Cold extrusion processing equipment of high-precision automobile clutch

A processing equipment and clutch technology, applied in the field of high-precision automotive clutch cold extrusion processing equipment, can solve the problems of high scrap rate, excessive press-fitting, inconvenient use, etc., to improve product quality, improve installation accuracy, and avoid installation and processing. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

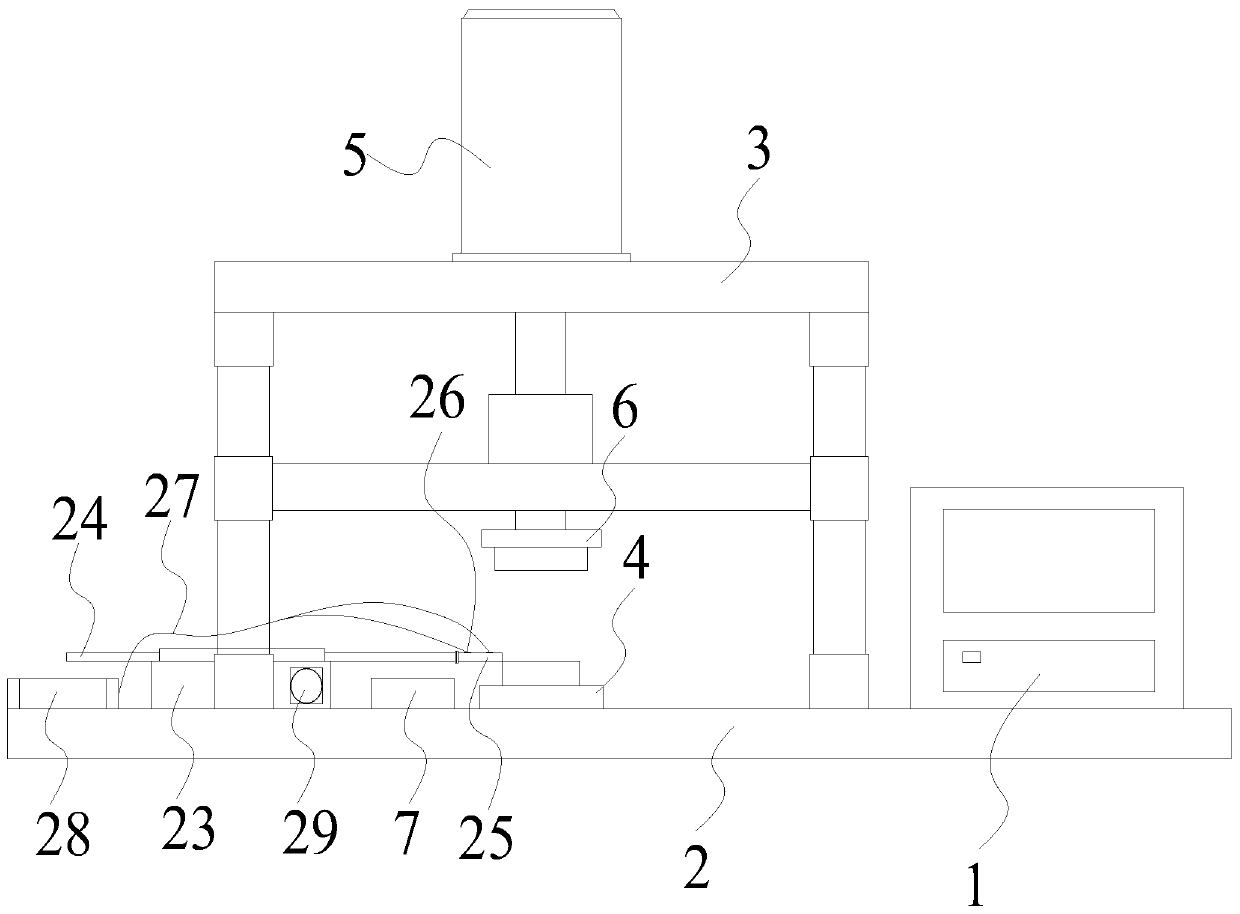

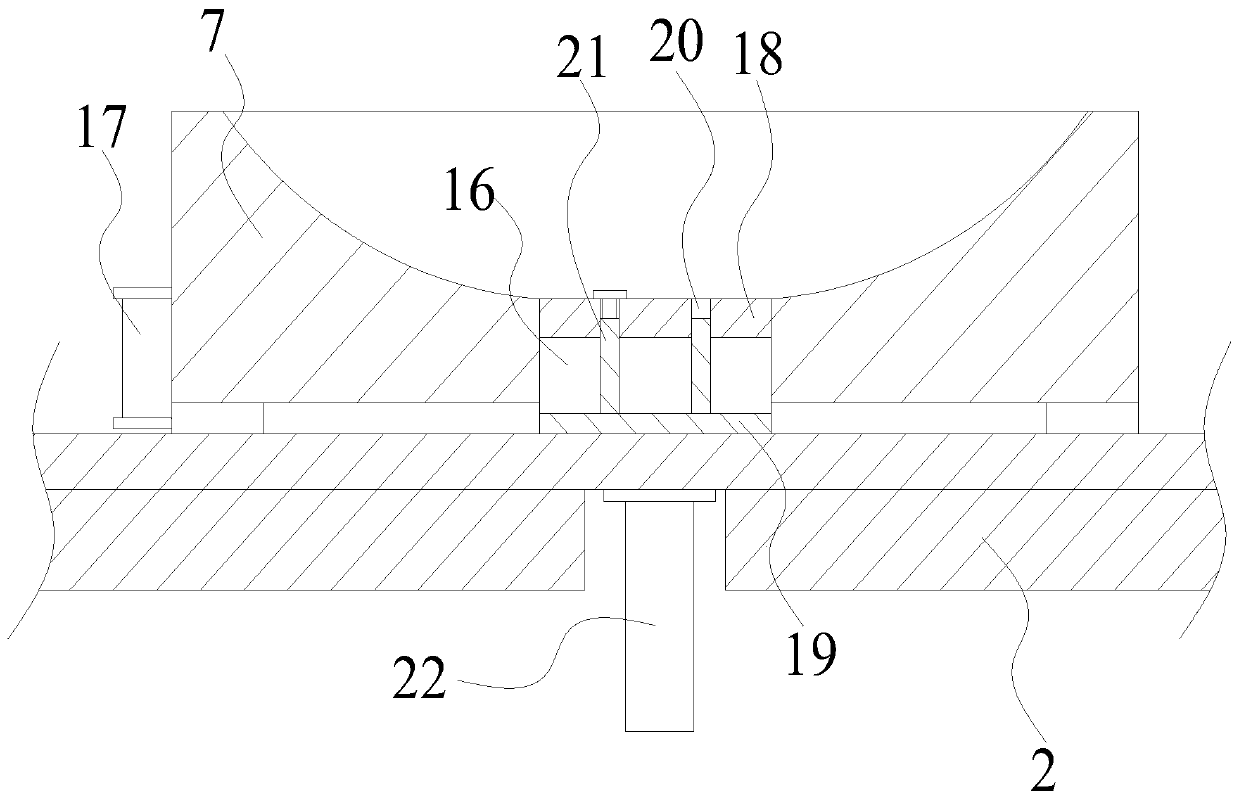

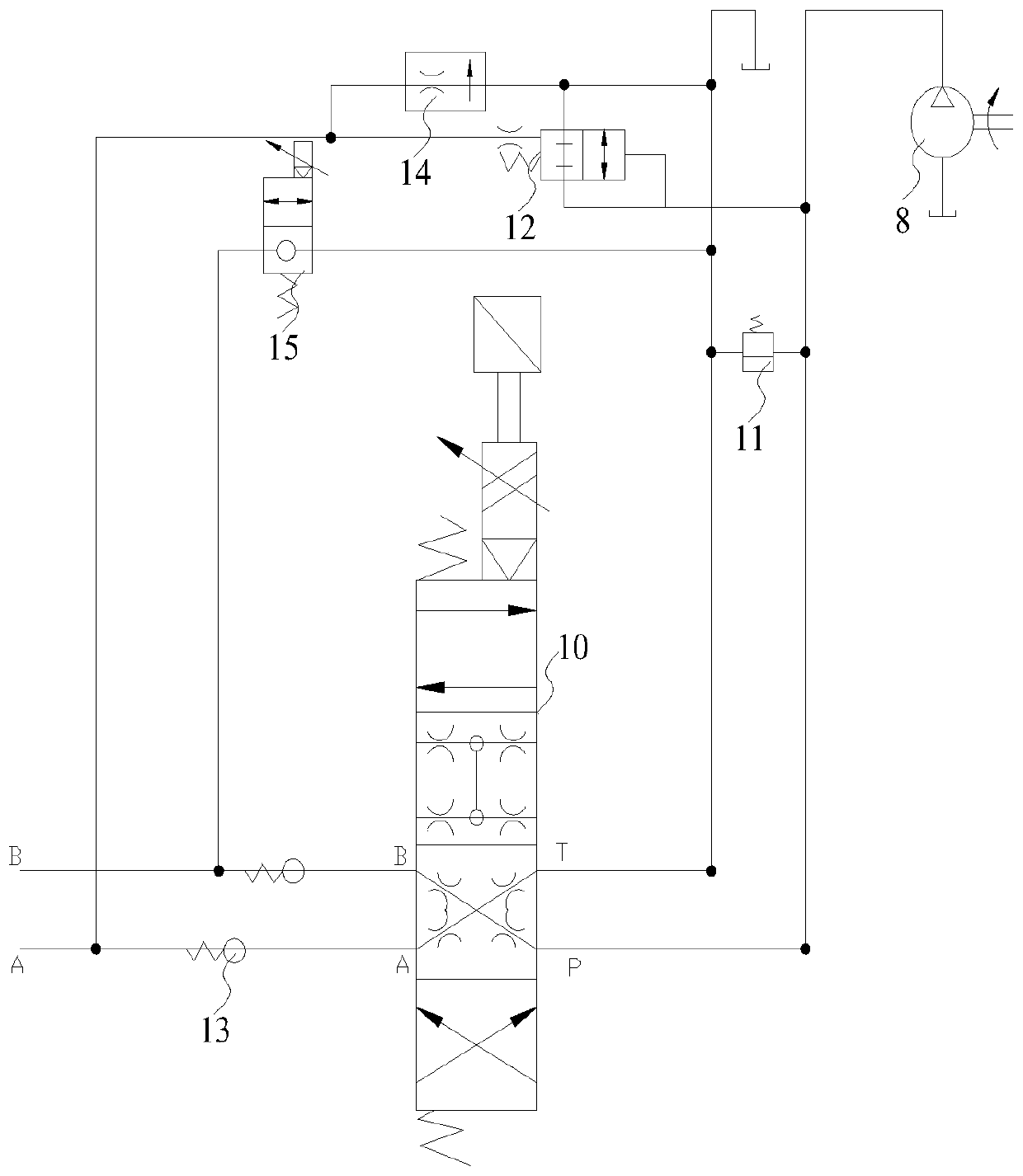

[0026] refer to Figure 1 to Figure 4 , the present invention includes a controller 1 with a built-in control system, a base 2 for fixing the controller 1 and a top seat 3 arranged above the base 2, and the base 2 is provided with a suction cup for fixing an automobile clutch The fixed mold 4, the top seat 3 is provided with a hydraulic cylinder 5 communicating with the servo hydraulic system, the hydraulic cylinder 5 is provided with a movable mold 6, and the servo hydraulic system supplies oil to the hydraulic cylinder 5 so that it can Drive the movable mold 6 to move towards the fixed mold 4, and one side of the fixed mold 4 is provided with an accommodating disc 7 for accommodating rivets, and the accommodating disc 7 is provided with an ejection mechanism for ejecting the rivets, so The base 2 is provided with a nailing mechanism located on one side of the accommodating plate 7 , and the nailing mechanism can absorb and move the rivets on the accommodating plate 7 to abov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com