Patents

Literature

60results about How to "Shorten the design and production cycle" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

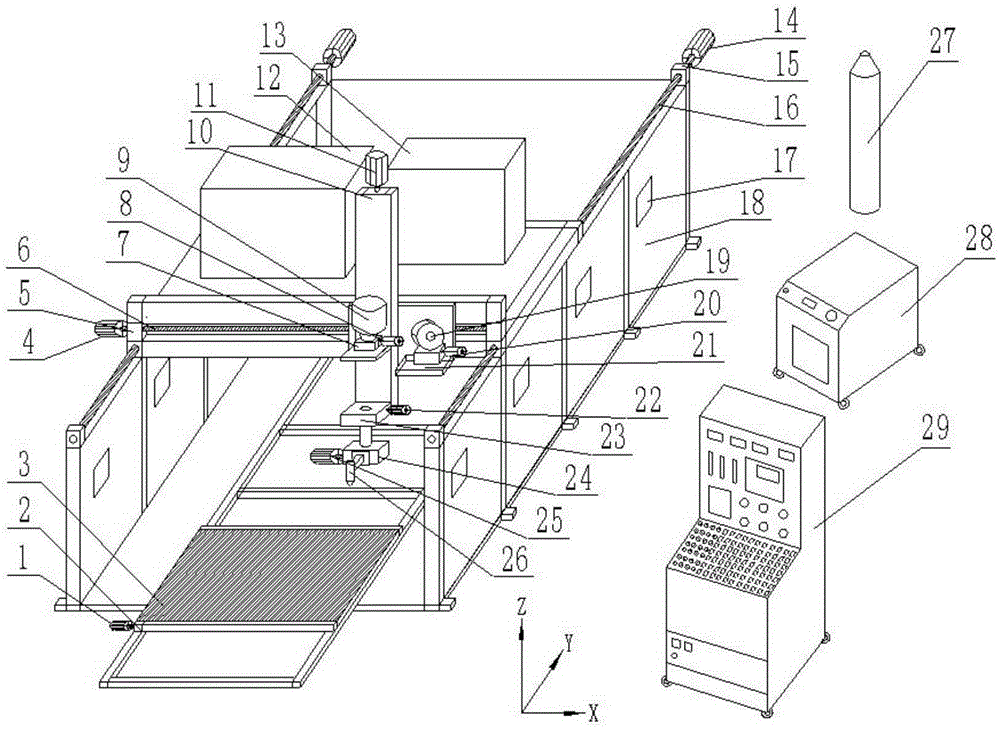

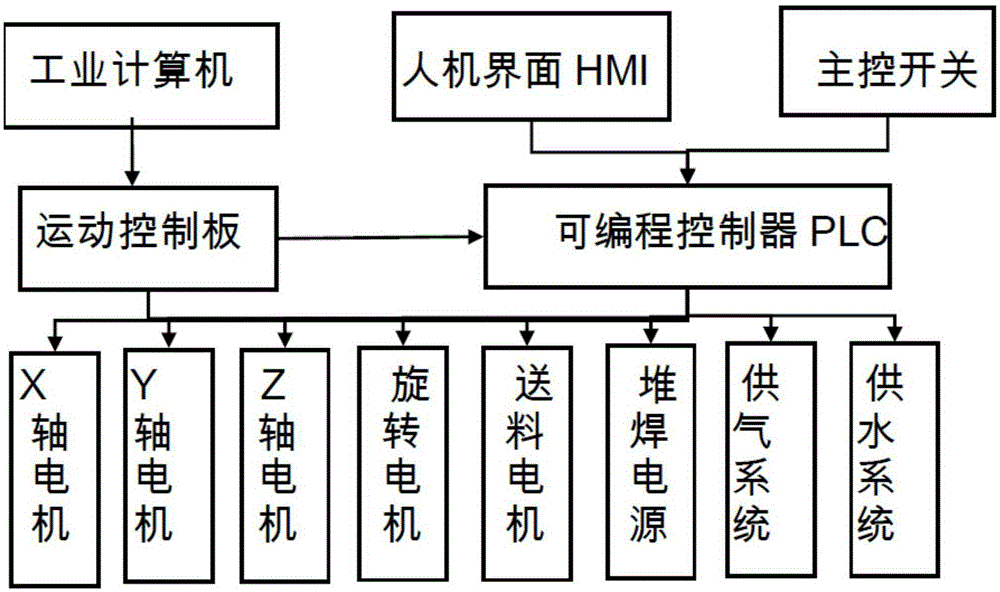

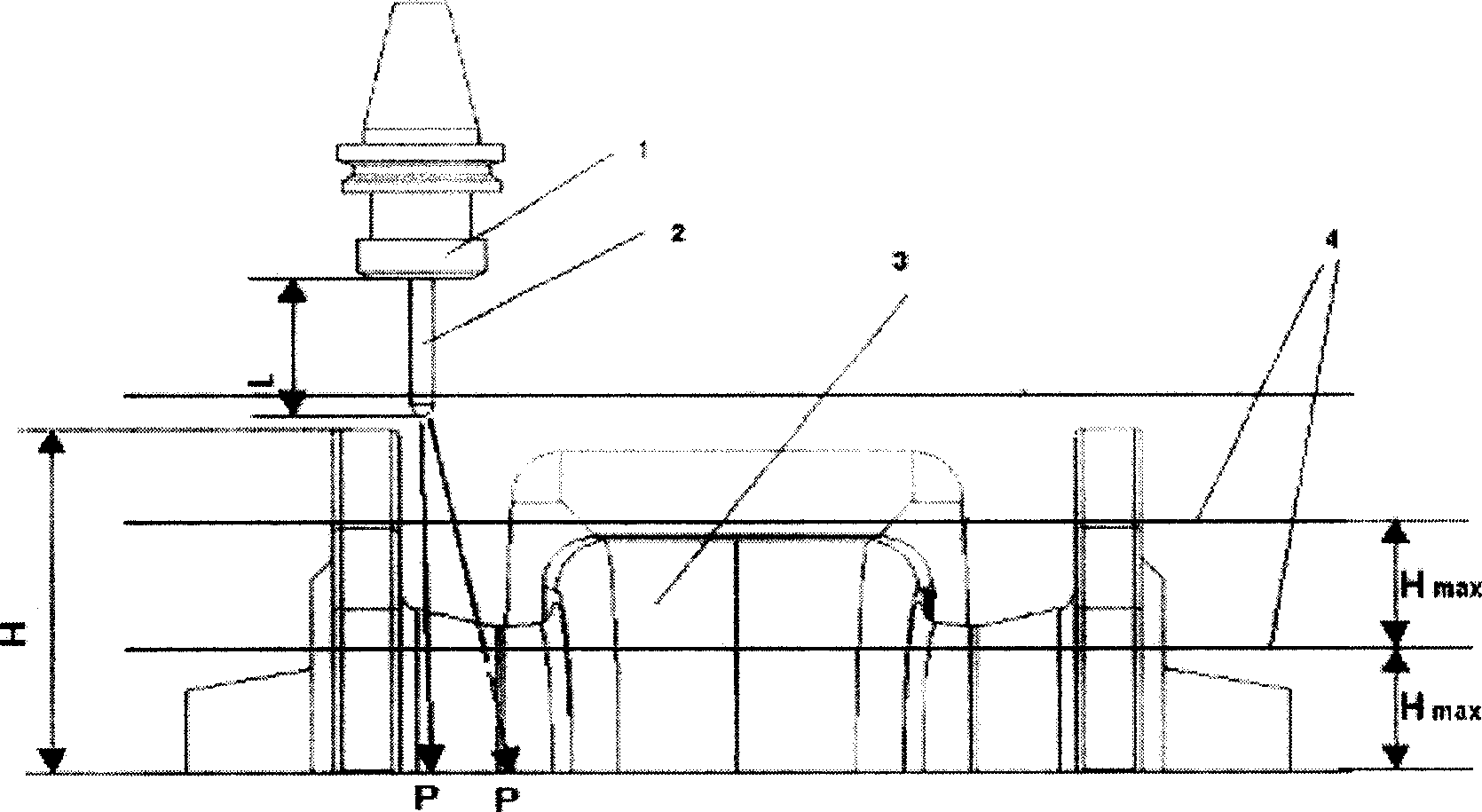

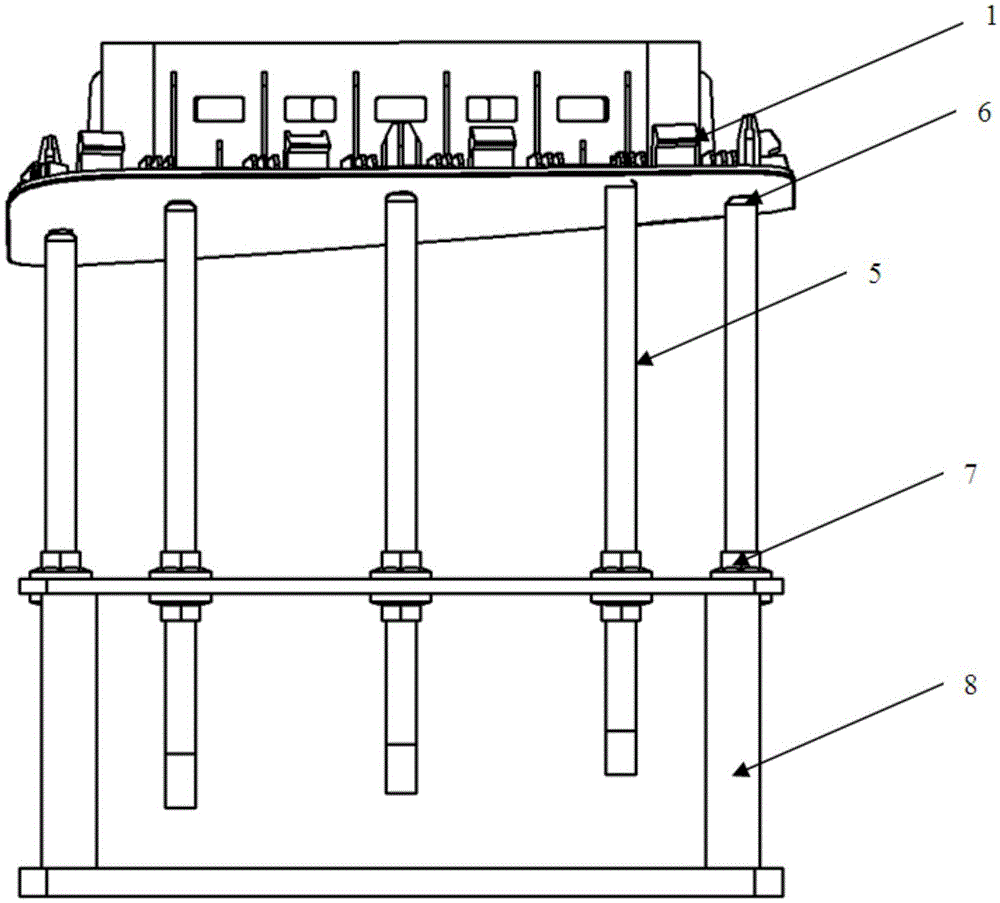

Gantry type high-power plasma arc 3D printing equipment and method

ActiveCN105234538AImprove printing efficiencyEasy to usePlasma welding apparatusHuman–machine interfaceDesign control

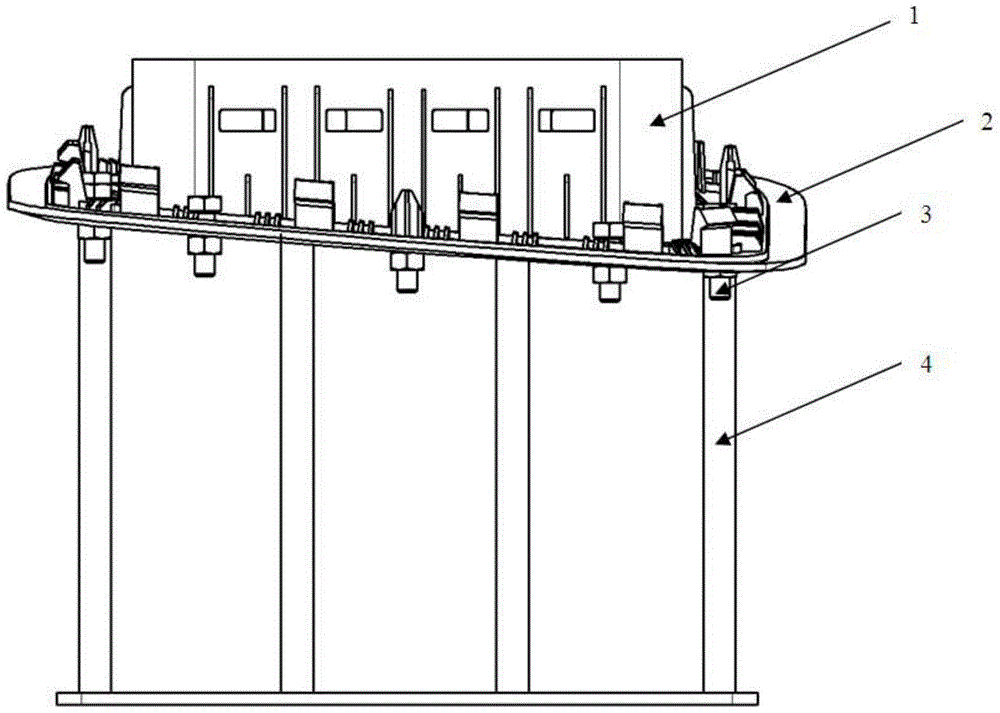

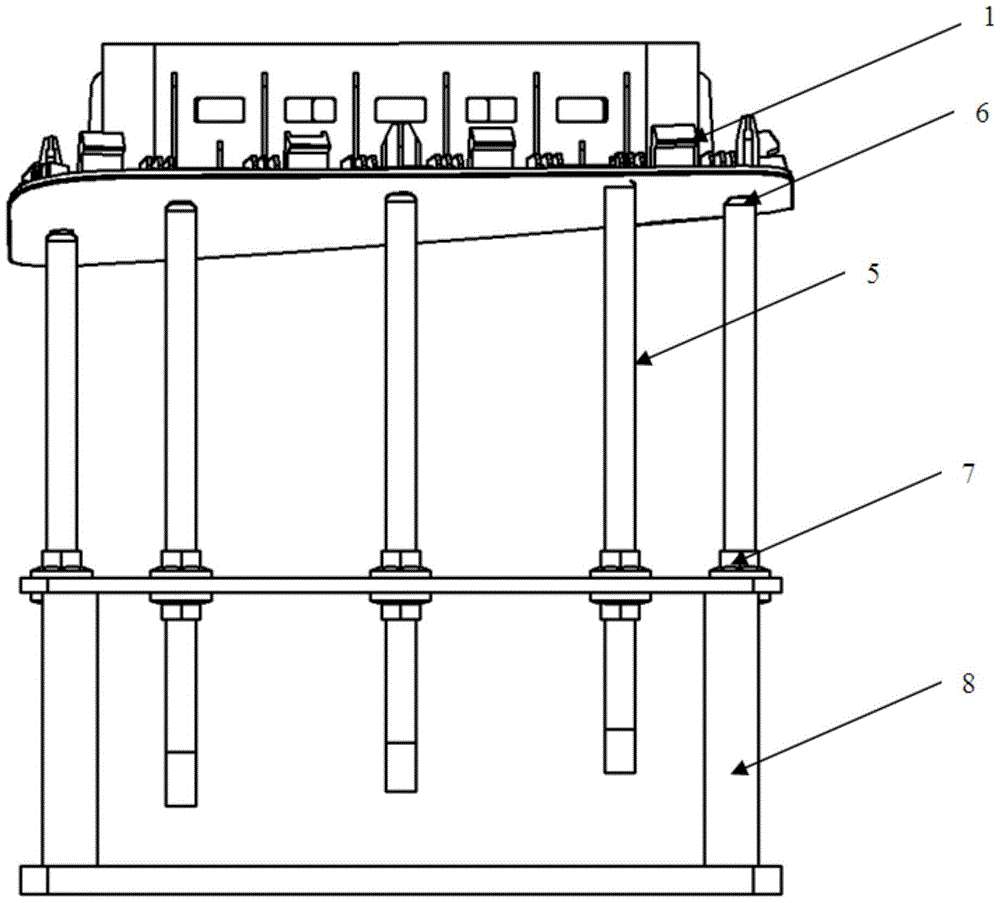

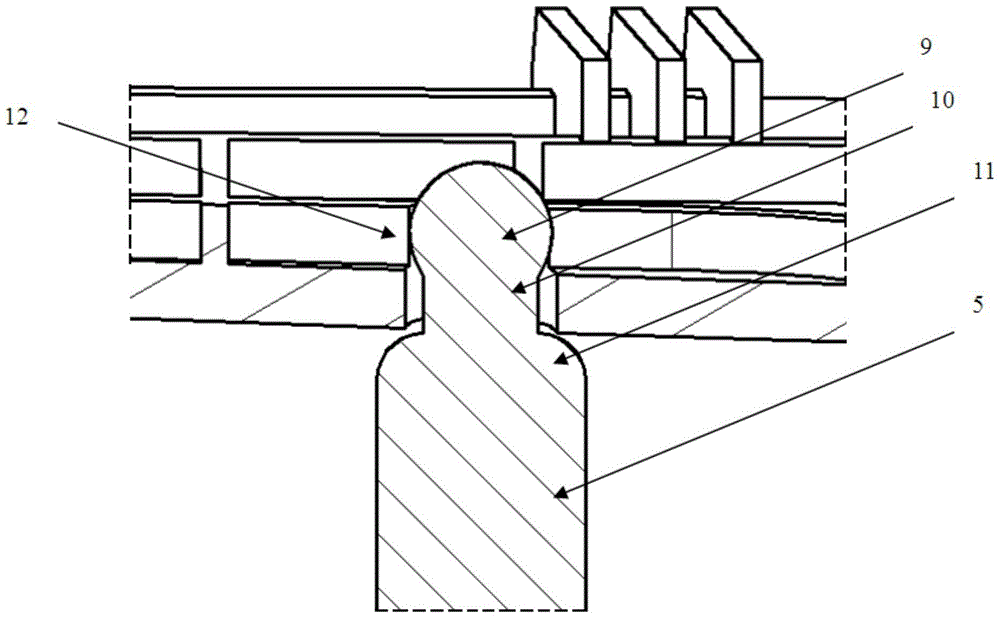

The invention discloses gantry type high-power plasma arc 3D printing equipment and a method. The printing equipment comprises a gantry type structure frame and elevated bearing walls, wherein a gantry platform of the frame is mounted at the upper ends of the elevated bearing walls at two sides. The printing equipment further comprises a printing machine head, a printing molding platform, an X-axle motion component, a Y-axle motion component, a Z-axle motion component, a powder feeding mechanism, an oscillator, a printing machine head rotating mechanism, a wire feeding device, a surfacing power supply and an electric cabinet. The printing method comprises the steps of three-dimensional modeling, layered slicing, process preparation and real-time printing. The plasma arc above 10kw is used for melting fed metal powder or wires to finish the 3D printing of large products under predesigned control programs, so that the 3D printing efficiency is greatly improved; the whole system adopts the full-digital control, and is provided with self-inspection and warning systems; and main process parameters are set by a human-computer interface, so that the use and the maintenance of operators are more convenient.

Owner:武汉高力热喷涂工程有限责任公司

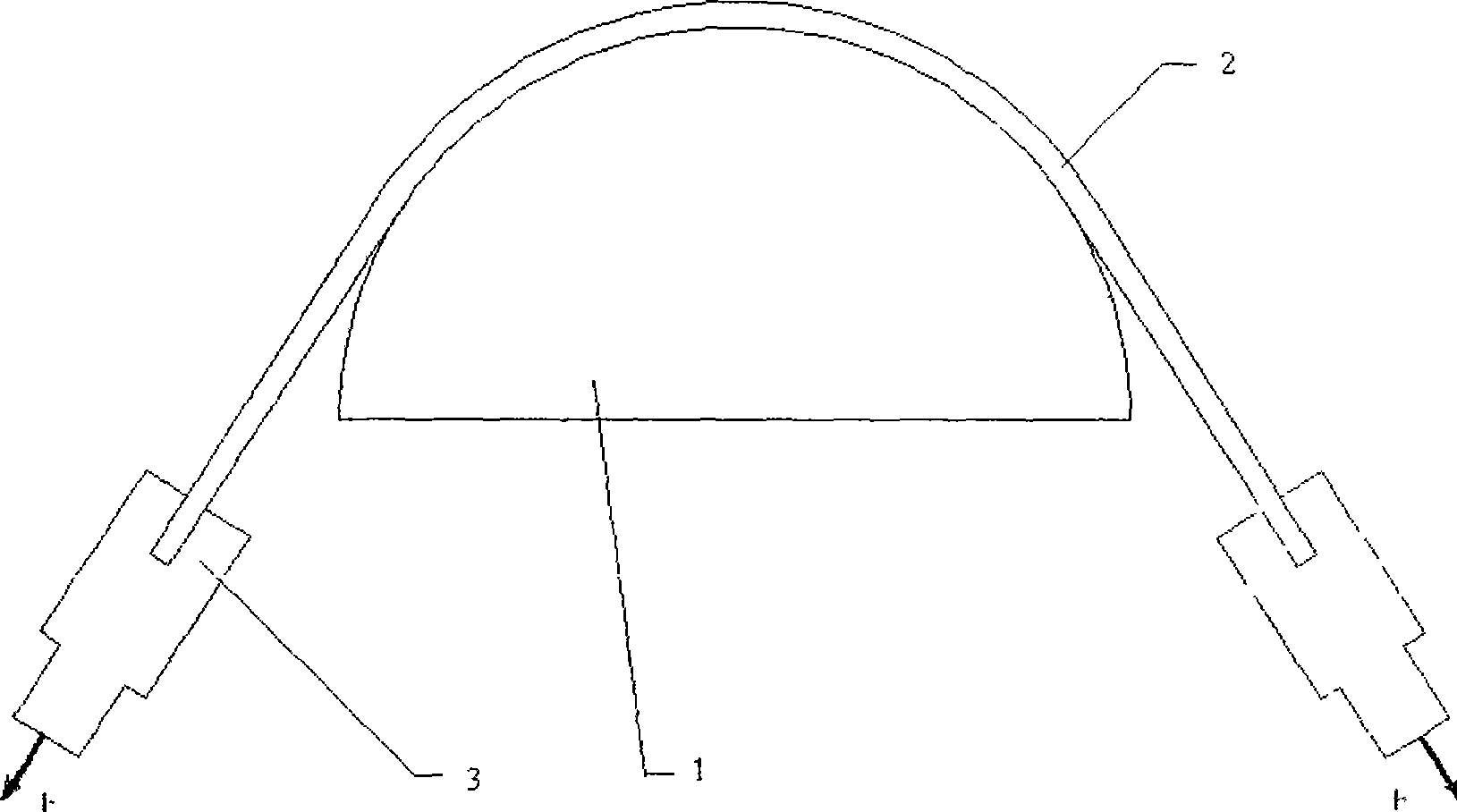

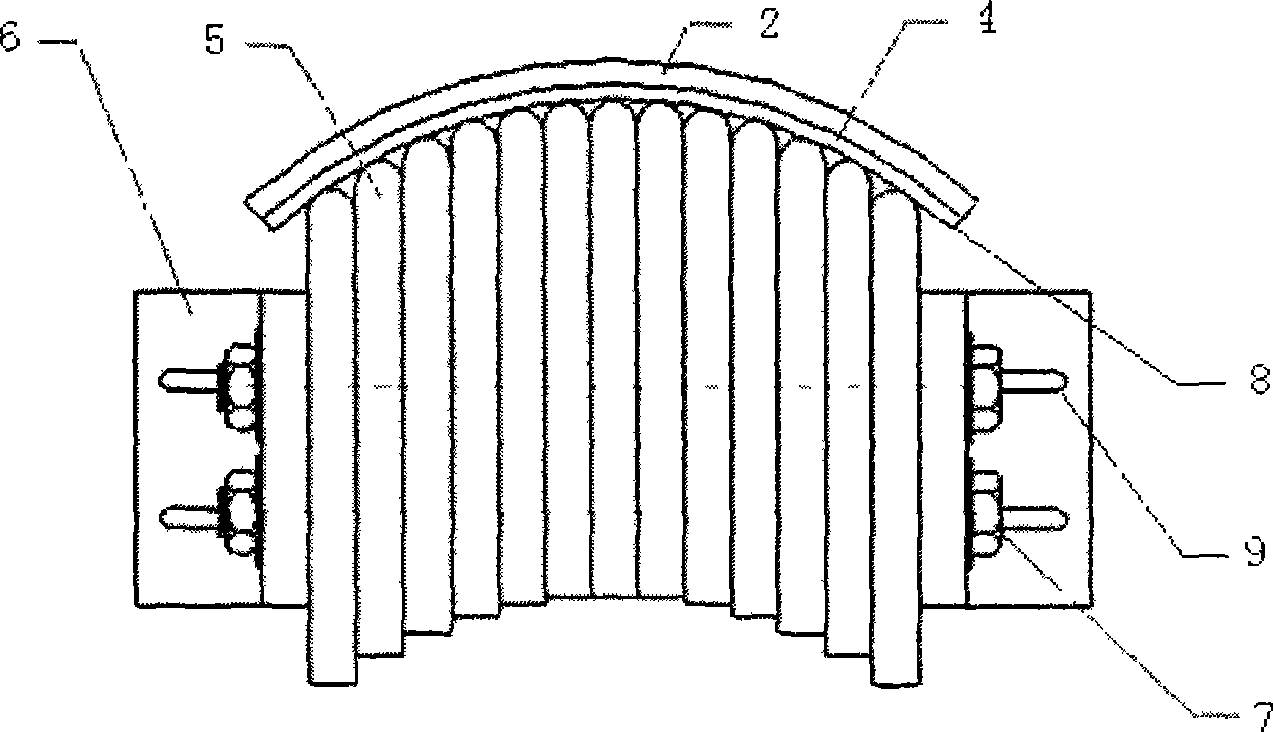

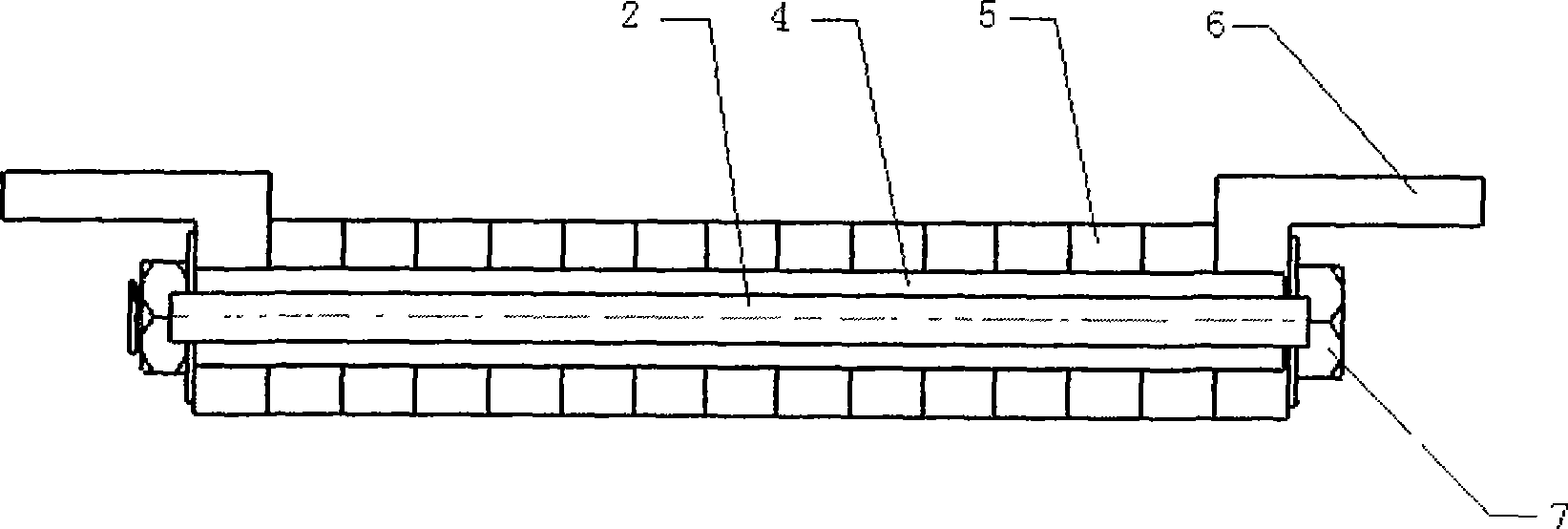

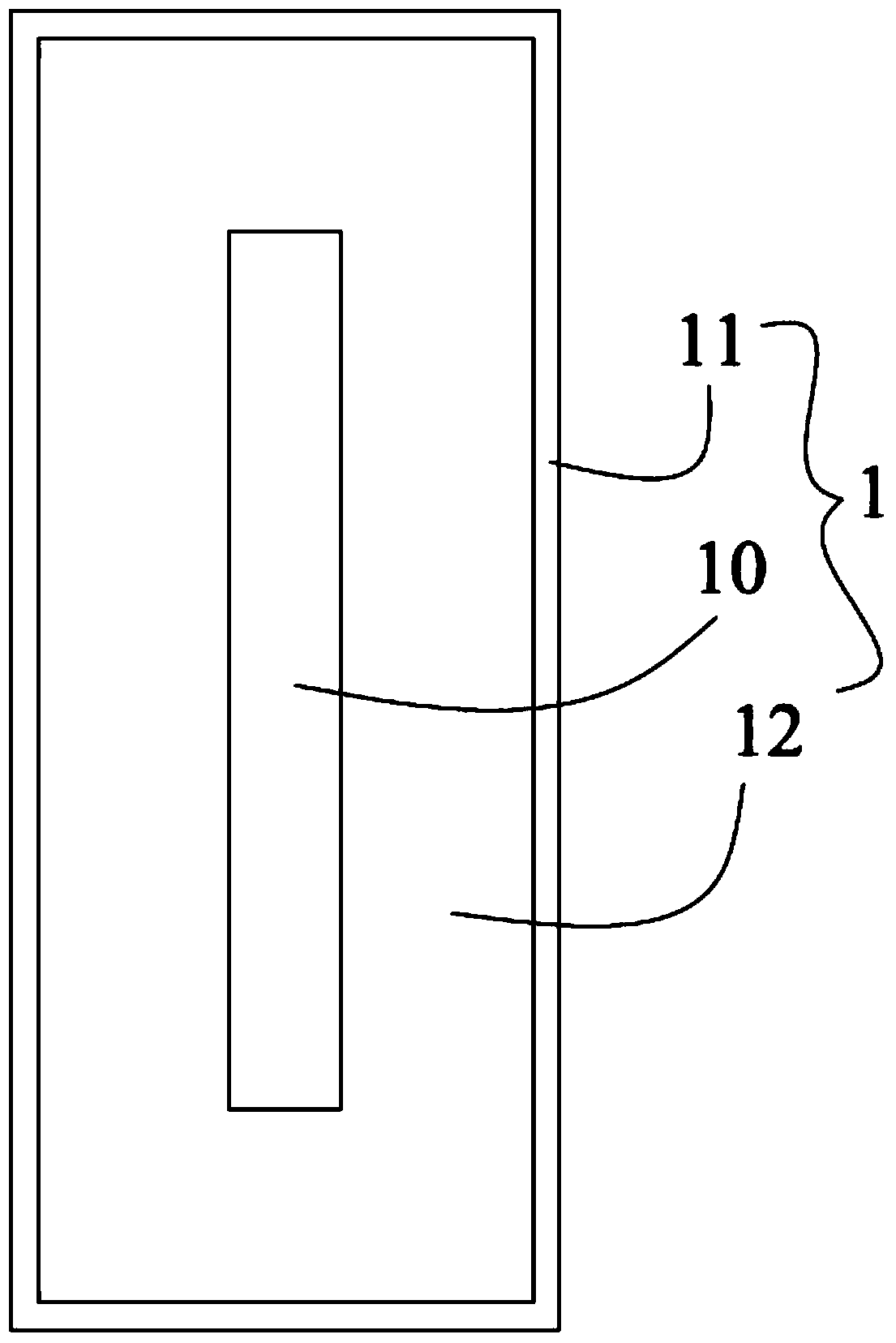

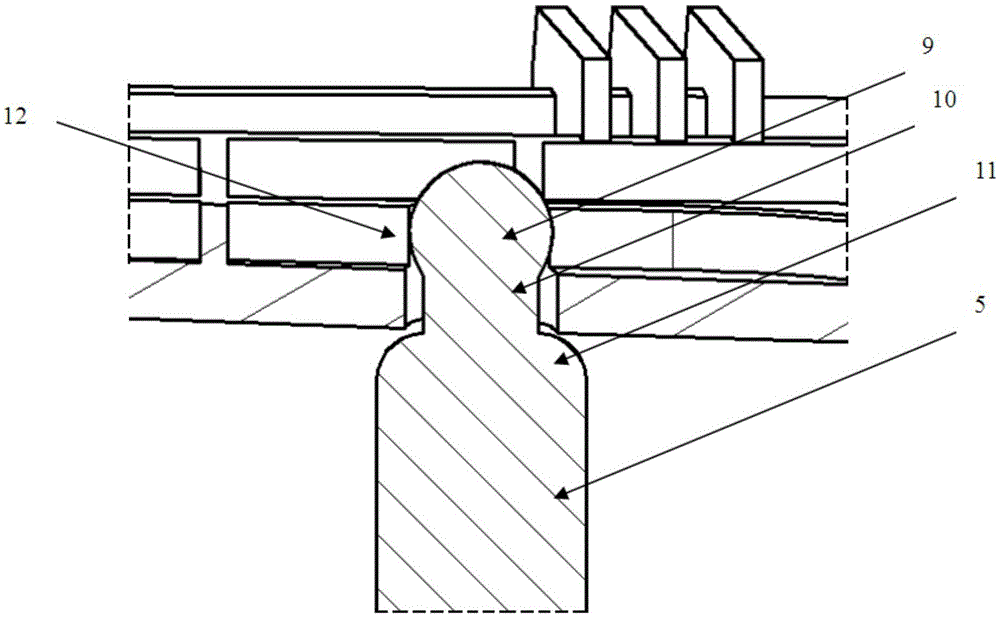

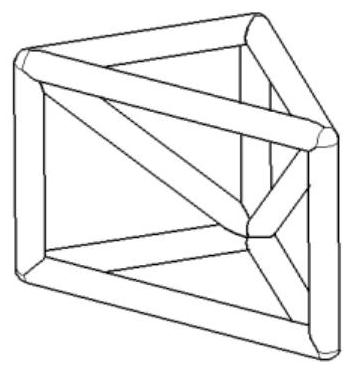

Stretch-bending forming die and forming method

InactiveCN101518802AAchieving Precise FormingShorten the design and production cycleShaping toolsEngineeringCushion

The invention discloses a stretch-bending forming die and a forming method, including a basic body (5), a cushion layer (4), a connecting bolt (7) and two clamp blocks (6). The end surface of one end of the basic body (5) is an arc working surface (10), with a through-hole (11) which is matched with the connecting bolt (7) in the middle. One clamp block, a plurality of basic bodies and another clamp block are sequentially arranged on the connecting bolt (7) in series and tightly clamped and fixed, thereby integrating a die; by adjusting the position (11) where the connecting bolt passes through a through groove on each basic body, the position of the working surface (10) of each basic body is adjusted; and by fixing the die onto the working table of a stretch bender by a mounting hole (9), the stretch-bending forming is carried out to a workpiece (2) to be formed. In the forming process, by slightly adjusting the position of the basic body (5), the shape of the external surface of the die is changed so as to compensate the rebounding effect on the forming accuracy and adapt to the rebounding control needs of different stretch-bending parts; and the invention is characterized by simple structure, convenient use, high production efficiency and low cost.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

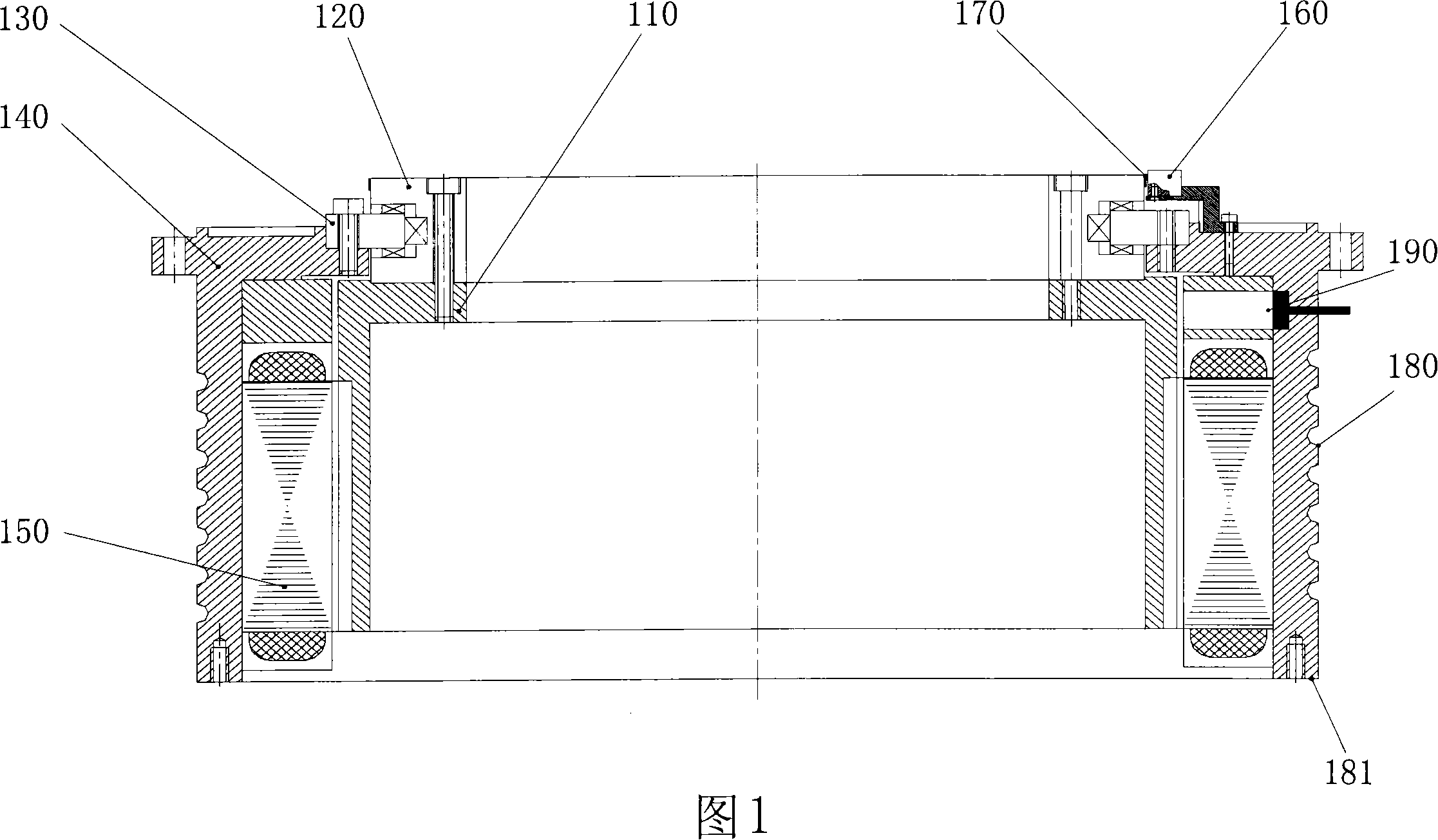

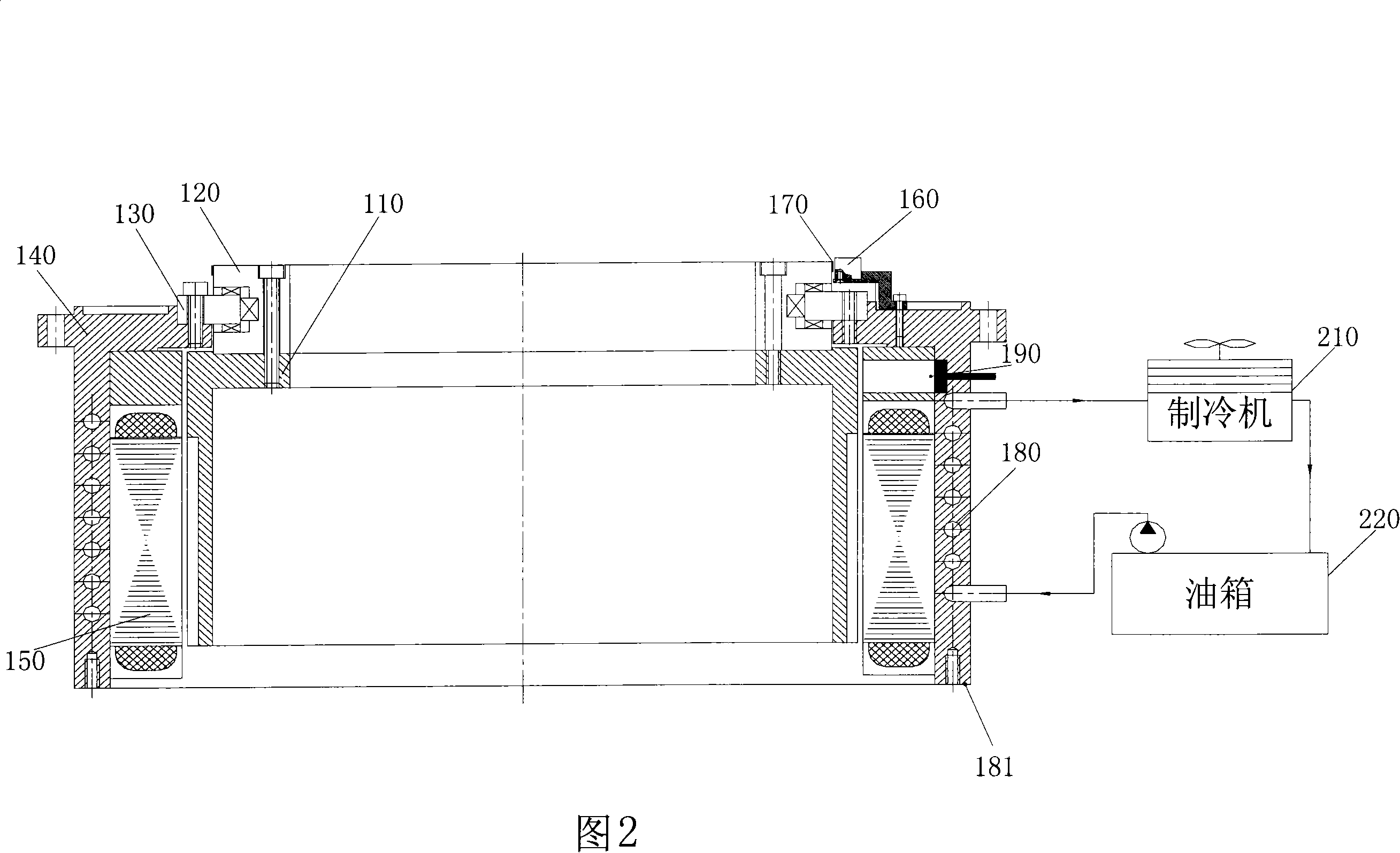

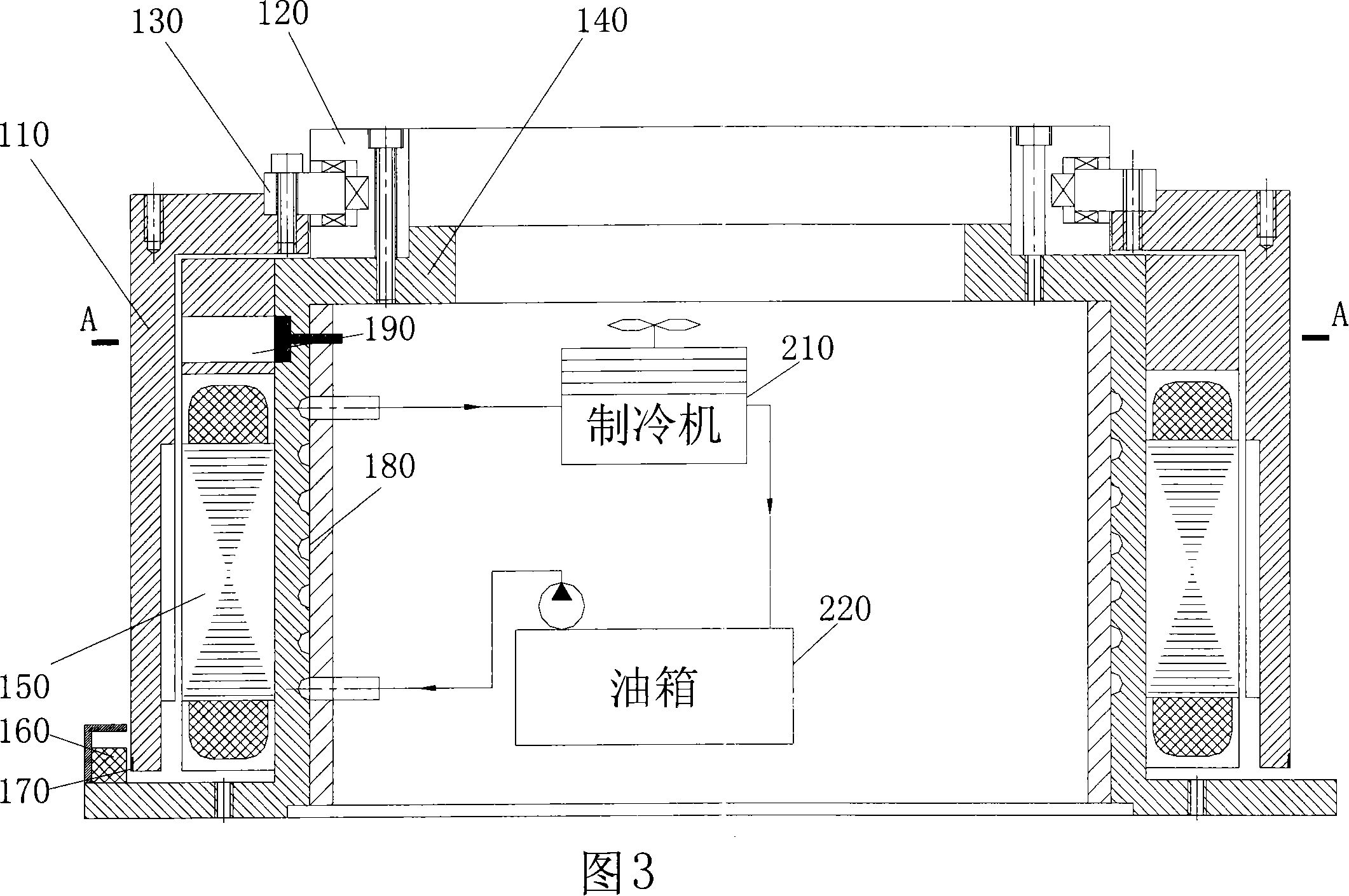

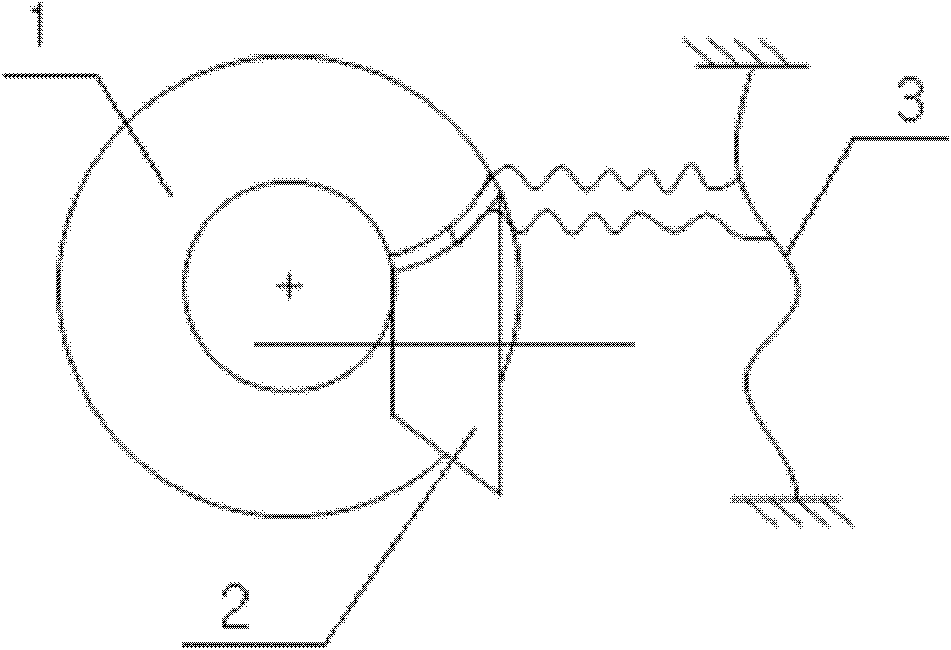

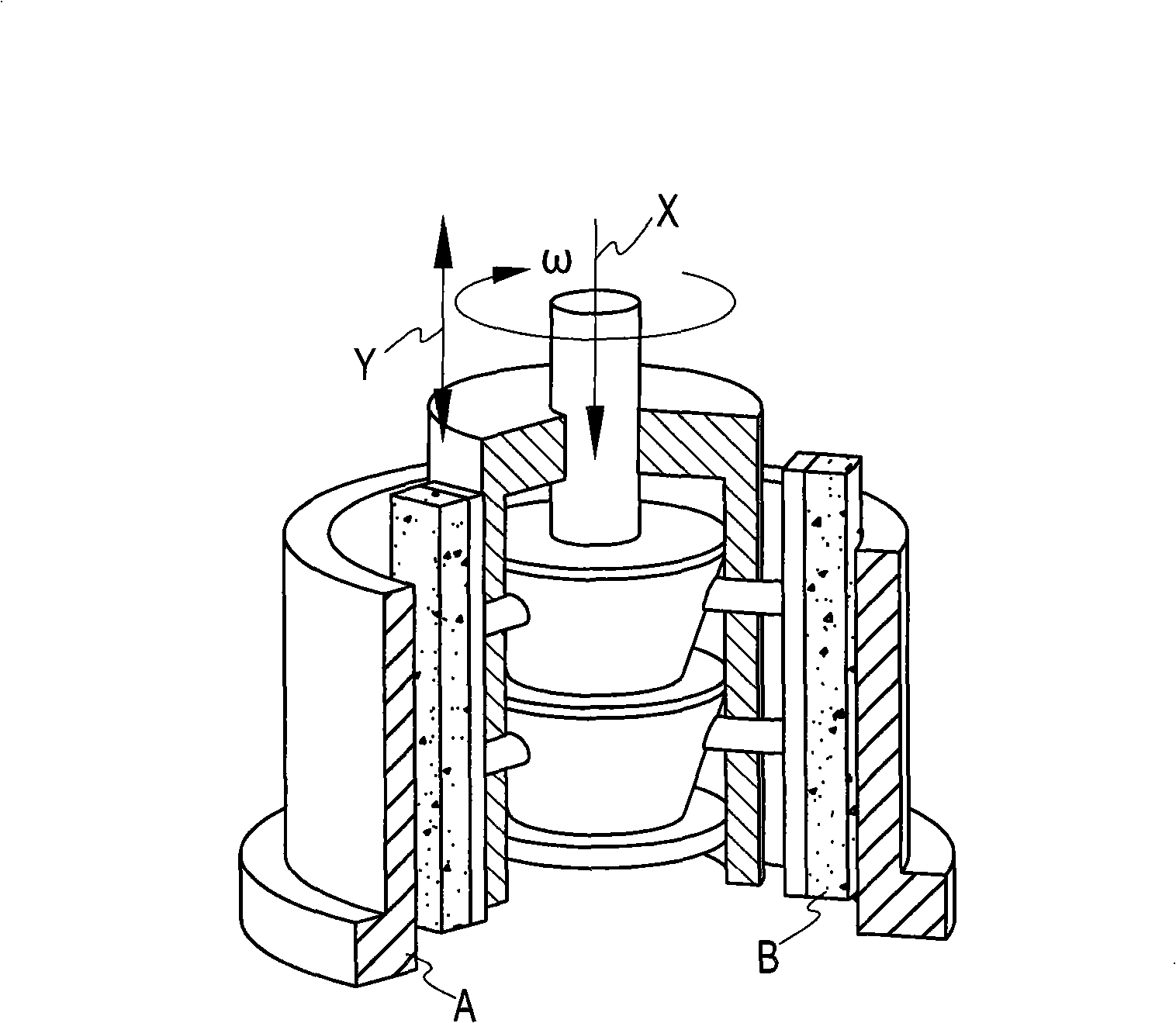

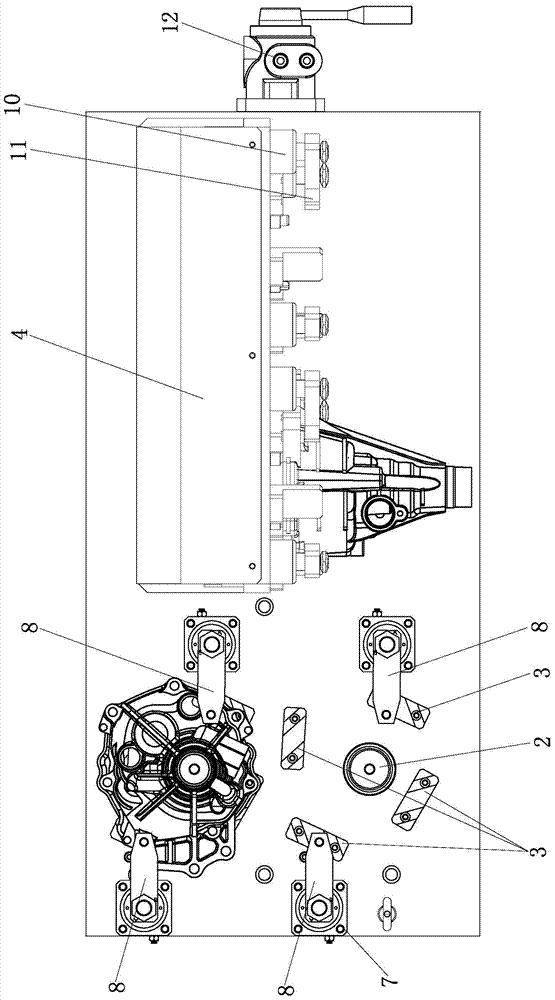

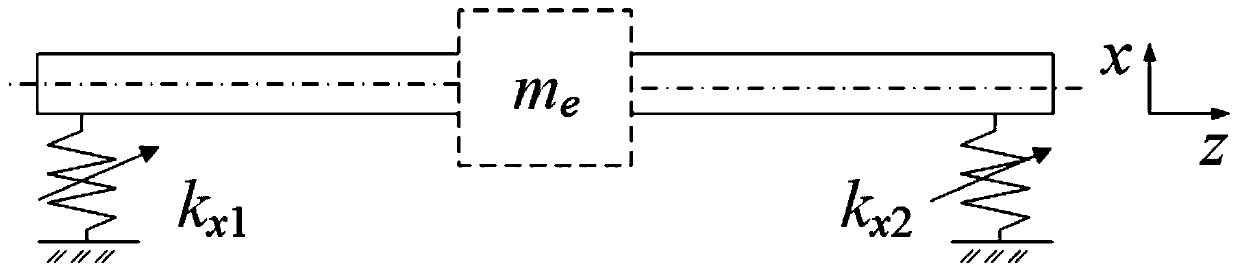

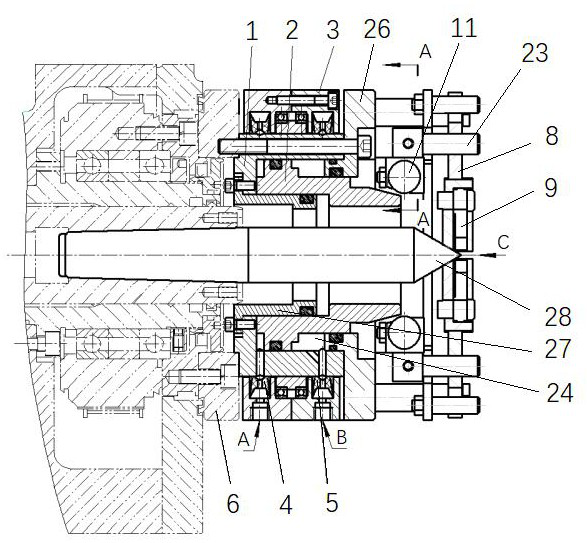

A direct drive turning device

ActiveCN101123377AShorten the design and production cycleReduce manufacturing costStructural associationMechanical energy handlingGratingDrive motor

The invention provides a direct drive slewer, which comprises an enclosure, a direct-drive motor, a bearing and a nontouch precise circular grating. The direct-drive motor comprises a direct-drive motor rotor and a direct-drive motor stator connected with the enclosure. The direct-drive motor rotor is connected with external output parts and is used to provide drive output. The bearing comprises a bearing inner ring and a bearing outer ring, and is arranged on the direct-drive motor and the enclosure. The nontouch precise circular grating comprises a photoreader and a precise circular grating. The photoreader is arranged on the enclosure. The precise circular grating is arranged on the direct-drive motor rotor or the bearing connected with the direct-drive motor rotor, and is used to survey and control speed and position of the direct-drive slewer.

Owner:北京首科凯奇电气技术有限公司

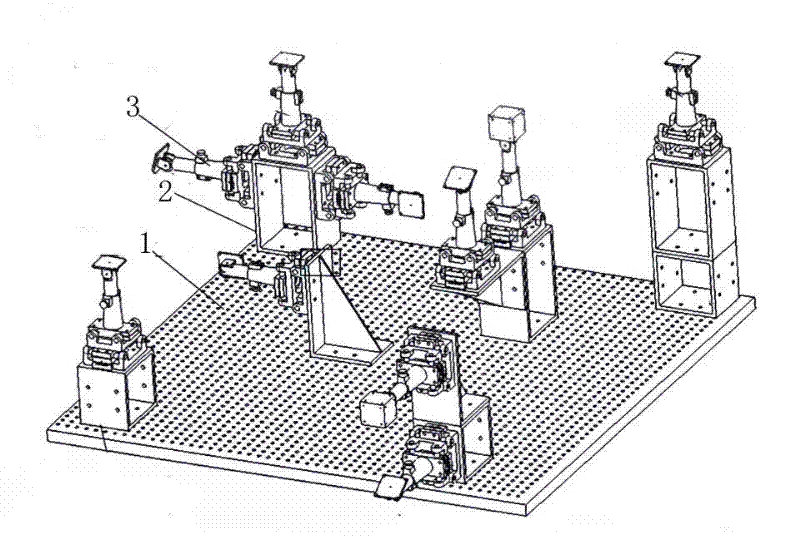

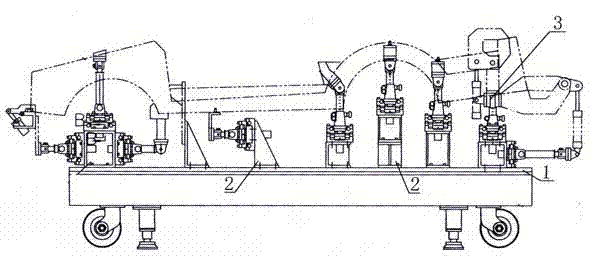

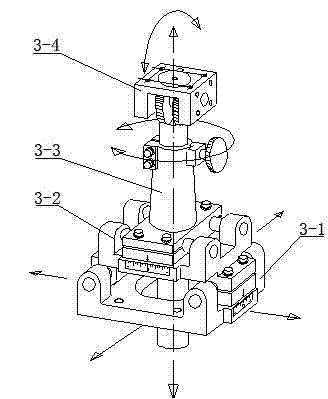

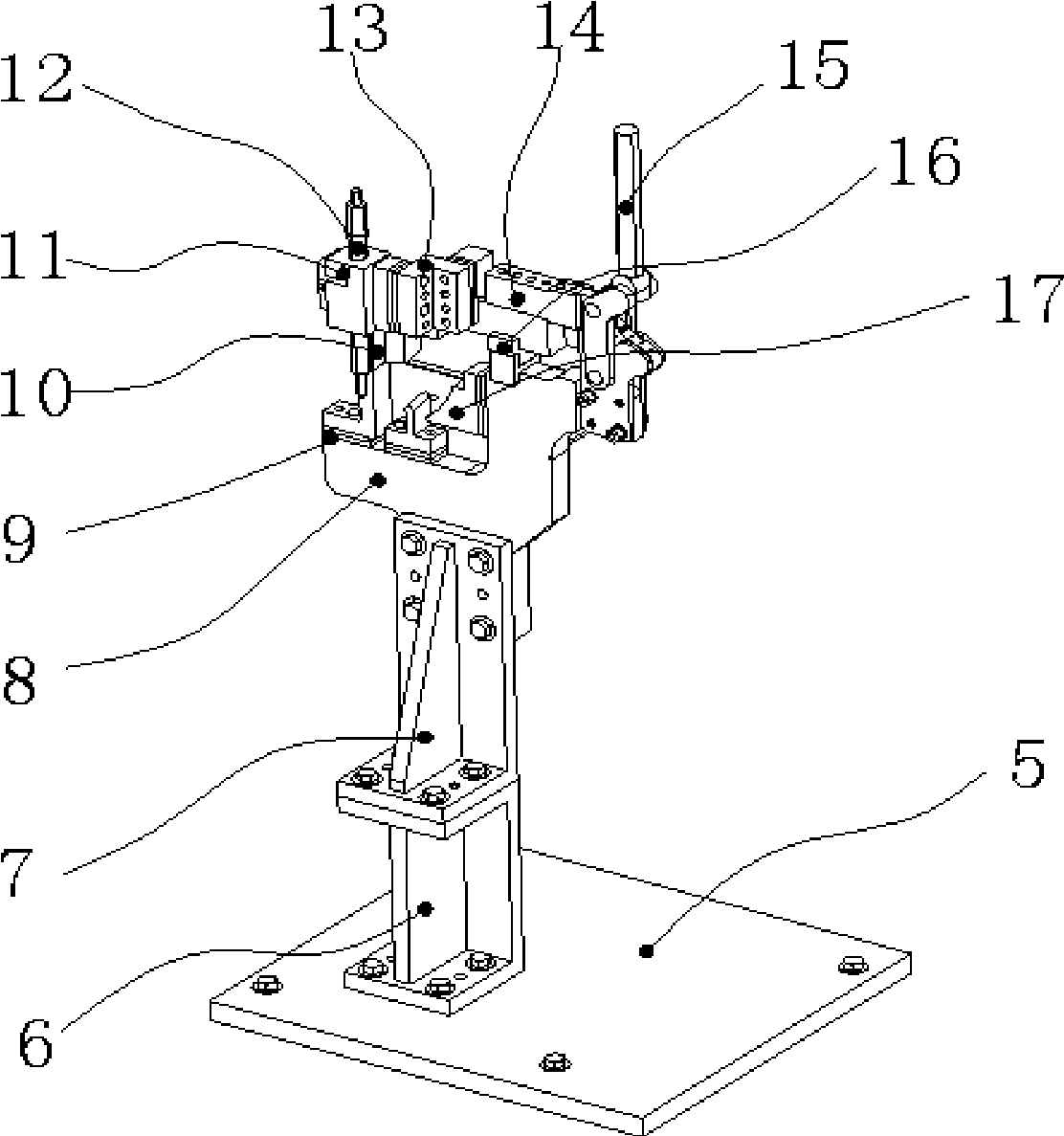

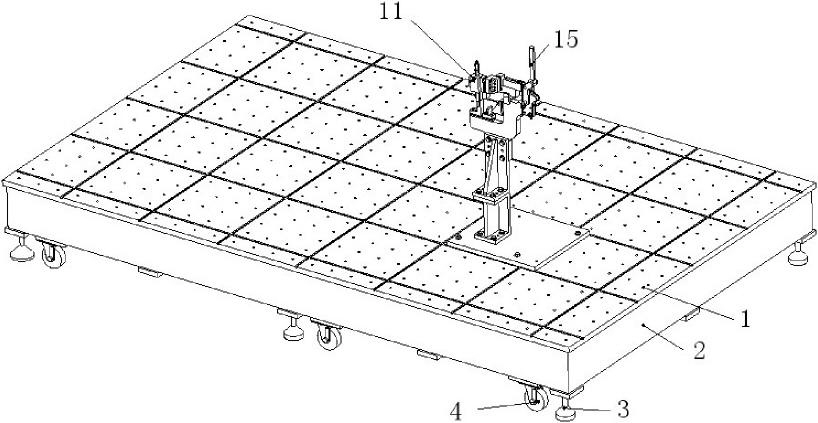

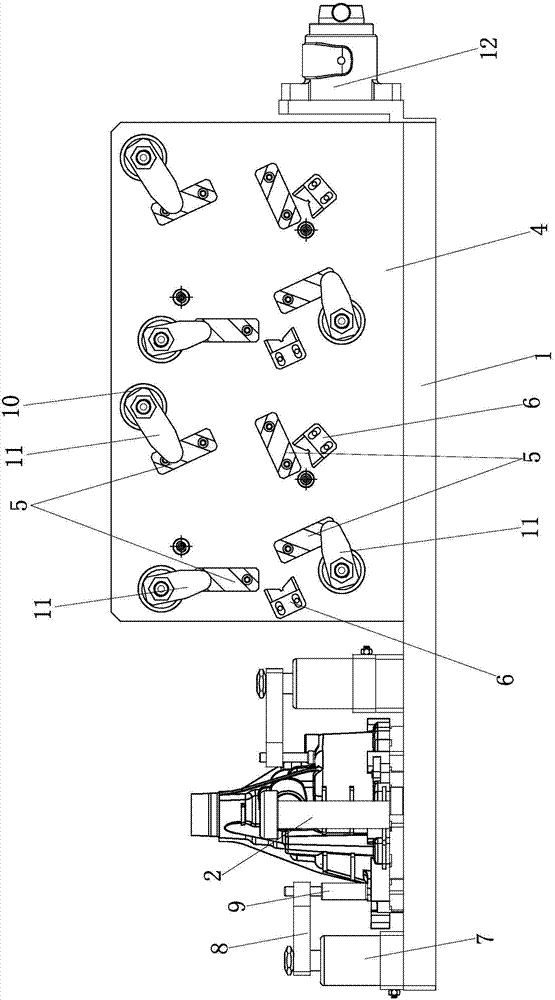

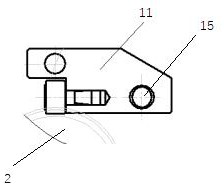

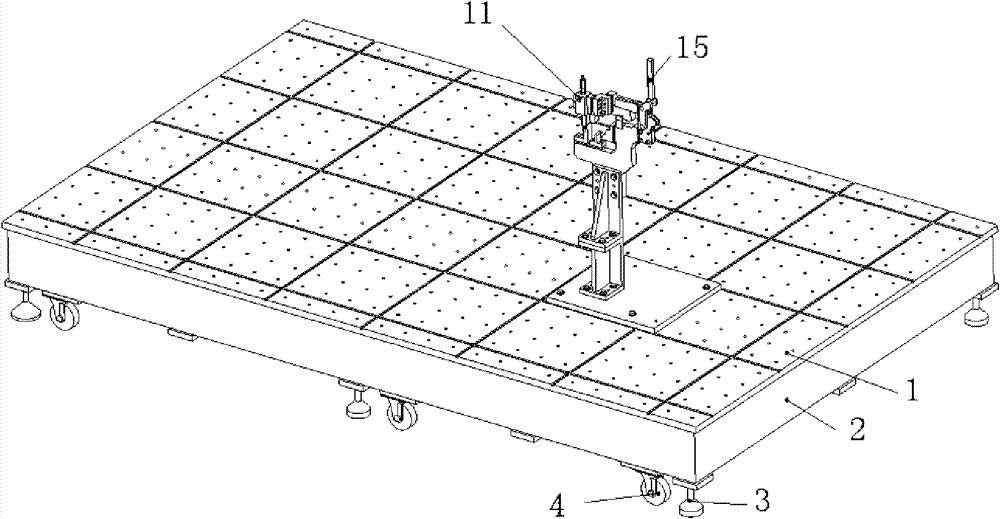

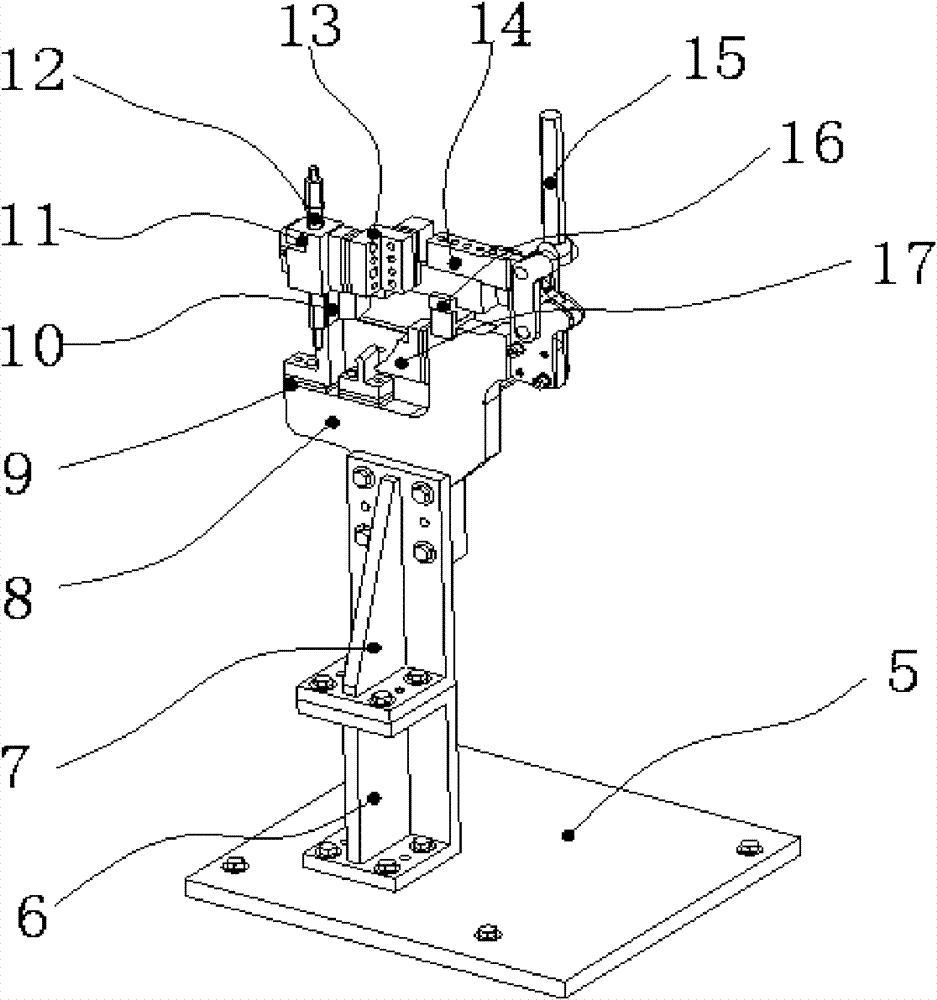

Flexible welding jig device for automotive body

InactiveCN102672382AShorten the design and production cycleLow costWelding/cutting auxillary devicesAuxillary welding devicesEngineeringMechanical engineering

The invention relates to a flexible welding jig device for an automotive body. The welding jig device is characterized in that a guide shaft is fixed on a seat of an X-directional adjustable seat component and a locating pin hole is opened on the seat; a slide seat of a Y-directional adjustable slide seat component is sleeved on the guide shaft of the X-directional adjustable seat component and connected with the seat through a lock bolt; a supporting seat of a Z-directional adjustable supporting seat component is sleeved on the guide shaft of the Y-directional adjustable slide seat component and connected with the slide seat through a lock bolt; a graduation fluted disc is arranged in a swing locating mechanism of a swing mounting seat component and meshed with a graduation locating block arranged in the supporting seat, resetting and locking are achieved through a spring and a screw, and a slide shaft is arranged in a clamping slide bushing in the Z-directional adjustable supporting seat component and connected through a locking screw on the side; a rectangular hole system with an interval of 100mm is arranged on a hole system seat board, and a flexible and adjustable support is connected with the seat board in a locating mode through the hole system. The flexible welding jig device has the advantages of being reliable in structural design, convenient to weld, operate and adjust, high in adaptability, and capable of greatly shortening the design and production period of the welding jig of the automotive body and effectively reducing equipment cost for welding technique of the automotive body.

Owner:CHANGCHUN INST OF TECH

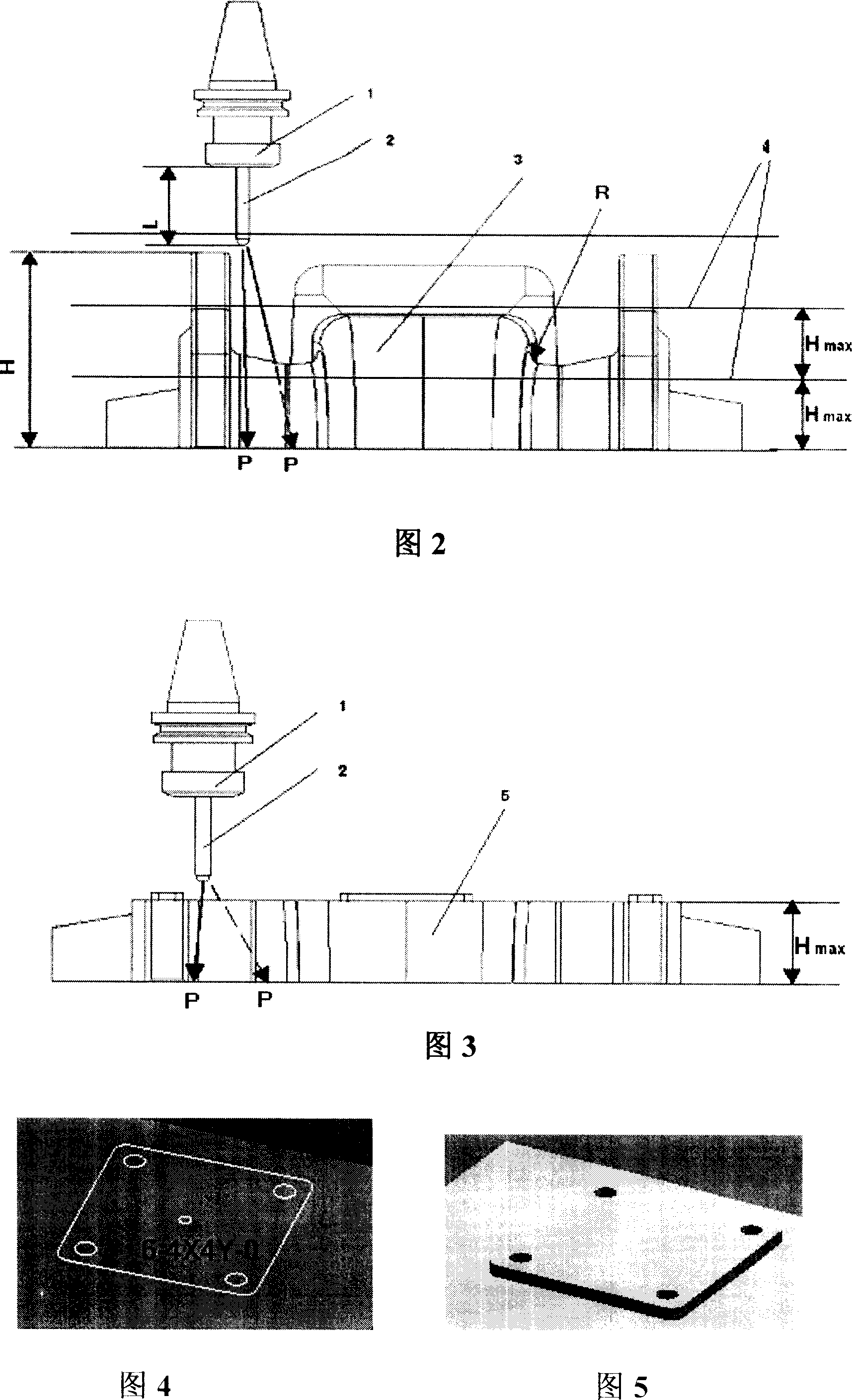

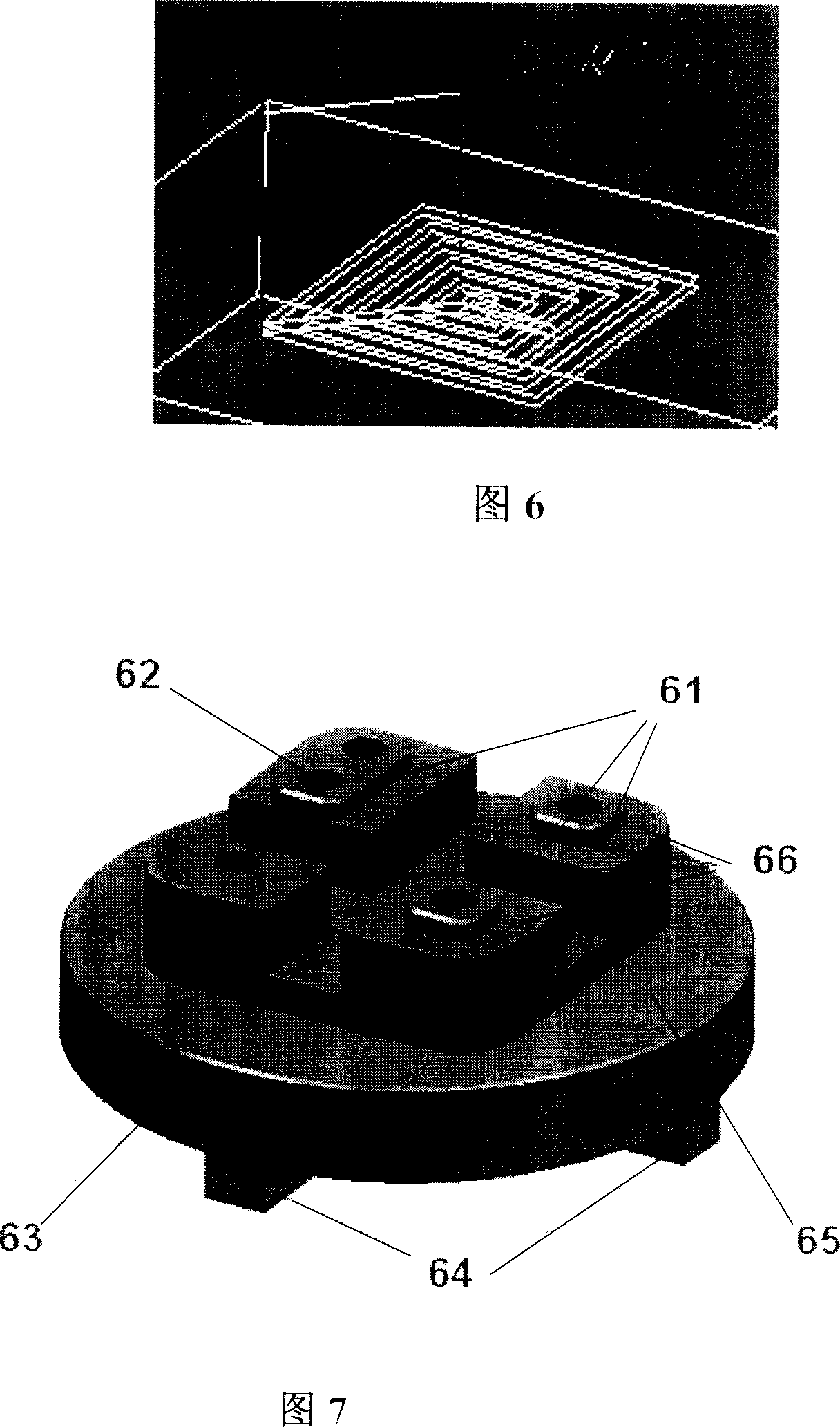

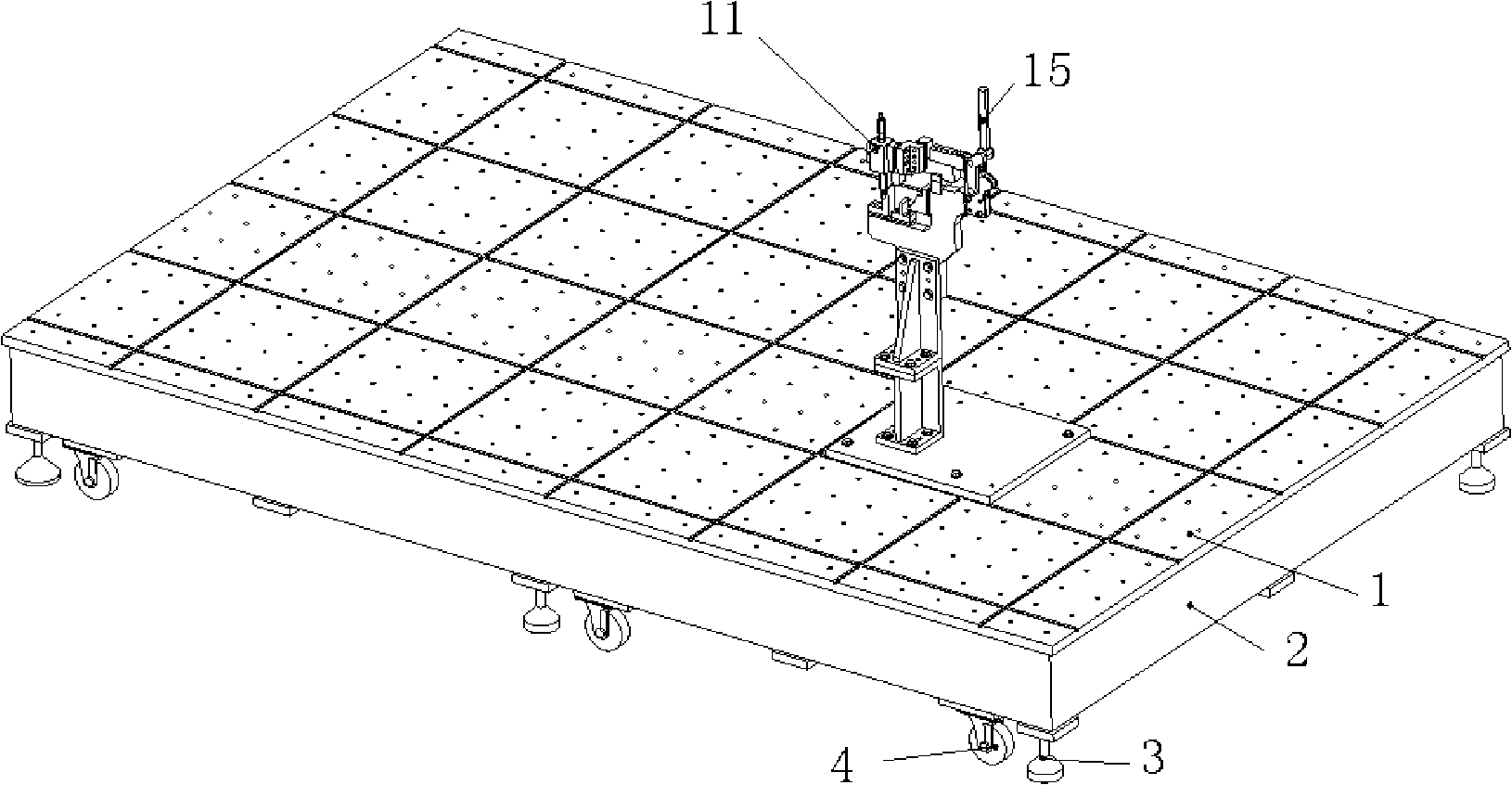

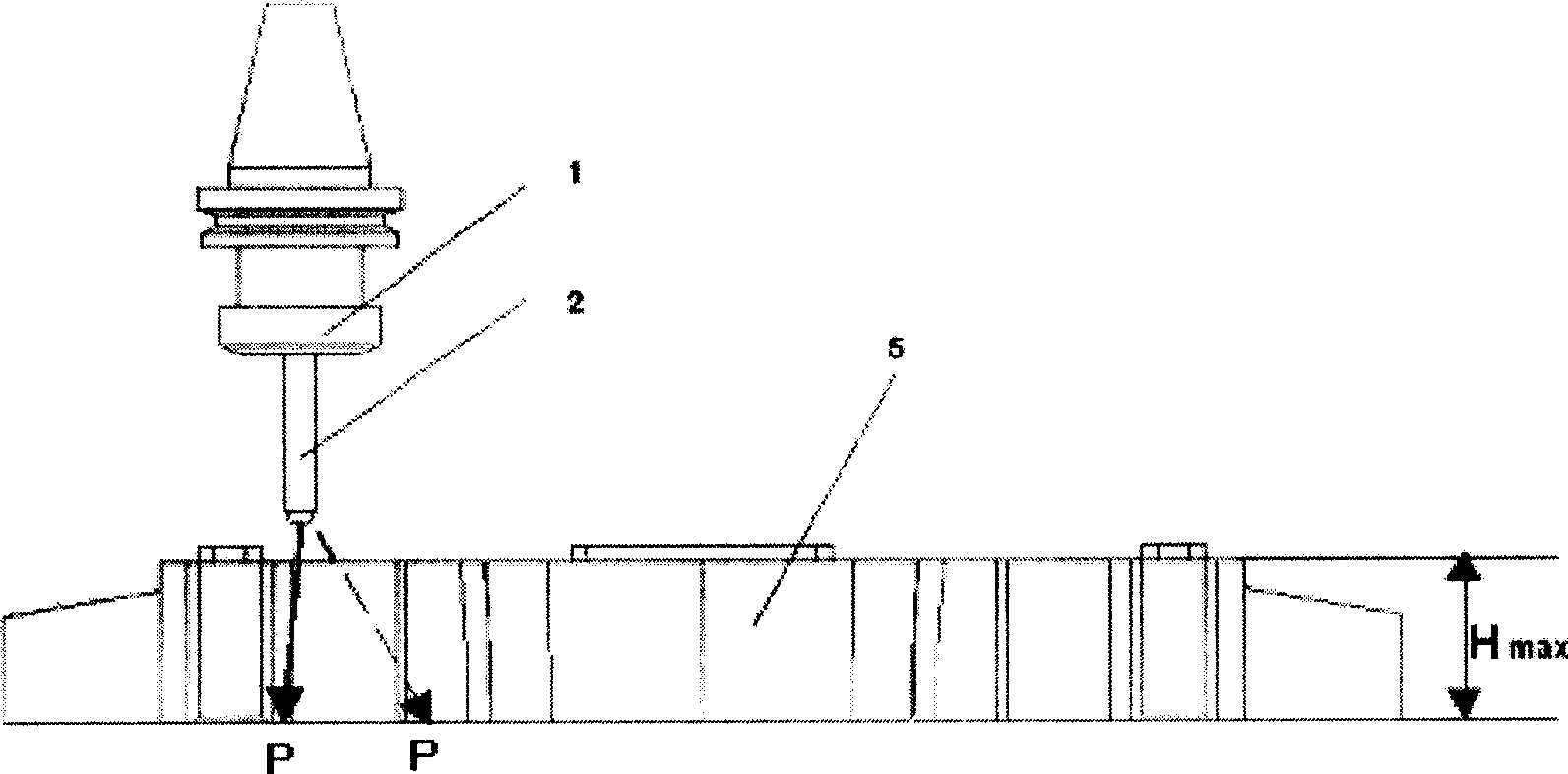

Equal-high segmenting combined numerical controlling milling manufacture method of complex shaped parts

InactiveCN101017376AEliminate knife sticking problemsImprove CNC Milling EfficiencyProgramme controlComputer controlNumerical controlDigital control

This invention relates to mechanic design process field and relates to one complex shape equal height cut combination digital control process method, which comprises complex shape cut design, module establishing, digital cutting, and shape combination. This invention can fulfill usual digital control bed process complexity task and eliminate the cut process knife problem without any change of knife tool and machine bed functions.

Owner:HEBEI UNIVERSITY OF SCIENCE AND TECHNOLOGY

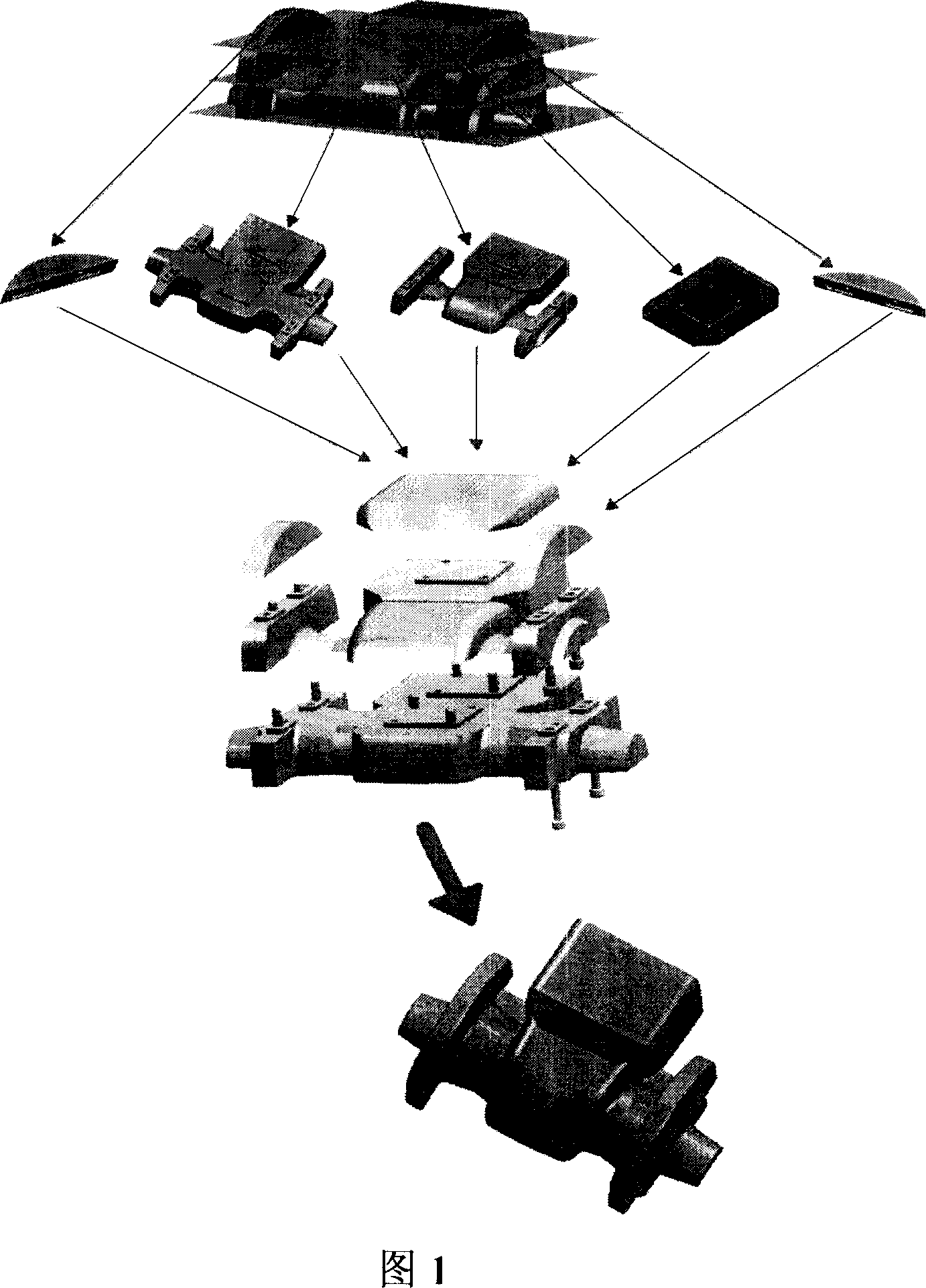

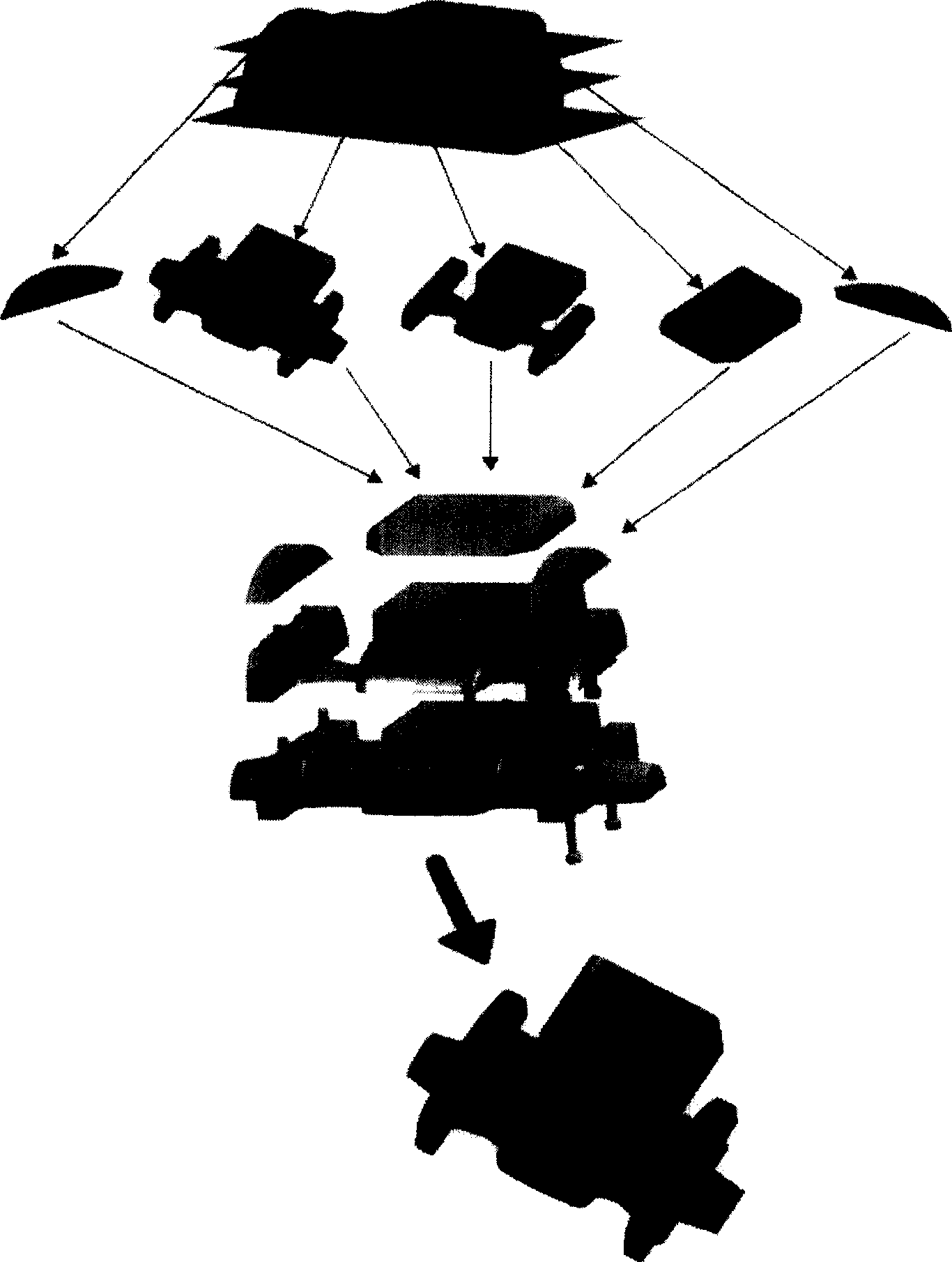

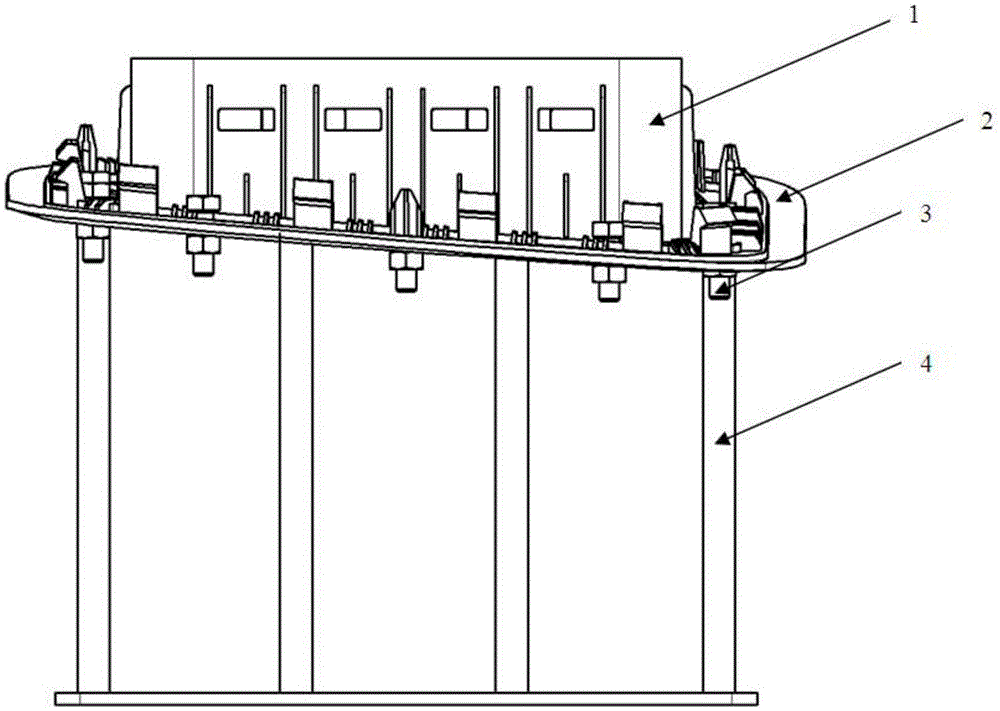

Modular design method and structure of welding fixture for trial-manufacture sample vehicles

ActiveCN101905403ASimple design methodShorten the design and production cycleWelding/cutting auxillary devicesAuxillary welding devicesModular designModularity

The invention relates to the technical field of automobile manufacturing equipment, in particular to a modular design method and a modular design structure of a welding fixture for trial-manufacture sample vehicles, which solve the problems of incapability of recycling, long design and manufacturing period and high manufacturing cost of sample vehicle trial-manufacture fixture parts of automobiles in the prior art. The welding fixture comprises a base and a fixture unit arranged on the base; structural members with the same functions in the welding fixture for the trial-manufacture sample vehicles are formulated into standard or standard series parts in the process of design and development to form a fixture module series, so that the standard or standard series parts are recycled in the development of the welding fixture for new type trial-manufacture sample vehicles and the welding fixture for small-lot vehicles, and non-standard parts in the fixture are subjected to structural design; and the standard parts and the non-standard parts in the welding fixture for the trial-manufacture sample vehicles are matched to form novel and complete welding fixture equipment for the trial-manufacture sample vehicles. Through the modular design method and the modular design structure, the aims of shortening the design and manufacturing period, recycling general and standard parts and reducing manufacturing cost are fulfilled.

Owner:ZHEJIANG GEELY AUTOMOBILE RES INST CO LTD +1

Method for obtaining properties of metal part based on 3D printing technique

ActiveCN104149340ARapid carrying capacityShorten the design and production cycleElement analysisProduct Part

The invention belongs to the field of bearing tests for large structural parts made of metal or non-metal materials, and particularly relates to a method for obtaining the properties of a corresponding metal part with an original size according to the properties of a scaled-down non-metal part which is machined and manufactured by using a 3D printing technique. According to the method, basic parameters of the physical and mechanical properties of the scaled-down non-metal part based on 3D printing are tested, and the load bearing state of the scaled-down non-metal part is calculated by adopting a finite element analysis method, so as to deduce the load bearing state of the metal part with the original size. The method has the characteristic and the beneficial effects that the bearing capability of the corresponding metal part can be quickly deduced at low cost within short time according to the scaled-down non-metal part which is machined and manufactured by using the 3D printing technique, thereby effectively shortening the design and manufacturing cycle of product parts and increasing the design success rate.

Owner:山东恒立重装新技术有限公司

Metal shell cast bus and method for manufacturing same

ActiveCN103474144APlay a protective effectImprove shielding effectLine/current collector detailsInsulated cablesMetallic enclosureElectrical conductor

The invention discloses a metal shell cast bus and a method for manufacturing the metal shell cast bus. The metal shell cast bus comprises a plurality of standard unit sections and a connecting assembly. Each standard unit section comprises an inner conductor, a metal shell and a middle insulation layer. The connecting assembly comprises an inner connecting assembly body, an outer connecting assembly body and a middle connecting insulation layer. In addition, the invention further discloses the method for manufacturing the metal shell cast bus. According to the technical scheme, assembling of the metal shell cast bus is made to be more convenient, the design and production period is greatly shortened, and the cost is saved. Moreover, the outer connecting assembly body in the connecting assembly serves as a die and can also bear mechanical stress, demolding is not needed during insulation material casting, the metal shell cast bus can be grounded in use, and operation is safer and more reliable.

Owner:BEIJING POWER EQUIP GRP +1

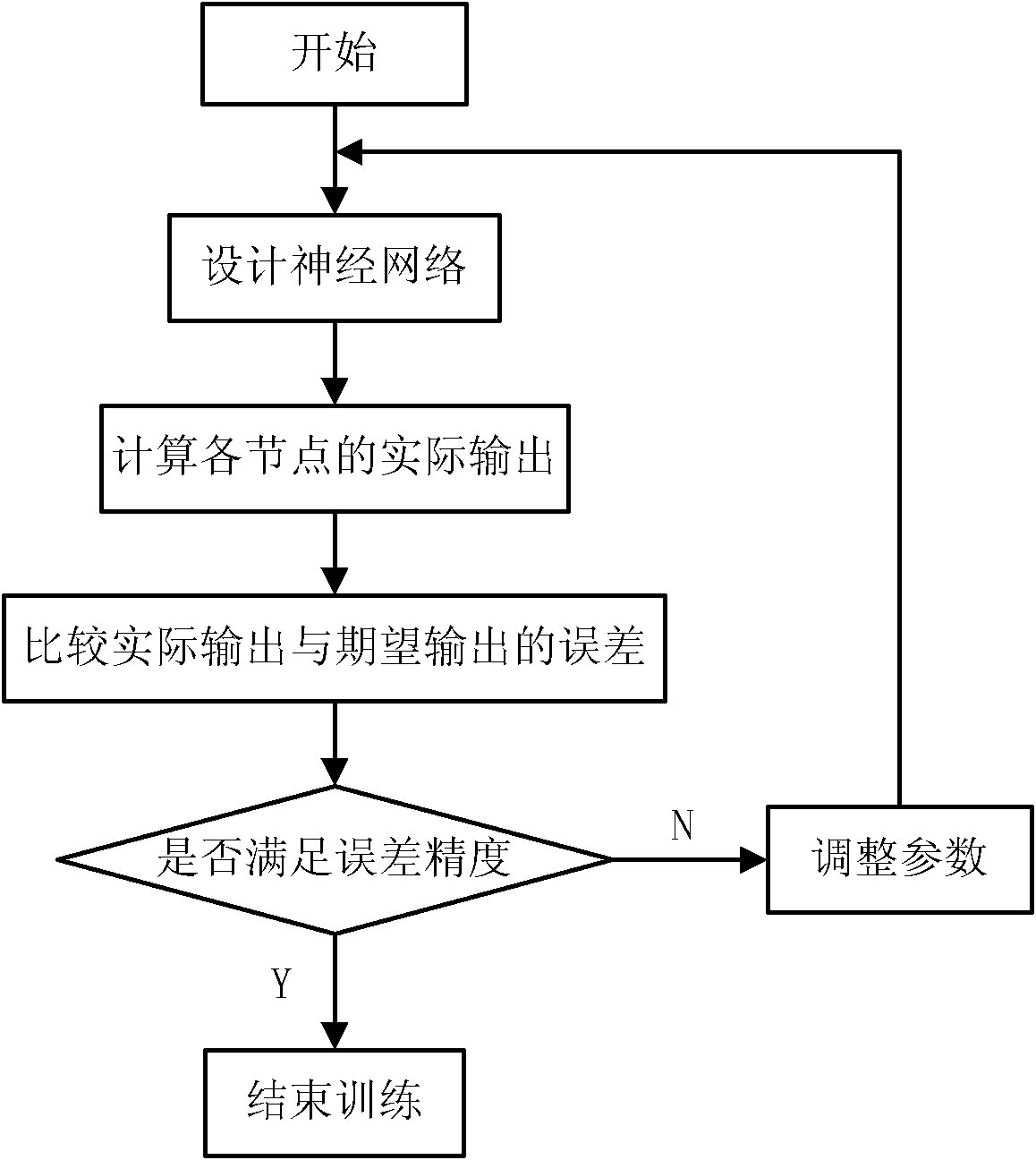

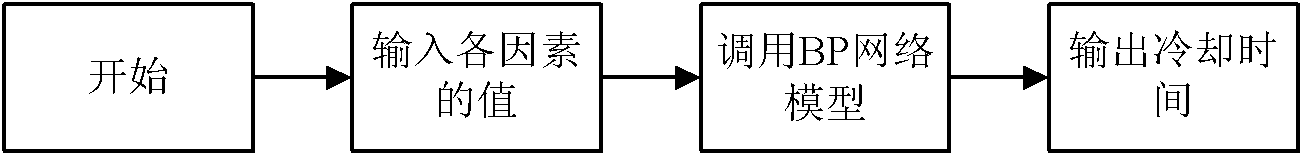

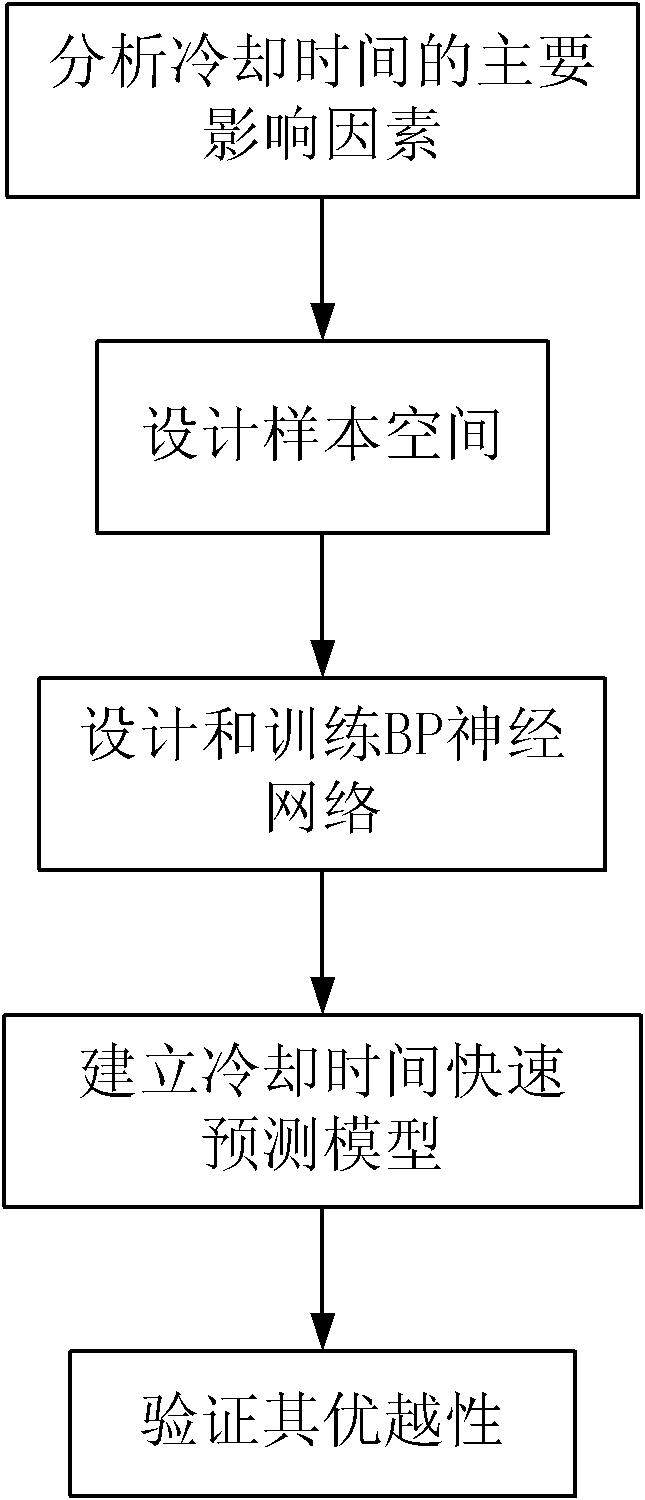

Method for quickly forecasting cooling time in injection molding of plastics

InactiveCN101853318AShorten the design and production cycleQuick forecastBiological neural network modelsSpecial data processing applicationsPredictive methodsBusiness forecasting

The invention discloses a method for quickly forecasting cooling time in injection molding of plastics, which is used for forecasting the required cooling time through known parameters of plastics and molds and the like. The concrete implementation scheme of the method comprises the following steps: (1) analyzing primary influence factors of the cooling time; (2) designing a training sample of a neural network; (3) designing and training a BP neural network; (4) establishing a quickly forecasting model of the cooling time; and (5) verifying the superiority of the model through embodiments. The invention can be used for quickly and accurately forecasting the cooling time in injection molding of plastics, and has important functions of shortening the designing and manufacturing cycle of molds and improving the manufacturing accuracy and performance of molds.

Owner:HUAZHONG UNIV OF SCI & TECH

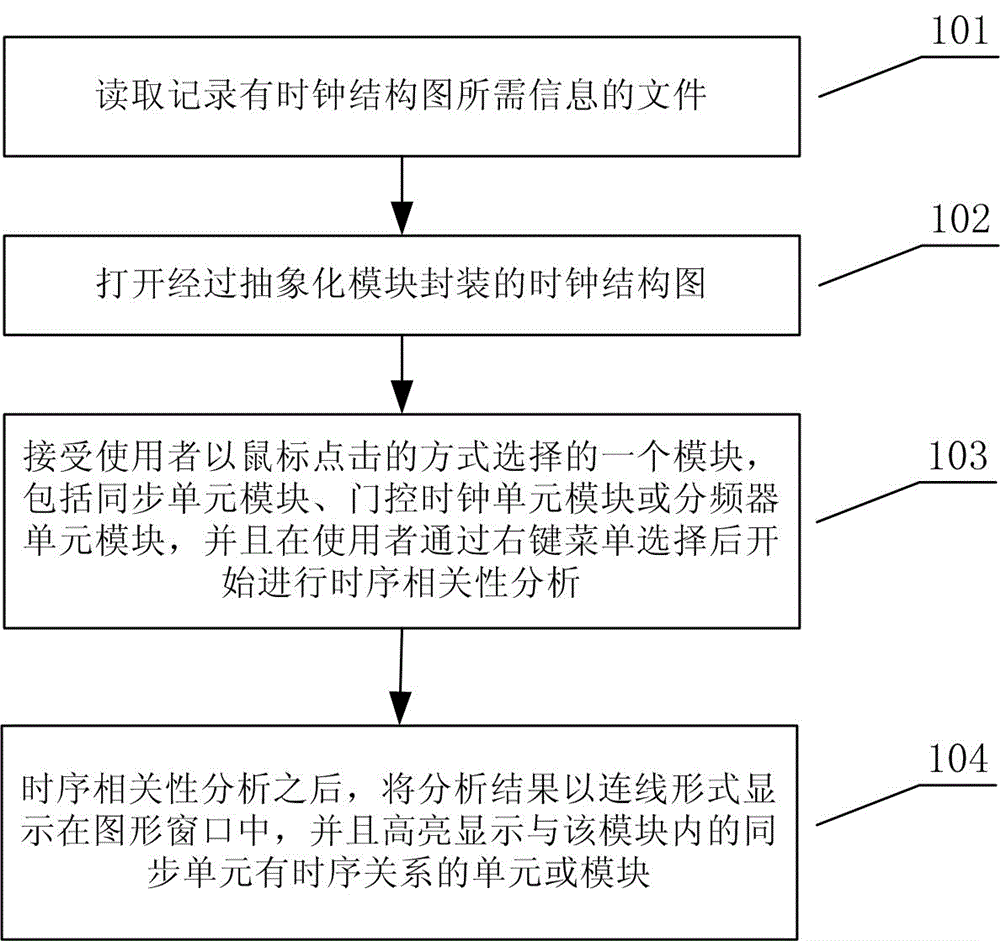

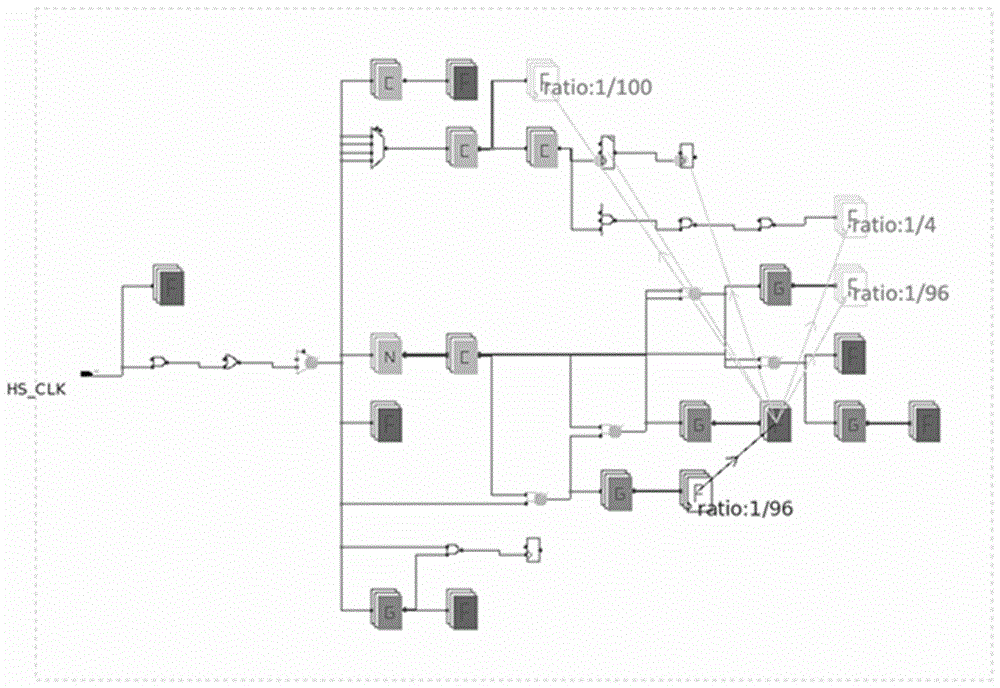

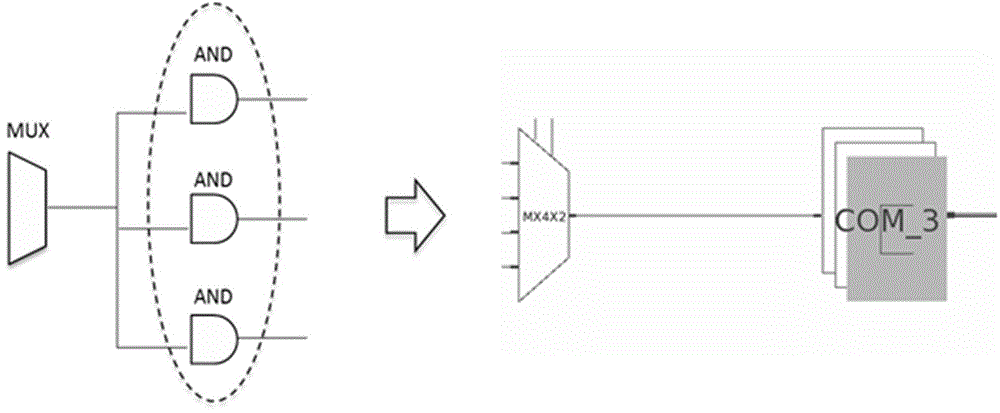

Method for graphically displaying clock structure and timing sequence correlation

ActiveCN106650128AShorten the design and production cycleQuality improvementCAD circuit designSpecial data processing applicationsGraphicsClock tree synthesis

The invention provides a method for displaying a clock structure and timing sequence correlation. The method comprises the following steps that an required information file recording a clock structure graph is read, and the clock structure graph encapsulated by an abstraction module is opened. Timing sequence correlation analysis is conducted on the module, and the analysis result is displayed in a graphics window. By means of the method for displaying the clock structure and the timing sequence correlation, the structure of a complicated clock system can be clearly displayed, the timing sequence correlation between synchronization units is effectively analyzed, a clock tree synthesis tool is assisted so as to improve the synthesis quality, accordingly the design and manufacturing period of a chip is shortened, and the design efficiency is improved.

Owner:北京华大九天科技股份有限公司

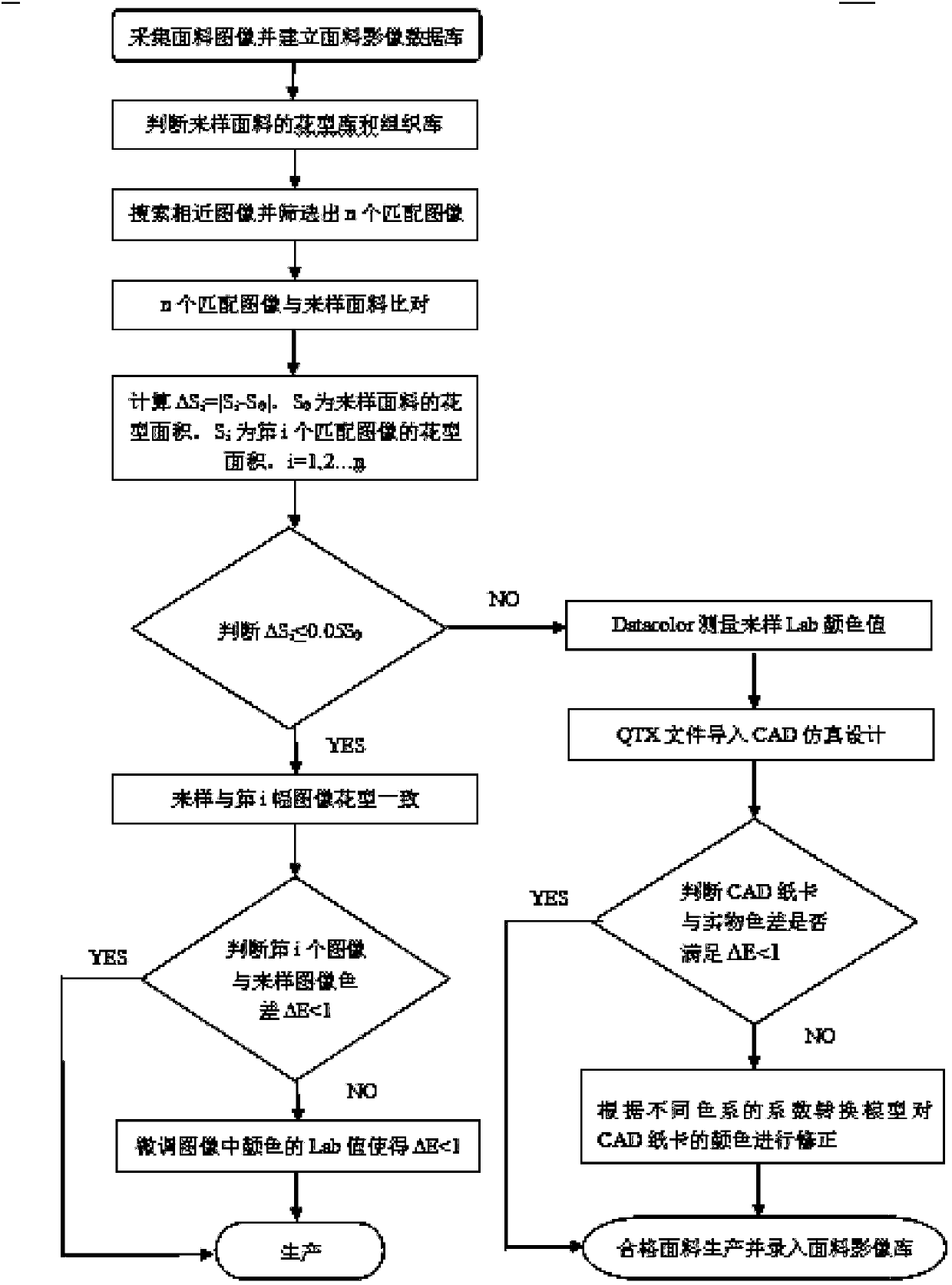

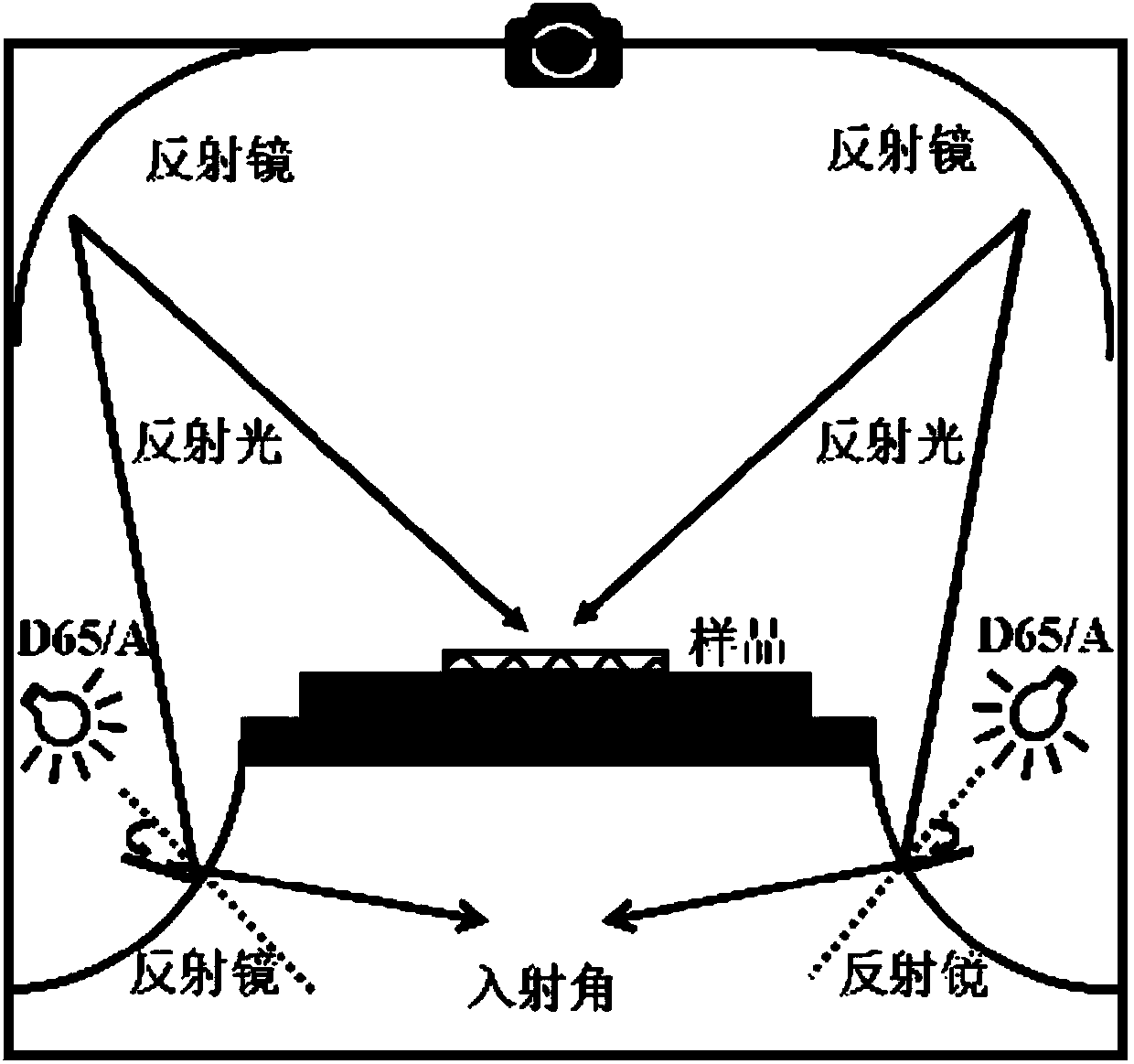

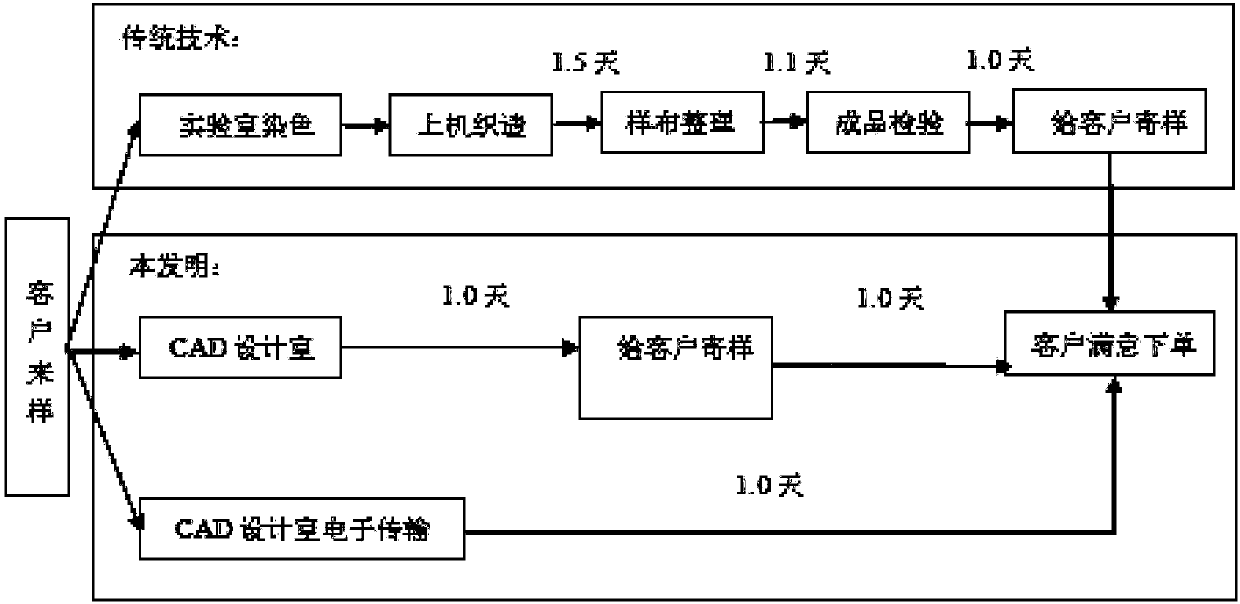

Yarn-dyed fabric design production method with quick response effect

ActiveCN107679106AHigh precisionReduce retrieval timeDesign optimisation/simulationSpecial data processing applicationsYarnResponse effect

The invention relates to a yarn-dyed fabric design production method with a quick response effect. The method comprises the steps of firstly collecting fabric images and performing classification according to patterns and organization structures to establish a fabric image database; secondly screening n images matched with an incoming sample fabric from the fabric image database; and finally comparing the patterns of the n matched images with the patterns of the incoming sample fabric, if the images with consistent patterns and color difference meeting the requirement exist, directly performing production, if the images with the consistent patterns and the color difference not meeting the requirement, adjusting the colors of the images until the color difference meets the requirement and performing production, and if the images with the consistent patterns do not exist, performing fabric simulation by adopting CAD to design the images meeting the requirement and performing production.According to the yarn-dyed fabric design production method with the quick response effect, the time and the labor cost for finding the required fabric are saved; the design and production cycle of theyarn-dyed fabric is greatly shortened; and quick, efficient and accurate design and production of the incoming sample fabric are realized.

Owner:DONGHUA UNIV

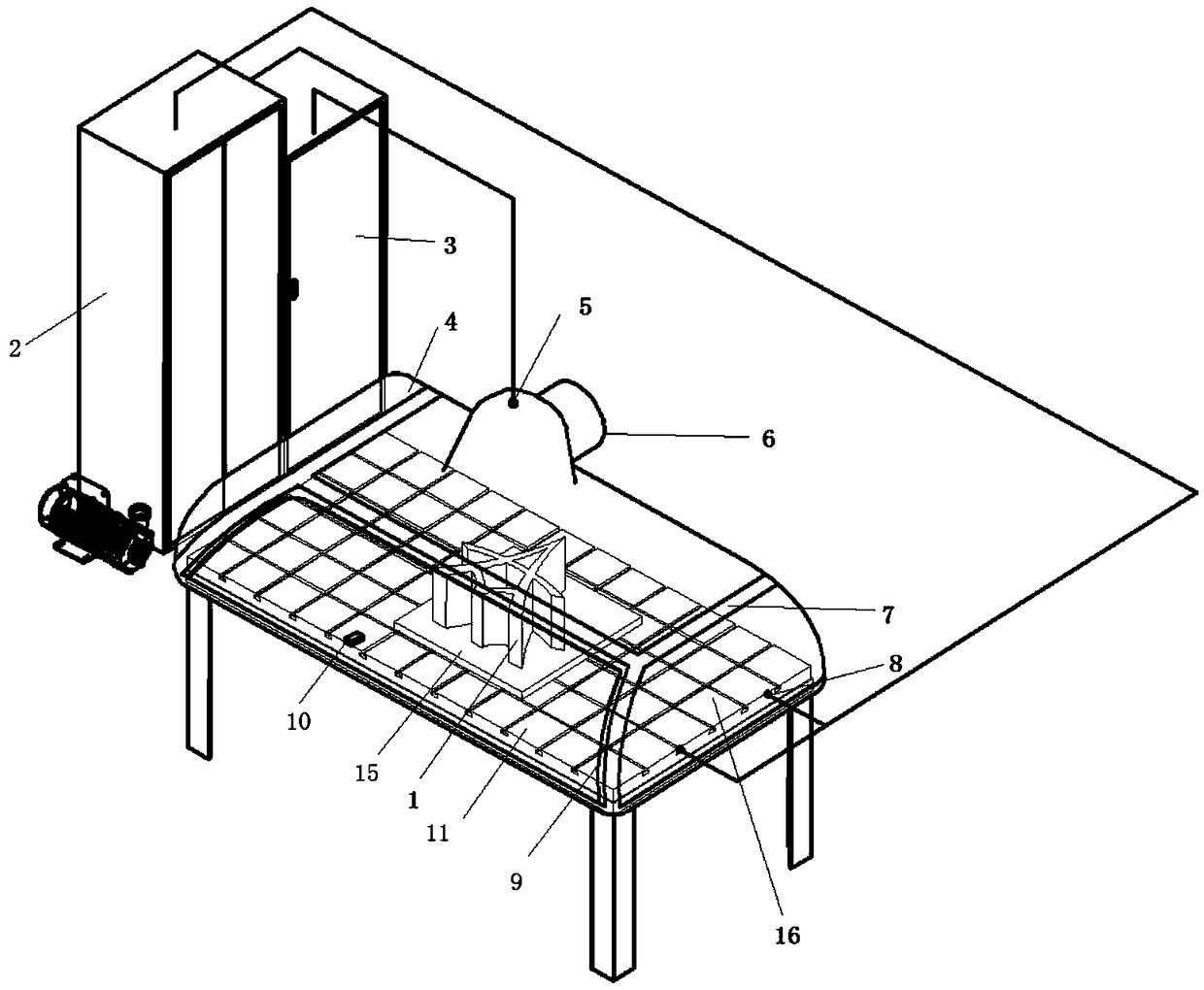

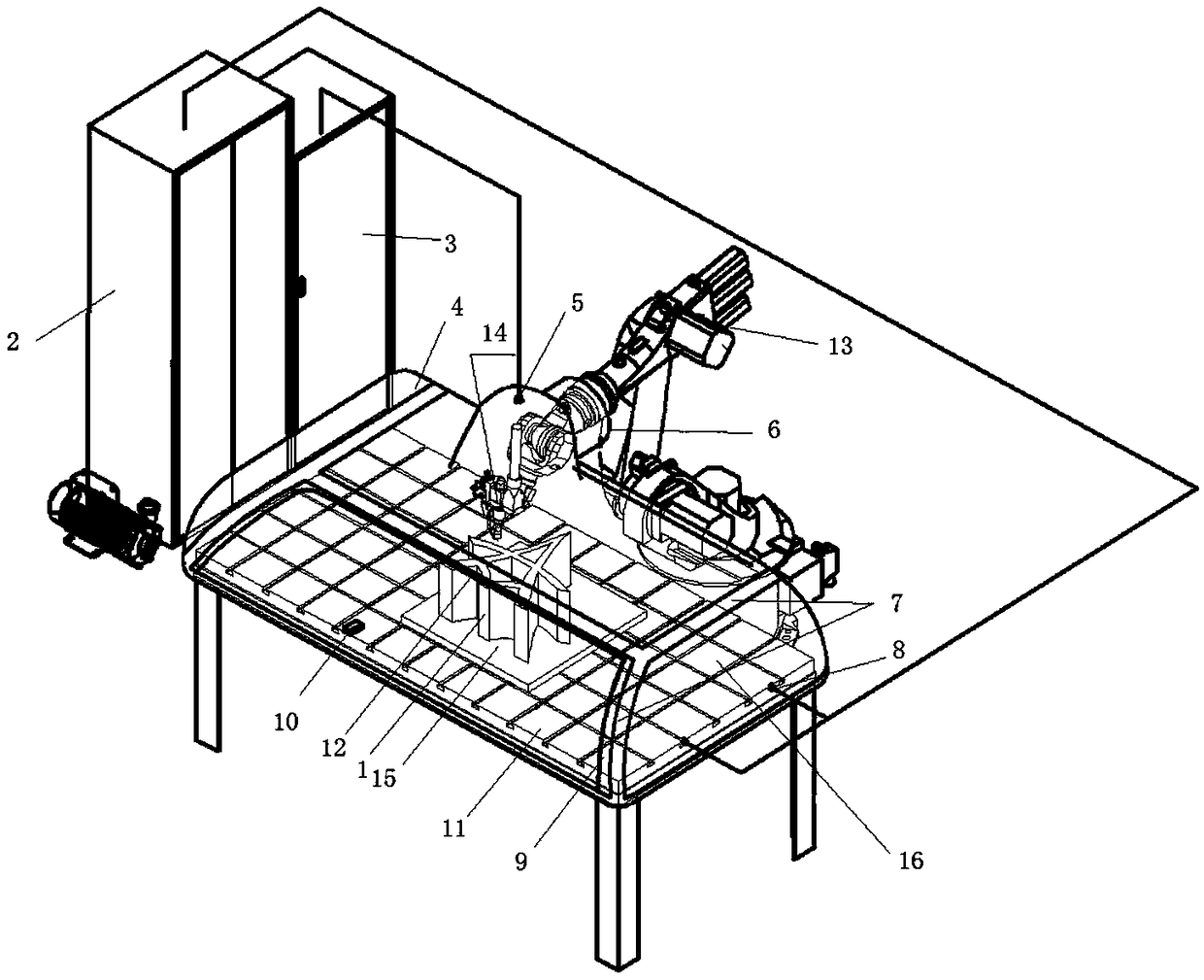

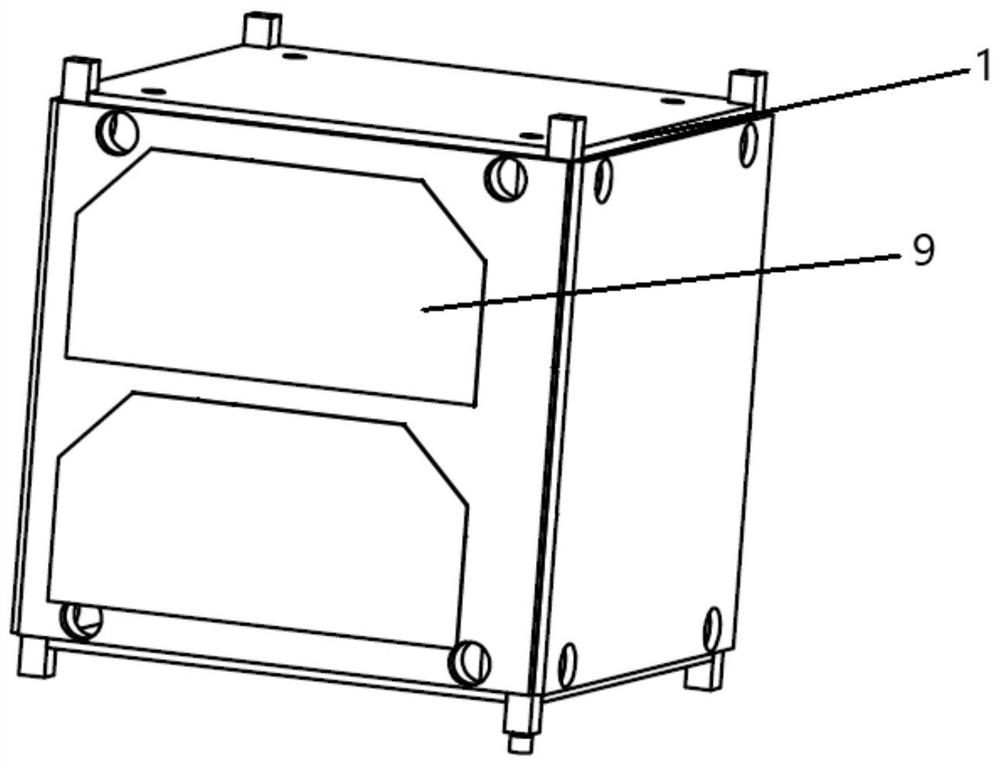

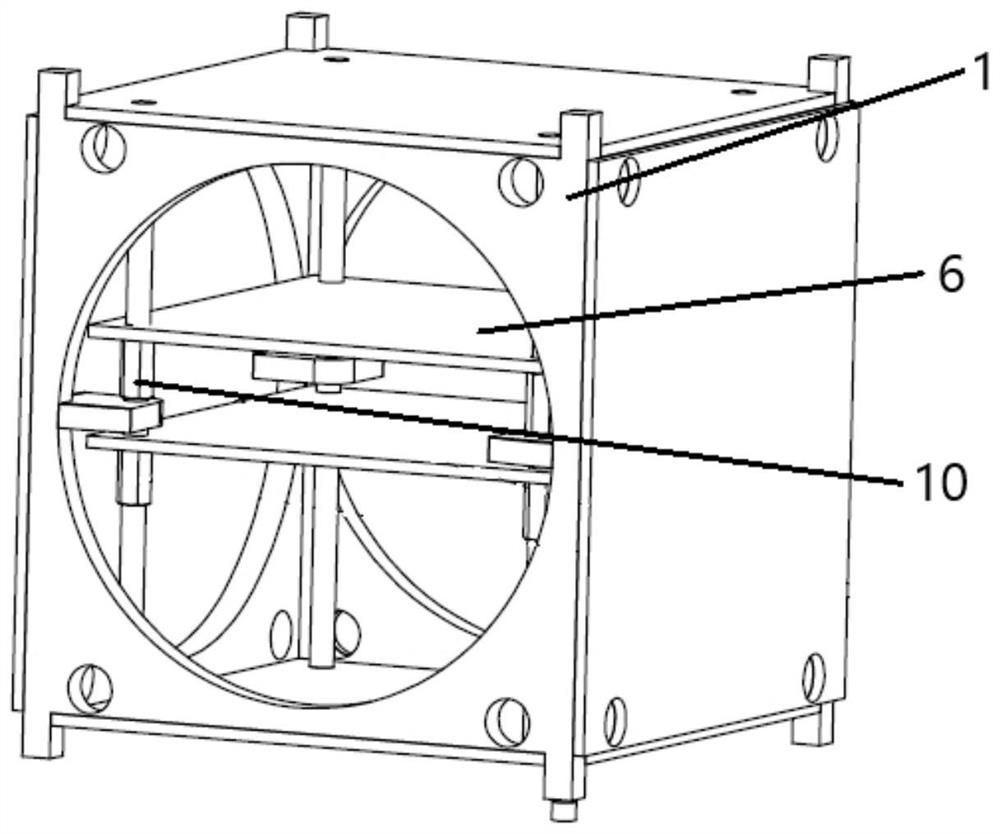

Additive manufacturing protective device and using method thereof

PendingCN108724708ASave spaceReduce replacement timeAdditive manufacturing apparatusManufacturing environment conditioningSpace environmentFlue gas

The invention discloses an additive manufacturing protective device and a using method thereof. The device comprises a protective cover, an inner environment regulating unit which is communicated with the inner space of the protective cover, and a dust flue gas treatment unit, wherein the inner space environment regulating unit is used for replacing gas inside the protective cover, so that the environment inside the protective cover is protective atmosphere in a printing process; the dust flue gas treatment unit is used for discharging waste gas generated in the printing process; the protective cover is matched with a working platform for sealing a formed part between the protective cover and the working platform, so that the space of the protective device is reduced, and all spaces of the protective device are effective spaces. The device covers an effective working area, reduces replacement time and amount for working environment air in comparison with a mode that a conventional whole working device is placed in the effective working area, and effectively saves time and reduces operation cost; and the protective device is arranged on the working platform for use, so that movement is convenient.

Owner:NAT INST CORP OF ADDITIVE MFG XIAN

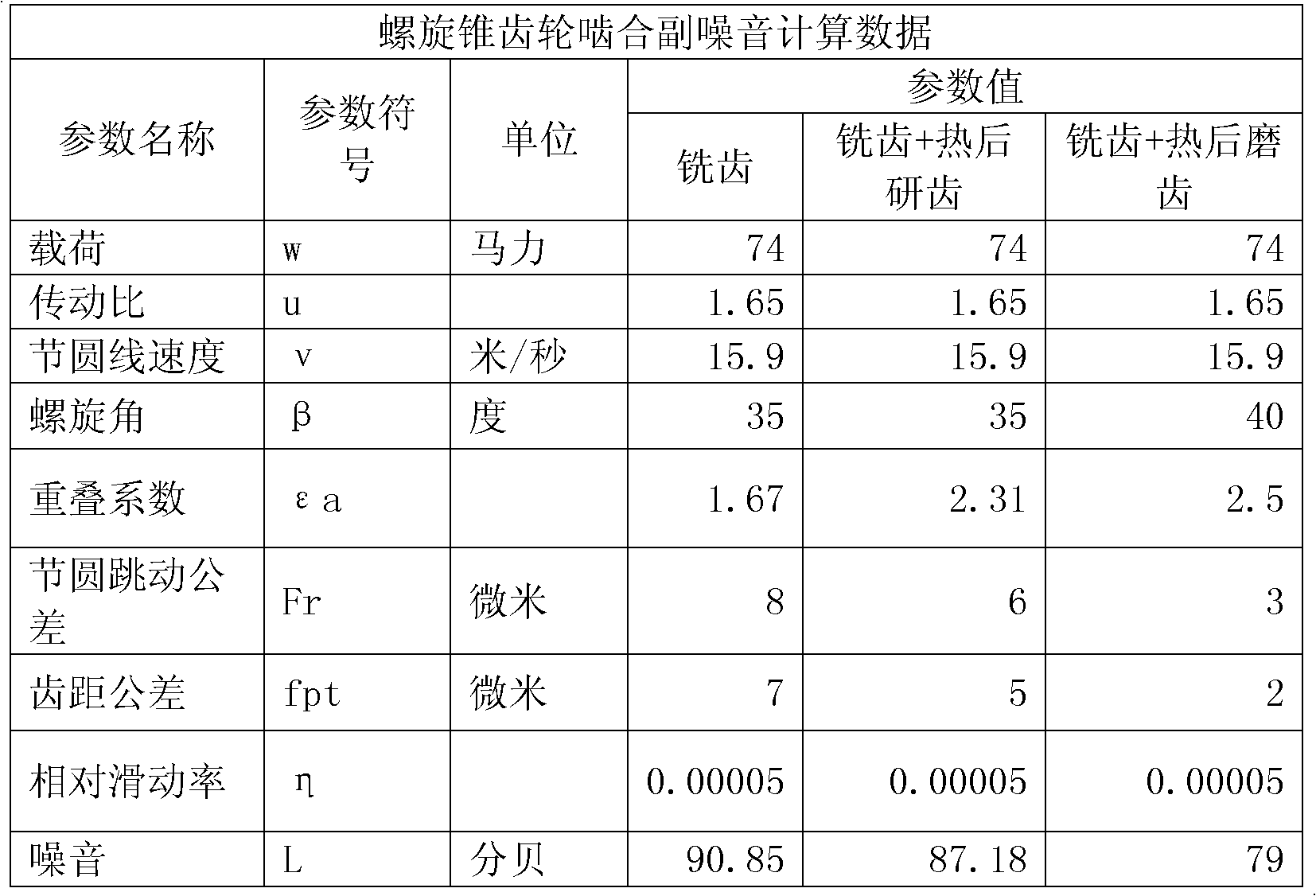

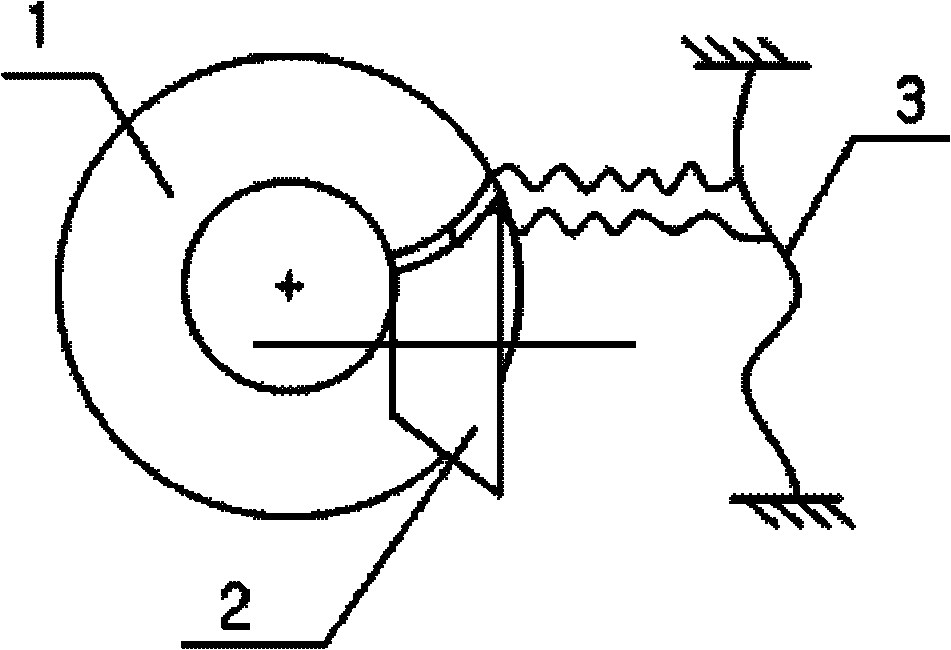

Method for calculating engagement noises of spiral bevel gear pair

ActiveCN102192303AReduce mistakesImprove accuracyPortable liftingGearing elementsDrive wheelEngineering

The invention relates to a method for calculating engagement noises of a spiral bevel gear pair. The calculating method comprises the followings steps: taking a tooth of the spiral bevel gear pair as a spring, and taking a gear body as a mass vibration system; setting a mounting system in a rigid non-vibration state except the environment noises; selecting a reference point according to a given load and noise value, confirming the noise value, the load, the transmission ratio of the spiral bevel gear pair and the pitch circle speed of a driving wheel according to the design requirement of a finished vehicle, and calculating the relative sliding ratio and the superposition degree; calculating the vibration speed coefficient of a spiral bevel gear and the amplitude of vibration of the spiral bevel gear pair, converting a helical angle, calculating the engagement noises of the spiral bevel gear pair, and analyzing the result. The calculating method provided by the invention is simple, the calculation time is short, the error is small, and the accuracy is high; through the calculation and analysis, the structural parameters of the spiral bevel gear pair is optimized, and references are provided for selecting manufacturing process and accuracy reasonably and reducing the engagement noises; and the design efficiency is improved, the design and manufacturing cycle is shortened, and the manufacturing cost is lowered effectively.

Owner:ZHUZHOU GEAR CO LTD

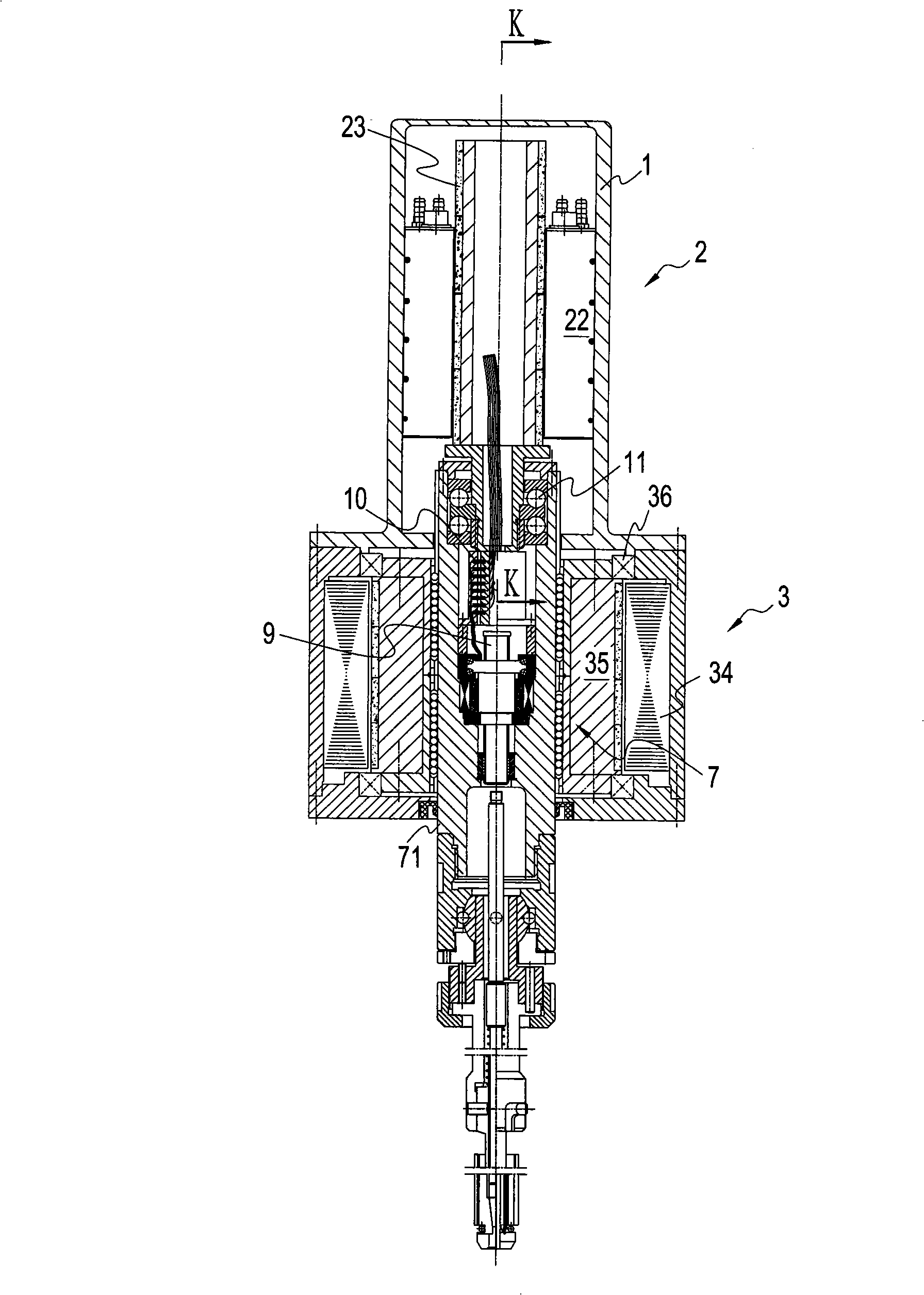

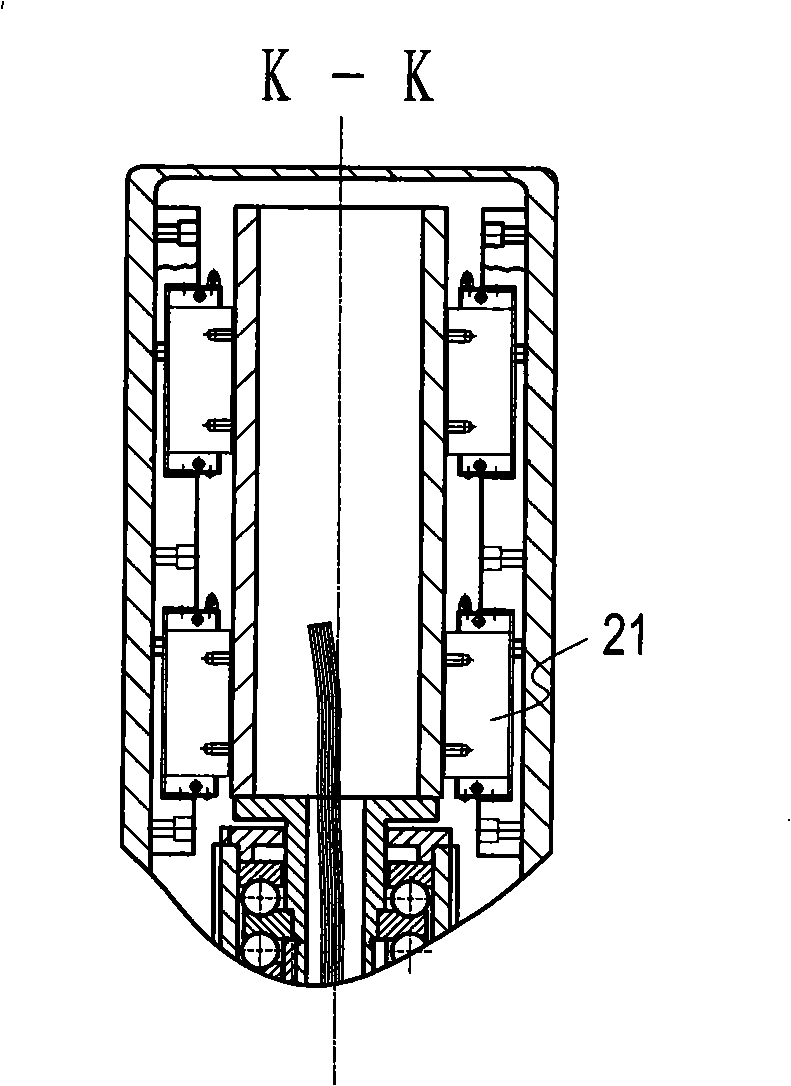

Direct drive type honing device

InactiveCN101337335ASimple structureImprove performanceHoning machinesReciprocating motionElectric machinery

The invention provides direct-drive honing equipment, which comprises an outer shell, a direct-drive linear motor and a direct-drive rotating motor, wherein the direct-drive linear motor and the direct-drive rotating motor are mounted in series; the direct-drive linear motor is mounted at the rear part of the outer shell, and drives the main shaft of the honing equipment to make a reciprocating movement; the direct-drive rotating motor is mounted at the front end of the outer shell, and drives the main shaft of the honing equipment to make a rotating movement. The honing equipment further comprises a direct-drive electric cylinder; the direct-drive electric cylinder drives the honing equipment to make a radial feed movement. The honing equipment adopts the direct-drive linear motor, the direct-drive rotating motor and the electric cylinder, thereby realizing that the driving of the honing function of the honing equipment to the three movements entirely adopts the direct-drive technology, performing the electromechanical integration whole optimization composite design, and overcoming the defect in the prior art that the hydraulic drive system and the regular motor are adopted for driving.

Owner:BEIJING KAIQI NEW TECH DEV

Extension box oil seal hole clamp and worm wheel hole clamp combined four-station clamp

ActiveCN103567790AIncrease production capacitySimple structurePositioning apparatusMetal-working holdersProduction lineVertical plane

The invention discloses an extension box oil seal hole clamp and worm wheel hole clamp combined four-station clamp. The left portion of the top face of a horizontal bottom plate is provided with two stations which include the front station and the rear station and are located side by side, and the front station and the rear station are respectively composed of a positioning column, four first positioning gaskets and two first pressing assemblies. A vertical plate is arranged at the right portion of the top face of the horizontal bottom plate, the front plate face of the vertical plate is provided with two stations which include the left station and the right station and are located side by side, and the left station and the right station are respectively composed of four second positioning gaskets, two V-shaped positioning blocks and three second pressing assemblies. Hydraulic parts of two stations of a four-station oil seal hole clamp in an existing production line and hydraulic parts of two stations of a four-station worm wheel hole clamp in the existing production line are combined and spliced, so that the oil seal hole clamp and worm wheel hole clamp combined four-station clamp is obtained. The oil seal hole clamp and worm wheel hole clamp combined four-station clamp is provided with the two stations in the horizontal plane and the two stations in the vertical plane, and therefore the design requirements are met.

Owner:CHONGQING BEIFANG QINGSHAN PRECISION MACHINERY MFG

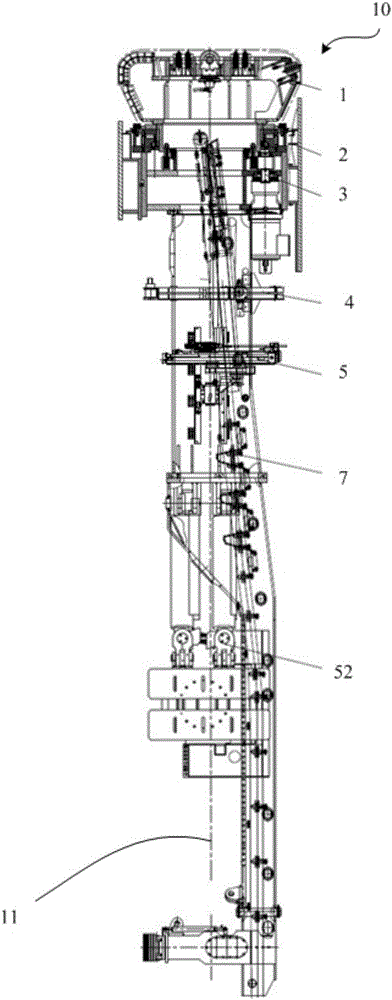

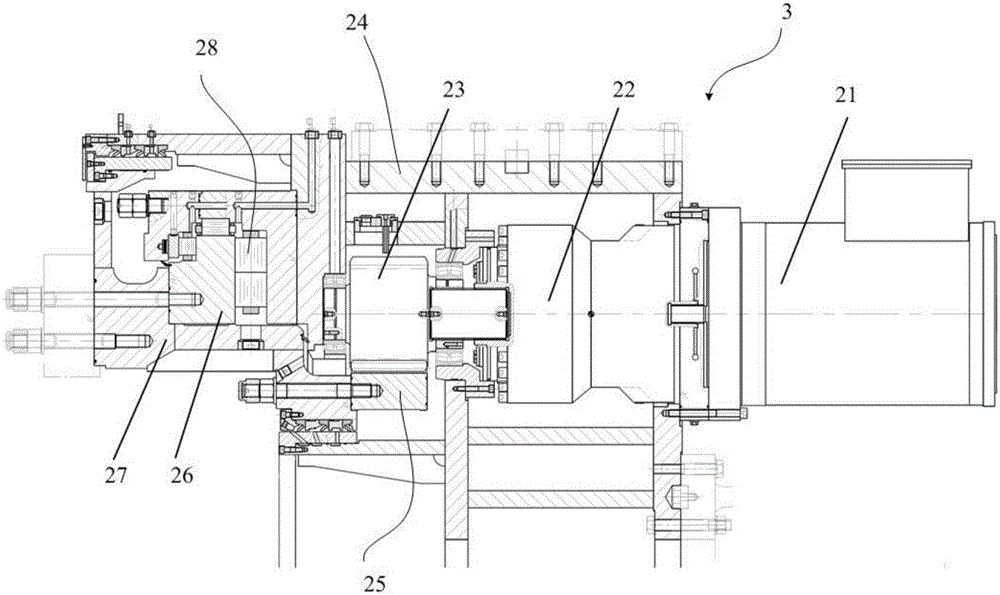

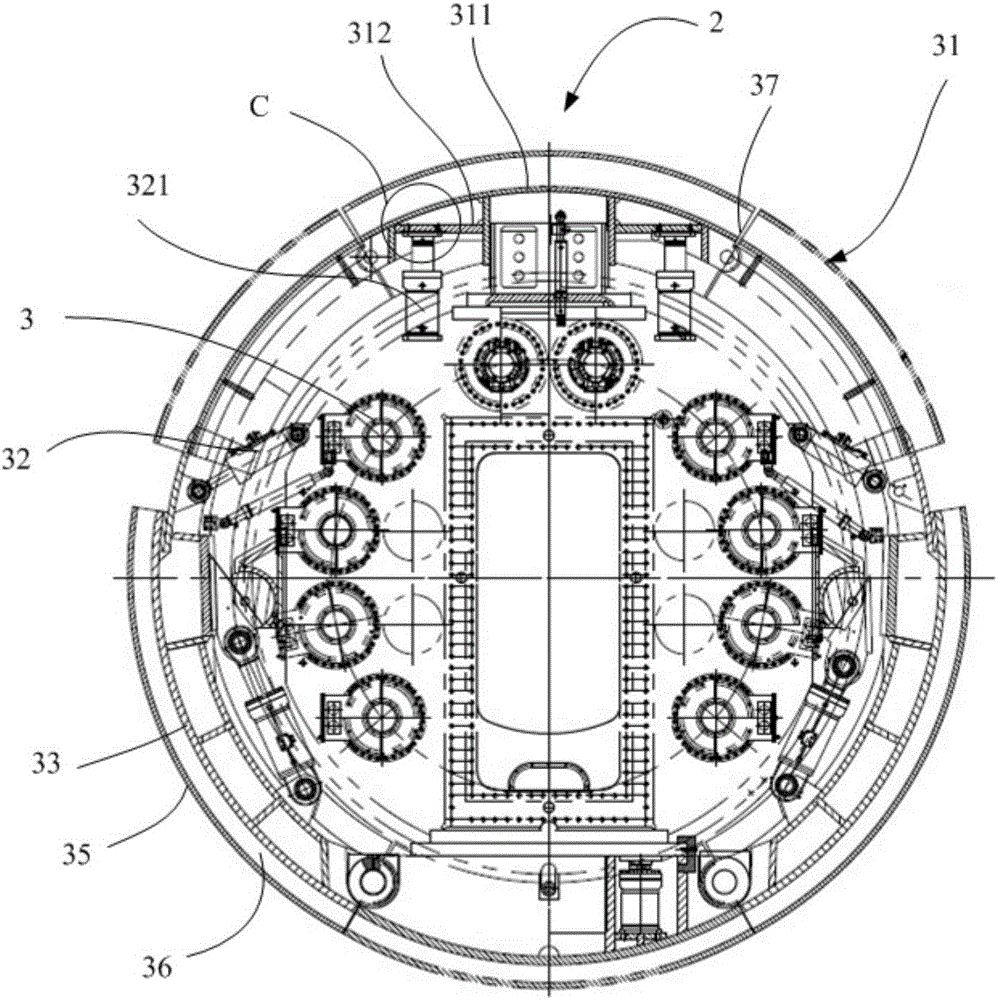

Tunnel boring machine

InactiveCN106285701AImprove versatilityShorten the design and production cycleTunnelsEngineeringTunnel boring machine

The invention relates to a tunnel boring machine. The tunnel boring machine is suitable for excavating tunnels with the diameter being 6.8-7.9 m. The tunnel boring machine comprises a main driving mechanism for driving a cutterhead, a transmission mechanism, the cutterhead and a shield, wherein the main driving mechanism comprises a plurality of driving power source assemblies; the transmission mechanism is driven by the multiple driving power source assemblies; the cutterhead is connected with the transmission mechanism; the shield surrounds the main driving mechanism in the circumferential direction; and the dimension of a shell of the shield can be changed so that the shell of the shield can adapt to the diameter of a tunnel to be excavated. When the diameter of the tunnel to be excavated is 6.8-7.9 m, only part of structures of the tunnel boring machine need to be changed, overall modification is not needed, in this way, universality of main parts and components can be achieved, the design and manufacturing cycle is greatly shortened, and production cost is greatly reduced.

Owner:CHINA RAILWAY CONSTR HEAVY IND

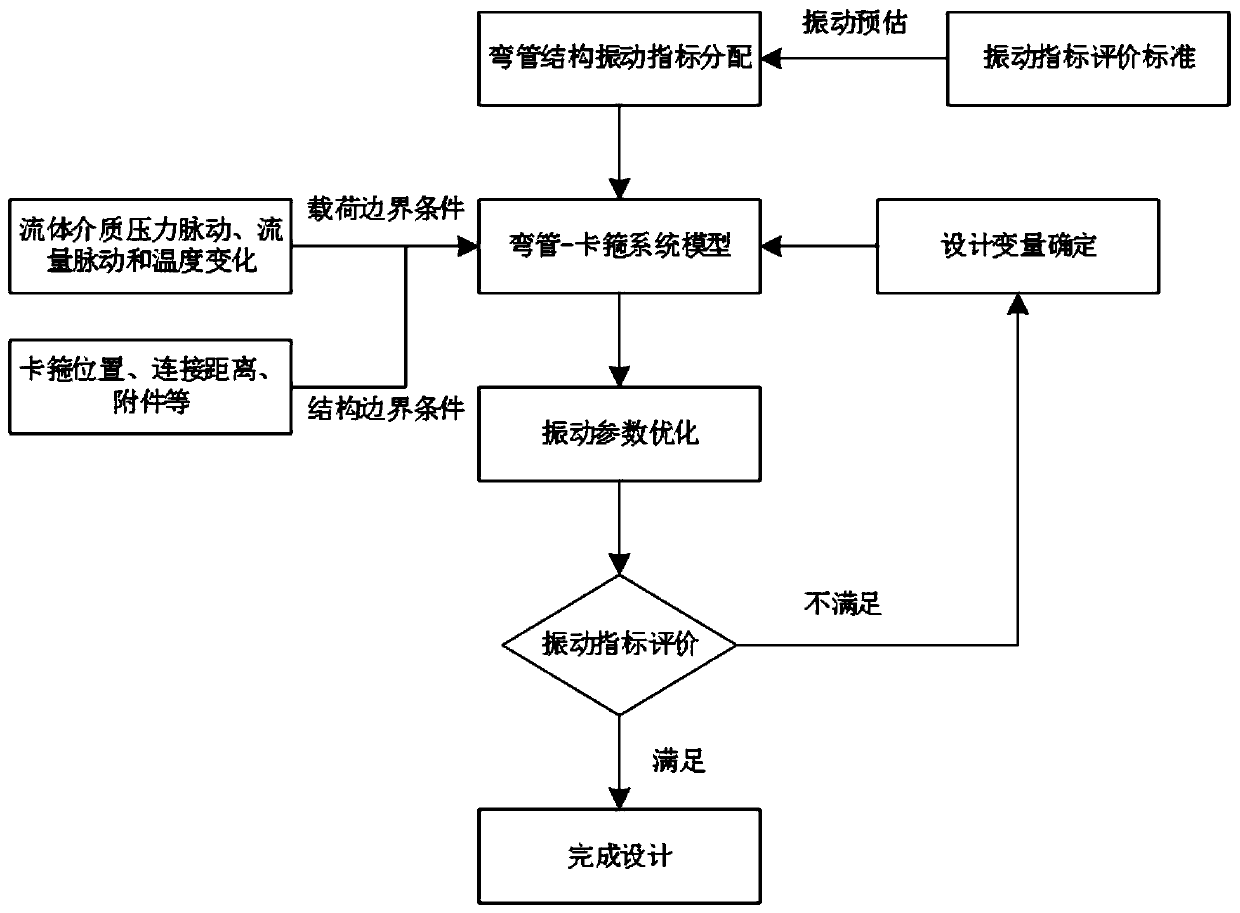

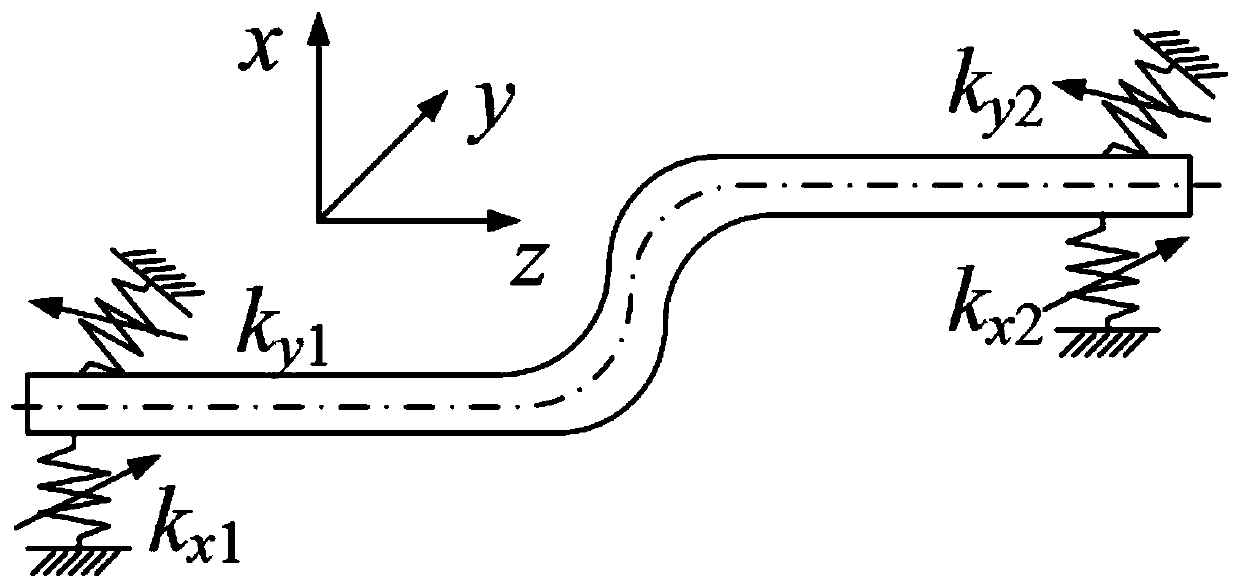

Method for quickly designing elbow structure in aero-engine external pipeline system

ActiveCN110427677ARapid designImprove reliabilitySiphonsSpecial data processing applicationsAviationEngineering

The invention relates to the field of external accessories of aviation and aerospace equipment, and discloses a method for quickly designing an elbow structure in an aero-engine external pipeline system, for completing the lightweight design of the elbow structure in the external pipeline system, reducing the vibration fault of the elbow structure and improving the vibration resistance of the elbow structure. According to the method, in the initial design stage of the elbow structure in an external pipeline system of aviation and aerospace equipment, the vibration condition of the elbow structure is estimated through the elbow structure rapid design method, and the technical variable parameters of the elbow structure are optimized according to the estimation result, and rapid design of theelbow structure is completed. Due to the method, the design cost can be reduced, and the development period is shortened, and the installation and arrangement success rate of the elbow structure in an external pipeline system is increased.

Owner:DALIAN UNIV OF TECH

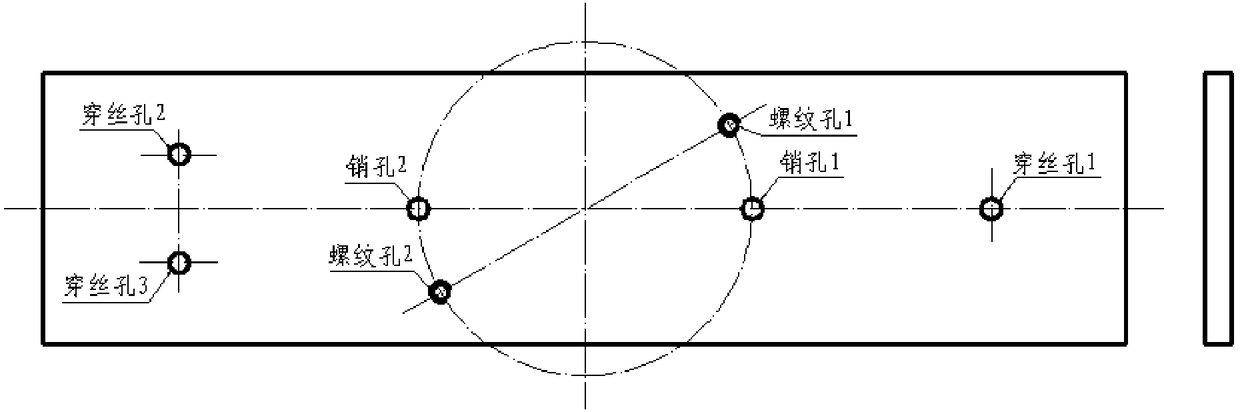

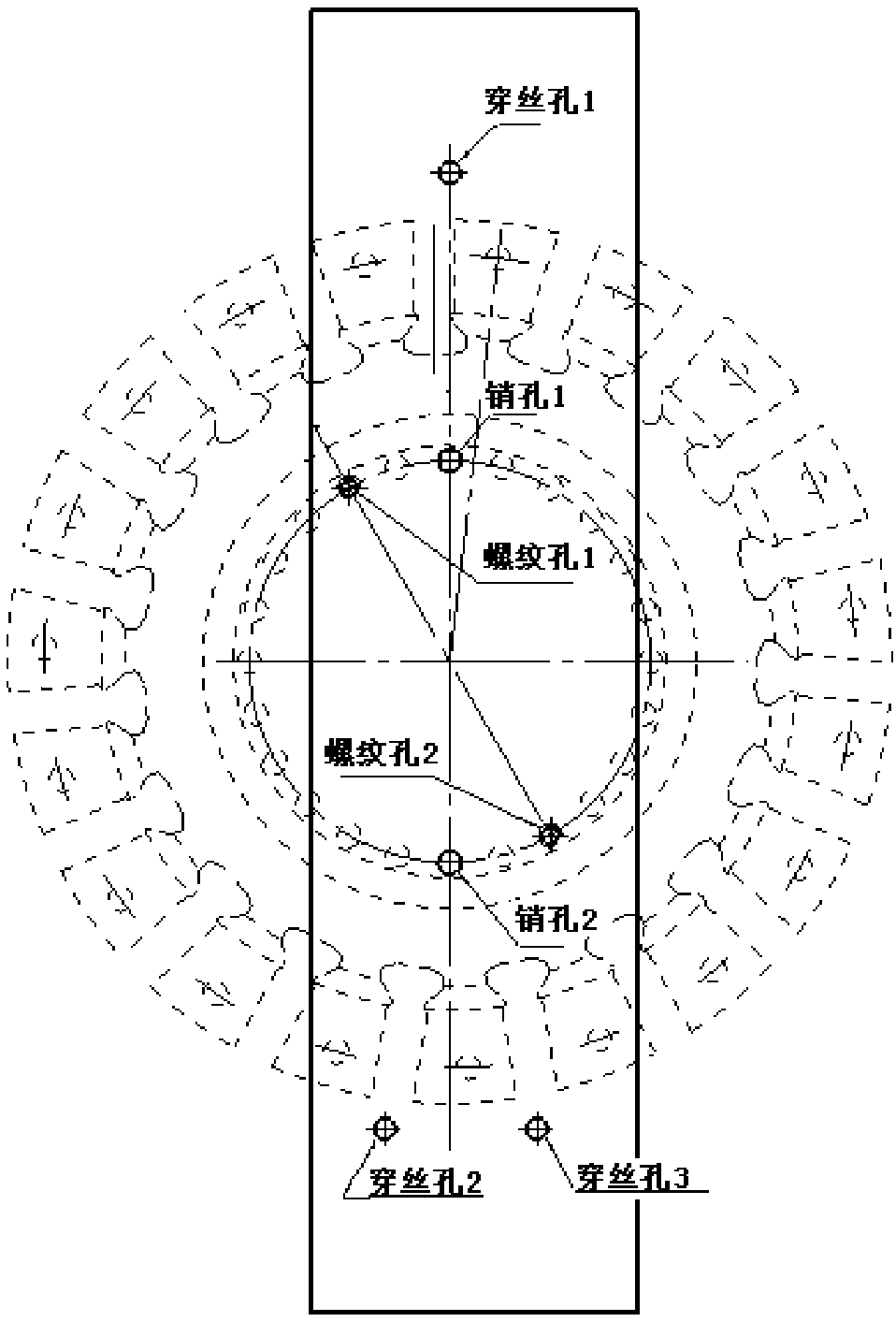

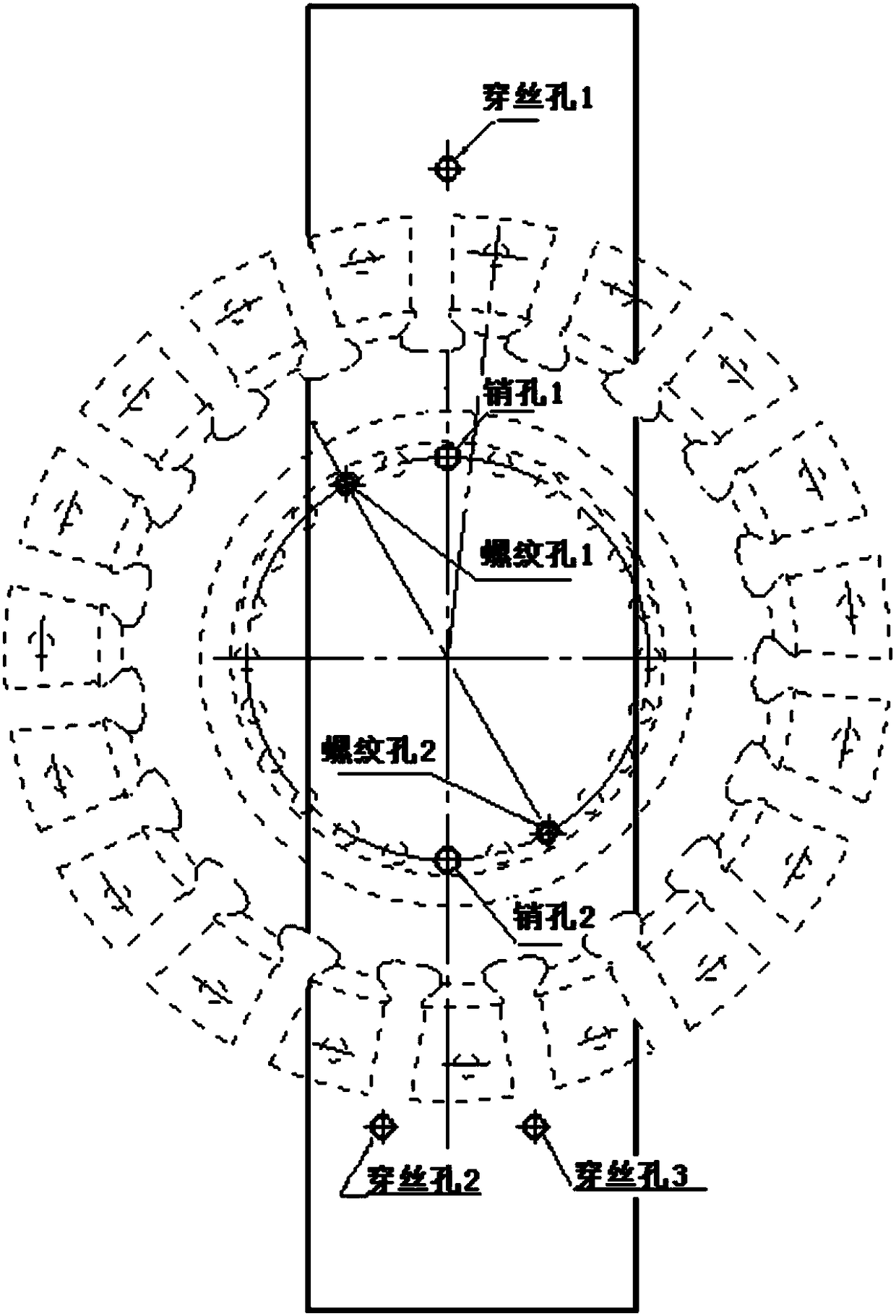

Linear cutting machining method for straight swallowtail-type mortises

InactiveCN108080890AReduce distortionShorten the design and production cycleEngineeringCutting force

The invention discloses a linear cutting machining method for straight swallowtail-type mortises. The linear cutting machining method comprises the steps that (1) mortise machining is conducted by adopting a linear cutting mode, and a plurality of bottom plates are made firstly; (2) in order to make the bottom plates in the step (1) adapt to universality in the machining process of different parts, a plurality of wire threading holes and a plurality of positioning holes are formed in the bottom plates according to the structures of the several parts; and (3) the bottom plates are fixedly connected with the parts by using bolts through the positioning holes, the bottom plates for mounting and clamping the parts are mounted on a linear cutting machine tool, the side faces of the bottom plates are used for straightening and alignment, all the mortises can be machined in the mounted and clamped parts at a time, cutting force does not exist in linear machining, and deformation in part machining can be reduced. The linear cutting machining method is further suitable for being used for removing of the allowance when surface quality requirements are high and reducing of part deformation caused by allowance removing in the machining process.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

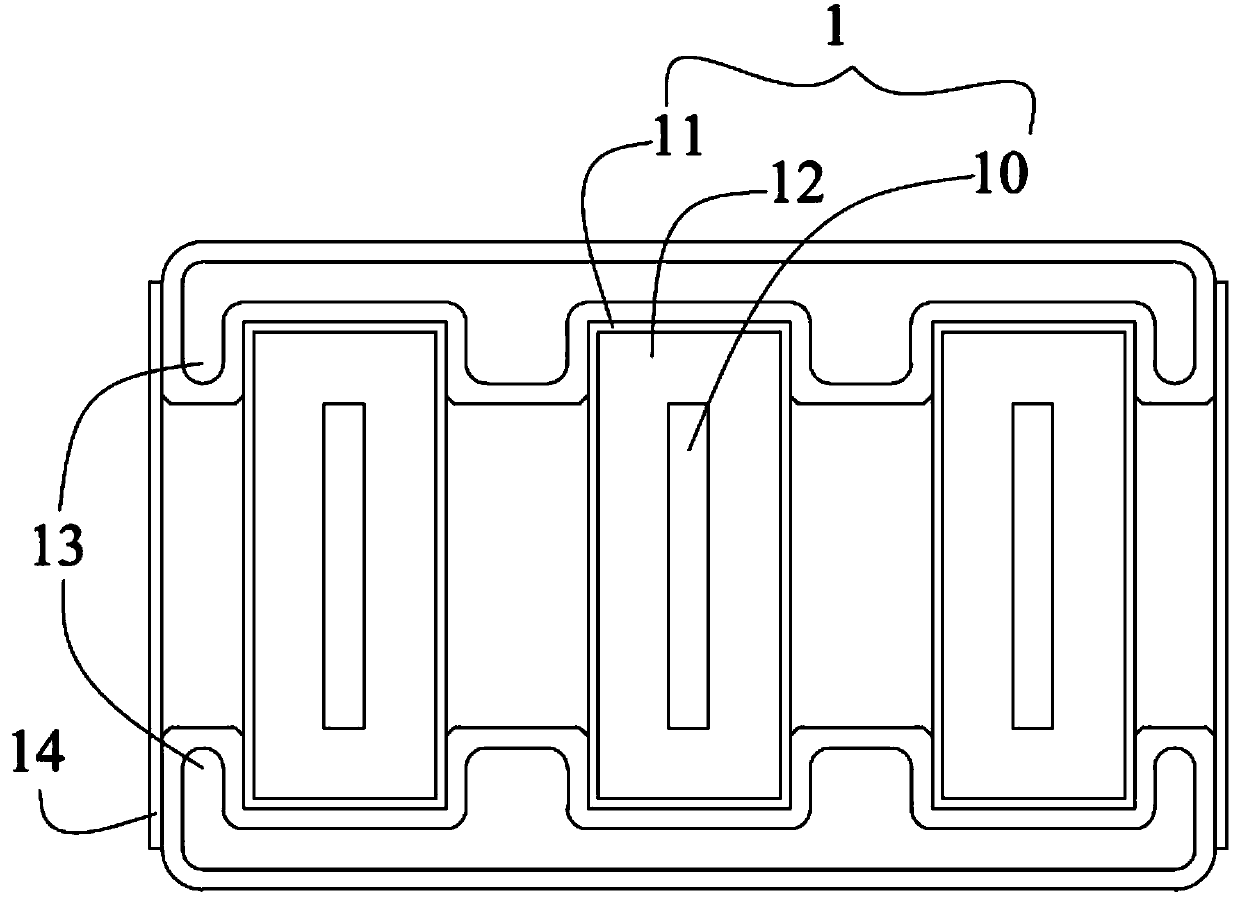

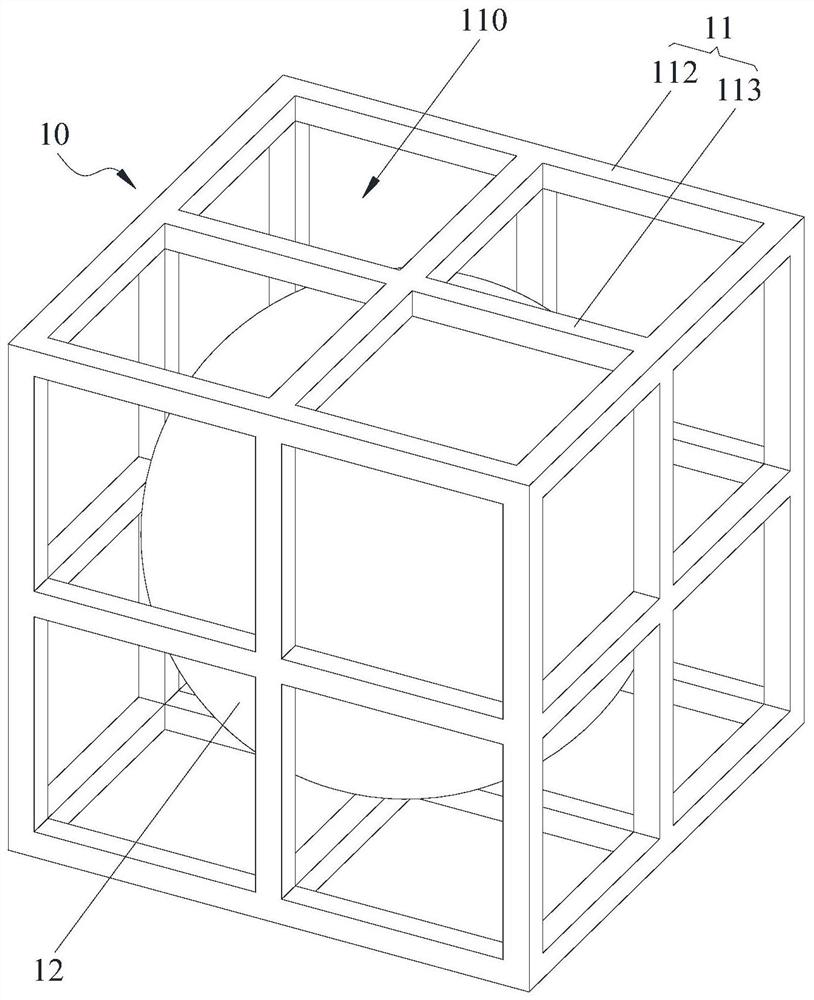

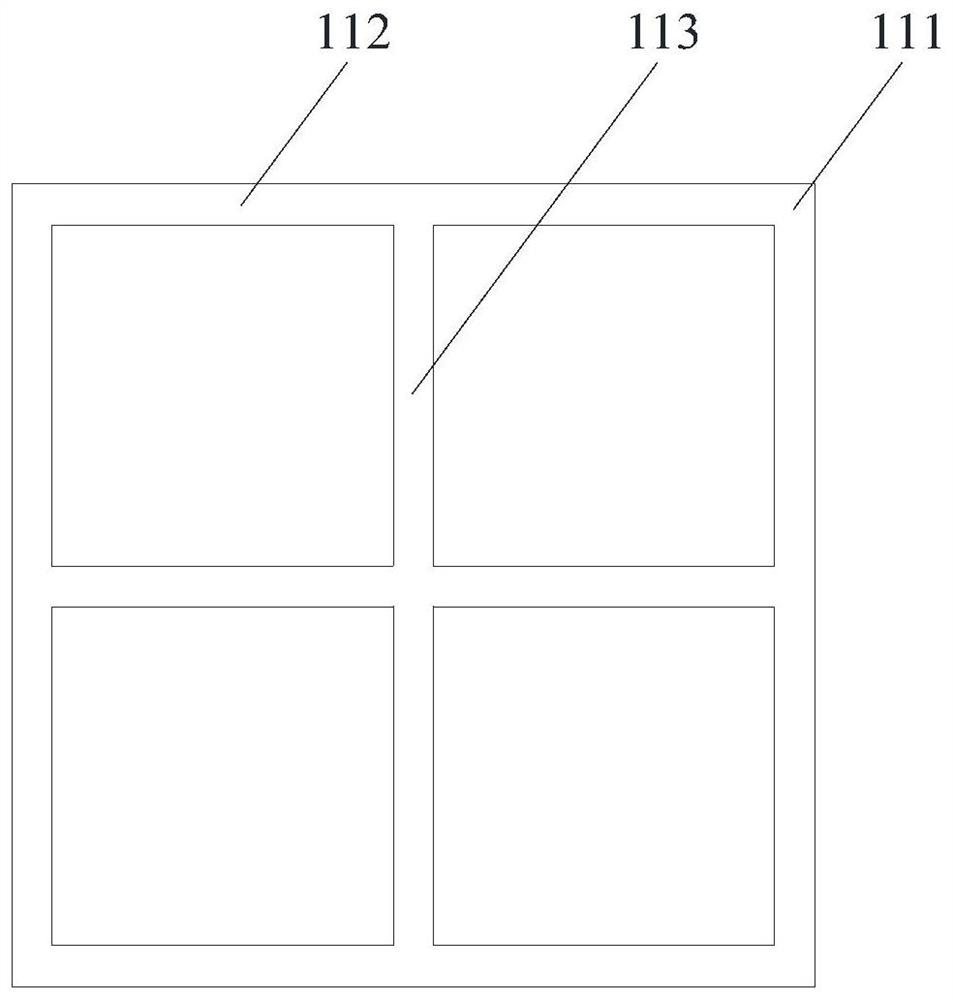

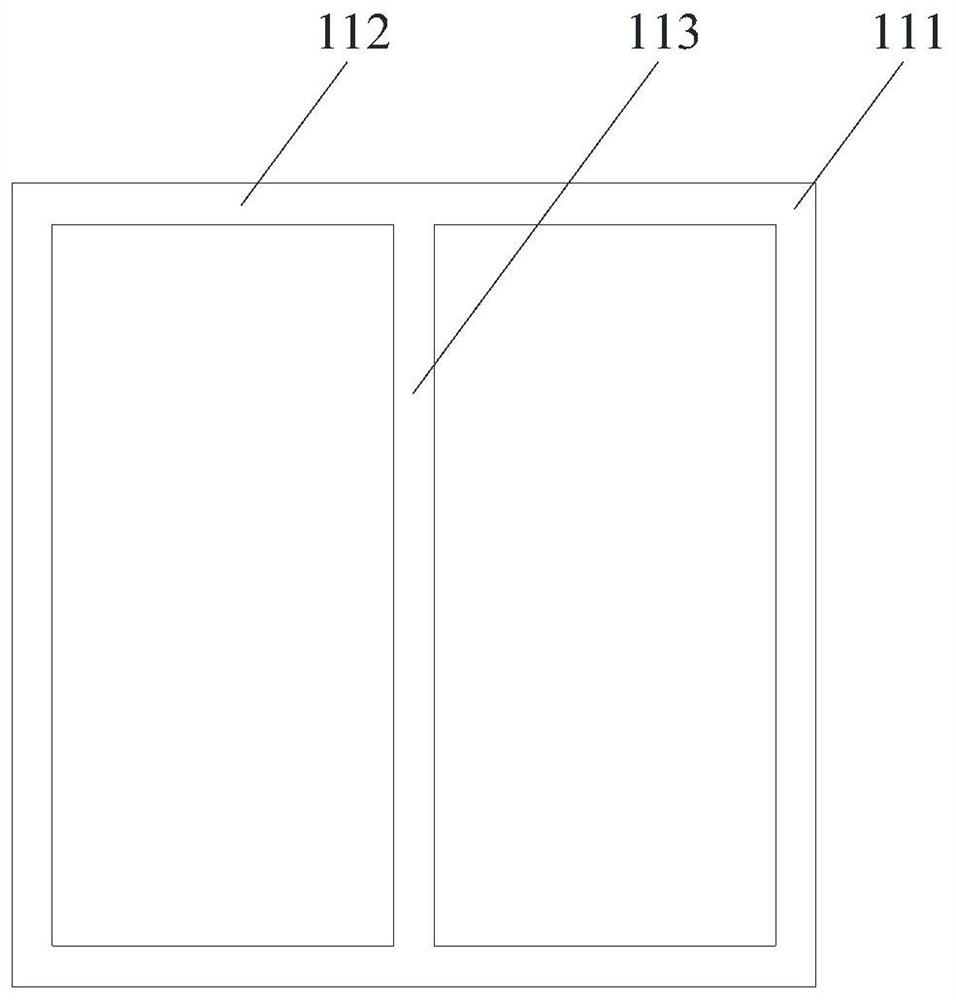

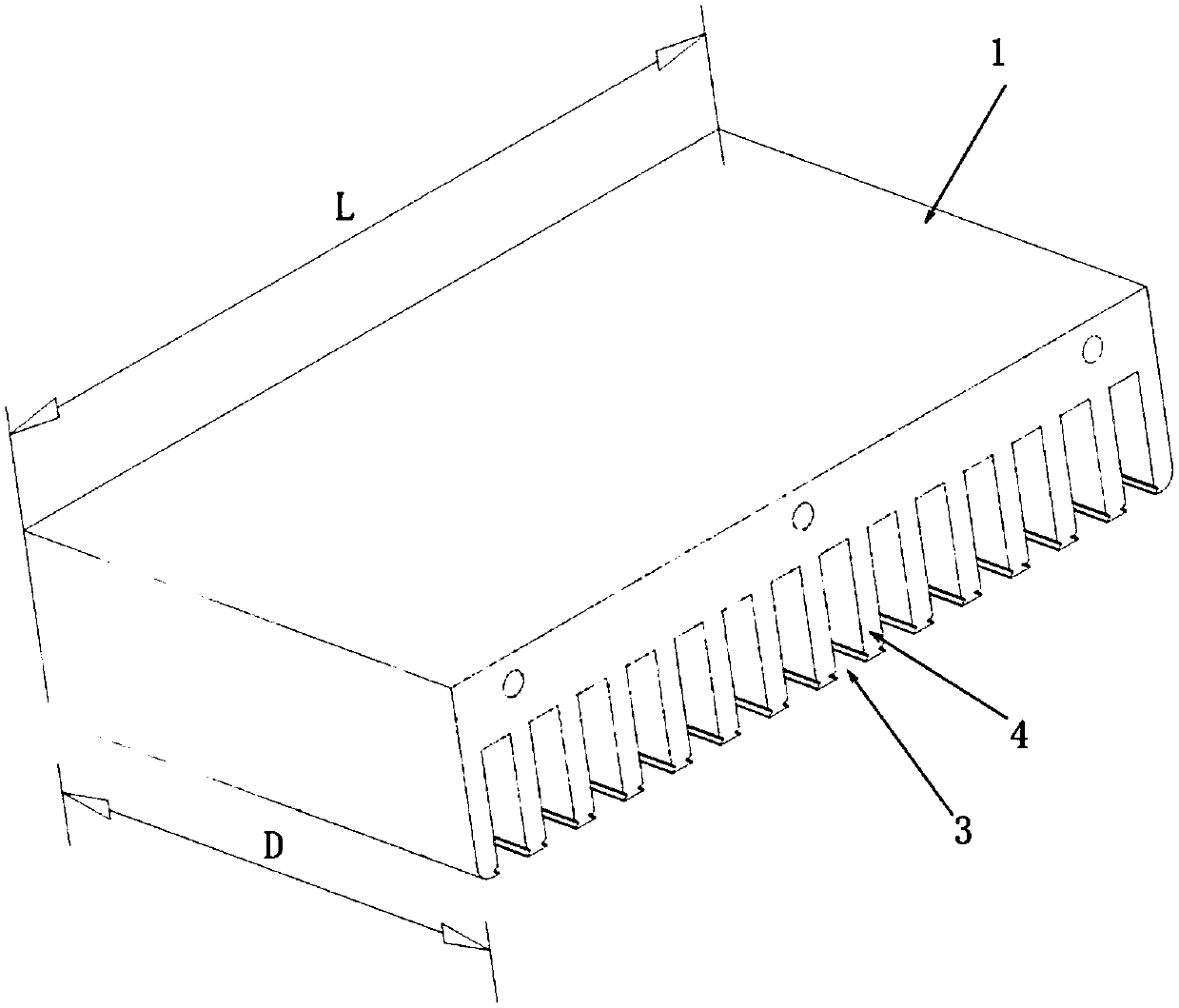

Energy absorption structure and energy absorption buffer device

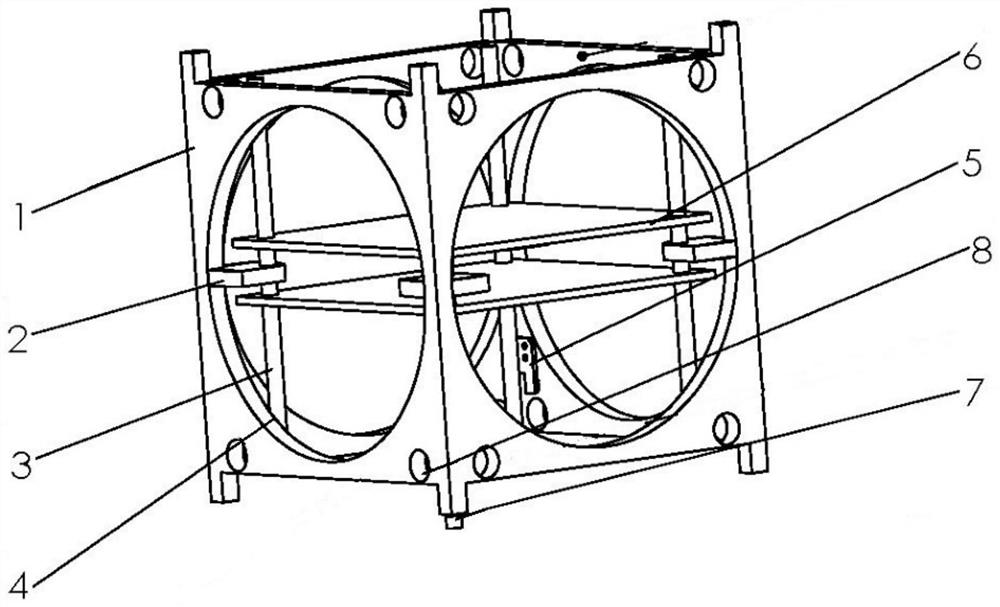

ActiveCN112249509AShorten the design and production cycleReduce manufacturing costExternal framesContainers to prevent mechanical damageEnergy absorptionMechanical engineering

The invention belongs to the technical field of passive safety protection, and provides an energy absorption structure and an energy absorption buffer device. The energy absorption structure comprisesa support body and an energy absorption body, wherein the support body is in a cubic form; a first cavity is formed in the support body; the energy absorption body is contained in the first cavity and is propped against the inner wall of the support body; the energy absorption buffer device comprises a plurality of energy absorption structures, and every two adjacent support bodies are fixedly connected. According to the energy absorption structure and the energy absorption buffer device provided by the invention, the cubic support bodies are adopted to be matched with the energy absorption bodies separately, the same energy absorption buffer effect can be achieved due to the fact that impact force transmitted to each energy absorption body through any surface of the corresponding supportbody is the same, the energy absorption buffer requirements of a protected object can be met only by splicing a plurality of energy absorption structures into the energy absorption buffer device under different use scenarios, and the structures of the energy absorption structures do not need to be changed, therefore, the technical problems that the energy absorption structures need to be independently designed according to specific scenarios, and the universality is not high are effectively solved.

Owner:HARBIN INST OF TECH SHENZHEN GRADUATE SCHOOL

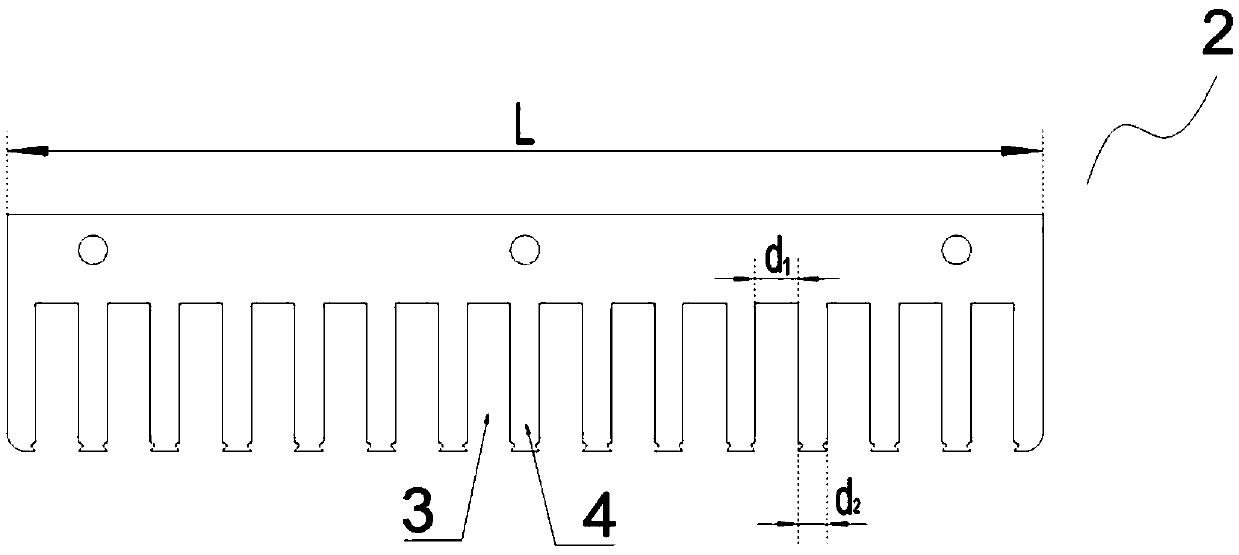

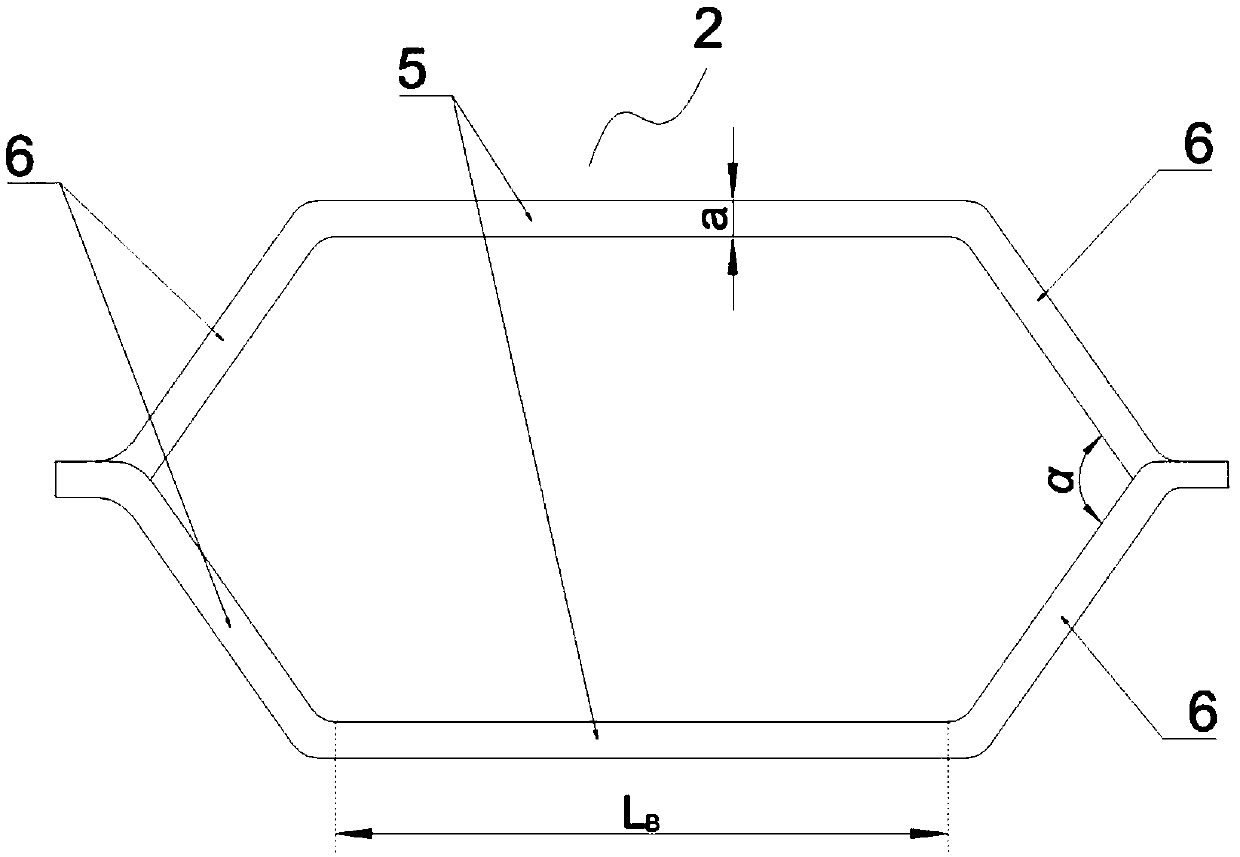

Design and verification method of winding coil of magnetic suspension linear motor

ActiveCN109687618AReasonable size designReduce manufacturing costWindings conductor shape/form/constructionProjection distanceStator

The invention provides a design and verification method of a winding coil of a magnetic suspension linear motor which can effectively solve the problem of long design and manufacturing cycle and highcost of the magnetic suspension linear motor caused by the existing design verification method. The method includes obtaining theoretical design values of a primary stator core and the winding coil according to the design speed of a maglev train and the design principle of the linear motor, comparing whether the linear distance b of the thickness a of the oblique portion of the isosceles trianglestructure at the end of the winding coil occupied on the length direction of the stator core is more than the sum of the stator slot width d1 of the stator core and the stator tooth portion width d2;determining whether the projection distance of the oblique portion of the isosceles triangle structure at the end of the winding coil in the width direction of the stator core is out of limit; whetherthe height h is out of limit after the whole isosceles triangle structure at the end of the winding coil is bent upward.

Owner:SUZHOU BETTER TECH

Equal-high segmenting combined numerical controlling milling manufacture method of complex shaped parts

InactiveCN100480919CEliminate knife sticking problemsImprove CNC Milling EfficiencyProgramme controlComputer controlNumerical controlDigital control

This invention relates to mechanic design process field and relates to one complex shape equal height cut combination digital control process method, which comprises complex shape cut design, module establishing, digital cutting, and shape combination. This invention can fulfill usual digital control bed process complexity task and eliminate the cut process knife problem without any change of knife tool and machine bed functions.

Owner:HEBEI UNIVERSITY OF SCIENCE AND TECHNOLOGY

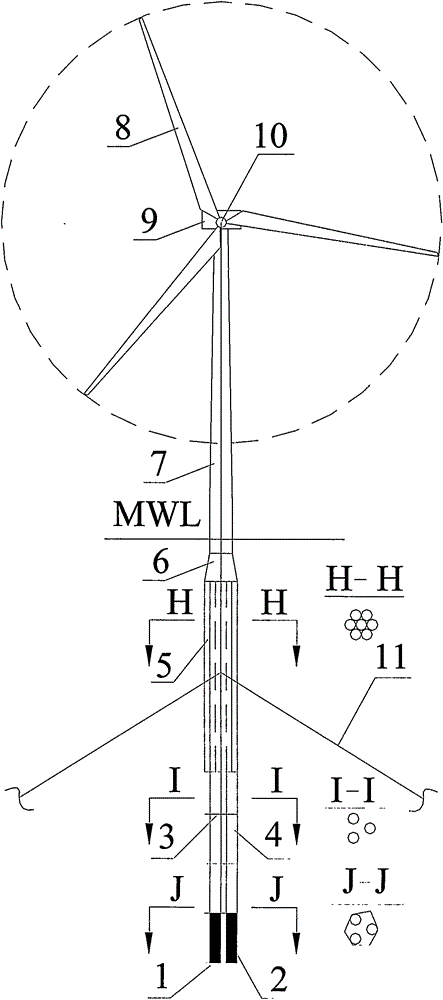

Floating type honeycomb-shaped platform wind turbine

InactiveCN104421112AImprove thickness uniformityCrack resistantFinal product manufactureMachines/enginesKeelHoneycomb

The invention discloses a floating type honeycomb-shaped platform wind turbine and belongs to the technical field of offshore wind power generation. The floating type honeycomb-shaped platform wind turbine is aimed to solve disadvantages of complex structure, long design and manufacturing period, heavy weight, high cost and the like of an existing floating type barrel-shaped platform wind turbine. The upper half part of the honeycomb-shaped platform is composed of six peripheral steel pipes and a central steel pipe, and the peripheral steel pipes surround the central steel pipe; the lower half part of the honeycomb-shaped platform is formed through enabling three of the six peripheral steel pipes to extend to a keel plate. Compared with the original barrel-shaped platform, the honeycomb-shaped platform has advantages of simple structure, short design and manufacturing period, large structure intensity, low cost and the like.

Owner:王立夫

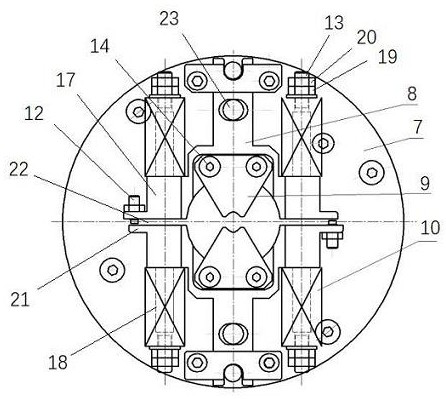

Automatic fixture of rotary cylinder front-mounted grinding machine

InactiveCN112405349AAchieve precise positioningShort transformation periodRevolution surface grinding machinesGrinding work supportsEngineeringCylinder block

The invention relates to an automatic fixture of a rotary cylinder front-mounted grinding machine, comprising a fixture, and further comprising a rotary cylinder and a spring device applying radial inward force to clamping members. The fixture comprises a connecting disc, and a plurality of clamping members arranged on the front side face of the connecting disc and connected with the connecting disc in a radial sliding manner; the rotary cylinder is arranged in the axial direction; the front portion of a piston body is conical and extends out of the front end of a cylinder block of the rotarycylinder; a plurality of radial transmission members are arranged on the rear side face of the connecting disc, the radial inner sides of the radial transmission members can make pressure contact withthe conical surface of the front portion of the piston body; the radial transmission members are movably connected with the connecting disc in the radial direction; the radial transmission members and the clamping members are in one-to-one correspondence, and adopt the same circumferential distribution manner as that of the clamping members; and the radial outer ends of the radial transmission members are in radial transmission connection with the corresponding clamping members, respectively. The fixture is simple in structure, and implements automatic clamping of parts on the premise that the main structure of a grinding machine headstock is not changed.

Owner:BEIJING NO 2 MACHINE TOOL WORKS

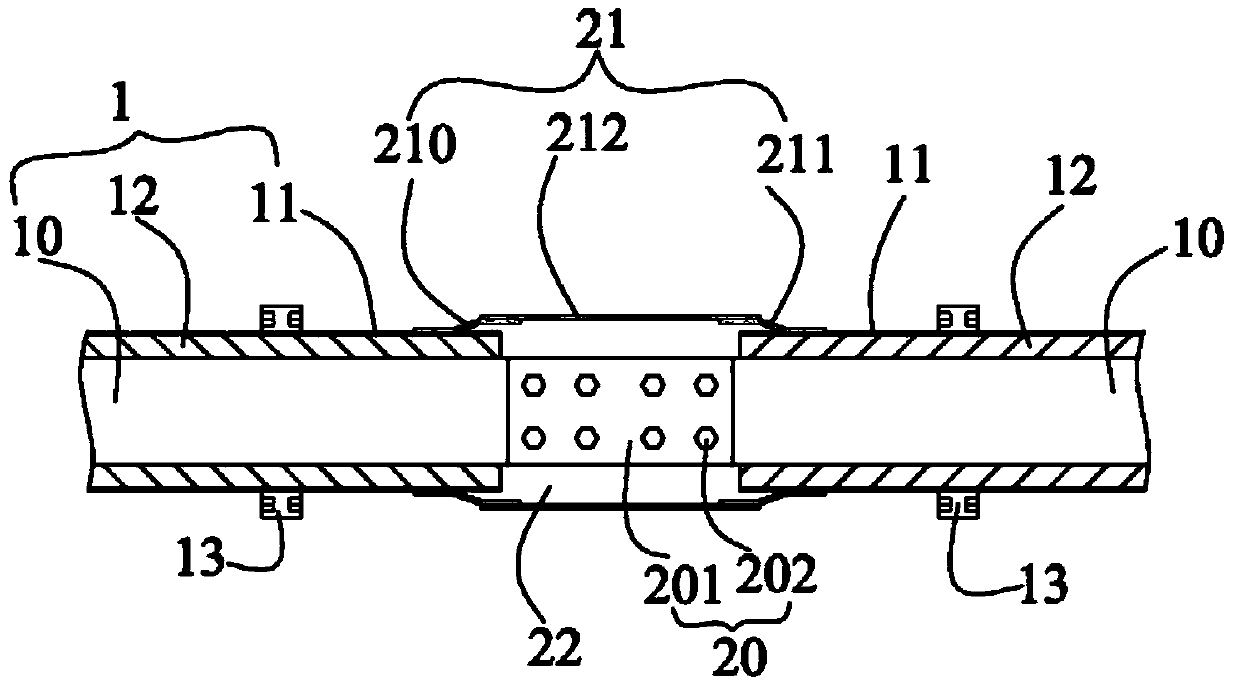

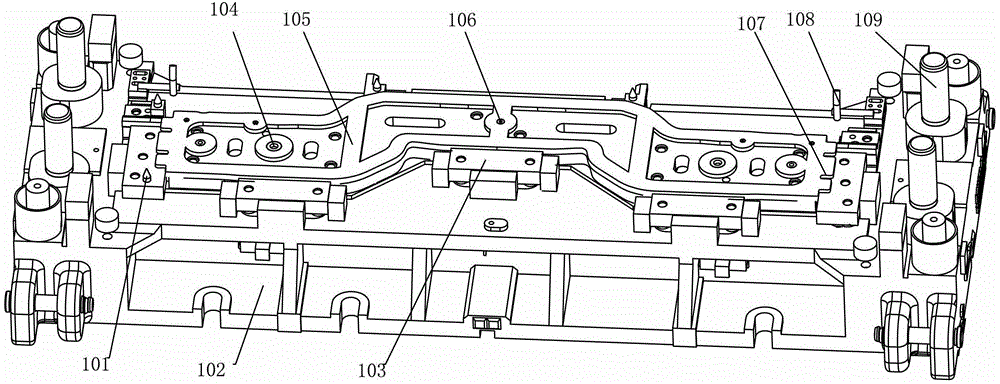

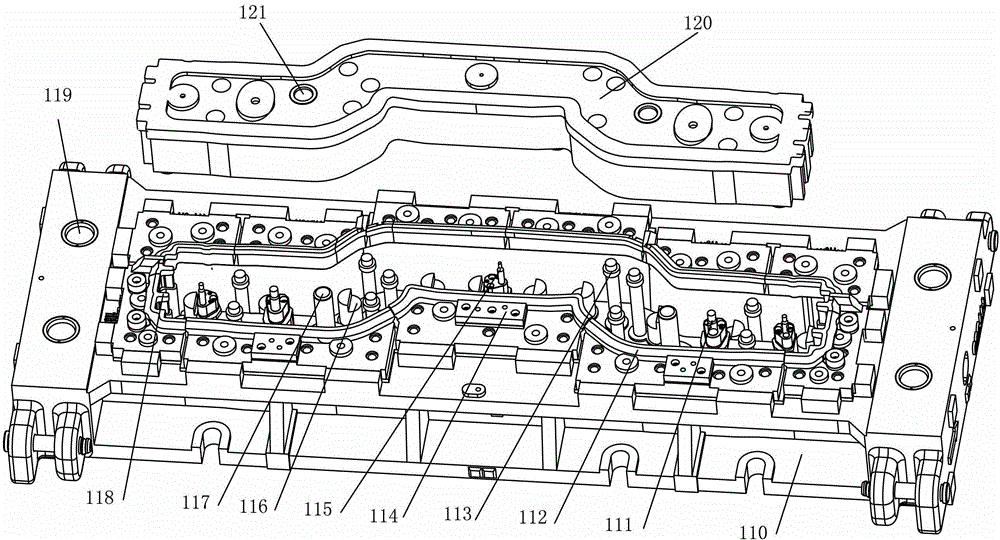

Modular design structure of welding fixture for trial-manufacture sample vehicles

ActiveCN101905403BSimplified design methodShorten the design and production cycleWelding/cutting auxillary devicesAuxillary welding devicesModular designModularity

The invention relates to the technical field of automobile manufacturing equipment, in particular to a modular design method and a modular design structure of a welding fixture for trial-manufacture sample vehicles, which solve the problems of incapability of recycling, long design and manufacturing period and high manufacturing cost of sample vehicle trial-manufacture fixture parts of automobiles in the prior art. The welding fixture comprises a base and a fixture unit arranged on the base; structural members with the same functions in the welding fixture for the trial-manufacture sample vehicles are formulated into standard or standard series parts in the process of design and development to form a fixture module series, so that the standard or standard series parts are recycled in the development of the welding fixture for new type trial-manufacture sample vehicles and the welding fixture for small-lot vehicles, and non-standard parts in the fixture are subjected to structural design; and the standard parts and the non-standard parts in the welding fixture for the trial-manufacture sample vehicles are matched to form novel and complete welding fixture equipment for the trial-manufacture sample vehicles. Through the modular design method and the modular design structure, the aims of shortening the design and manufacturing period, recycling general and standard parts and reducing manufacturing cost are fulfilled.

Owner:ZHEJIANG GEELY AUTOMOBILE RES INST CO LTD +1

Copying fixing tooling for automotive parts

ActiveCN105458978AShorten the design and production cycleShorten the development cycleWork holdersEngineeringMechanical engineering

The invention relates to the technical field of automotive part processing, in particular to a copying fixing tooling for automotive parts. The copying fixing tooling for the automotive parts comprises a plurality of needle bars and a fixing tooling body; the needle bars are arranged on the fixing tooling body; the height of the end part of each needle bar is adjusted by lengthening and shortening the corresponding needle bar; end parts of the needle bars form profiles matched with automotive bodies or interior and exterior decoration parts. Compared with the prior art, the copying fixing tooling disclosed by the invention has the characteristics that the telescoping needle bars are adopted to be matched with the profiles of the automotive bodies or interior and exterior decoration part products for different automotive types, the profiles are fixed through a support positioning mechanism, and the needle bars are adjusted in height and are fixed by a height adjustment and fixing device; the same copying fixing tooling disclosed by the invention can be repeatedly used by same-type products for different automotive types, therefore the design and manufacturing cycle of the tooling is shortened, the cost is reduced, the development cycle and the development cost of the automotive bodies or the interior and exterior decoration parts are respectively shortened and reduced, and the efficiency is improved; the copying fixing tooling disclosed by the invention can be applied to development of various automotive bodies or the interior and exterior decoration part products.

Owner:SHANGHAI LINGANG JOYSON SAFETY SYST CO LTD +1

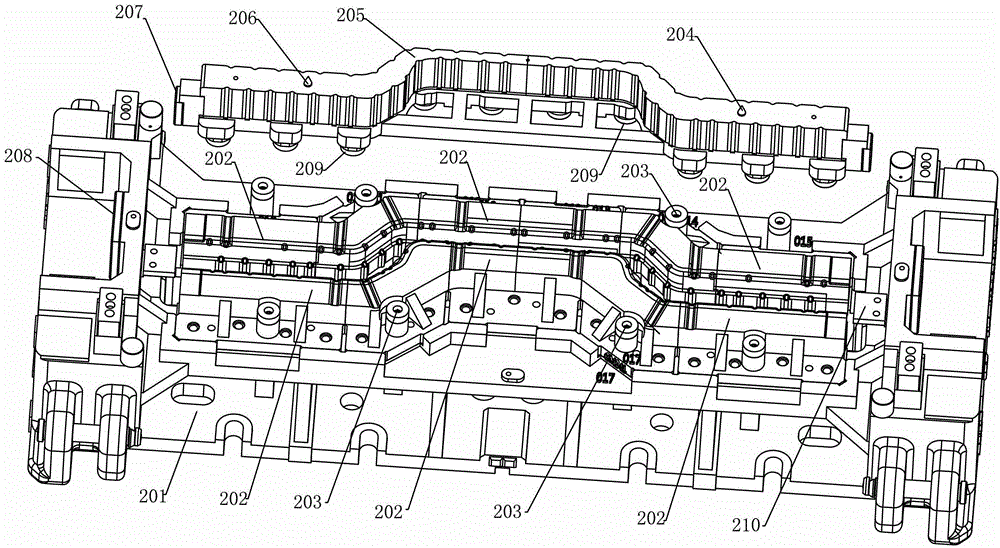

Forming mould and stamping technology for n-shaped automobile cross beam

ActiveCN103357754BShorten the design and production cycleReduce design and manufacturing costsShaping toolsLoad-supporting pillarsManufacturing technologyNitrogen gas

The invention provides a forming mould and a stamping technology for an n-shaped automobile cross beam. The forming mould comprises an upper mould assembly and a lower mould assembly, wherein the upper mould assembly comprises an upper mould base body, an upper mould pressing side ring and an upper mould forming inserted block; a nitrogen gas spring for ejecting the upper mould pressing side ring and a working screw for preventing a self-mounted groove of the upper mould pressing side ring from falling are arranged between the upper mould pressing side ring and the upper mould base body; the lower mould assembly at least comprises a lower mould base body, a lower mould material support body, and a lower mould forming inserted block; a cover plate for preventing a self-mounted groove of the lower mould material support body from falling and a ejection rod mechanism for ejecting the lower mould material support body from the lower mould base body; a pressure machine provides an upward pressure source for the lower mould material support body. According to the invention, the design manufacturing technology of the traditional mould is changed, the mould design manufacturing technology is changed into 3-procedure mould, so that the mould design manufacturing cycle is shortened, and the mould design manufacturing cost is greatly reduced.

Owner:SHANDONG XIAOYA PRECISE MACHINERY

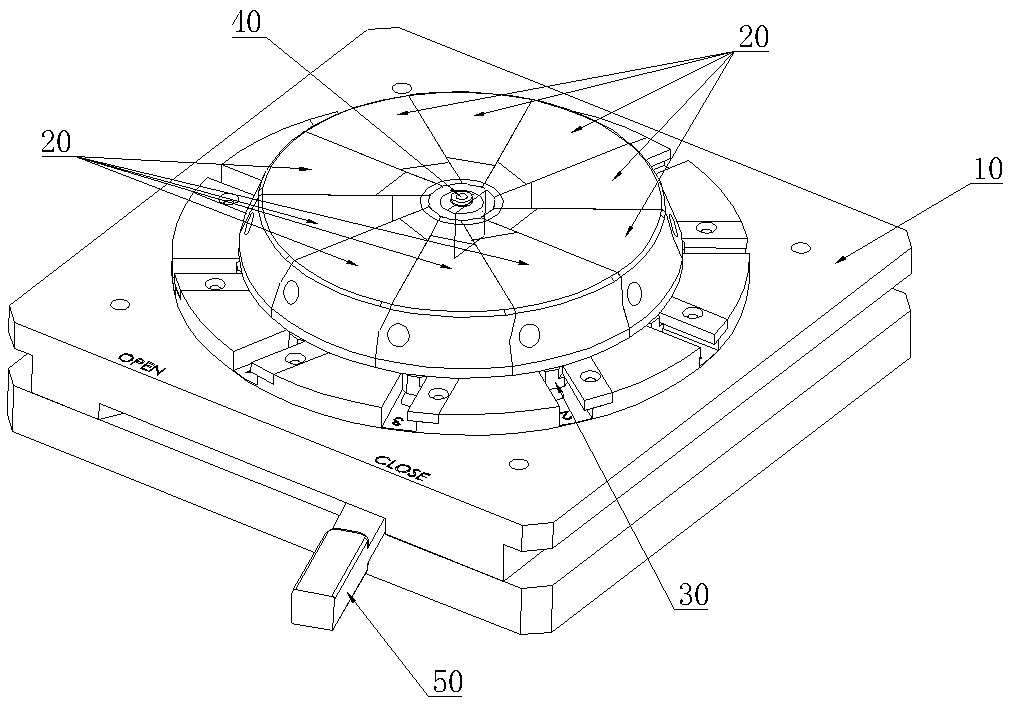

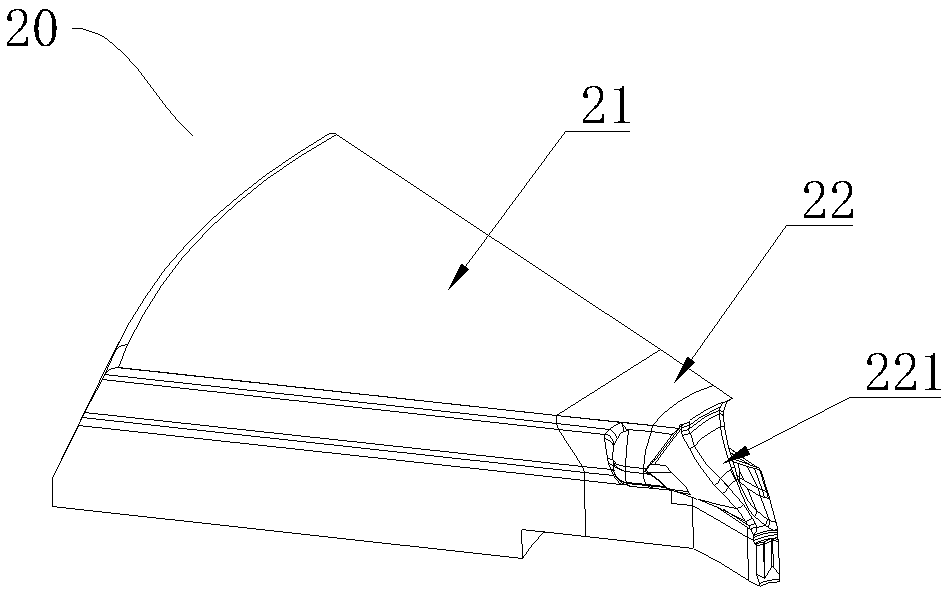

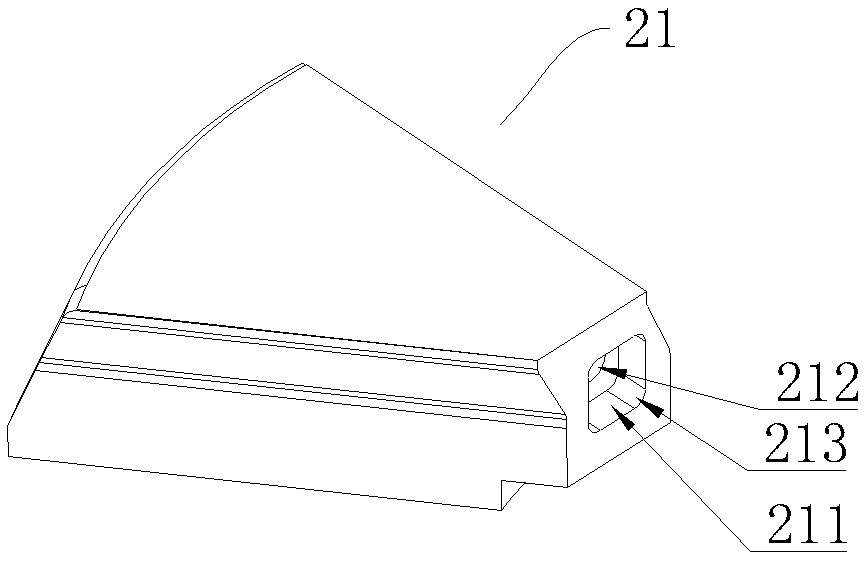

Wax pattern mold for impeller investment casting

InactiveCN106607563BShorten the design and production cycleSmall structureFoundry mouldsFoundry coresImpellerWax

The invention provides a wax mould for impeller investment casting and can solve the problems that a wax mould of an existing impeller is high in development and manufacturing cost and long in cycle. The wax mould comprises a base and a plurality of sliding blocks, the base is uniformly provided with a plurality of sliding rails extending in the radial direction in the peripheral direction, and each sliding block is slidably installed between every two adjacent sliding rails. The wax mould is characterized in that each sliding block comprises a sliding block base body and a forming head, each forming head is provided with a wax mould forming cavity, and each forming head is detachably installed at the front end of the corresponding sliding block base body.

Owner:FALCON AEROTECH LTD

A profiling fixing tool for auto parts

ActiveCN105458978BShorten the design and production cycleShorten the development cycleWork holdersEngineeringMechanical engineering

The invention relates to the technical field of automotive part processing, in particular to a copying fixing tooling for automotive parts. The copying fixing tooling for the automotive parts comprises a plurality of needle bars and a fixing tooling body; the needle bars are arranged on the fixing tooling body; the height of the end part of each needle bar is adjusted by lengthening and shortening the corresponding needle bar; end parts of the needle bars form profiles matched with automotive bodies or interior and exterior decoration parts. Compared with the prior art, the copying fixing tooling disclosed by the invention has the characteristics that the telescoping needle bars are adopted to be matched with the profiles of the automotive bodies or interior and exterior decoration part products for different automotive types, the profiles are fixed through a support positioning mechanism, and the needle bars are adjusted in height and are fixed by a height adjustment and fixing device; the same copying fixing tooling disclosed by the invention can be repeatedly used by same-type products for different automotive types, therefore the design and manufacturing cycle of the tooling is shortened, the cost is reduced, the development cycle and the development cost of the automotive bodies or the interior and exterior decoration parts are respectively shortened and reduced, and the efficiency is improved; the copying fixing tooling disclosed by the invention can be applied to development of various automotive bodies or the interior and exterior decoration part products.

Owner:SHANGHAI LINGANG JOYSON SAFETY SYST CO LTD +1

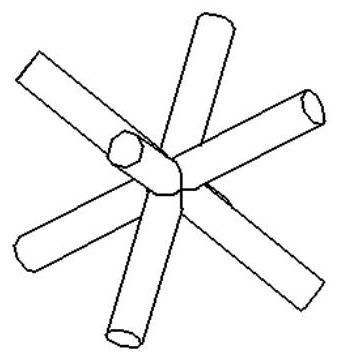

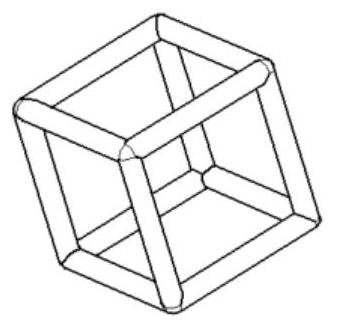

Cubesat framework based on 3D printing

InactiveCN112896559AImprove structural strengthSimple structureCosmonautic vehiclesCosmonautic partsSelective laser meltingPower switching

The invention discloses a CubeSat framework based on 3D printing, which comprises a side frame and a connecting screw rod, and further comprises fixing tables and a solar cell panel, four fixing tables are connected in the side frame, the surfaces of the fixing tables are connected with the connecting screw rod, the outer surface of the connecting screw rod is sleeved with a circuit board. A large circular hole and a small circular hole are formed in the outer surface of the side frame, and a power switch is arranged on the inner side wall of the side frame. According to the CubeSat framework based on 3D printing, the selective laser melting metal 3D printing technology is adopted, the structural strength of the CubeSat framework reaches up to 500 MPa, the weight of the CubeSat framework is half of that of a traditional method, the design and manufacturing period is shortened, and on the basis that an original CubeSat framework loads different functional loads, the strict requirement of a spacecraft for the load quality can be better met.

Owner:星众空间(北京)科技有限公司

A structural design method for helicopter blades based on 3D metal printing

ActiveCN109334971BSimple designShorten the design and production cycleAdditive manufacturing apparatusIncreasing energy efficiencySectional planeLatticework

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com