Patents

Literature

49results about How to "Avoid overpacking" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

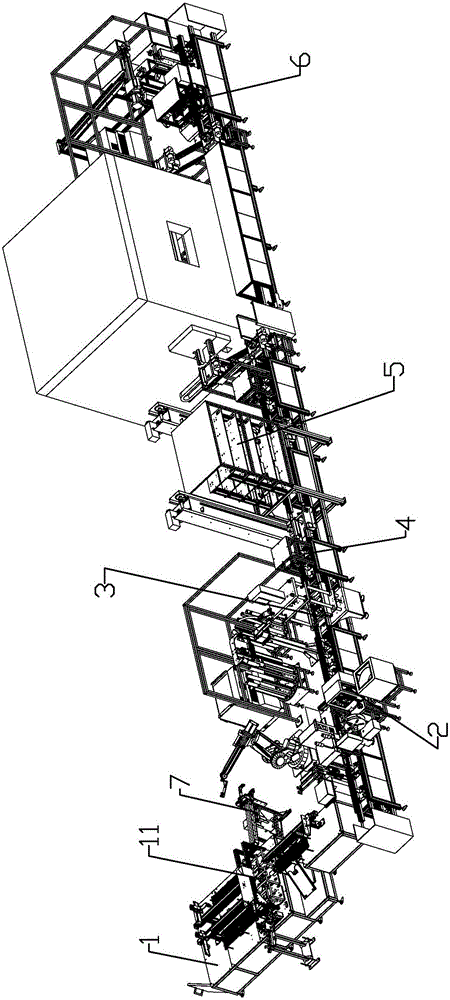

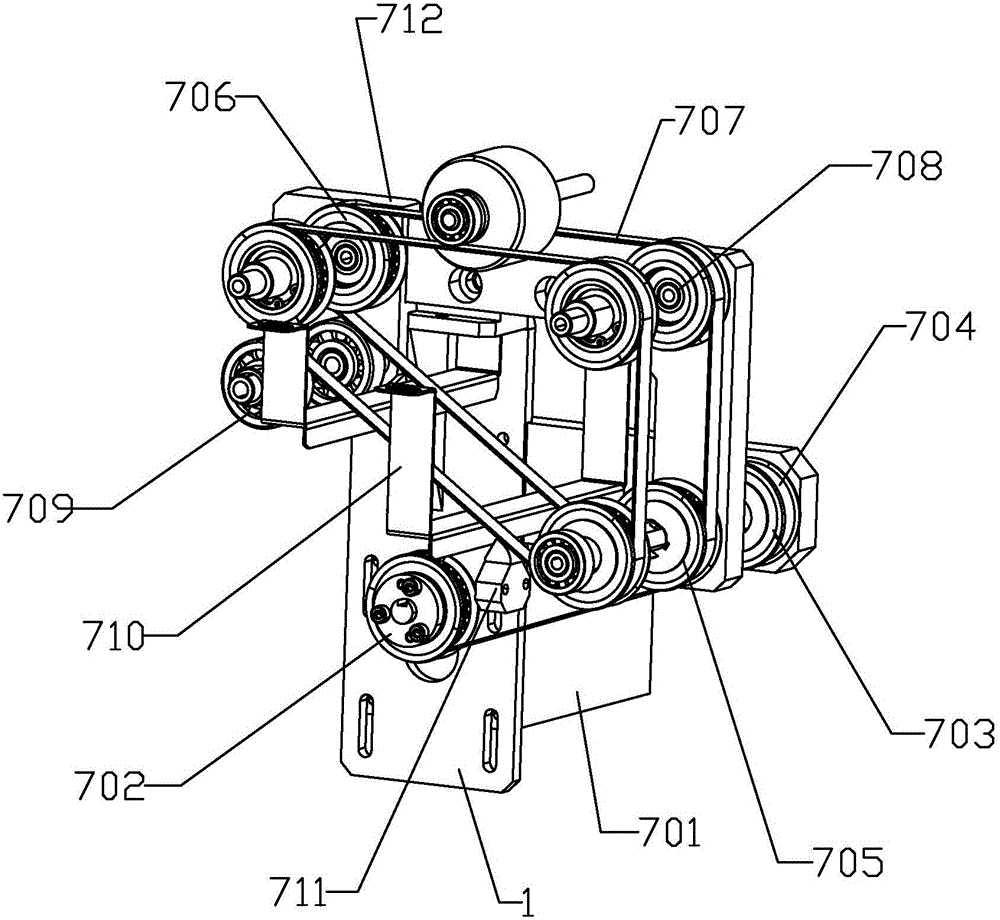

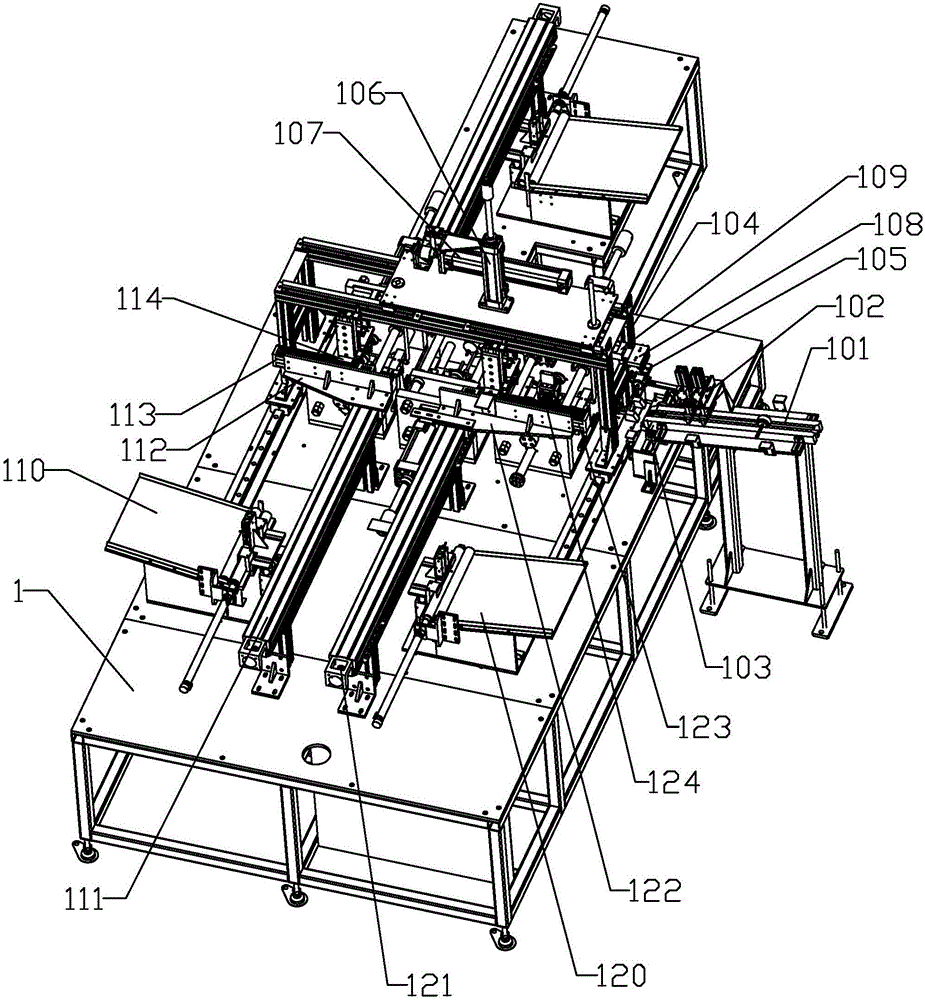

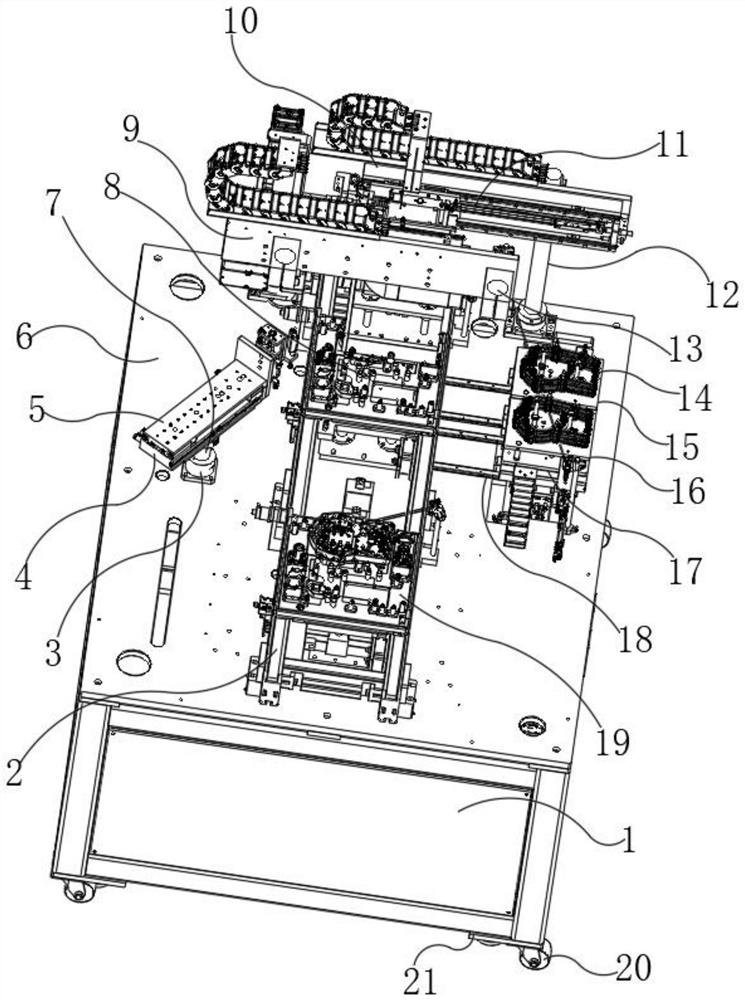

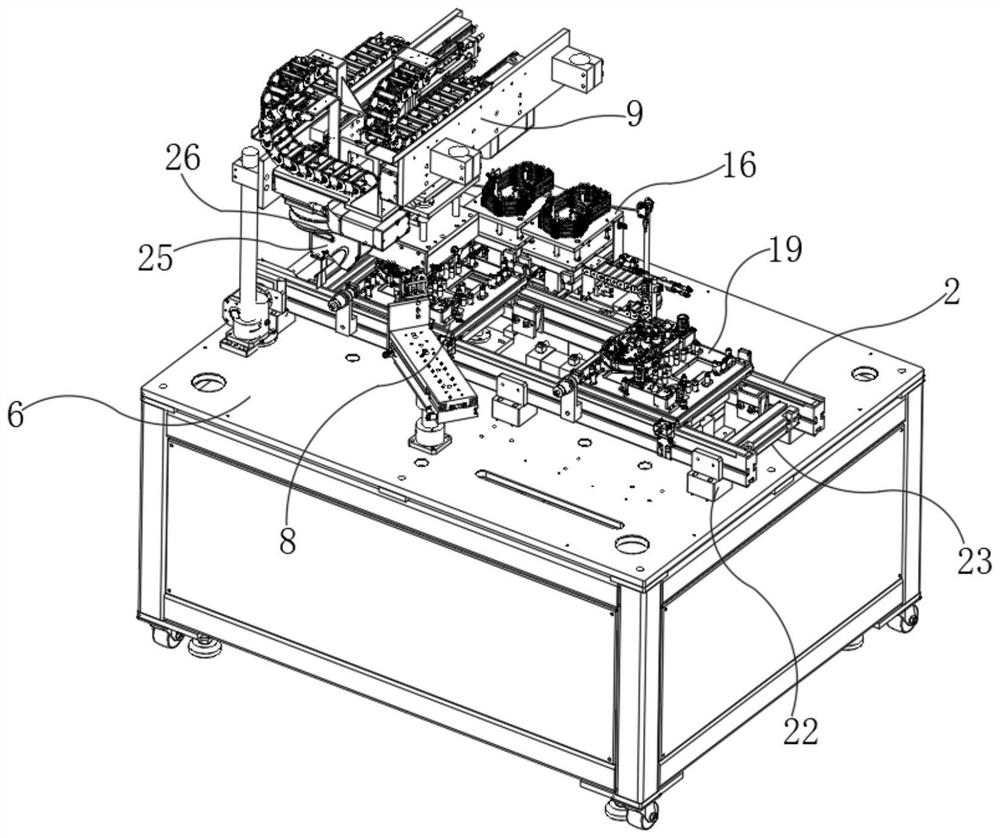

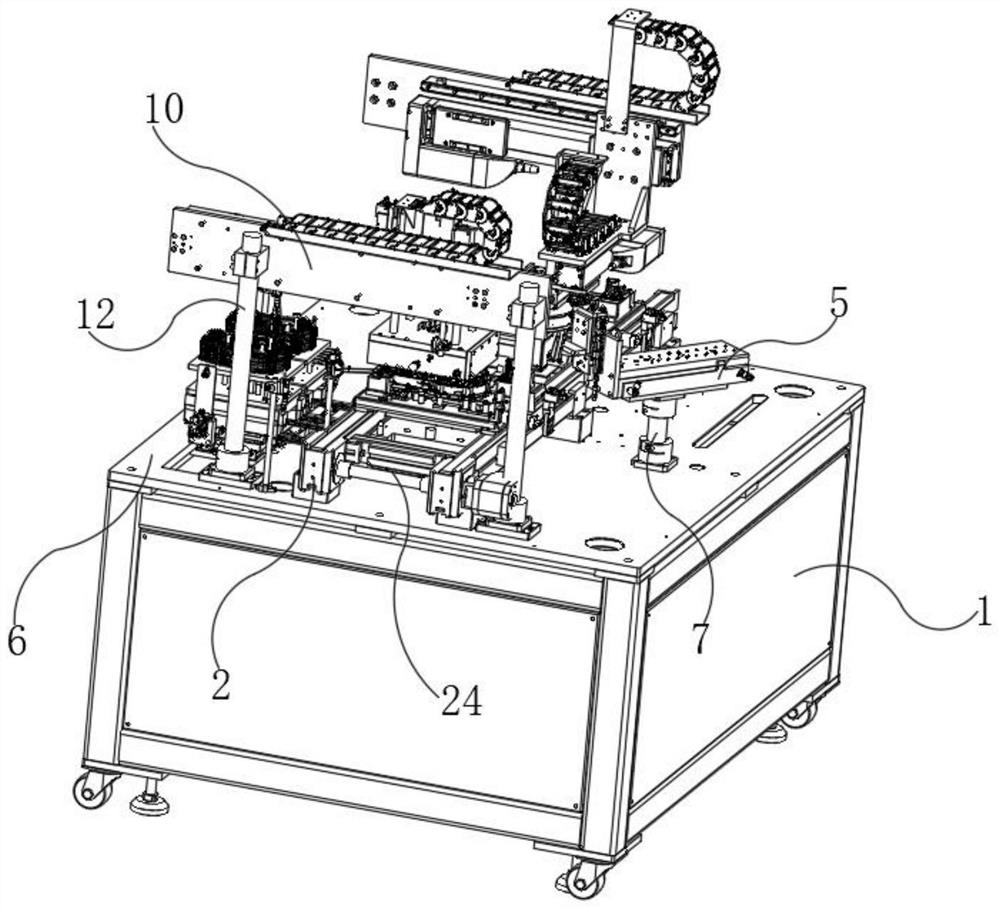

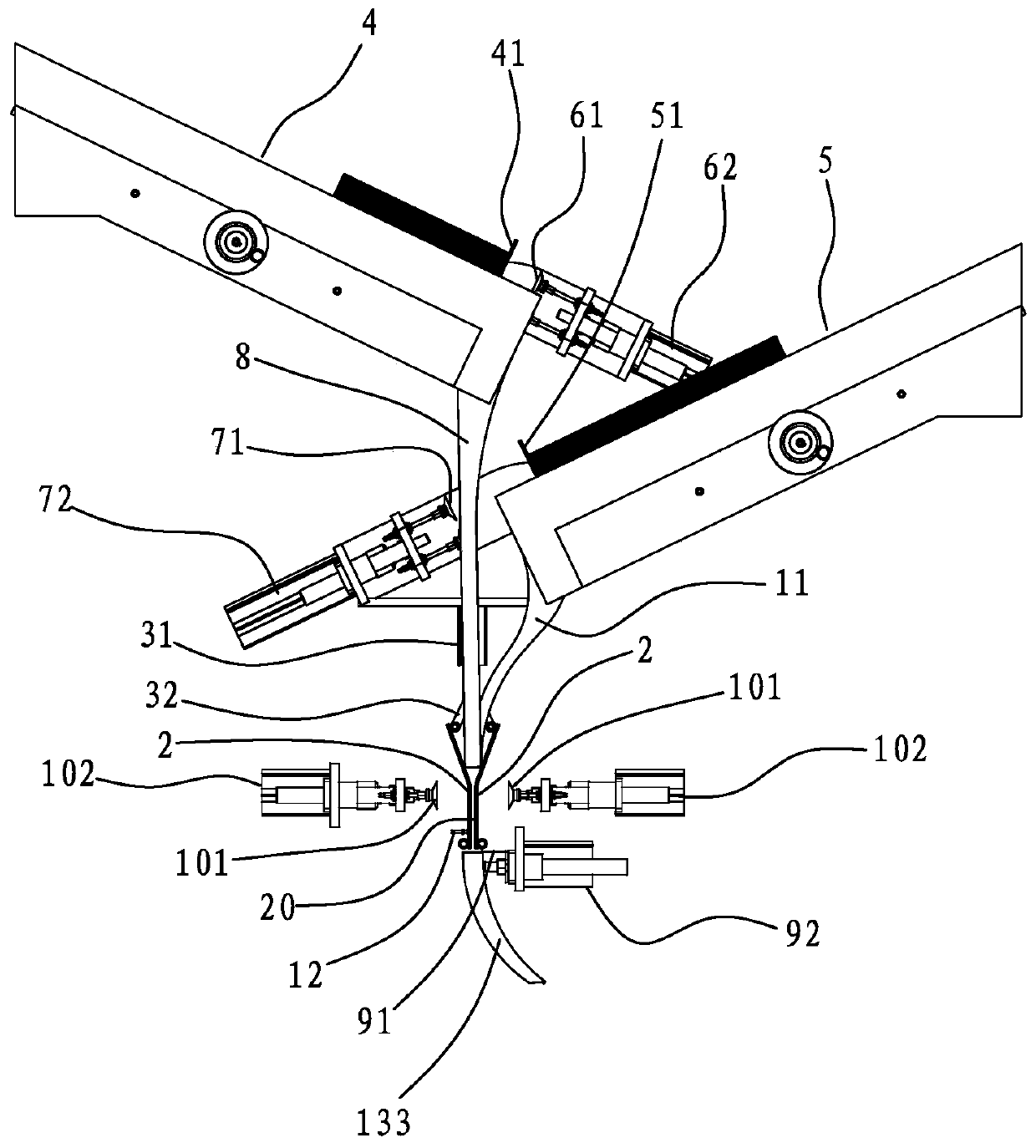

Automatic assembling line for motors

ActiveCN105871129AHigh degree of automationImprove assembly qualityManufacturing dynamo-electric machinesElectricityEngineering

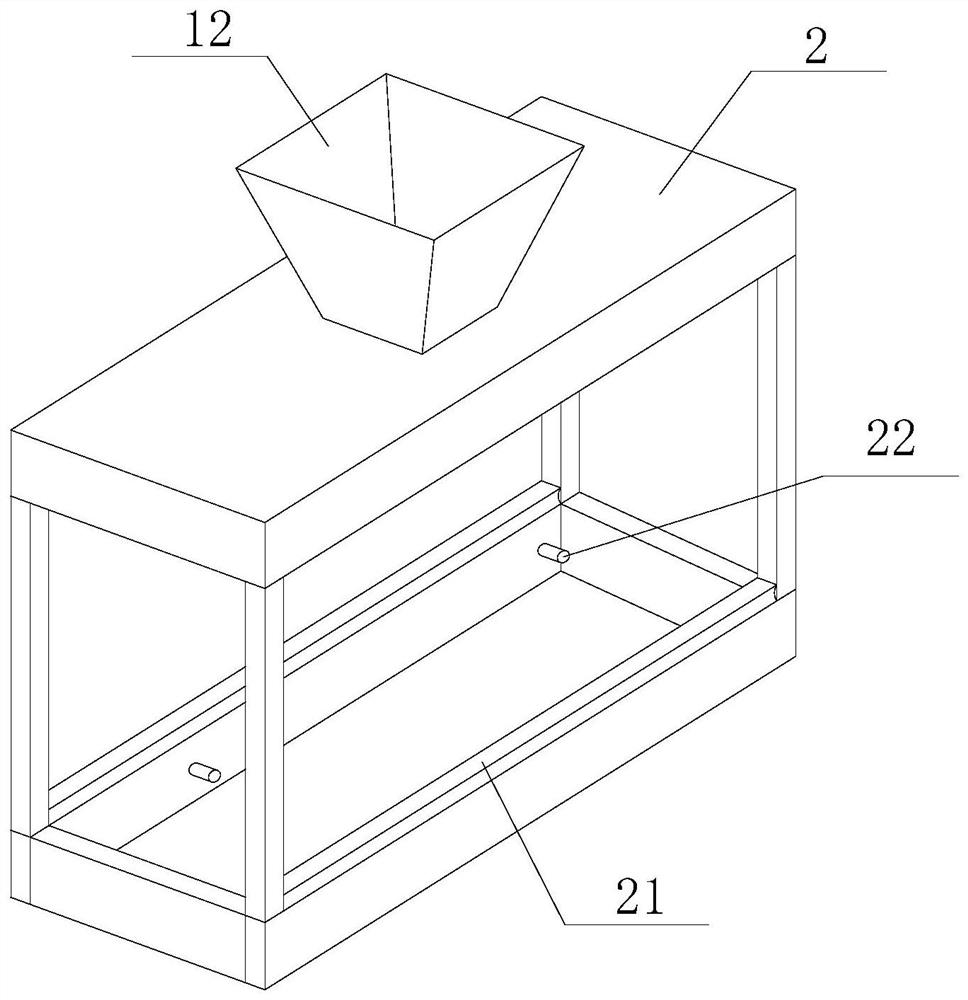

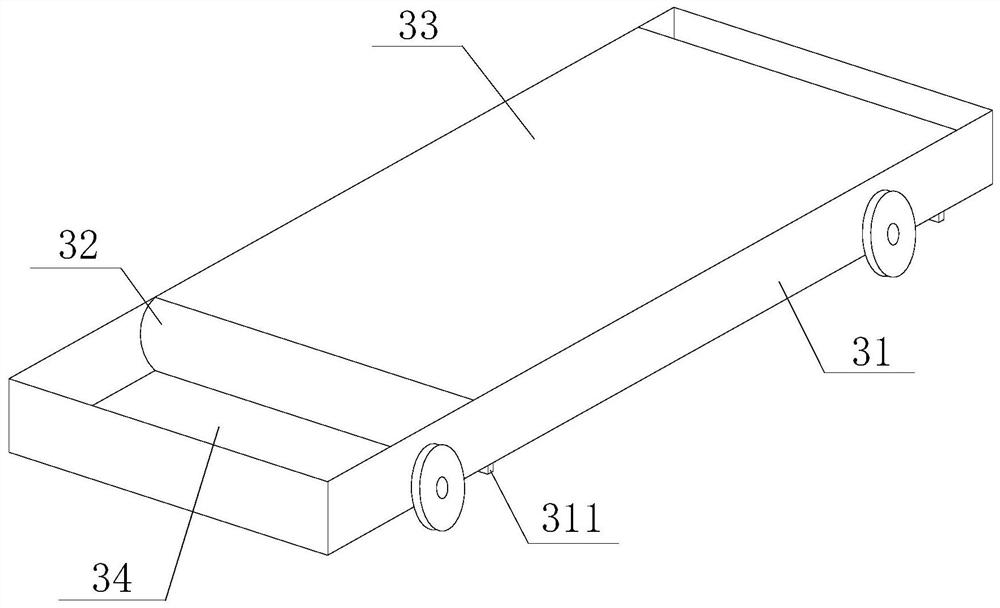

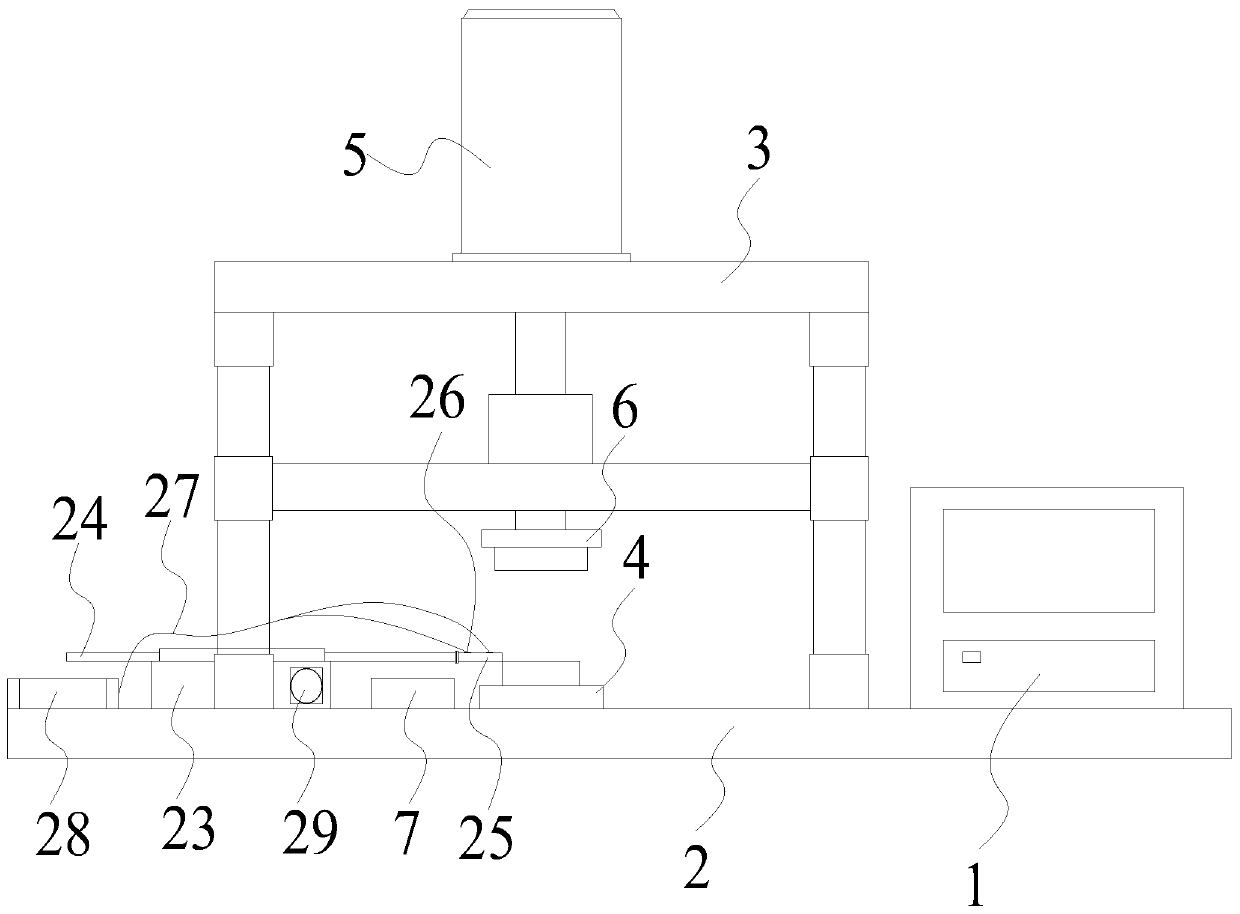

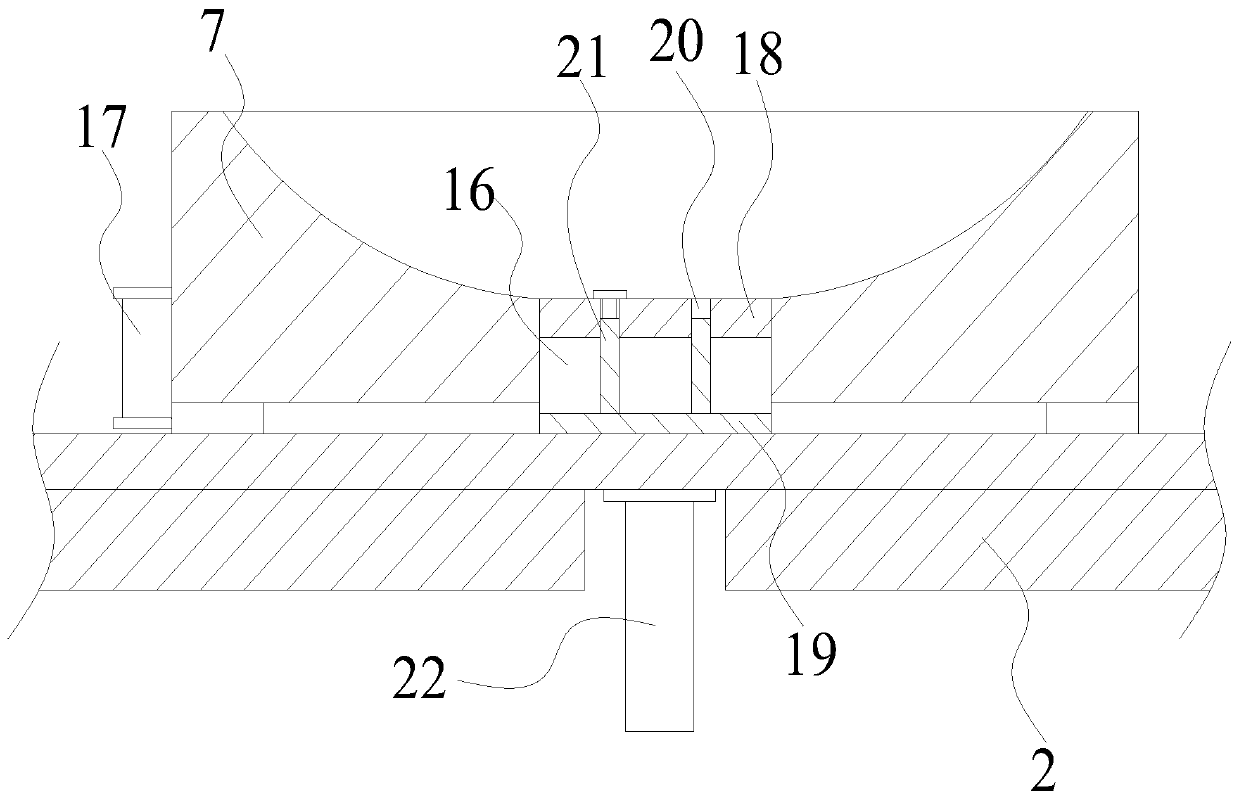

The invention discloses an automatic assembling line for motors. The automatic assembling line for the motors comprises a frame, an automatic conveying belt, a motor rotor bearing bit synchronization oiling device, an automatic motor rotor bearing press-fitting device, an automatic spring washer distributing and detecting device, a motor end cap press-fitting device, an automatic motor bearing gap detecting device, an automatic motor ageing testing device and an automatic gluing air dryer for the motors, wherein the automatic conveying belt which is electrically connected with a circuit controller is arranged on the frame; and the motor rotor bearing bit synchronization oiling device, the automatic motor rotor bearing press-fitting device, the automatic spring washer distributing and detecting device, the motor end cap press-fitting device, the automatic motor bearing gap detecting device, the automatic motor ageing testing device and the automatic gluing air dryer for the motors are successively connected together by the automatic conveying belt and are electrically connected with the circuit controller. The automatic assembling line for the motors is high in assembling stability and good in assembling quality, and testing automation of components of the motors can be realized.

Owner:GUANGDONG LXD ROBOTICS CO LTD

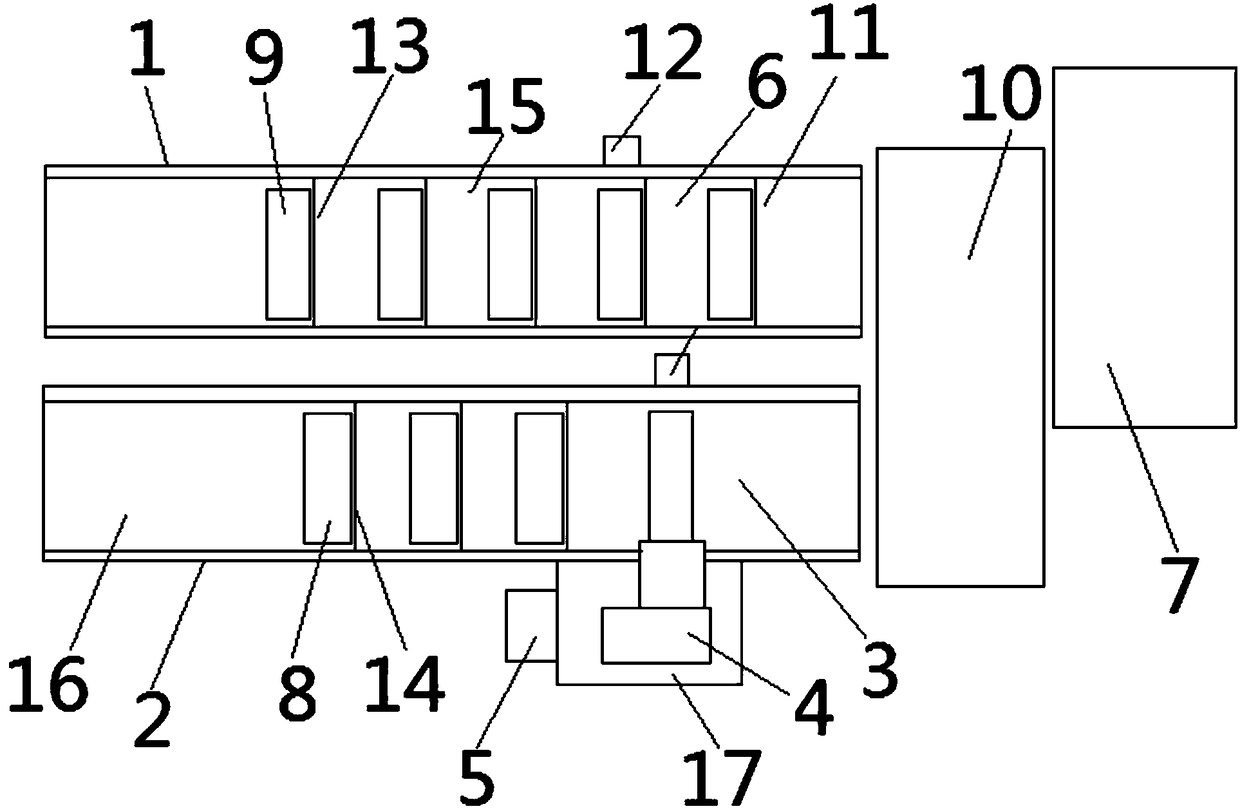

Automatic packaging system for bagging small-sized baked food in independent inflation mode

ActiveCN103587741AAvoid overpackingAvoid underpackingPackaging under vacuum/special atmosphereIndividual articlesBaked goodsEngineering

The invention discloses an automatic packaging system for bagging small-sized baked food in an independent inflation mode. The automatic packaging system comprises a material supply device, a material management device and a bagging device. The material supply device comprises a guiding and monitoring device. The material management device comprises a positioning device and a mechanical arm. The bagging device comprises a bag opening device, a bag feeding device and a material pushing device. The input end of the automatic packaging system is connected with the output end of equipment for bagging the small-sized baked food in an independent inflation mode. When the small-sized baked food is conveyed into the automatic packaging system at a certain speed, two symmetric packaging stations can accurately, correctly and automatically complete a series of processes like gas leakage checking, sequential arrangement, counting and bagging, missing detection and wrong detection of leaking inflation packaging bags can be effectively avoided, excessive independent packaging or insufficient independent packaging of food in the whole-bag packaging process can also be avoided, the problem that food in the whole bag is not sequentially ordered is solved, and manpower during each set period can be greatly economized on. The automatic packaging system has the advantages of being simple in structure, high in production efficiency, low in processing cost and the like.

Owner:无锡昌顺烘焙器具有限公司

Petrochemical engineering intelligent loading and unloading vehicle system and using method

InactiveCN110288748AExact searchReduce waiting timeLiquid transferring devicesIndividual entry/exit registersElectricityManagement unit

The invention discloses a petrochemical engineering intelligent loading and unloading vehicle system, and relates to the technical field of petrochemical engineering equipment. The system comprises a control unit, an information input end, an access control unit, an information identification terminal, a vehicle queuing management unit, a weighing unit and a goods transfer unit; and the access control unit, the information identification terminal, the vehicle queuing management unit, the weighing unit and the goods transfer unit are all electrically connected with the control unit. By using the system, the goods transfer efficiency is improved, and the waiting time of a truck is shortened; IC card data and order data are in one-to-one correspondence, wrong loading, mixed loading, excessive loading and insufficient loading are avoided, and the accuracy of loading and unloading operation is improved.

Owner:上海贵晋新能源科技有限公司

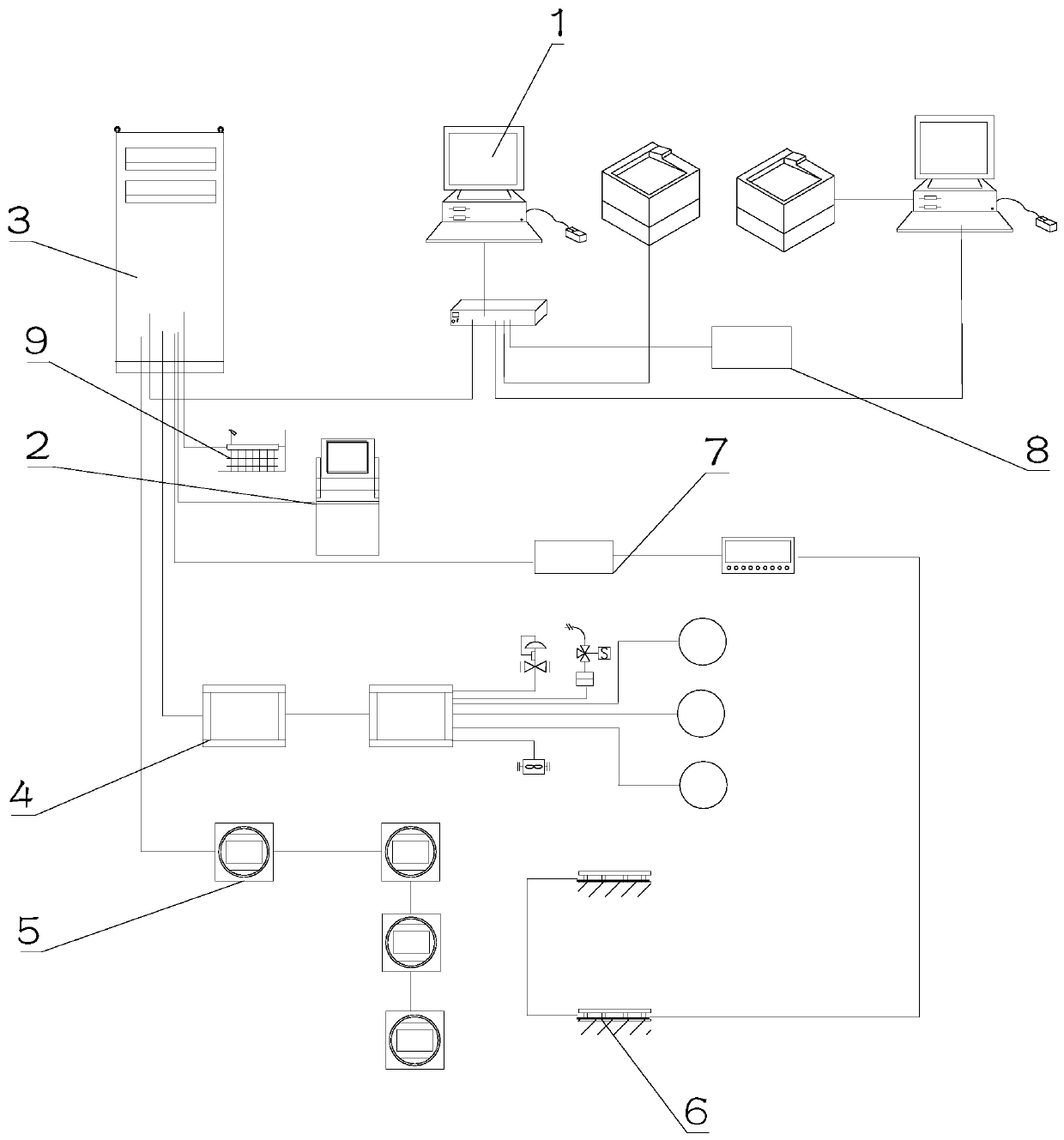

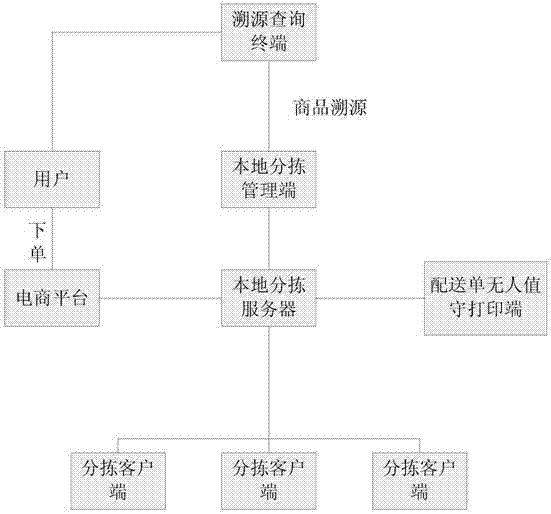

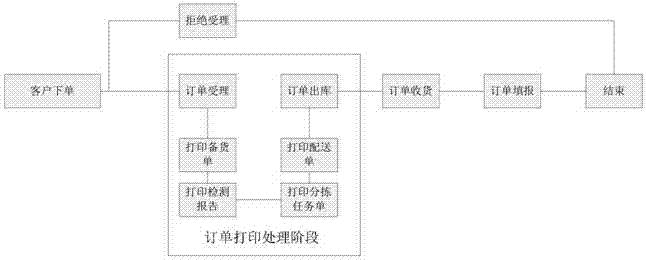

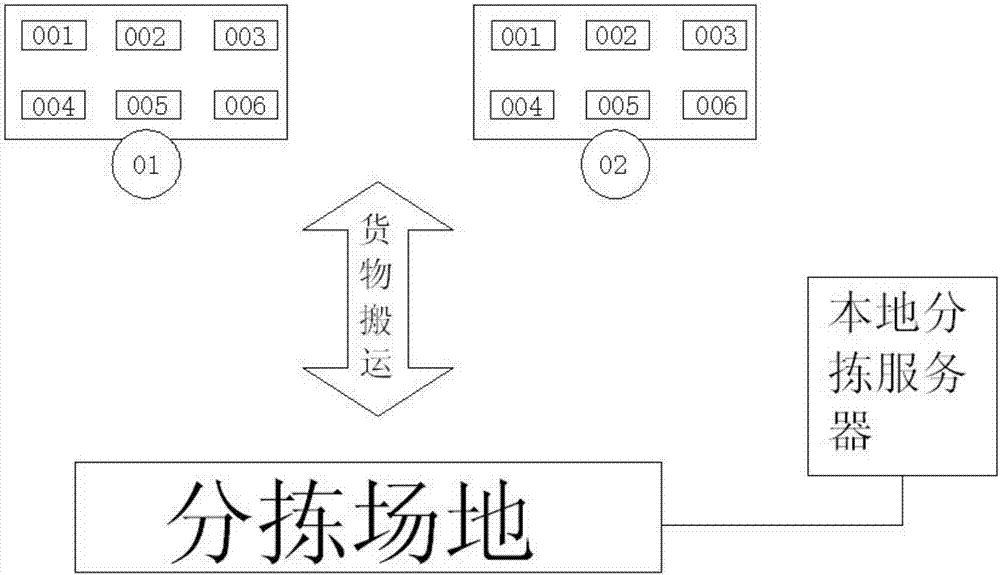

Transaction-based food circulation traceability system

InactiveCN107146093AReduce manual errorsAvoid overpackingBuying/selling/leasing transactionsE-commerceClient-side

A transaction-based food circulation traceability system disclosed by the present invention comprises an e-commerce platform, a local sorting server, a management terminal, a delivery terminal and a sorting client, the e-commerce platform enables the transaction commodities to be numbered via a commodity numbering module and transmits the information to the local sorting server, the local sorting server carries out the trading area numbering on the regions of a city, numbers the commercial tenants of purchasing the commodities in the numbered trading areas and sends the commodity information, the trading area information and the commercial tenant information to the sorting client, and the sorting client determines the types and weights of the commodities via the commodity information, sorts according to the trading area information and the commercial tenant information, updates the weights of the sorted commodities real-timely, transmits the actual weighing weights to the local sorting server, at the same time, prints the sorting information.

Owner:成都顺点科技有限公司

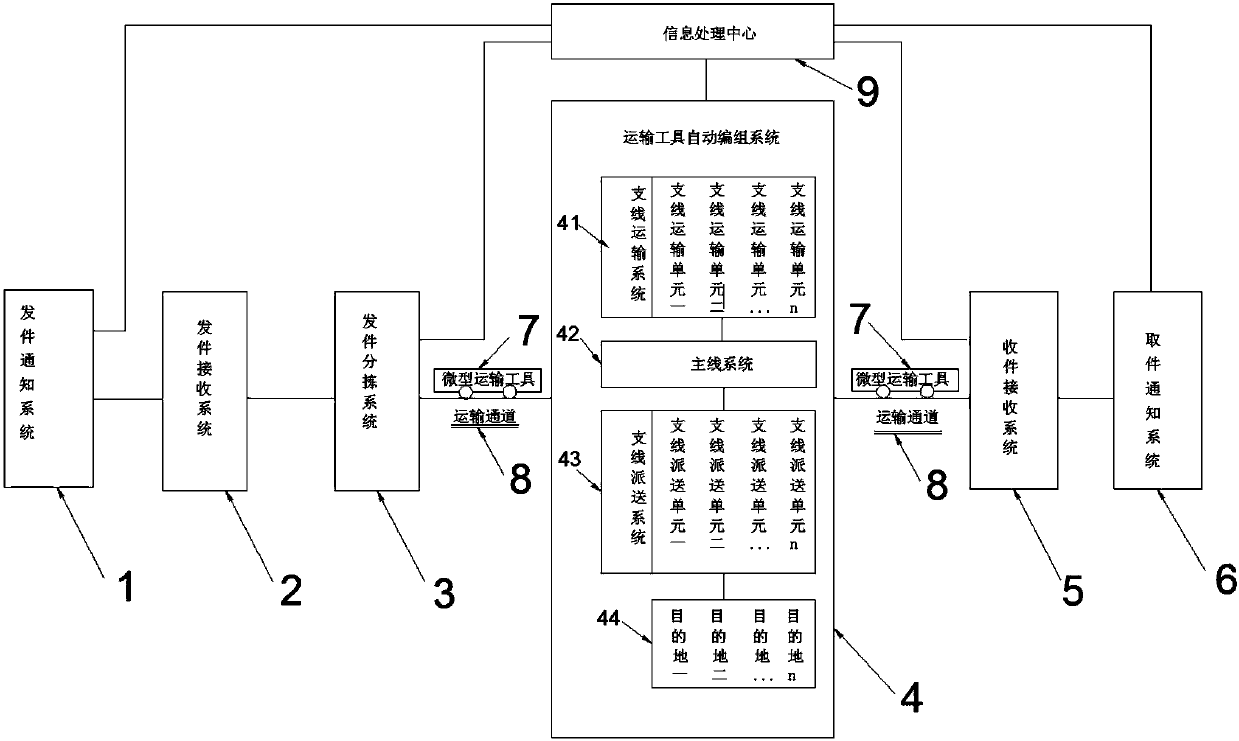

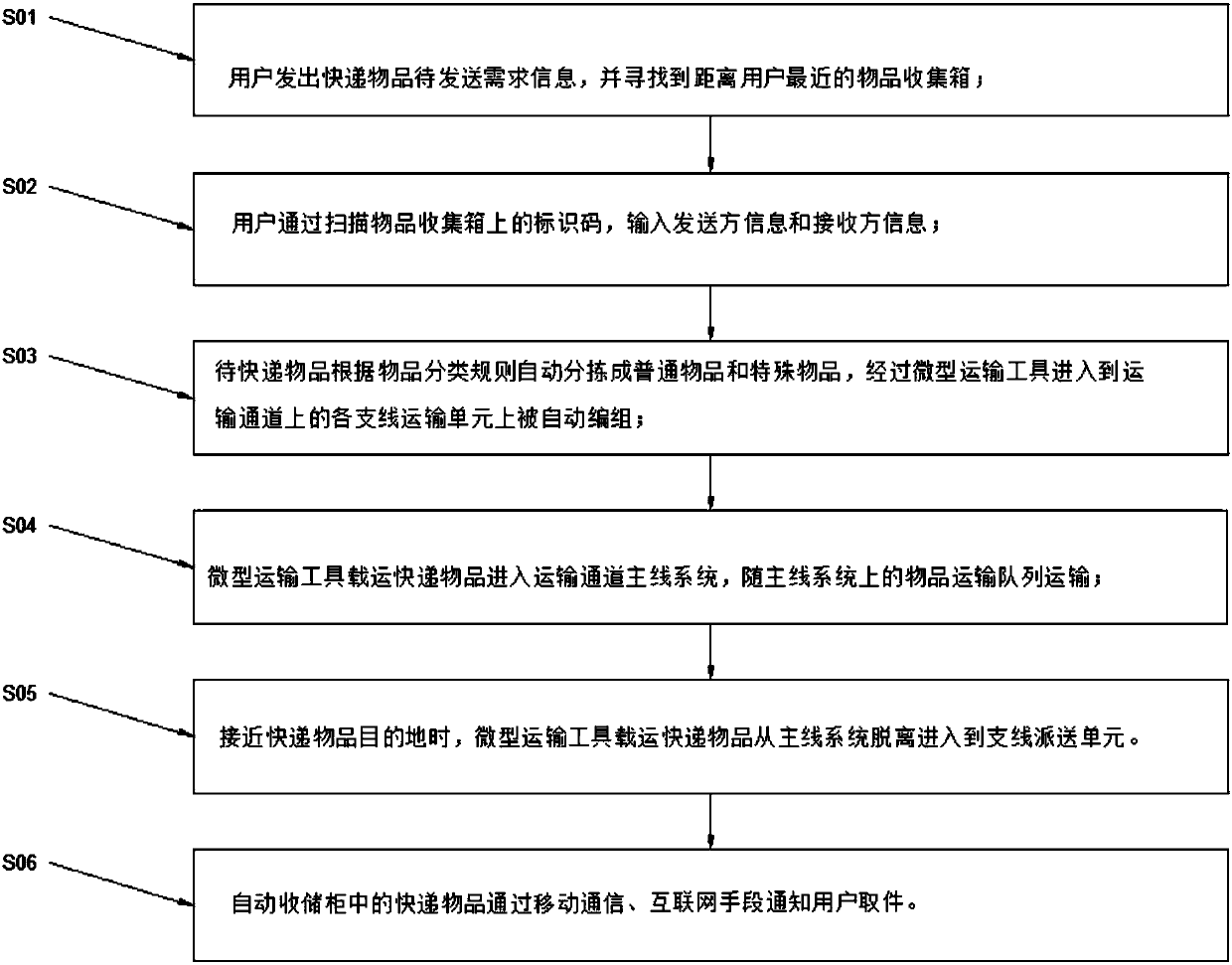

Urban express automatic delivery system and delivery method

InactiveCN107818445AAvoid overpackingAvoid transport risks such as transport rolloverCo-operative working arrangementsLogisticsInformation processingRoad surface

The invention discloses an urban express automatic delivery system. The system comprises a dispatch notification system which is used by a user to send out an express demand, a dispatch receiving system which is used to receive an express item to be sent by the user and the information, a dispatch sorting system which is used to sort out the express item to be sent according to an item classification rule, a micro-transport tool which is used to transport the item according to a transport lane, a transport tool automatic marshalling system which is used to automatically marshal the micro-transport tool according to a marshalling rule, a pick-up receiving system which is used to receive the express item which is transported to a destination through the micro-transport tool, and an information processing center which is used to control and process information generated by the dispatch notification system, the pick-up receiving system, the dispatch sorting system, the micro-transport tool, the transport tool automatic marshalling system and the pick-up receiving system. According to the invention, disadvantages brought by the road vehicle transport of large-scale express items in theprior art are solved, and true unmanned transport is realized by scientific means.

Owner:上海图珠信息科技有限公司

Battery encasing equipment and encasing method

InactiveCN102849277AAvoid disunityAvoid overfilling the batteryPackaging automatic controlSensing by electromagnetic radiationElectrical batteryElectrical and Electronics engineering

Owner:DONGGUAN NVT TECH

Screening device

ActiveCN107098143AAvoid scratchesAvoid wastingConveyorsConveyor partsPattern recognitionProcess efficiency

The invention relates to a screening device. The screening device comprises a discharge unit, a turnover unit and a pickup unit, and further comprises a recognition unit. The obverse side and the reverse side of a material can be accurately judged through the recognition unit, the recognition speed is high, recognition is precise, and thus the problem of low artificial recognition process efficiency is solved. In the artificial recognition process, problems such as visual fatigue and wrong judgment are prone to occurring, obverse side and the reverse side recognition errors generated by artificial recognition can be effectively avoided through the recognition unit, and the percent of pass of products in the subsequent product assembly process is further guaranteed.

Owner:ZHEJIANG SUNNY OPTICAL CO LTD

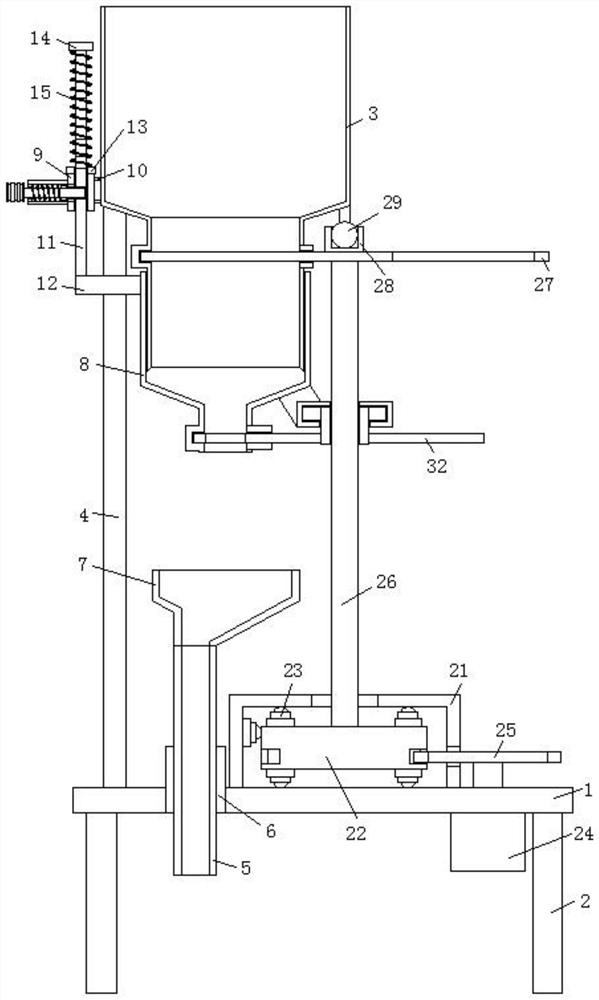

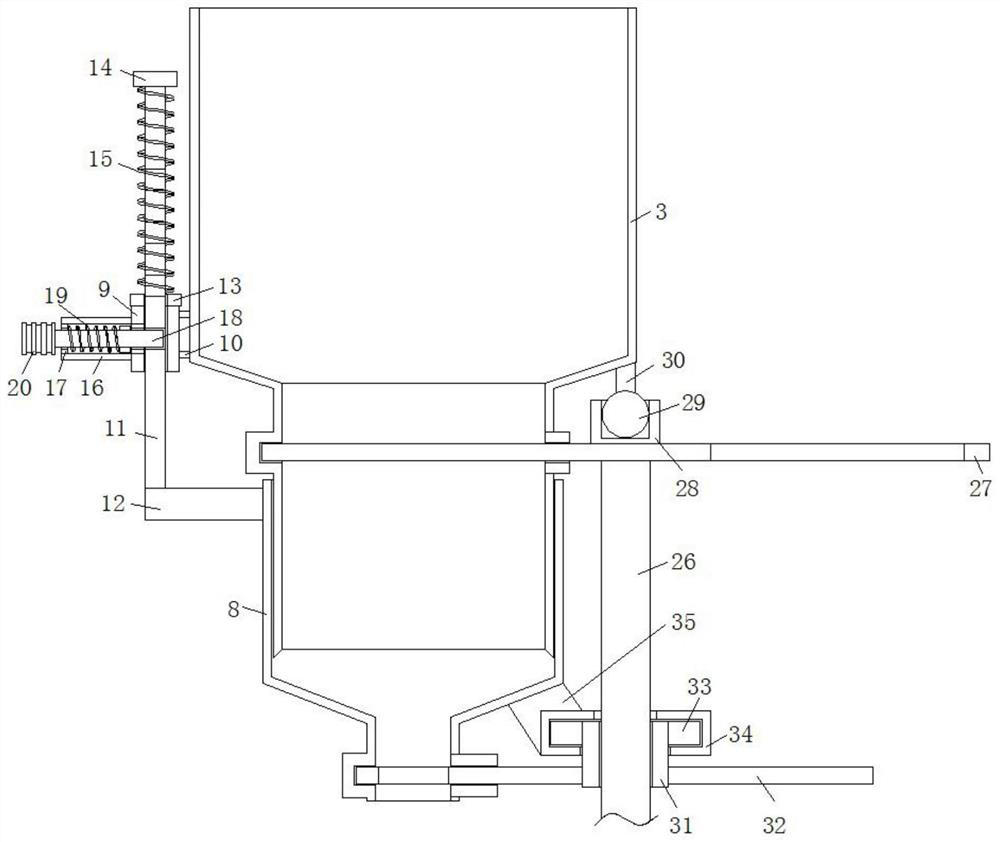

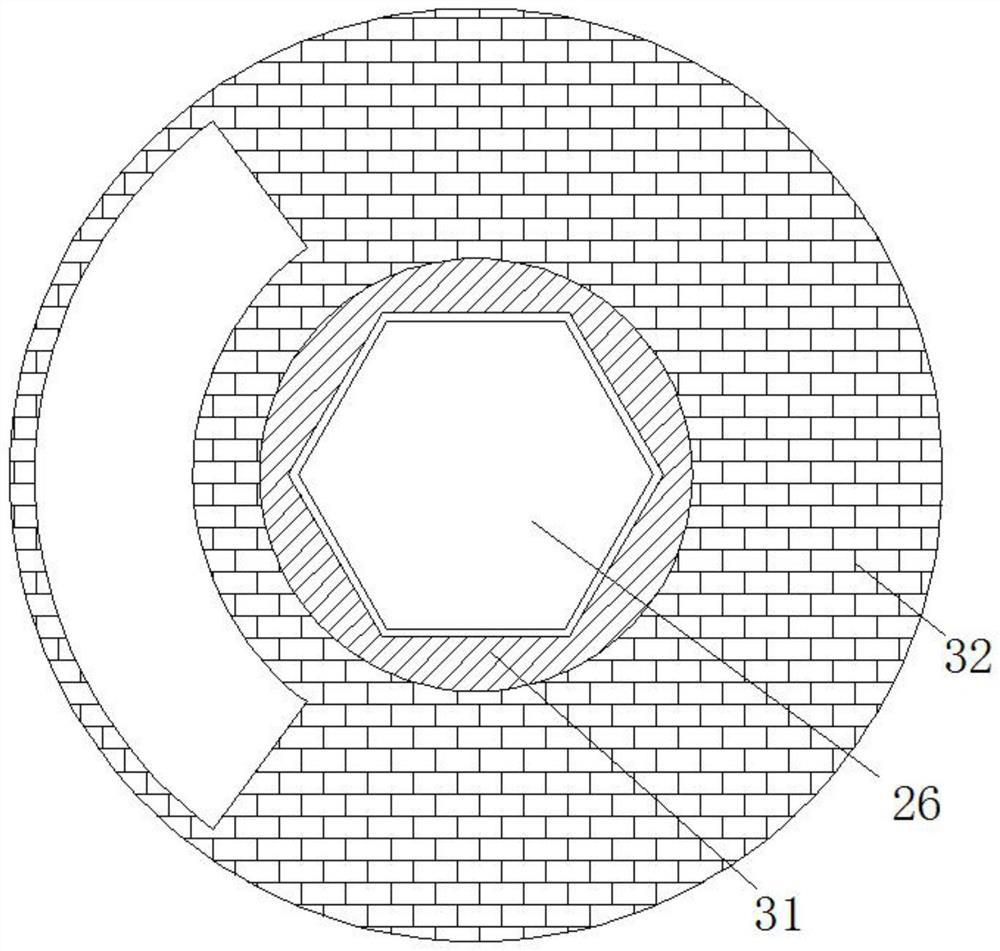

Material control device for bagging during rice processing

The invention discloses a material control device for bagging during rice processing. The device comprises a workbench; support columns are fixedly connected to four corners of the bottom of the workbench; a raw material bin is arranged vertically above the workbench; a support frame is fixedly connected between the bottom of the raw material bin and the workbench; a vertical through hole is formed in the table top of the workbench, and an installation barrel is fixedly connected to the table top of the workbench; a terminal material guide pipe is fixedly connected to the installation barrel;the top of the terminal material guide pipe communicates with a receiving hopper; the bottom of the raw material bin is of a closed structure, and a material control hopper is slidably arranged on theouter side of the raw material bin in a sleeving manner; a track barrel is arranged on one side of the raw material bin; a support arm is fixedly connected between the track barrel and the raw material bin; the inner side of the track barrel slidably penetrates through a track board; and a linkage arm is fixedly connected between the bottom of the track board and the material control hopper. Thematerial control device for bagging during rice processing has the advantages that convenience is brought to use, labor is saved, the production efficiency is improved, and the use requirements of people in production and living are met.

Owner:怀宁县谷丰米业有限公司

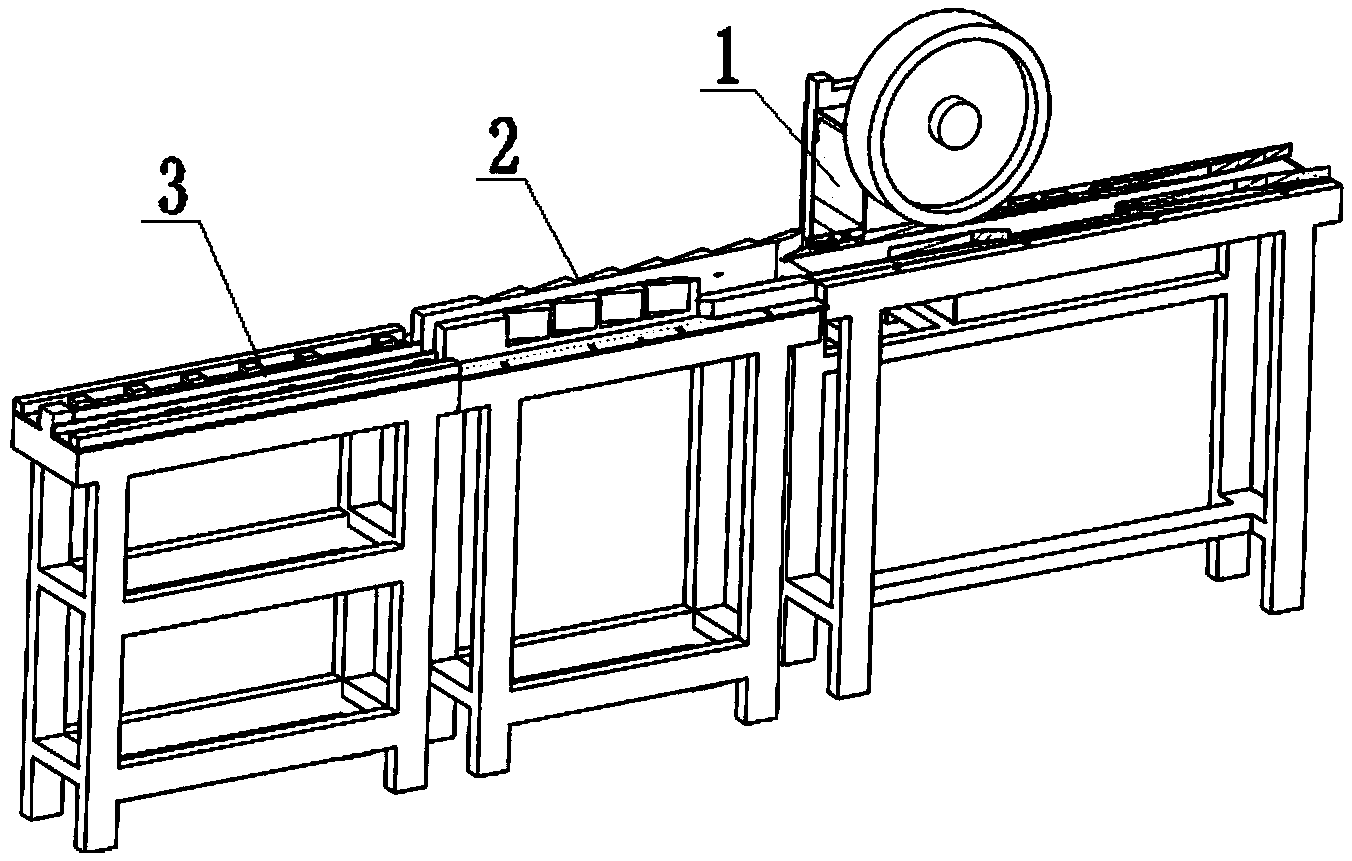

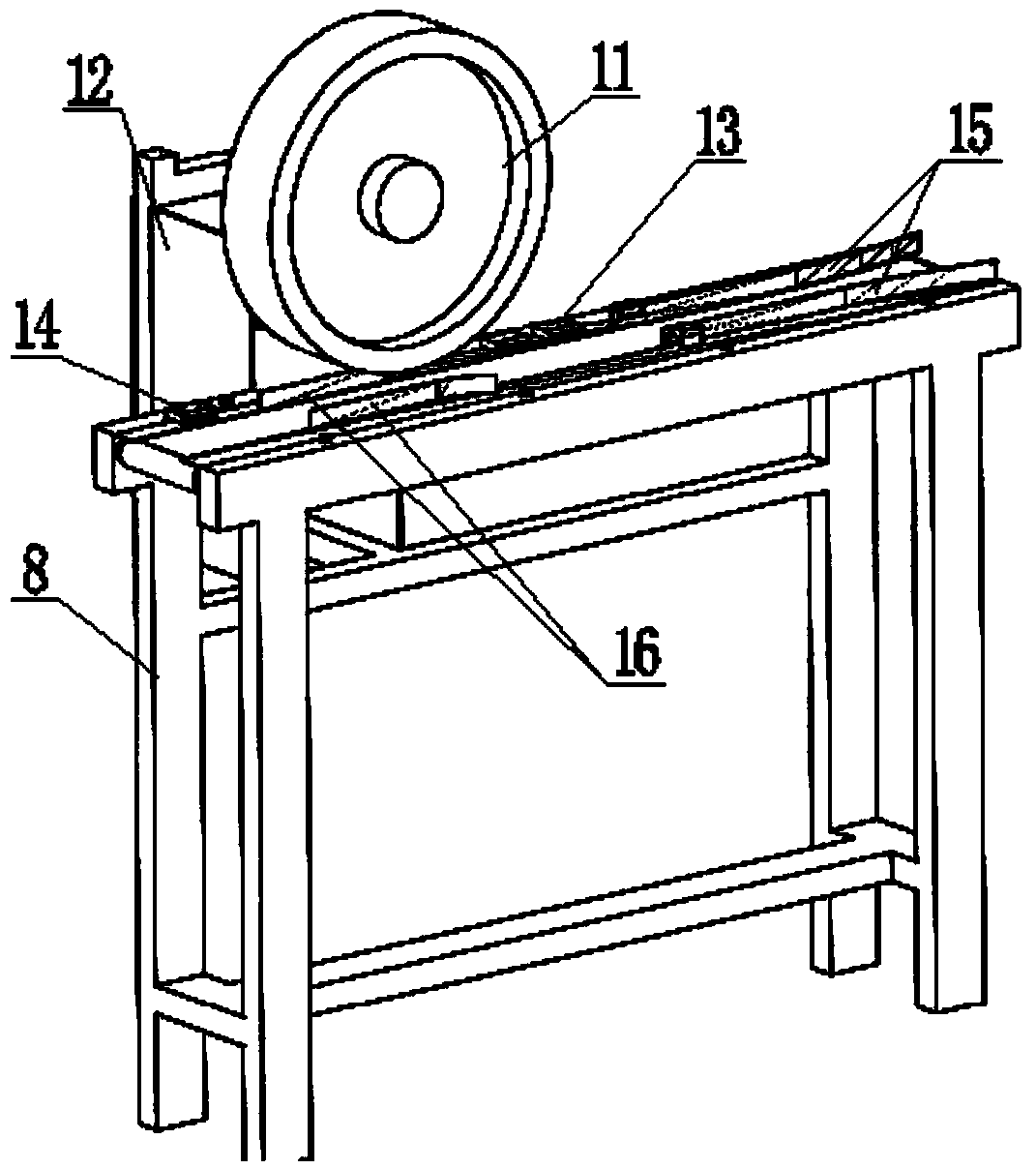

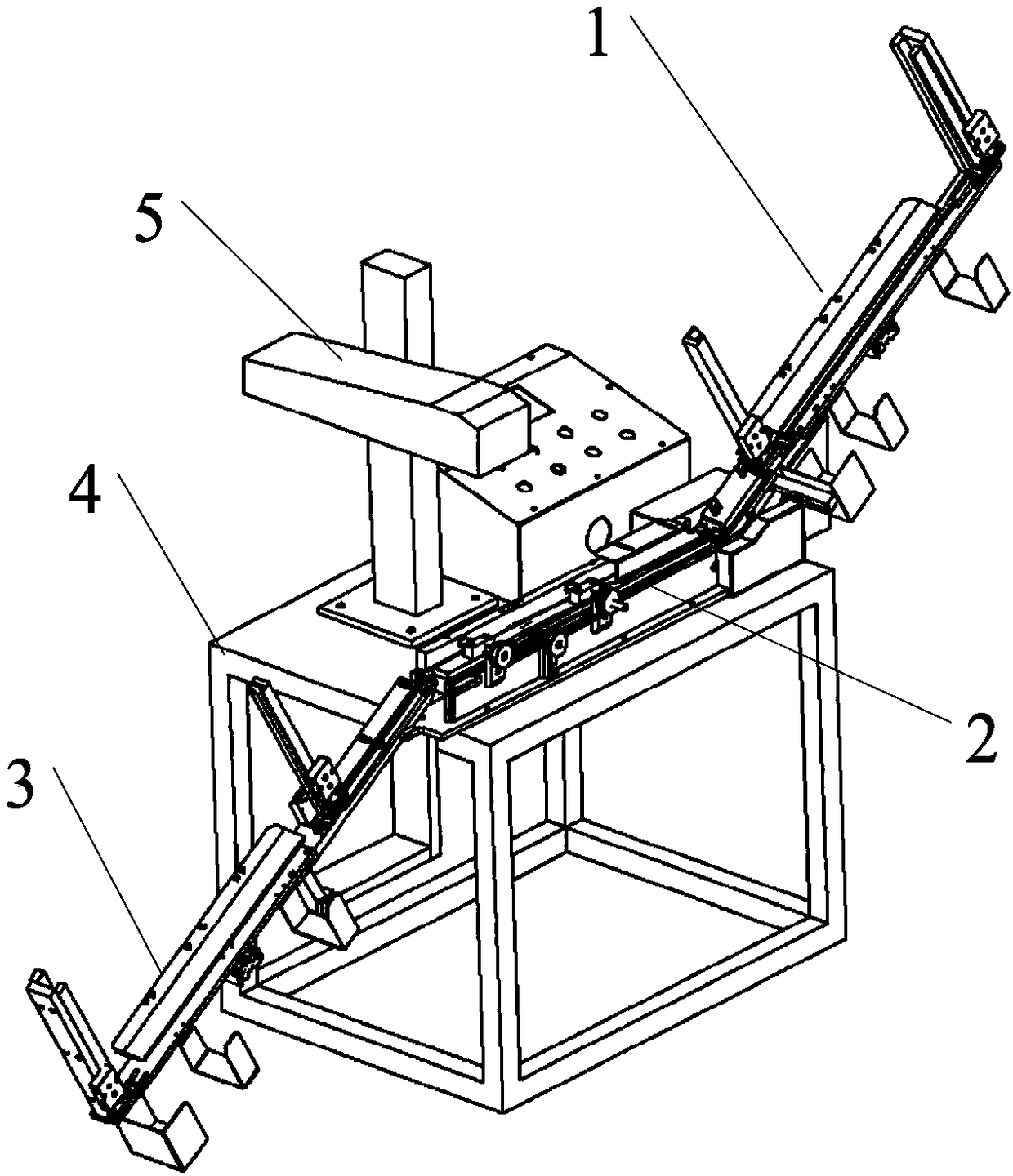

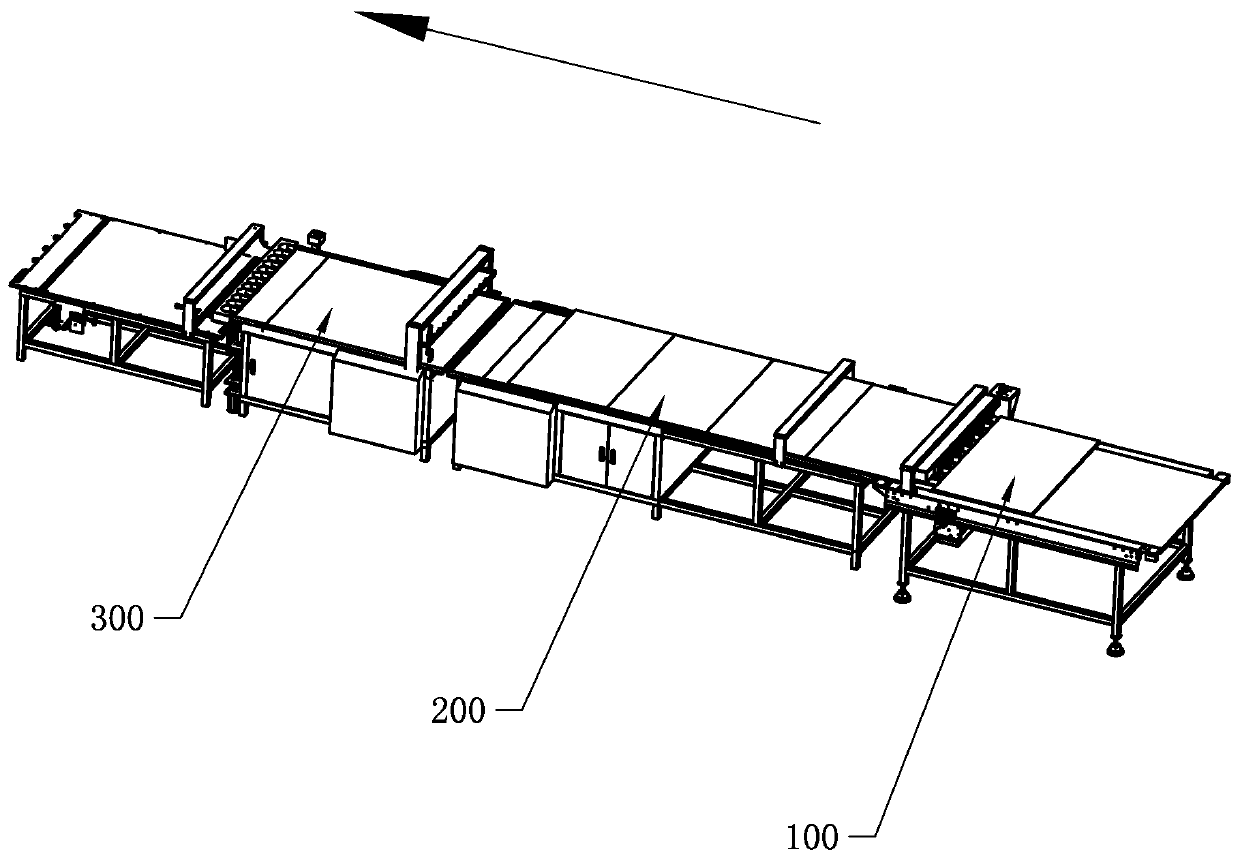

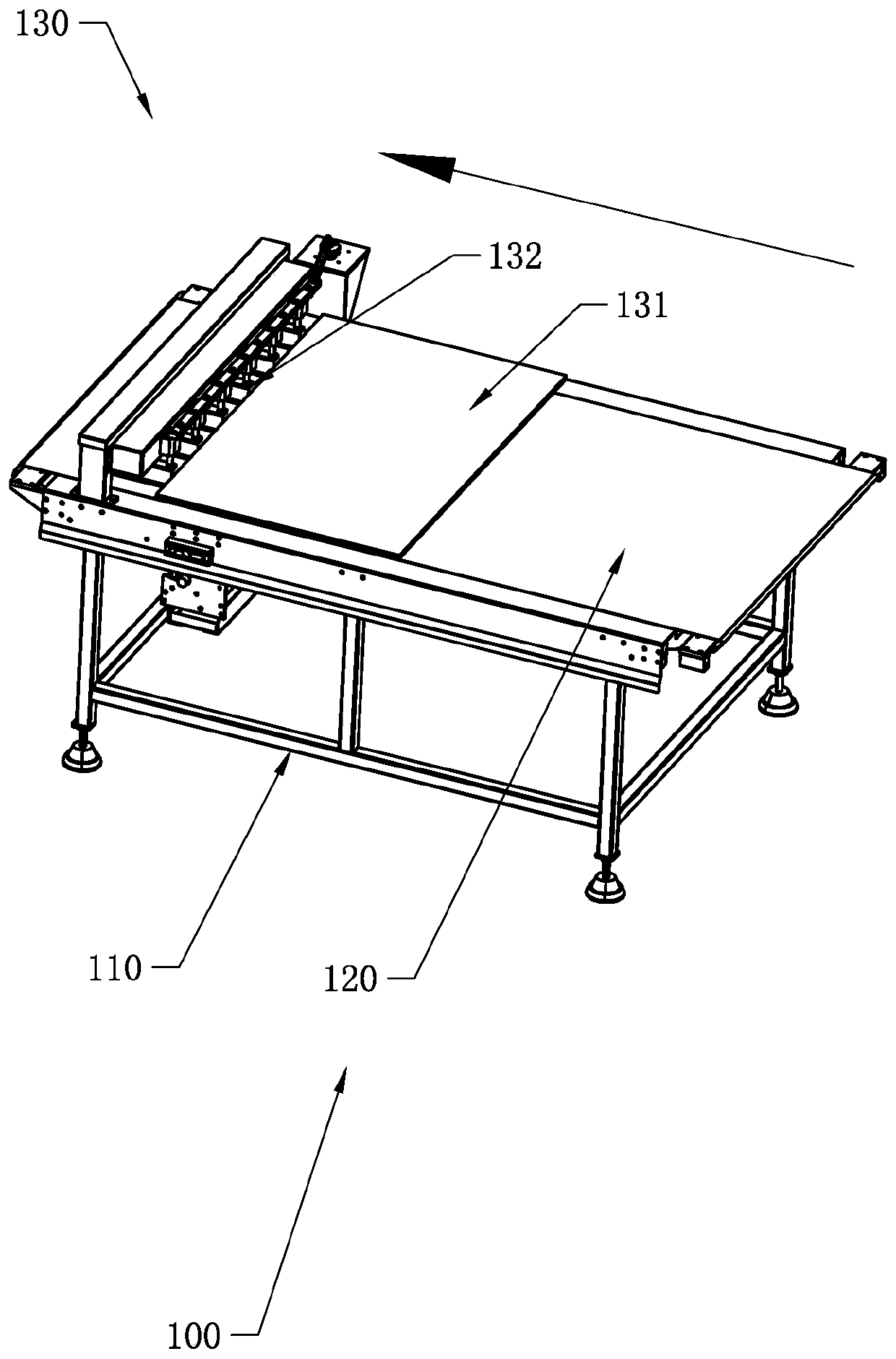

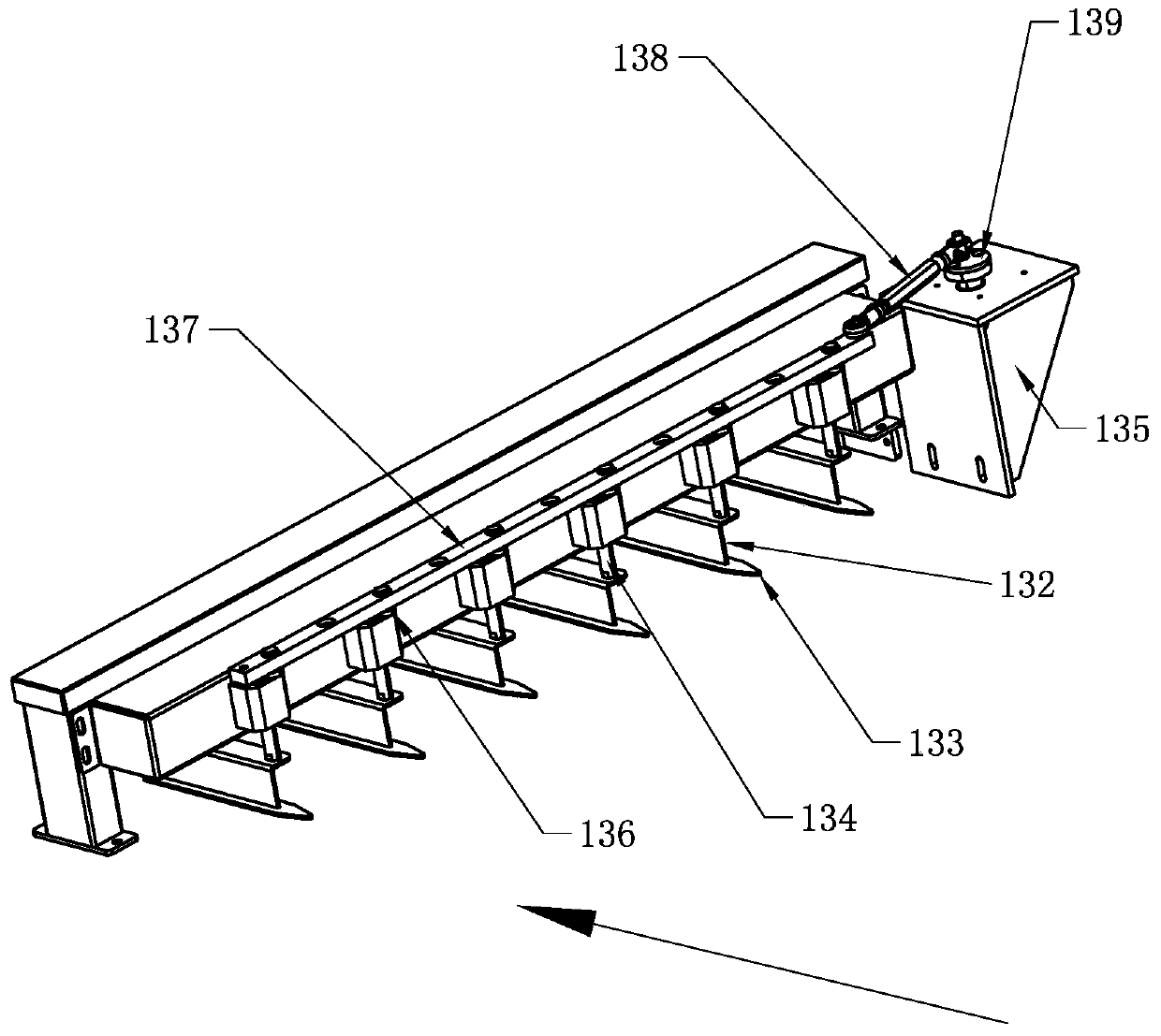

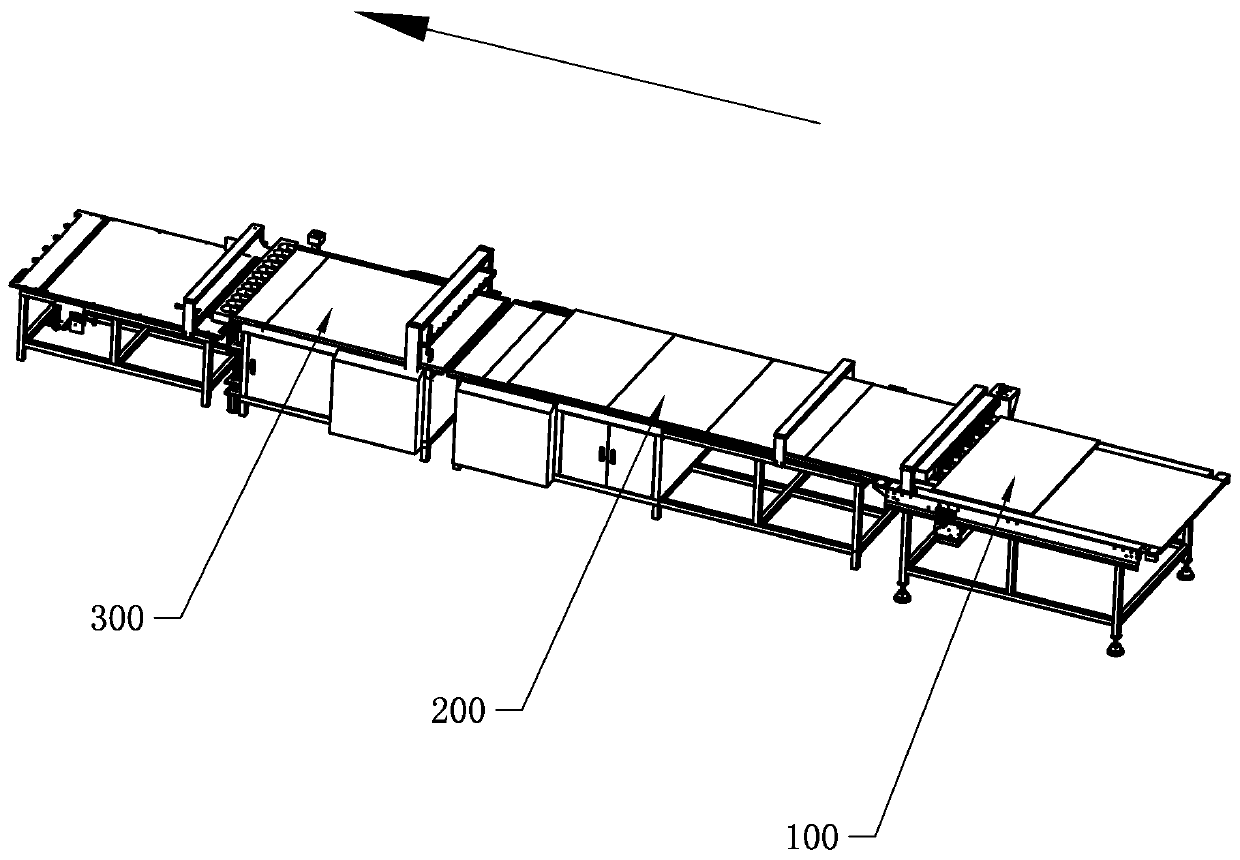

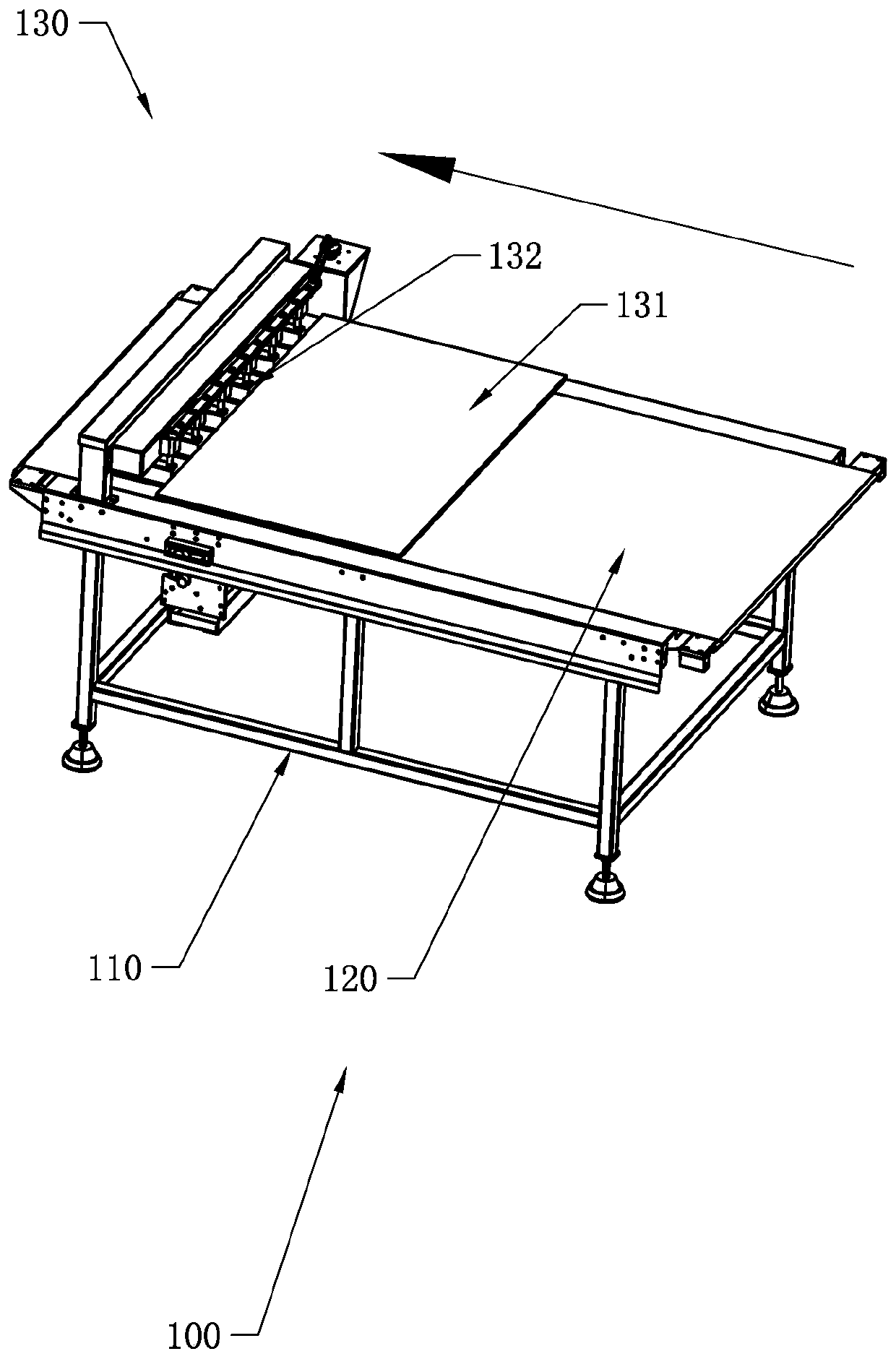

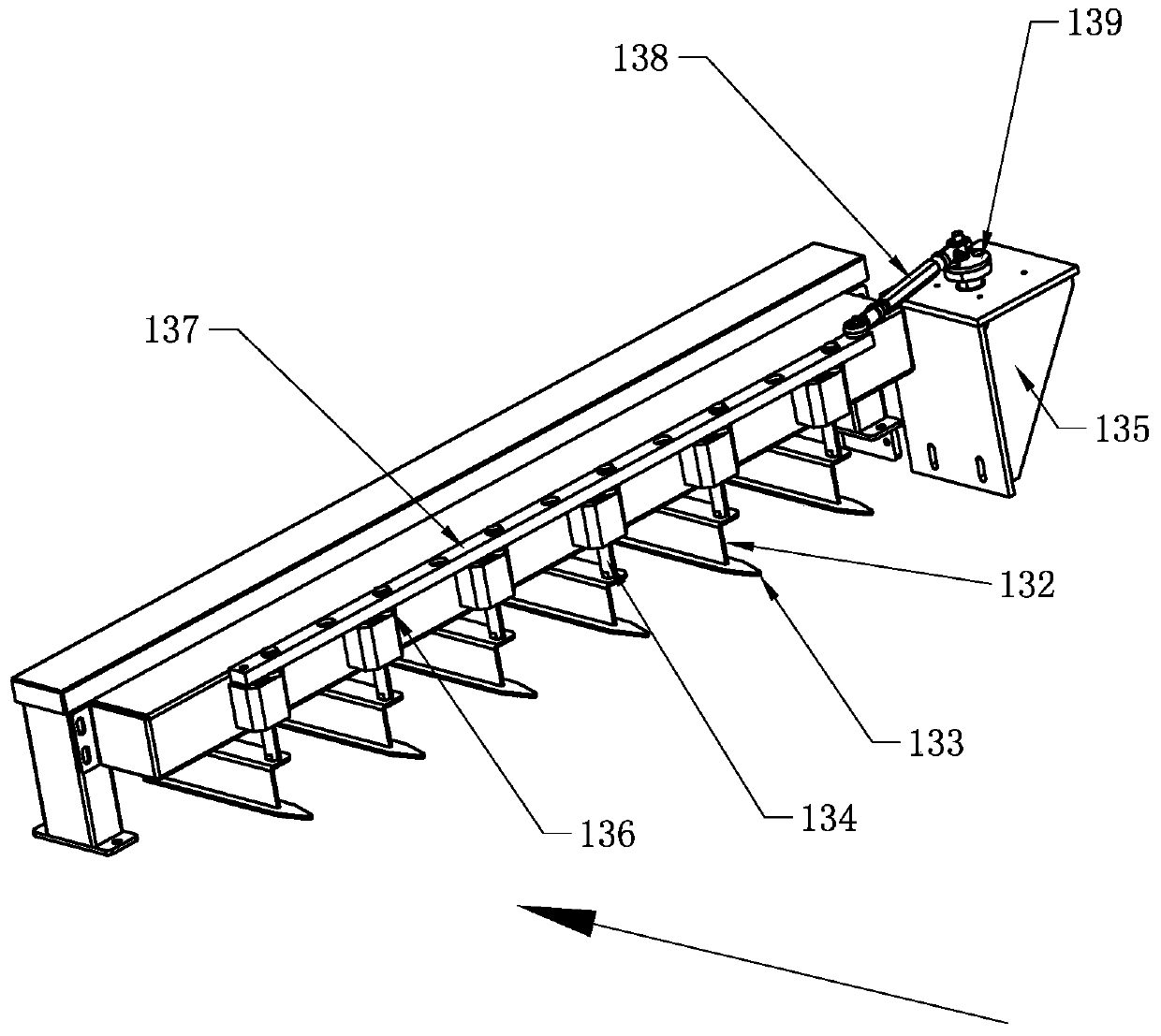

Fully automatic tubular material transferring device

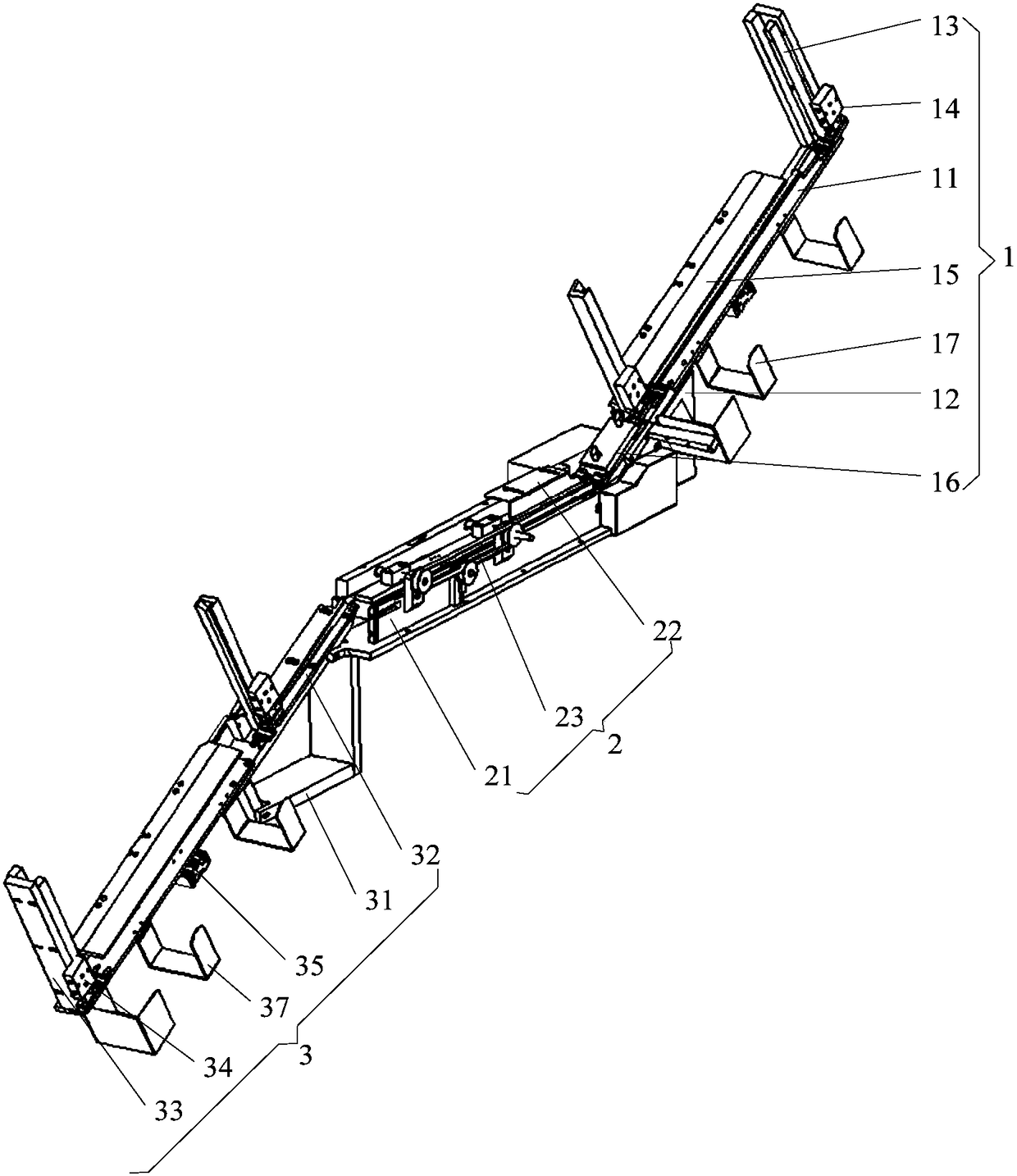

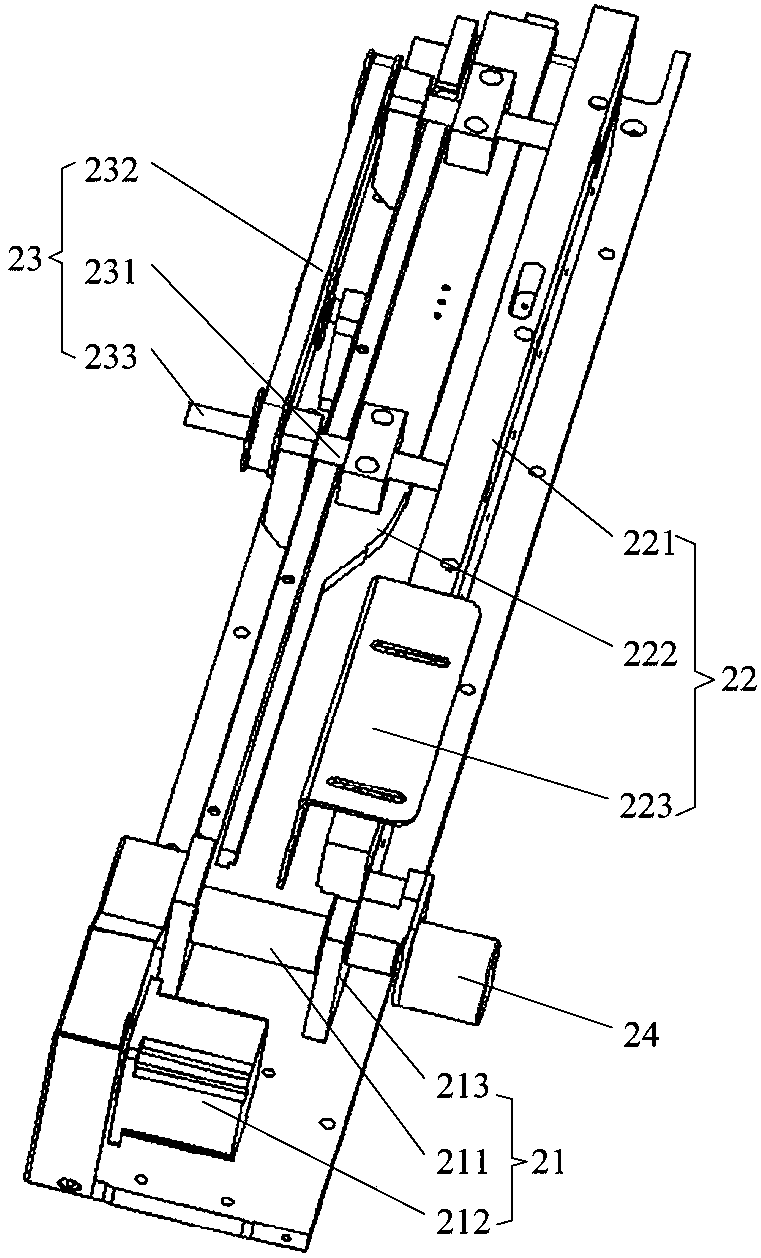

PendingCN108190484AAvoid inconsistencies in directionReduce labor costsConveyorsWelding/cutting auxillary devicesElectronic componentFully automatic

The invention discloses a fully automatic tubular material transferring device. The fully automatic tubular material transferring device comprises a feeding mechanism, a conveying mechanism and a discharging mechanism. The feeding mechanism, the conveying mechanism and the discharging mechanism are connected in sequence. The feeding mechanism is used for feeding materials to the conveying mechanism. The conveying mechanism is used for conveying the materials to a position corresponding to an external processing device for processing, and then the materials are conveyed to the discharging mechanism after processing is completed. The discharging mechanism is used for conducting discharging operation on the materials in the conveying mechanism. The conveying mechanism comprises a conveying belt assembly, a conveying limiting assembly and a screw rod assembly. The conveying belt assembly is used for conveying the materials. The conveying limiting assembly is arranged above the conveying belt assembly in the length direction of the conveying belt assembly and used for preventing the materials from deviating from the direction in the conveying process. The screw rod assembly is used foradjusting the limiting spacing of the conveying limiting assembly. According to the fully automatic tubular material transferring device, material pipes are replaced fully and automatically in the feeding and discharging processes, and the design of the conveying mechanism can effectively avoid the problem that directions are inconsistent when electronic components are installed back into the material pipes after the electronic components are processed.

Owner:深圳市三五五装备技术有限公司

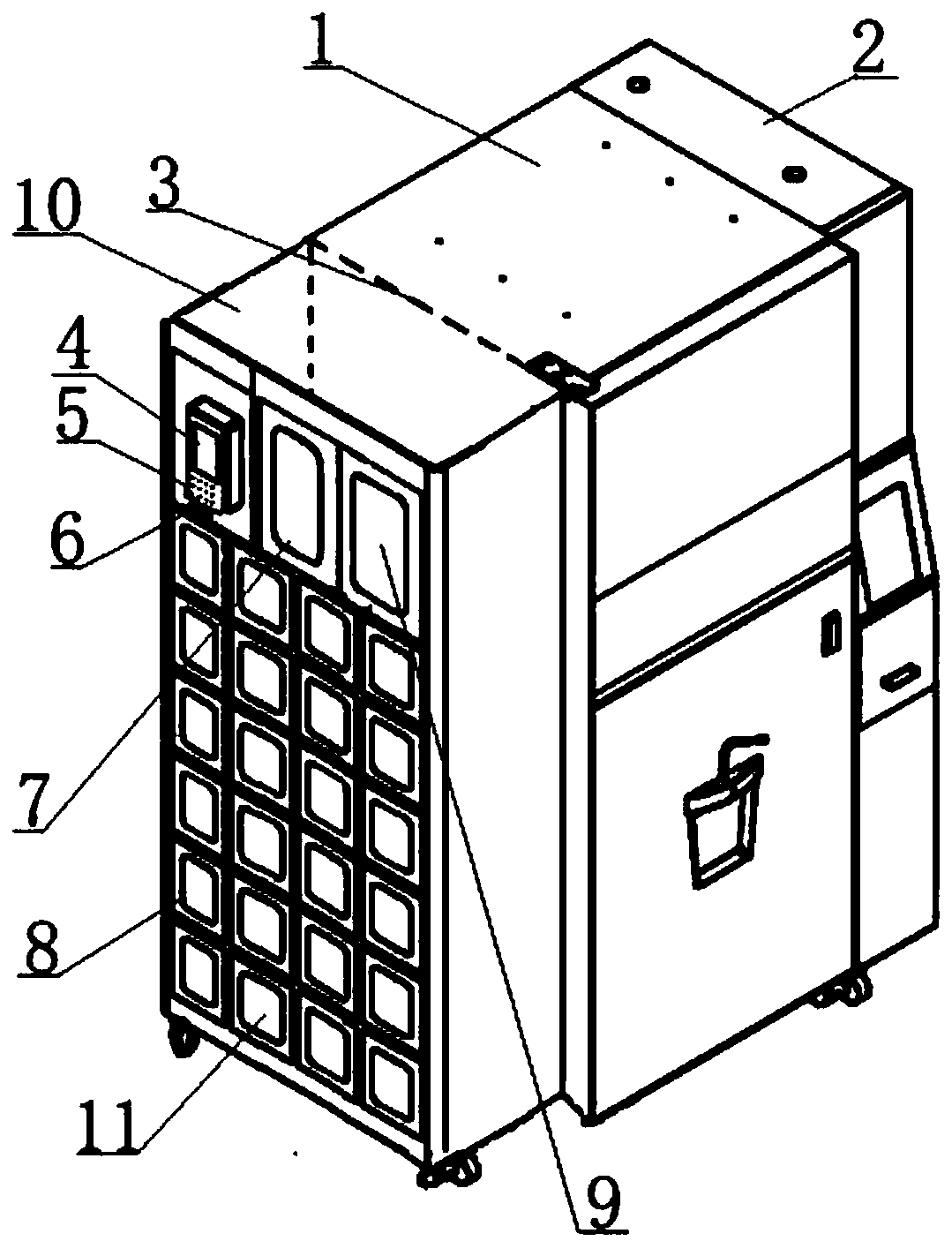

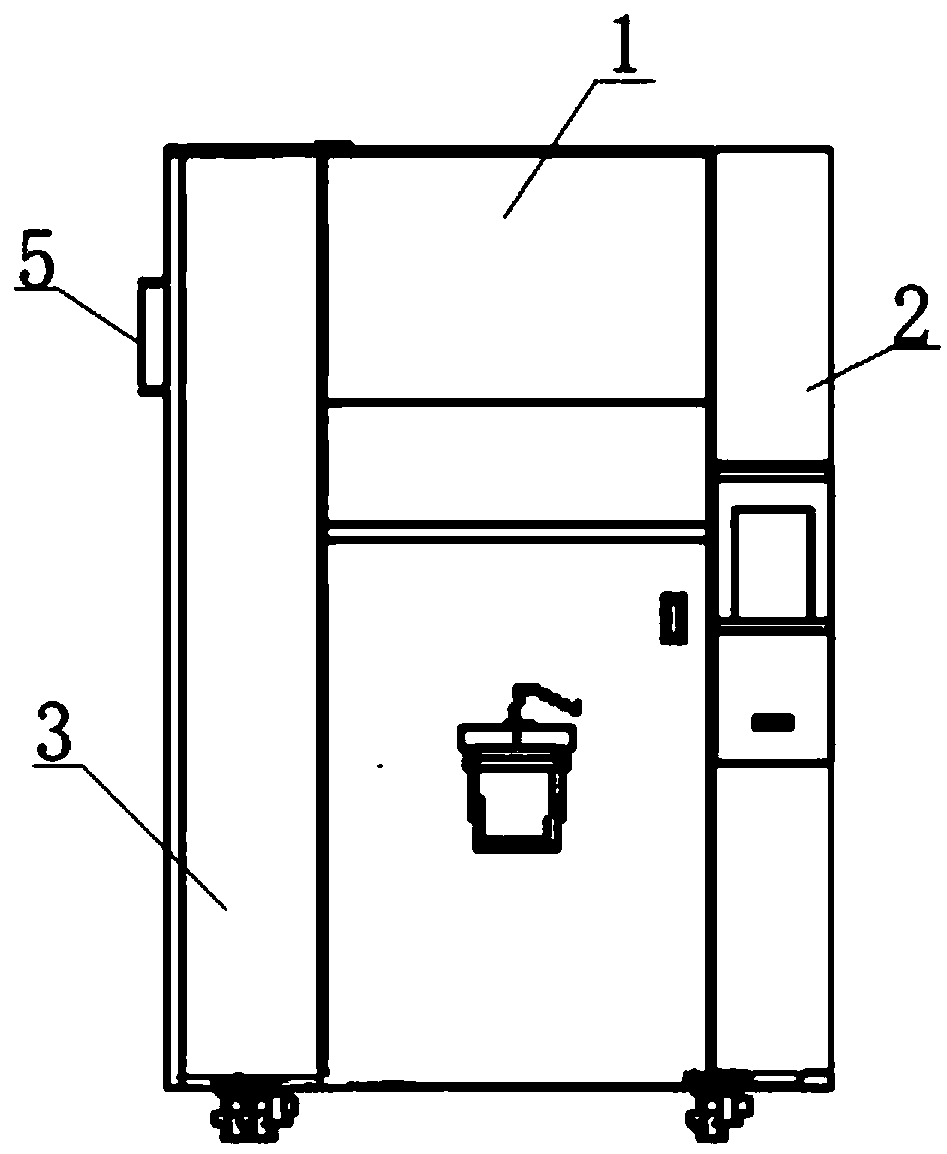

Self-service fresh juice all-in-one vending machine and vending method thereof

InactiveCN109147189ARealize comprehensive salesMeet different needsApparatus for dispensing fluids/granular materialsPaymentCustomer requirements

The invention relates to the field of self-service vending machine, and in particular relates to a self-service fresh juice all-in-one vending machine and a vending method thereof. The self-service fresh juice all-in-one vending machine comprises a self-service fresh juice vending machine; a display cabinet is arranged on one side of the cabinet of the self-service fresh juice vending machine; thedisplay cabinet is provided with multiple display grids; doors are arranged on the display grids; each door is provided with an intelligent electronic lock used for controlling the opening and closing of the door. The self-service fresh juice all-in-one vending machine also comprises a payment device in control connection with the intelligent electronic lock. According to the self-service fresh juice all-in-one vending machine, the display cabinet is added on one side of the self-service fresh juice vending machine, the display cabinet is provided with the multiple display grids, and fruits can be placed into the display grids, so that comprehensive vending of the fruits and the fruit juice is achieved, the utilization rate of space is improved, the operation cost is reduced, and the customer requirement on the fresh fruits can be met.

Owner:HENAN HENGCHUN AGRI S&T

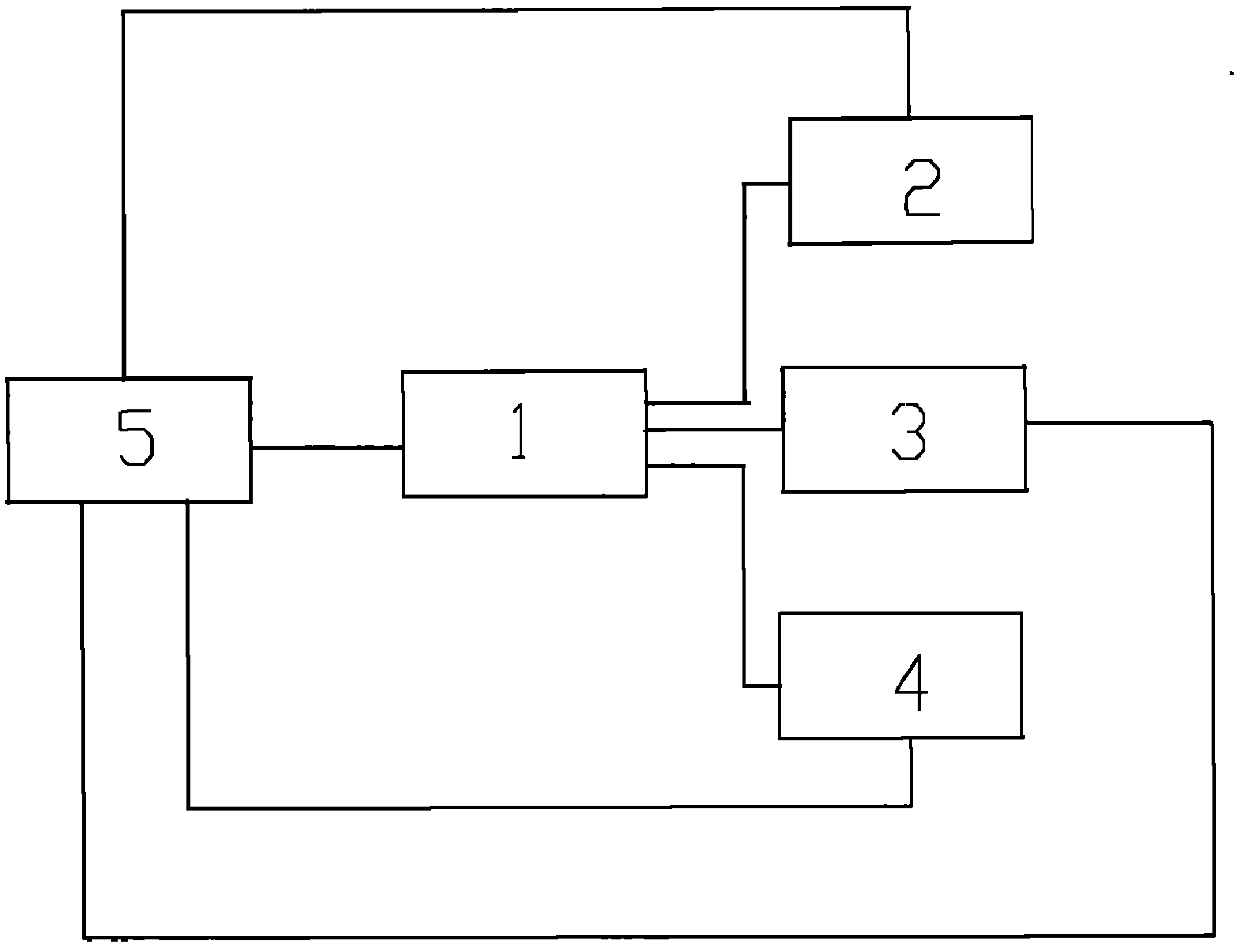

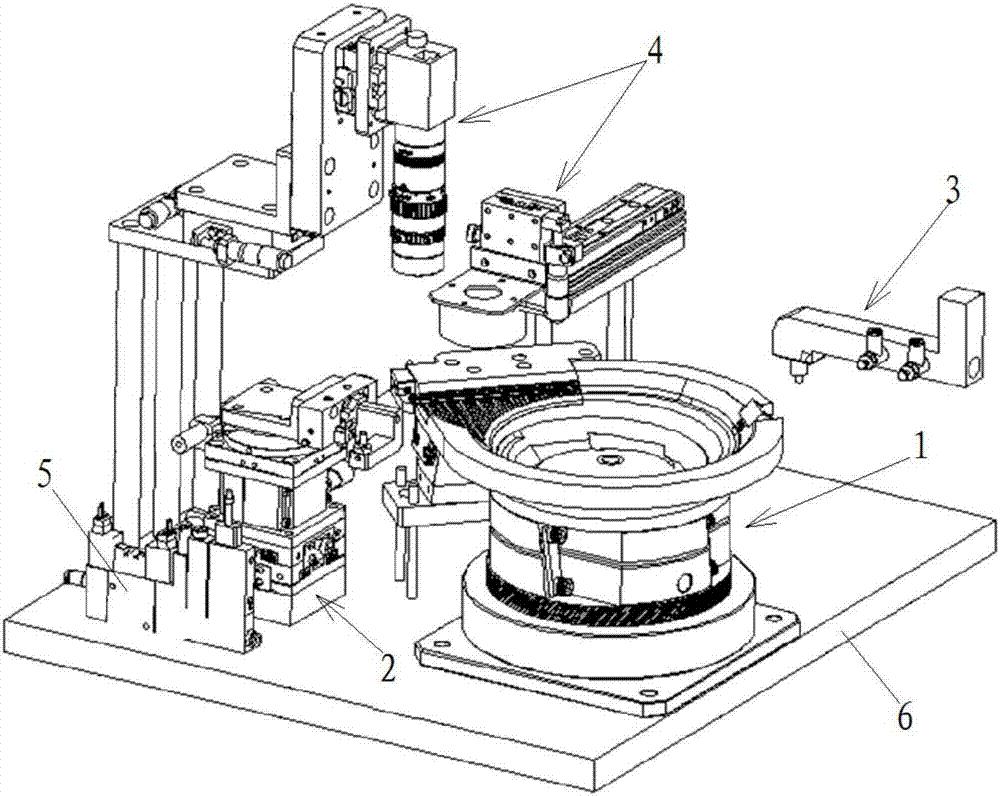

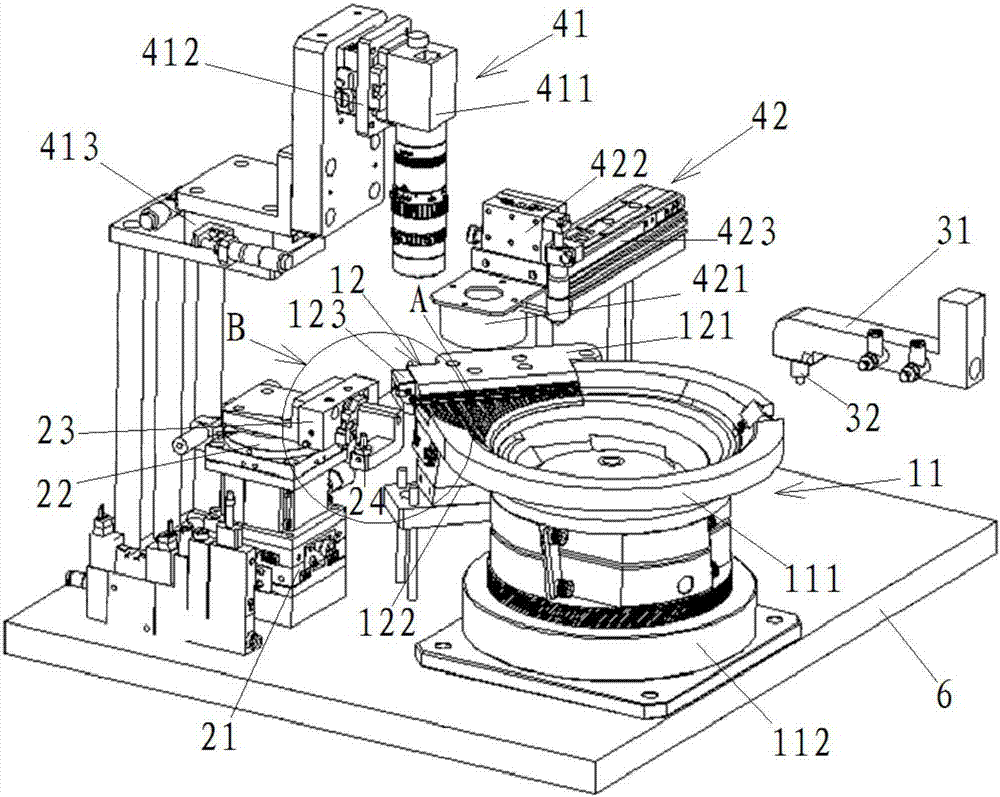

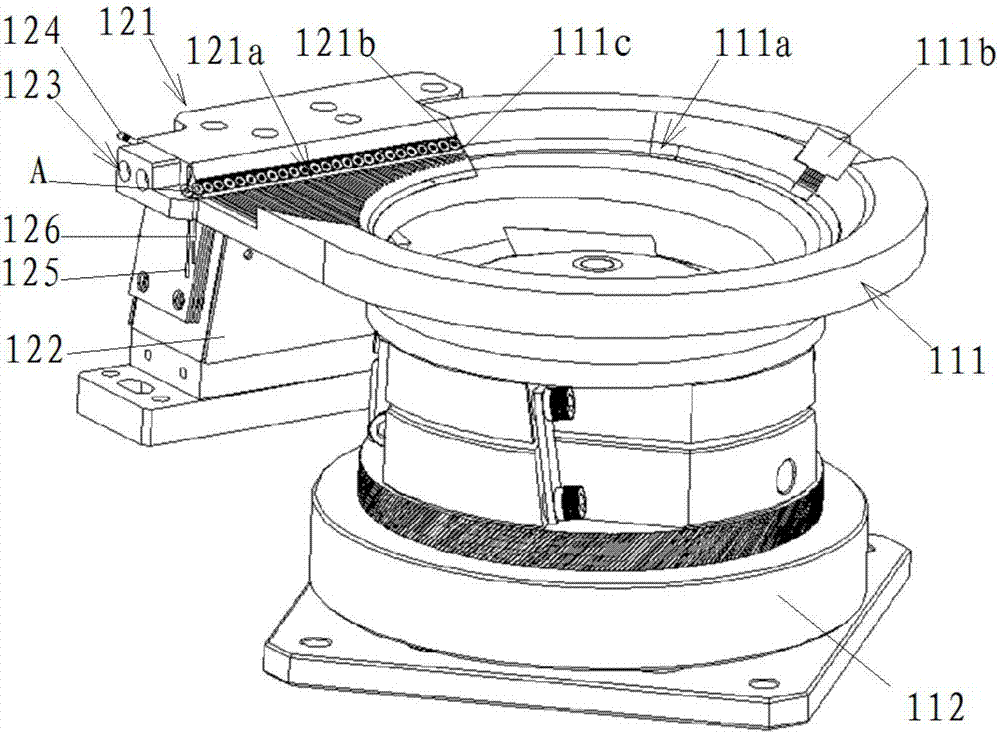

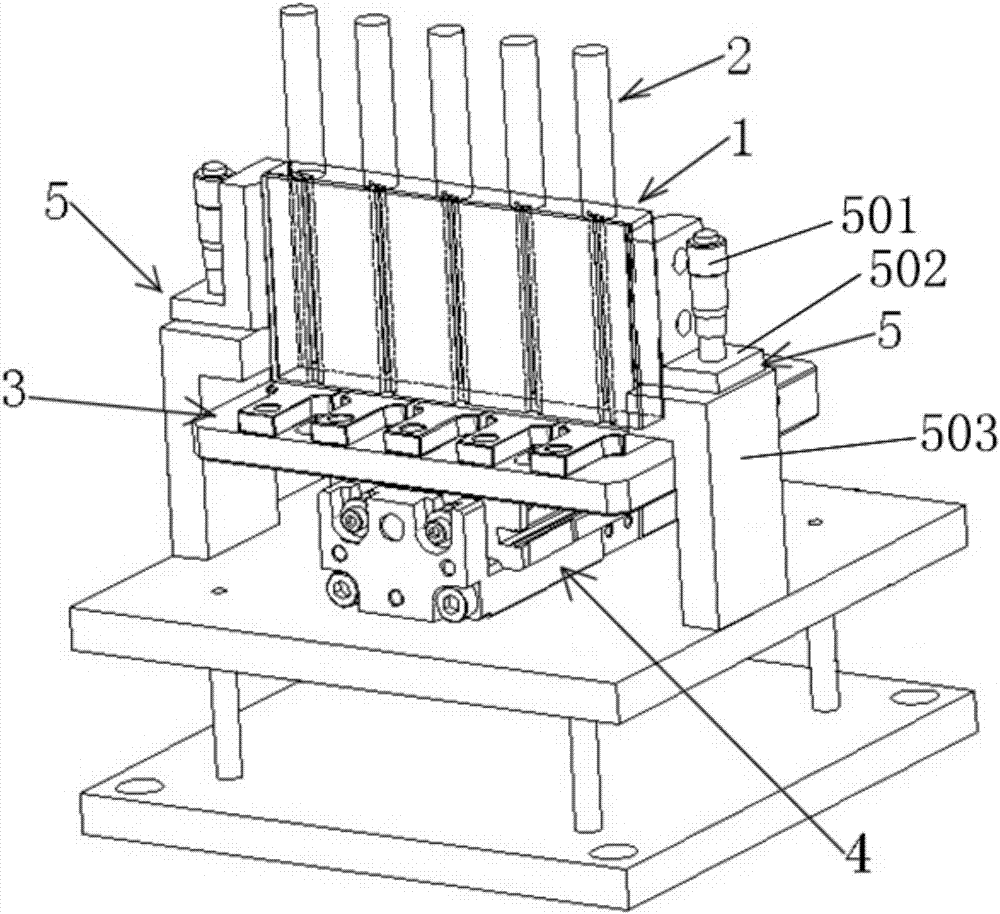

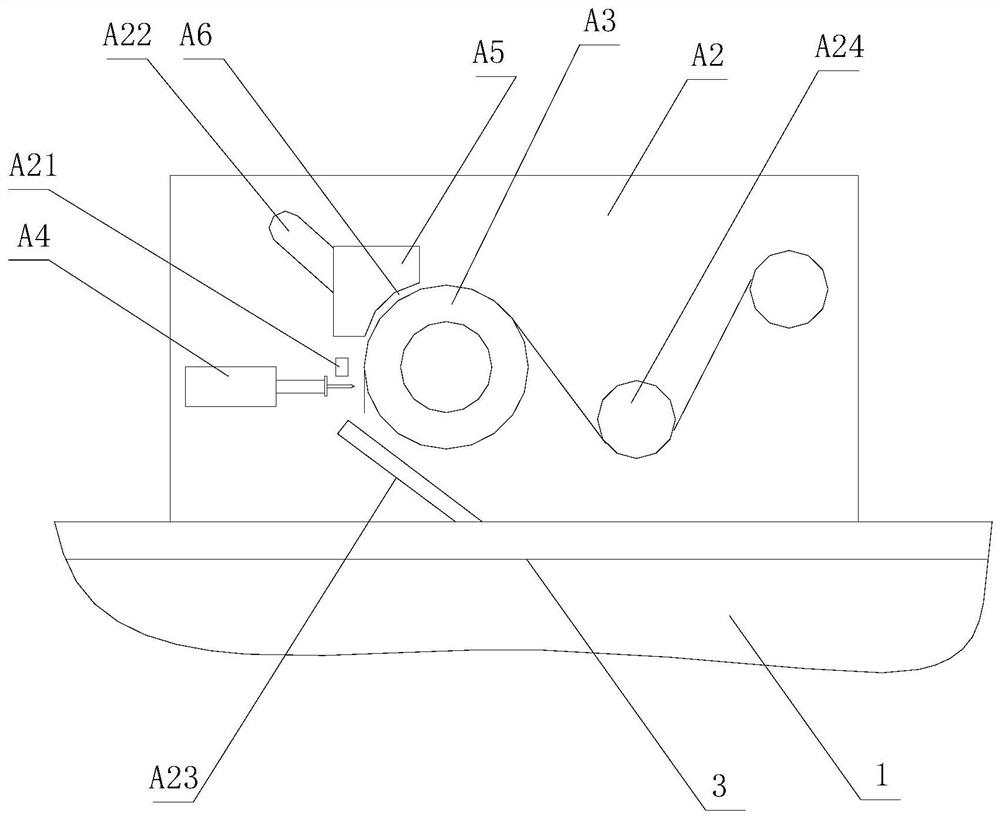

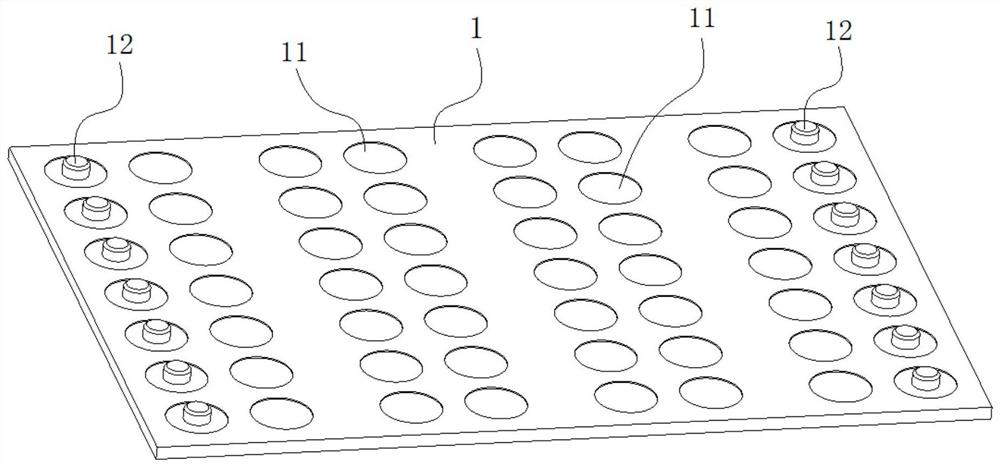

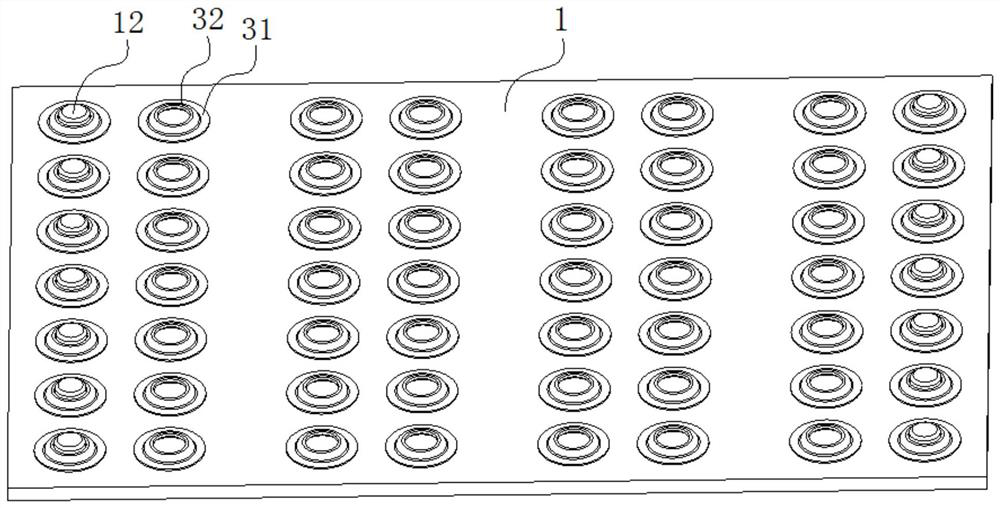

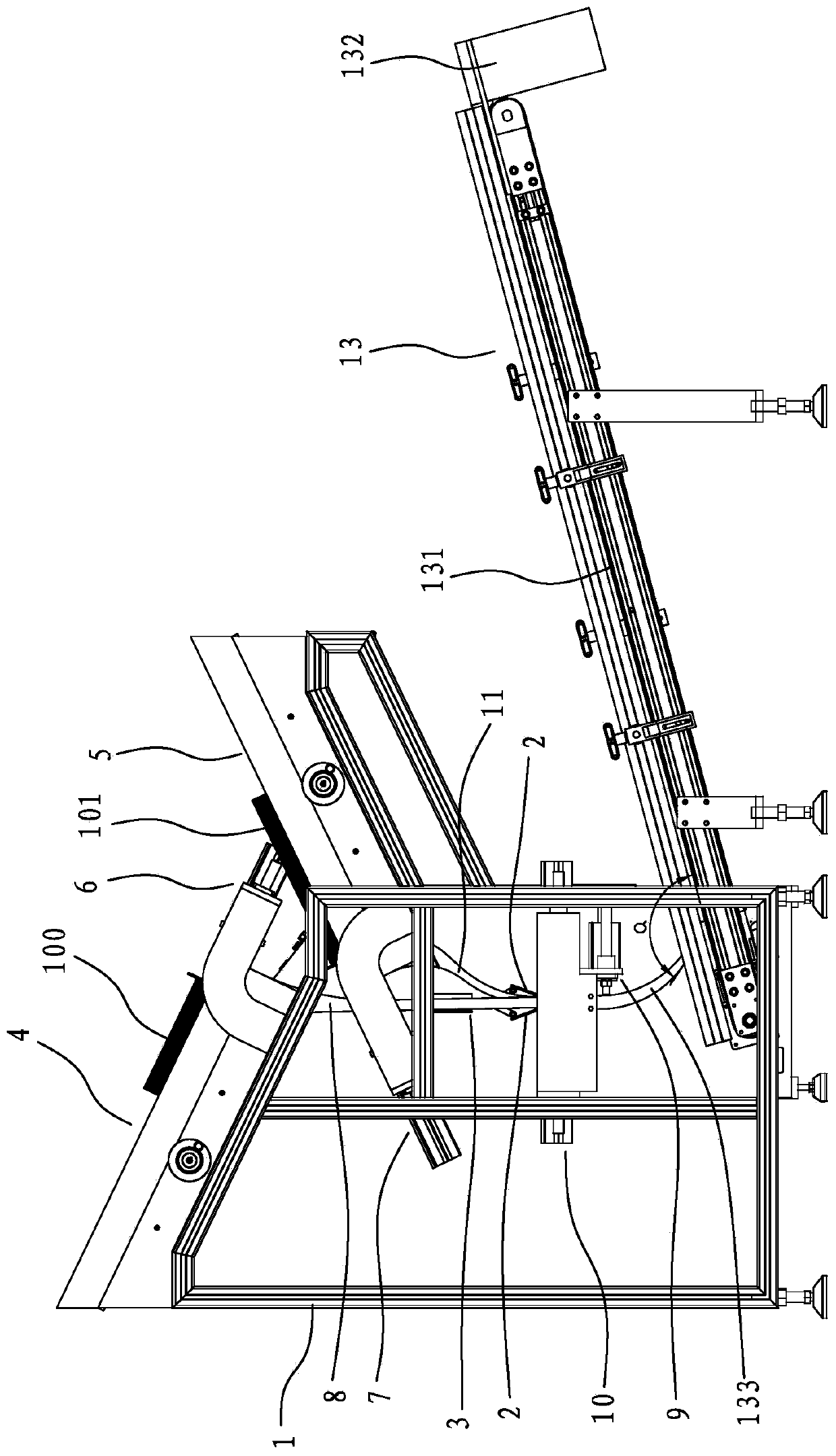

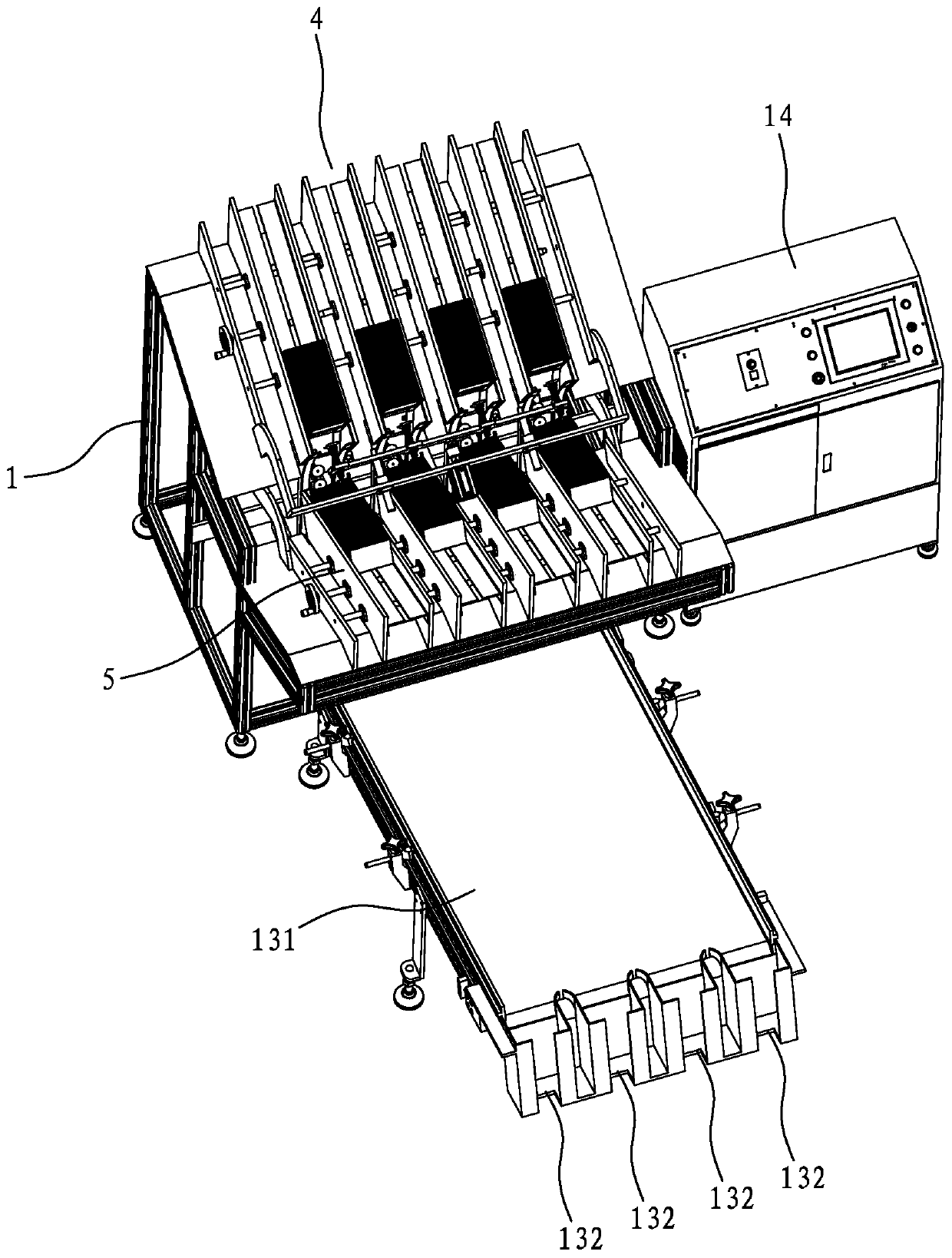

Automatic loader for swing-type pipettor

ActiveCN104176313ASimple structureAvoid missingIndividual articlesJigging conveyorsPipetteEngineering

The invention discloses an automatic loader for a swing-type pipettor. The automatic loader comprises a vibrating disc, a linear vibrator, a swing mechanism, a movable base and a loading disc, the vibrating disc is connected with the linear vibrator, one end of the linear vibrator is connected with the swing mechanism, the movable base is arranged below the swing mechanism, the loading disc is arranged on the movable base, and the swing mechanism and the movable base are controlled by a controller. By the above mode, the automatic loader has the advantages of high reliability, accuracy in positioning, compact and simple structure, high transposition speed, accuracy in placing, freeness of missing placement and mistaken placement, convenience in operation and the like, and has wide market prospect in packaging market.

Owner:JIANGSU LONGRUN IRRIGATION & DRAINAGE

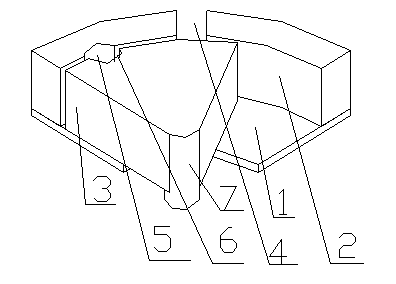

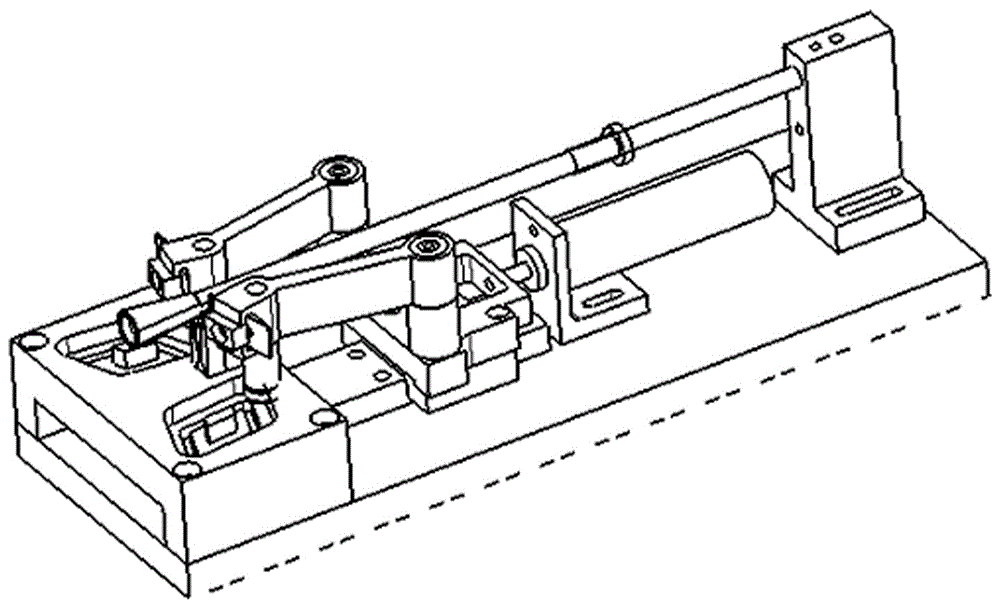

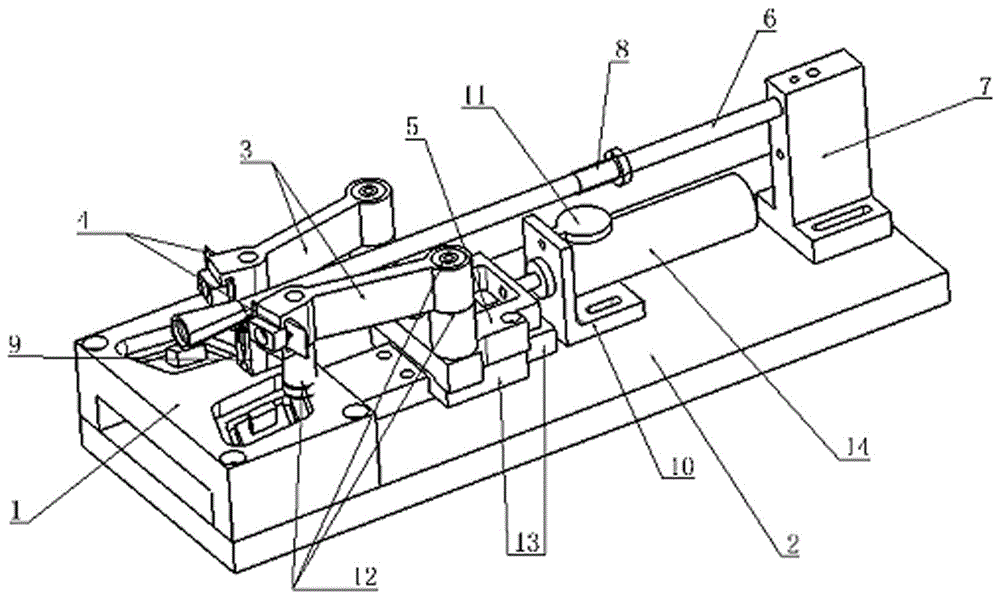

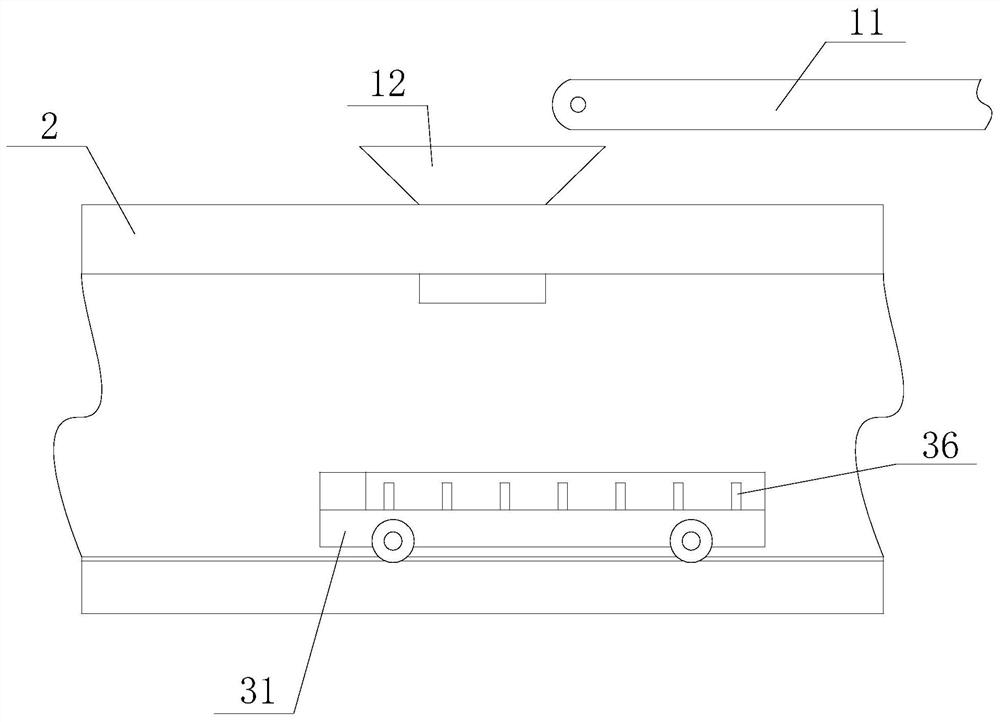

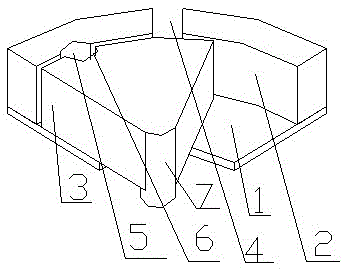

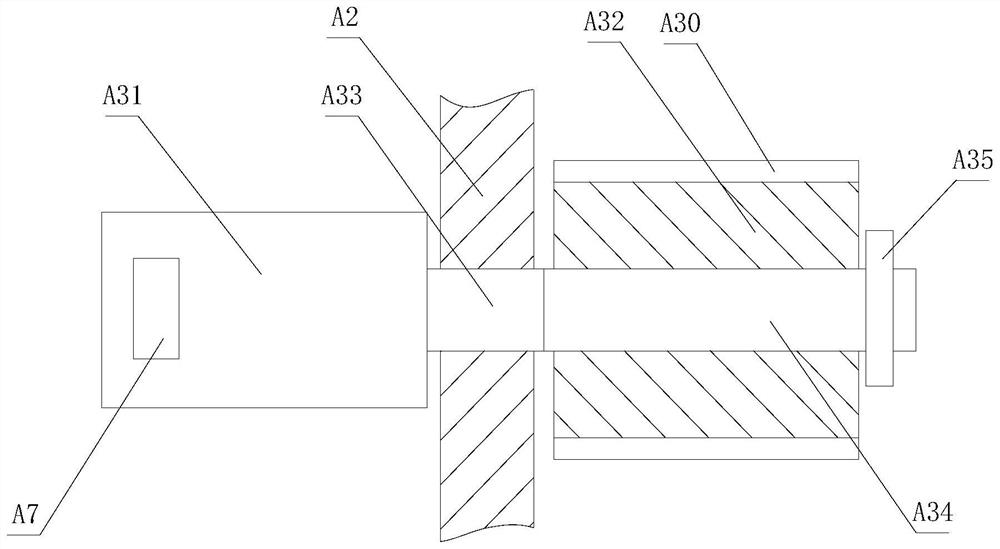

Tool for automatically mounting O-shaped ring and method for mounting O-shaped ring

InactiveCN106217024AImprove efficiencyFast processingMetal working apparatusEngineeringProduct processing

The invention discloses a tool for automatically mounting an O-shaped ring. The tool comprises a bottom plate, a slide block base and a turning plate rod. The tool is characterized in that a bottom plate is equipped with an O-shaped ring mandrel; a counter bore is formed in the front end of the O-shaped ring mandrel; the O-shaped ring mandrel is sleeved by the O-shaped ring; the counter bore is used for mounting a pipeline with an O-shaped slot; the slide block base is connected with an air cylinder, and the air cylinder drives the slide block base to move; a turning plate is mounted on the turning plate rod; the turning plate rod is mounted on the slide block base; the air cylinder pushes the slide block base to move forwards, and drives the turning plate rod to move forwards; and the turning plate on the turning plate rod is used for forwards turning the O-shaped ring sleeving the O-shaped ring mandrel, so that the O-shaped ring is sleeved by the O-shaped slot of a pipeline in the counter bore at the front end of the O-shaped ring mandrel. The tool disclosed by the invention has the advantages of being capable of automatically mounting the O-shaped ring, increasing product processing speed, and avoiding neglected mounting or excessive mounting in production while guaranteeing product cleanness.

Owner:上海汽车空调配件股份有限公司

Automatic loading and conveying device

PendingCN111908182AEffective load transportGood for fallingConveyorsControl devices for conveyorsControl systemProcess engineering

The invention is suitable for the technical field of coal mine conveying, and provides an automatic loading and conveying device. The automatic loading and conveying device comprises a material guiding device, a supporting frame and a discharging device. The material guiding device comprises a conveyor belt and a guide material; the discharging device comprises a moving trolley, a rotating rollerand a discharging belt which sleeves the rotating roller; the adjusting device comprises adjusting rods, threaded rods and threaded sleeves which sleeve the threaded rods; and the discharging device is connected with a control system, and the control system comprises a rotating roller rotating speed adjusting unit, a moving vehicle moving speed adjusting unit, a limiting unit and a safety protection unit. Therefore, according to the automatic loading and conveying device, coal materials can be effectively conveyed, secondary matching of a vehicle and the conveyor belt is avoided, and the conveying efficiency and the conveying quality of the coal materials are improved.

Owner:山东能源集团鲁西矿业有限公司

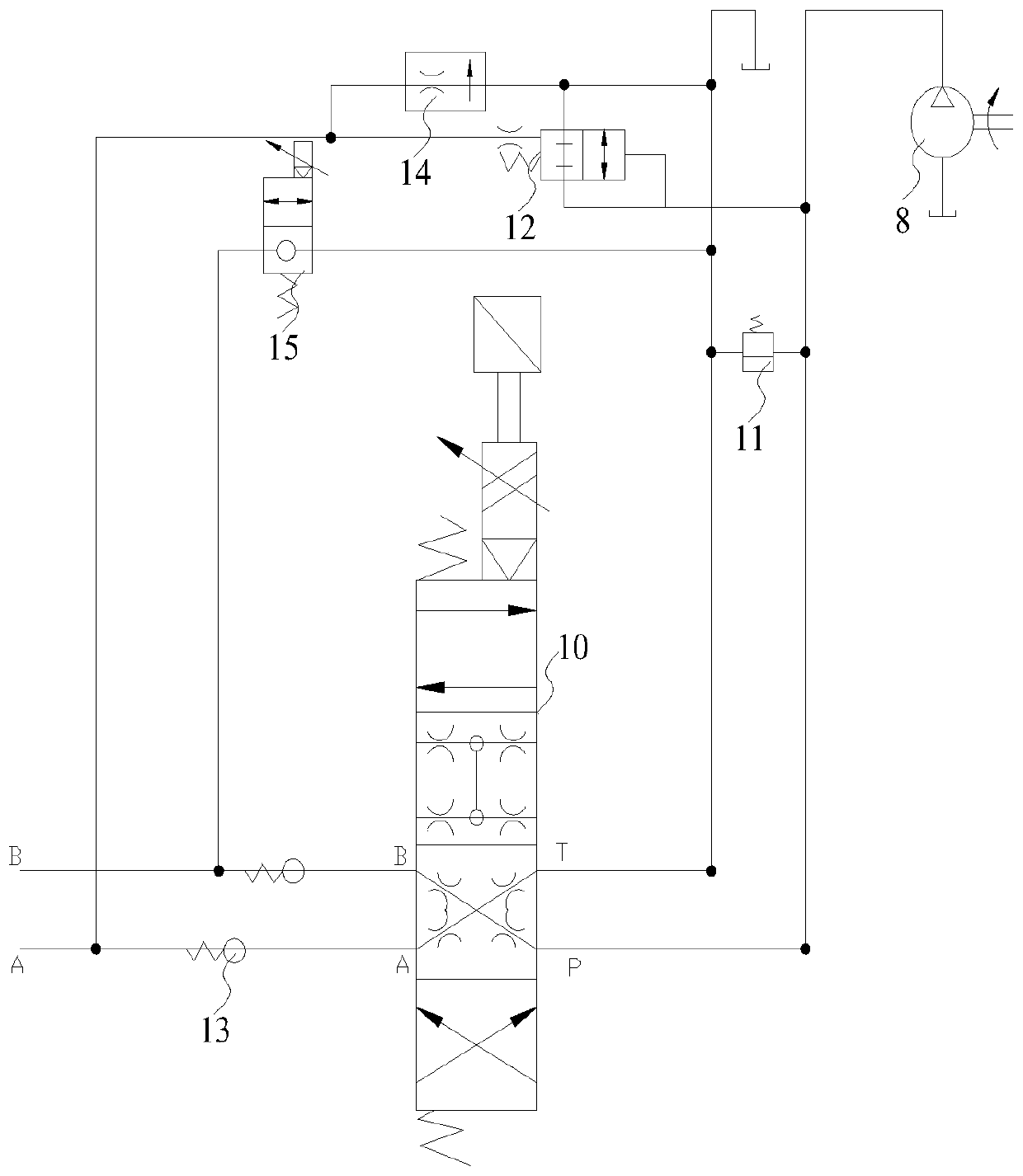

Cold extrusion processing equipment of high-precision automobile clutch

ActiveCN110076276ATo achieve mechanized installationAvoid overpackingHydraulic cylinderControl system

The invention discloses cold extrusion processing equipment of a high-precision automobile clutch. The cold extrusion processing equipment comprises a controller, a base and a top seat, wherein a control system is arranged in the controller, the base is used for fixing the controller, the top seat is arranged above the base, a servo hydraulic system is used for supplying oil to a hydraulic cylinder so as to drive a movable die to move to a fixed die by the hydraulic cylinder, a containing disc which is used for containing a rivet is arranged on one side of the fixed die, an ejection mechanismwhich is used for ejecting the rivet is arranged in the containing disc, a riveting mechanism which is located on one side of the containing disc is arranged on the base, and the rivet on the containing disc can be sucked and moved to the upper part of the fixed die by the riveting mechanism. Compared with the prior art, the cold extrusion processing equipment has the advantages that the flow of hydraulic oil which flows into the hydraulic cylinder is controlled by using the servo hydraulic system, so that the displacement, the moving speed and the pressure of the movable die are accurately controlled, the rivet is prevented from being excessively pressed, additionally, the rivet is mechanically installed, the installation accuracy is increased, the installation mode that the rivet extendsinto the die manually is avoided, and the product quality is increased.

Owner:LONGQUAN XINCHENG DUONENG AUTO ELECTRIC APPLIANCECO

Feeding device of egg tart cooking machine

PendingCN110447670ARealize continuous baking productionImprove production efficiencyCharging/discharging ovensEngineeringTransfer mechanism

The invention discloses a feeding device of an egg tart cooking machine, which includes a third frame body, the third frame body is provided with an intermittent transfer mechanism, and the intermittent transfer mechanism is used to make the egg tarts move in batches. The intermittent transfer mechanism includes a third conveyor belt and a fourth conveyor belt arranged along an egg tart conveyingdirection, the third conveyor belt is higher than a fourth conveyor belt, and the intermittent transfer mechanism further includes a transfer assembly for transferring the egg tarts from the third conveyor belt to the fourth conveyor belt. The transfer assembly is disposed between the third conveyor belt and the fourth conveyor belt. The transfer assembly includes a receiving cavity that receivesthe tart from up and down, a support plate that intermittently closes the bottom of the receiving cavity, a carrier board disposed below the support plate for placing egg tarts, a third power component for driving the carrier board to move up and down, and a side pushing plate for pushing the egg tarts from the carrier board to the fourth conveyor belt. The feeding device of the egg tart cooking machine of the present invention can output the egg tarts in a set quantity, is convenient for packaging, and does not affect the use of the egg tart cooking machine.

Owner:WUYI UNIV

Feeding device of egg tart processor

PendingCN110477058ARealize continuous baking productionImprove production efficiencyBaking ovenEngineering

Owner:WUYI UNIV

Material supply device

PendingCN107186456AFalling steadilyTimely adjustmentAssembly machinesMountingsReciprocating motionProcess engineering

The invention relates to a material supply device. The material supply device comprises a storage unit, an extruding part, a supply unit, a drive part and regulating units, wherein the extruding part can be supported on the storage unit in a movable mode; the supply unit is positioned below the storage unit and is opposite to the extruding part; and certain gap is formed between the supply unit and the storage unit. The two ends, in the length direction, of the storage unit are fixedly connected with the regulating units for regulating height of the storage unit. The supply unit is fixedly arranged on the drive part which can drive the supply unit to perform linear reciprocating motion. According to the material supply device provided by the invention, a magnet sheet is put into the storage unit, the size of the gap between the storage unit and the supply unit is regulated through the regulating units, and the drive part drives the supply unit to move, so that only one magnet sheet drops into the supply unit every time, and therefore, automatic supply of single magnet sheet is realized, manual operation is replaced, efficiency is improved, a rejection rate of the magnet sheet is reduced, and cost is reduced.

Owner:ZHEJIANG SUNNY OPTICAL CO LTD

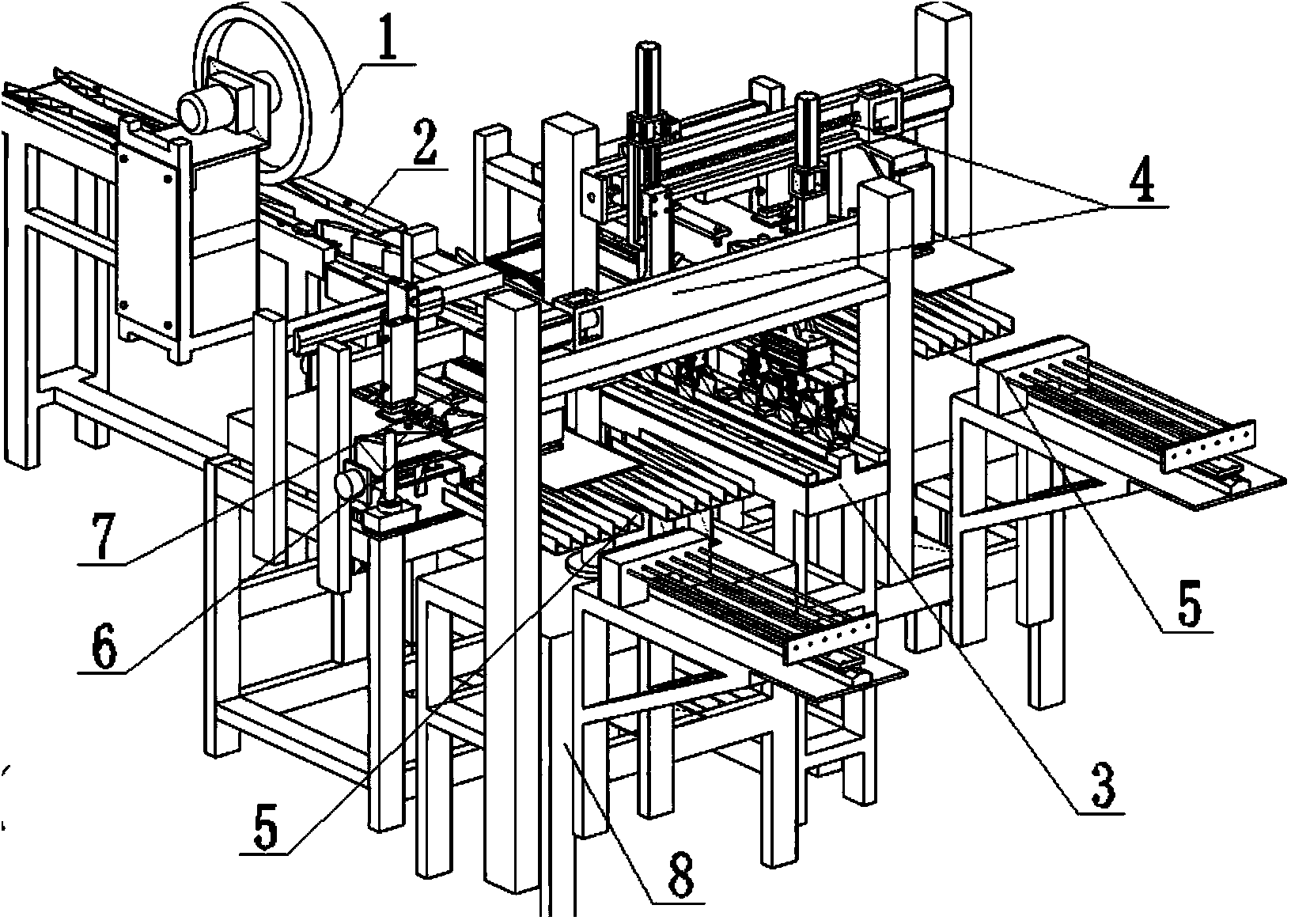

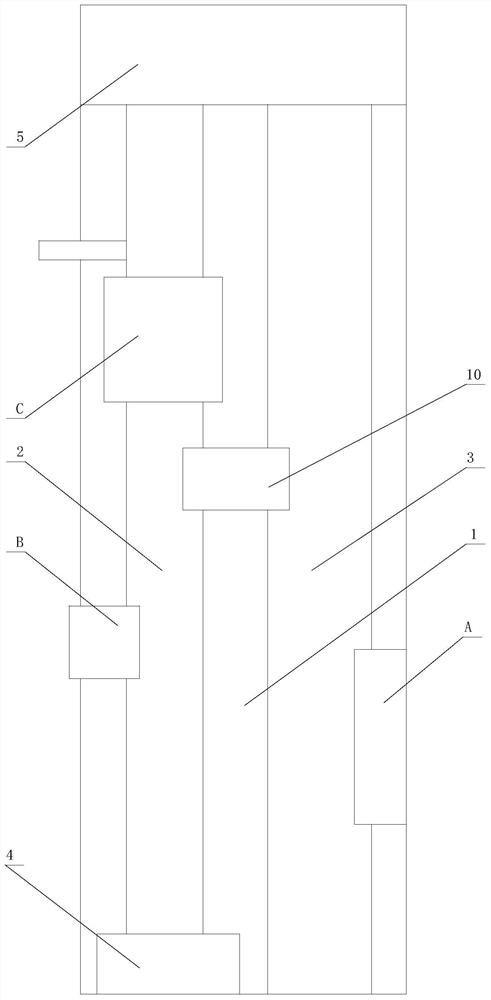

Lee Lok Pillow milk boxing method

InactiveCN108238314ARealize automatic controlMeet the production rhythmPackaging automatic controlPackaging machinesMechanical engineeringCow milk

The invention provides a Lee Lok Pillow milk boxing method in the technical field of milk production equipment. The Lee Lok Pillow milk boxing method comprises the following boxing steps that firstly,a milk filling conveying line (1) conveys bagged milk to a boxing station conveying line (9); secondly, a box body conveying line (11) conveys milk box bodies to the boxing station conveying line (9); thirdly, a control component (8) controls a boxing robot (3) to grab bagged milk to milk box bodies from the boxing station conveying line (9) through a suction cup (6) mounted at the tail end of arobot mechanical arm; fourthly, the boxing station conveying line (9) conveys boxed box bodies to a box sealing station (4). According to the Lee Lok Pillow milk boxing method, the boxing method is simple in step, the Lee Lok Pillow milk batched automatic boxing can be conveniently and rapidly achieved, meanwhile, boxing reliability is ensured, appearing of less loading, much loading and mis loading can be avoided, and the boxing efficiency can be comprehensively improved.

Owner:WUHU ZHANGHONG ENG TECH CO LTD

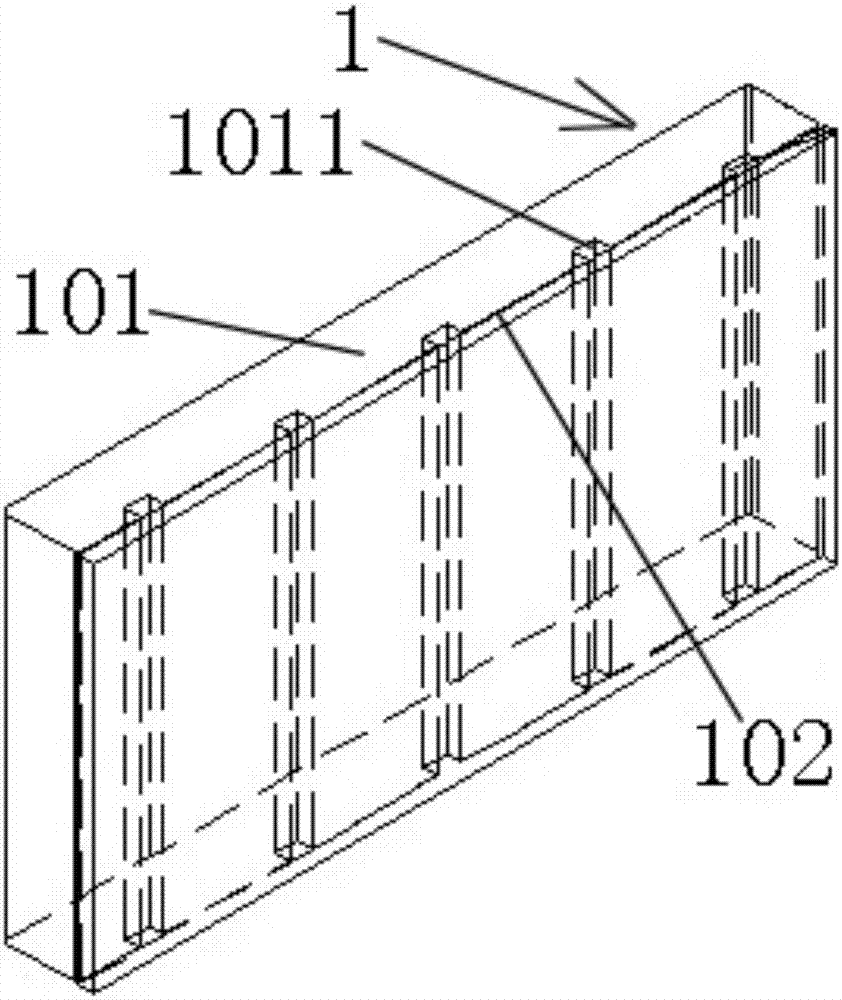

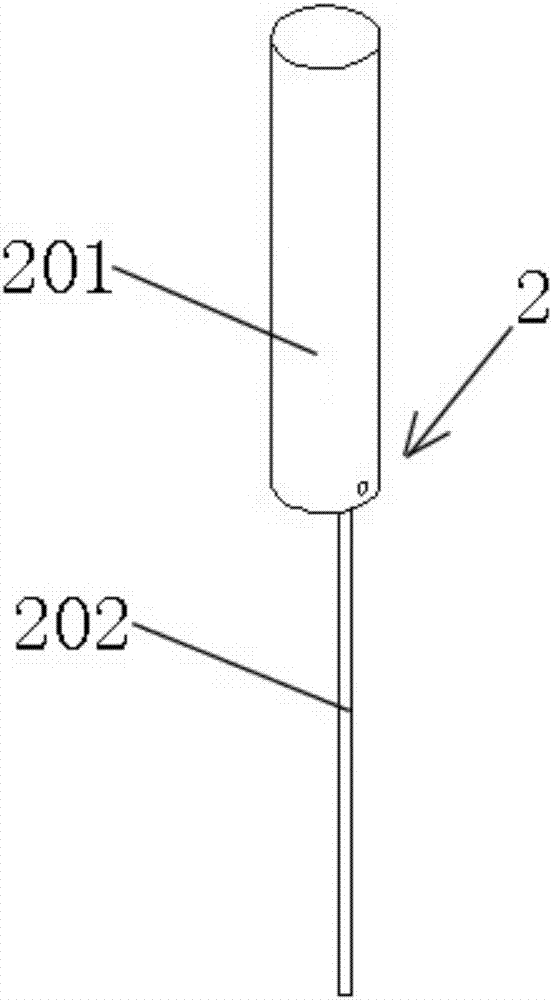

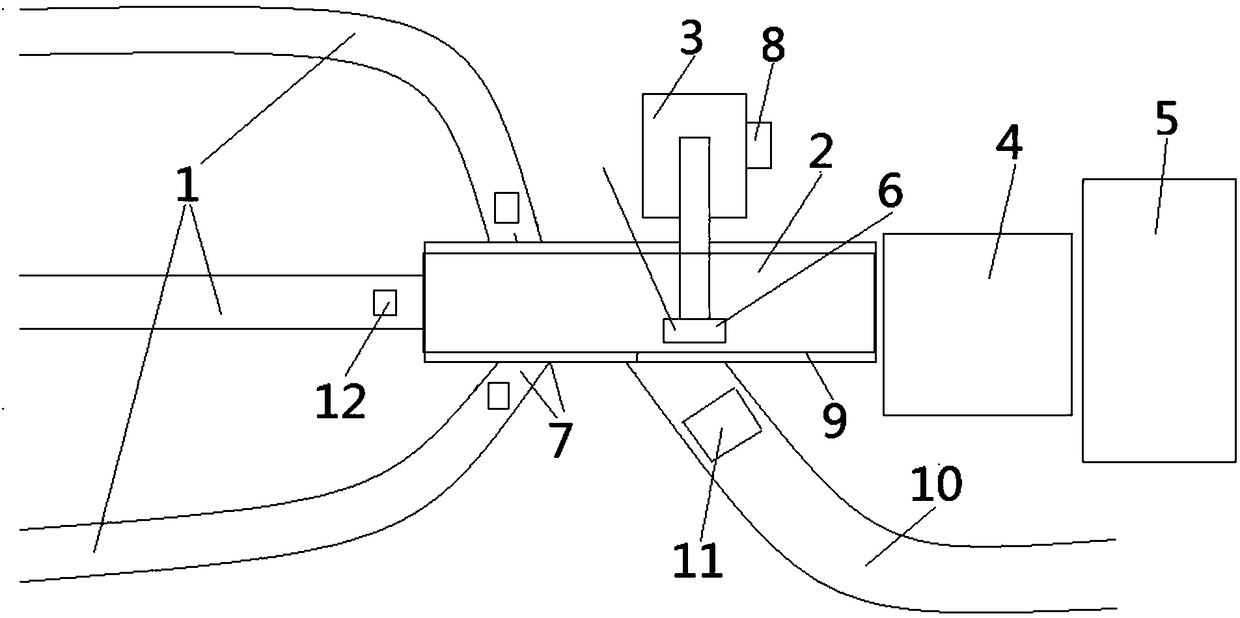

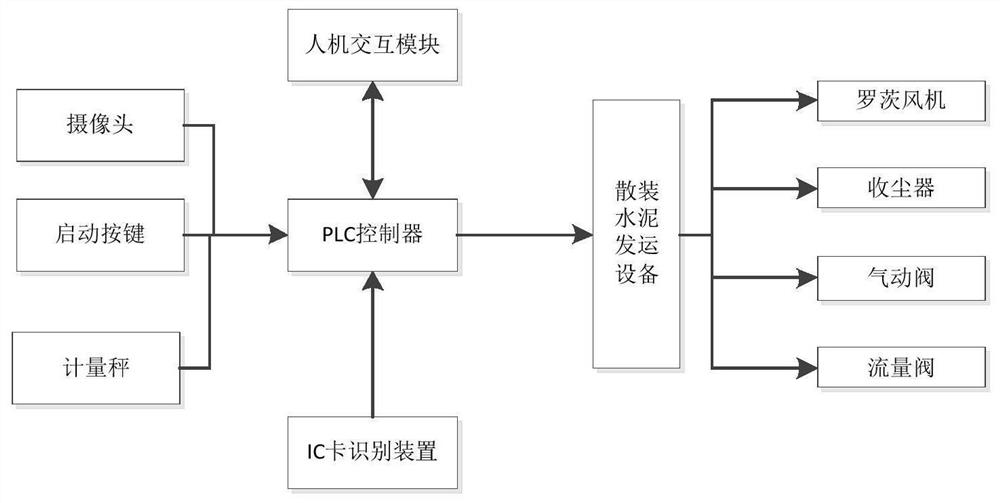

Bulk cement delivery one-key start control system and method

PendingCN114237149AReduce labor intensityProtection securityProgramme control in sequence/logic controllersAutomatic controlControl system

The invention discloses a bulk cement delivery one-key start control system which comprises bulk cement delivery equipment used for loading cement; the control system further comprises a PLC and a start button, the output end of the PLC is connected with the bulk cement delivery equipment, and the PLC is used for driving and controlling operation of all mechanisms in the bulk cement delivery equipment. The starting button is connected with the PLC and used for sending a starting signal to the PLC, and the PLC controls all mechanisms in the bulk cement dispatching equipment to be started according to a preset sequence according to preset starting control logic. According to the invention, the PLC is adopted to carry out automatic control on cement shipping and loading of the bulk machine, so that the manual operation amount is reduced, the shipping efficiency is improved, and the labor intensity of workers is reduced; and the operation is simple, and only one-key start control and automatic shutdown are needed after the loading capacity is input.

Owner:ANHUI CONCH DESIGN & RES INST OF BUILDING MATERIALS CO LTD +1

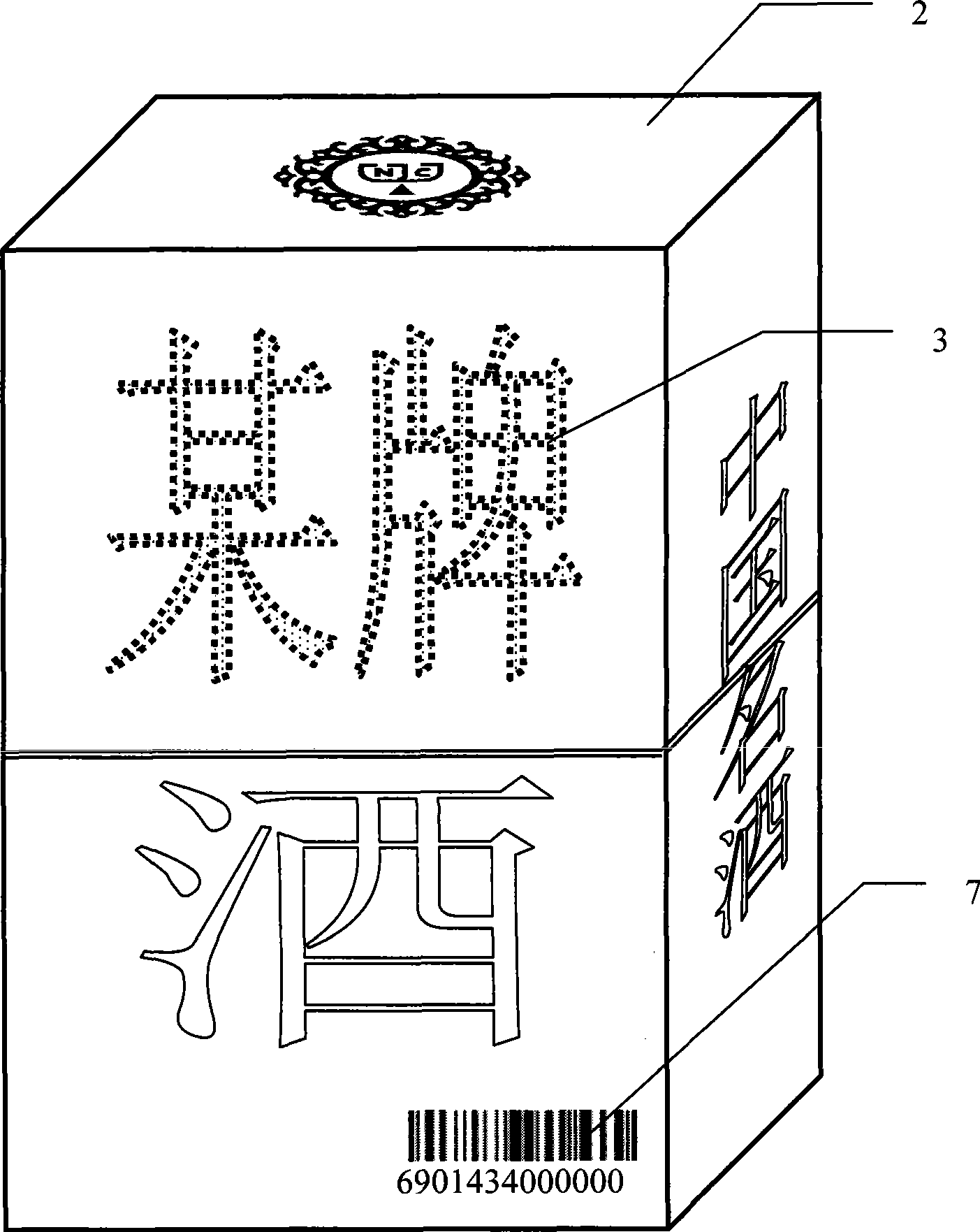

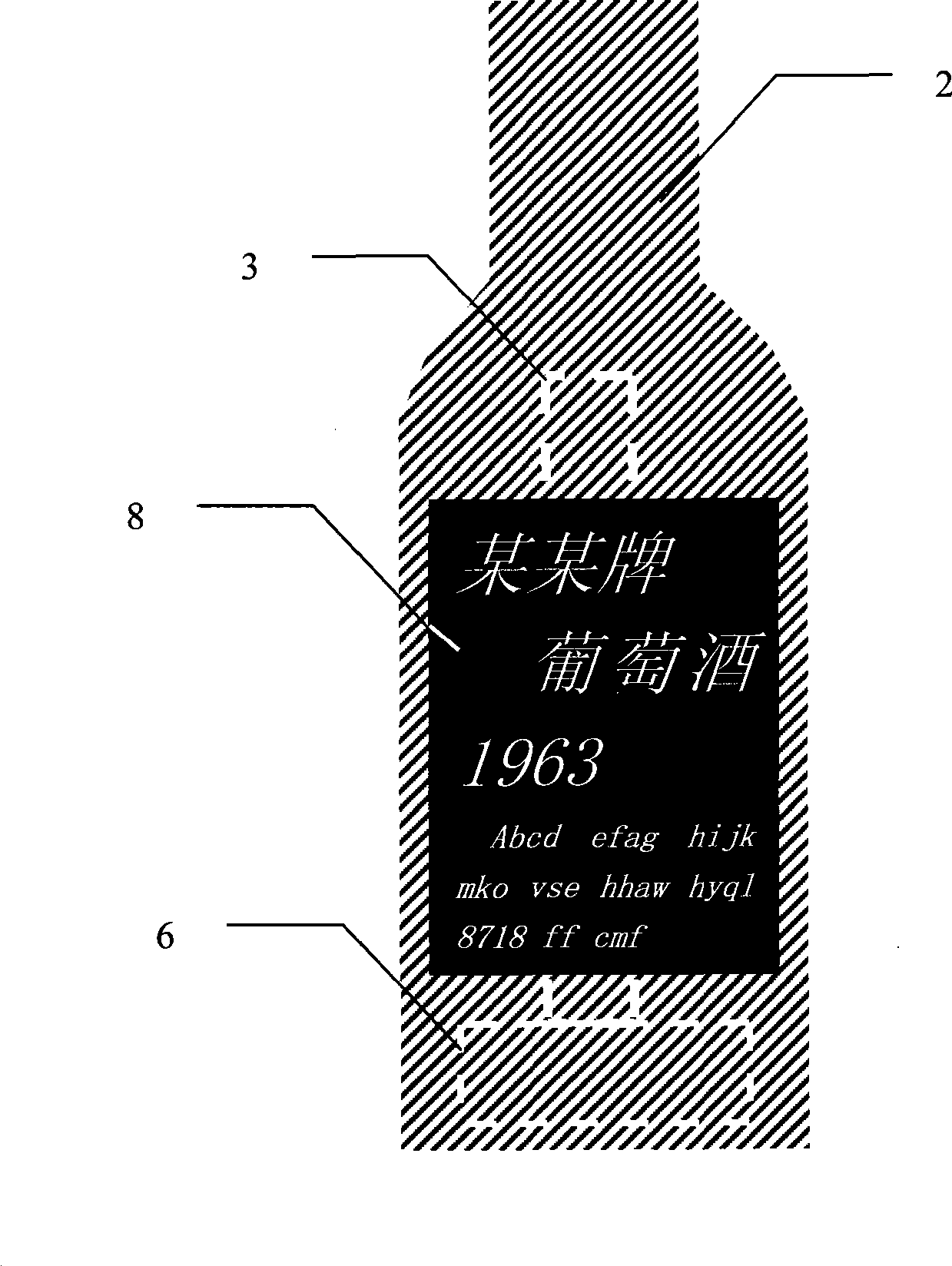

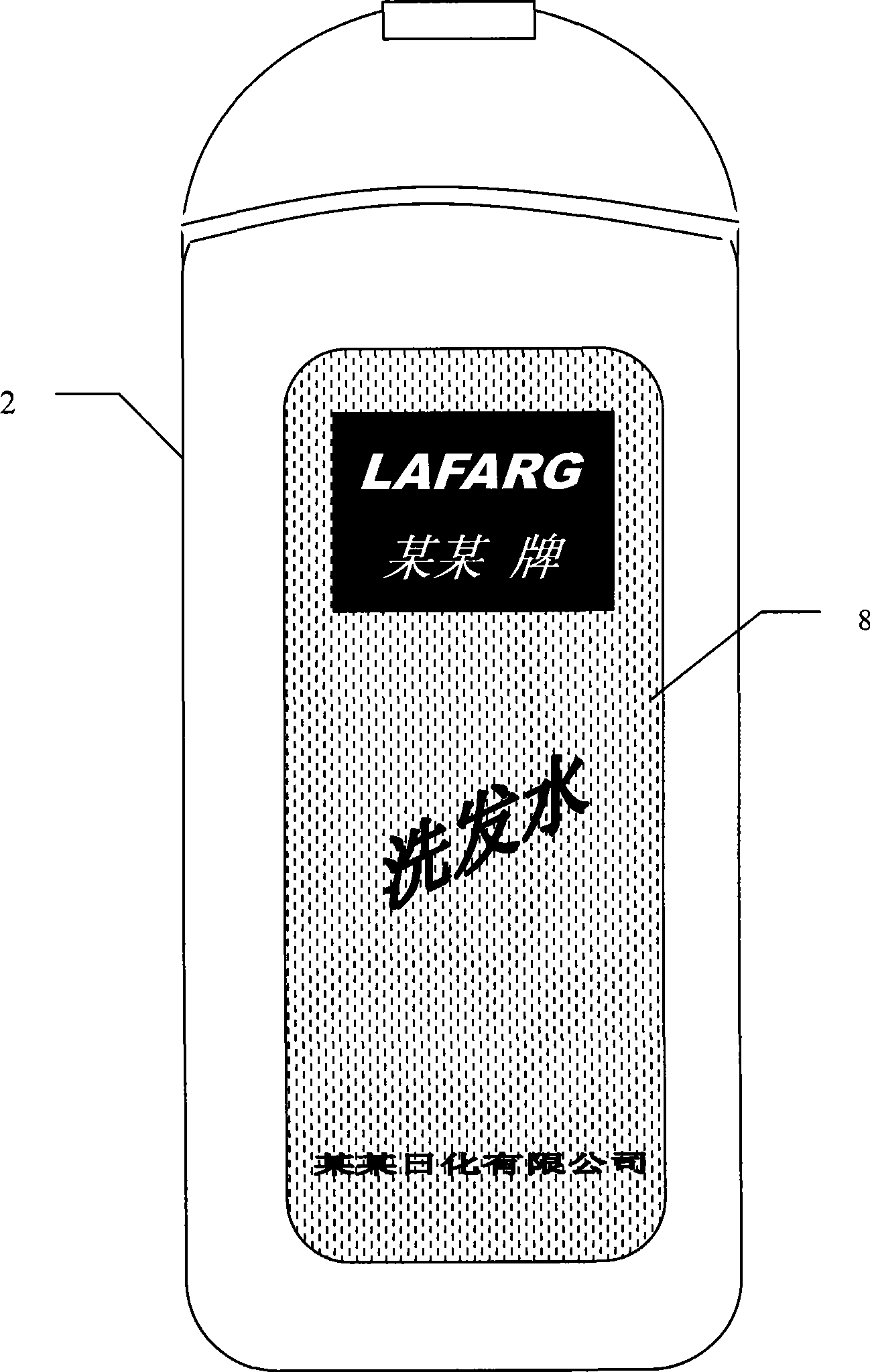

Product dynamic display method

InactiveCN101447155ATrigger the desire to buyIncrease salesArticle advertisingIlluminated signsEnvironmental resistanceProcess engineering

The invention provides a product dynamic display method. An electronic flash color lamp is arranged on an exhibit, thereby producing a flashing and shining simulation exhibit; the exhibit and the product are exhibited on the storage racks of a supermarket together, the frequently flashing dynamic effect can attract customers to pay attention to and purchase the product; as the product does not adopt a shining package, the product dynamic display method can avoid the waste caused by adopting shining packages to all the products in the prior art, thereby avoiding excessive package reducing the packing cost of the product, saving packing resources, and promoting the environmental protection.

Owner:KHAINAN YAYUAN ANTI TSOUNTERFEIT TECH RES INST

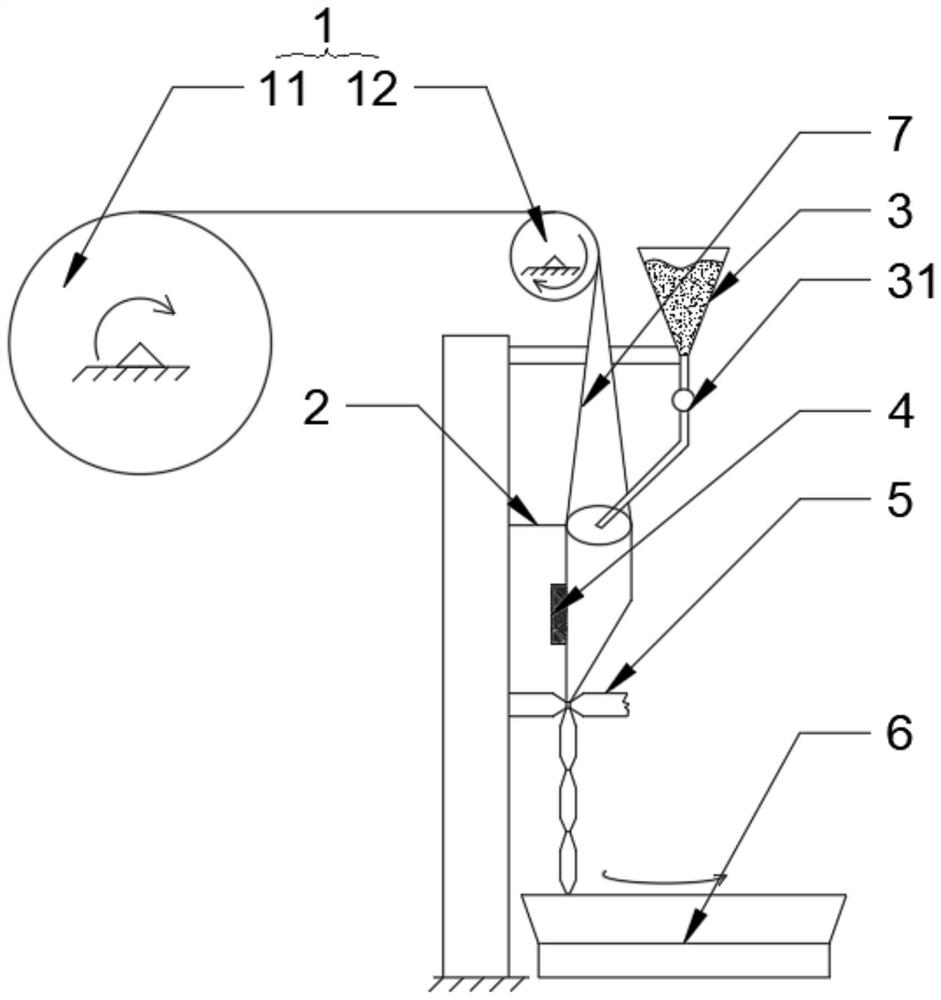

Full-automatic particle packaging machine

InactiveCN112455808AAvoid overpackingWrapper twisting/gatheringSolid materialIndustrial engineeringFully automated

The invention discloses a full-automatic particle packaging machine. The full-automatic particle packaging machine comprises an automatic packaging bag feeding machine, an edge rolling device, a quantitative discharging machine, an edge sealing machine, a cutting machine and a rotary collecting device, wherein the automatic packaging bag feeding machine is used for conveying packaging bags for packaging to a packaging area; the edge rolling device is arranged on a rack and used for overlapping two edges of each packaging bag to roll the packaging bag into a cylinder; the quantitative discharging machine is arranged on the rack and used for quantitatively adding products into the packaging bags which are rolled into the cylinders in a timing manner; the edge sealing machine is used for sealing two edges of each packaging bags in a hot-pressing manner; the cutting machine is used for carrying out hot-pressing sealing on the head end and the tail end of each sealed packaging bag and carrying out intermittent cutting on the sealing position, so that quantitative particle products exist in small packaging bags defined by the edge sealing machine and the cutting machine; and the rotary collecting device is arranged at the bottom of the cutting machine, and collects the packaged products in a rotary manner.

Owner:JIANGXI ZHONGSHAN PHARMA IND

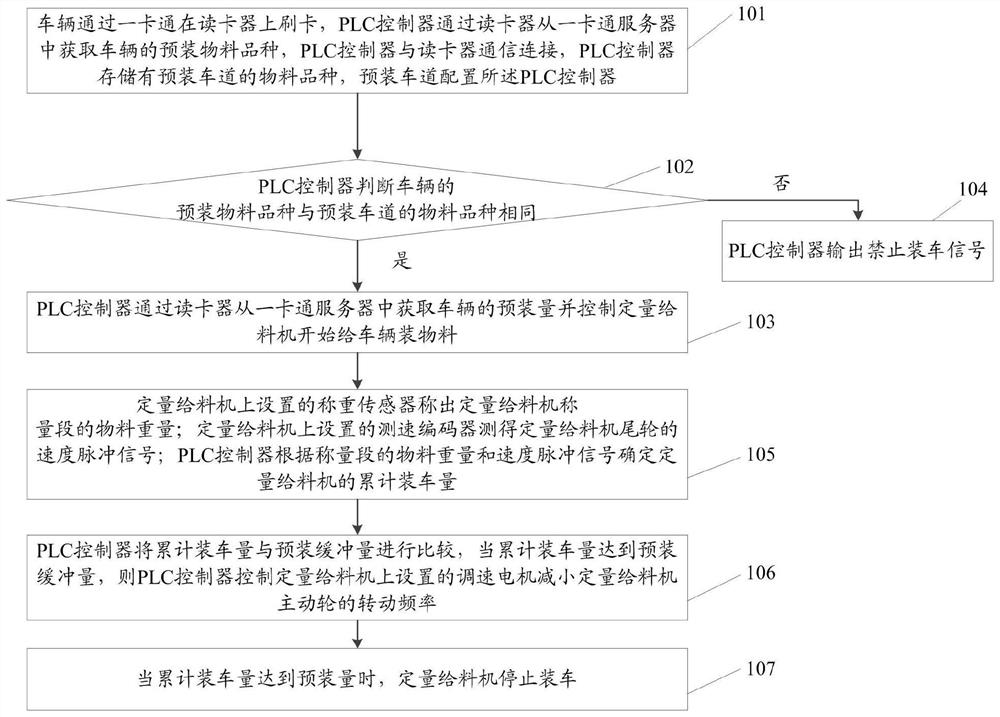

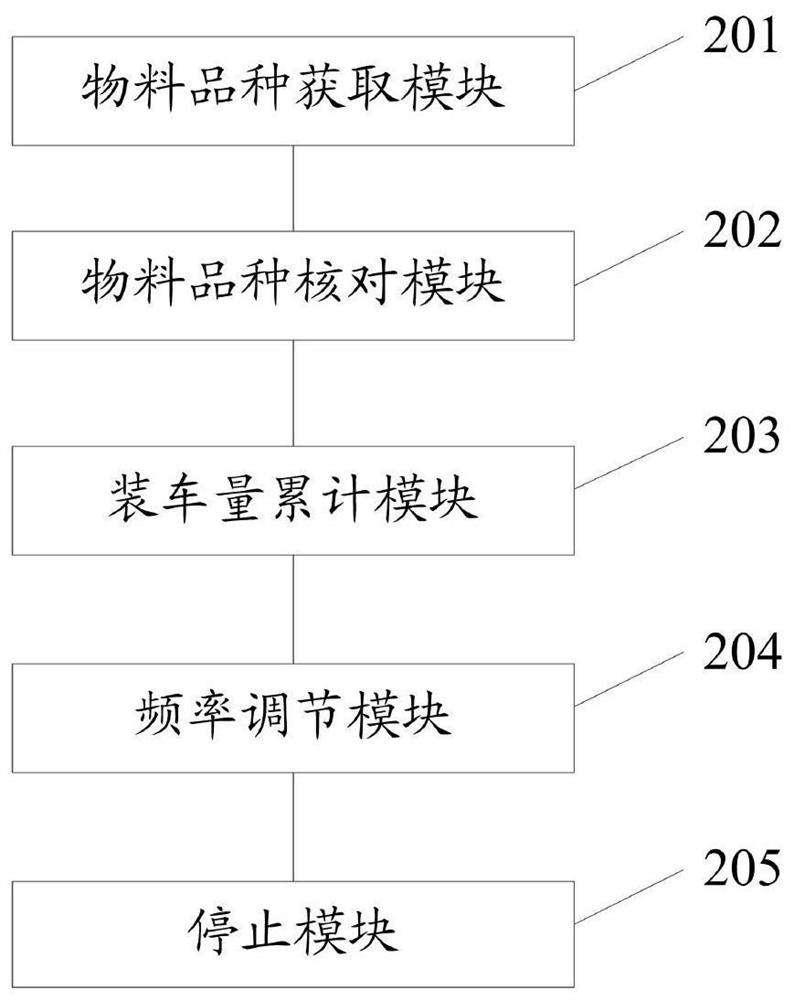

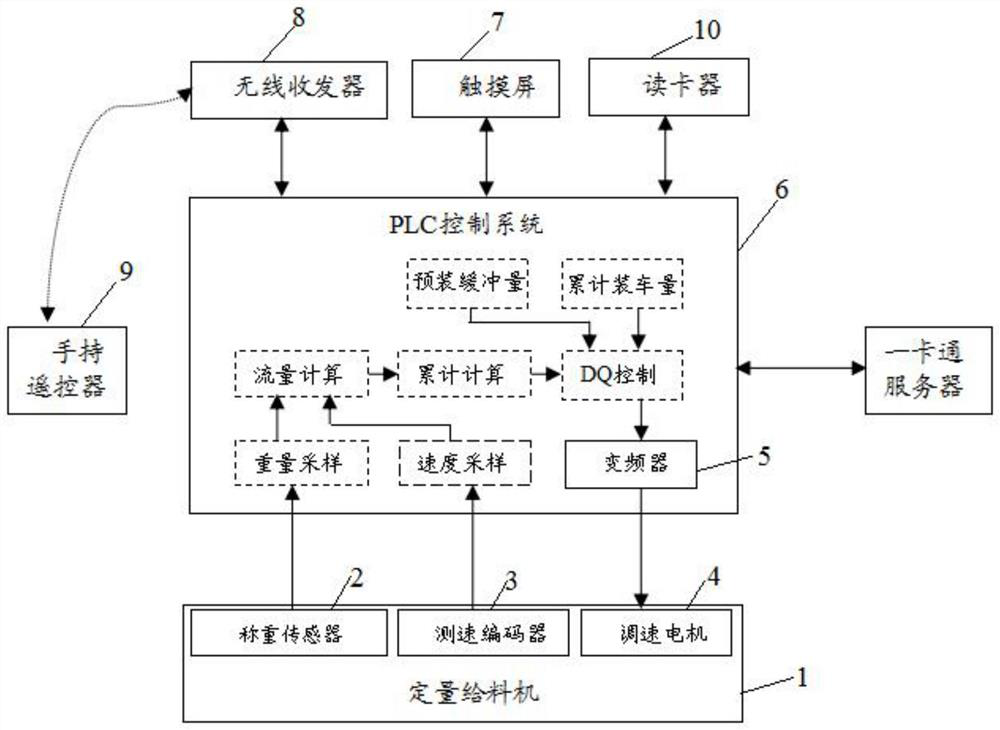

Clinker and aggregate divergence expected quantity control method and system

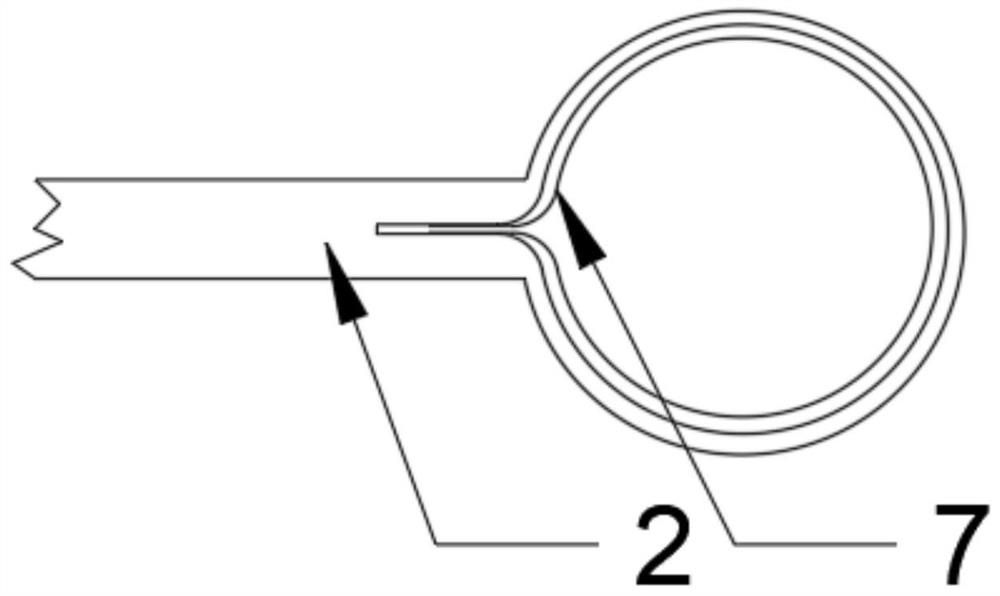

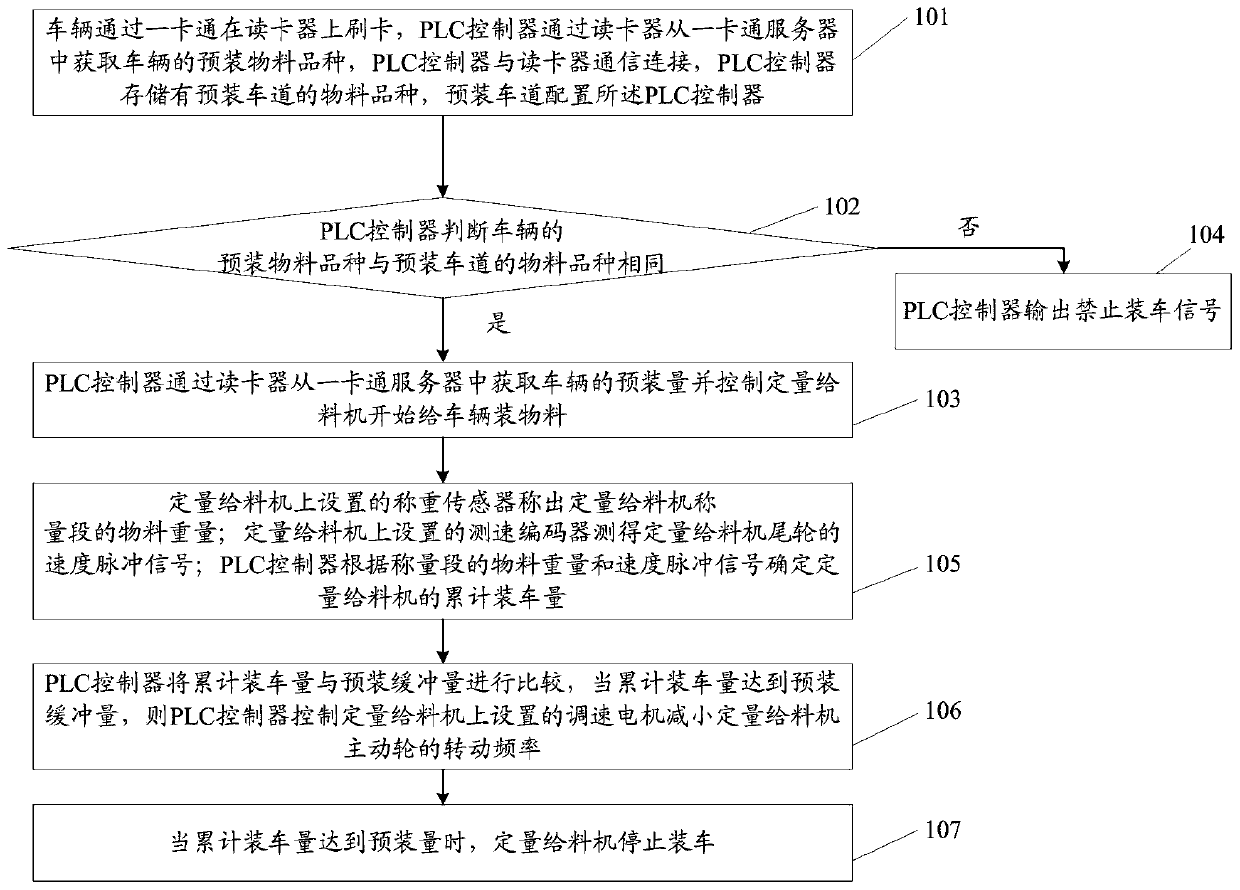

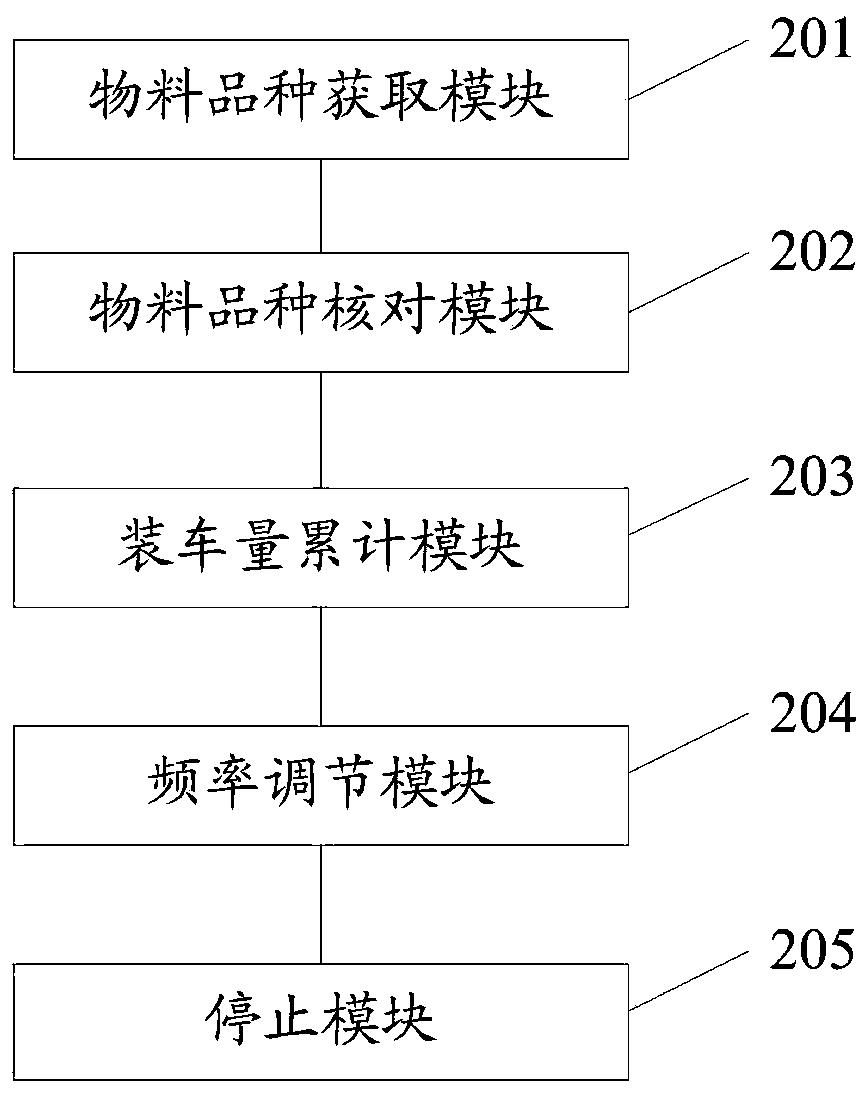

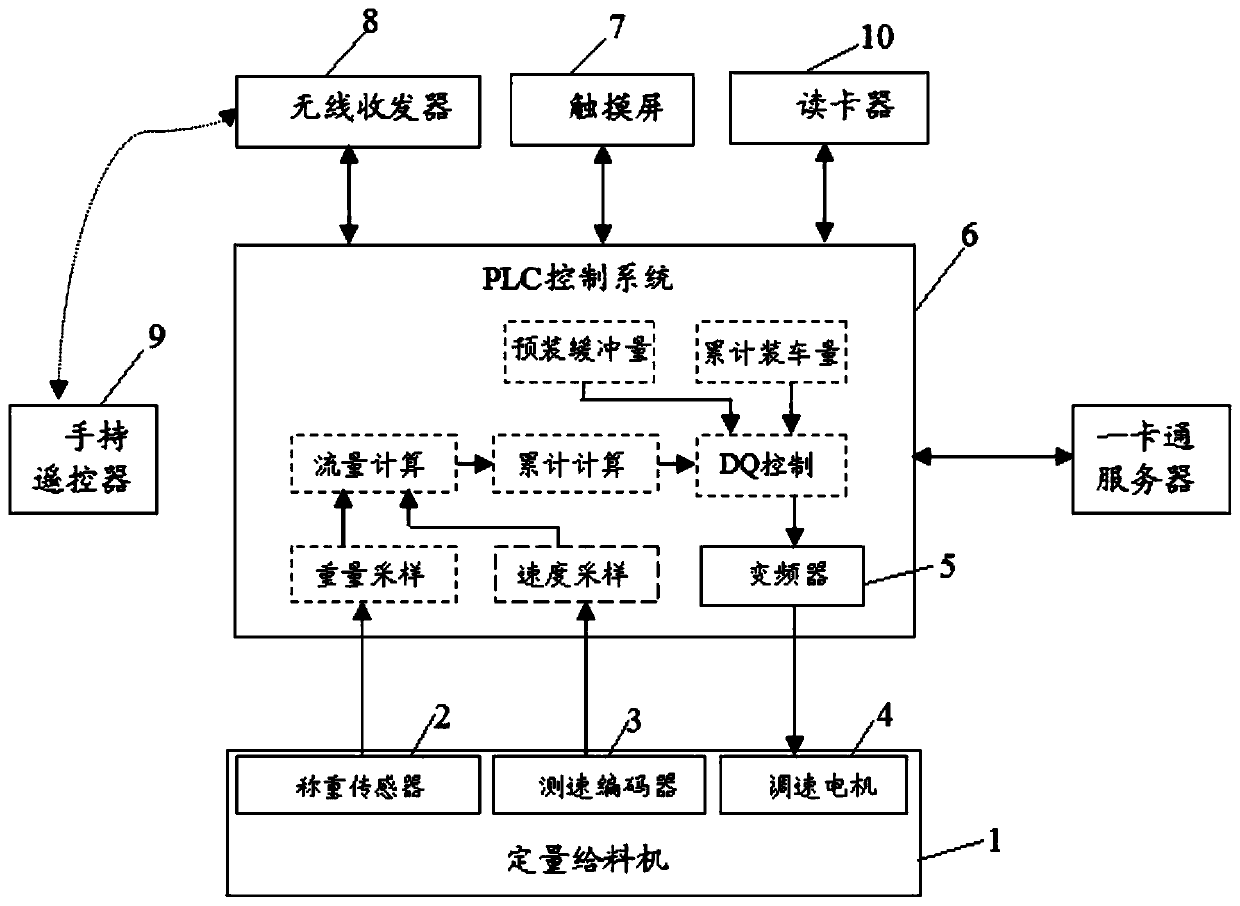

ActiveCN110683378AGuaranteed accuracyImprove accuracyConveyorsControl devices for conveyorsDrive wheelMaterial type

The invention discloses a clinker and aggregate divergence expected quantity control method and system. The method comprises the steps that a PLC judges whether the preloaded material type of a vehicle and the material type of a preloaded lane are the same or not, and if the material types are the same, a quantitative feeding machine starts to load materials onto the vehicle; a weighing sensor, aspeed measuring encoder and a speed regulating motor are arranged on the quantitative feeding machine, and the weighing sensor is used for weighing the material weight of the weighing section of the quantitative feeding machine; the speed measuring encoder measures a speed pulse signal of a tail wheel of the quantitative feeding machine; the PLC determines the accumulated loading quantity according to the material weight and the speed pulse signal of the weighing section; the accumulated loading quantity is compared with the preloading buffer quantity, when the accumulated loading quantity reaches the preloading buffer quantity, the PLC controls the speed regulating motor to reduce the rotating frequency of a driving wheel of the quantitative feeding machine; and when the accumulated loading quantity reaches the preloading quantity, the quantitative feeding machine stops loading. According to the clinker and aggregate divergence expected quantity control method and system, the situations of wrong loading, inefficient loading and excessive loading are avoided, and the loading metering accuracy and the loading efficiency are improved.

Owner:CHUZHOU ANRI HUILONG ELECTRONICS CO LTD

Automatic assembling mechanism for special-shaped sealing ring

PendingCN114227197AOptimizing Automatic TechnologySimple structureMaterial analysis by optical meansMetal working apparatusMachiningIndustrial engineering

The automatic assembling mechanism for the special-shaped sealing ring comprises a machining table, a machining station is installed at the upper end of the machining table, an installation connecting block is installed at the bottom of the machining table, and movable rolling wheels are arranged at the bottom of the installation connecting block; a positioning support, a stand column, a drawer type quick-change clamp and a servo module are installed on the machining station, a first stock bin and a second stock bin are installed on the drawer type quick-change clamp, a carrying module is installed at the upper end of the stand column, a sliding way is installed on the carrying module, and a carrying mechanism is installed at the front end of the sliding way. According to the automatic assembling mechanism for the special-shaped sealing rings, the double stock bins can achieve non-stop feeding, the production efficiency is improved, different tools are interchanged to be compatible with various special-shaped sealing rings, the situation that the sealing rings are neglected to be assembled, too many sealing rings are assembled and not assembled in place can be prevented through CCD detection, the automatic technology of the special-shaped sealing rings is optimized, automation is achieved to the maximum degree, and the production efficiency is improved. And the working efficiency and the product yield are improved.

Owner:昆山迈征自动化科技有限公司

Production method for toothpaste combination

InactiveCN108248934ARealize automated productionSimple structurePackaging automatic controlPackaging machinesProduction lineToothpaste

The invention provides a toothpaste combination production line and belongs to the technical field of toothpaste production equipment. A control cylinder (4) is arranged at the side surface of the tail end (3) of a late packaging toothpaste conveying line (2) of the toothpaste combination production line. The control cylinder (4) is connected with a control part (5), a combined toothpaste packaging machine (10) is connected with the tail end (6) of an early-packaging toothpaste conveying line, and the combined toothpaste packaging machine (10) is connected with the combined toothpaste collecting box (7). The toothpaste combination production line and the toothpaste combination production method are simple in structure, batch automatic combination of early-packaging toothpaste and late-packaging toothpaste can be conveniently and quickly realized, the reliability of the toothpaste combination is ensured, the problems of less, more and wrong packaging are avoided, and the efficiency of toothpaste combination and the quality of toothpaste combination are improved.

Owner:WUHU IROBSYS ROBOT CO LTD

Swing-out pipette tip autoloader

ActiveCN104176313BSimple structureAvoid missingIndividual articlesJigging conveyorsPipetteEngineering

The invention discloses an automatic loader for a swing-type pipettor. The automatic loader comprises a vibrating disc, a linear vibrator, a swing mechanism, a movable base and a loading disc, the vibrating disc is connected with the linear vibrator, one end of the linear vibrator is connected with the swing mechanism, the movable base is arranged below the swing mechanism, the loading disc is arranged on the movable base, and the swing mechanism and the movable base are controlled by a controller. By the above mode, the automatic loader has the advantages of high reliability, accuracy in positioning, compact and simple structure, high transposition speed, accuracy in placing, freeness of missing placement and mistaken placement, convenience in operation and the like, and has wide market prospect in packaging market.

Owner:JIANGSU LONGRUN IRRIGATION & DRAINAGE

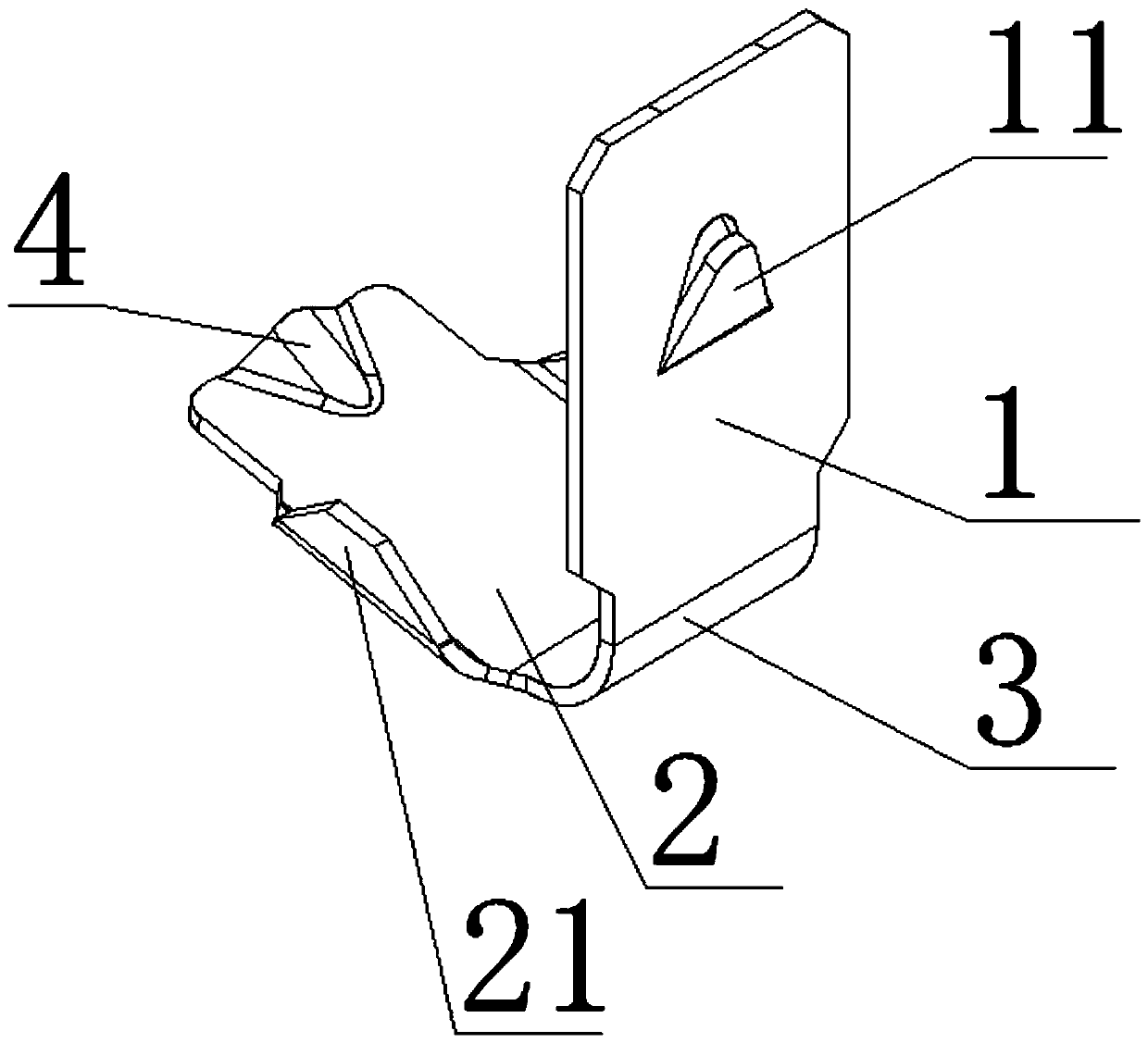

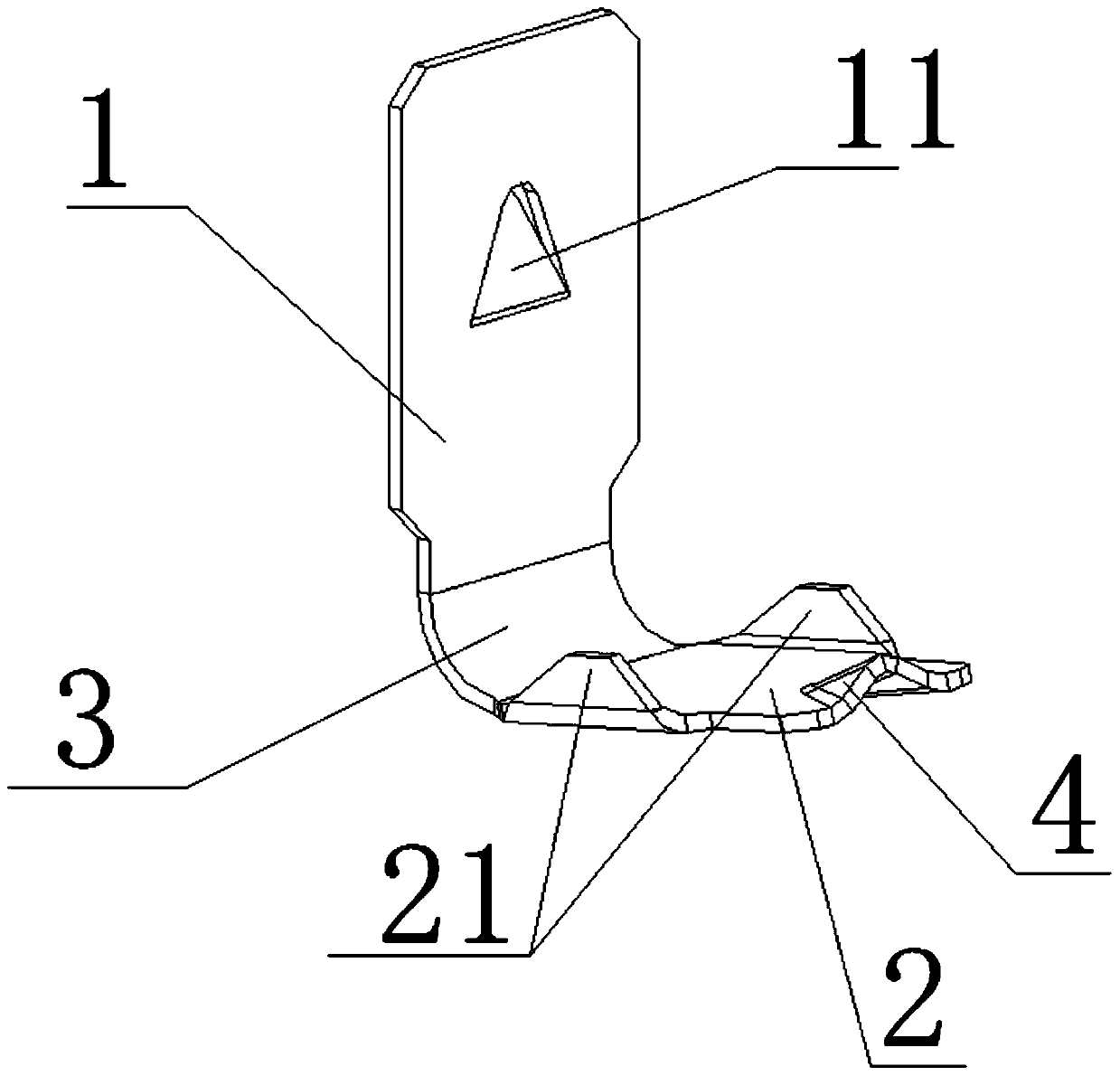

a spoon machine

ActiveCN112173308BEasy to operateRealize automatic bondingPackagingConveyor partsAdhesive glueWaste product

The invention relates to a scoop pointing machine, which comprises a frame, on which a cup cover conveyor belt and a spoon conveyor belt are respectively arranged, a glue spraying device, a manipulator, and a visual recognition waste discharge device are arranged on the frame along the conveying direction, and the frame is equipped with There is a spoon-dividing device; the advantage of the present invention is that the cup lid on the cup lid conveyor belt is sprayed with glue by the glue spraying device, and then the spoon conveyed on the spoon conveyor belt is put into the cup lid through the robot arm. Glue, so that the spoon can be automatically glued to the cup cover, and then the cup cover can be detected by the visual recognition waste discharge device, so as to effectively avoid the missing or overfilling of the spoon. Secondly, the visual recognition waste discharge device includes The detection mechanism and the push-out mechanism use the detection mechanism to detect the number of spoons in the cup lid. When the information detected by the detection mechanism does not match the set value, the waste product can be pushed out of the cup lid conveyor belt in time through the push-out mechanism, thus ensuring that the rack is released. The quality of the lid of the material.

Owner:JIAXING YANDANG PACKAGING

A control method and system for clinker and aggregate divergence pre-measurement

ActiveCN110683378BGuaranteed accuracyImprove accuracyConveyorsControl devices for conveyorsDrive wheelMaterial type

The invention discloses a clinker and aggregate divergence expected quantity control method and system. The method comprises the steps that a PLC judges whether the preloaded material type of a vehicle and the material type of a preloaded lane are the same or not, and if the material types are the same, a quantitative feeding machine starts to load materials onto the vehicle; a weighing sensor, aspeed measuring encoder and a speed regulating motor are arranged on the quantitative feeding machine, and the weighing sensor is used for weighing the material weight of the weighing section of the quantitative feeding machine; the speed measuring encoder measures a speed pulse signal of a tail wheel of the quantitative feeding machine; the PLC determines the accumulated loading quantity according to the material weight and the speed pulse signal of the weighing section; the accumulated loading quantity is compared with the preloading buffer quantity, when the accumulated loading quantity reaches the preloading buffer quantity, the PLC controls the speed regulating motor to reduce the rotating frequency of a driving wheel of the quantitative feeding machine; and when the accumulated loading quantity reaches the preloading quantity, the quantitative feeding machine stops loading. According to the clinker and aggregate divergence expected quantity control method and system, the situations of wrong loading, inefficient loading and excessive loading are avoided, and the loading metering accuracy and the loading efficiency are improved.

Owner:CHUZHOU ANRI HUILONG ELECTRONICS CO LTD

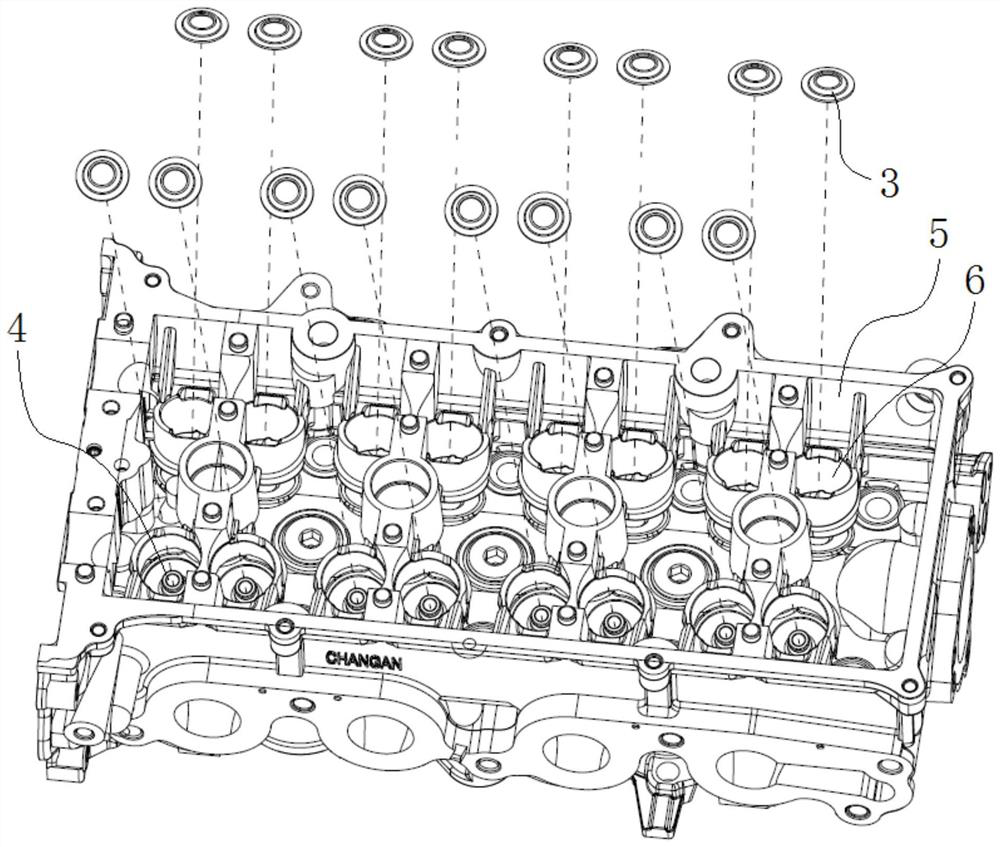

An assembly device for a valve spring base

ActiveCN110883543BRealize the assemblyReduce labor intensityAssembly machinesCylinder headEngineering

The invention discloses an assembly device for a valve spring base, which comprises a collection plate and an assembly tool; the same m rows of blind holes are opened on the collection plate, and the number n of each row of blind holes is the same as the number n of the intake side valves on the cylinder head. The number k of conduits is equal and the arrangement positions are corresponding. The assembly tooling includes a pressing assembly, an elastic connector and an adsorption assembly. The pressing assembly includes a pressing plate and a row of pressing rods. The adsorption assembly includes a support plate, n magnets and a row of sleeves , the support plate is provided with an assembly through hole communicating with the sleeve, n magnets are fixedly connected to the lower ends of the n sleeves, one end of the elastic connector is connected to the pressure plate, and the other end is connected to the support plate, and n pressure rods pass through the The n assembly through holes extend into the n sleeves, and the n magnets can respectively absorb n valve spring bases placed in the n blind holes in each row. By adopting the invention, the assembly of the valve spring base on the intake side or the exhaust side can be completed at one time, avoiding over-assembly or missing assembly, and effectively improving assembly efficiency at the same time.

Owner:CHONGQING CHANGAN AUTOMOBILE CO LTD

Automatic card clamping machine

The invention discloses an automatic card clamping machine. The automatic card clamping machine comprises a machine frame, a left paper clamping plate, a right paper clamping plate and a paper clamping driving device for driving the left paper clamping plate and the right paper clamping plate to be opened or clamped are arranged on the machine frame, a paper clamping groove is formed between the left paper clamping plate and the right paper clamping plate, a paper sheet feeding device and a card feeding device are arranged above the paper clamping groove, the discharging end of the paper sheetfeeding device and the discharging end of the card feeding device are provided with a paper sheet falling device for dropping downwards paper sheets on the paper sheet feeding device and a card falling device for dropping downwards cards on the card feeding device respectively, a paper sheet falling groove for guiding the paper sheets dropped by the paper sheet falling device to fall into the paper clamping groove is further comprised, a limiting device capable of extending to stop the dropped paper sheets so as to limit the dropped paper sheets in the paper clamping groove is arranged belowthe paper clamping plates, the two sides of the paper clamping groove are provided with opening devices used for opening the paper sheets located in the paper clamping groove, and a card falling groove is arranged to be used for guiding the cards dropped by the card falling device to fall into the opened paper sheets. Automatic card clamping is realized, and the production efficiency is high.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA ZHONGSHAN INST

Wire clamping spring structure and switch structure

PendingCN111477475AImprove structural strengthAvoid deformationContact electric connectionEngineeringStructural engineering

The invention provides a wire clamping spring structure and a switch structure. The structure comprises: a longitudinal arm which is in a sheet shape, and a transverse arm which is sheet-shaped and isconnected with the longitudinal arm to form a V-shaped bend; a connecting part is arranged to be arc-shaped, a guide clamping groove is formed in the end part, extending back to the connecting part,of the cross arm; and a longitudinal arm inner side face and a transverse arm inner side face are oppositely arranged in the V-shaped bend, an edge folding part is arranged on the transverse arm innerside face in a protruding mode, the edge folding part is arranged along the edges of the two sides of the extending direction of the transverse arm, and / or a clamping lug part is arranged on the longitudinal arm inner side face, and the clamping lug part is arranged back to the longitudinal arm inner side face in a protruding mode. Through the arrangement, the structural strength and the installation stability of the wire clamping spring are improved, after the wire clamping spring is installed and matched, the phenomena of plug wire loosening and plug wire deviation are not likely to happen,and the problem that a switch control circuit is poor in contact or cannot be powered on is avoided.

Owner:GREE ELECTRIC APPLIANCES ZHONGSHAN SMALL HOUSEHOLD APPLIANCES MFG +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com