Automatic assembling line for motors

An assembly line, automatic technology, applied in the direction of electromechanical devices, electric components, manufacturing motor generators, etc., can solve the problems that the assembly quality of the automatic assembly line of the motor cannot be well guaranteed, the motor automation has not been realized, and the stability of the assembly quality is poor. Achieve the effects of improving assembly quality, saving labor, and improving the quality of pressing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] The present invention will be further described below in conjunction with the accompanying drawings.

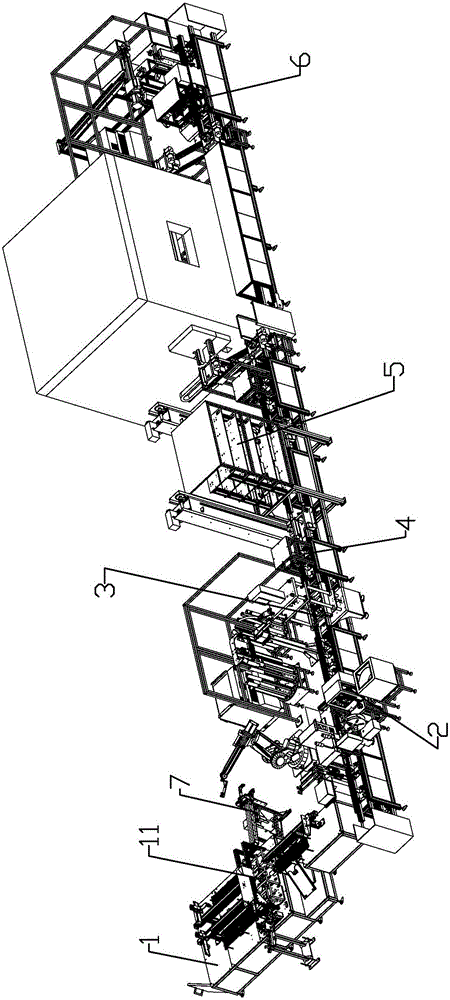

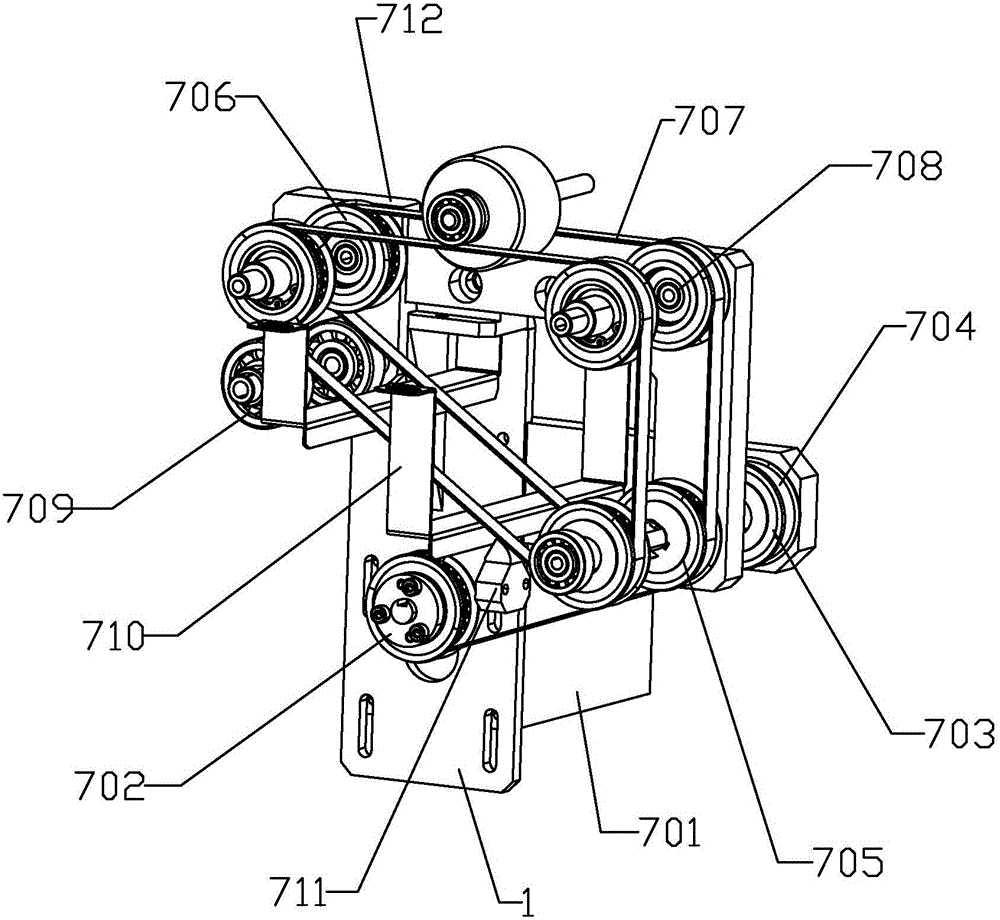

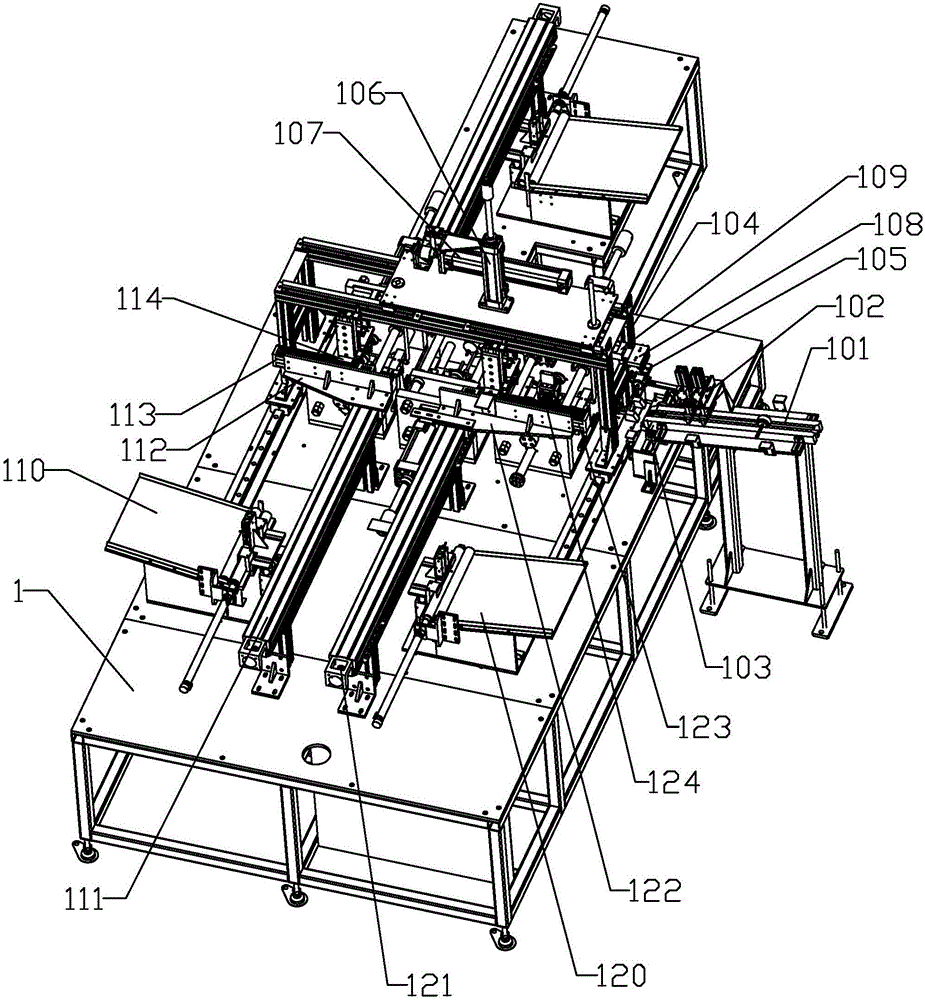

[0054] according to figure 1 As shown, the motor automatic assembly production line of the present invention mainly includes a frame 1, a circuit controller, an automatic transmission belt, a synchronous oiling device 7 for motor rotor bearing positions, an automatic press-fitting device 11 for motor rotor bearings, and an automatic material distribution and detection device for elastic washers 2. Motor end cover pressing device 3. Automatic detection device for motor bearing clearance 4. Automatic motor aging test device 5 and automatic glue dispensing air dryer for motor 6. Among them, the automatic transmission belt, the motor rotor bearing position synchronous oiling device 7, the motor rotor bearing automatic press-fitting device 11, the elastic gasket automatic material distribution and detection device 2, the motor end cover press-fitting device 3, the motor bea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com