Automatic fixture of rotary cylinder front-mounted grinding machine

A rotary cylinder and front-mounted technology, which is applied to grinding machines, machine tools designed for grinding the rotating surface of workpieces, manufacturing tools, etc., can solve the problems of high cost and structural load, achieve convenient operation, shorten the transformation cycle, and save costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

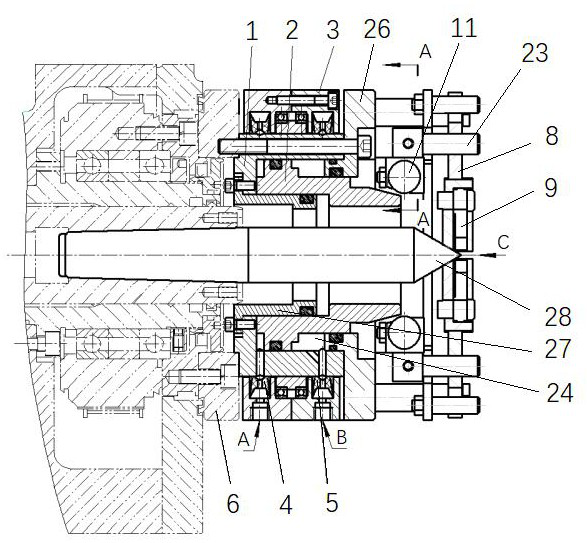

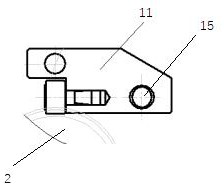

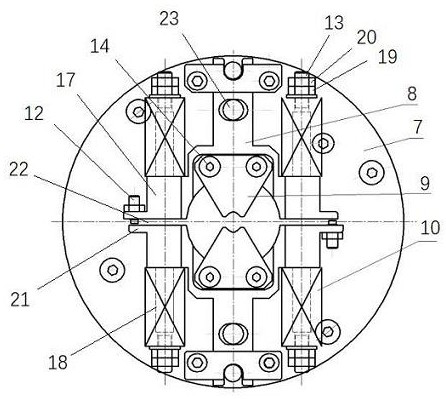

[0027] The fixture includes a connection plate (or chuck) 7 and a plurality of clips (or clamps) that are arranged on the front side of the connection plate and are radially slidably connected with the connection plate (a movable connection that only allows radial movement). The rotary cylinder is arranged axially, and the front part of the piston body 2 is conical (truncated cone), extending from the front end of the cylinder body of the rotary cylinder, and the rear side of the connecting plate is provided with multiple A radial transmission member (or drive member) 11 whose radial inner side can be in pressure contact with the front cone surface of the piston body, the radial transmission member is radially and movably connected with the connecting plate (allowing a diameter The radial transmission part corresponds to the clamping part one by one and adopts the same circumferential distribution method as the clamping part, and the radial outer ends of the radial transmission...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com