Wire clamping spring structure and switch structure

A wire clamping and clamping lug technology, which is applied in the direction of electric switches, contacts, electrical components, etc., can solve the problems of poor contact of switch control lines, variable installation of clamping spring structure, and inability to energize, so as to avoid poor contact or failure The effect of power on, not easy to loosen the wire, and not easy to misalign the wire

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

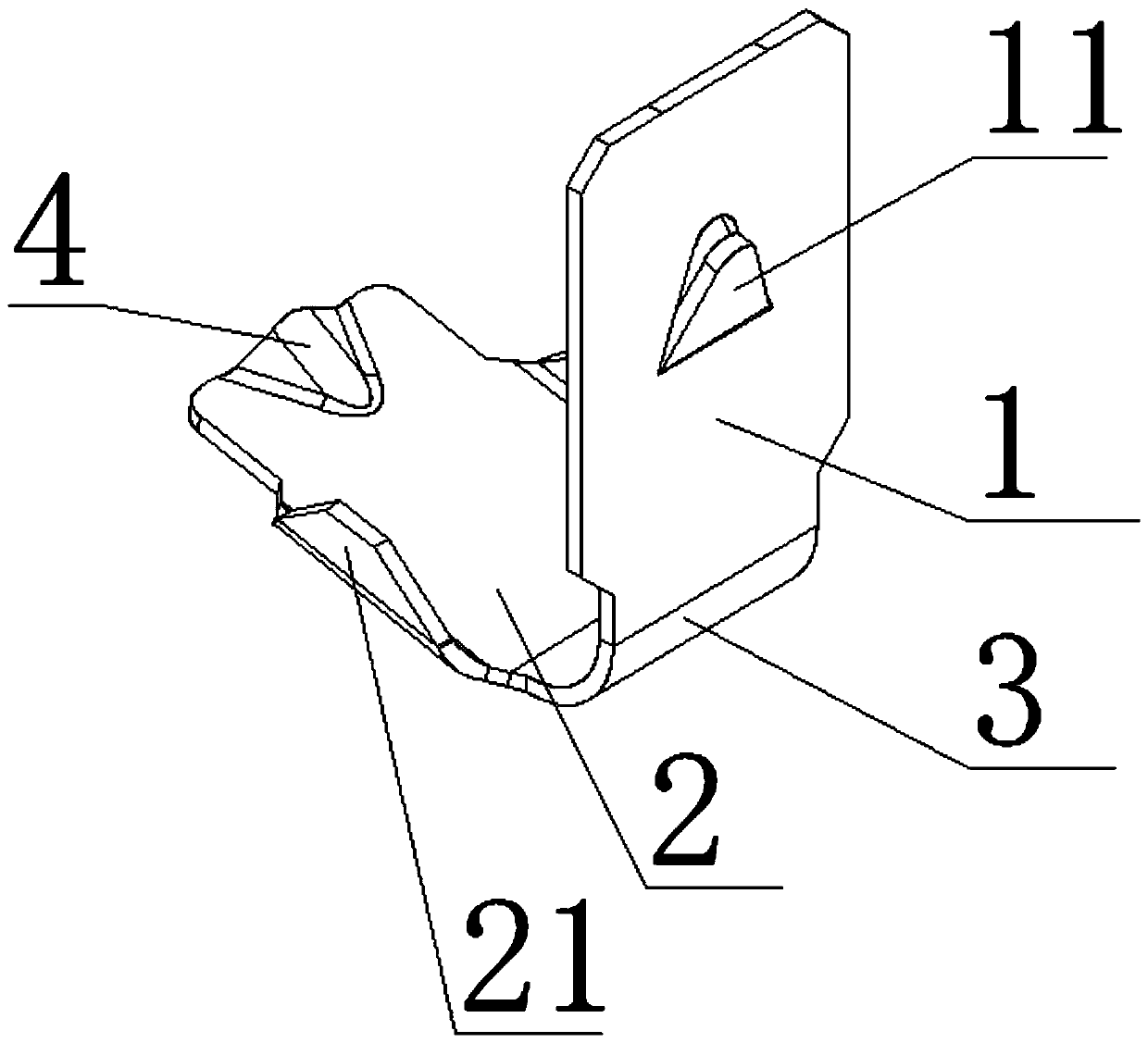

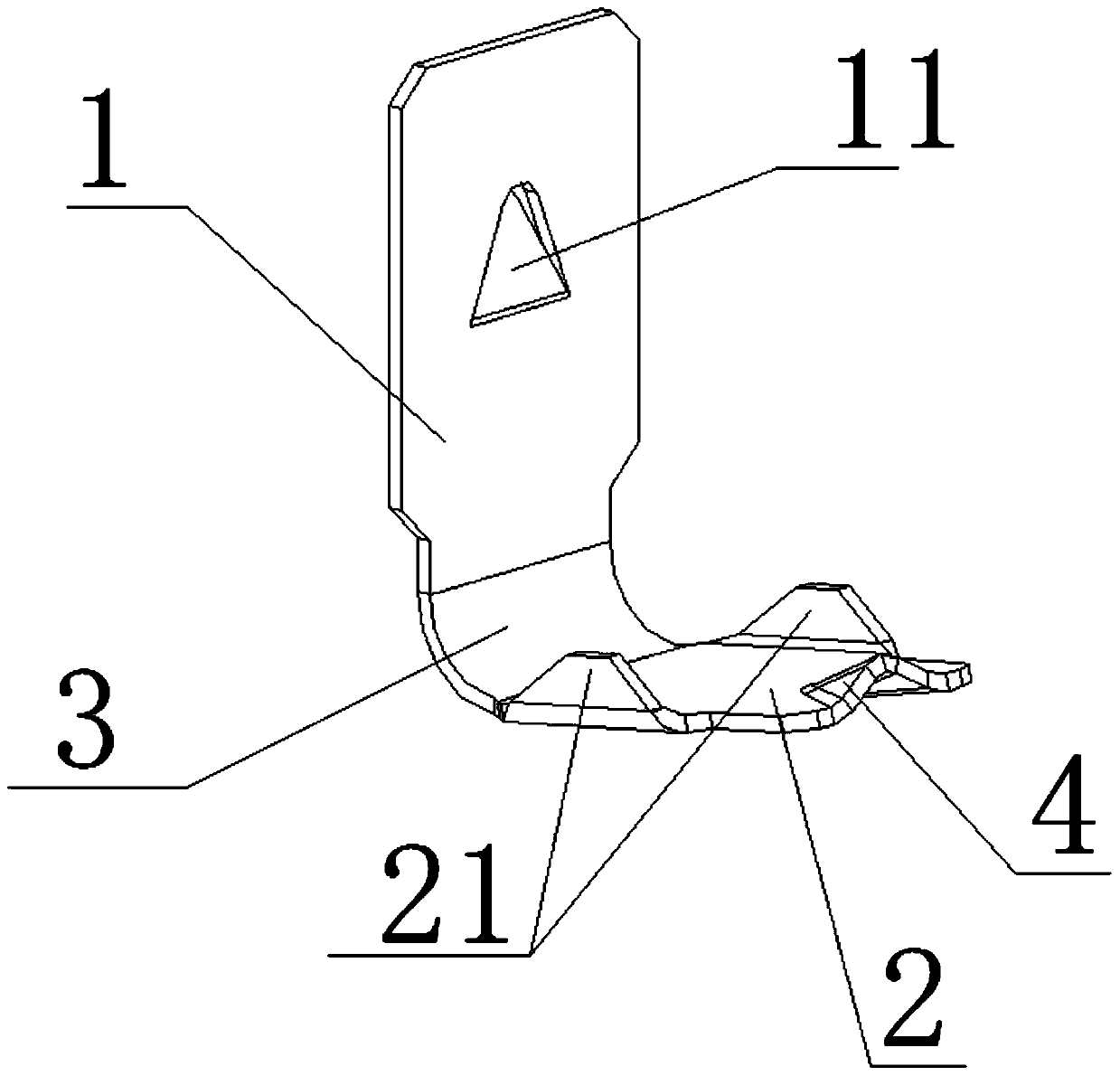

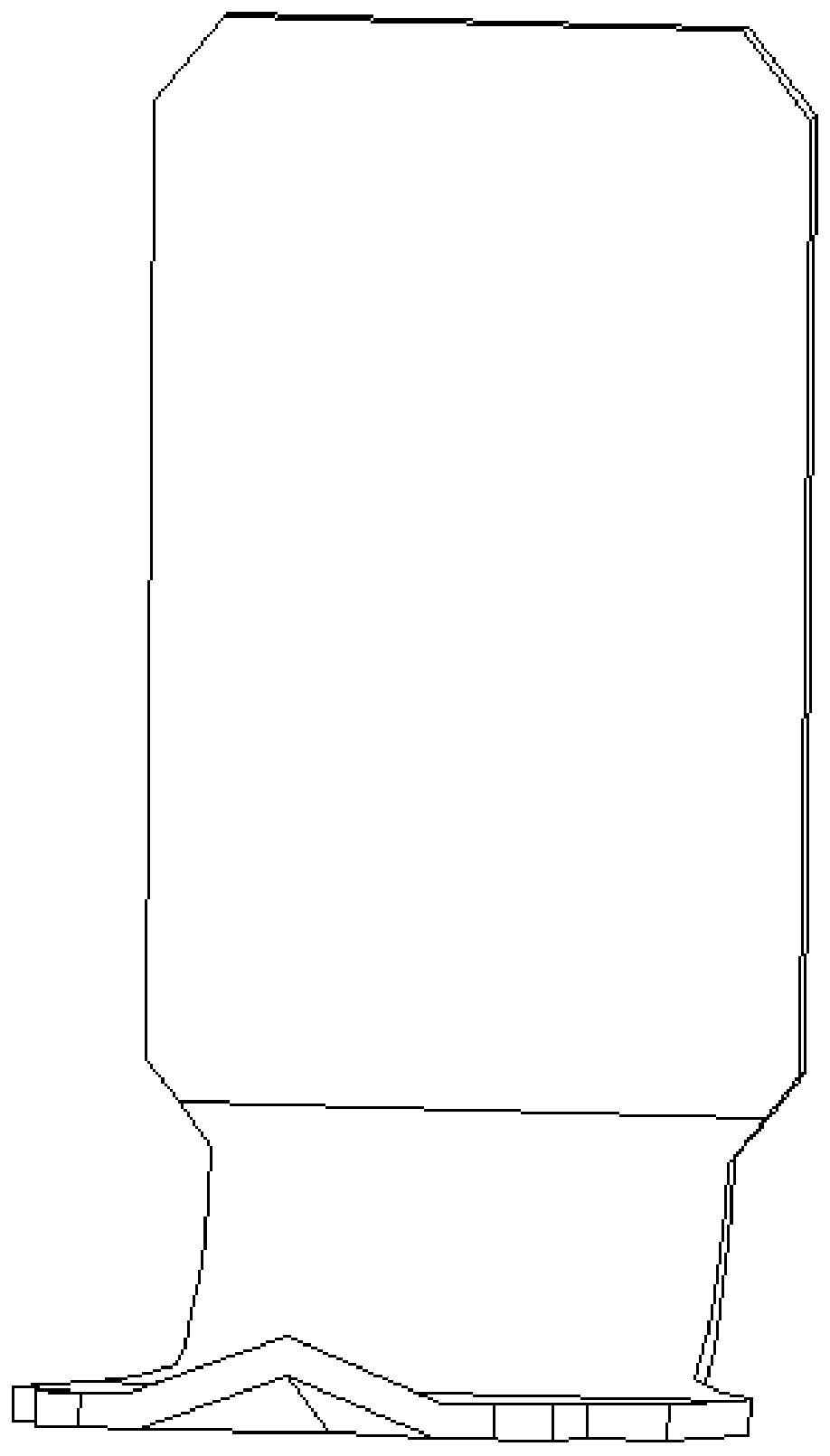

[0043] Such as figure 1 - Figure 4 , In this embodiment, a clamp spring structure is provided, including: a longitudinal arm 1 and a transverse arm 2 .

[0044] The longitudinal arm 1 and the cross arm 2 are connected to form a "V"-shaped bend. The connecting part of the two is the connecting part 3. The connecting part is arranged in an arc shape to avoid scratching the user and disperse the load to improve the strength of the parts. The "V"-shaped bend The inner side of the longitudinal arm 1 and the inner side of the cross arm 2 are oppositely arranged in the bend.

[0045] Wherein the longitudinal arm 1 is arranged in a square sheet shape, and the middle part is provided with a lug part 11, and the lug part 11 protrudes away from the inner surface of the longitudinal arm 1,

[0046]The cross arm 2 is arranged in a sheet shape, and the end portion facing away from the connecting portion 3 is provided with a guide slot 4 protruding along the inner surface of the cross arm...

Embodiment 2

[0066] This embodiment is based on the above-mentioned embodiment 1, such as Figure 5 - Figure 6 As shown, a switch structure is provided in this embodiment, including the above-mentioned clamping spring structure. The switch structure includes a seat body 5, the seat body 5 is fixed with the clamping spring structure, the clamping spring is arranged in the insertion port of the seat body, the tab part 11 on the longitudinal arm 1 is in contact with the inner side wall of the seat body, and the cross arm 2 The end portion of the seat abuts against the inner wall on the other side of the seat body, and a conductive sheet is arranged on the inner wall here. In this way, through the setting of the lug part 11, the phenomena such as loose wire insertion and offset wire insertion that may occur inside the switch are avoided, and problems such as poor contact or inability to power on the whole machine are avoided.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com