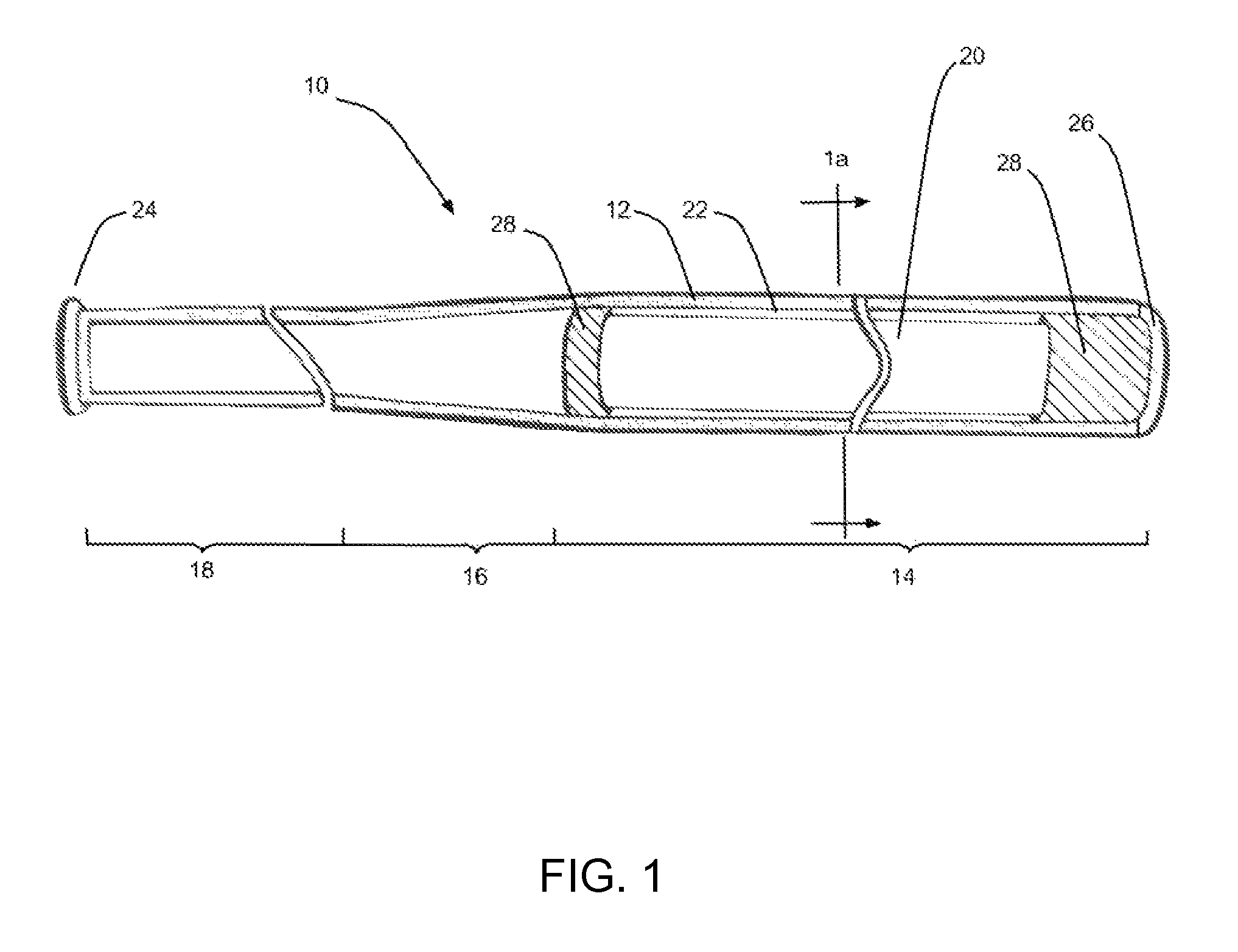

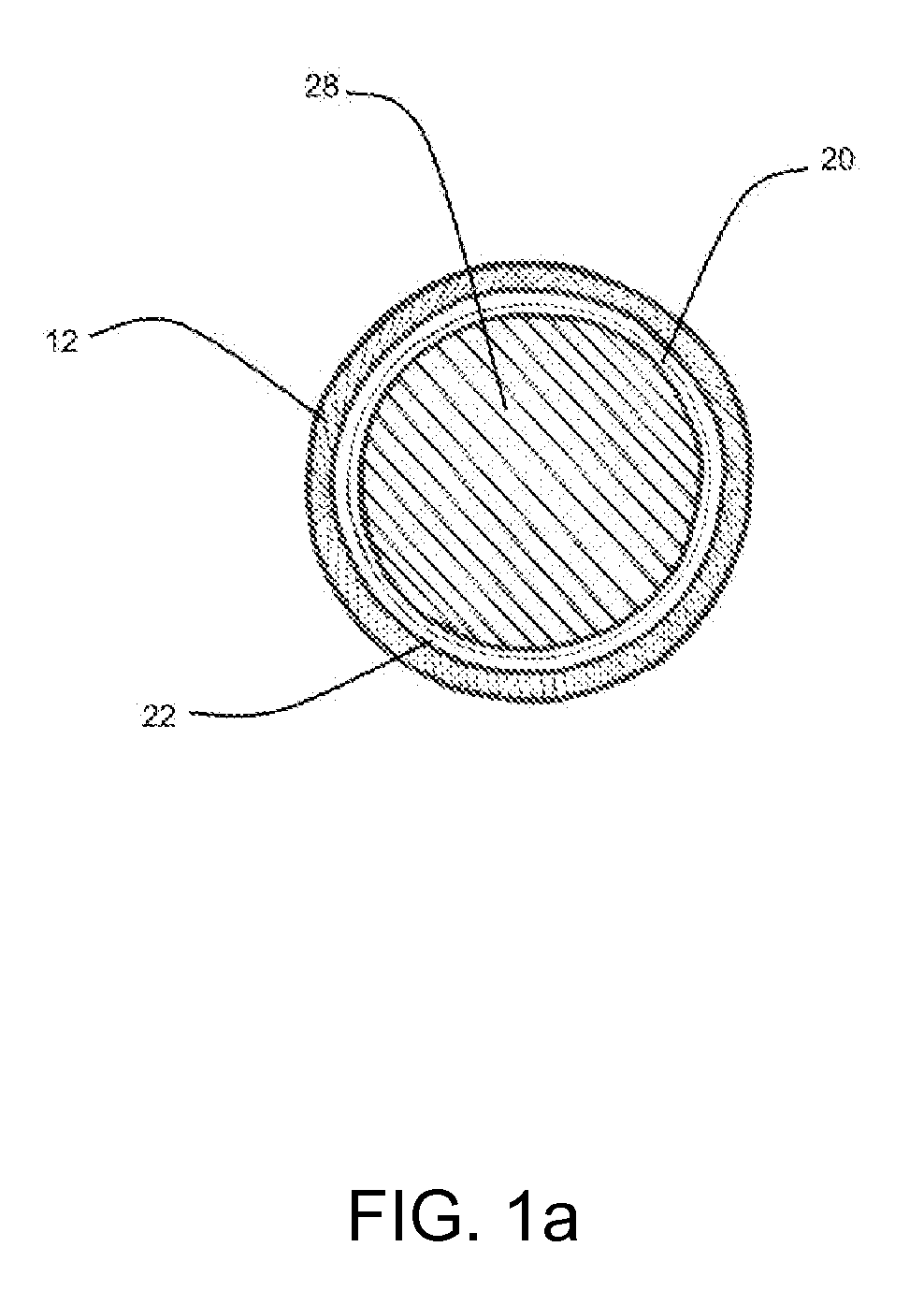

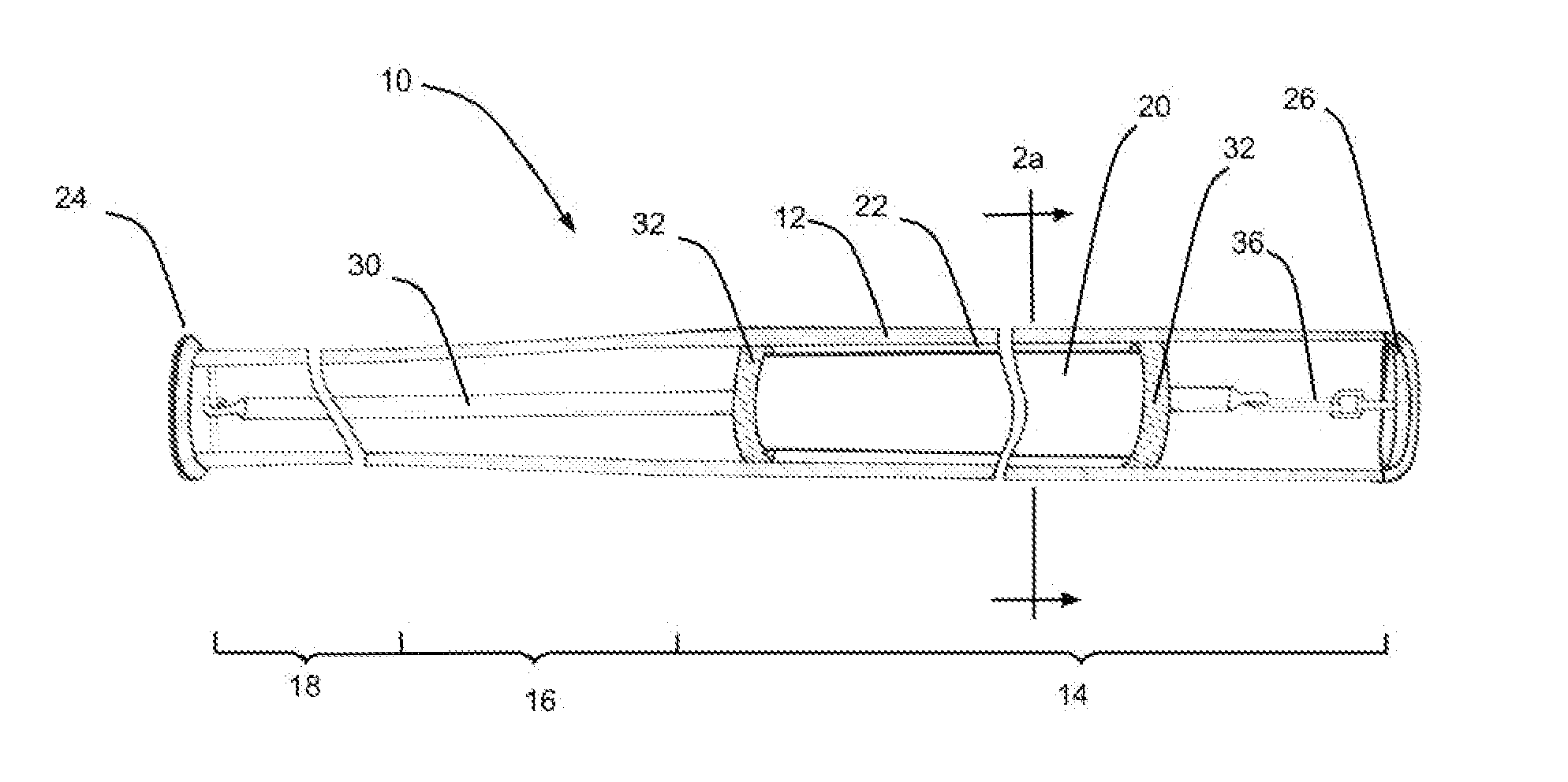

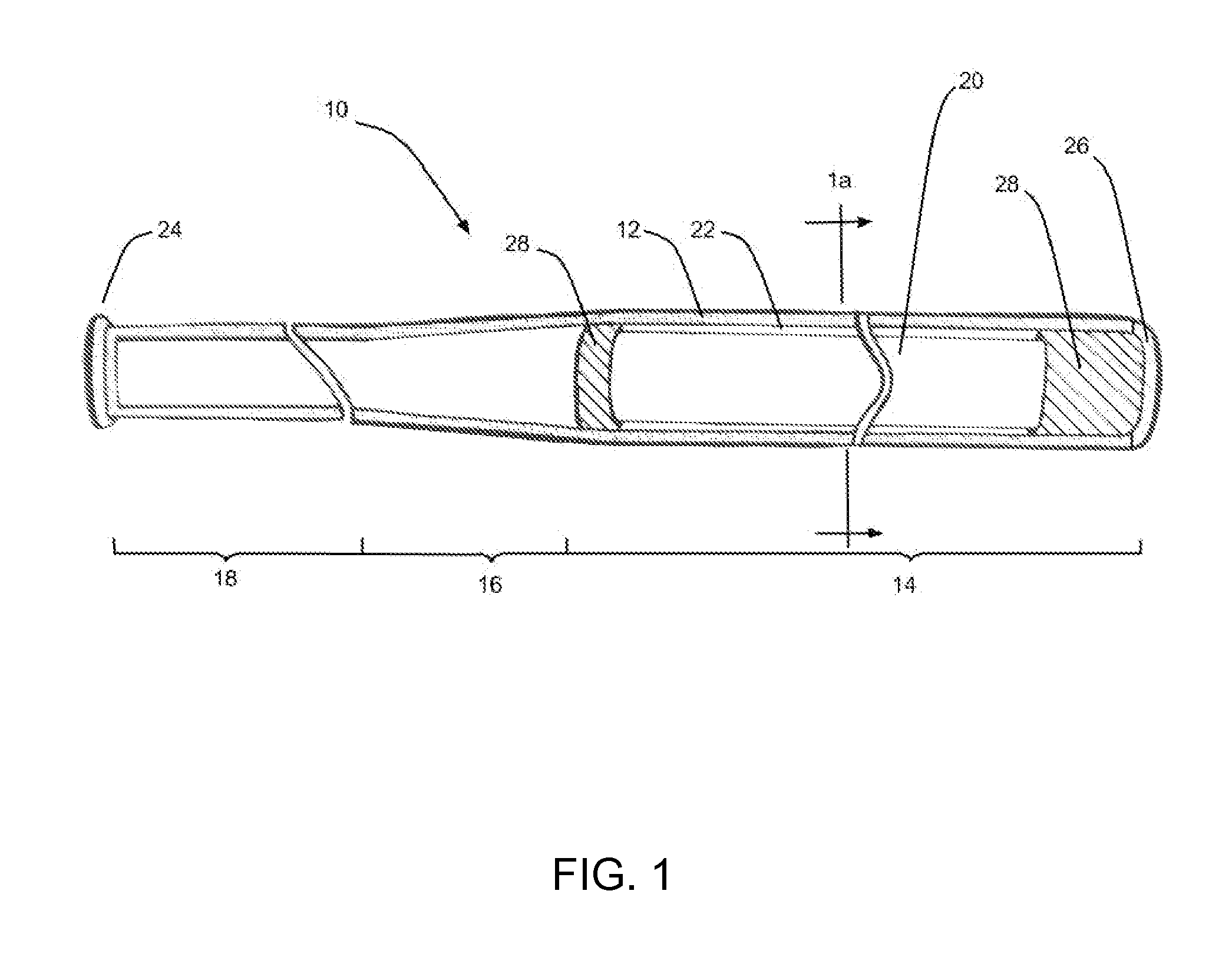

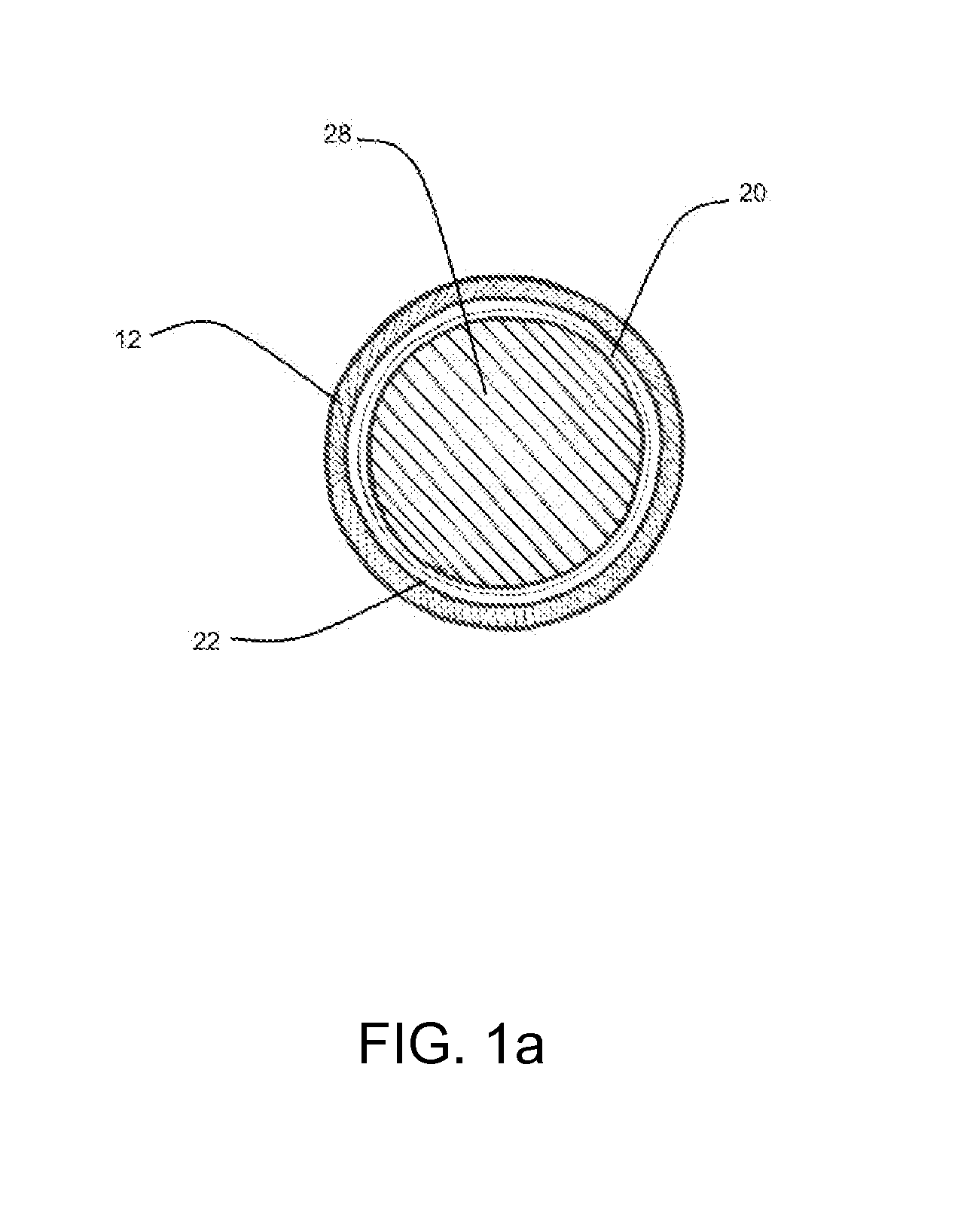

Baseball bat

A hollow non-wood baseball or softball bat wherein the impact portion of the bat contains an inner barrel that is positioned by means of a (i) foam insert, (ii) tube extending from the bat's knob, or (iii) line attached to the bat's knob and end cap and extending throughout the bat such that the inner barrel does not come into contact with the inside wall of the bat when the bat is at rest yet when swung the inner barrel is allowed to move so as to amplify the rebound effect given to the ball upon impact with the bat.

Owner:PEGNATORI CARL

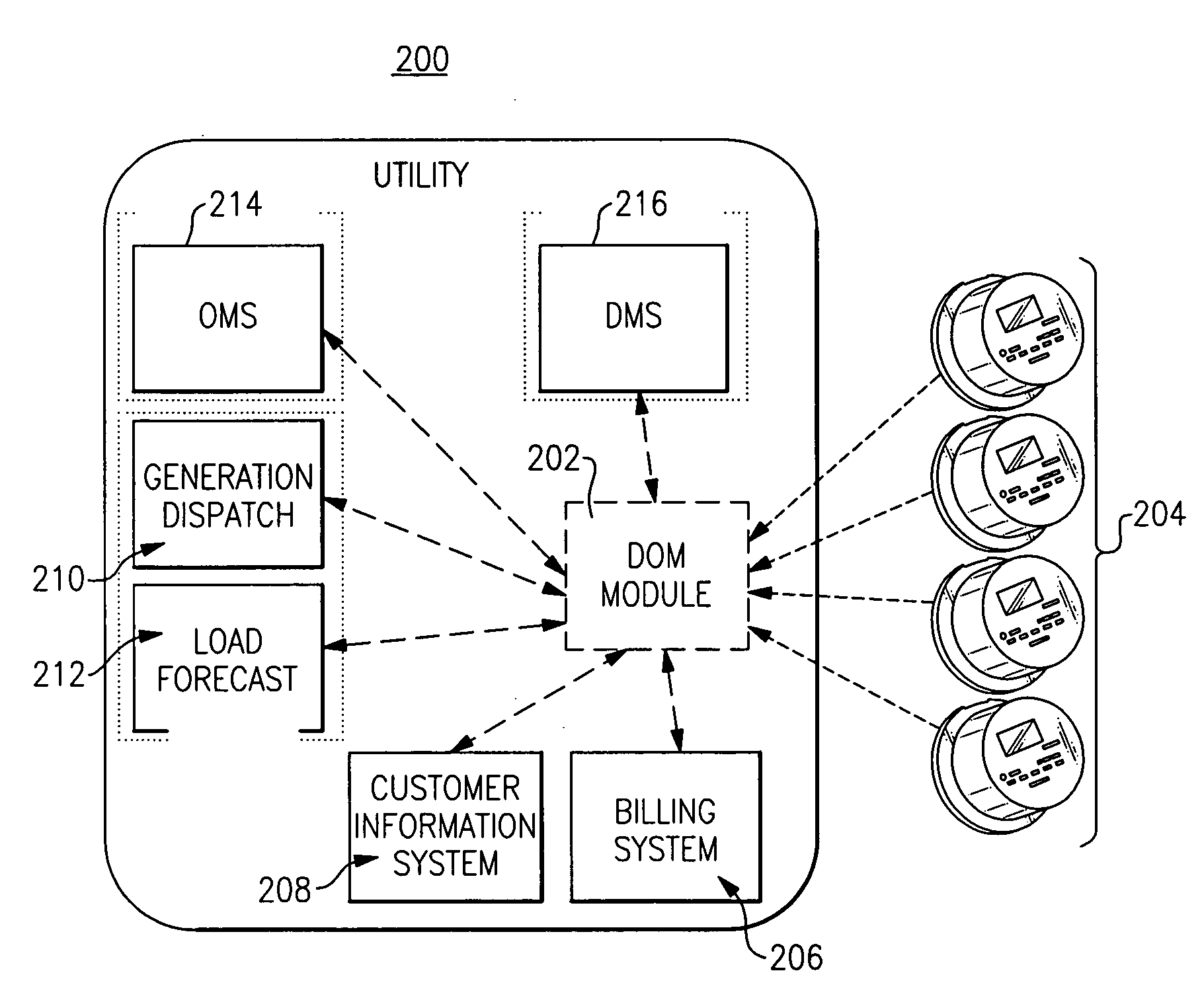

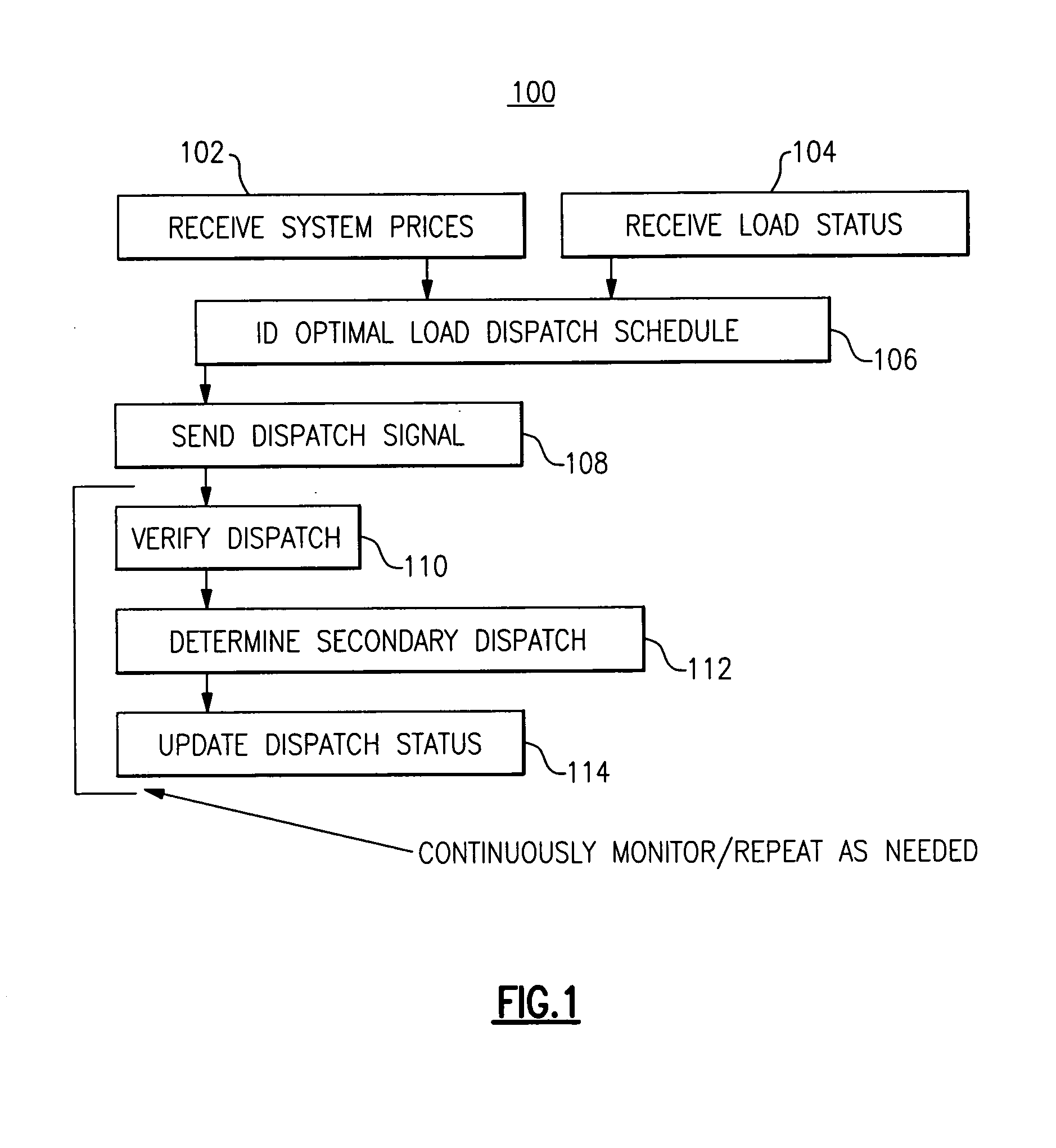

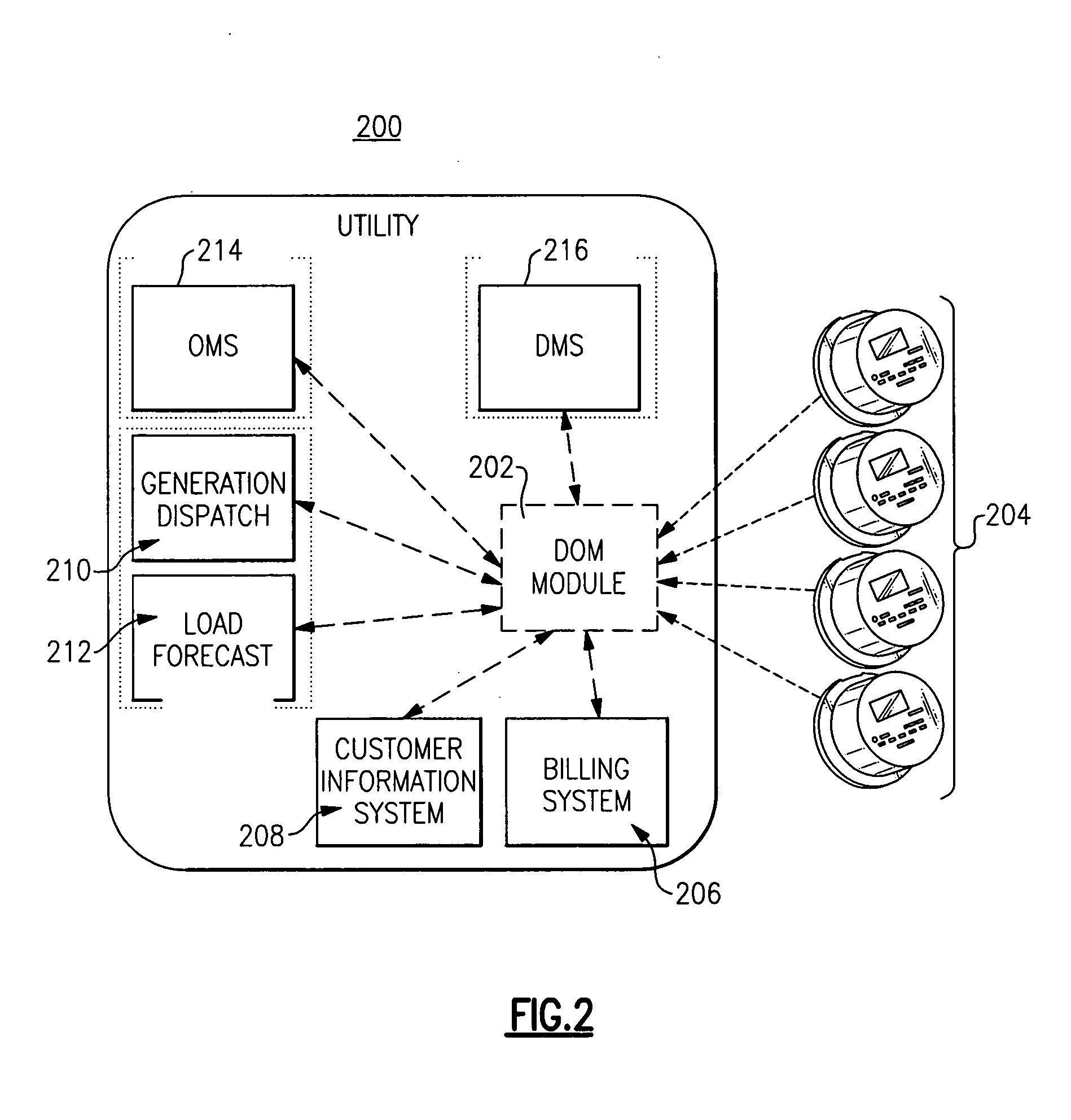

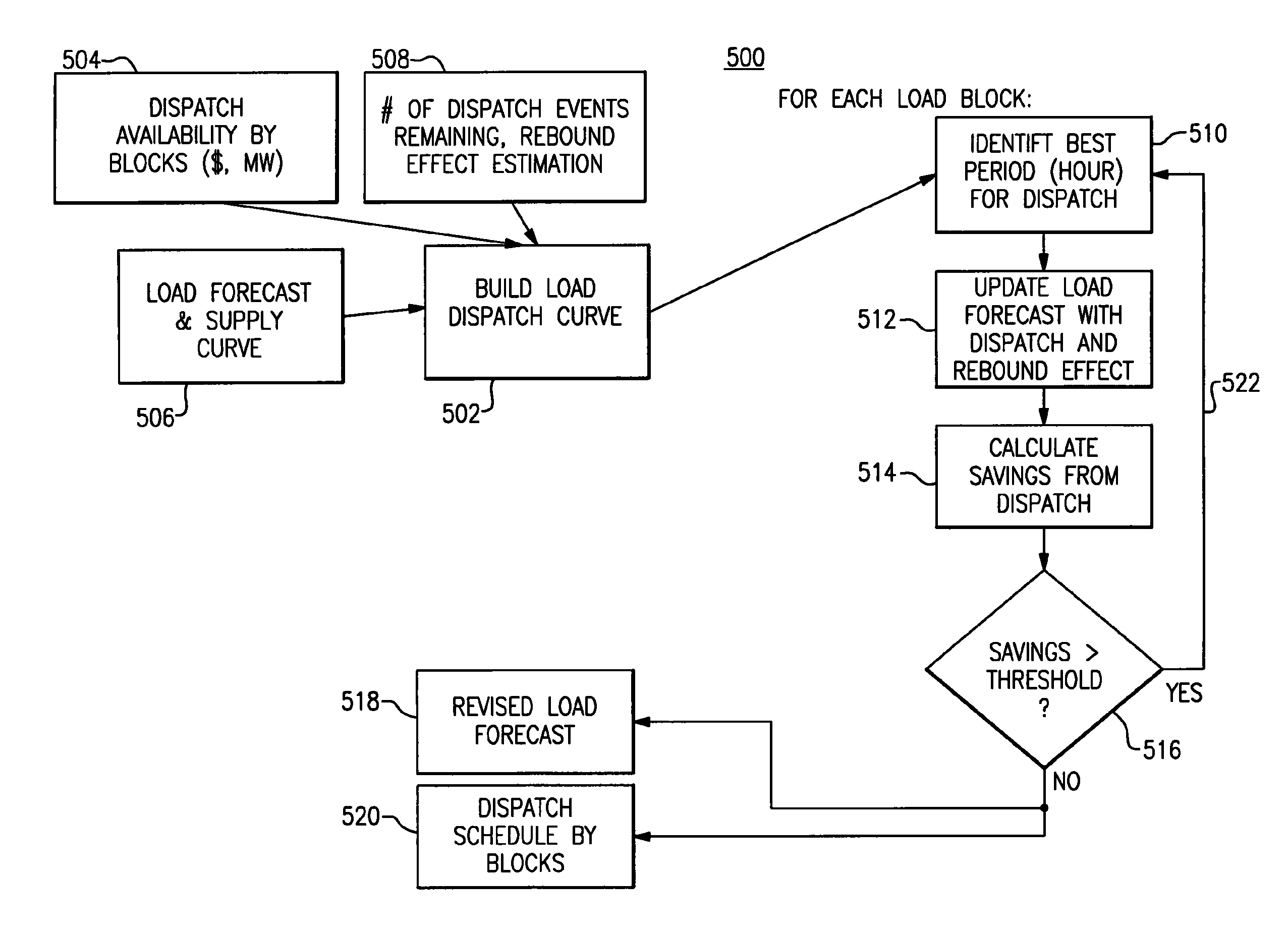

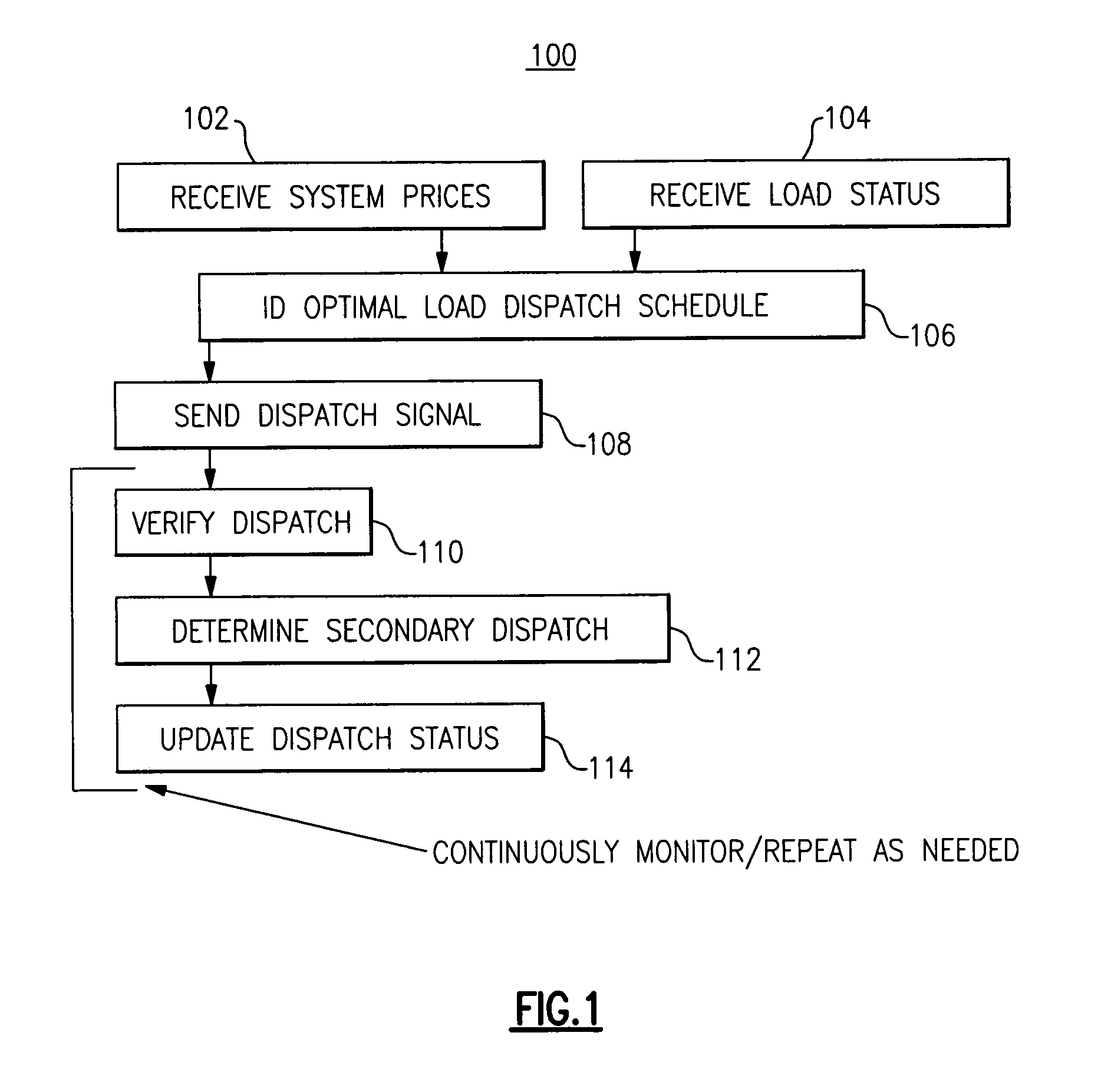

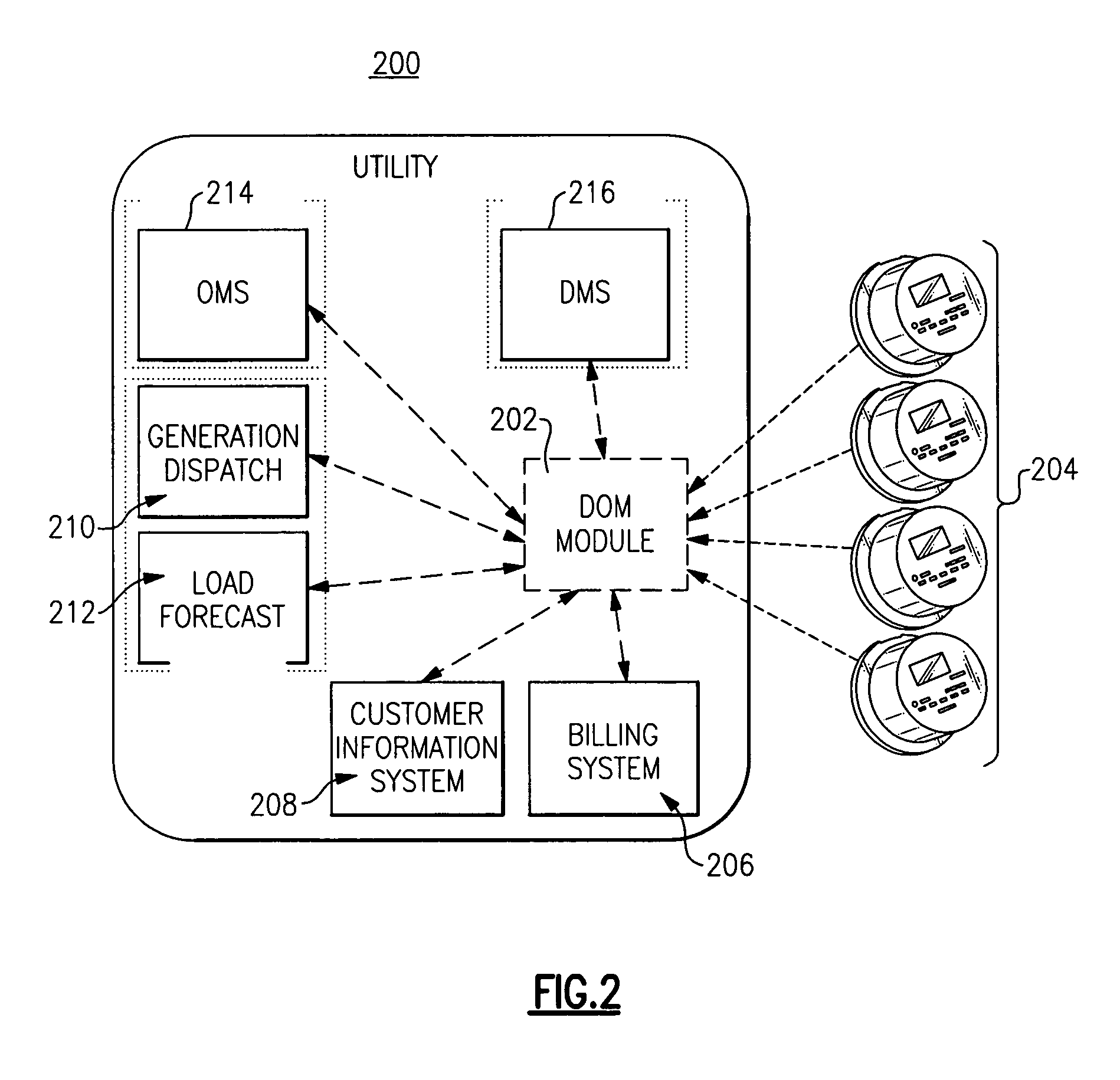

Optimal dispatch of demand side electricity resources

A load dispatch system operates in response to algorithmic software to generate an optimized load dispatch schedule based on data selected from one or both of rebound effect data or optimized load dispatch schedule opportunity cost data corresponding to dispatching of resources with a contractually limited number of dispatches in a given time period.

Owner:GENERAL ELECTRIC CO

Optimal dispatch of demand side electricity resources

A method of load dispatch generates a load dispatch curve in response to both the opportunity cost of dispatching resources with a contractually limited number of dispatches in a given time period and estimated rebound effect data. The method identifies a best time period for dispatch based on the load dispatch curve and also supply curve data and generates a resultant load dispatch schedule. The resultant load dispatch schedule is transmitted to one or more smart home meters to dispatch loads in a manner that provides the greatest economic benefit.

Owner:GE DIGITAL HLDG LLC

Quinoline derivatives, their production and use

The present compounds are intermediates for the preparation of quinoline derivatives and compositions having gonadotropin-releasing hormone antagonistic activity useful as propylactics or therapeutic agent for the prevention or treatment of several hormone dependent diseases, for example, a sex hormone dependent cancer (e.g. prostatic cancer, uterine or cervical cancer, breast cancer, pituitary adenoma), benign prostatic hypertrophy, myoma of the uterus, endometriosis, precocious puberty, amenorrhea, premenstrual syndrome, polycystic ovary syndrome and acne vulgaris; are effective as a fertility controlling agent in both sexes (e.g. a pregnancy controlling agent and a menstrual cycle controlling agent); can be used as a male or female contraceptive, as an ovulation-inducing agent; can be used as an infertility treating agent by using a rebound effect owing to a stoppage of administration thereof; and are useful for modulating estrous cycles in animals in the field of animal husbandry, as agents for improving the quality of edible meat or promoting the growth of animals, and as agents for promoting spawning in fish.

Owner:TAKEDA PHARMA CO LTD

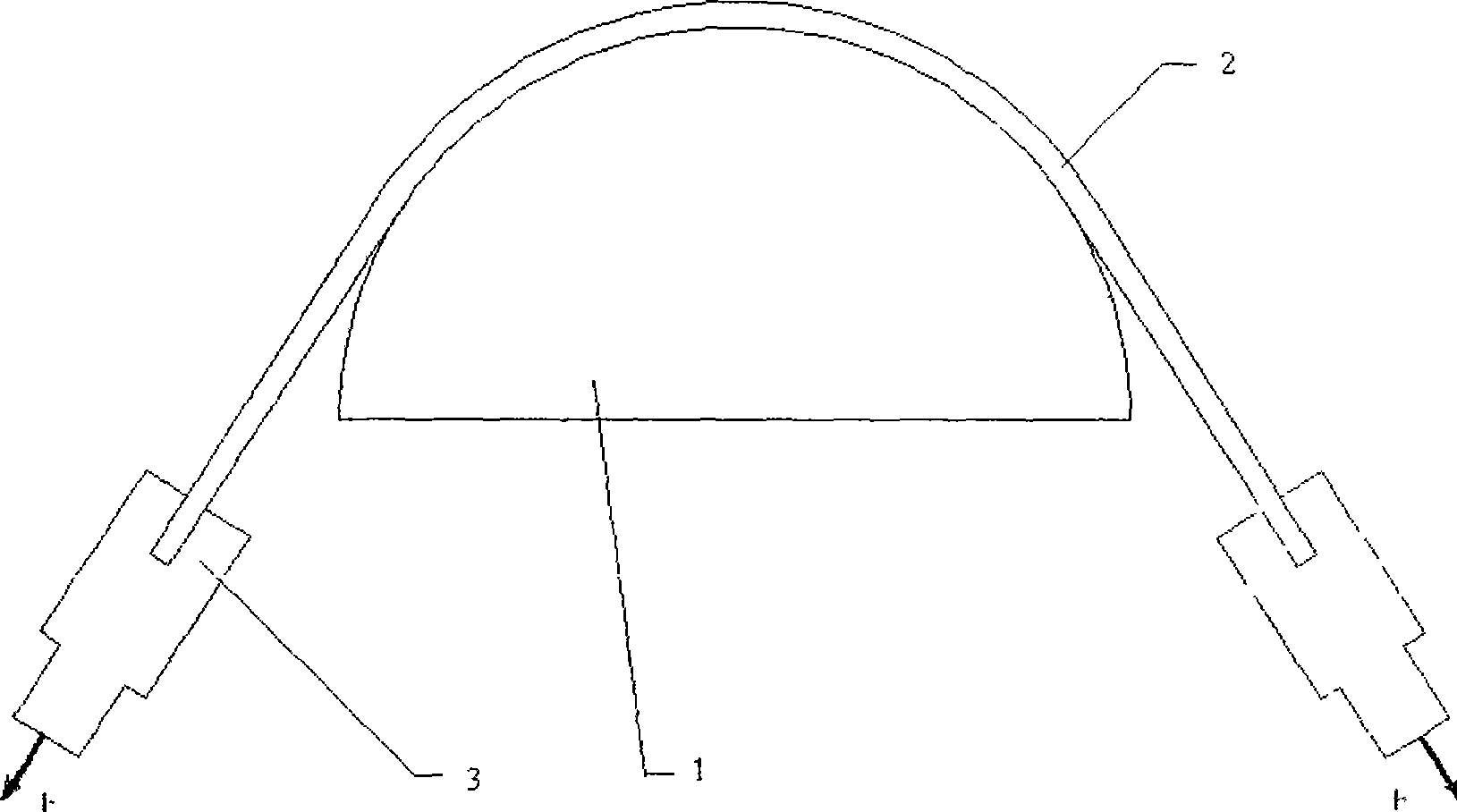

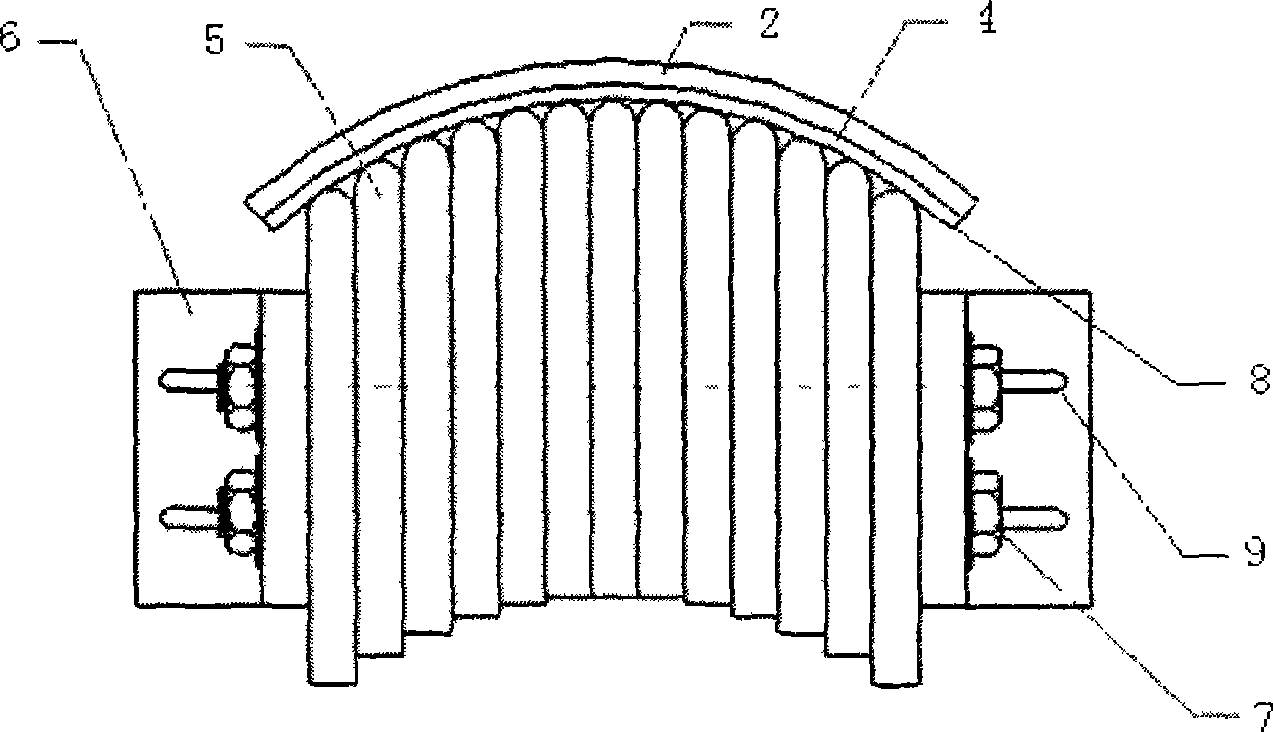

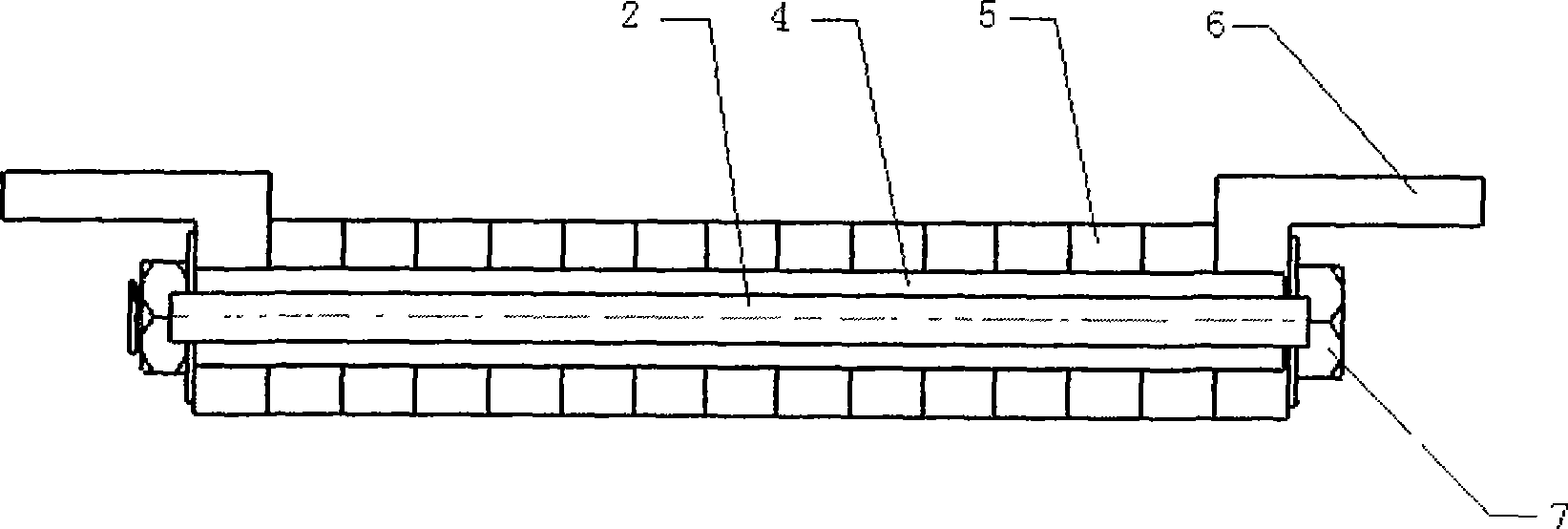

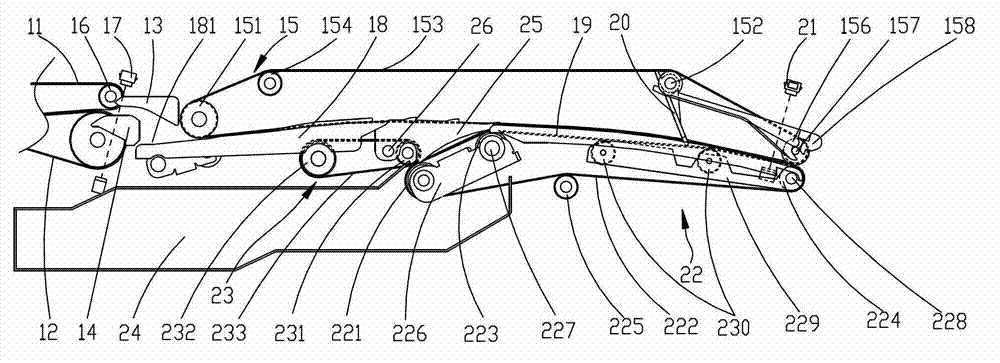

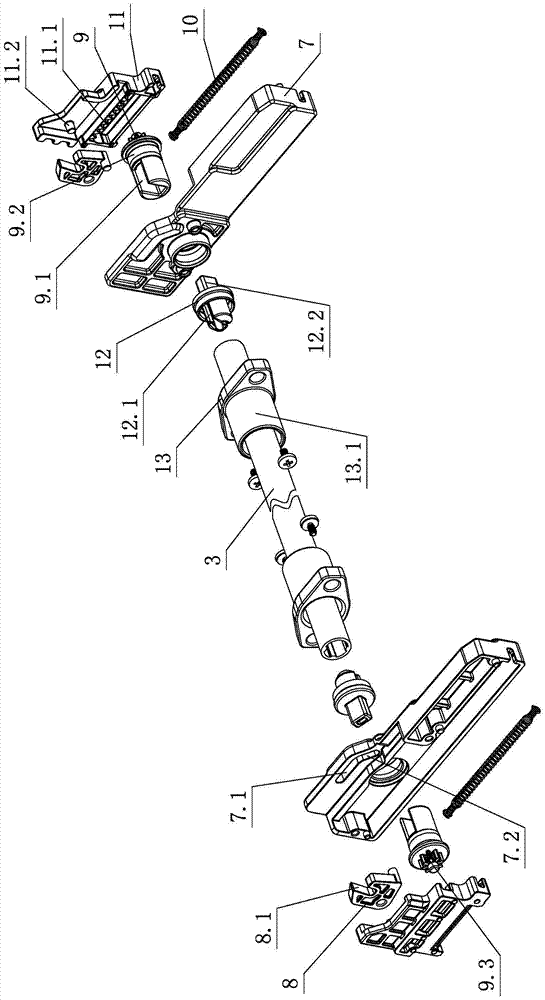

Stretch-bending forming die and forming method

InactiveCN101518802AAchieving Precise FormingShorten the design and production cycleShaping toolsEngineeringCushion

The invention discloses a stretch-bending forming die and a forming method, including a basic body (5), a cushion layer (4), a connecting bolt (7) and two clamp blocks (6). The end surface of one end of the basic body (5) is an arc working surface (10), with a through-hole (11) which is matched with the connecting bolt (7) in the middle. One clamp block, a plurality of basic bodies and another clamp block are sequentially arranged on the connecting bolt (7) in series and tightly clamped and fixed, thereby integrating a die; by adjusting the position (11) where the connecting bolt passes through a through groove on each basic body, the position of the working surface (10) of each basic body is adjusted; and by fixing the die onto the working table of a stretch bender by a mounting hole (9), the stretch-bending forming is carried out to a workpiece (2) to be formed. In the forming process, by slightly adjusting the position of the basic body (5), the shape of the external surface of the die is changed so as to compensate the rebounding effect on the forming accuracy and adapt to the rebounding control needs of different stretch-bending parts; and the invention is characterized by simple structure, convenient use, high production efficiency and low cost.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

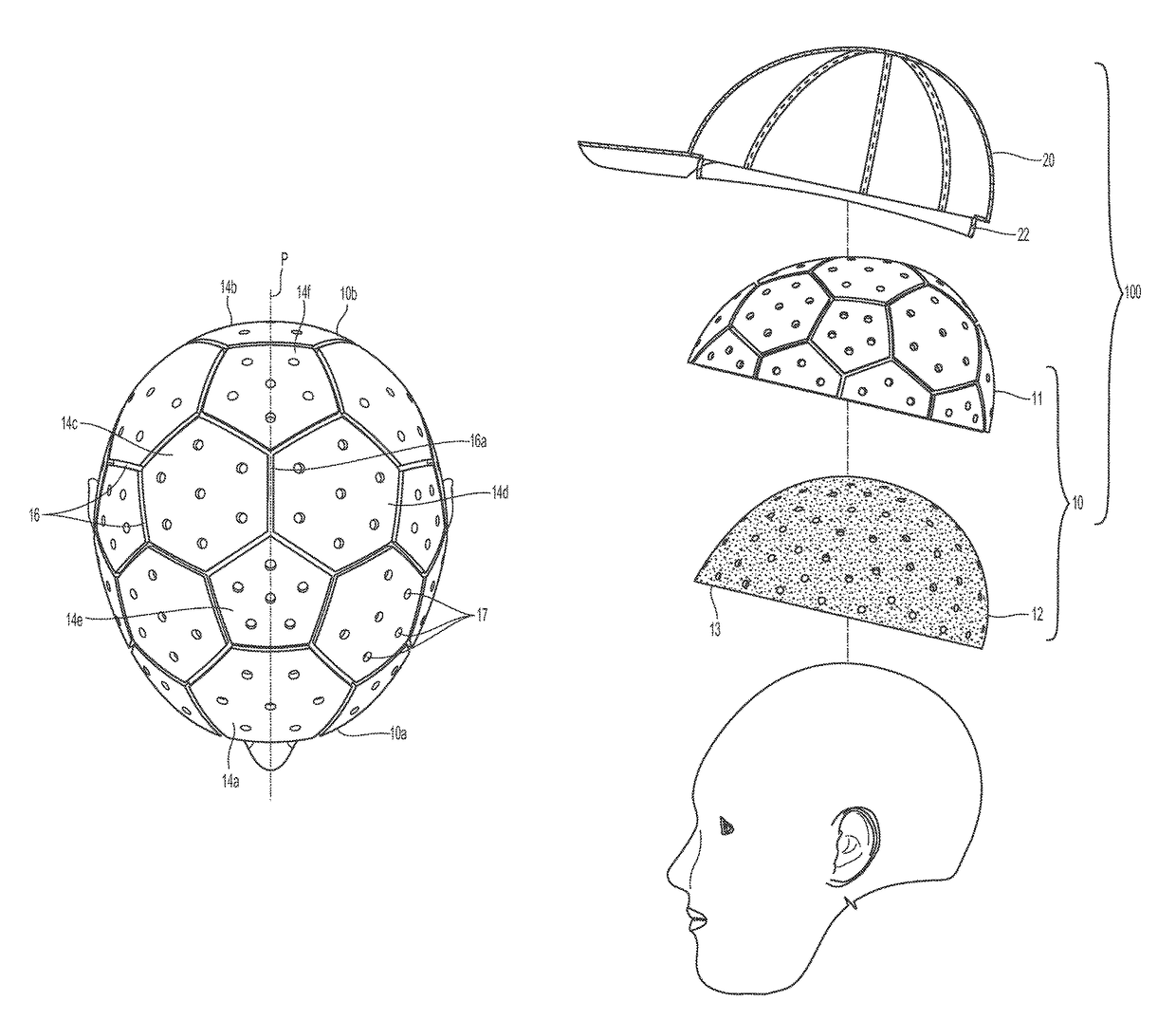

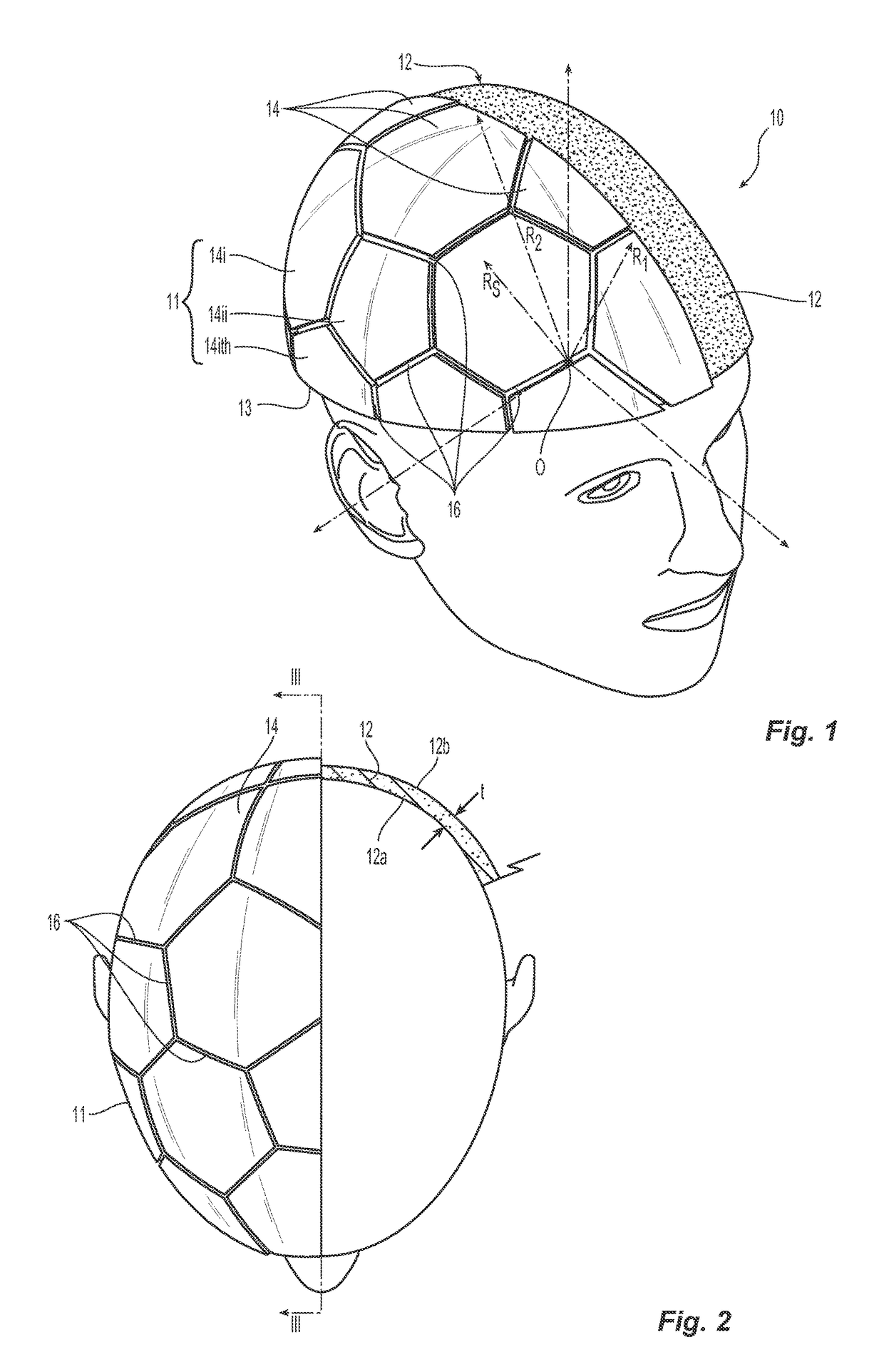

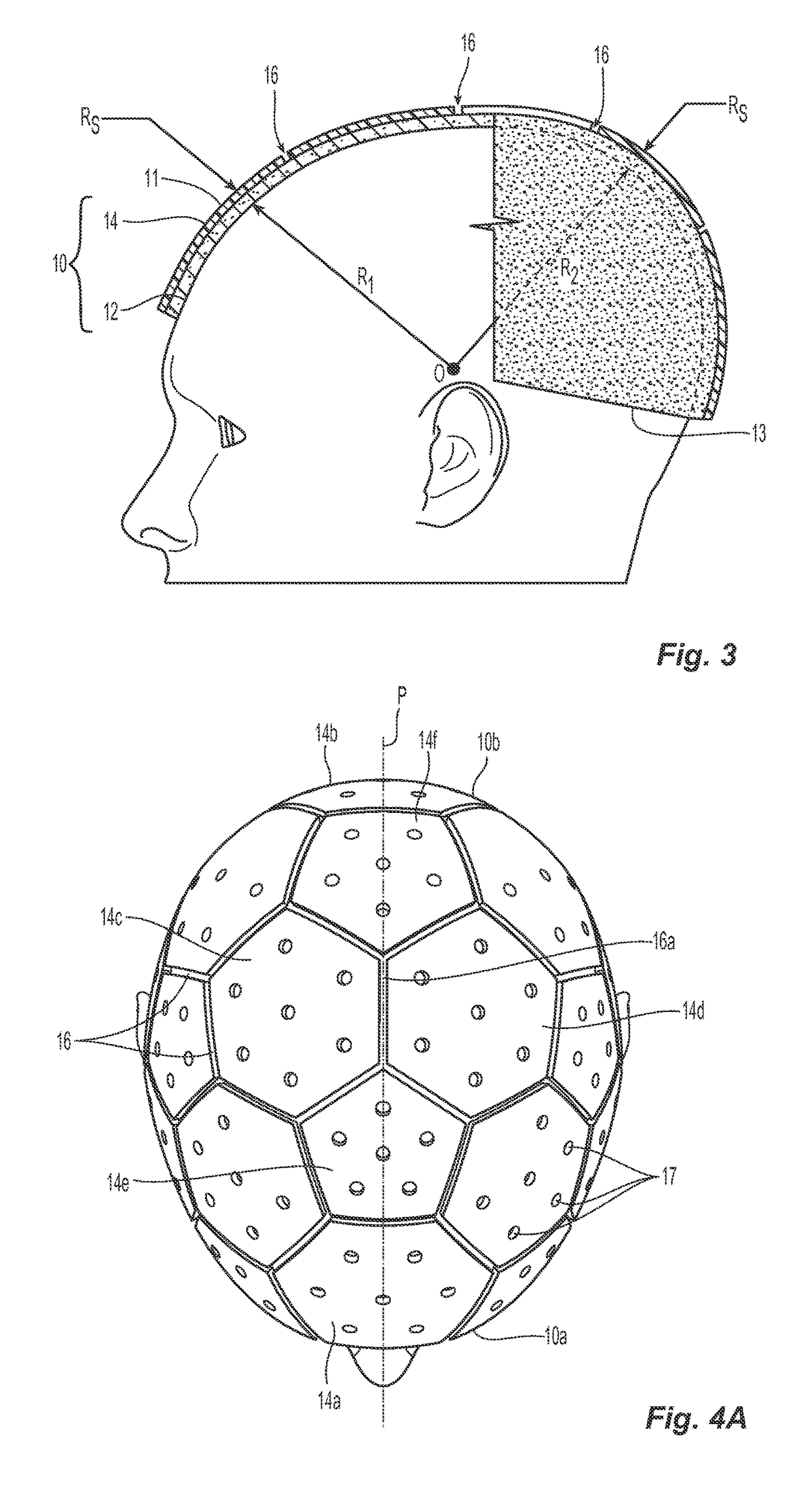

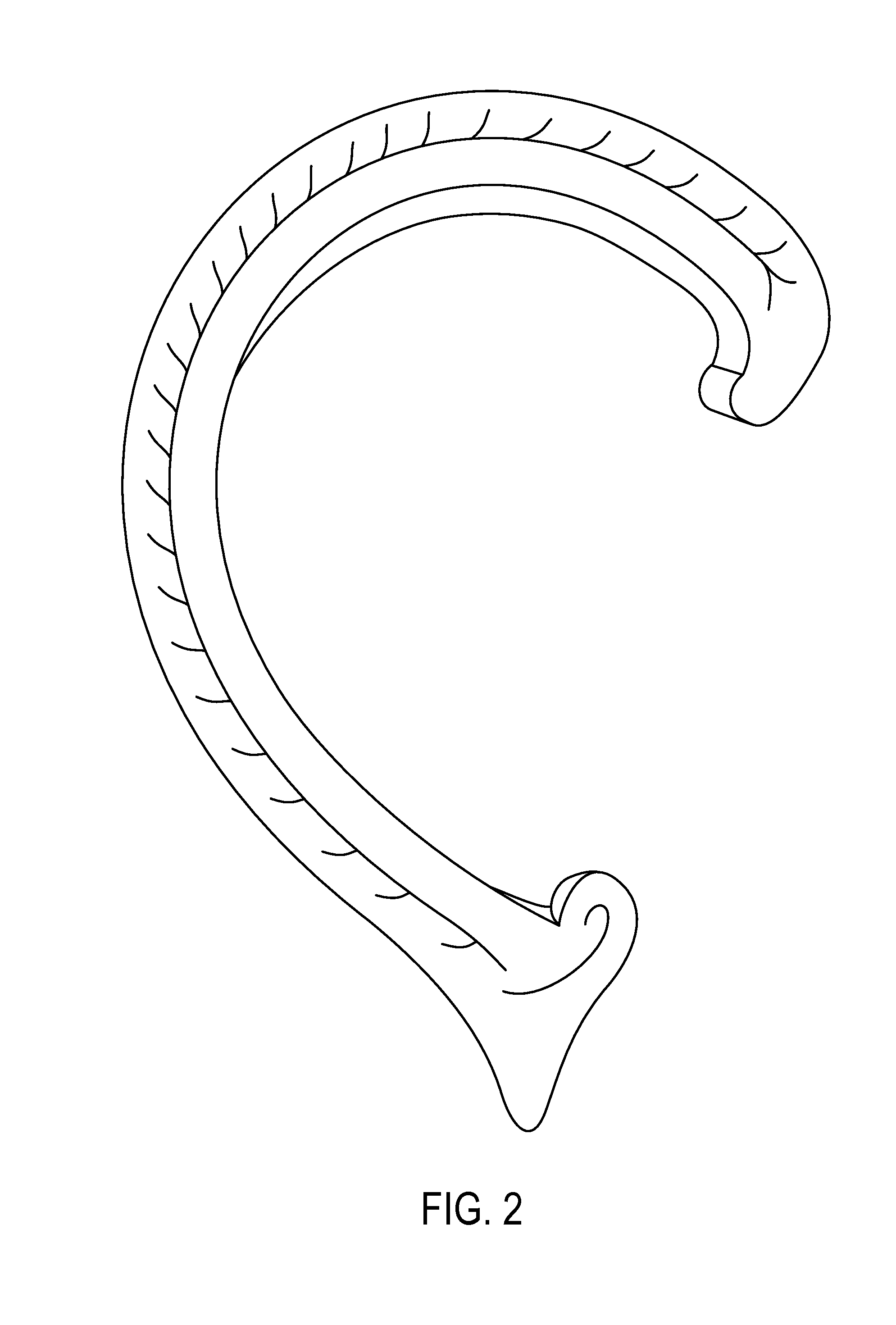

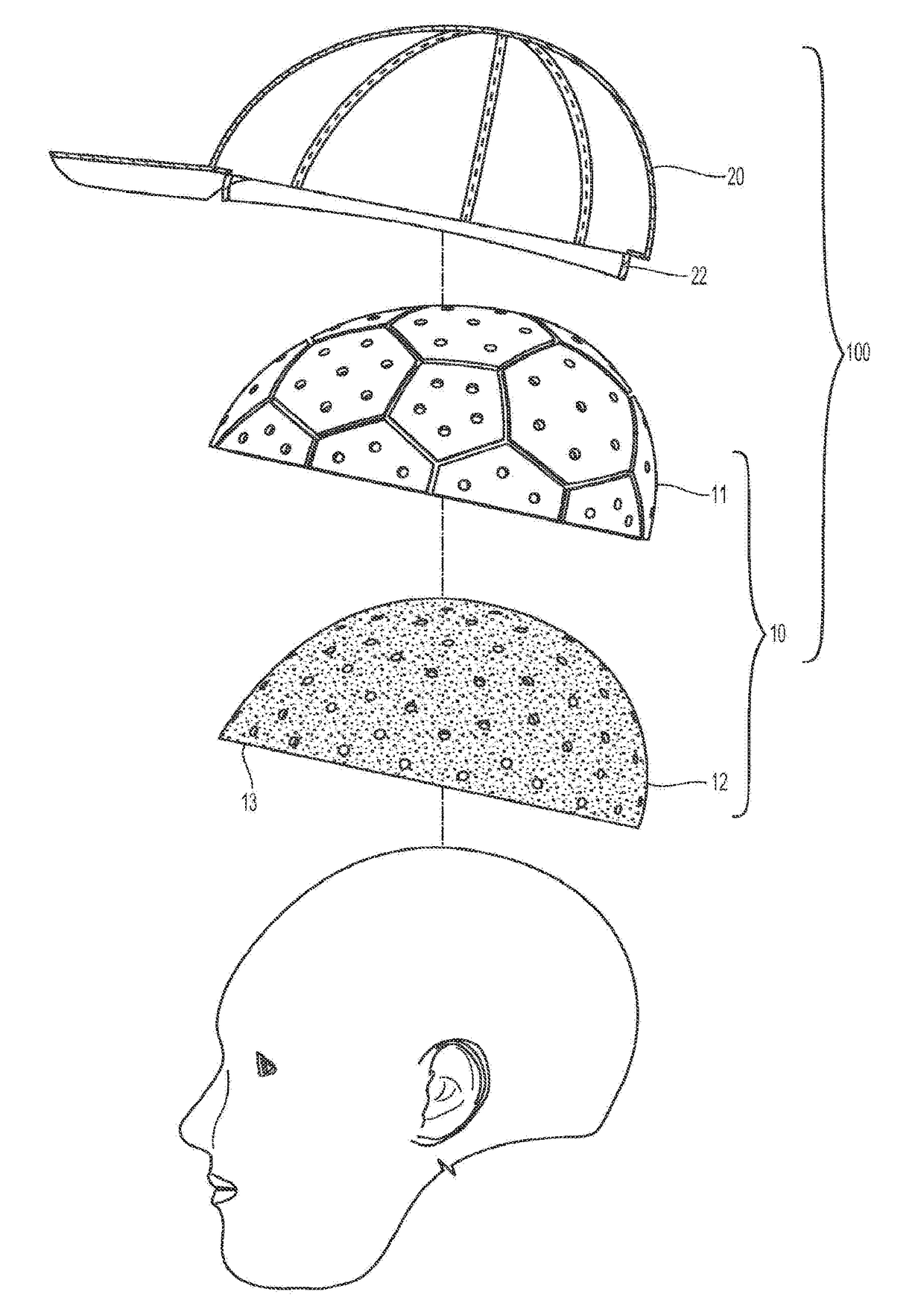

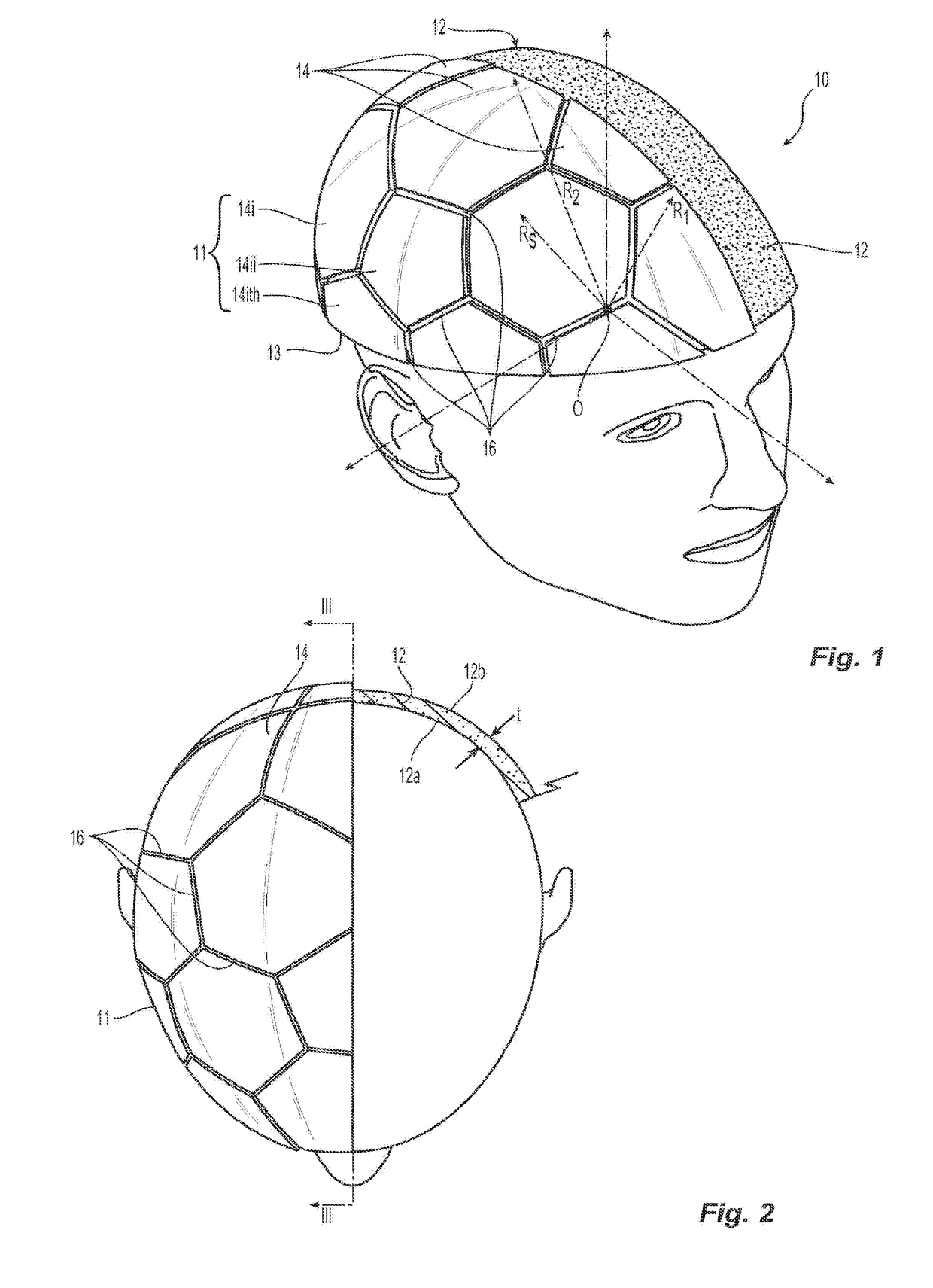

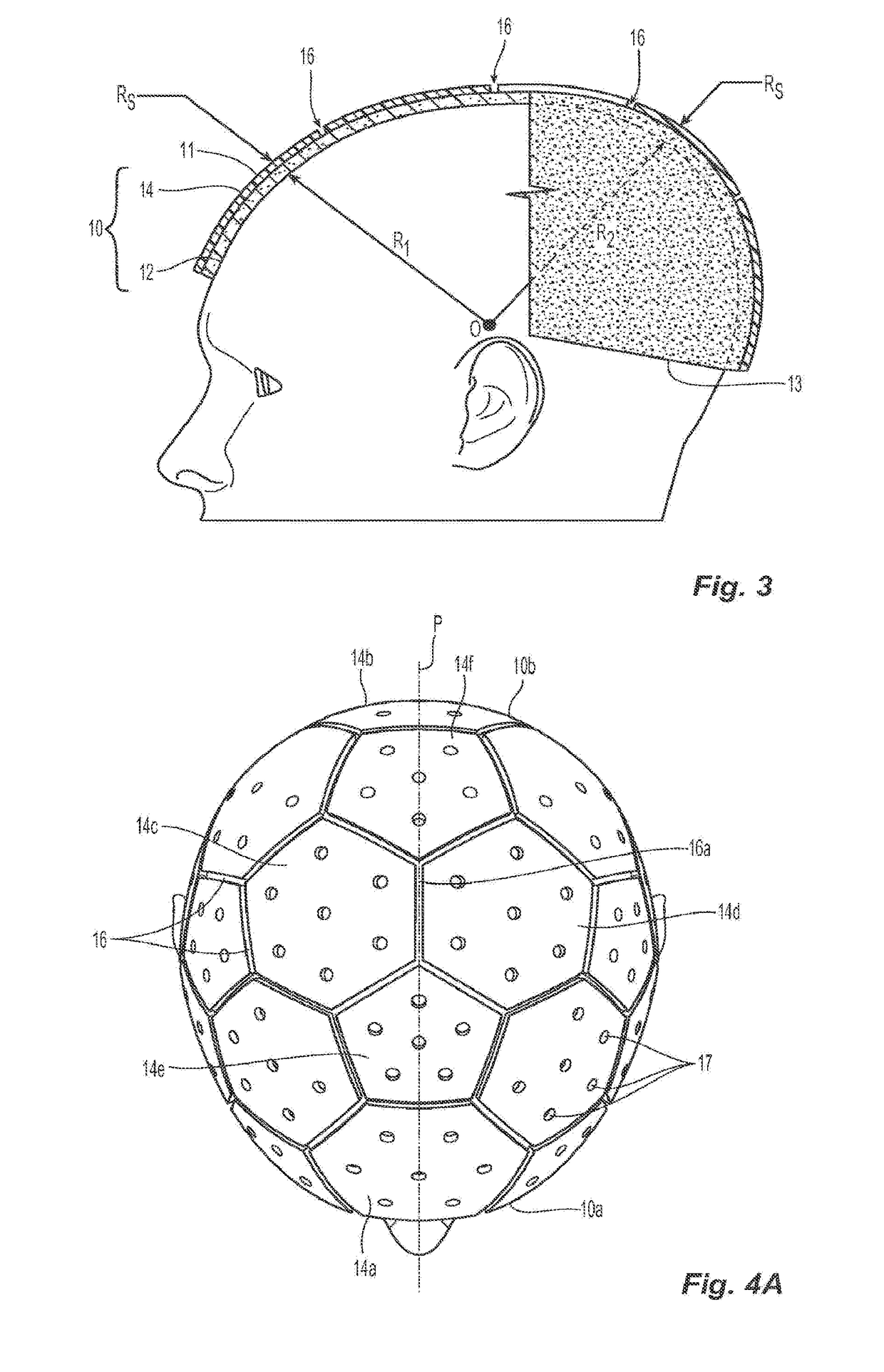

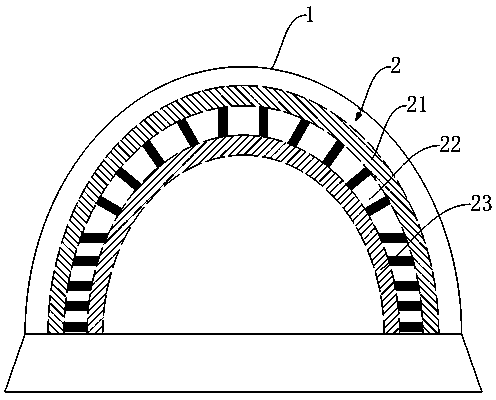

Protective headgear

ActiveUS9693594B1Energy-absorbing and dissipating propertyHatsHeadwear capsProtective headgearDevice form

A protective device for a head of an individual person. The protective device forms a cap that includes a flexible headpiece and a segmented outer protective shell disposed about the flexible headpiece for distributing an impact load. The device covers and protects the front, top, sides and back of the head from impact injuries and rebound effects of high speed objects as seen for example, a baseball or softball moving at a speed of up to about 125 mph.

Owner:CASTRO MYNOR J +1

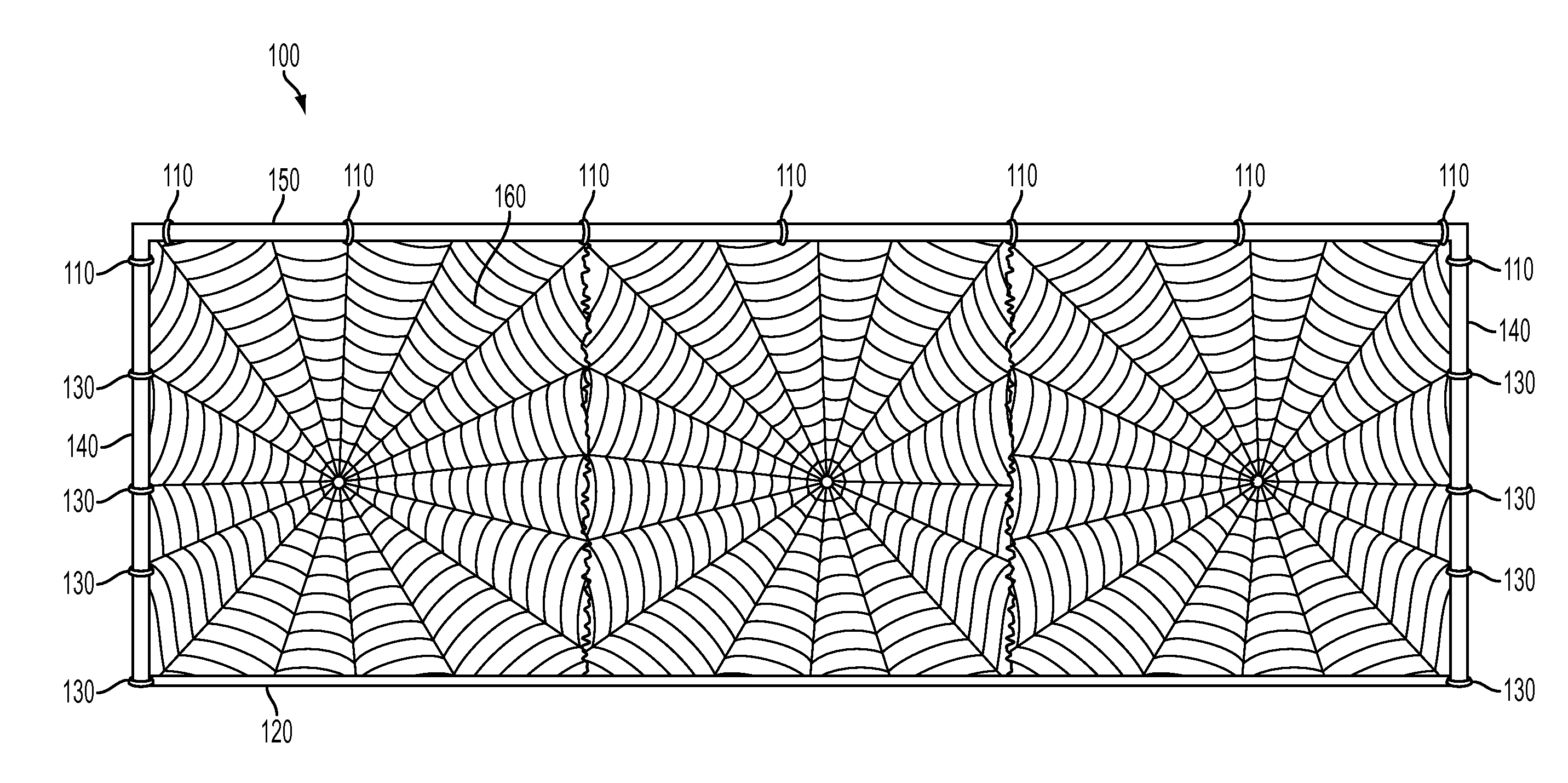

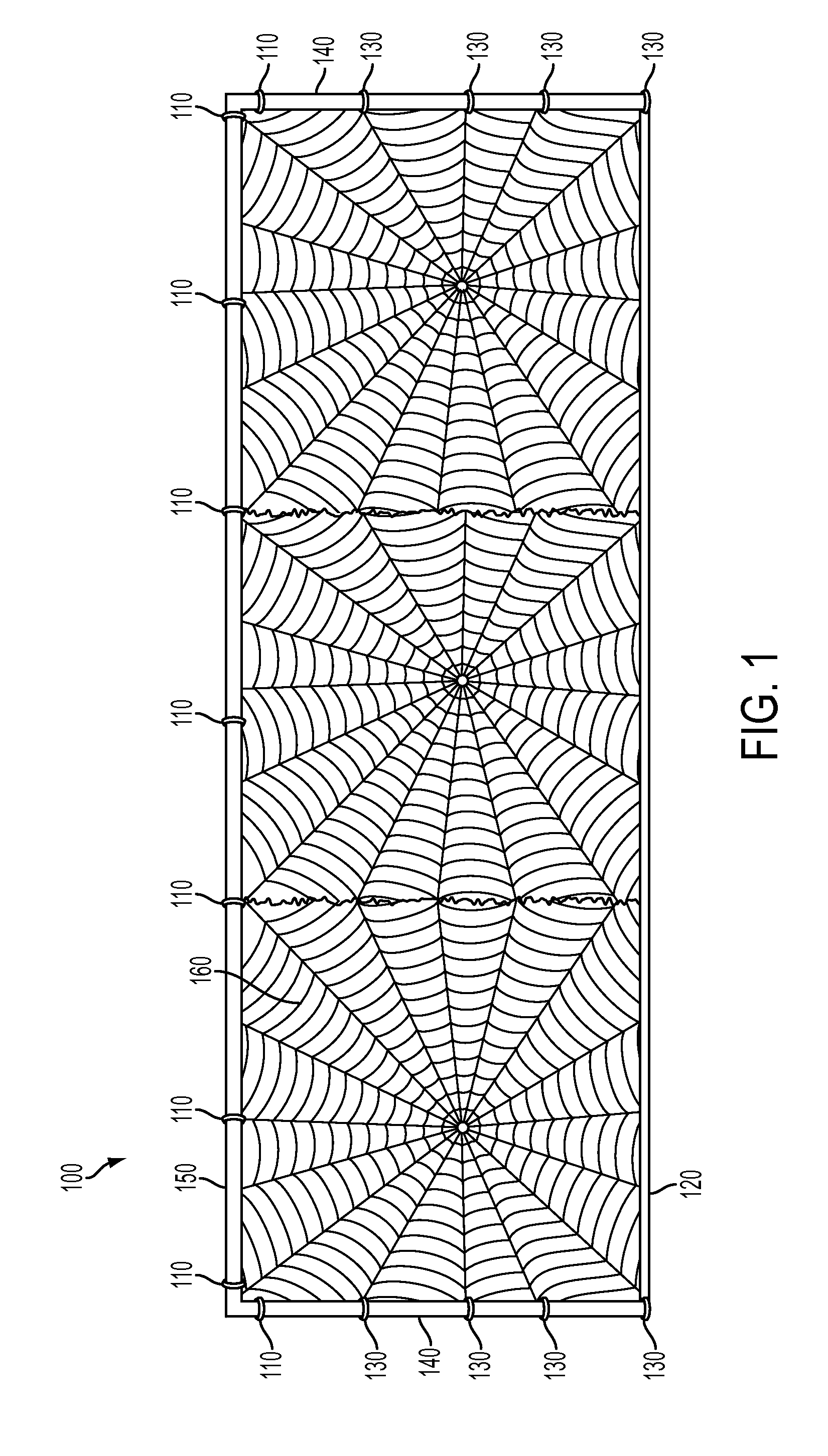

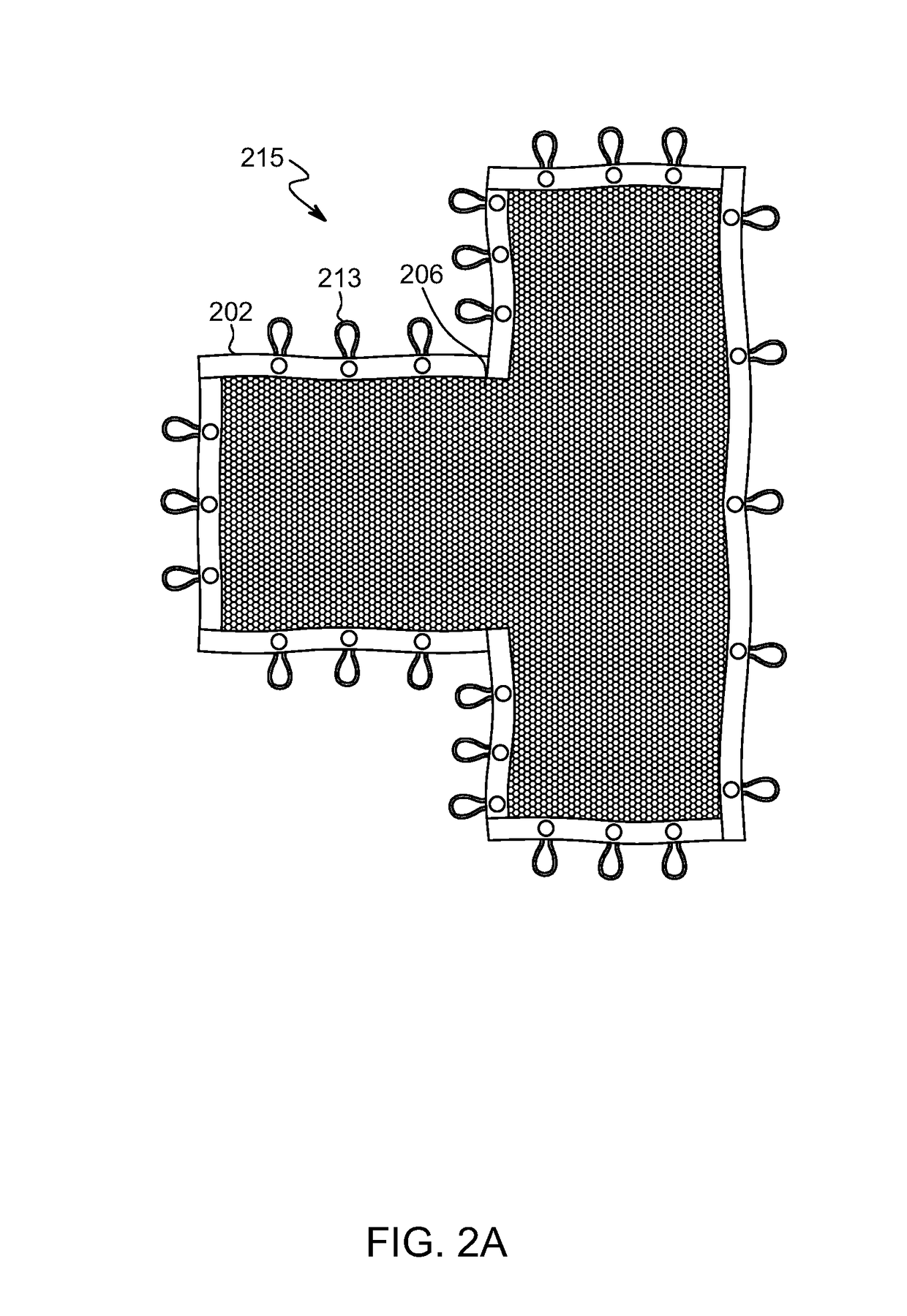

Attachable Soccer Rebound Net

This invention provides a lightweight, portable rebound net from an elastic material that can be attached to an existing regulation-sized soccer goal frame by a single person without the use of a ladder. It has the ability to be tightened quickly to create tension and prevent a ball from slipping under the net with a single mechanism. It provides a rebound net for recreational use with properties like that of a training net available to sports teams. It can be used for soccer or adapted for any other sport for which it would be useful to rebound a ball rather than retrieving it during practice or play. It can be adapted to convert to a catch net without rebound properties in situations for which that would be desirable.

Owner:JONES GREGORY A

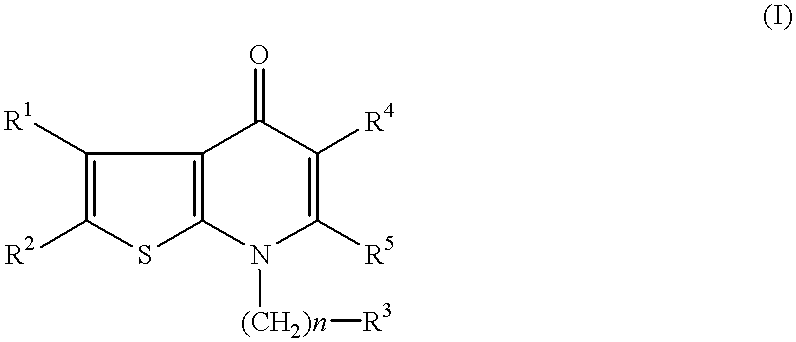

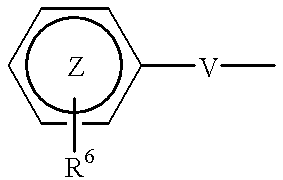

Condensed-ring thiophene derivatives, their production and use

A gonadotropin-releasing hormone antagonistic composition, which comprises an optionally substituted condensed-bicyclic compound consisting of a homo or hetero 5 to 7 membered ring and a homo or hetero 5 to 7 membered ring is effective as a propylactic or therapeutic agent for the prevention or treatment of several hormone dependent diseases, for example, a sex hormone dependent cancer (e.g. prostatic cancer, cancer of uterine cervix, breast cancer, pituitary adenoma), benign prostatic hypertrophy, myoma of the uterus, endometriosis, precocious puberty, amenorrhea, premenstrual syndrome, polycystic ovary syndrome and acne vulgaris; is effective as a fertility controlling agent in both sexes (e.g. a pregnancy controlling agent and a menstrual cycle controlling agent); can be used as a contraceptive of male or female, as an ovulation-inducing agent of female; can be used as an infertility treating agent by using a rebound effect owing to a stoppage of administration thereof; is useful as modulating estrous cycles in animals in the field of animal husbandry, as an agent fro improving the quality of edible meat or promoting the growth of animals; is useful as an agent of spawning promotion in fish.

Owner:TAKEDA PHARMA CO LTD

Weight-reducing food and production method thereof

The invention pertains to a health-care food, which particularly relates to a weight-losing food and a preparation method thereof. The technical proposal of the invention is that: the raw materials of the weight-losing food comprise: pearl barley, yam, hawthorn, medlar, lentils, thallus eckloniae, cumin, dry ginger and cinnamon; the preparation method comprises that the pearl barley, the yam, the hawthorn, the medlar, the lentils, the herba laminariae, the cumin, the dry ginger and the cinnamon are ground into powder respectively and are mixed according to proportion by weight and are sub packaged or prepared into various foods according to conventional methods. The raw materials of the slimming food of the invention support and complement each other, essentially aiming at 'invigorating spleen to remove dampness, promoting yang and eliminating wastes and reducing fat and weight'; after being tried out by people who want to loose weight for a long time, the weight-losing food is proved to have obvious weight reduction effect without any side or toxic effect for long-term taking and without being restricted by dosage when taking, therefore, the weight-losing food can be taken as staple food, is safe in weight reduction without rebound effect and can strengthen physique for long-term taking.

Owner:黄杨琳

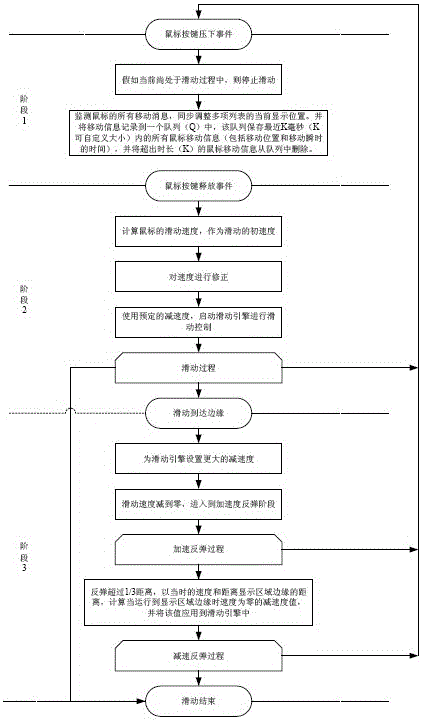

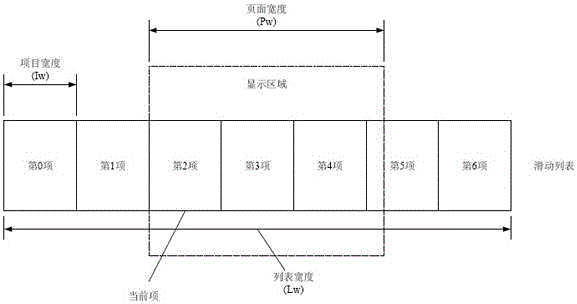

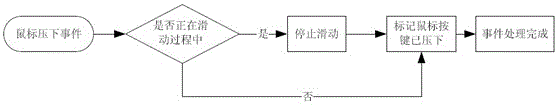

Method for interface switching through mouse dragging and sliding

ActiveCN105022567ASmooth sliding animation effectEasy to operateInput/output processes for data processingAnimationDisplay list

The invention relates to a method for interface switching through mouse dragging and sliding. The method is mainly used for enabling a mouse to slide in a display region through a mouse dragging and sliding list, and switching display of a plurality of display lists in the display region respectively through sliding of the sliding list. The method specifically comprises the following steps of: step S100, making a response to mouse pressing-down and moving events; step S200, entering a mouse release event after releasing a mouse pressing-down action; and step S300, after sliding to the edge, controlling over-edge sliding and rebound sliding. According to the method, the smooth sliding animation effect can be realized by a sliding animation technology realized by simple uniformly accelerated (retarded) rectilinear motion combination and having a rebound effect as well as a technology for calculating the mouse sliding speed by monitoring mouse sliding through mouse dragging and sliding. The method is simple and easy to operate, and can effectively achieve the purpose of switching WinCE system interfaces through mouse dragging and sliding.

Owner:HUIZHOU DESAY SV AUTOMOTIVE

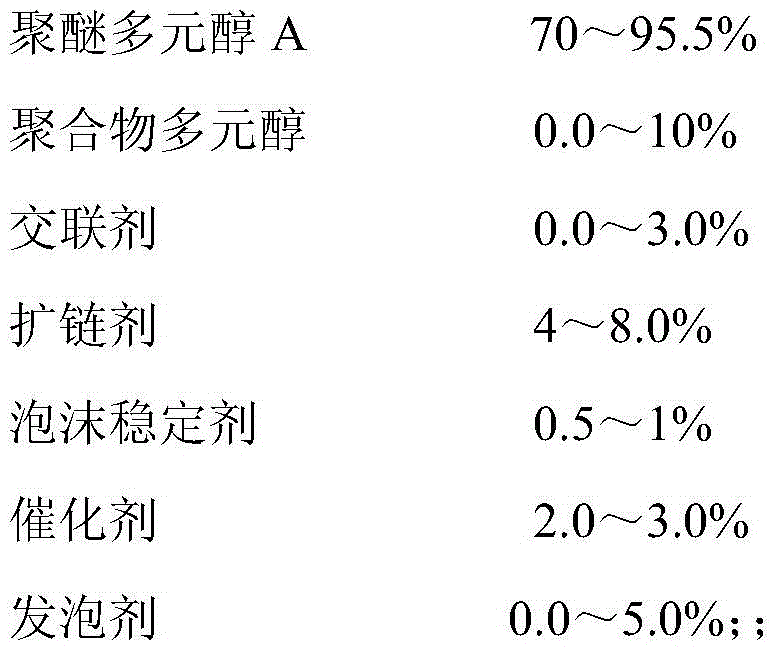

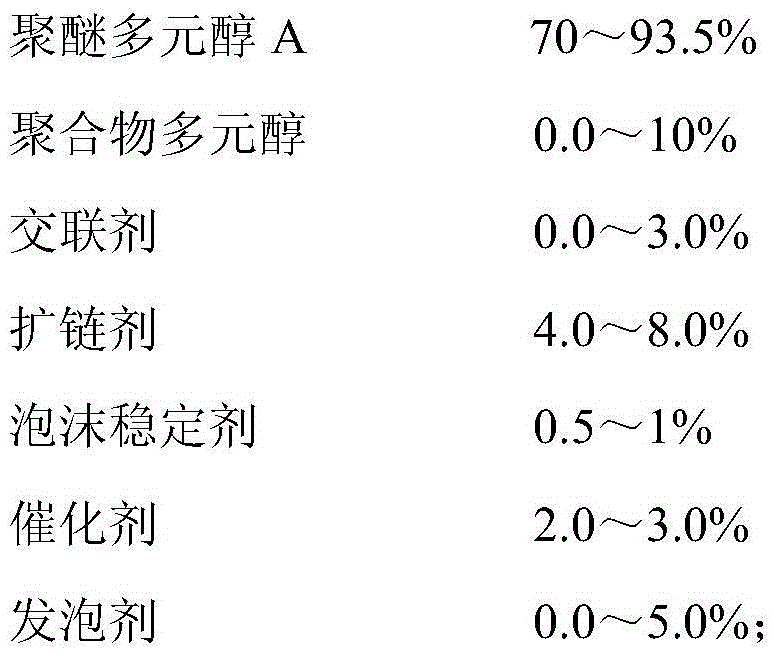

Polyurethane mixed component applied to slow-rebound damping pad and preparation method of polyurethane mixed component

The invention relates to a polyurethane mixed component applied to a slow-rebound damping pad and a preparation method of the polyurethane mixed component and belongs to the technical field of polyurethane application. The polyurethane mixed component applied to the slow-rebound damping pad is composed of a component A and a component B, and the weight ratio of the component A to the component B is 100 (50-60); the component A is composed of polyether polyol A, polypolyols, a cross-linking agent, a chain extender, a foam stabilizer, a catalyst and a foaming agent; the component B is composed of polyether polyol B and isocyanate. The pad made of the polyurethane mixed component is good in rebound effect, and the shock absorption capacity and the hand feeling are improved; the invention further provides a preparation method which is simple, easy to conduct and capable of saving energy and protecting the environment.

Owner:SHANDONG INOV POLYURETHANE

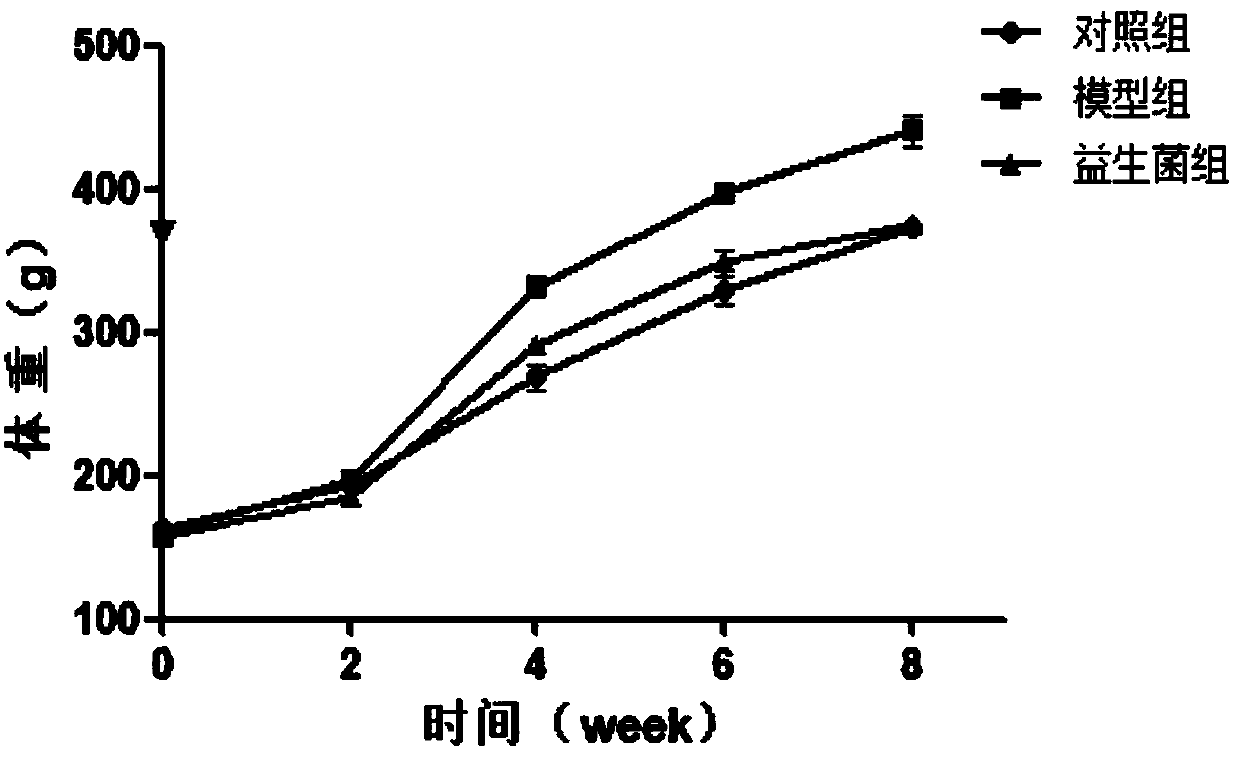

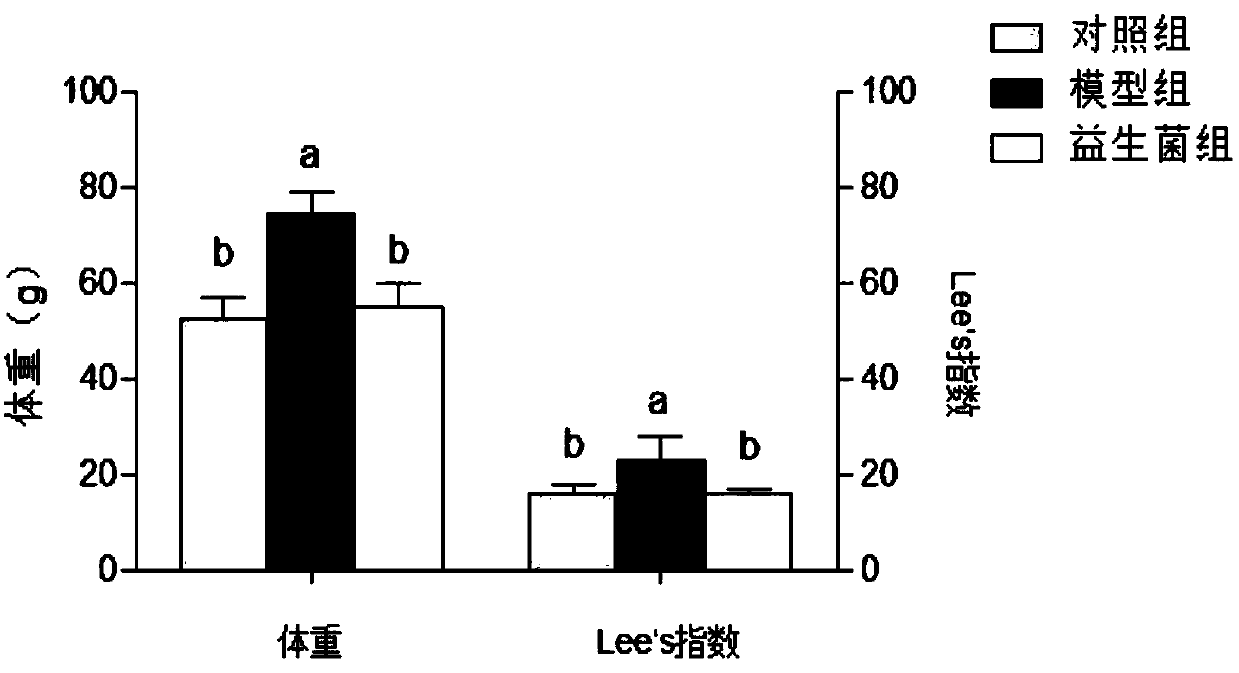

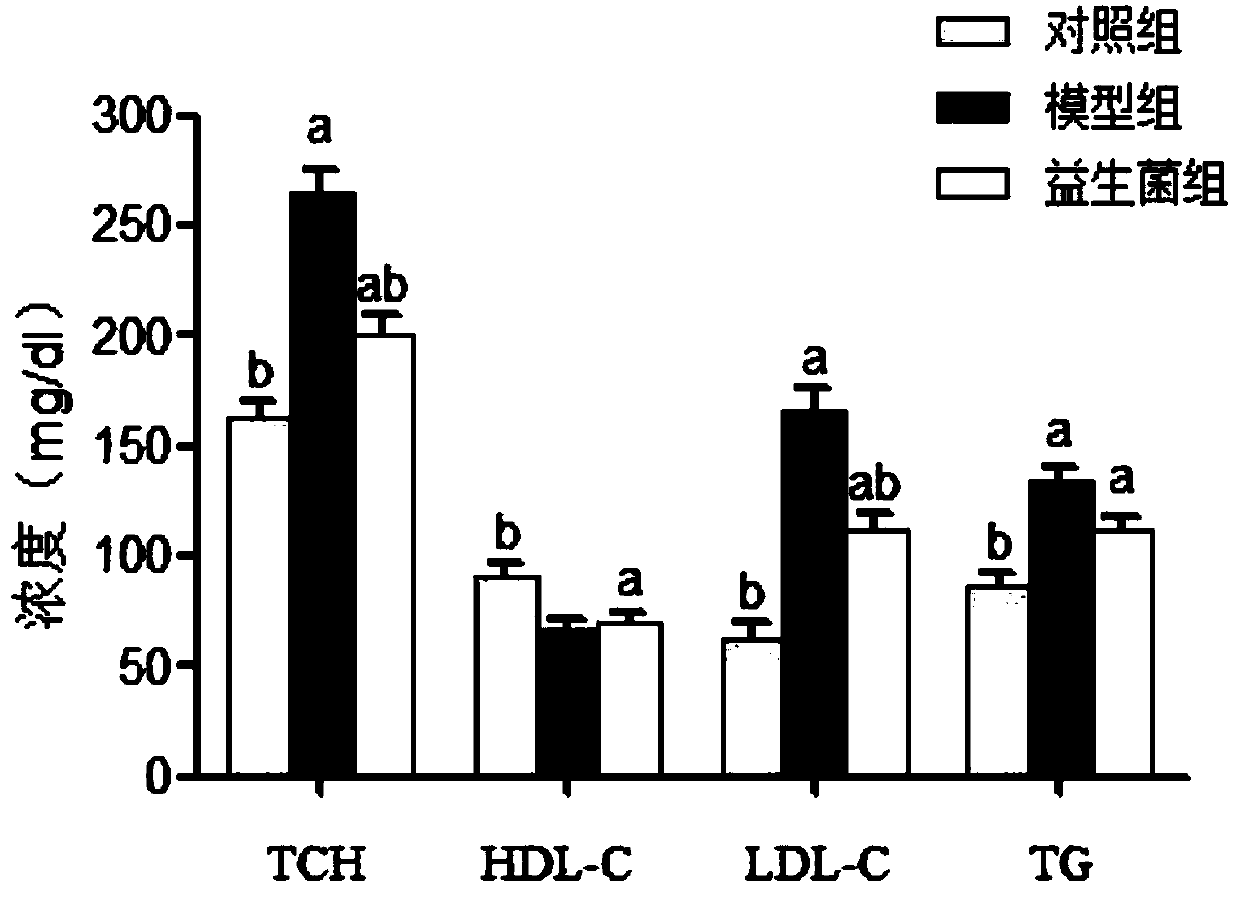

Lactobacillus plantarum improving easily-fat body and offspring weight and application thereof

ActiveCN107760620AExcellent acid and bile salt resistanceHigh activityBacteriaMicroorganism based processesFat bodiesGut flora

The invention provides a lactobacillus plantarum improving easily-fat body and offspring weight and application thereof, and is preserved in the General Microbiology Center of China Microbiological Culture Collection Management Committee, and the preservation number is CGMCC No.14570. The lactobacillus plantarum has excellent acid and bile salt resistance, bile salt hydrolase activity and intestinal colonization ability. Animal experiments and human food experiments show that the lactobacillus plantarum can control weight gain of pregnant women and offsprings caused by a high-fat and high-sugar diet by bile salt hydrolase activity and regulating intestinal flora, at the same time, the lactobacillus plantarum can regulate the intestinal flora, optimize intestinal flora structure, increase number of beneficial bacteria, and improve ratio of bacteroidetes and firmicutes, thereby improving the easily-fat body. The animal experiments and human food experiments show that the lactobacillus plantarum has clear efficacy and high safety, and can reverse the easily-fat body by fundamentally improving the intestinal flora of humans, has a long-lasting non-rebound effect, and has great potential for market development.

Owner:天津科睿恒生物科技有限公司

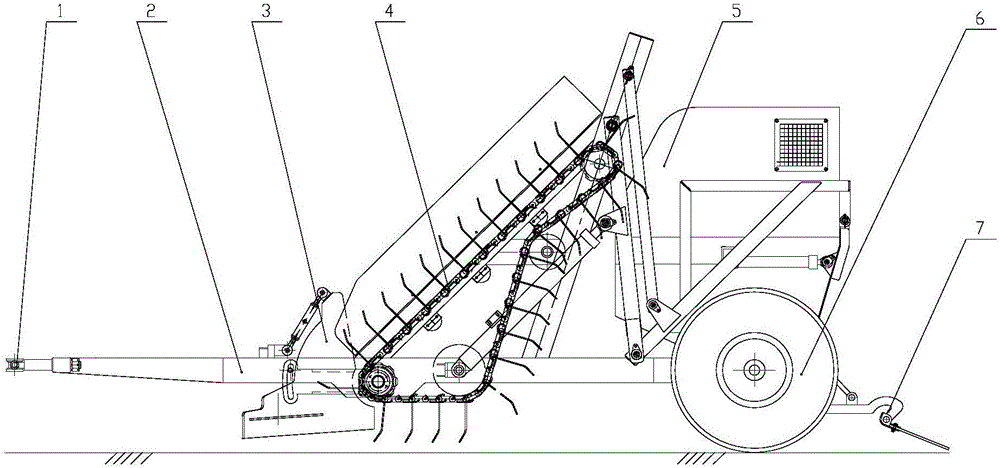

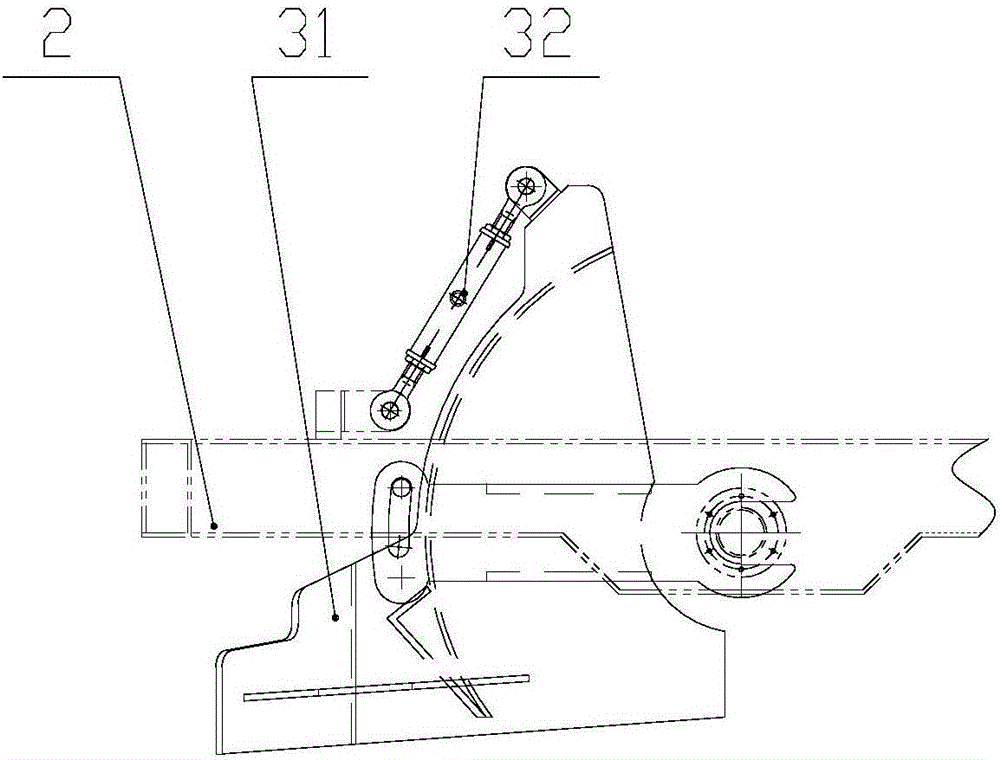

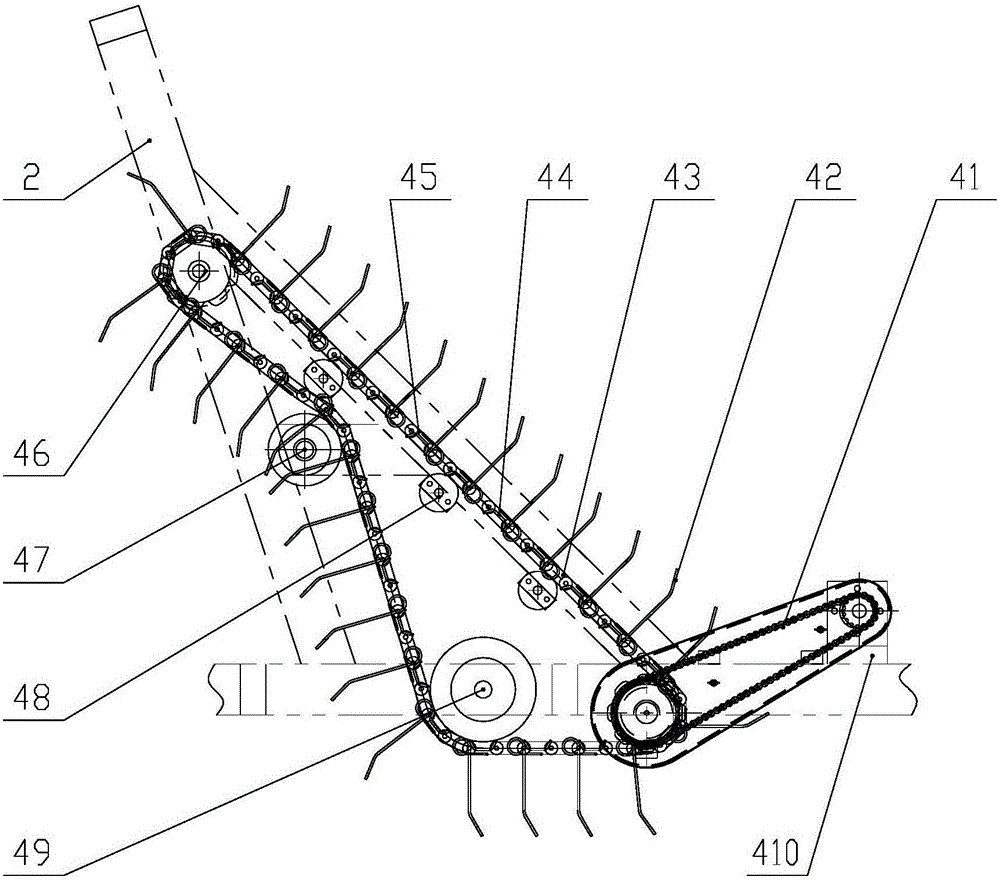

Sand beach cleaning machine

ActiveCN106544981AEasy to cleanAchieve separationConstructionsCleaning bleachesTraction frameEngineering

The invention belongs to the technical field of environmental sanitation machinery, and particularly relates to a sand beach cleaning machine. According to the technical scheme, the sand beach cleaning machine comprises a traction frame (1), a rack (2), a guide device (3), a sieving and conveying device (4), a garbage self-discharging device (5) and driven wheels (6). Garbage in sand is turned up by a plurality of rows of spring pawls which are arranged in a staggered manner, is conveyed to the guide device under the effect of inertia, and then is rebounded onto the sieving and conveying device by the rebounding effect of the guide device, and therefore, the garbage is separated from most of sand; and a small amount of sand which is taken onto the sieving and conveying device is filtered out through sand leaking holes of filter screens, and finally, the garbage is conveyed into the garbage self-discharging device through the sieving and conveying device. The sand beach cleaning machine has good cleaning effects on garbage in dry sand, wet sand and tidal zones, and is suitable for various sand beach conditions. The problem that an existing net belt type sand beach cleaning machine has imperfect effect of cleaning wet sand beaches is solved.

Owner:CHINA HARZONE IND CORP

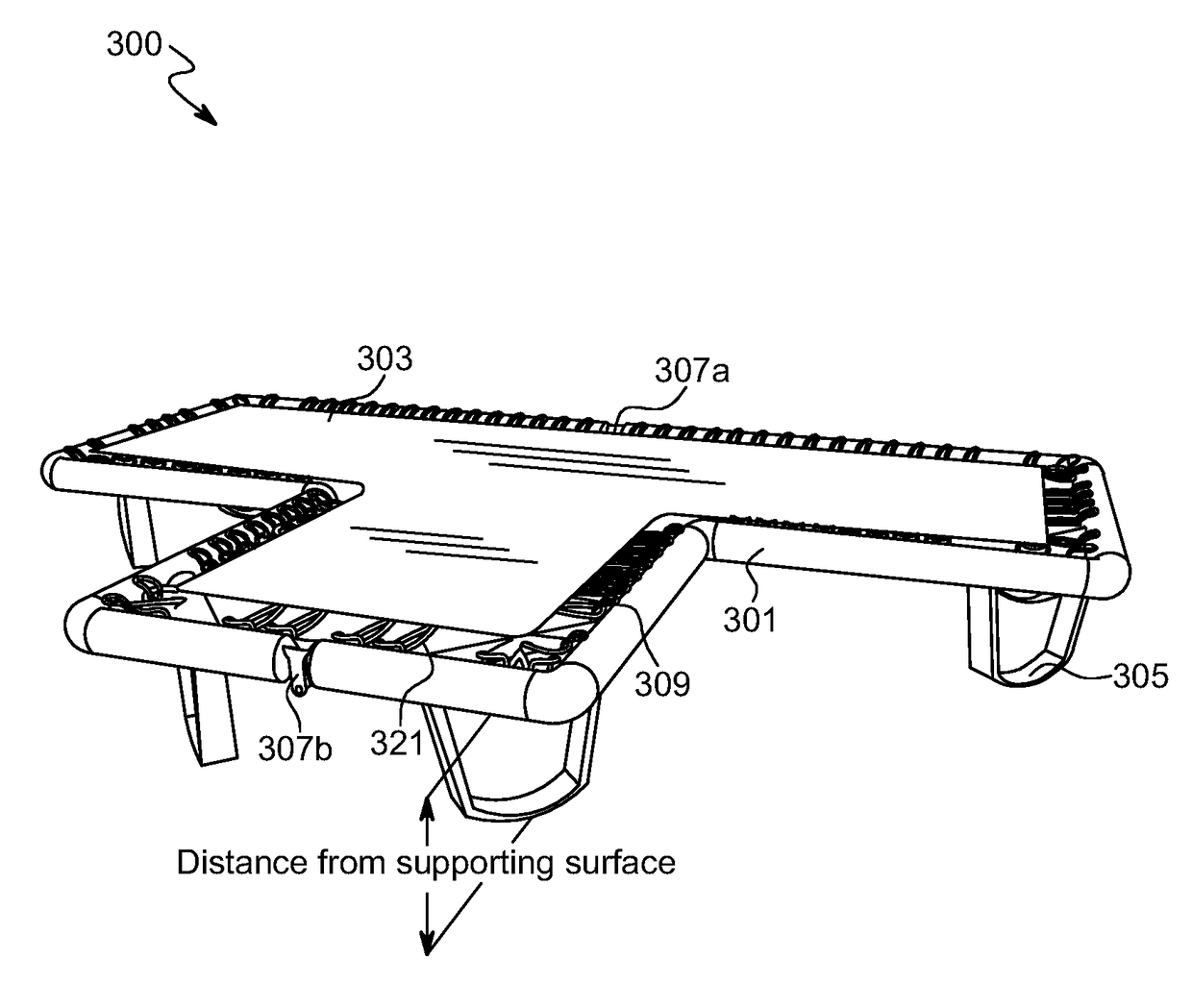

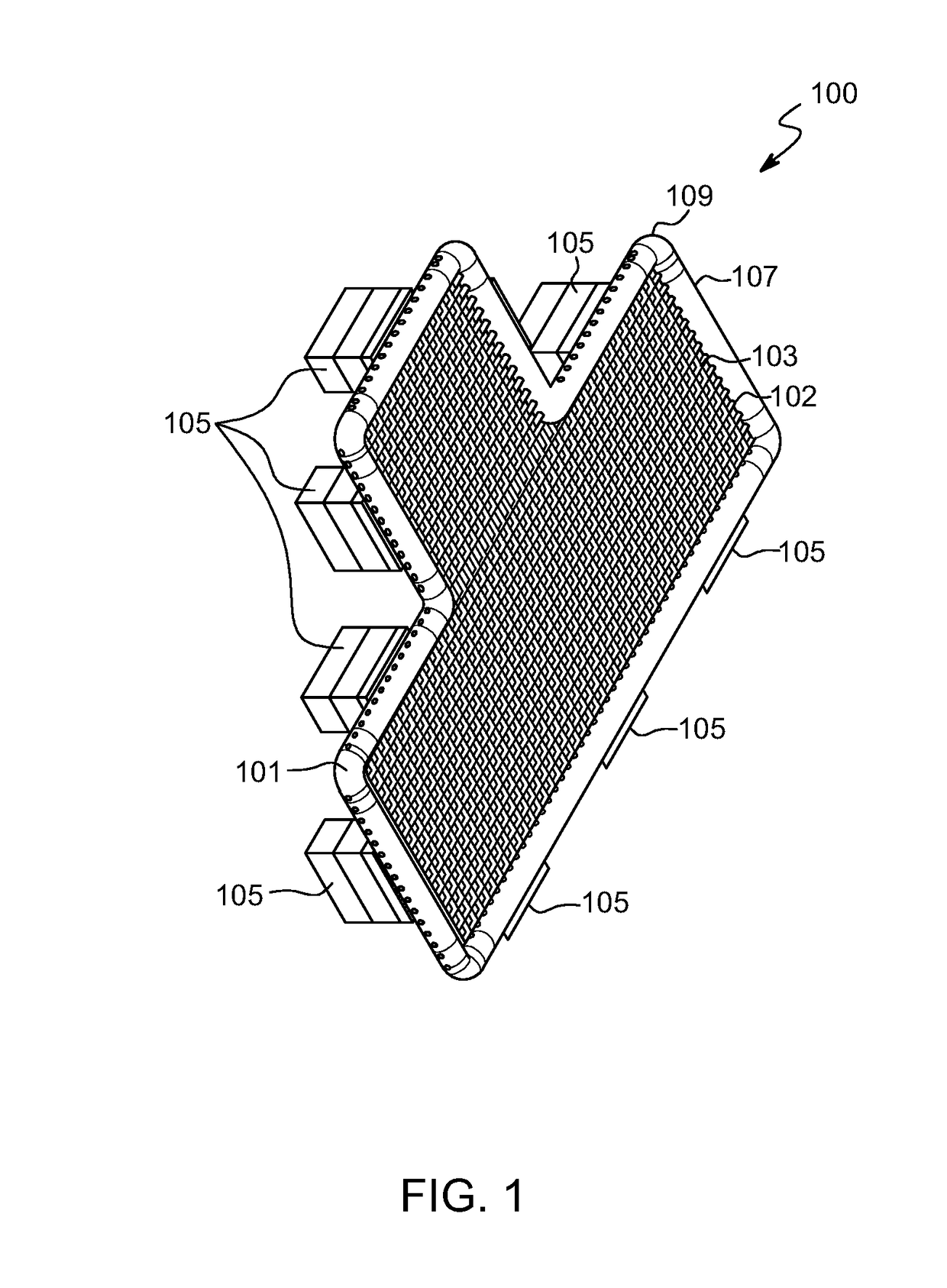

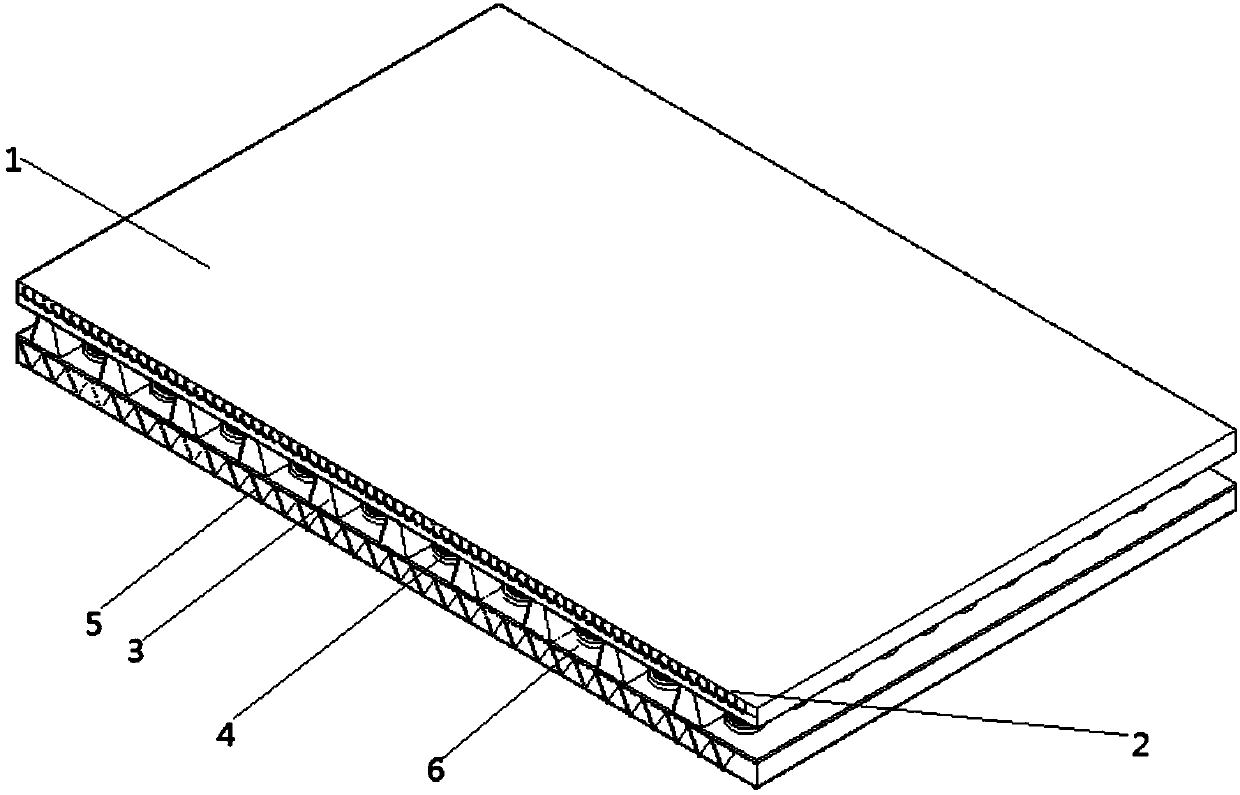

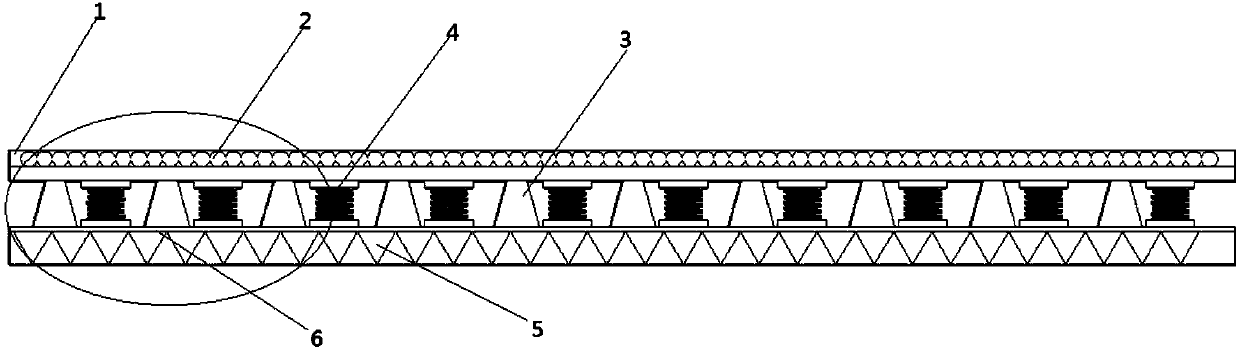

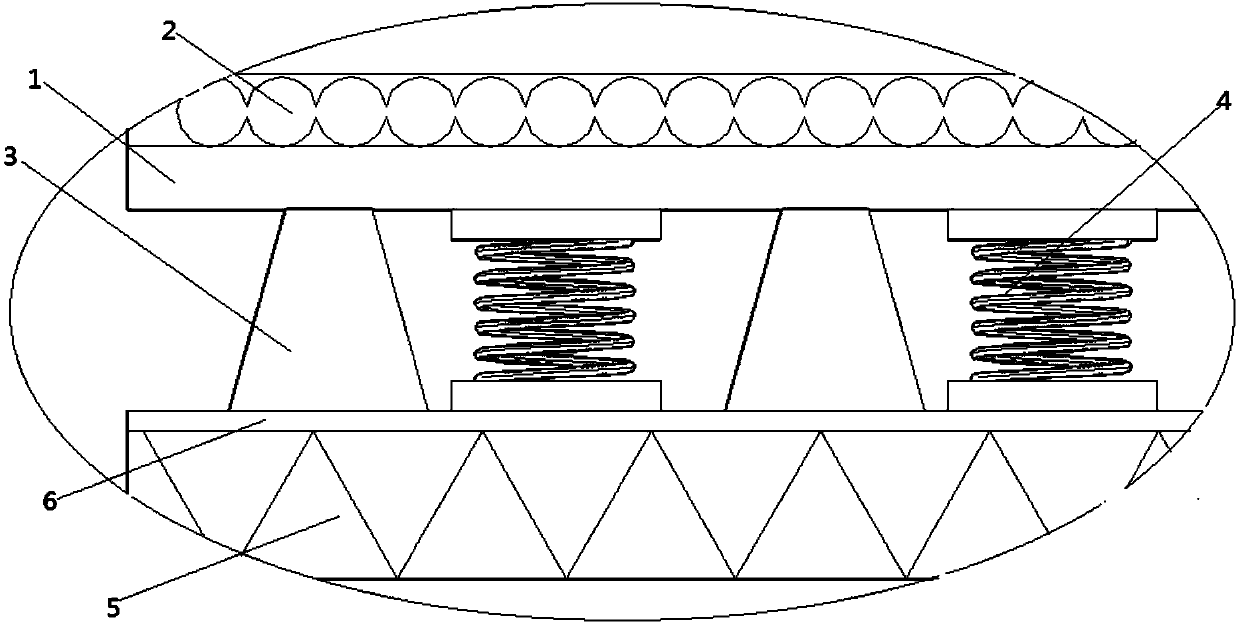

Sound absorbing rebounding device

ActiveUS9844713B1Minimizing sound and vibrationIncrease elasticityTrampolinesBall sportsEngineeringRebound effect

Owner:DREAM DRIBBLE LLC

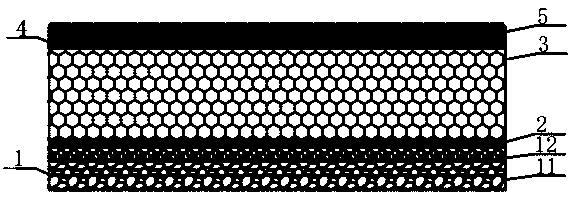

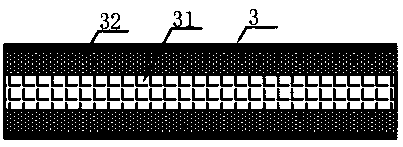

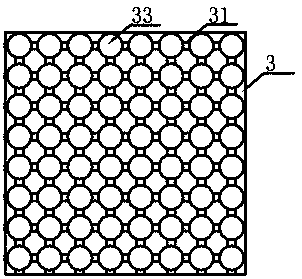

Solvent-free ultrafine fiber mirror synthetic leather

InactiveCN106436341ASimple production processReduce manufacturing costTextiles and paperFiberEnvironmental resistance

The invention discloses solvent-free ultrafine fiber mirror synthetic leather. The solvent-free ultrafine fiber mirror synthetic leather comprises an ultrafine fiber Base fabric layer as well as a first sizing agent layer, a second sizing agent layer and a bonding layer which are transferred onto the ultrafine fiber Base fabric layer through mirror release paper, wherein the bonding layer is bonded with the ultrafine fiber Base fabric layer. A preparation method comprises steps as follows: step 1, the mirror release paper is coated with a prepared sizing agent for the first sizing agent layer and the sizing agent is dried; step 2, the first sizing agent layer is coated with a prepared sizing agent for the second sizing agent layer, and the sizing agent is dried; step 3, the second sizing agent layer is coated with a prepared sizing agent for the bonding layer, and the second sizing agent layer is attached to the ultrafine fiber Base fabric layer and dried; step 4, the mirror release paper is removed, and the synthetic leather is obtained. The production process is simple, the production cost is low, and the crease-free and environment-friendly mirror synthetic leather produced with the process and having good rebound effect and physical property can be widely applied to shoe leather, bag leather, decoration and the like.

Owner:张家港嘉泰超纤科技有限公司

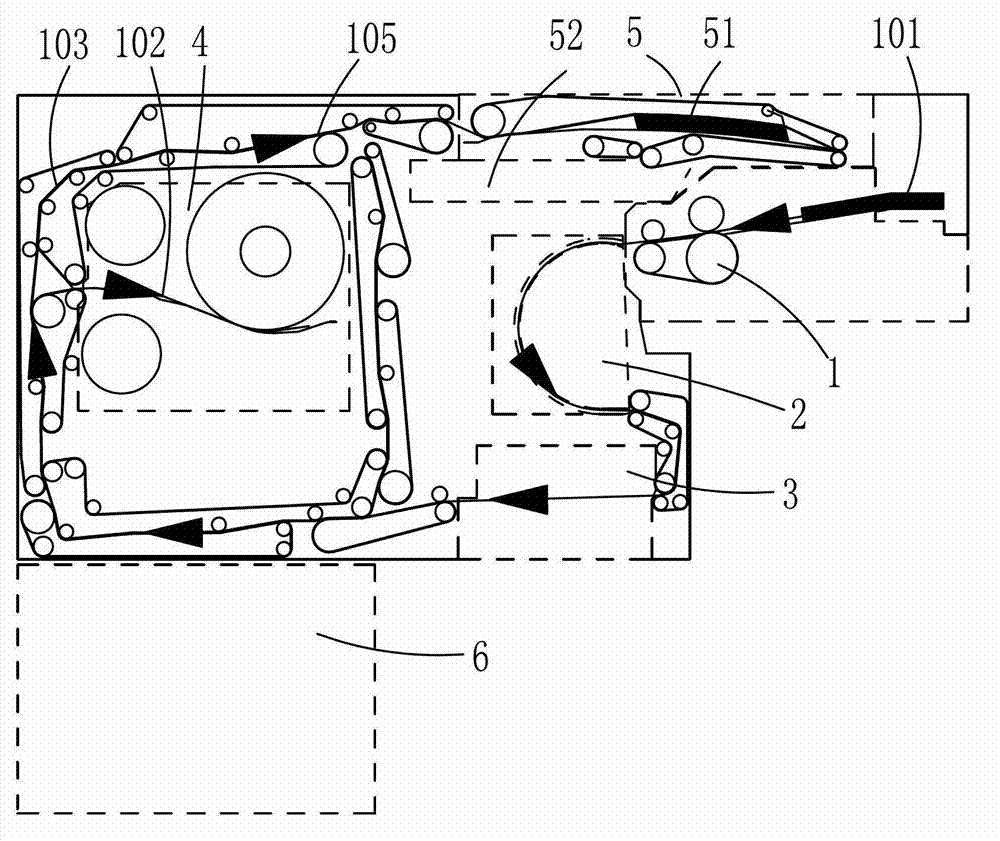

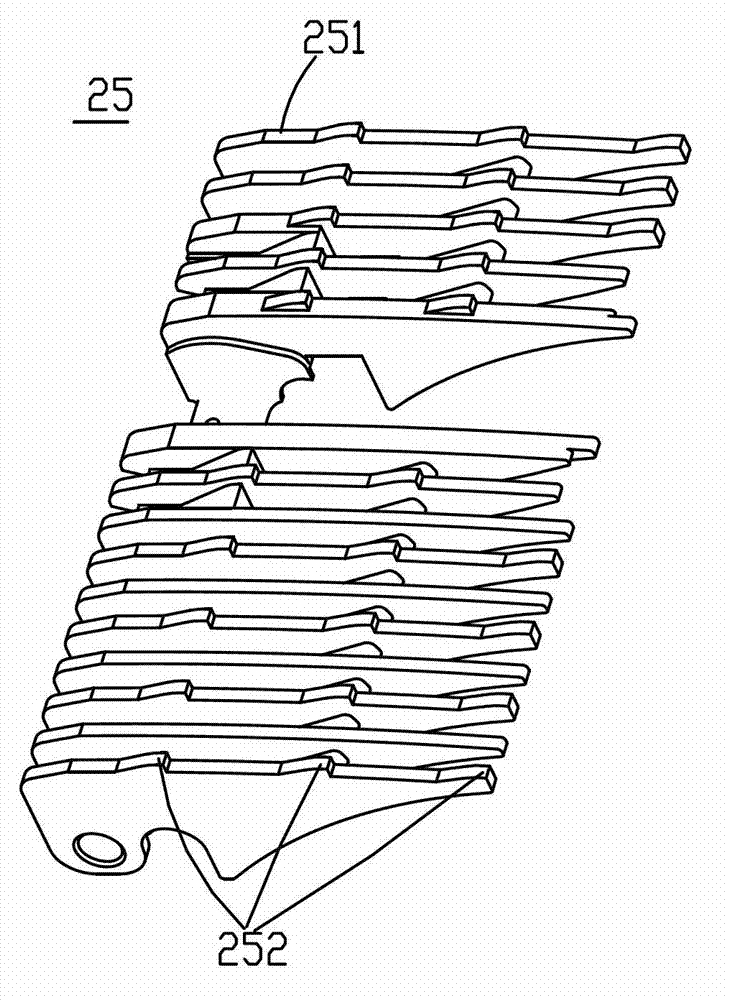

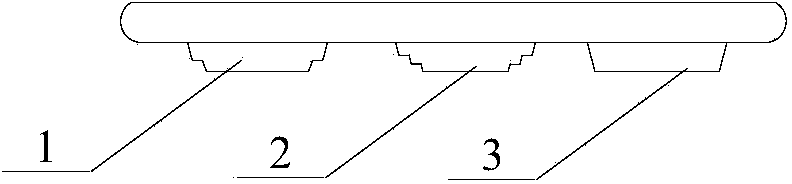

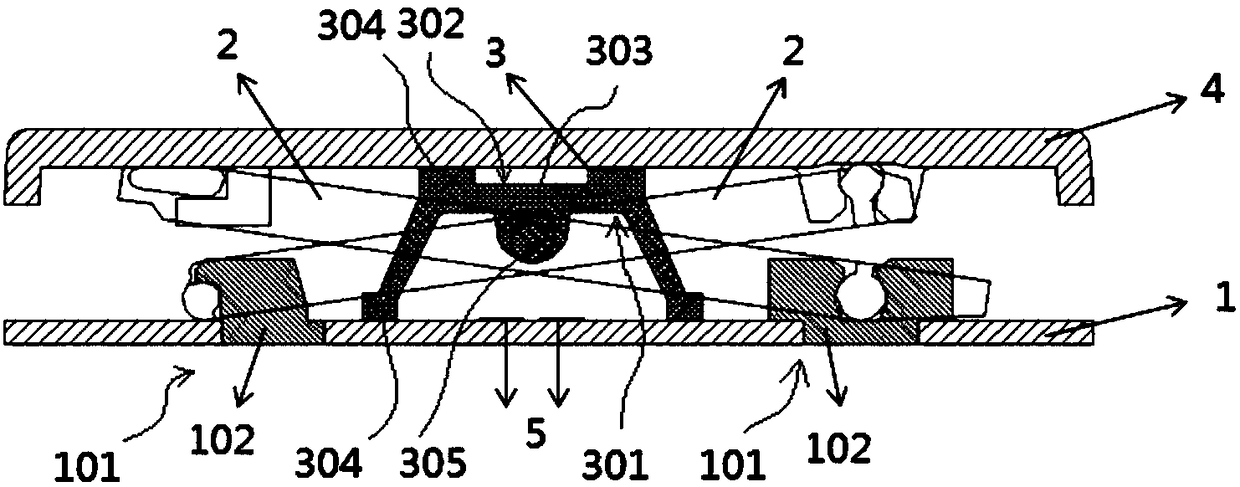

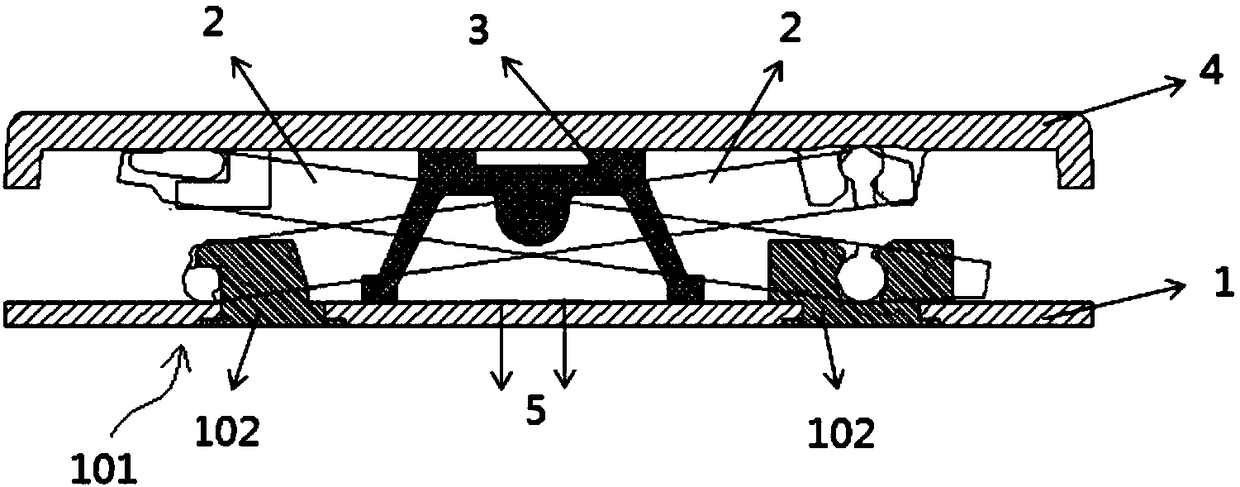

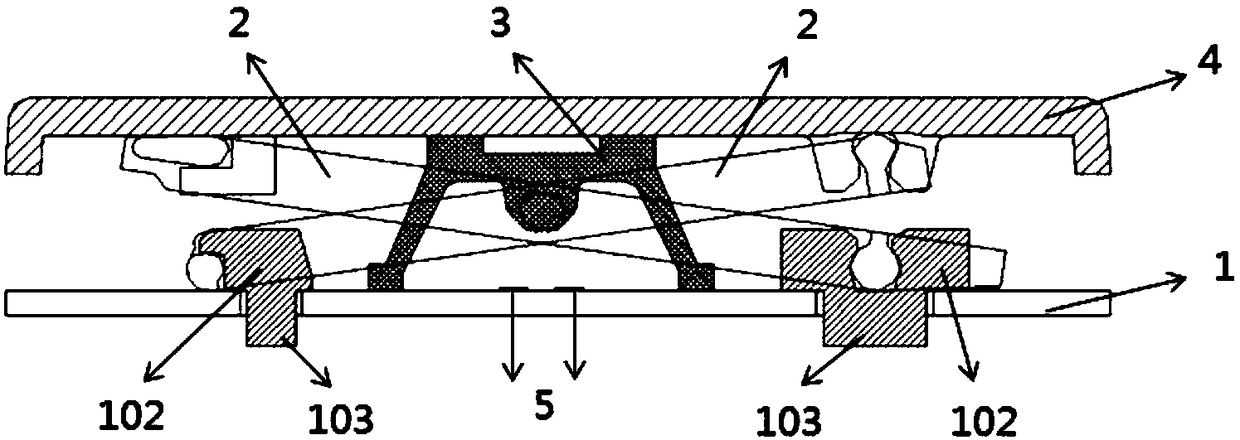

Paper sheet type medium stacking device

ActiveCN102930639ASolve the problem of creeping backAchieve the desired effectCoin/currency accepting devicesPile receiversPulp and paper industryPaper sheet

The invention relates to a sheet type medium treatment technology, in particular to a device through which paper sheet type media are stacked piece by piece and the whole stacked media do not wriggle and draw back. The device comprises a single-piece paper sheet type medium conveying mechanism, an upper portion conveying belt, an arc-shaped stacking plate, a movable stopping mechanism, a sensor device and a control part. An acanthoid protruding rib is arranged at the position on the arc-shaped surface of the arc-shaped stacking plate, between which and the movable stopping mechanism the distance is the length of one piece of paper sheet type medium. The acanthoid protruding rib enables the paper sheet type media to pass only in a discharging direction. Due to the fact that the acanthoid protruding rib is arranged on the working surface of the arc-shaped stacking plate, the acanthoid protruding rib has the single-direction performance of paper sheet type medium conveying, the acanthoid protruding rib is provided with a guide-out surface and a blocking surface, the paper sheet type media can be conveyed along one direction, moving is irreversible, the problem that the paper sheet type media wriggle and draw back because of the rebound effect of the conveying belt is effectively solved, and the expected effect of sheet type medium stacking is achieved.

Owner:GRG BAKING EQUIP CO LTD

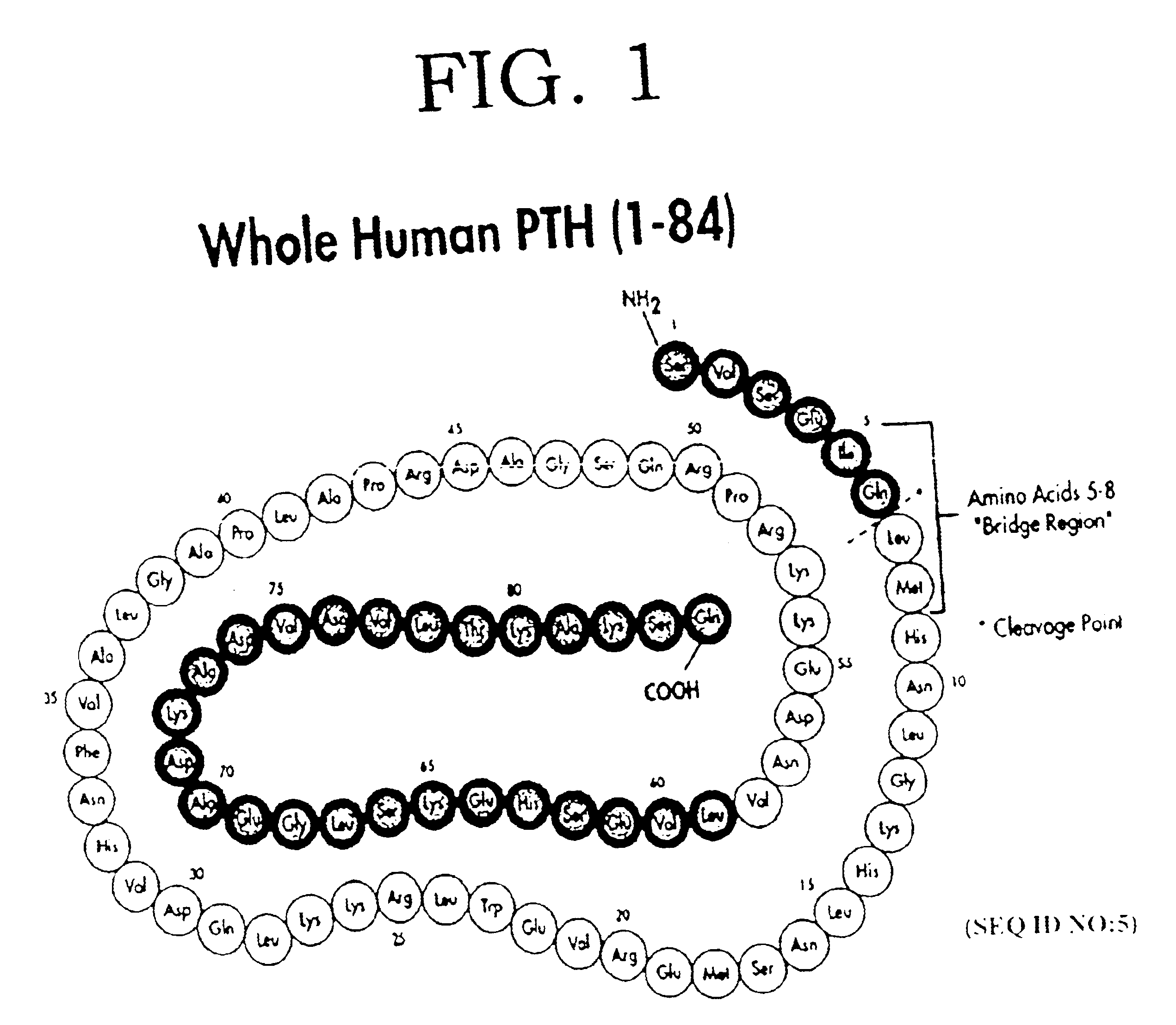

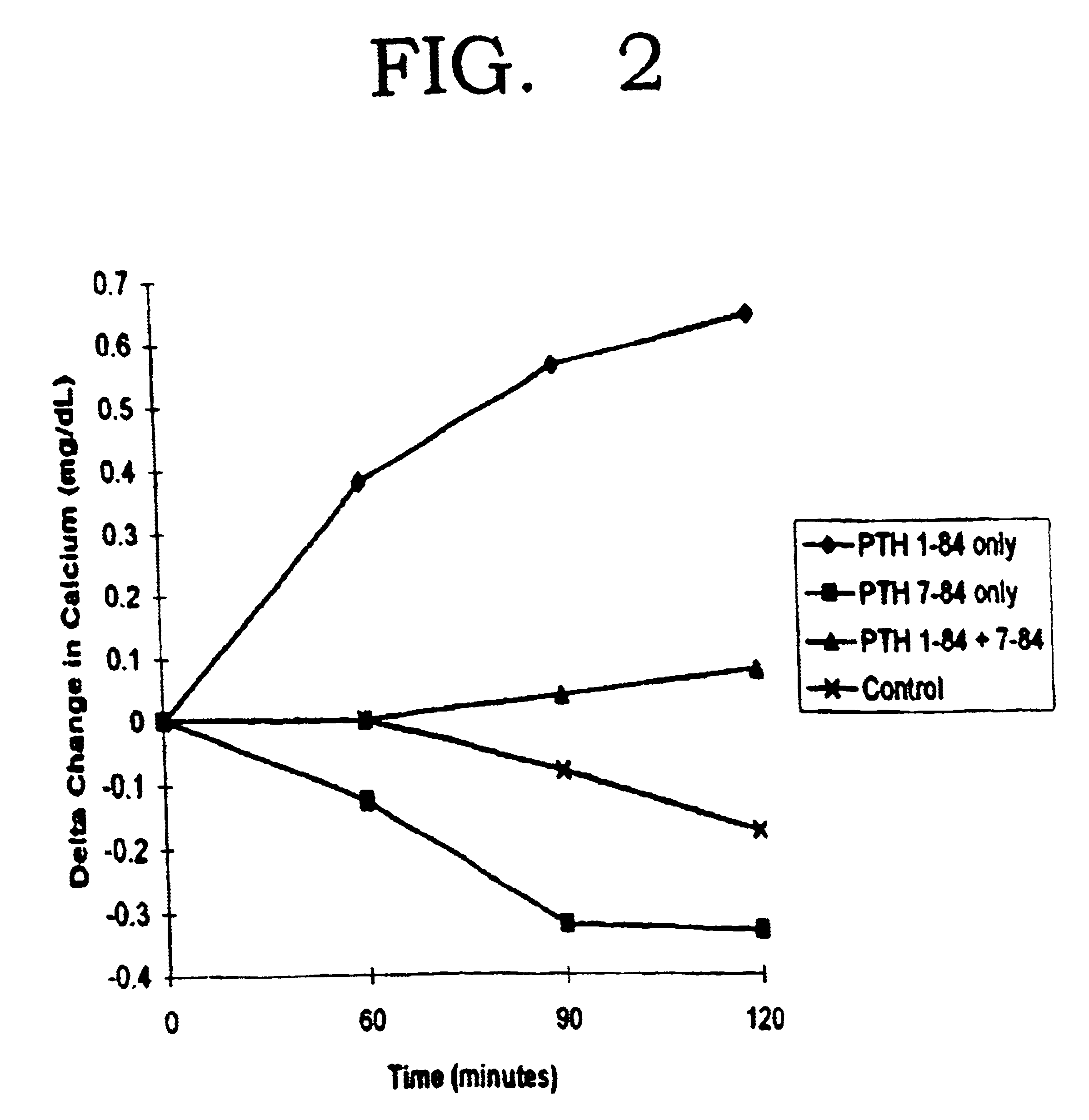

Cyclase inhibiting parathyroid hormone antagonists or modulators and osteoporosis

The present invention relates to a novel method for treating a patient that has osteoporosis and the patient may be having administered cyclase activating parathyroid hormone (CAP) or analogues. The patient receives an administration of a cyclase inhibiting parathyroid hormone peptide (CIP) having an amino acid sequence from between (SEQ ID NO:1 [PTH2-84]) and (SEQ ID NO:3 [PTH34-84]) (i.e., a contiguous portion of PTH having an amino acid sequence set forth in SEQ ID NO:5 (PTH1-84), having the N-terminal amino acid residue starting at any position spanning from position 2 through position 34 of the PTH1-84, and the C-terminal amino acid residue ending at position 84 of the PTH1-84), (preferably (SEQ ID NO:2 [PTH3-84]) and (SEQ ID NO:8 [PTH28-84])), or a conservatively substituted variant thereof exhibiting parathyroid hormone (PTH) antagonist activity in a therapeutically effective, but non-toxic amount that reduces the occurrence of hypercalcemia or osteosarcoma in the patient resulting from the administration of CAP, and yet, through a CAP rebound effect, is effective in itself in the treatment of osteoporosis.

Owner:SCANTIBODIES LAB

Prefabricated coil polyurethane runway surface layer and construction process thereof

The invention discloses a prefabricated coil polyurethane runway surface layer and a construction process thereof and specifically relates to the field of sports materials. The prefabricated coil polyurethane runway surface layer comprises a laid base layer, wherein the top of the laid base layer is provided with a prefabricated laid coil; a polyurethane bonding layer is arranged between the prefabricated laid coil and the laid base layer; a polyurethane reinforcing layer is arranged on the top of the prefabricated laid coil; a spraying surface layer is arranged on the top of the polyurethanereinforcing layer; and the prefabricated laid coil comprises an elastic supporting layer and foaming polyurethane layers. According to the prefabricated coil polyurethane runway surface layer and theconstruction process thereof, disclosed by the invention, by preparing a polyurethane two-component composite material, and preparing water-based polyurethane foaming fluid in a factory to cast the integrated prefabricated laid coil with the elastic supporting layer, the quality of the coil is improved; laying is convenient; the elastic supporting layer is cooperated with the foaming polyurethanelayers to improve the elastic properties; the coil is resistant to deformation; the rebound effect is good; a woven mesh is arranged in the polyurethane reinforcing layer; the runway toughness is improved; the tensile strength is improved; and the impact absorptivity and overall performance of a surface layer structure are improved.

Owner:江苏长诺运动场地新材料有限公司

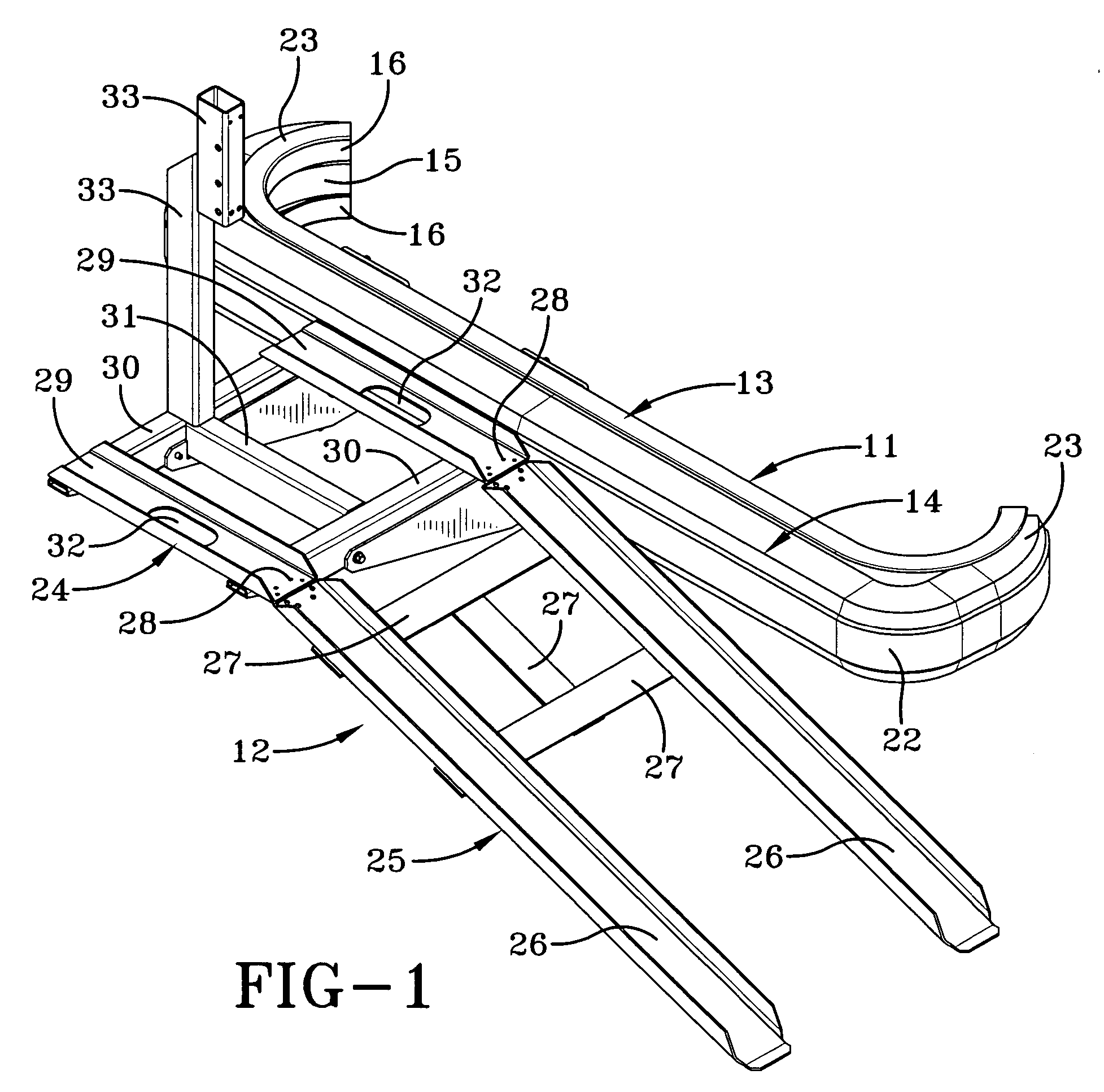

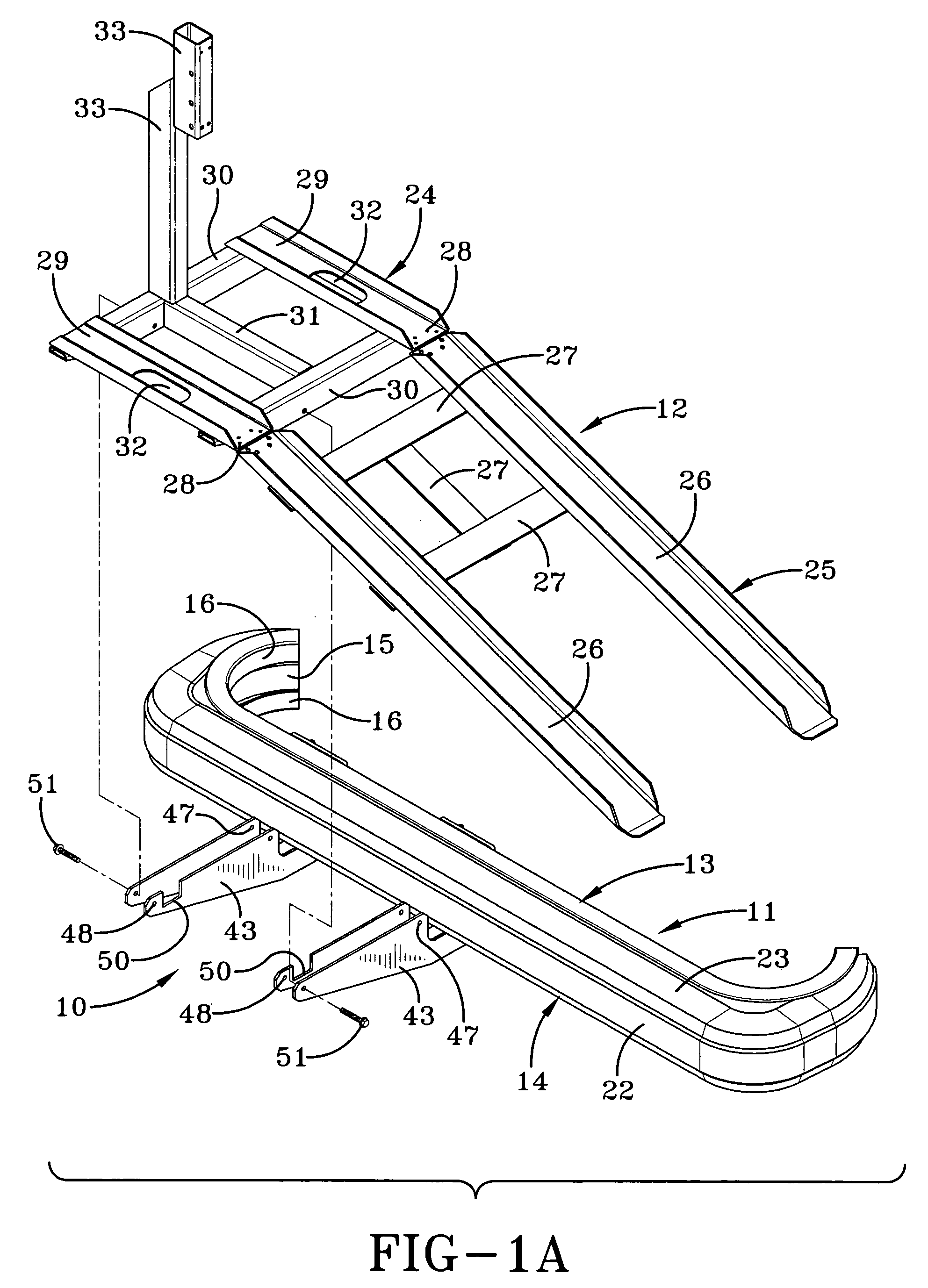

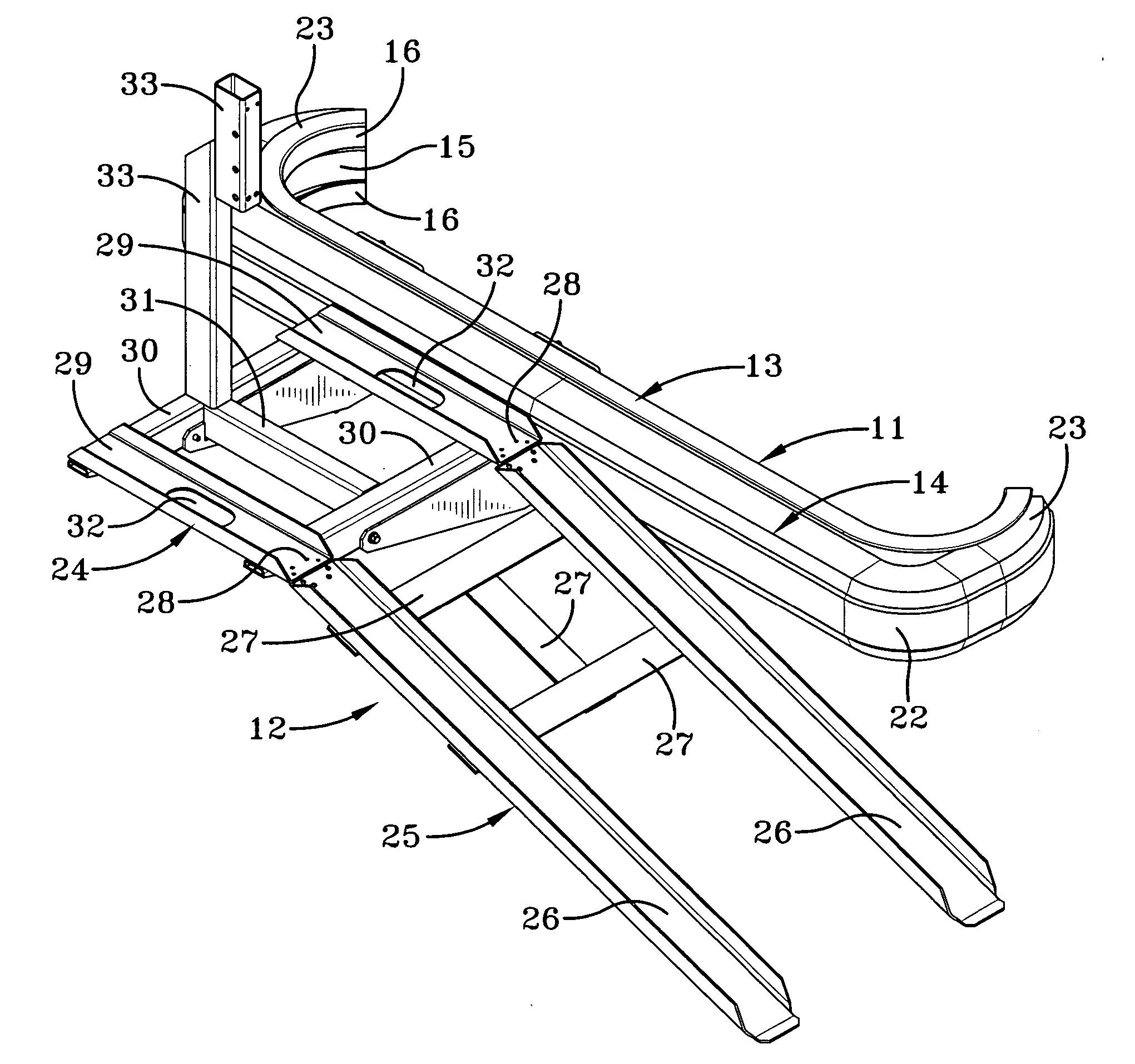

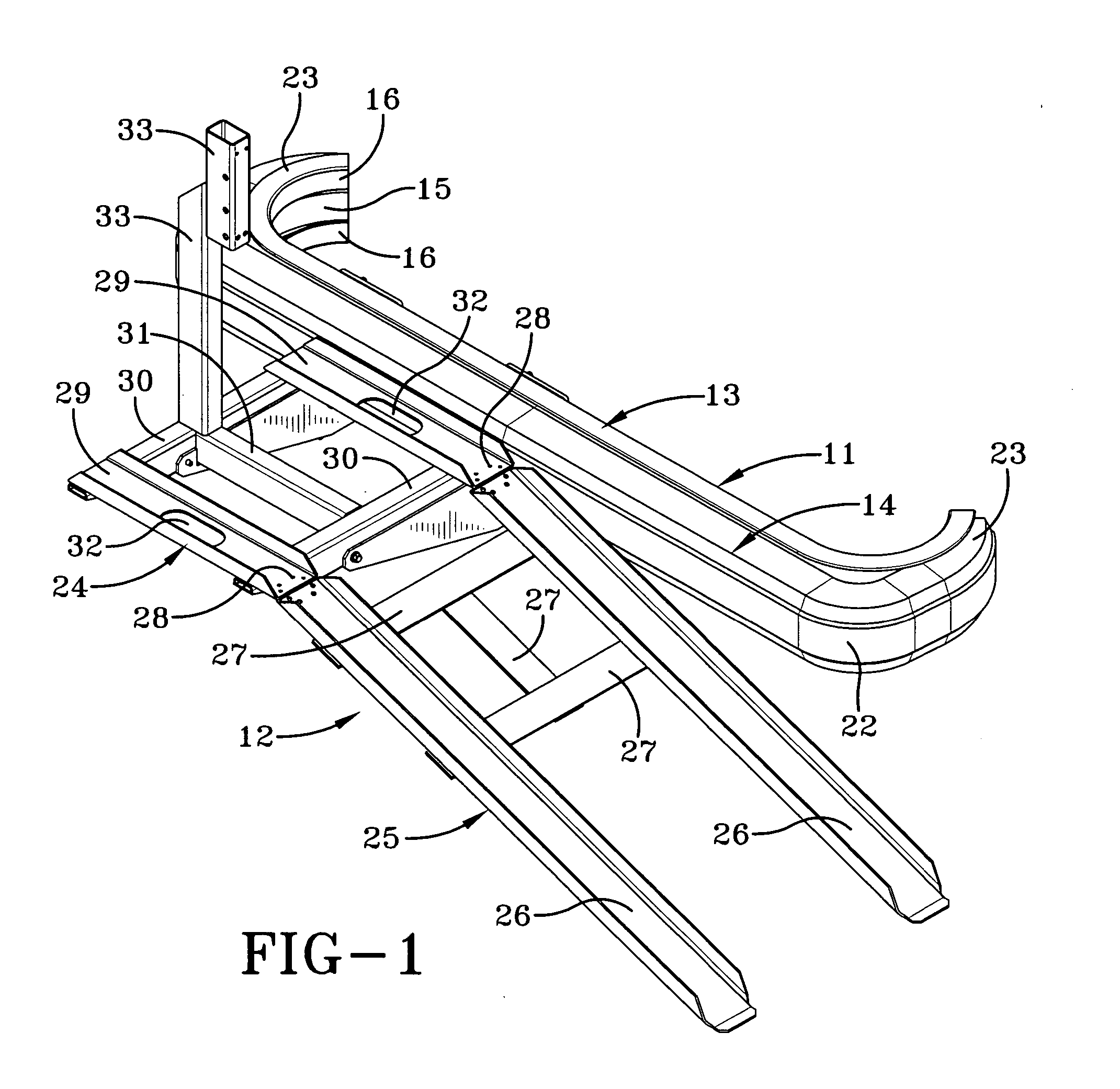

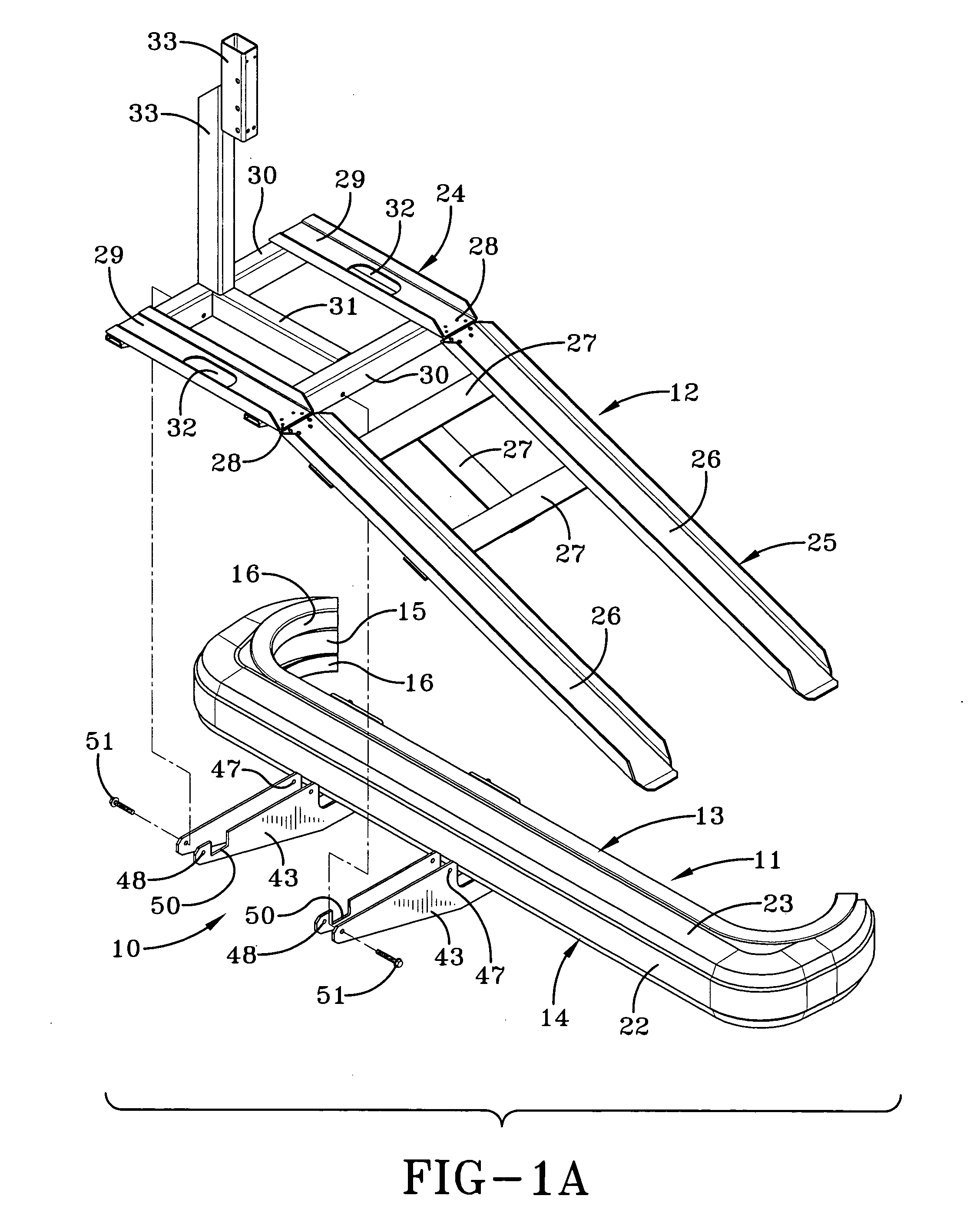

Energy absorbing system for attaching a trailing device to a vehicle

InactiveUS7246833B2Protection from damagePedestrian/occupant safety arrangementSupplementary fittingsBack structureEnergy absorption

Owner:ROMEO RIM

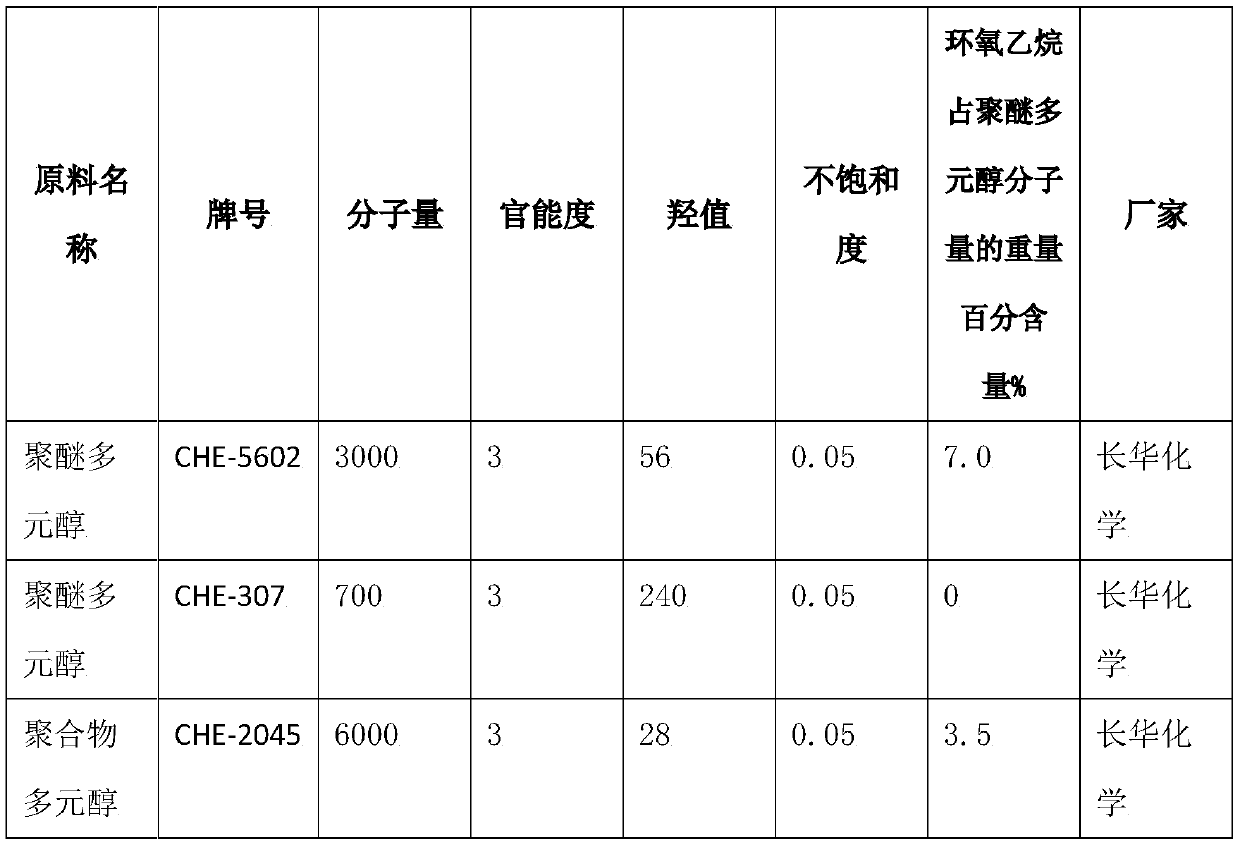

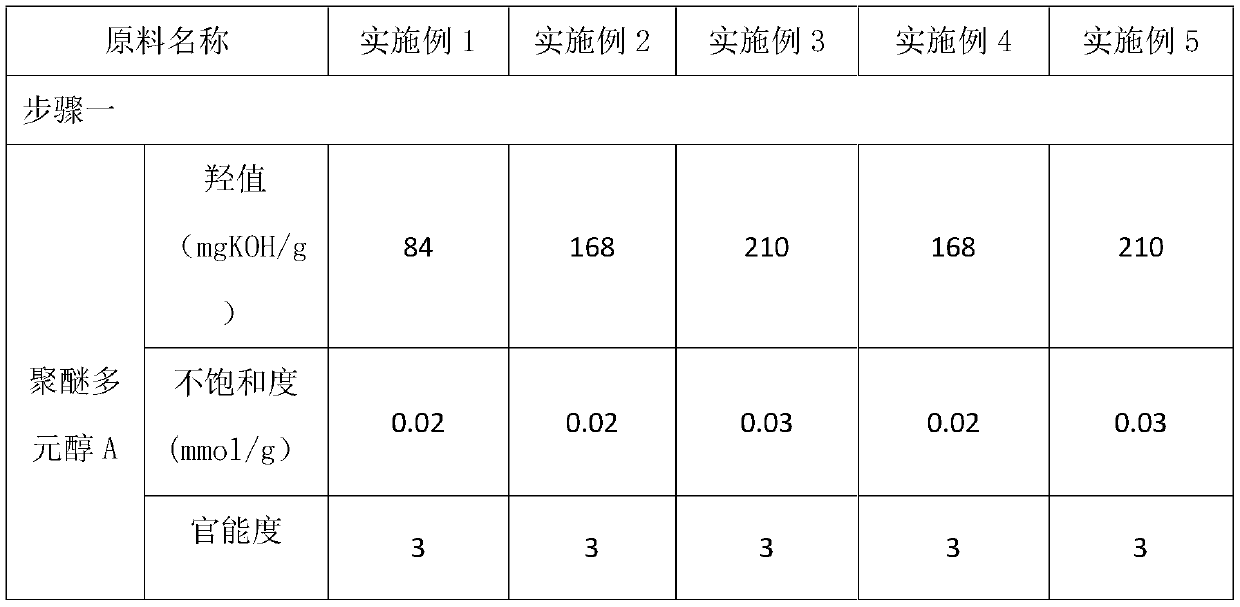

Air-permeable slow-rebound polyurethane foam plastic, and preparation method and application thereof

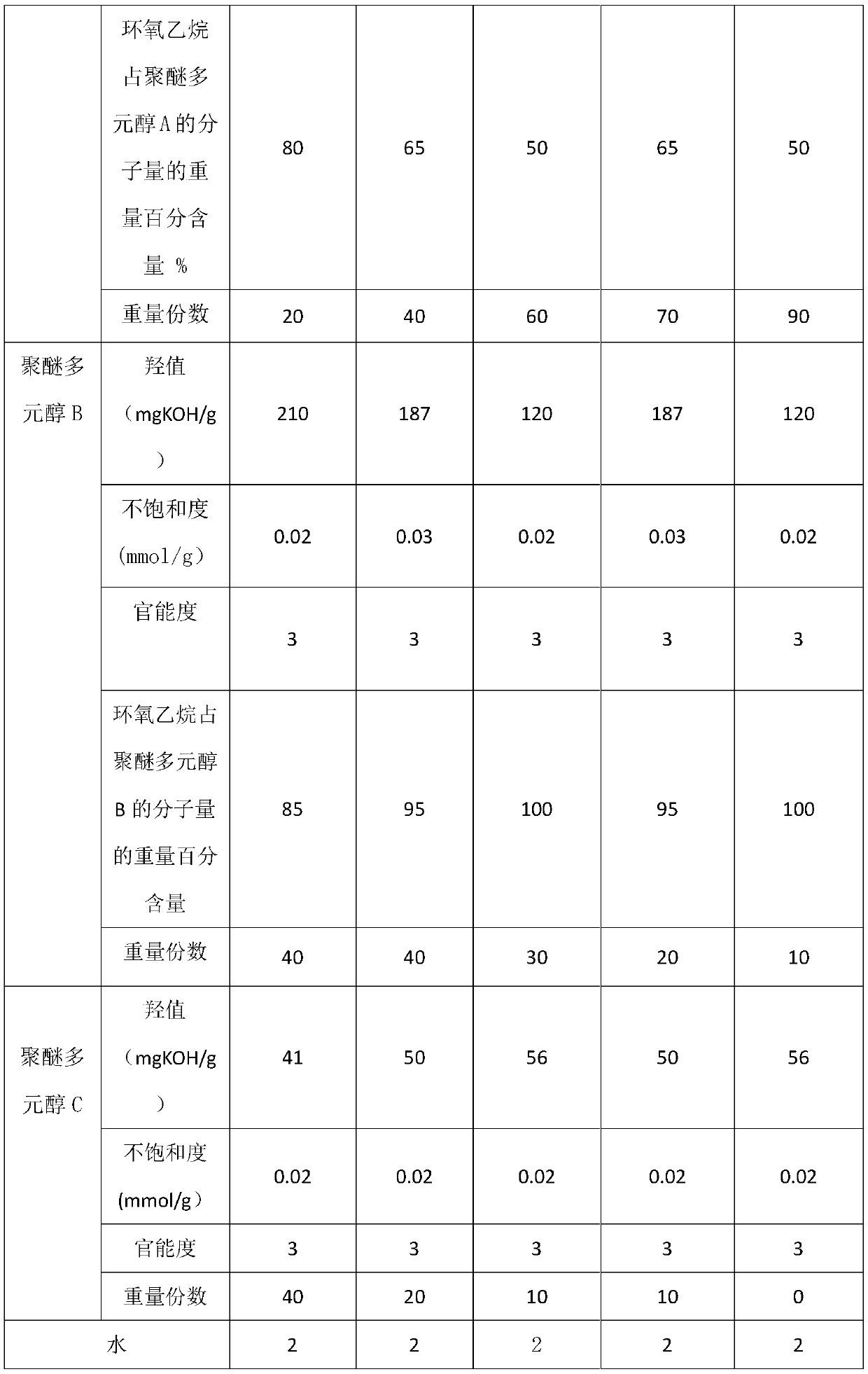

The invention relates to an air-permeable slow-rebound polyurethane foam plastic, and a preparation method and an application thereof. The problem of low air permeability of a slow-rebound polyurethane foam plastic in the prior art or the problems low air permeability and poor slow-rebound effect of the slow-rebound polyurethane foam plastic is / are mainly solved. The air-permeable slow-rebound polyurethane foam plastic comprises, by weight, 10-100 parts of a polyether polyol A, 1-50 parts of a polyether polyol B, 1-50 parts of a polyether polyol C, 40-80 parts of isocyanate, 1-5 parts of water, 0.2-0.8 part of an amine catalyst, 0.01-0.4 part of a tin catalyst and 0.5-3 parts of a foam stabilizer, wherein the hydroxyl value of the polyether polyol A is 60-230 mg KOH / g, the unsaturation degree is 0.01-0.2 mmol / g, the functionality is 2-4, and ethylene oxide accounts for 50-80% of the molecular weight of the polyether polyol A; the hydroxyl value of the polyether polyol B is 120-210 mg KOH / g, the unsaturation degree is 0.01-0.2 mmol / g, the functionality is 2-4, and the ethylene oxide accounts for 85-100% of the molecular weight of the polyether polyol B; and the hydroxyl value of thepolyether polyol C is 35-59 mg KOH, the unsaturation degree is 0.01-0.2 mmol / g, and the functionality is 2-4. The preparation method and the application of the product achieves good technical effects, and the preparation method can be used in industrial production of the air-permeable slow-rebound foam plastic.

Owner:JIANGSU CHANGHUA POLYURETHANE SCI & TECH

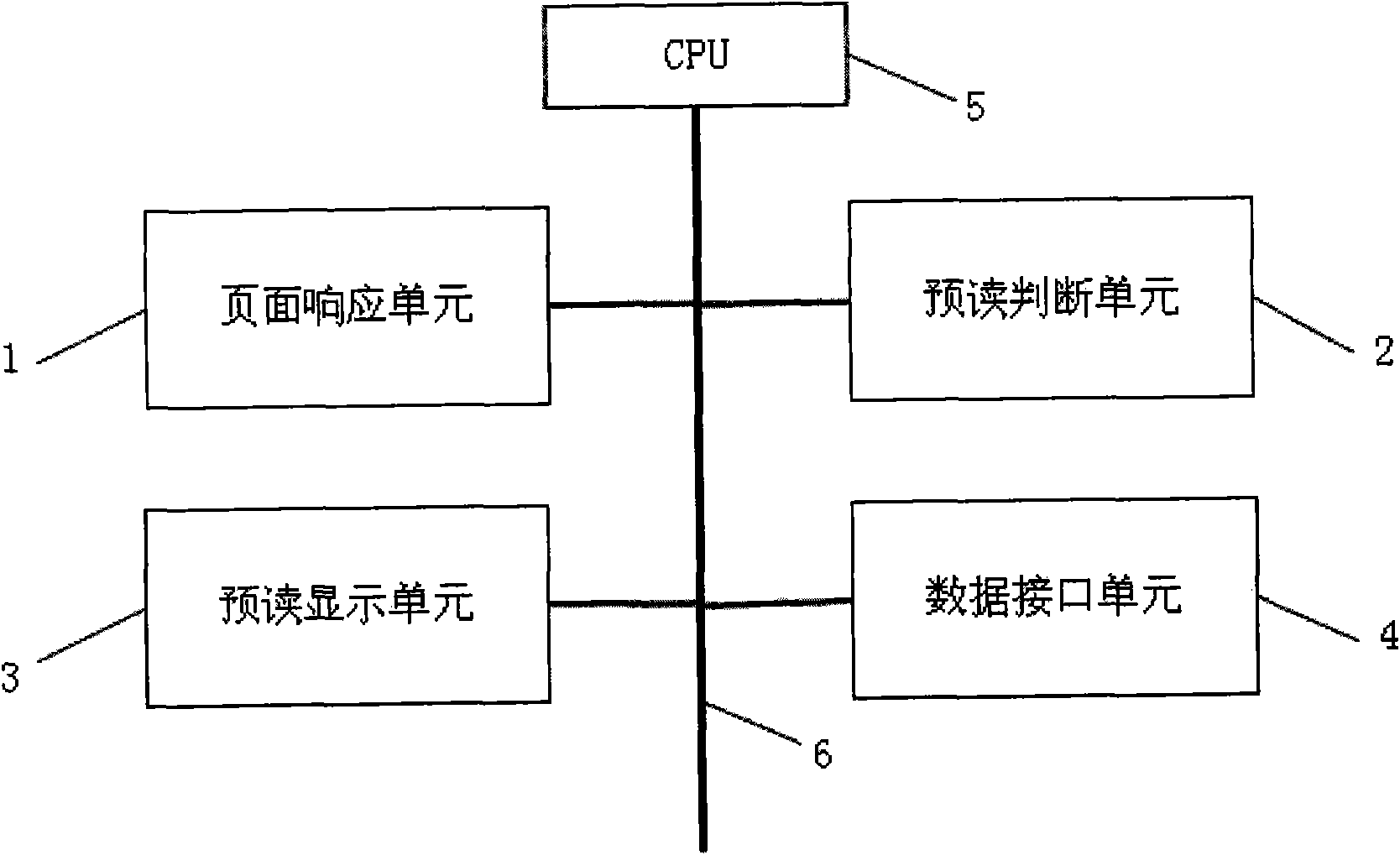

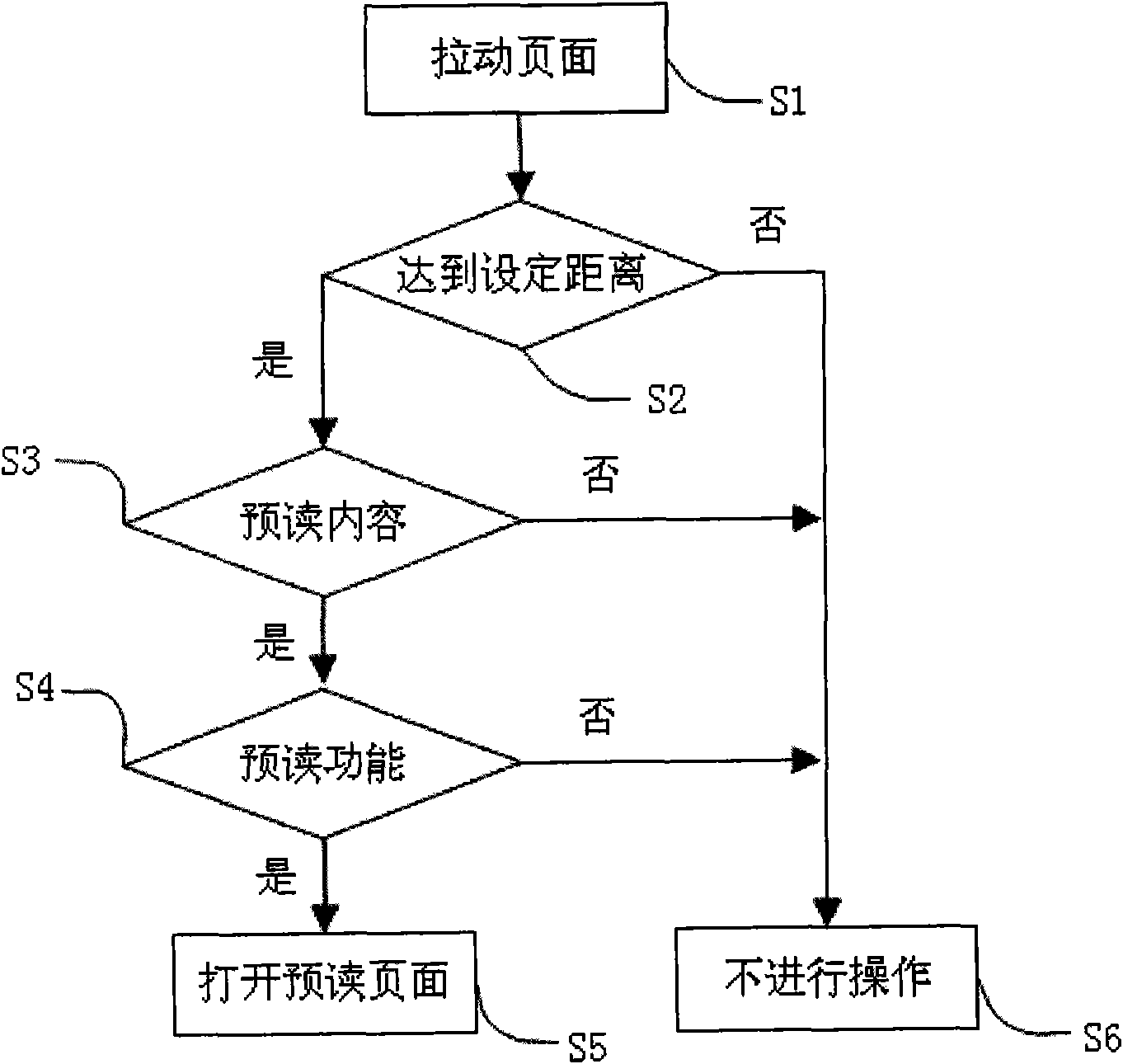

Automatic page turning method and system of browser of touch type mobile terminal

InactiveCN101968708AImprove reading experienceSmart Reading ExperienceInput/output processes for data processingRebound effectWorld Wide Web

The invention provides an automatic page turning method of a browser of a touch type mobile terminal, comprising the steps of: pulling a page to reach a distance set by the browser, and opening a pre-read page when the page has pre-read content and supports pre-read function. The invention also provides an automatic page turning system of the browser of the touch type mobile terminal, comprising a page response unit, a pre-read judgment unit and a pre-read display unit. Through the invention, when visiting the page with the pre-read function, a user can open the pre-read page through pulling the rebound effect at the bottom of the page; therefore, the invention decreases the operation of clicking the buttons by the user, and provides more convenient and intelligent reading experience for the user.

Owner:UCWEB

Baseball Bat

A hollow non-wood baseball or softball bat wherein the impact portion of the bat contains an inner barrel that is positioned by means of a (i) foam insert, (ii) tube extending from the bat's knob, or (iii) line attached to the bat's knob and end cap and extending throughout the bat such that the inner barrel does not come into contact with the inside wall of the bat when the bat is at rest yet when swung the inner barrel is allowed to move so as to amplify the rebound effect given to the ball upon impact with the bat.

Owner:PEGNATORI CARL

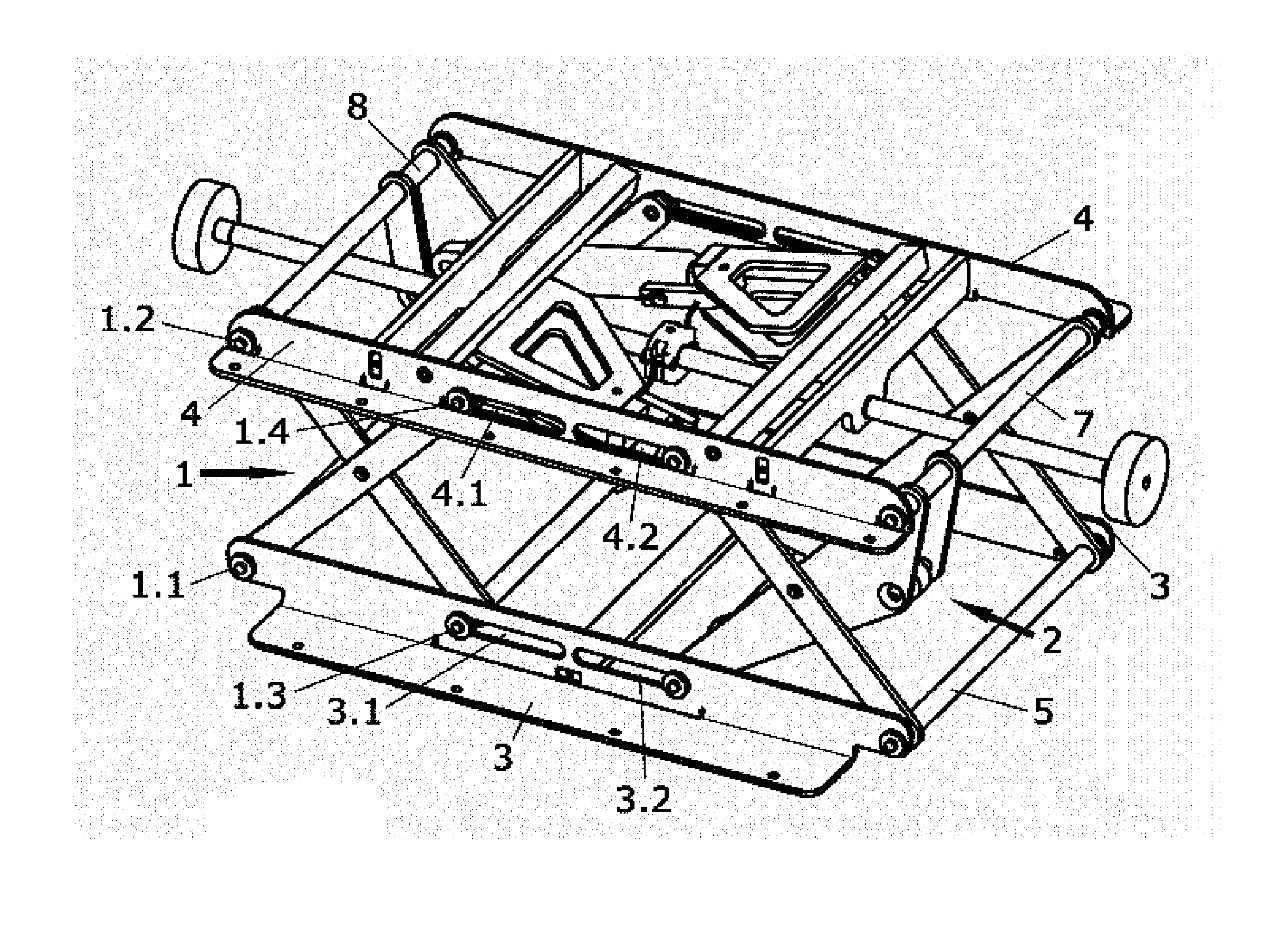

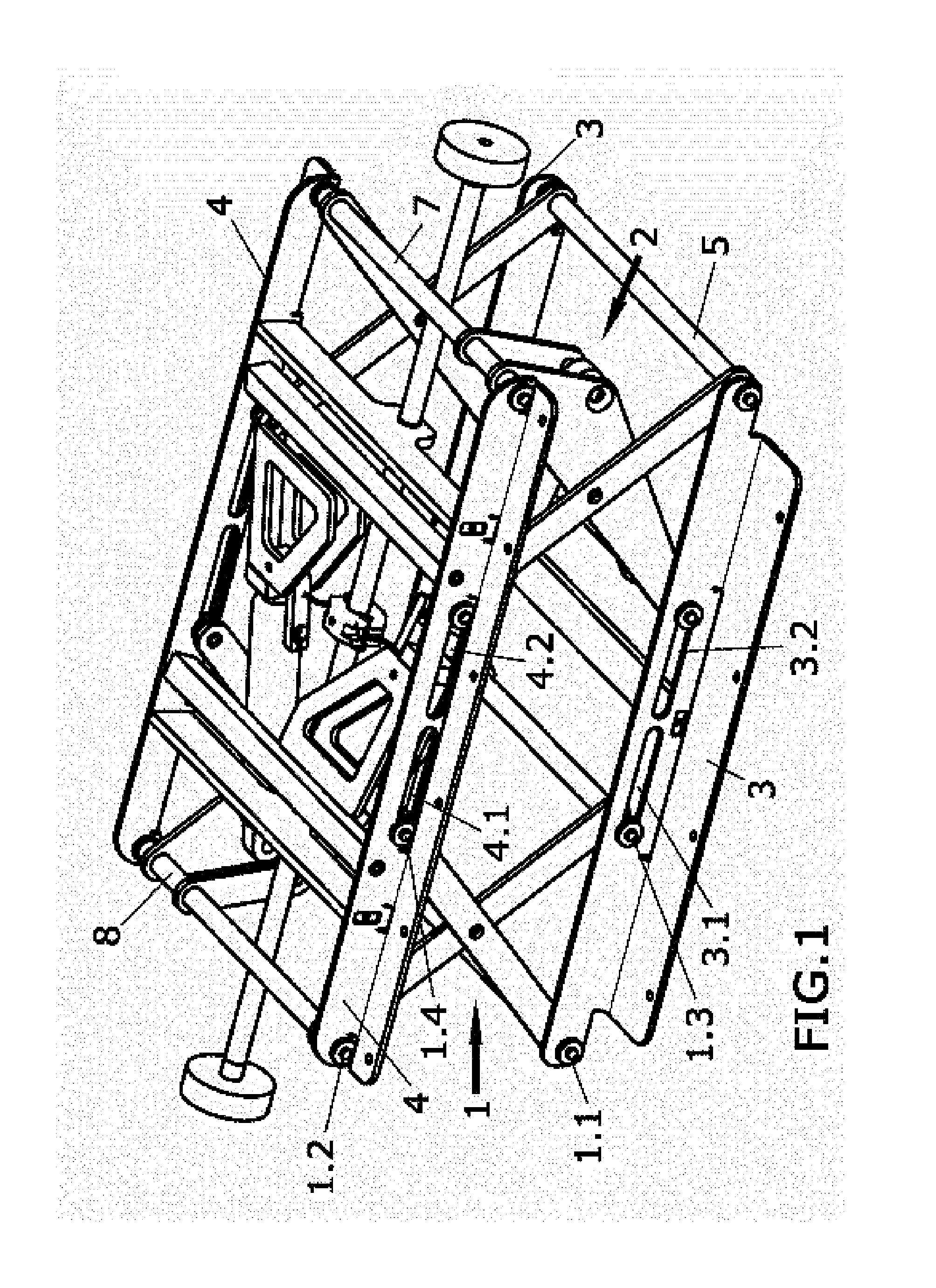

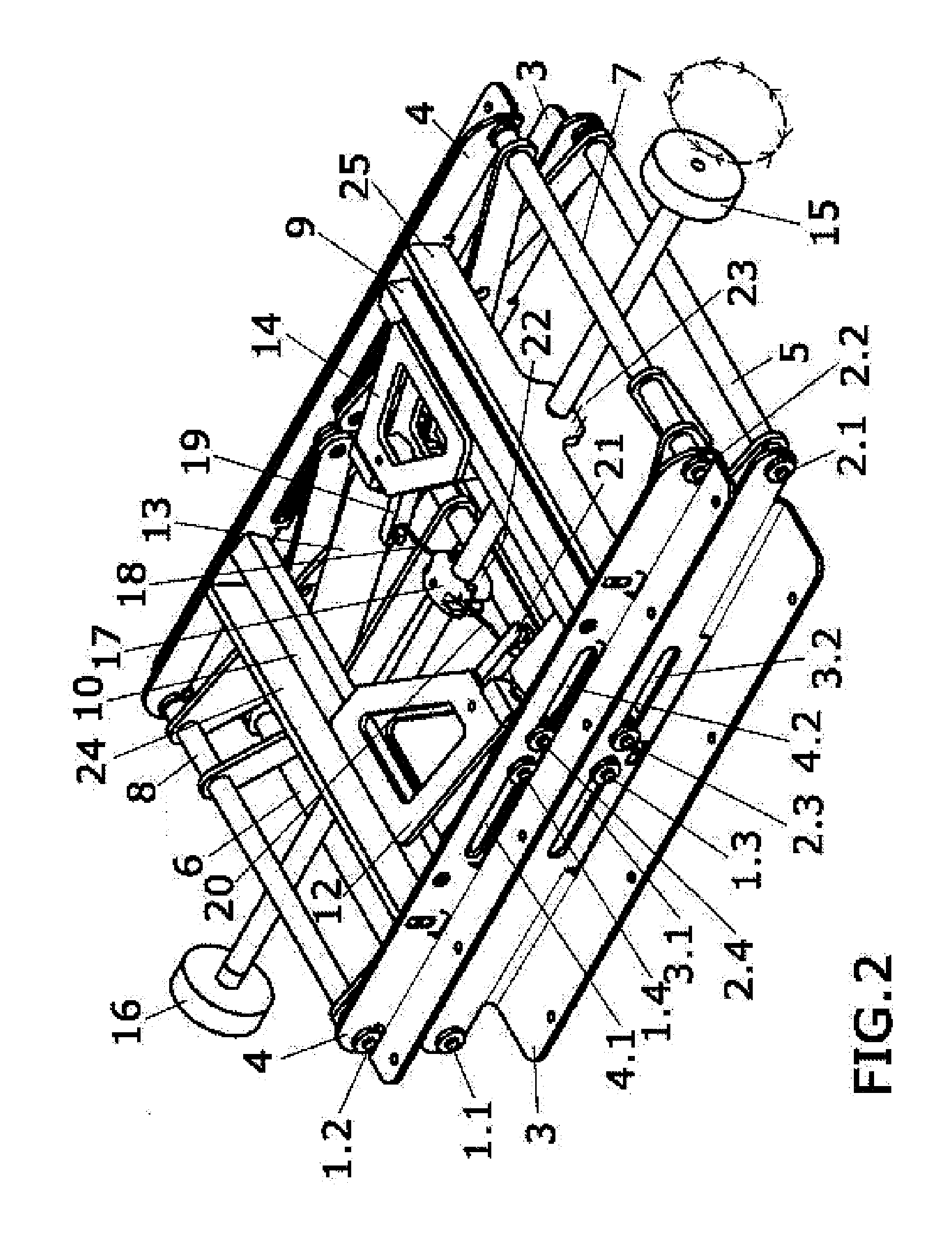

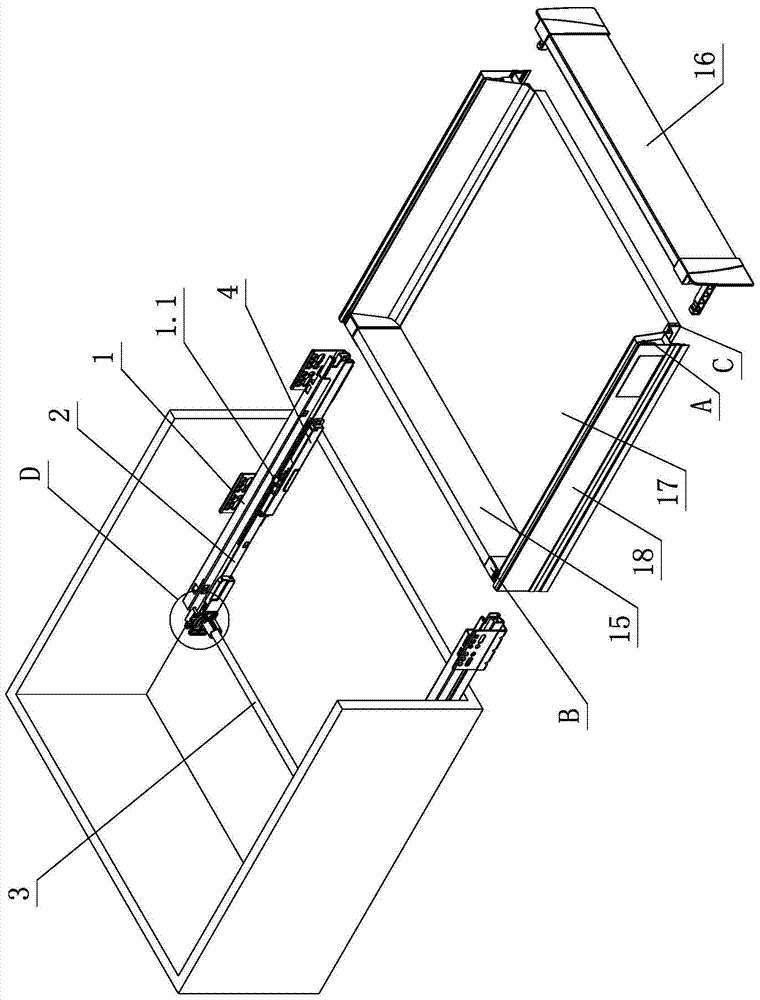

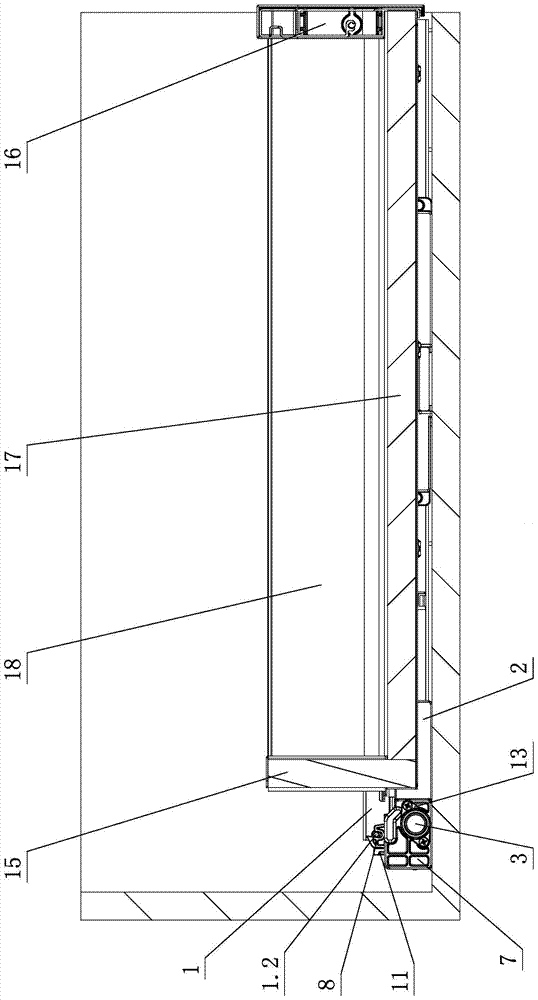

Piano Seat With Automatic Height Adjustment

Piano seat that has a structure for raising and lowering that is formed by two pairs of “L”-section profiles arranged in a facing manner, two at the bottom and two at the top, which are connected together by individual pairs of scissor-type mechanisms, or assemblies in the form of an “X”, which are articulated and arranged in a facing manner, and also by a series of transverse bars, there being, at the end of the scissor-type mechanisms, articulations connecting to the upper and lower profiles, which are stationary and movable, these latter running via oblong slots in the upper and lower “L”-profiles; the entire assembly is moved by gas springs actuated by actuators, which results in a seat that is noiseless when adjusted and used, which requires no effort on the part of the user, is easy and convenient to use and also to assemble, and which has no rebound effect and is rigid and robust.

Owner:HIDRAU MODEL

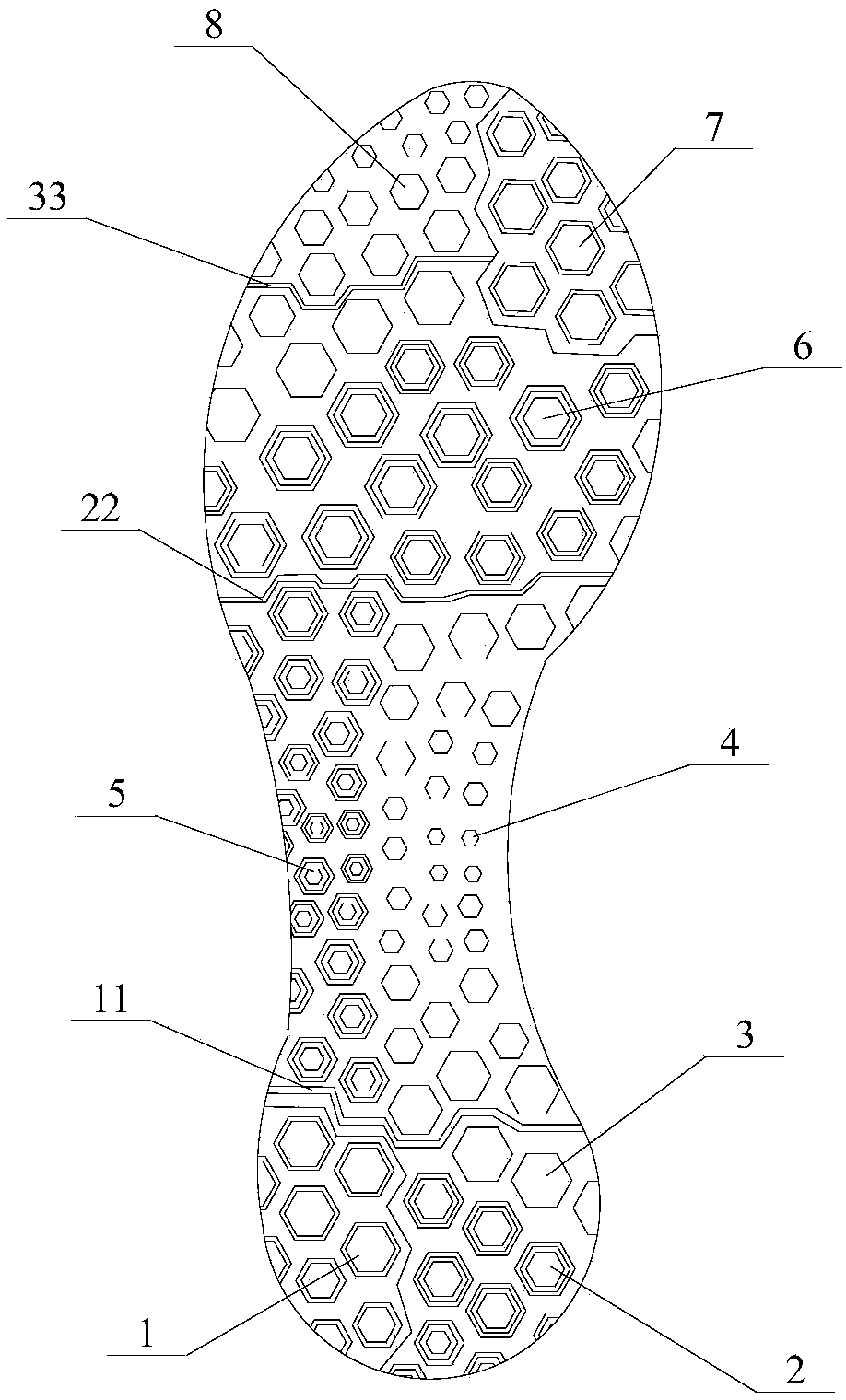

Sports shoe and sole thereof

The invention discloses a sports shoe and a sole of the sports shoe. A heel outer side region, a heel middle region, a foot arch outer side region, a foot palm region and a first toe region of the bottom face of the sole of the sports shoe are respectively provided with multiple multilayer cushioning rebound columns; a heel inner side region, a foot arch inner side region and a second toe region are respectively provided with multiple monolayer cushioning rebound columns; the cross section of each multilayer cushioning rebound column and the cross section of each monolayer cushioning rebound column are in a regular hexagon shape. The cushioning rebound columns on the sole can generate deformation energy to disperse impact force when pressed and have a great damping and cushioning effect; the multilayer cushioning rebound columns conduct extrusion layer by layer like springs when extruded, so that the rebound effect is better; since the cushioning rebound columns are in the regular hexagon shape, the edges of the cushioning rebound columns can supply friction force in multiple directions; besides, cavities between the cushioning rebound columns can not make the sole generate brake force due to too large friction force exerted on the sole in a certain direction, so that skid resistance is increased, and flexibility is ensured.

Owner:QUANZHOU QUANYONG MACHINERY DEV

Protective Headgear

InactiveUS20180000185A1Energy-absorbing and dissipating propertyHatsHeadwear capsProtective headgearDevice form

A protective device for a head of an individual person. The protective device forms a cap that includes a flexible headpiece and a segmented outer protective shell disposed about the flexible headpiece for distributing an impact load. The device covers and protects the front, top, sides and back of the head from impact injuries and rebound effects of high speed objects as seen for example, a baseball or softball moving at a speed of up to about 125 mph.

Owner:HARVEST MOON INVENTIONS LLC

Novel keyboard structure

InactiveCN108172440AThe overall thickness is thinLow costInput/output for user-computer interactionContact mechanismsElastomerMaterial type

Owner:JIANGSU TRANSIMAGE TECH CO LTD

Novel helmet for ship

InactiveCN104305620AHas a rebound effectInnovative designHatsHeadwear capsWaste managementRebound effect

The invention discloses a novel helmet for a ship. The novel helmet for the ship comprises a helmet body. The novel helmet for the ship is characterized in that a buffering device is arranged in the helmet body; the buffering device comprises a fixing pad, a spring assembly and a sponge pad which are arranged from inside to outside in sequence; the buffering device is detachably mounted in the helmet body. The novel helmet for the ship is novel in design, has a good buffering effect, brings the rebounding effect, and is high in safety performance.

Owner:JIANGYIN BINJIANG SHIP EQUIP

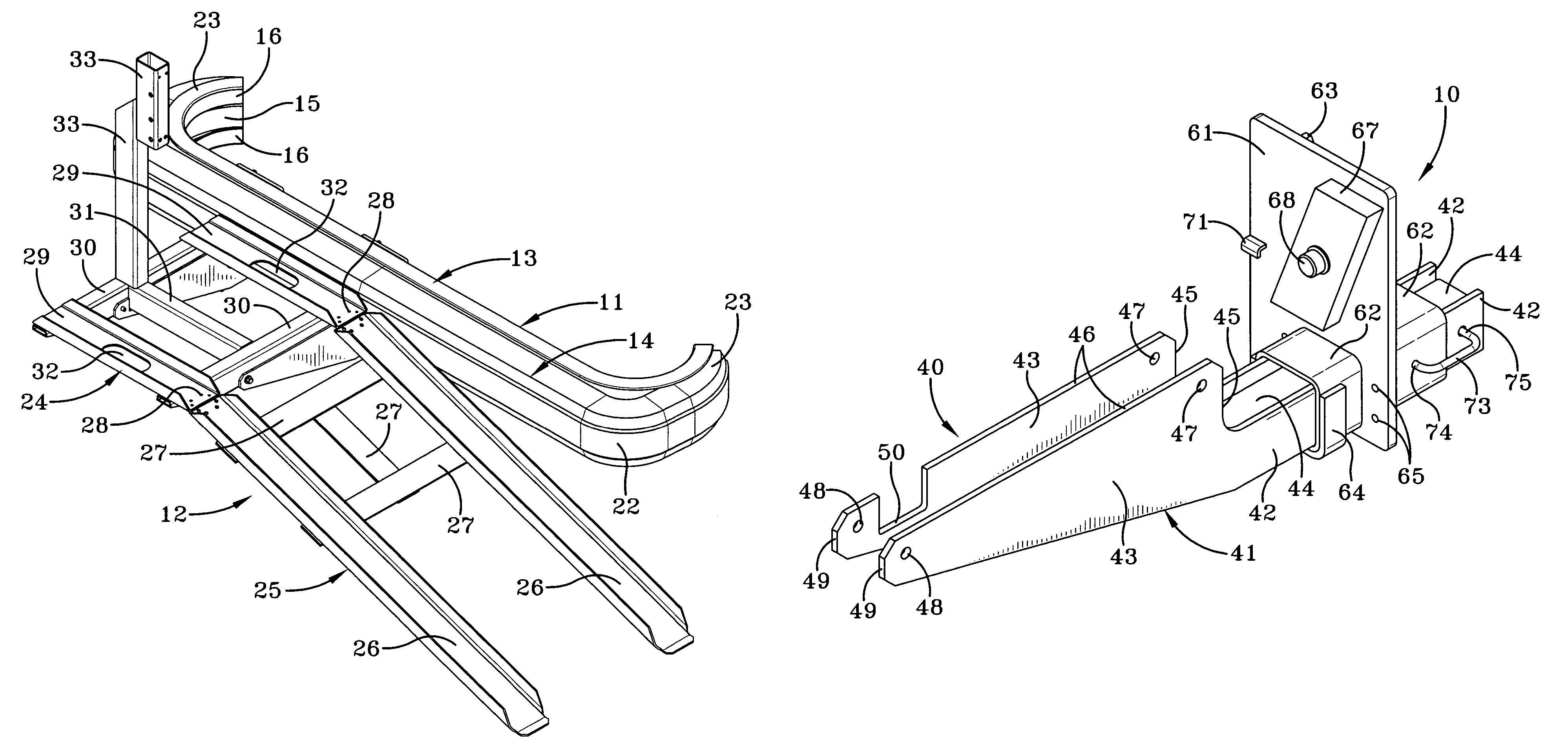

Energy absorbing system for attaching a trailing device to a vehicle

InactiveUS20050057052A1Protection from damagePedestrian/occupant safety arrangementSupplementary fittingsBack structureEnergy absorption

A system (10) for attaching a trailing device (12) to a vehicle includes a bumper assembly (11) having a back structure (13) which carries an energy absorbing module (14). The system (10) includes receiver assemblies (60) which are attached to the bumper back structure (13) and which include a tube (62). The system (10) also includes carrier assemblies (40) which carry the trailing device (12) and which each includes an arm end (42) slidably received in the tubes (62). Shear pins (73) attach the arm ends (42) to the tubes (62) and upon impact to the trailing device (12), a leg (74) of each pin (73) can be sheared allowing relative movement between the arm ends (42) and the tubes (62). As a result, the carrier assemblies (40) contact the energy absorbing bumper module (14) to absorb some of the energy of the impact. As the arm ends (42) begin to move in the other direction through tubes (62), by virtue of the rebound effect of the energy absorbing module (14), another leg (75) of each pin (73) engages the tube (62) to stop the rebounding movement.

Owner:ROMEO RIM

Buffer energy-absorbing wall structure for front of highway tunnel

The invention provides a buffer energy-absorbing wall structure for the front of a highway tunnel. The buffer energy-absorbing wall structure comprises a concrete layer, springs and lower washers. Space between the surface of cylinder connectors and gaps is filled with the concrete layer; the cylinder connectors are horizontally arranged on the surface of a wall body; the bottom of the concrete layer below the cylinder connector is fixed to the tops of trapezoidal blocks; the trapezoidal blocks are arranged at intervals, and a damping unit is arranged between every two trapezoidal blocks; a support plate is arranged below the damping units and the trapezoidal blocks; a pressure staggered member is laid at the bottom of the support plate. The cylinder connectors are mutually connected through connections 3 MM in middle width so that the wall surface structure has higher toughness and great rigidity; in case of external impact, impact energy can deform and shift greatly the cylinder connectors on the wall while resilience of the wall is decreased, and damage of an impacted vehicle and damage to the overall structure of the tunnel are decreased.

Owner:邵书微

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com