Patents

Literature

40results about How to "Realize automatic bonding" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

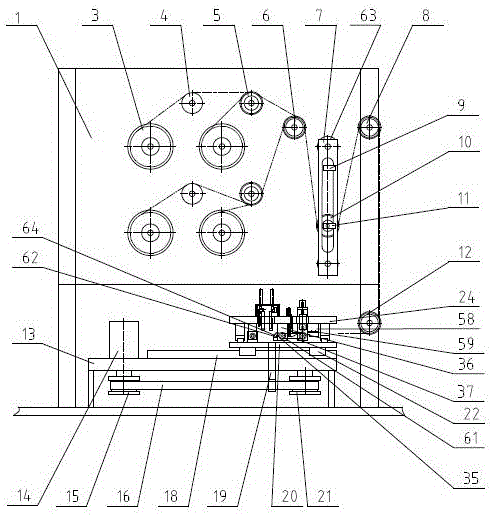

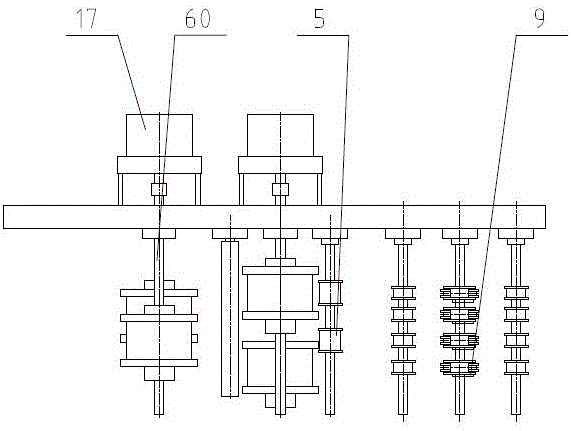

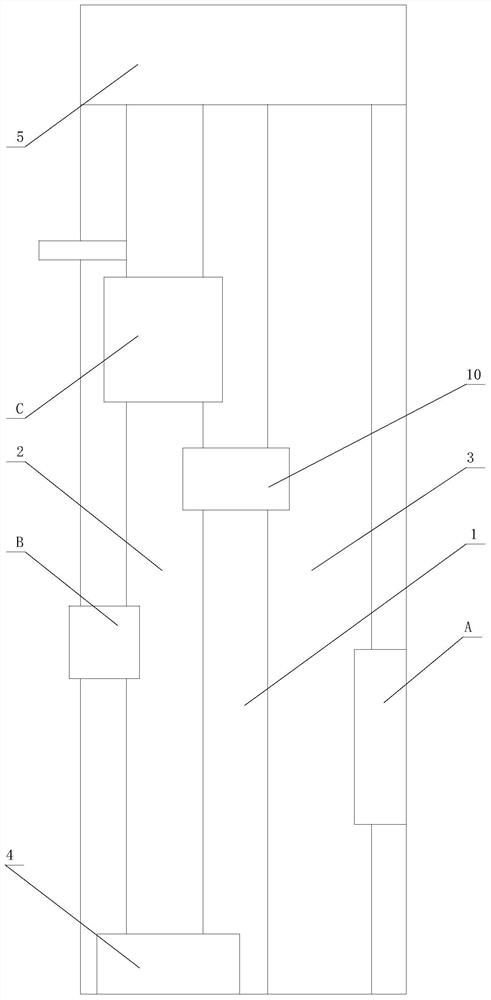

Adhesive tape sticking device

ActiveCN104192624ARealize automatic unwindingRealize automatic bondingFinal product manufactureArticle deliveryAdhesive beltIdler-wheel

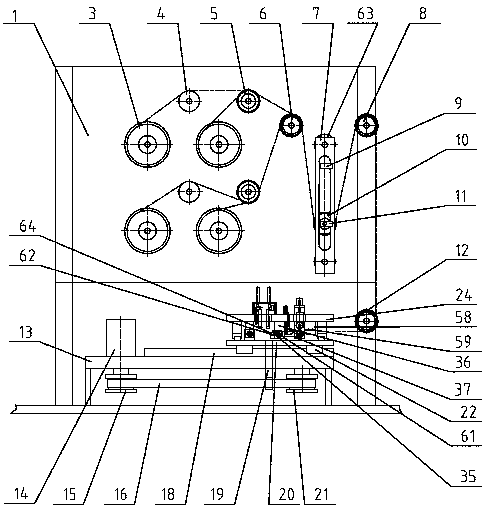

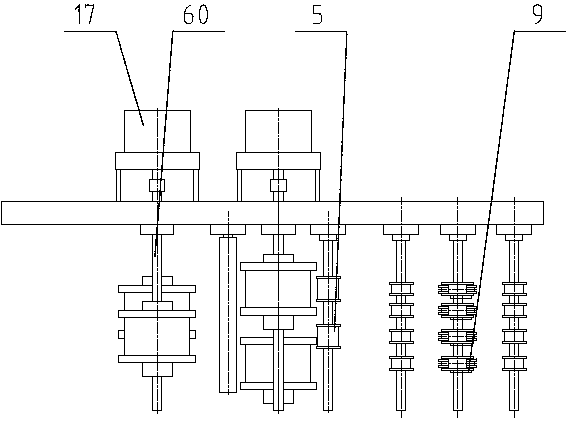

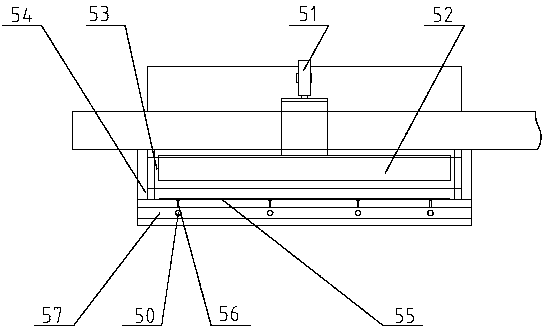

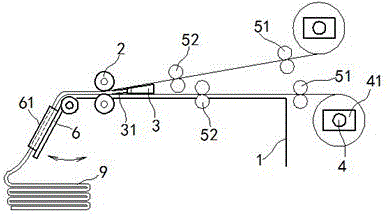

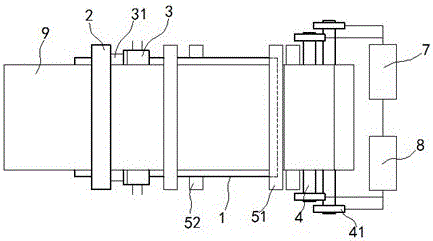

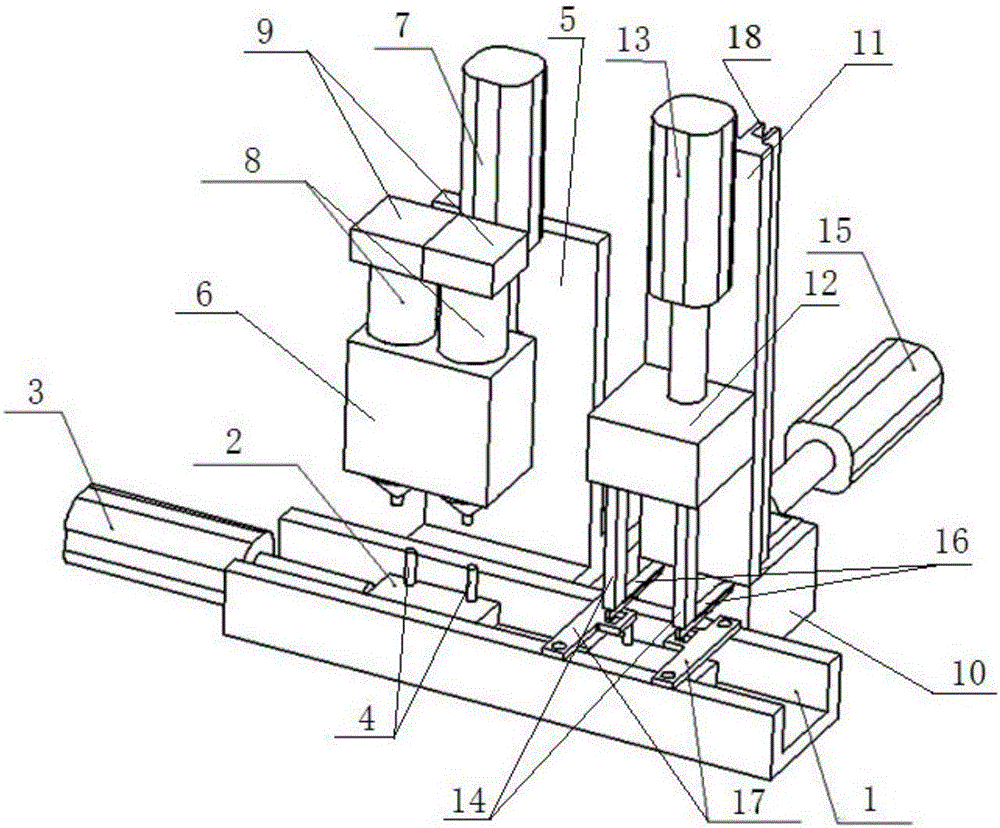

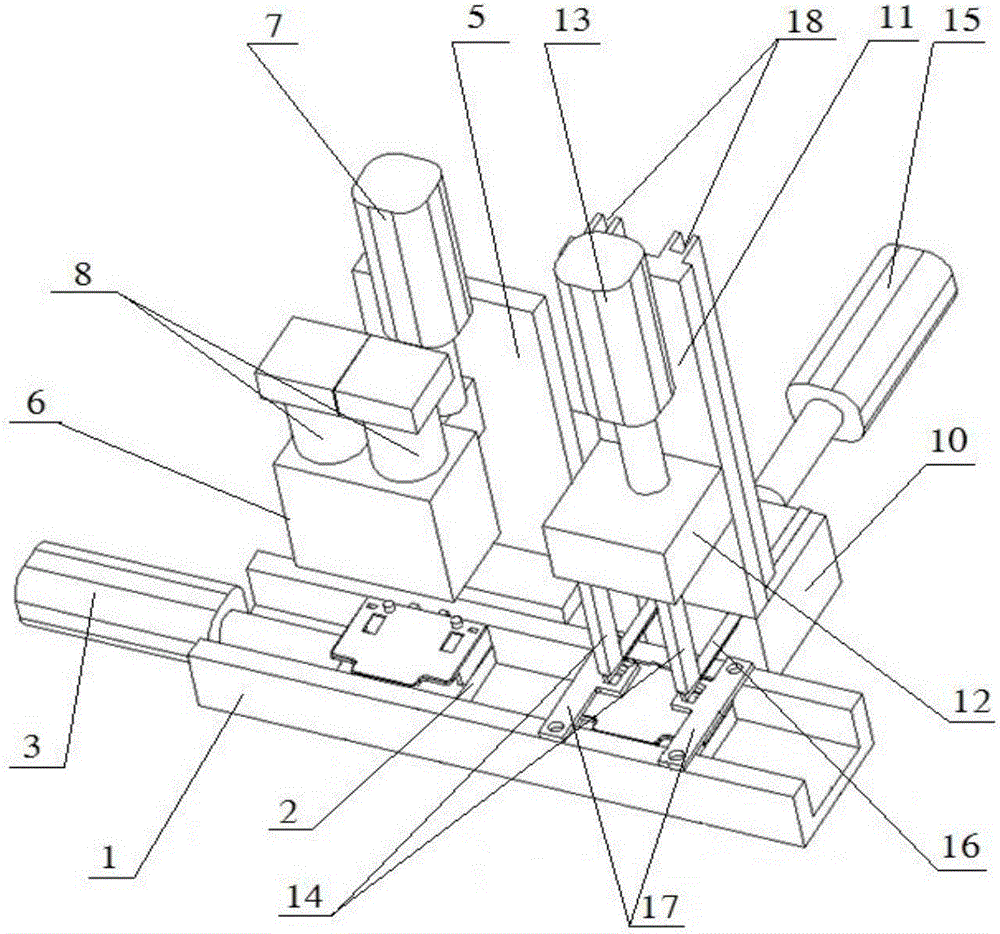

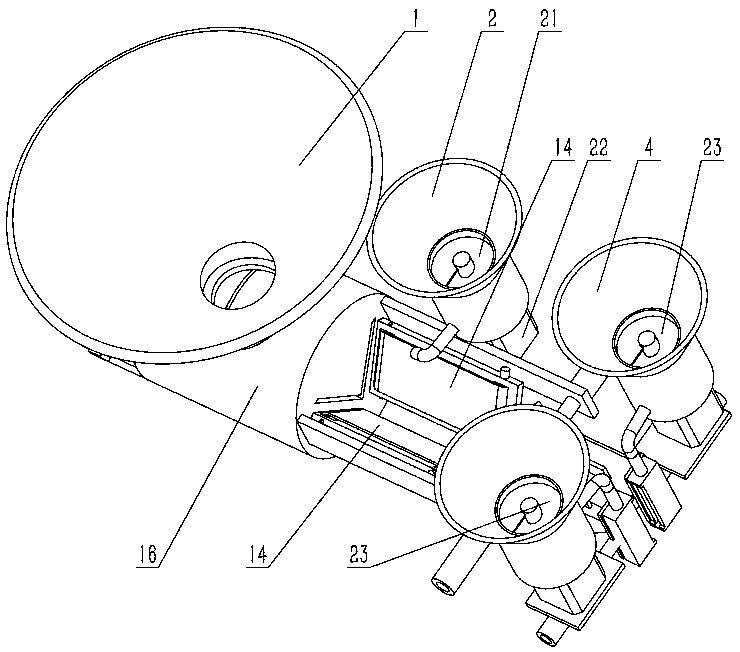

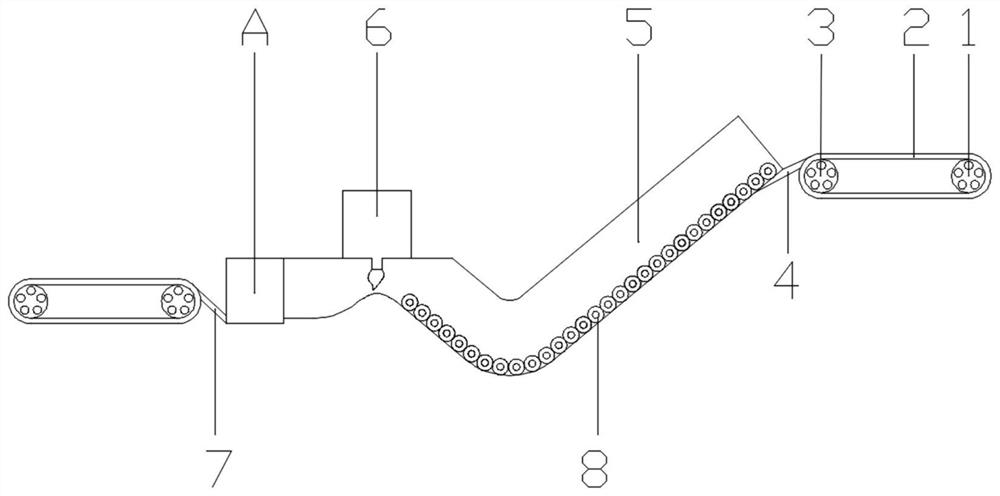

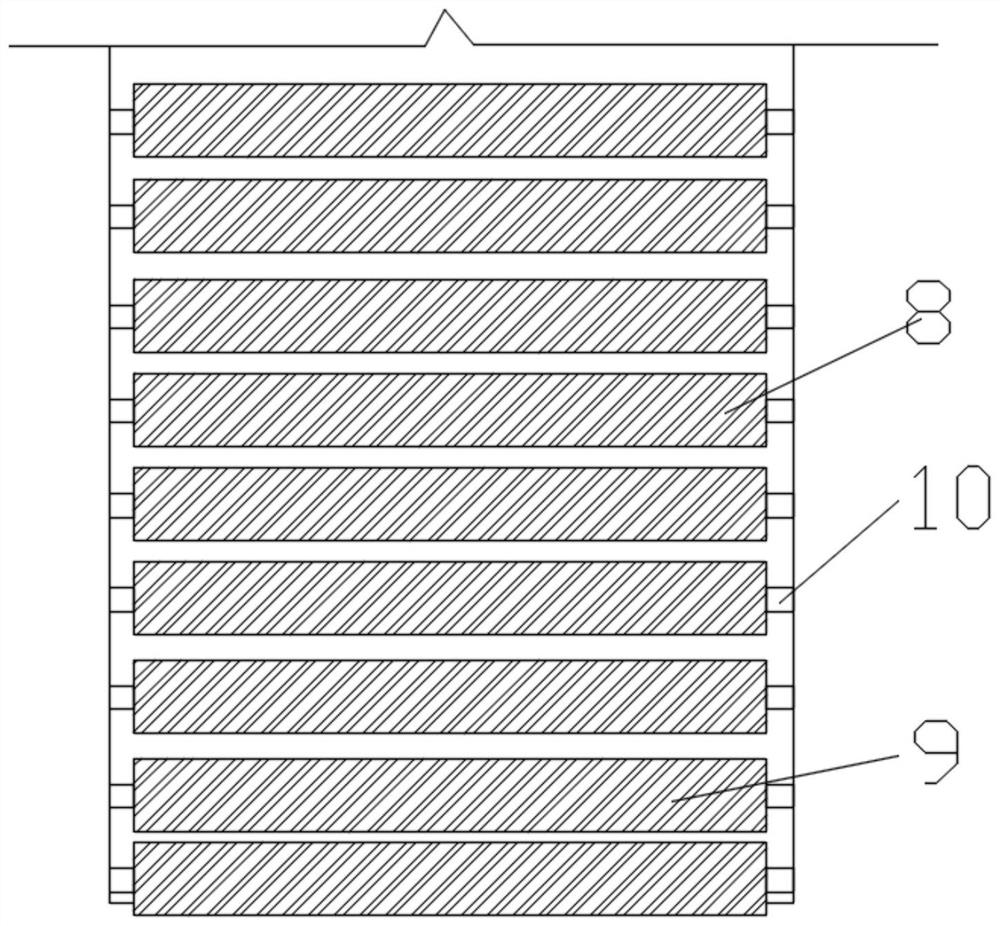

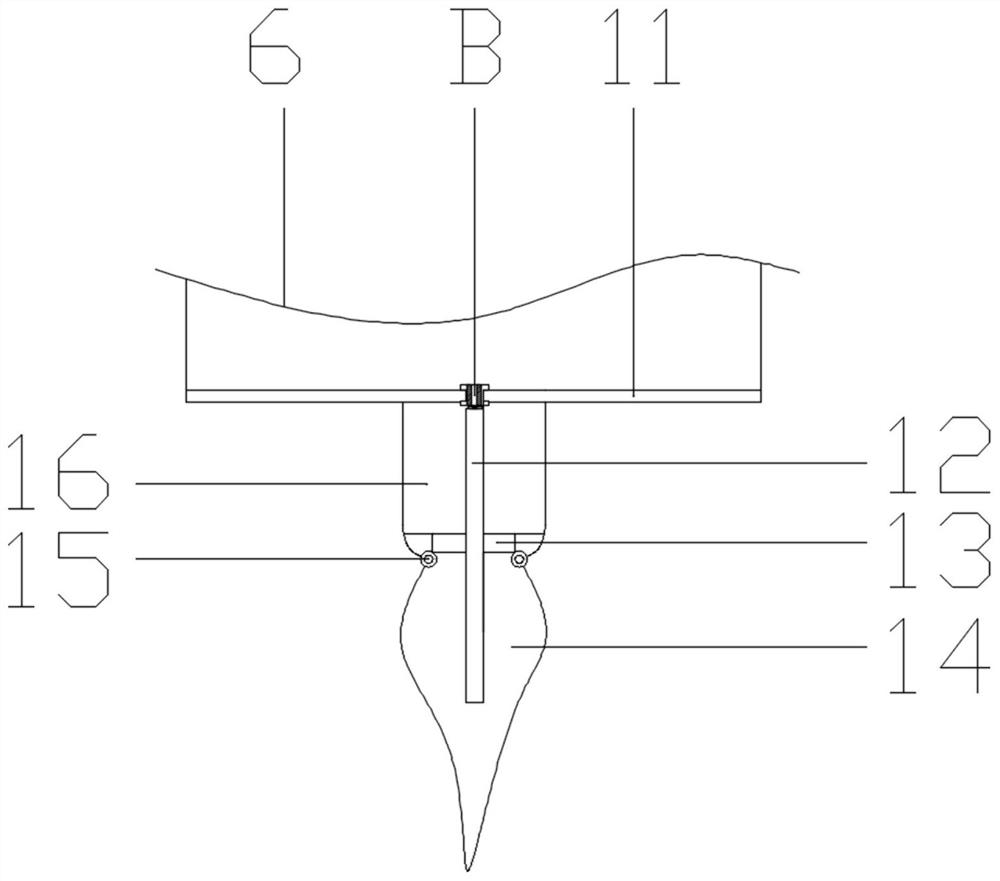

The invention relates to an adhesive tape sticking device. The adhesive tape sticking device comprises a machine frame, an adhesive tape paying-off device, an adhesive tape driving device, an adhesive tape cutting deice, an adhesive tape adsorption device, a press wheel device and a conveying device, wherein the adhesive tape paying-off p device and the conveying device are arranged on the machine frame, the adhesive tape paying-off device comprises an adhesive tape paying-off mechanism and an adhesive tape conveying mechanism, the conveying device comprises a first installation plate and a first movement mechanism, a second installation plate is arranged on the first installation plate, the adhesive tape driving device is fixed to the second installation plate, and the adhesive tape adsorption device and the press wheel device are fixedly arranged on the rear side of the adhesive tape driving device sequentially. The adhesive tape cutting device is arranged between a seventh idler wheel and a ninth idler wheel and comprises a fourth air cylinder, a cutter connecting plate, a cutter and a guide seat. The adhesive tape sticking device can automatically stick adhesive tape to a welding strip of a battery piece, and improve the conversion efficiency of a battery string.

Owner:WUXI LEAD INTELLIGENT EQUIP CO LTD

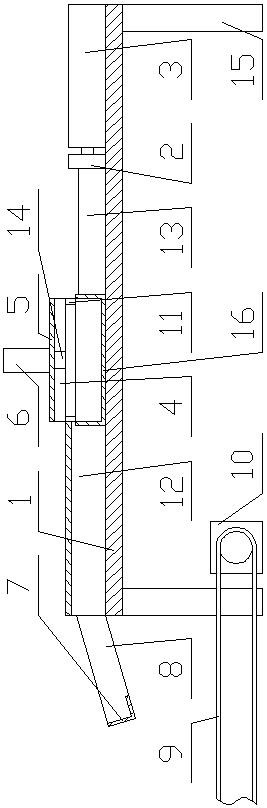

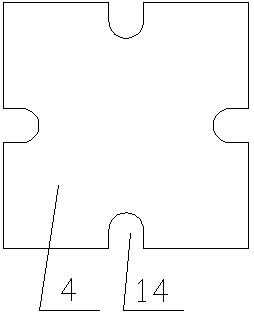

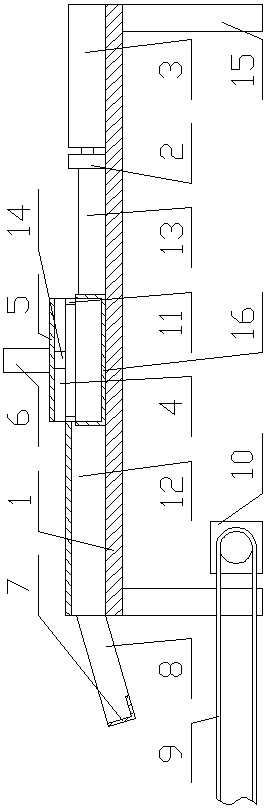

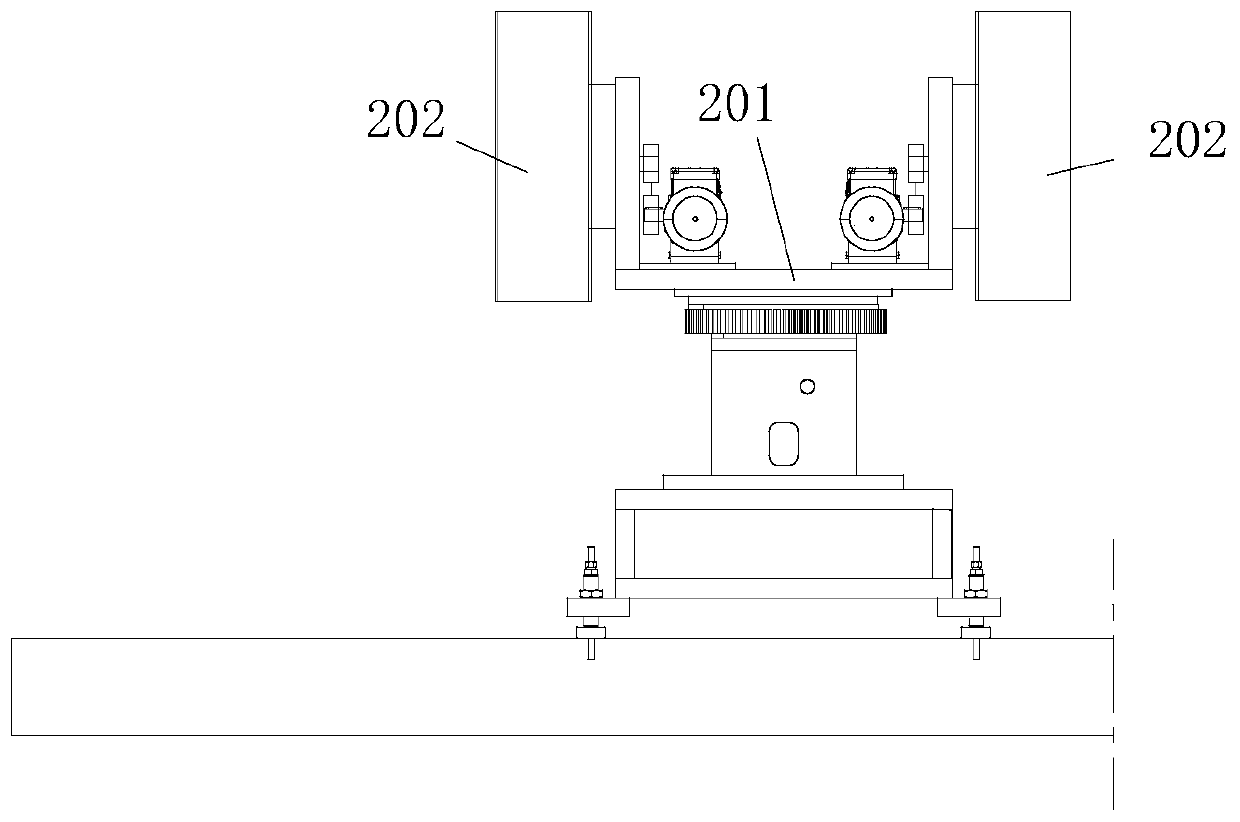

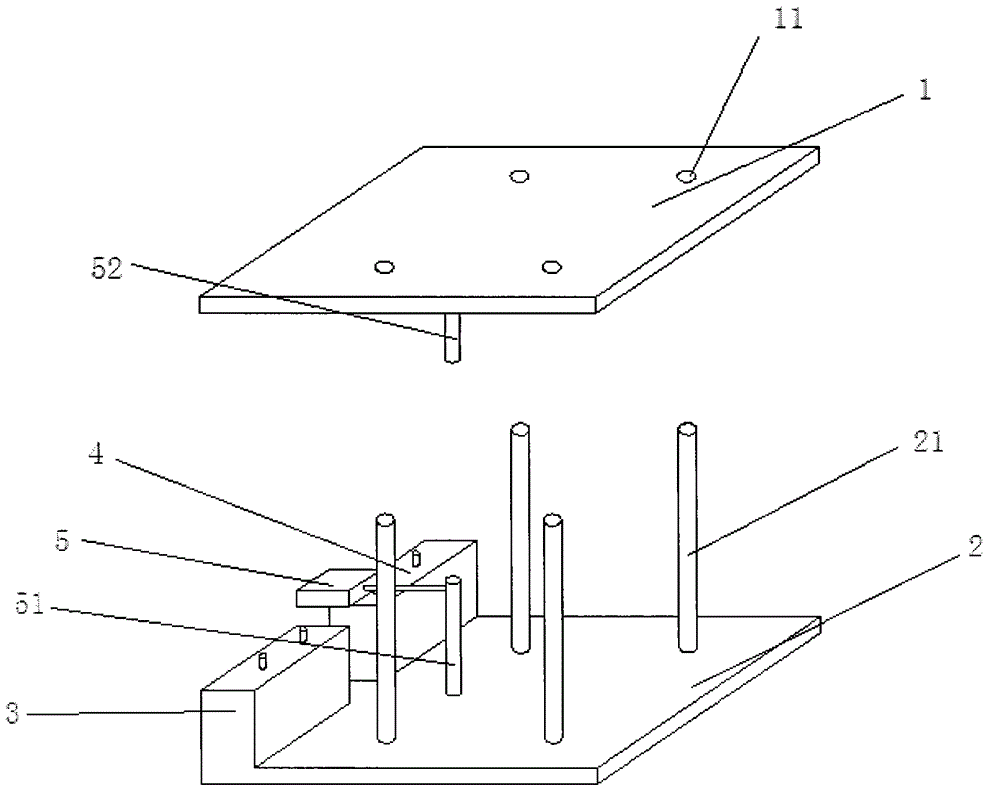

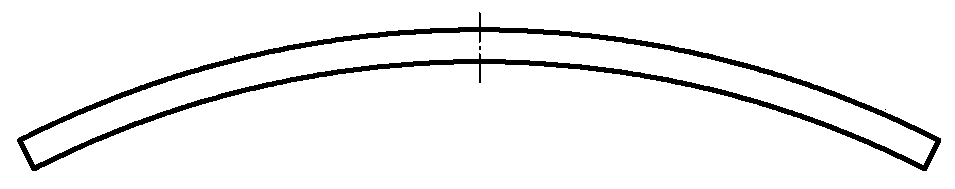

Automatic monocrystal silicon bonding machine

InactiveCN103267050ARealize automatic bondingAchieve mass productionFastening meansEngineeringMechanical engineering

The invention discloses an automatic monocrystal silicon bonding machine. The automatic monocrystal silicon bonding machine comprises a monocrystal silicon feeding system, a monocrystal silicon fixture feeding system, a resin feeding system and an operating system matching with the monocrystal silicon feeding system, the monocrystal silicon fixture feeding system and the resin feeding system. The monocrystal silicon feeding system comprises a first conveying device, and the monocrystal silicon fixture feeding system comprises a second conveying device. The automatic monocrystal silicon bonding machine is capable of achieving automatic bonding of monocrystal silicon fixtures, resin and monocrystal silicon, so that large-scale production of silicon wafers is achieved.

Owner:SIP GOLDWAY TECH

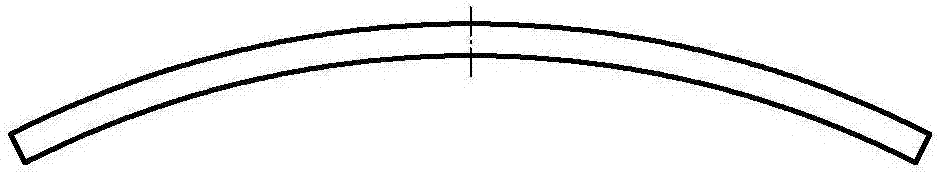

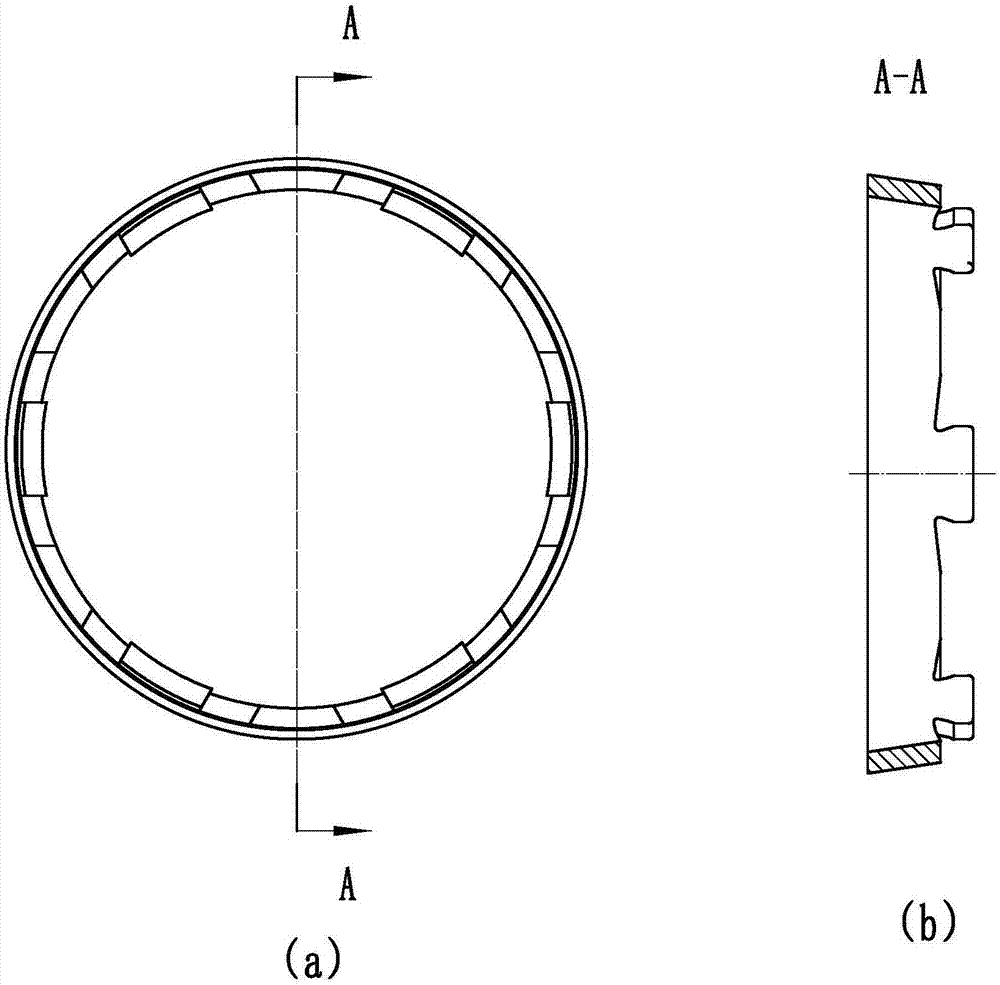

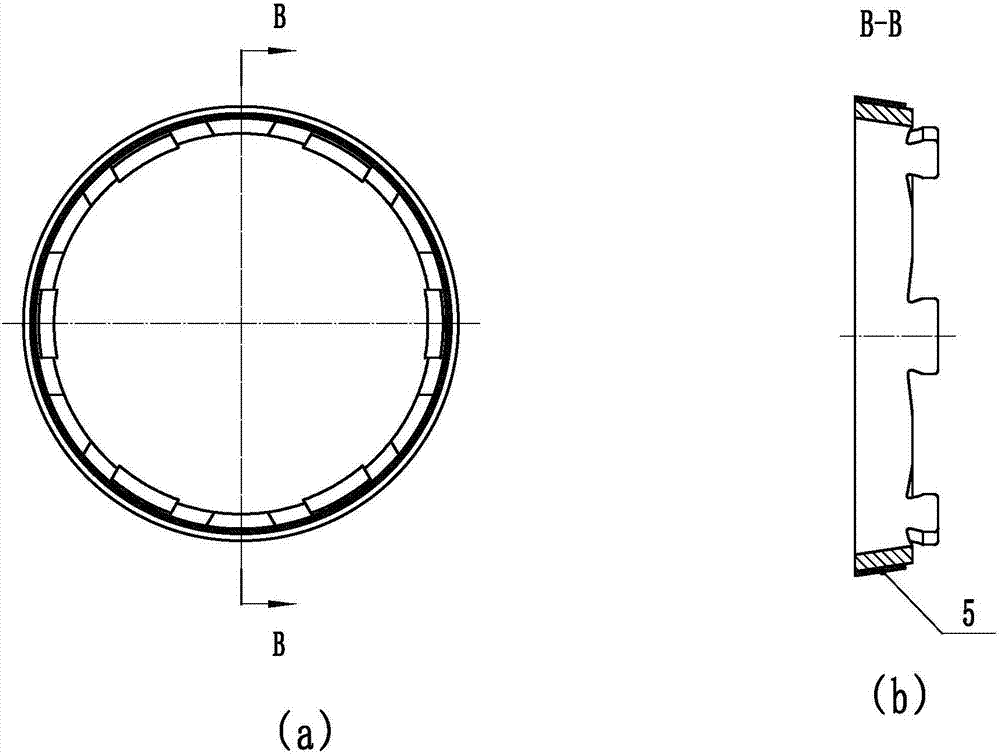

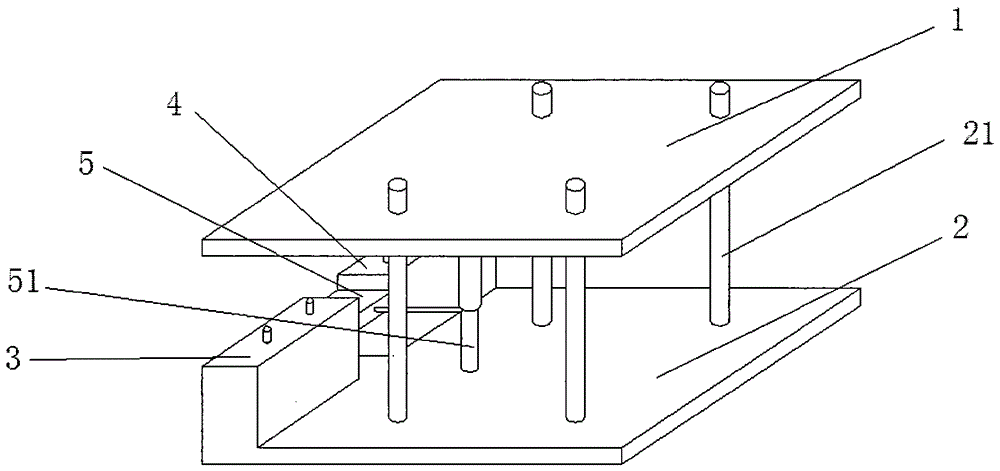

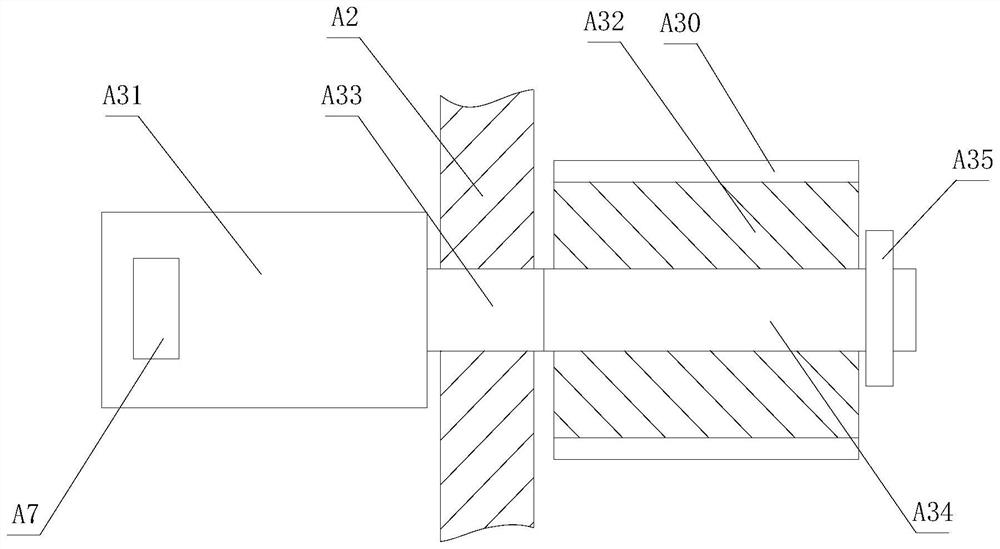

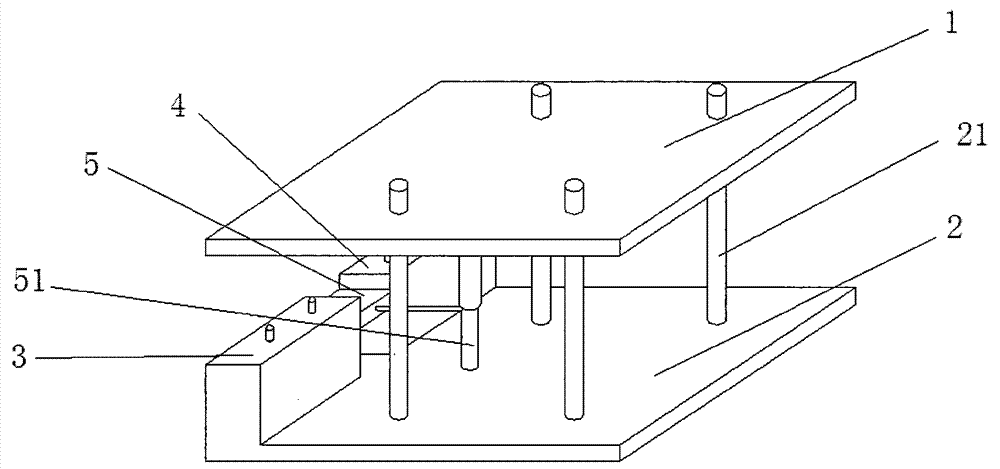

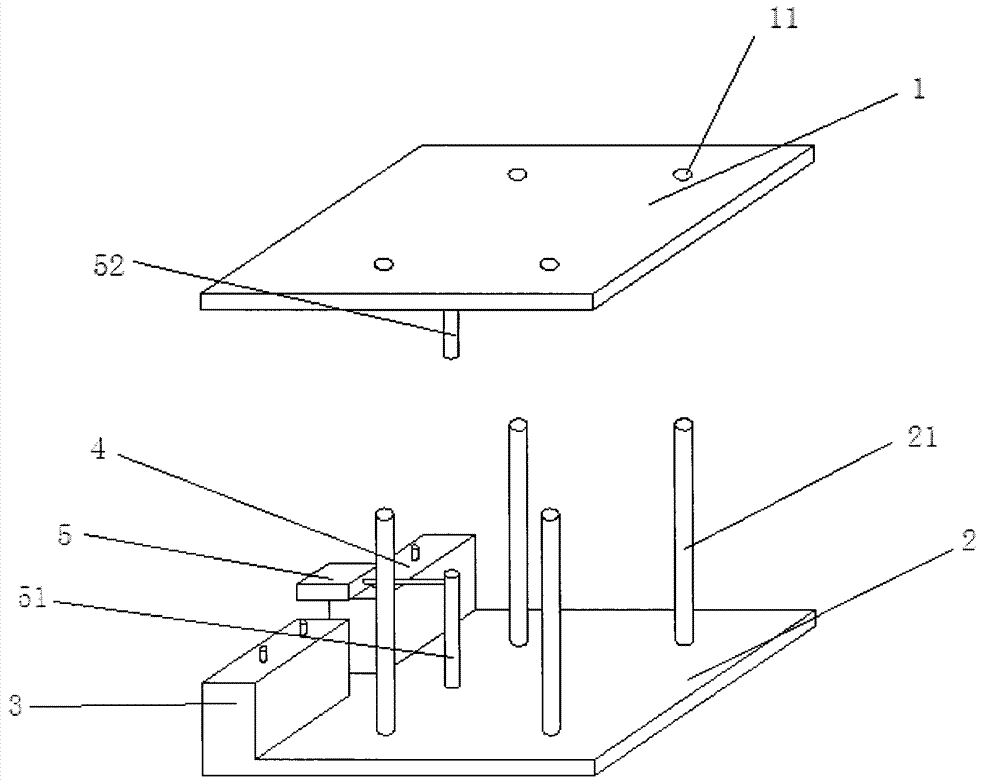

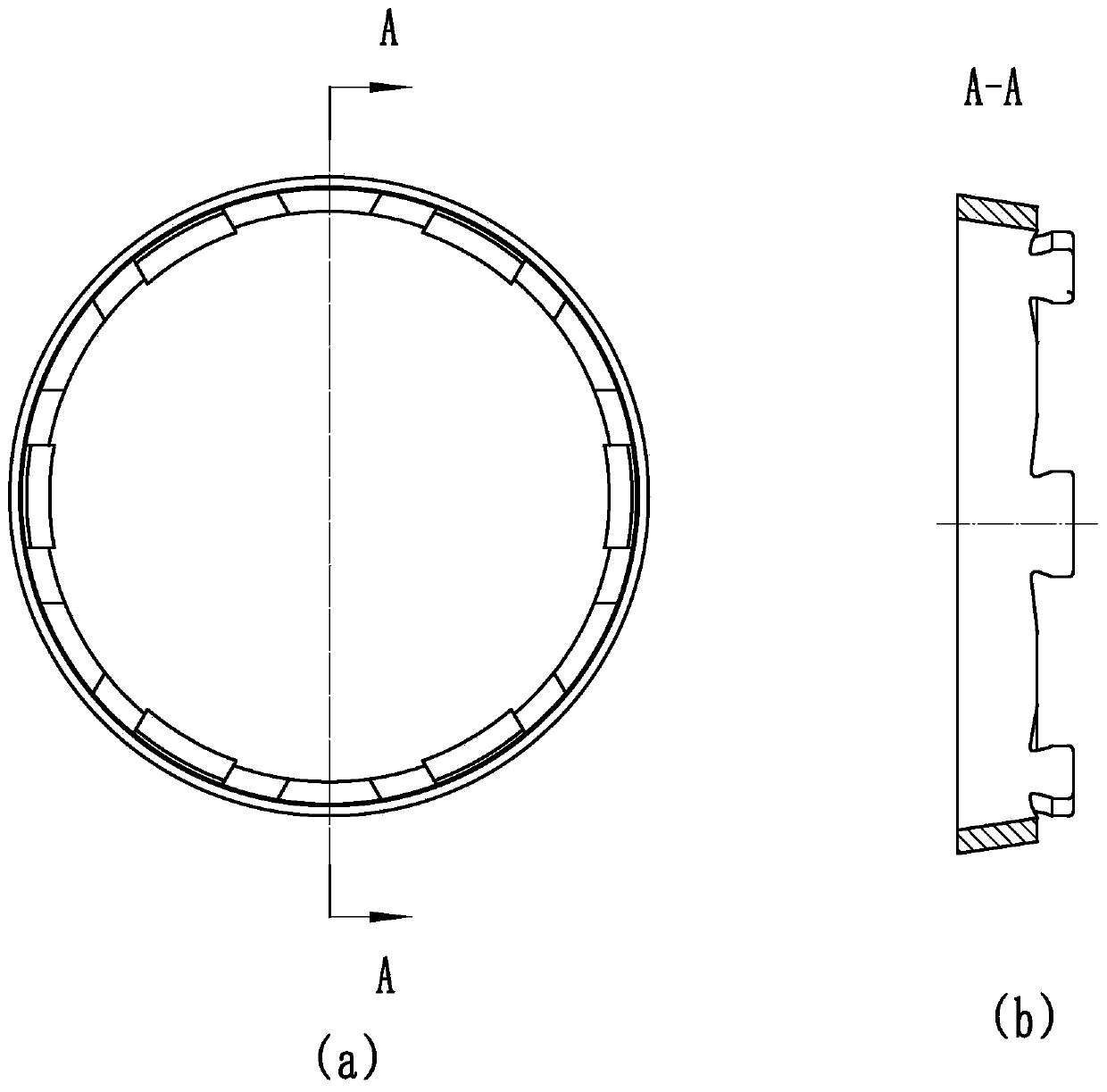

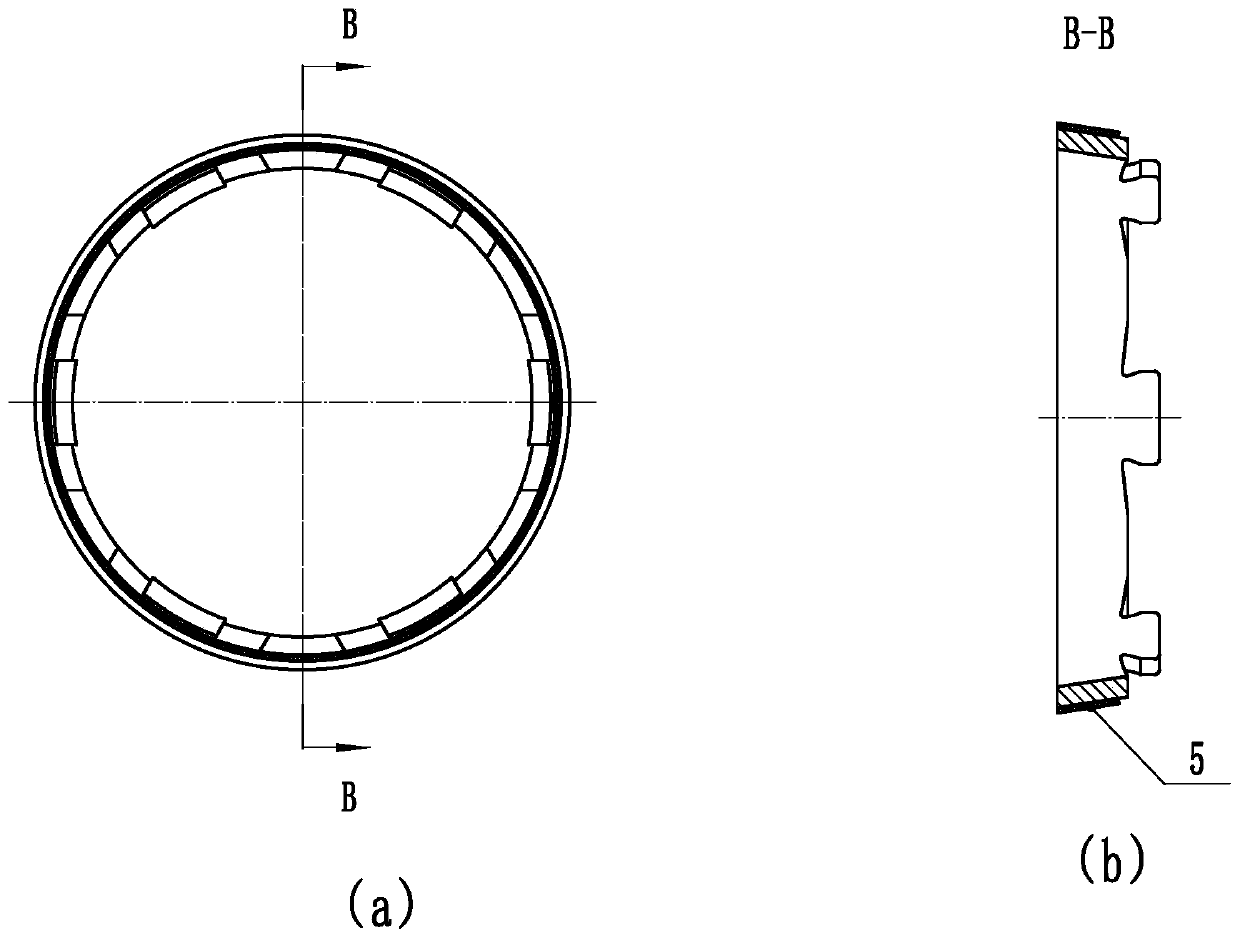

Synchronizer inner ring conical surface friction material bonding mold and bonding method thereof

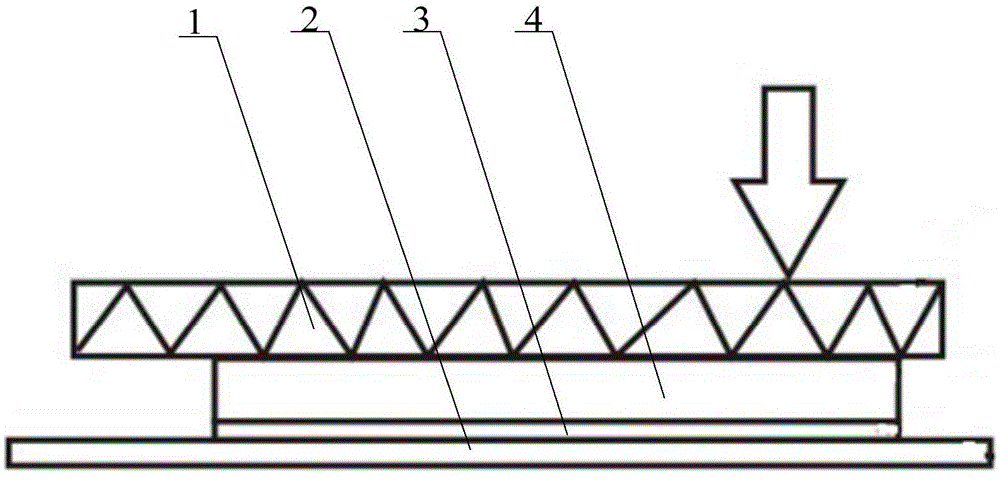

ActiveCN107225790AAvoid Adhesion EffectsRealization of heat and pressure bondingPressesBond qualityHeating effect

The invention discloses a synchronizer inner ring conical surface friction material bonding mold and bonding method thereof. The bonding mold is mainly formed by an upper mold, a lower mold and a heating mechanism, wherein the upper mold is provided with a discharging assembly and a floating assembly, and the lower mold is provided with a material butting assembly. Through the bonding mold, not only can pressurized heating bonding of a synchronizer inner ring conical surface subjected to prebonding of friction materials be achieved, but also automatic discharging and automatic material butting after bonding is finished can be achieved, uniformity of the heating effect is guaranteed, bonding efficiency is improved, adhesion influences of contact parts between an inner ring and the upper mold and between the inner ring and the lower mold are avoided, and bonding quality and production efficiency are improved.

Owner:CHENGDU HAONENG TECH CO LTD

Automatic alignment gluing machine

InactiveCN105752738AImprove processing efficiencyAvoid unevennessFunction indicatorsFolding thin materialsSpray coatingEngineering

The invention relates to an automatic alignment gluing machine. The automatic alignment gluing machine comprises a machine tool, cloth pressing rollers and a gluing brush; the gluing brush is of a wedge shape, and a spray-coating opening of the gluing brush is formed in the tip of the wedge shape; two cloth winding rollers for winding and placing cloth are fixedly mounted at the head part of the machine tool; a weighing instrument is mounted on each cloth winding roller; each weighing instrument is sequentially and electrically connected with an analyzer and a controller; two groups of cloth regulating rollers are also mounted on the machine tool; each group of cloth regulating rollers further comprises speed limiting rollers and cloth drawing rollers; rotating speeds of both the speed limiting rollers and the cloth drawing rollers are regulated by the controller; the cloth pressing rollers and the cloth drawing rollers rotate at the same speed; a rotating speed of the cloth drawing rollers is higher than that of the speed limiting rollers. According to the automatic alignment gluing machine, cloth can be flatly glued, and meanwhile, the condition that tail edges of the cloth are aligned can be guaranteed, so that a tail edge cutting process is avoided, cloth processing efficiency is improved, and meanwhile, texture, aesthetics and flatness of the cloth are ensured.

Owner:马根昌

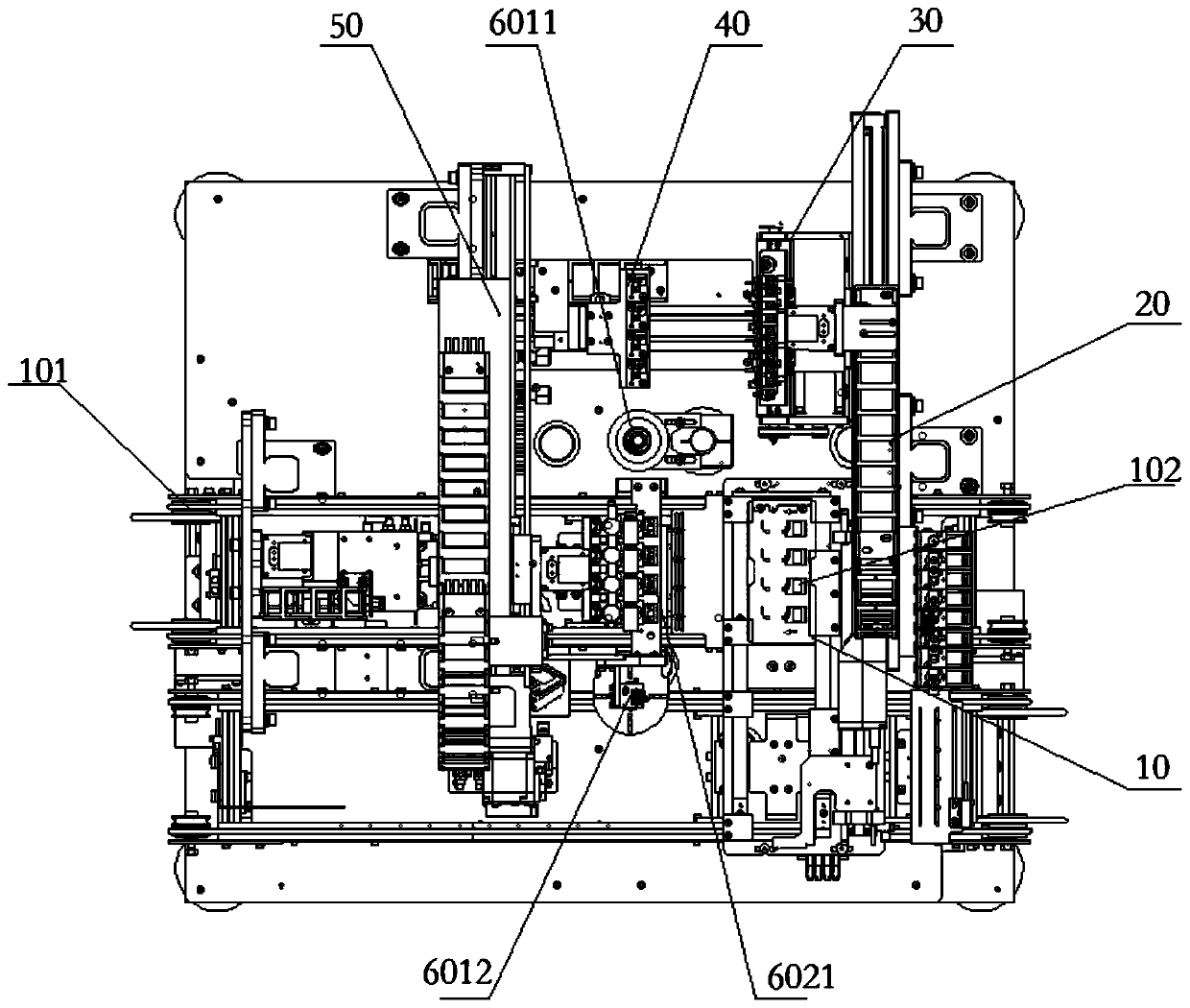

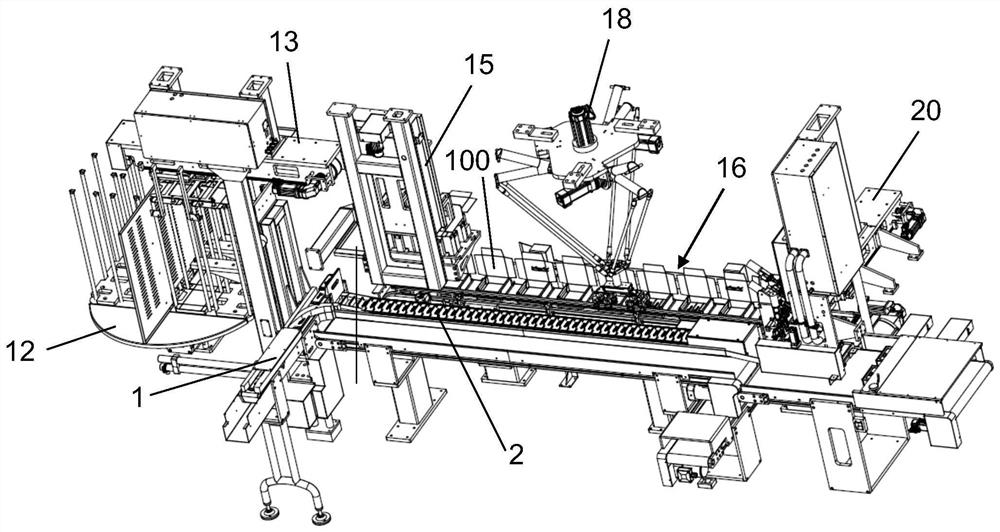

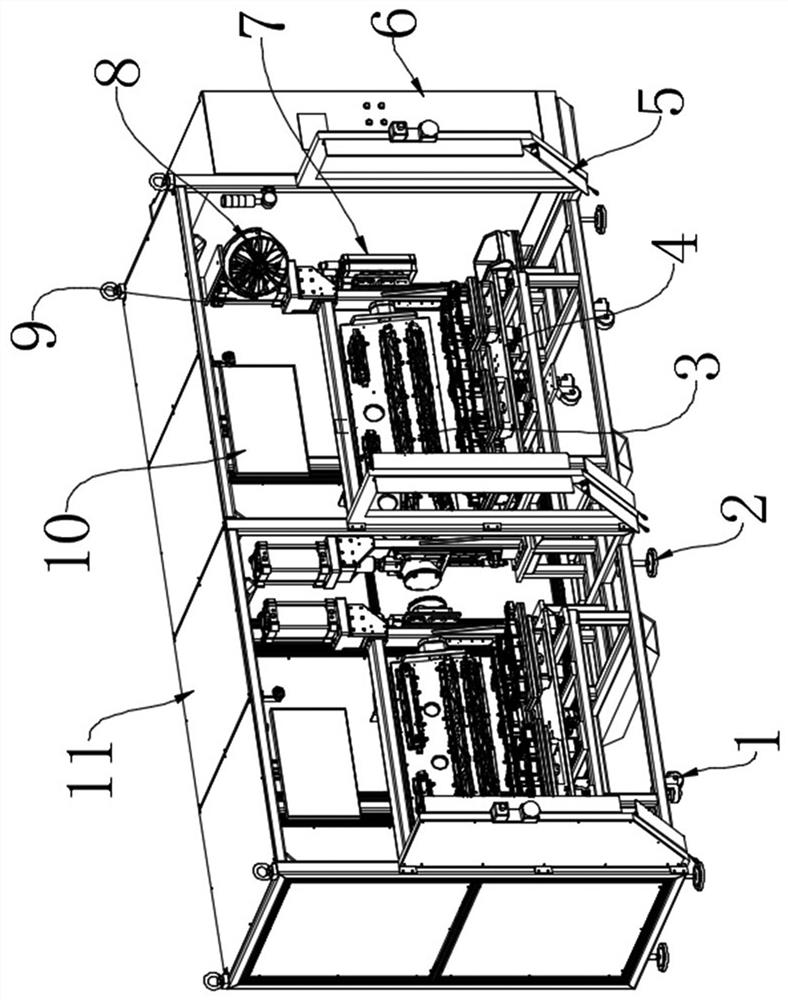

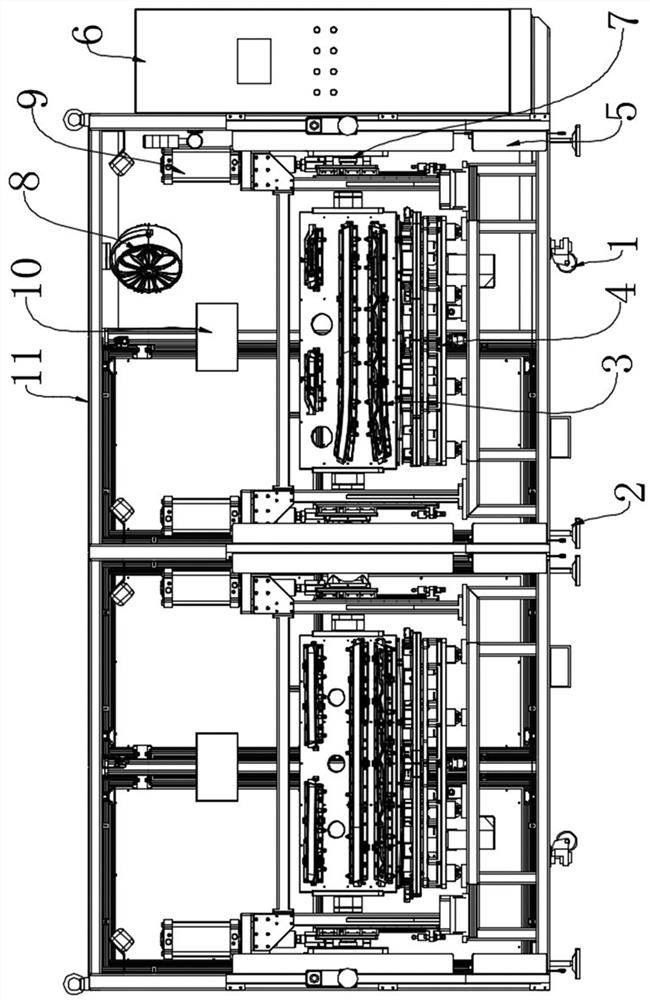

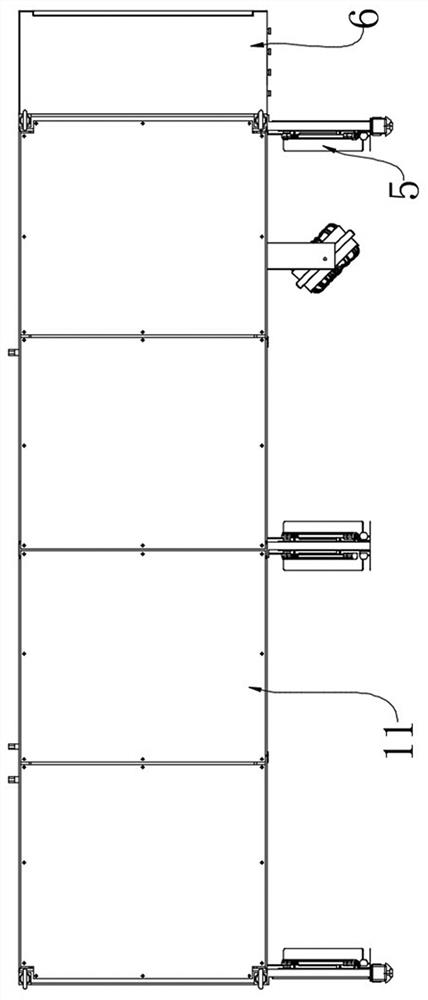

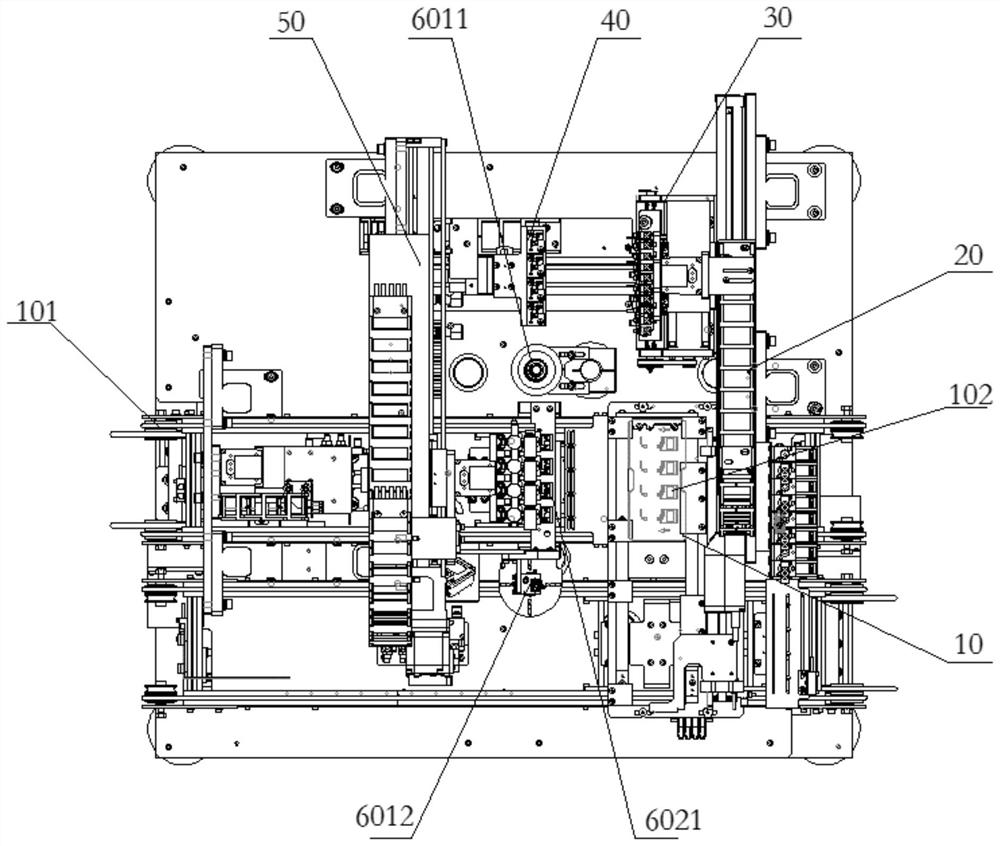

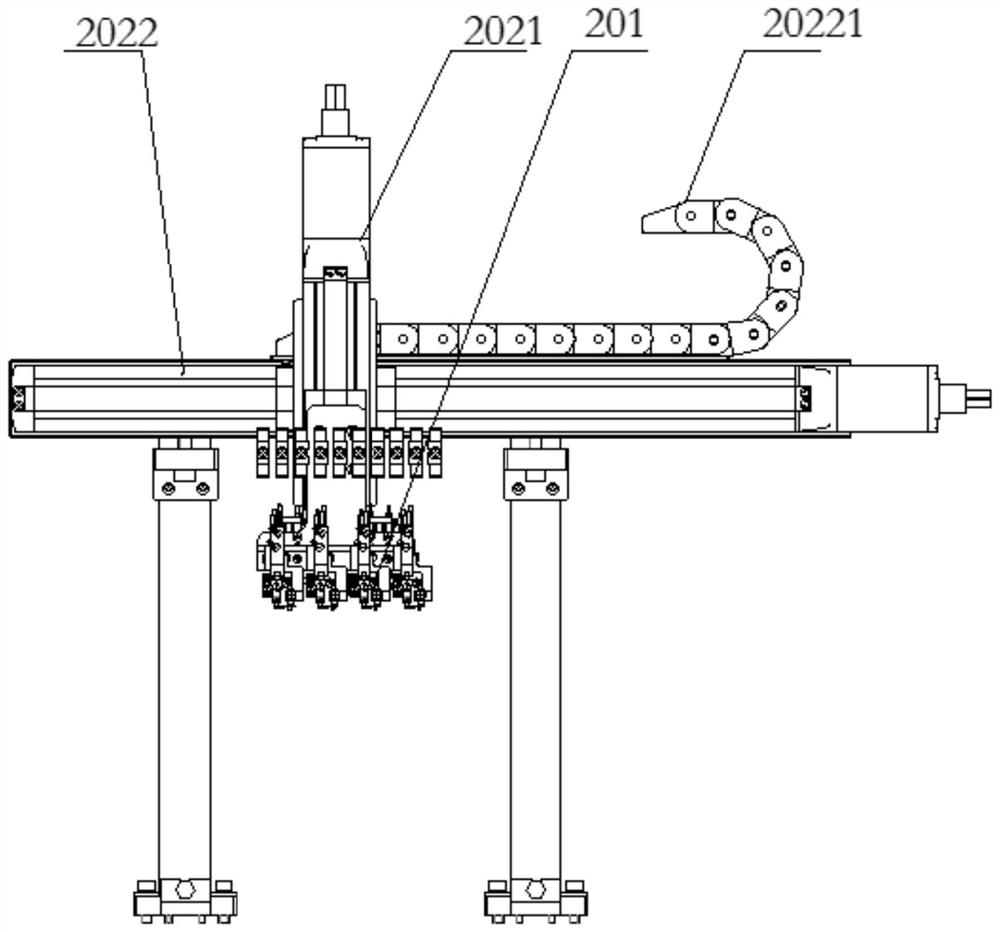

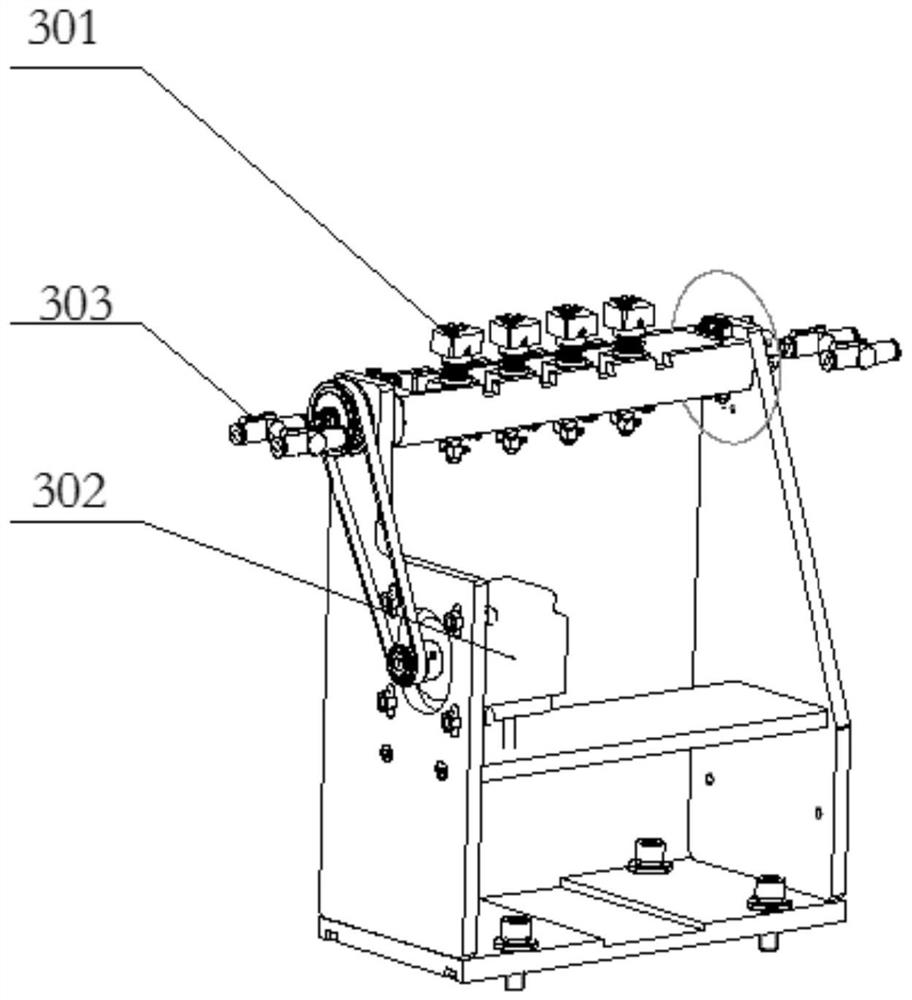

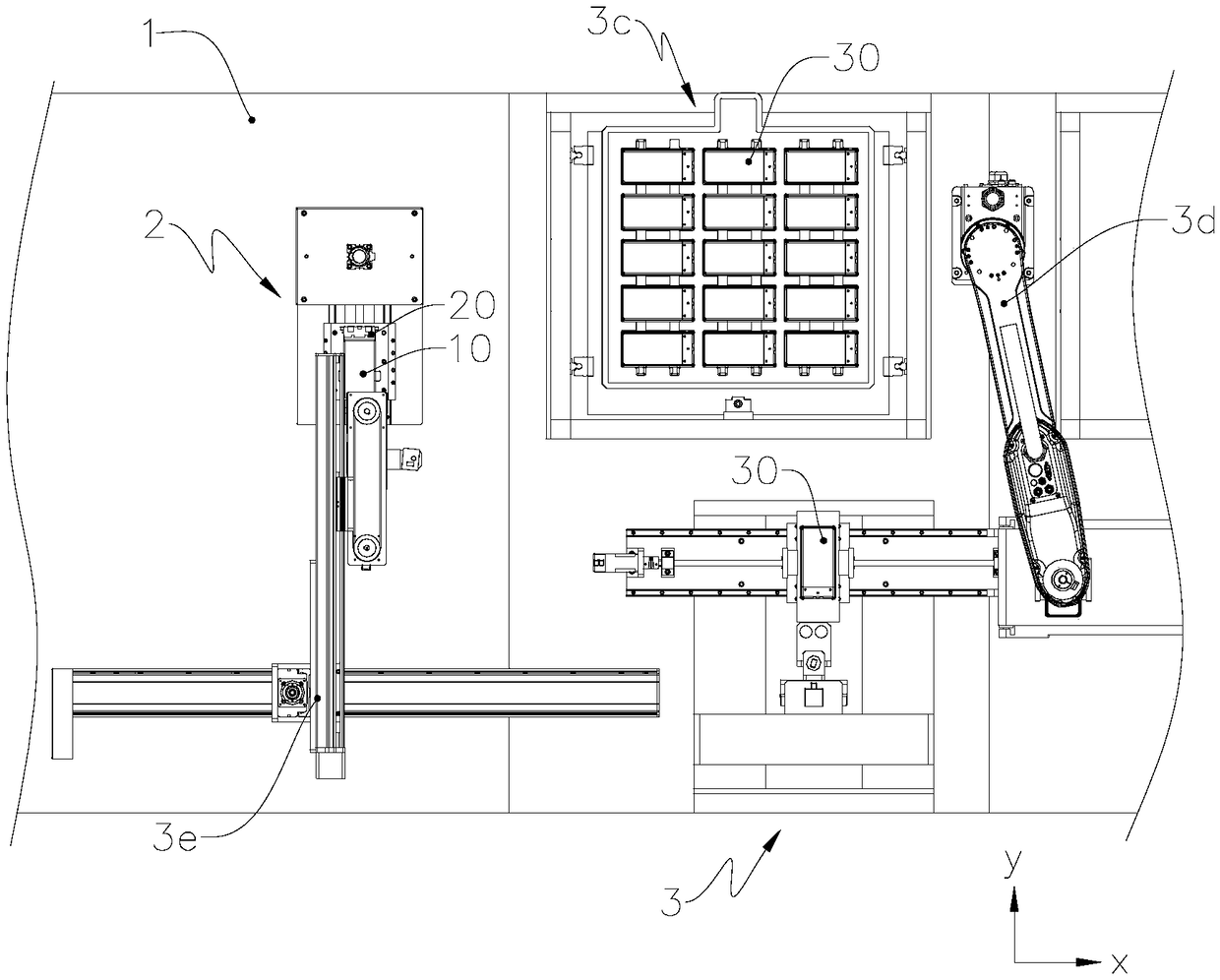

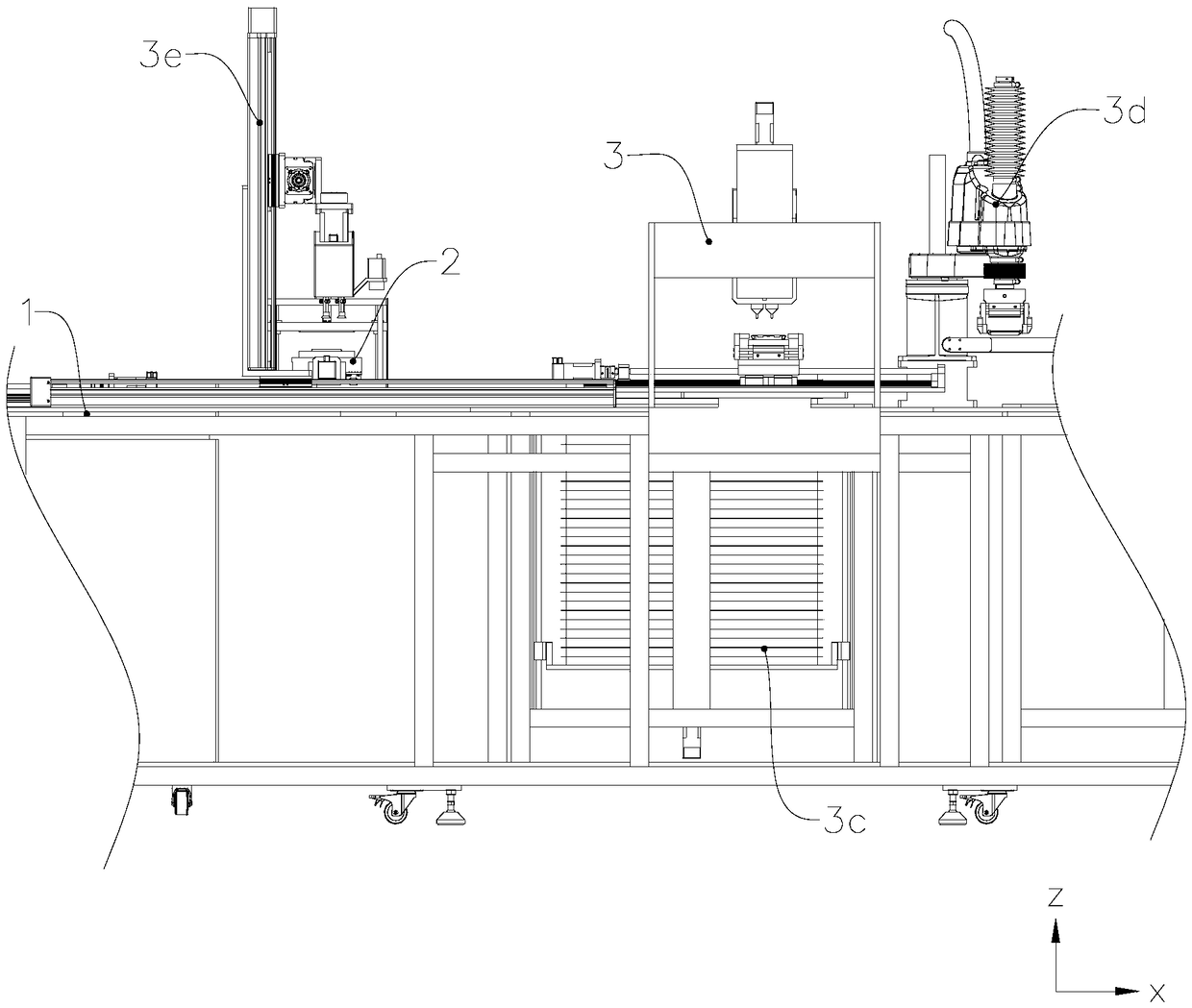

Packaging equipment

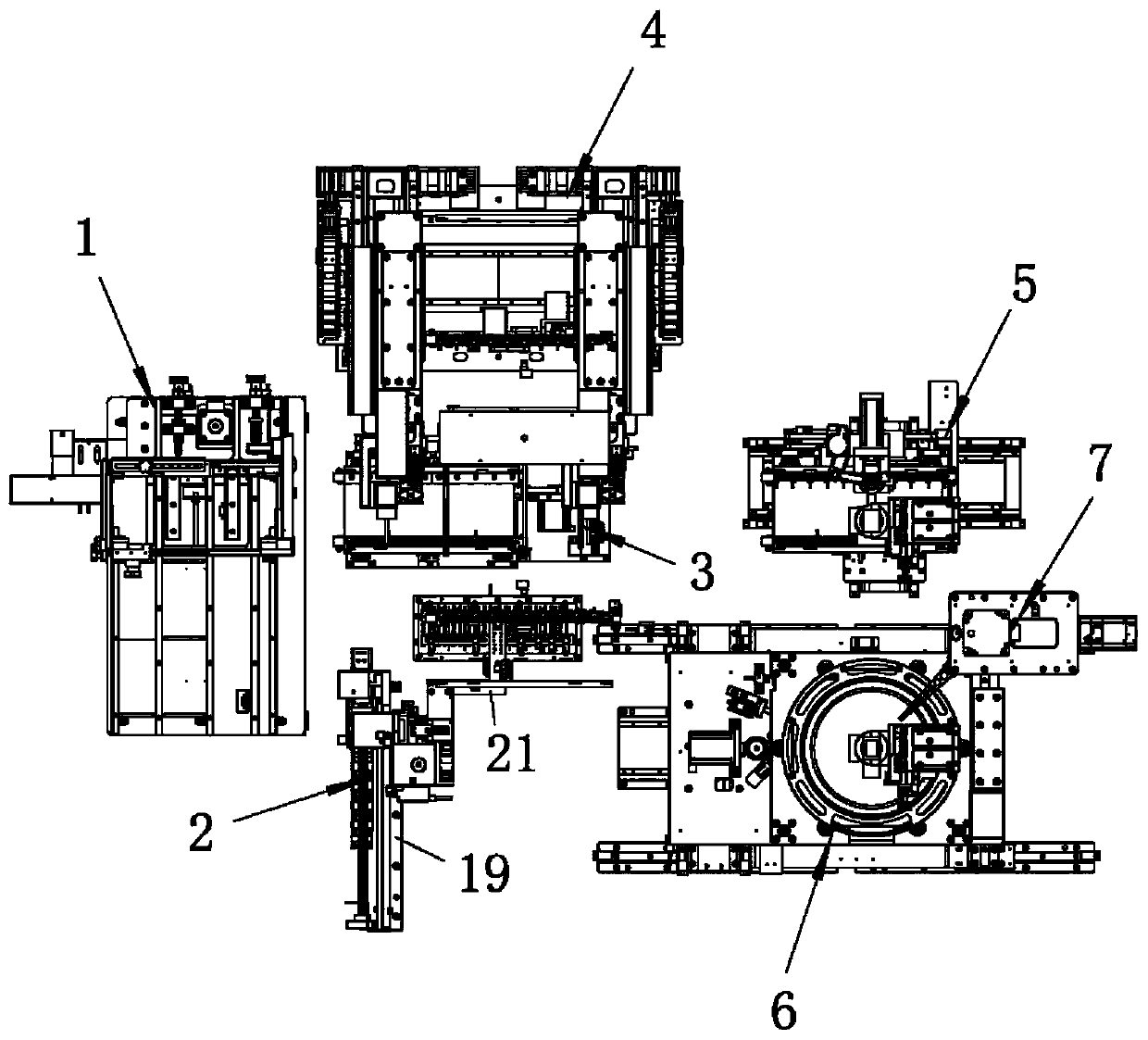

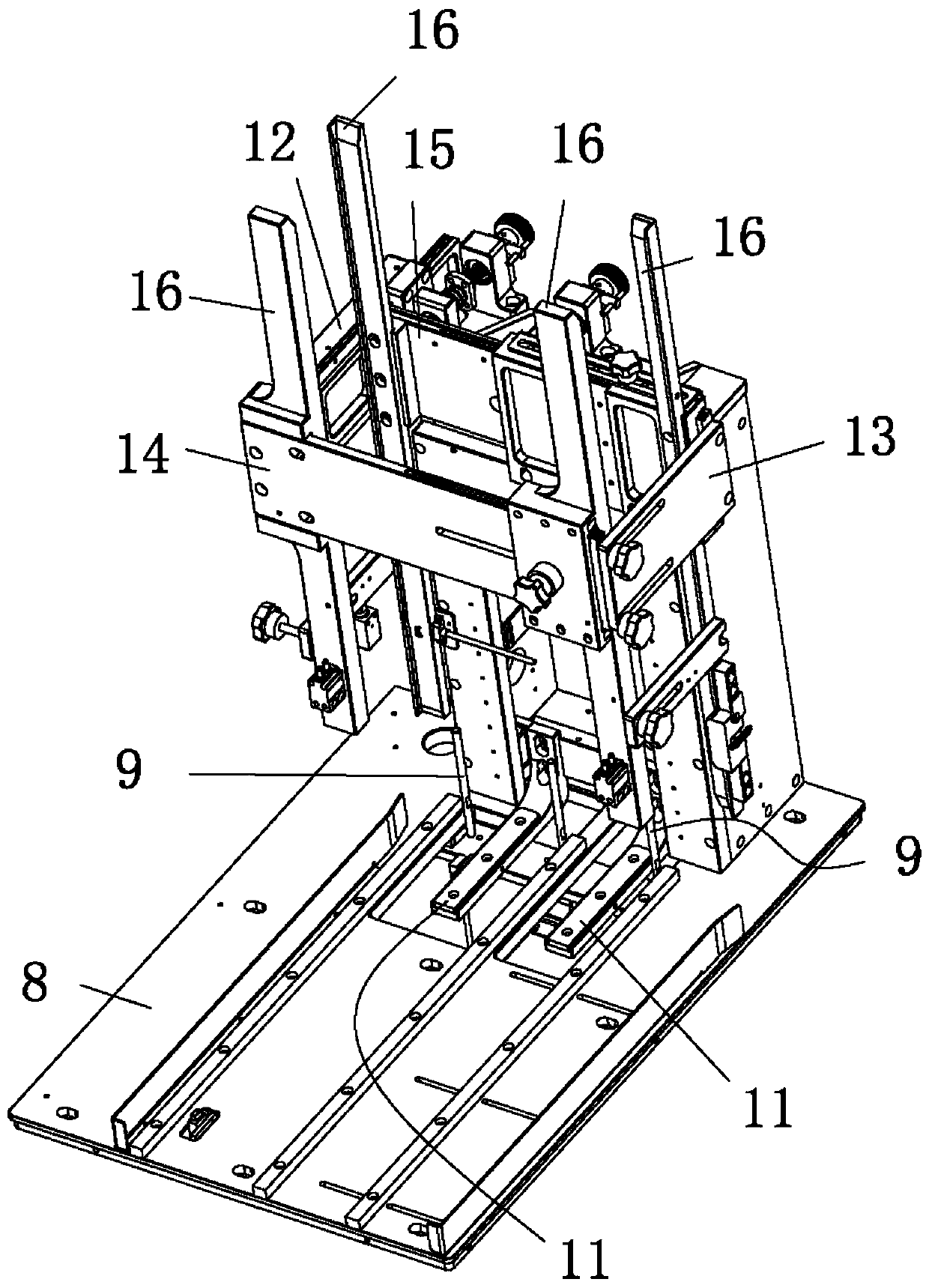

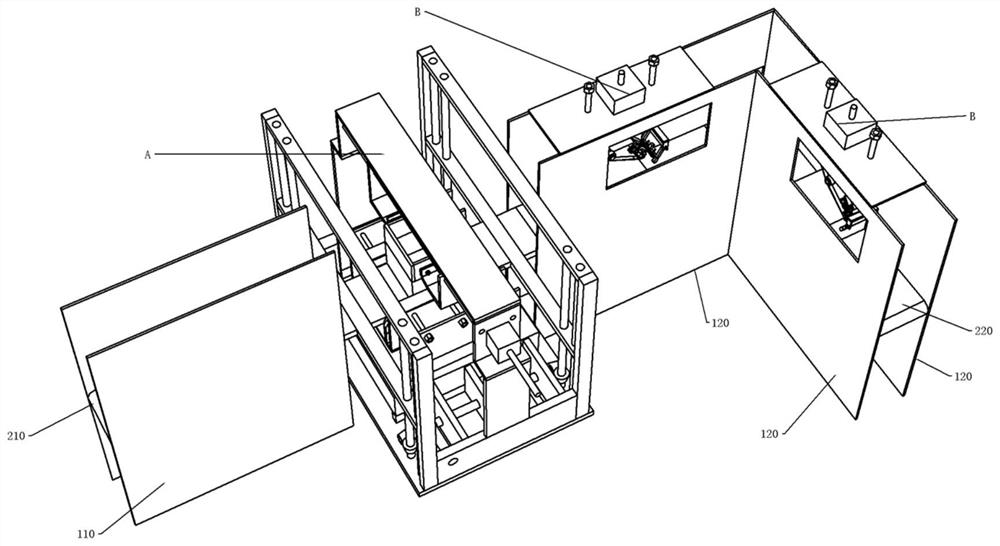

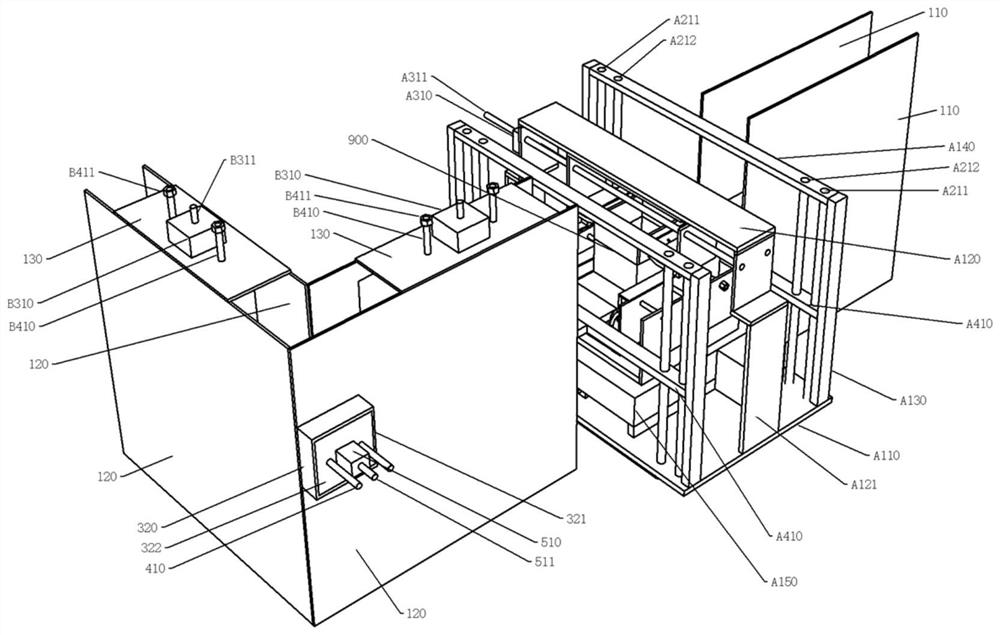

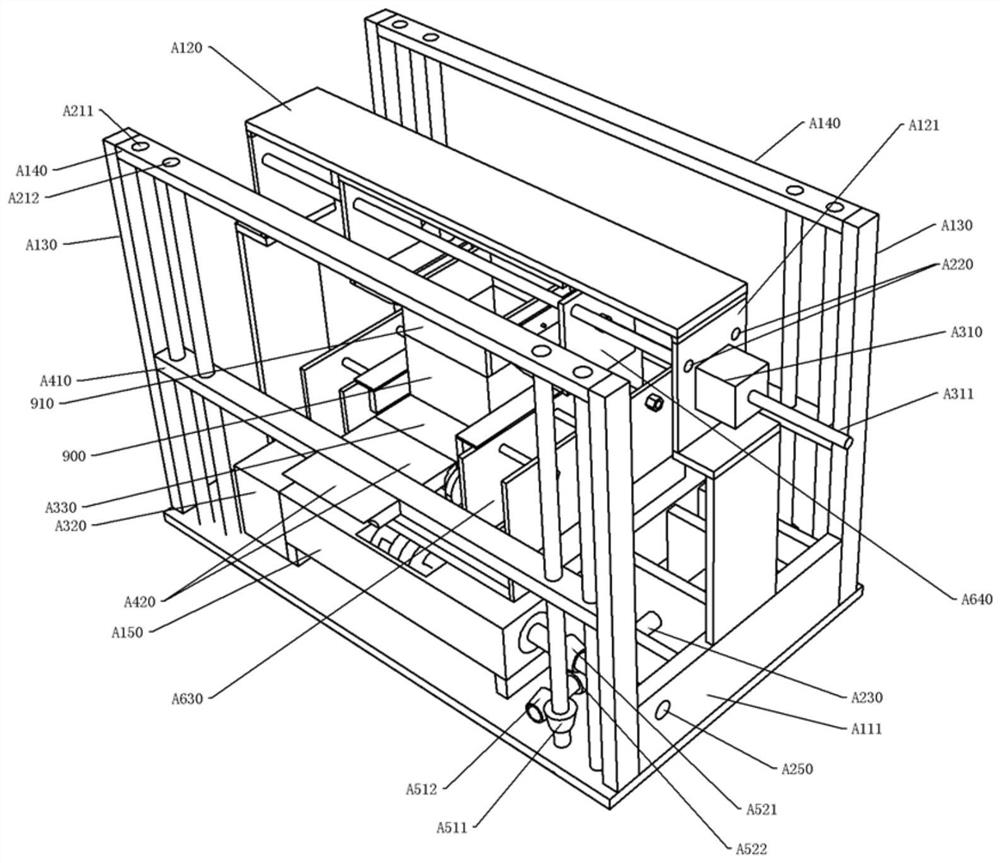

PendingCN110931398ARealize automatic bondingImprove compatibilitySemiconductor/solid-state device manufacturingEngineeringMaterial supply

The invention relates to the technical field of wafer packaging, and particularly discloses packaging equipment. A first feeding device automatically supplies a material box carrying a plurality of frames, and a second feeding device automatically supplies a plurality of stacked frames; a first feeding unit of the double-layer material rolling device is used for transferring the frame transferredby the material supply device; a pneumatic dispensing device conducts pneumatic dispensing on the frame borne by the first feeding unit. An electric gluing device is used for carrying out electric dispensing on the frame borne by the first feeding unit; a wafer expanding device is used for carrying out wafer expanding treatment on the wafer assembly, a bonding head device is used for bonding the wafer element subjected to wafer expanding treatment by the wafer expanding device to the dispensed frame, and a second feeding unit is used for moving the frame bonded with the wafer element; automatic bonding packaging of the crystal element and the frame is realized, and the packaging efficiency of the crystal element and the frame is improved; two dispensing processing modes of pneumatic dispensing and electric gluing, and two feeding modes of material box feeding and material piece feeding are adopted, so that the compatibility of packaging equipment is improved.

Owner:深圳市意沨科技有限公司

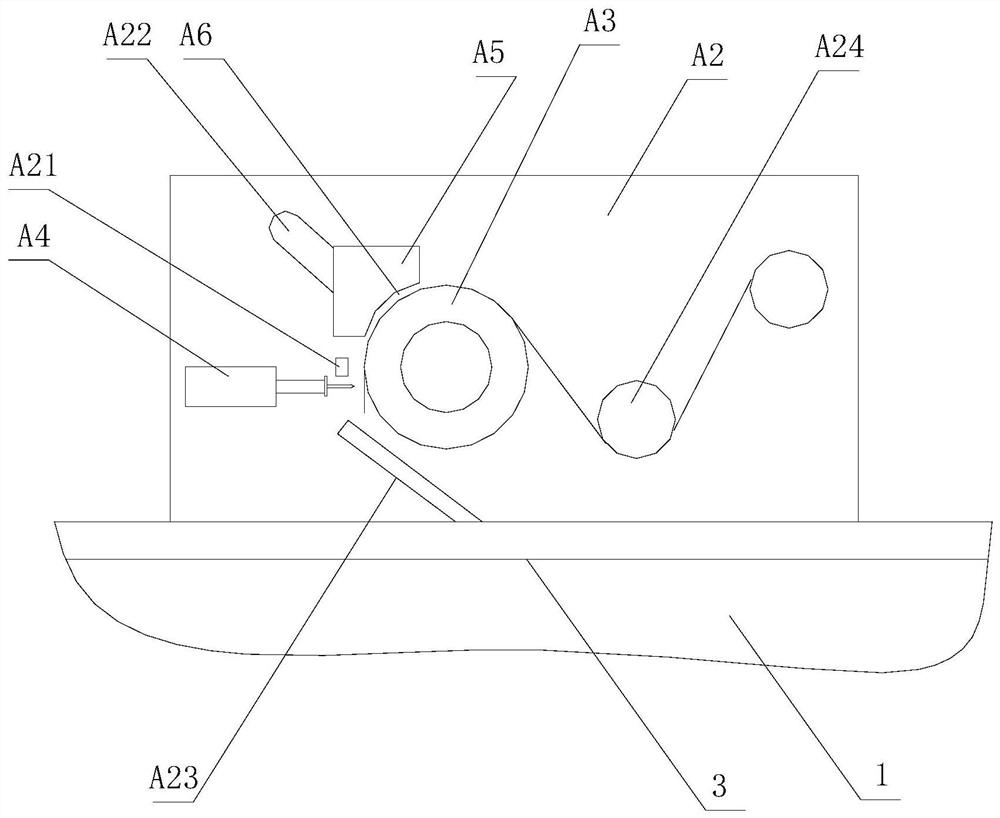

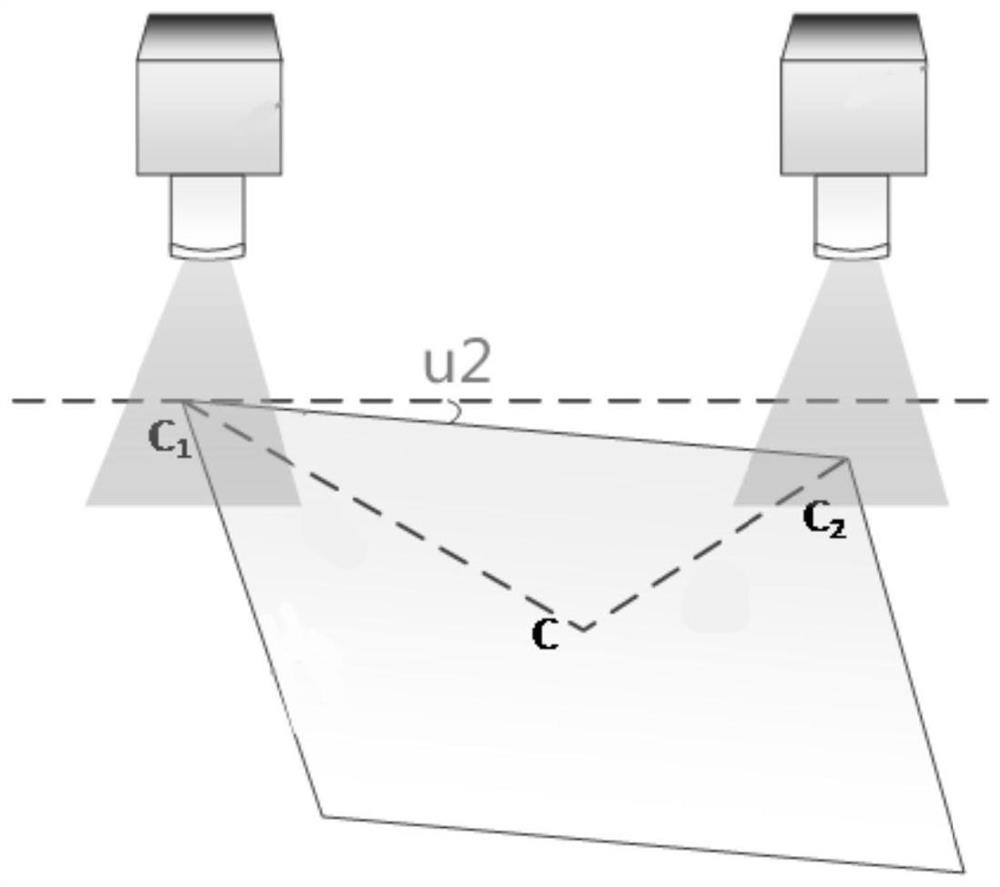

FPC automatic pasting machine

The invention provides an FPC automatic pasting machine. The FPC automatic pasting machine comprises a bearing device, an overturning device, a pasting device, a transferring device and a positioningdevice. The bearing device is configured to bear FPCs and products. The overturning device comprises a first receiving mechanism, an overturning mechanism and a first drive mechanism, the first receiving mechanism is configured to bear the FPCs, the first receiving mechanism is arranged on the overturning mechanism, the first drive mechanism is connected with the overturning mechanism, the first drive mechanism is configured to drive the overturning mechanism to be overturned, and the pasting surfaces of the FPCs are opposite to the to-be-pasted surfaces of the products. The pasting device isconfigured to paste the FPCs on the products. The transferring device is configured to transfer the FPCs on the bearing device to the overturning device and transferring the FPCs on the overturning device to the pasting device. The positioning device comprises a position acquisition mechanism and a deviation correction mechanism. The position acquisition mechanism is configured to acquire positioninformation of the FPCs and the products, and the deviation correction mechanism corrects the positions of the FPCs and the products according to the position information. The FPCs can be automatically pasted through the overturning mechanism, and the pasting precision of the FPCs can be improved through the positioning device.

Owner:GOERTEK INC

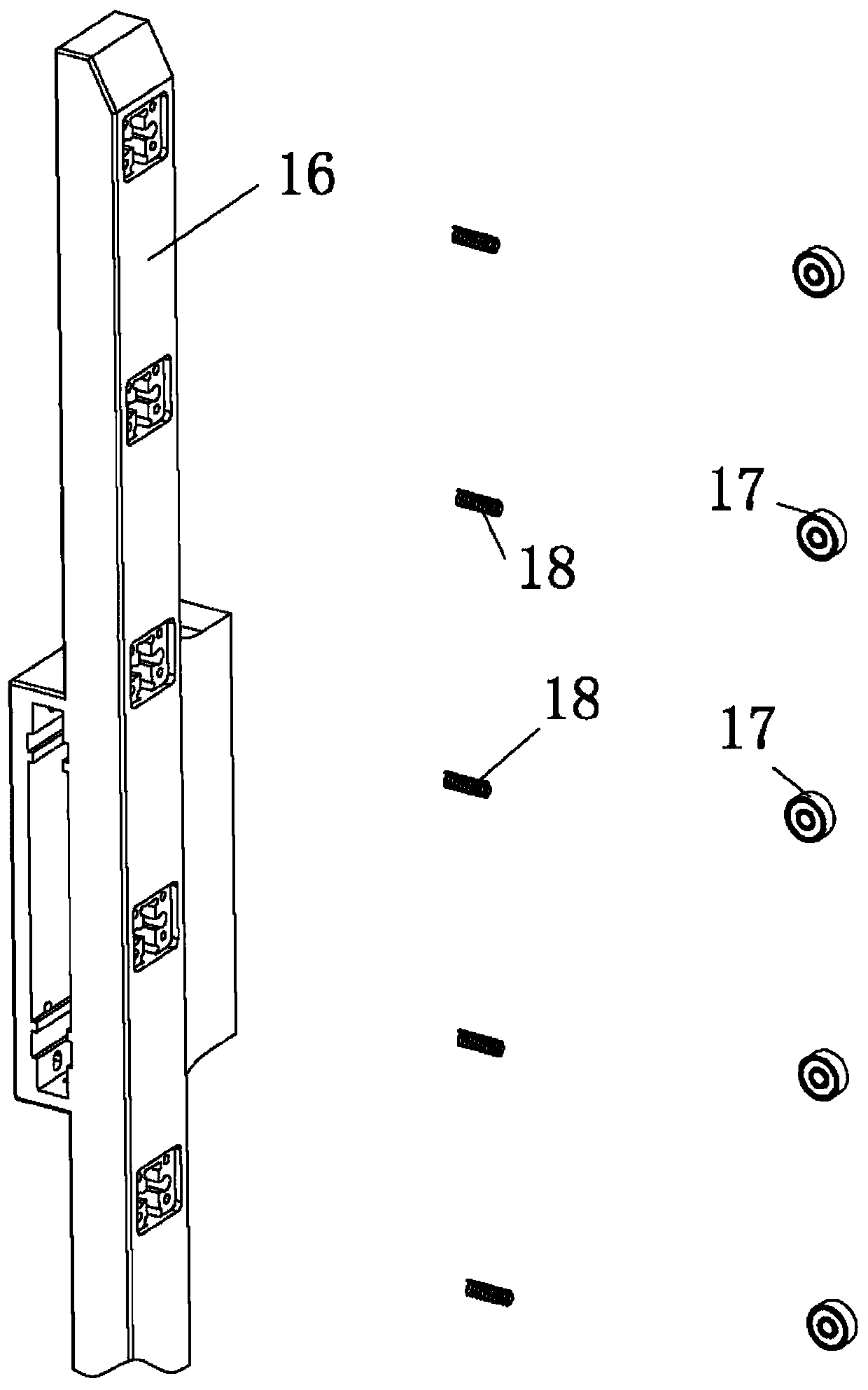

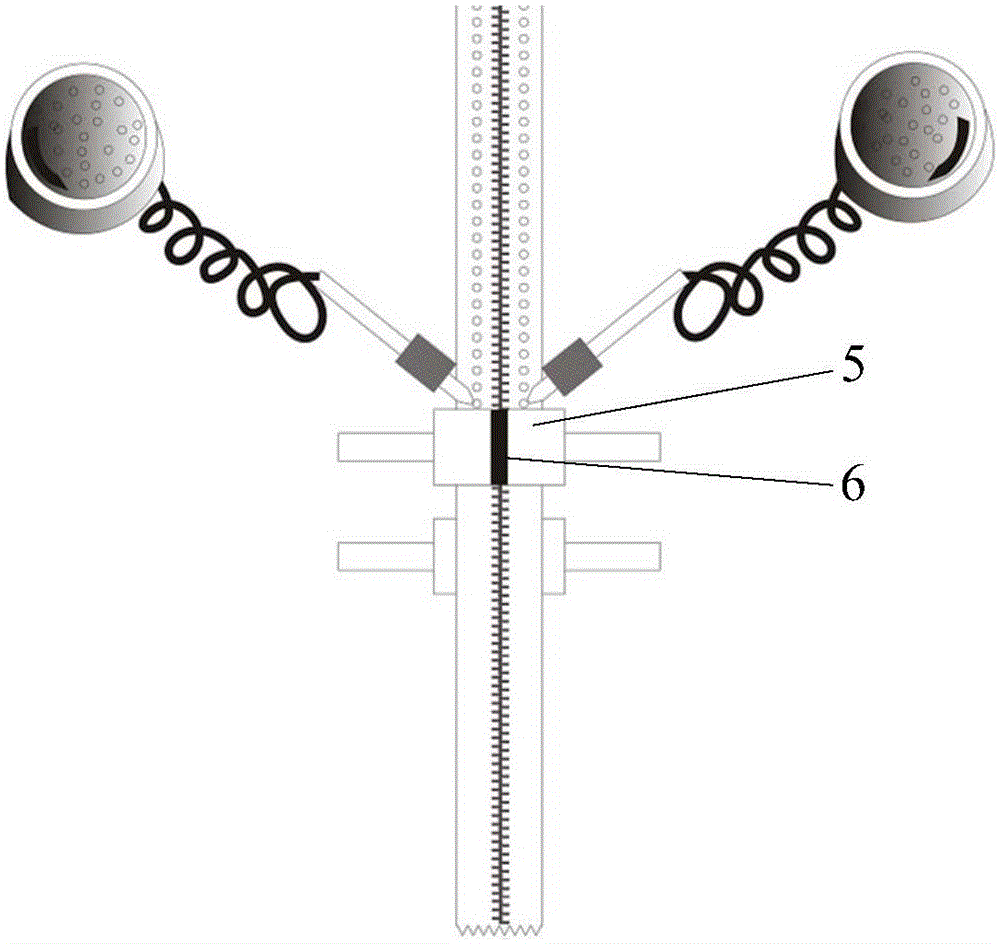

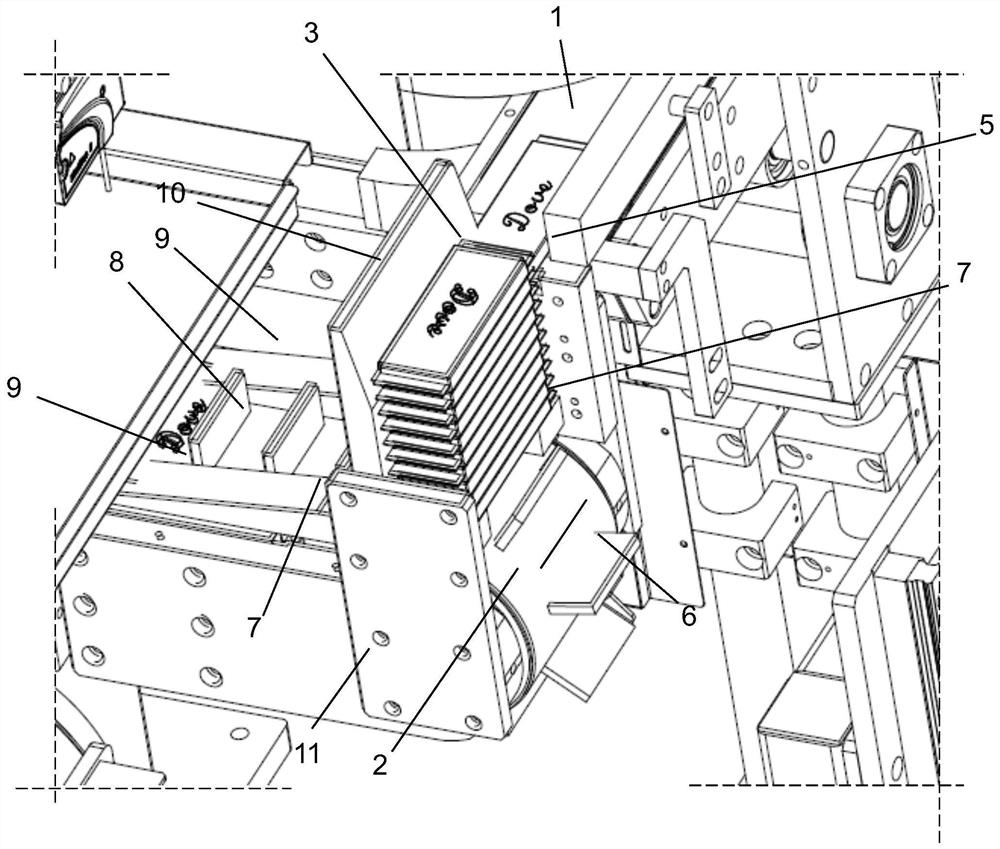

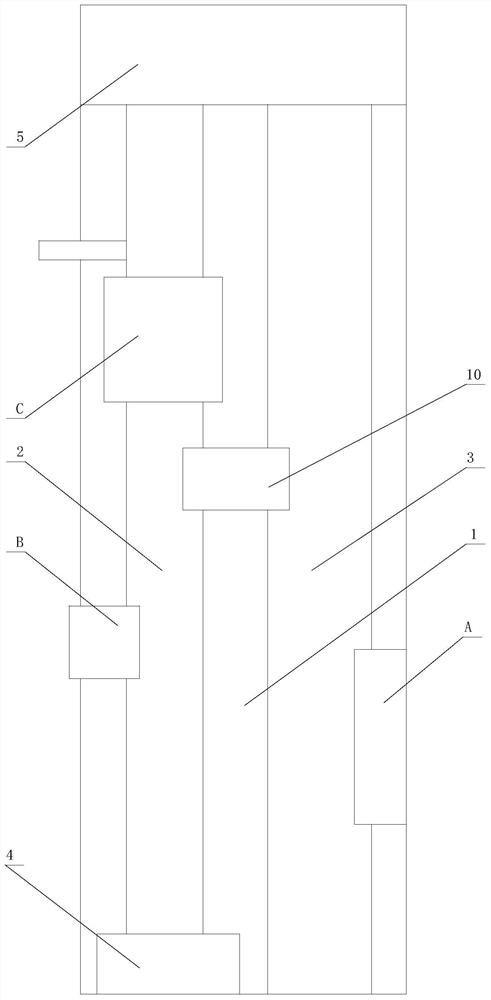

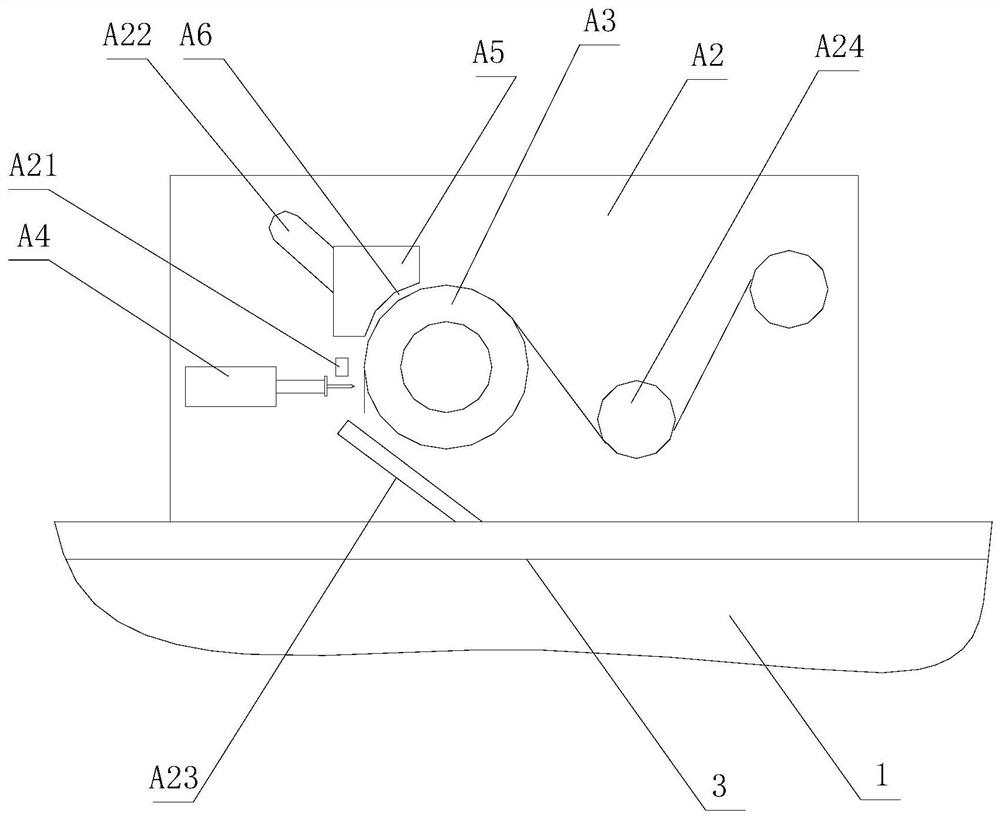

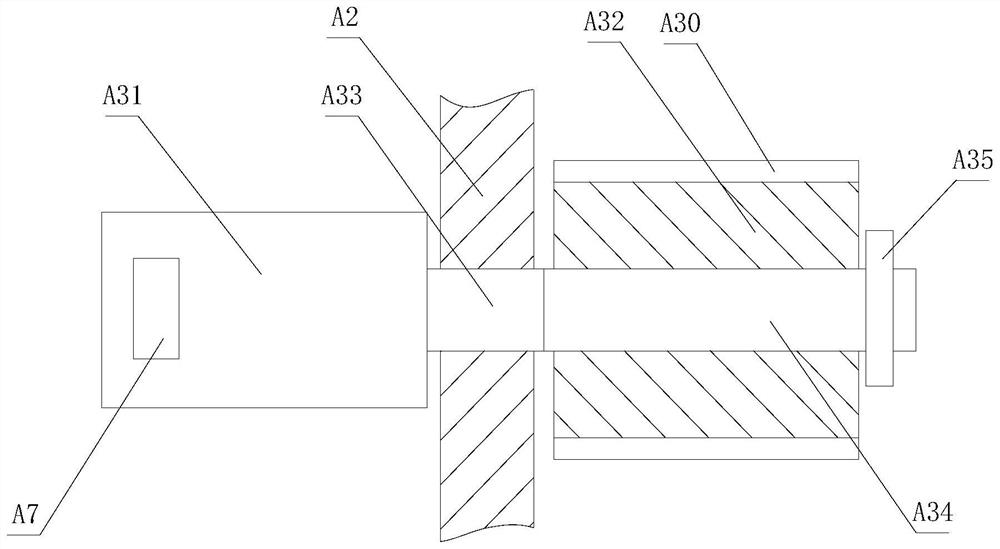

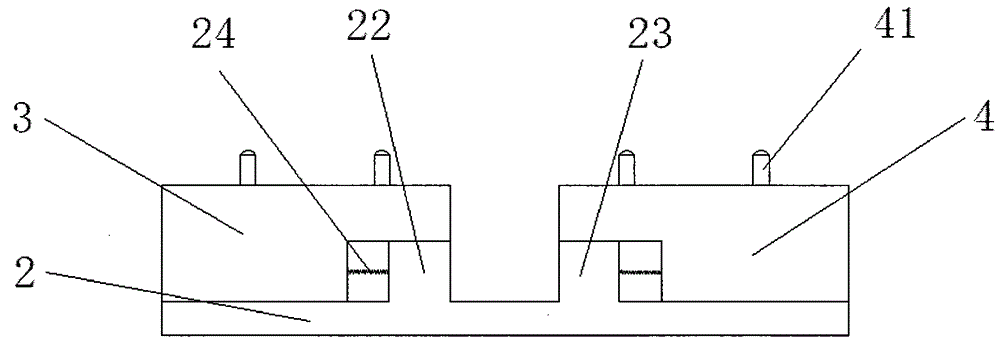

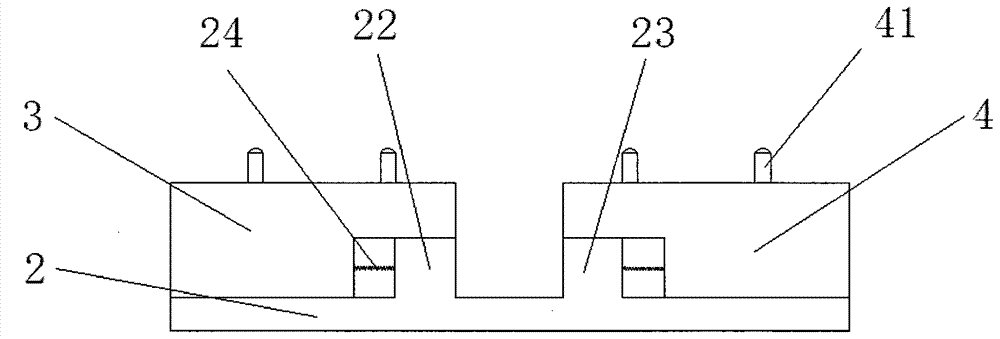

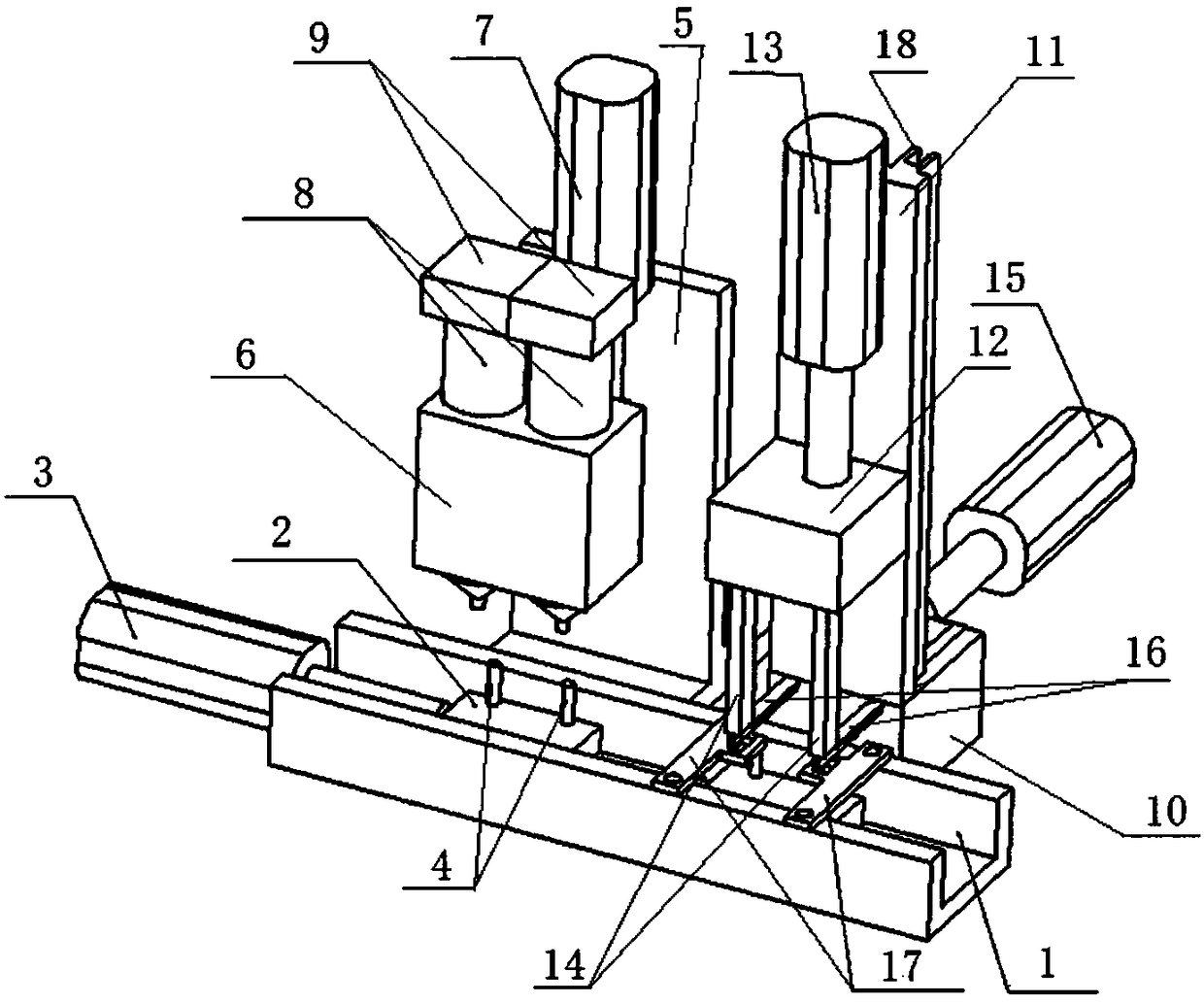

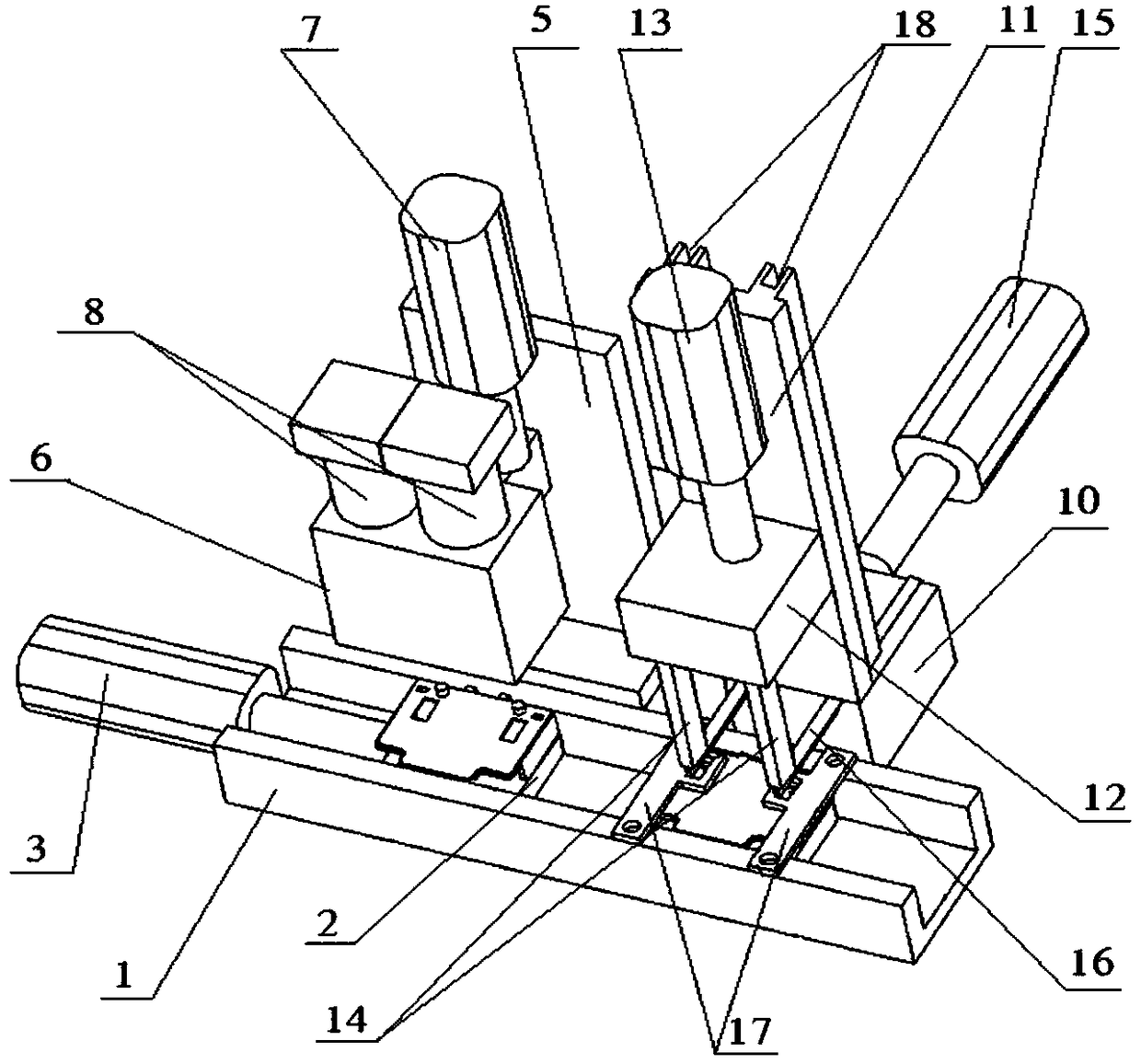

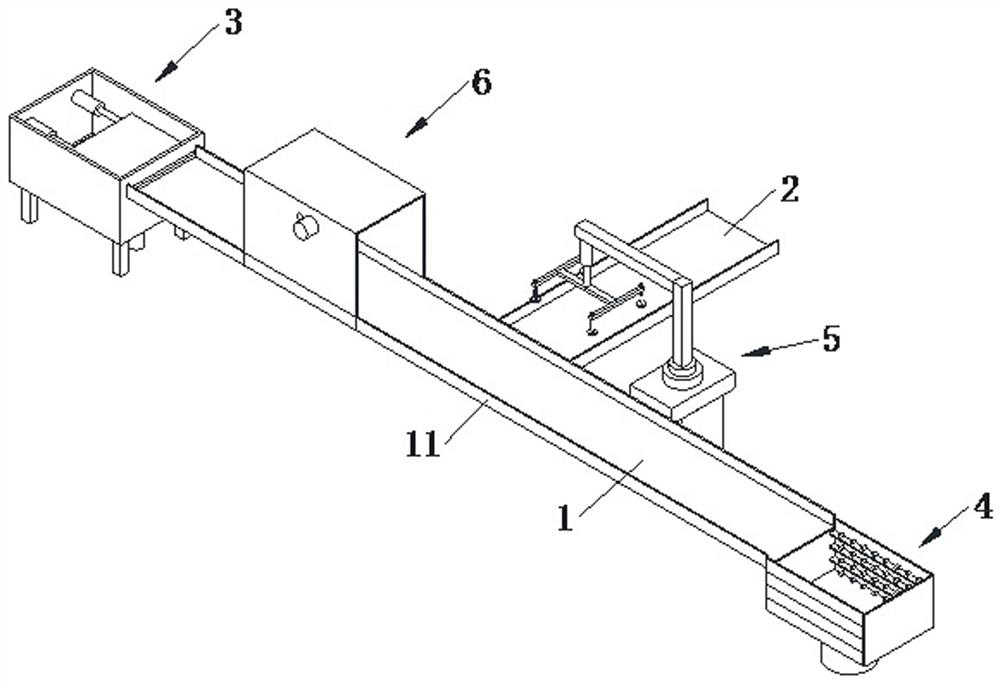

Automatic magnetic steel bonding device for quick-action switch

ActiveCN106208564ASolve the problem that small volume magnetic steel cannot be bondedRealize automatic bondingManufacturing stator/rotor bodiesSolenoid valveMagnetic poles

The invention relates to an automatic magnetic steel bonding device for a quick-action switch. The automatic magnetic steel bonding device comprises a working groove (1) of a long-striped structure with the U-shaped cross section, a positioning component is arranged in the working groove (1) in the length direction, and a glue dispensing component and a magnetic steel assembling component are arranged on one side of the working groove (1). The automatic magnetic steel bonding device for the quick-action switch has the advantage that the problem that an existing magnetic steel bonding device cannot carry out bonding on small magnetic steel is solved. Bonding assembling of small magnetic steel of the quick-action switch can be achieved through cooperation of the positioning component, the glue dispensing component and the magnetic steel assembling component. Glue dispensing cylinders are provided with pressure regulating valves so that the glue dispensing amount can be controlled by regulating air pressure, and quality uniformity of the product can be ensured; glue adding can be prompted in time through early-warning devices on the outer walls of the glue dispensing cylinders. The magnetic poles of magnetic steel fixed by a magnetic steel base in advance can be distinguished, and production efficiency is improved. In addition, the device can achieve automatic bonding of magnetic steel by controlling air cylinders to work with a PLC and a solenoid valve.

Owner:XIAN KAITIAN RAILWAY ELECTRICAL

Hot-pressed decoration zipper manufacturing device

InactiveCN105077862ARealize automatic operationRealize automatic bondingSlide fastenersEngineeringMechanical engineering

Owner:ZHEJIANG WEIXING IND DEV

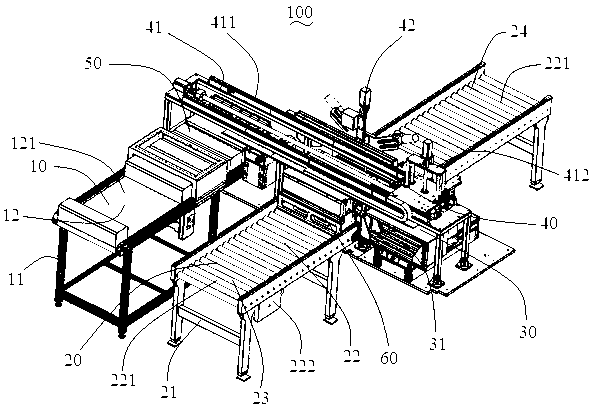

Automatic boxing and packaging equipment for blocky products

PendingCN113022953AAchieving Bond MoldingAvoid bending and other bad phenomenaWrapper twisting/gatheringProcess engineeringIndustrial engineering

Owner:苏州希派智能科技有限公司

A tape sticking device

ActiveCN104192624BRealize automatic unwindingRealize automatic bondingFinal product manufactureArticle deliveryEngineeringIdler-wheel

The invention relates to an adhesive tape sticking device. The adhesive tape sticking device comprises a machine frame, an adhesive tape paying-off device, an adhesive tape driving device, an adhesive tape cutting deice, an adhesive tape adsorption device, a press wheel device and a conveying device, wherein the adhesive tape paying-off p device and the conveying device are arranged on the machine frame, the adhesive tape paying-off device comprises an adhesive tape paying-off mechanism and an adhesive tape conveying mechanism, the conveying device comprises a first installation plate and a first movement mechanism, a second installation plate is arranged on the first installation plate, the adhesive tape driving device is fixed to the second installation plate, and the adhesive tape adsorption device and the press wheel device are fixedly arranged on the rear side of the adhesive tape driving device sequentially. The adhesive tape cutting device is arranged between a seventh idler wheel and a ninth idler wheel and comprises a fourth air cylinder, a cutter connecting plate, a cutter and a guide seat. The adhesive tape sticking device can automatically stick adhesive tape to a welding strip of a battery piece, and improve the conversion efficiency of a battery string.

Owner:WUXI LEAD INTELLIGENT EQUIP CO LTD

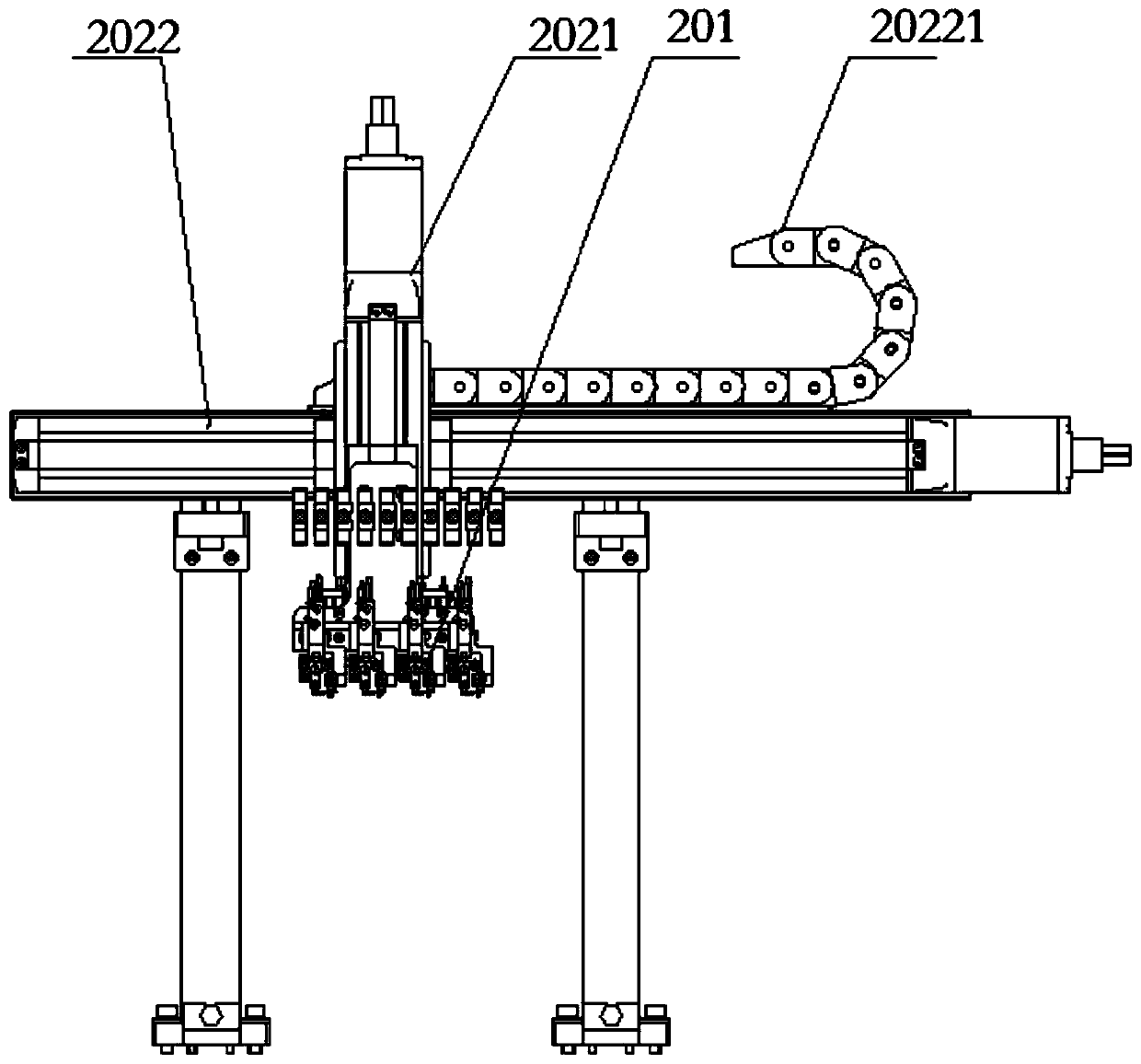

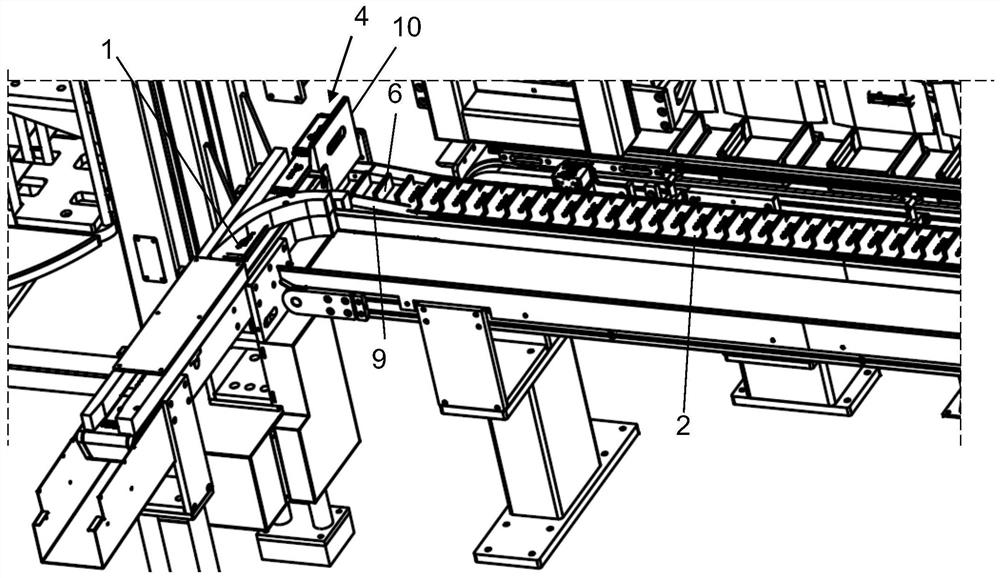

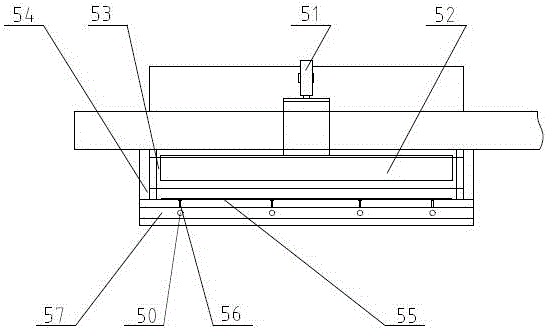

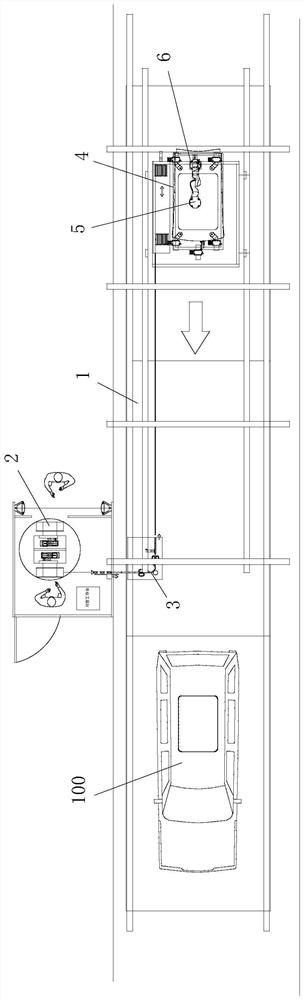

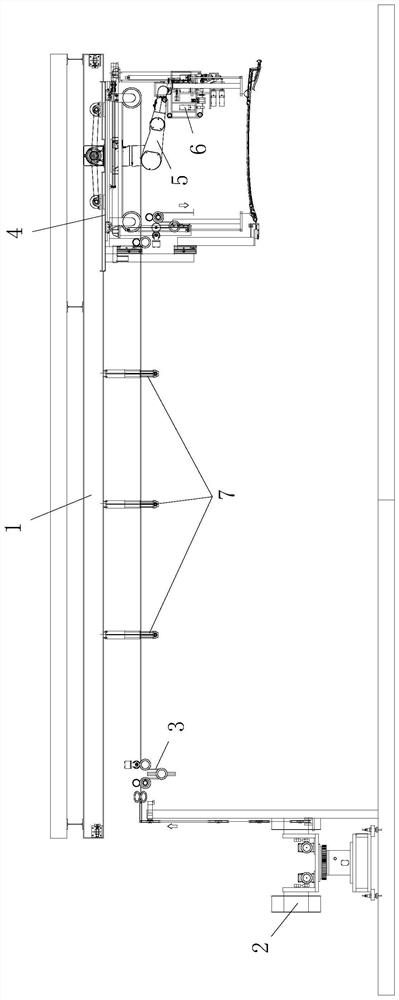

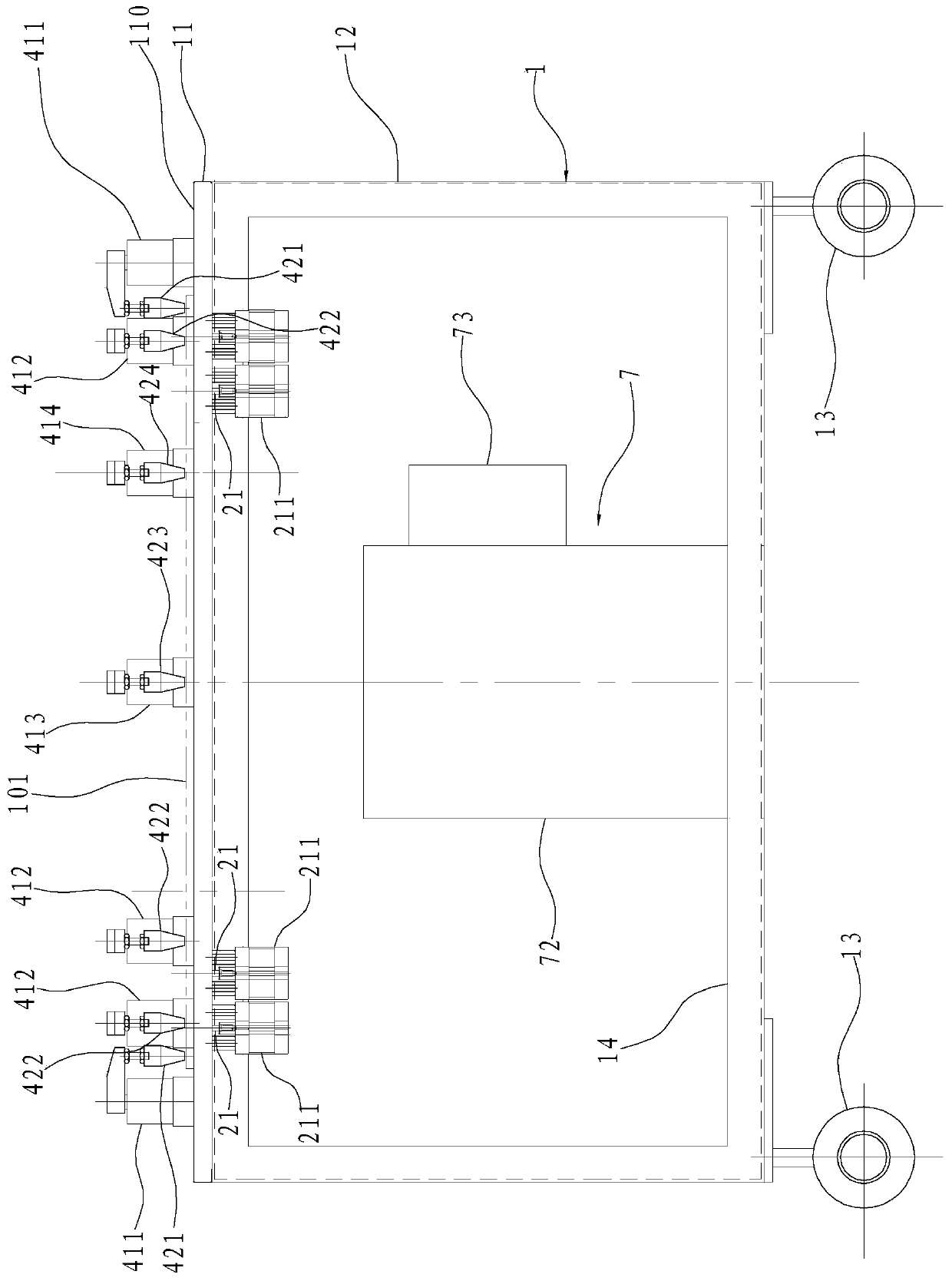

Glue strip automatic bonding equipment

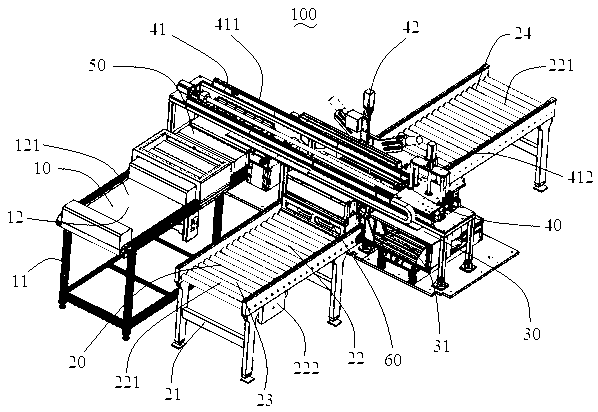

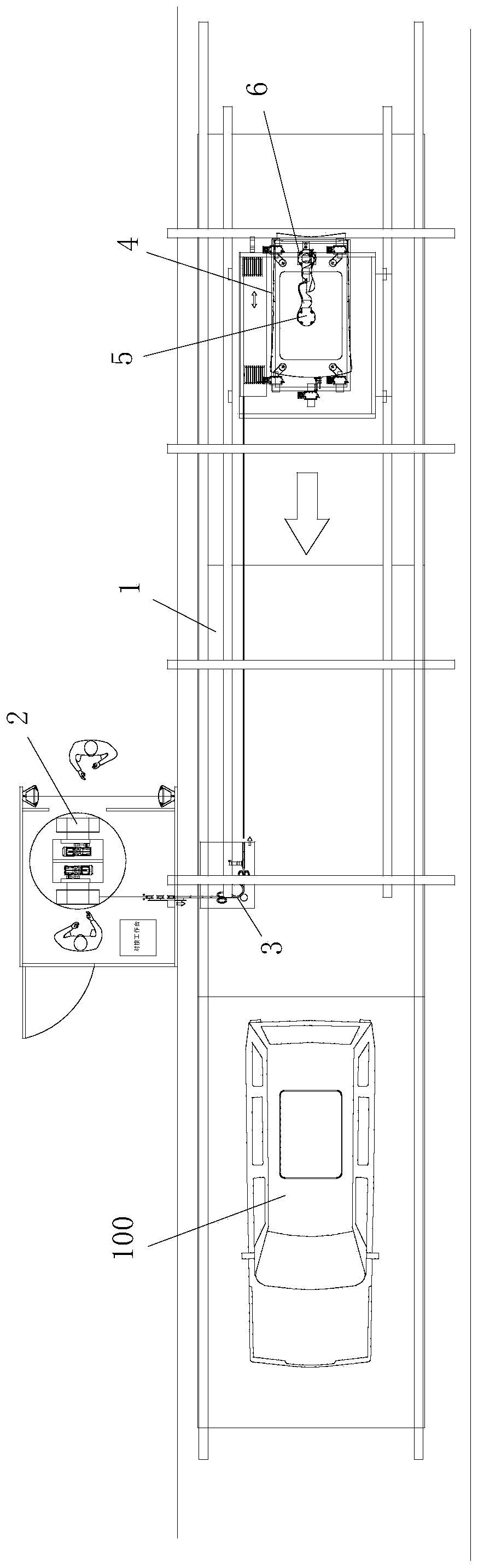

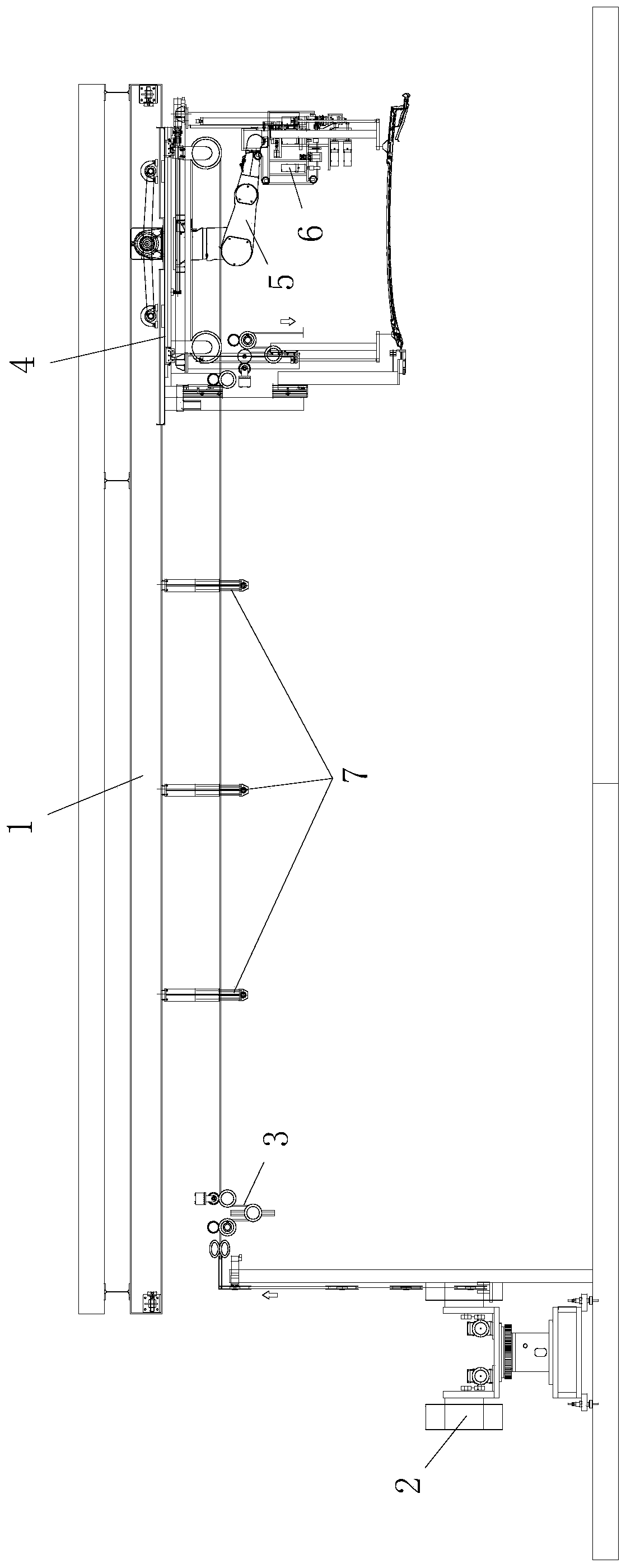

ActiveCN110293689BRealize automatic bondingRealize automatic supplyDomestic articlesManufacturing lineIndustrial engineering

The present invention provides an automatic bonding equipment for adhesive strips, which is used to attach adhesive strips to products located on the production line and moving forward with the production line, and the bonding equipment includes a feeding mechanism for outputting the adhesive strips outward, The frame arranged along the production line, and the accompanying mechanism arranged on the frame to accompany the product, is connected to the robot arranged on the accompanying mechanism, and is connected to the following mechanism arranged on the robot. Bonding mechanism for adhesive tape bonding. The adhesive strip automatic bonding equipment described in the present invention can realize the automatic supply of the adhesive strip through the feeding mechanism, use the accompanying mechanism to realize the synchronous advancement of the bonding part and the product, and use the bonding mechanism driven by the robot to feed the adhesive strip It is automatically bonded to the product, so that it can realize the automatic bonding of the adhesive strips on products such as automobile sunroofs, and has good practicability.

Owner:精诚工科汽车系统有限公司

A carton sealing machine

A carton sealing machine, which realizes the automatic bending and closing of cartons through the sealing module, and then uses the adhesive tape module to realize the tape packaging of the cartons; it includes: a frame, used to transport the cartons; a sealing module, used to put the cartons on the The opened flaps are folded together to close the carton; the adhesive tape module is used to paste the tape on the carton and move to complete the pasting of the carton; Flap-closed, adhesive-tape modules seal the carton with tape. The invention has a simple structure, and can realize full automation of packing and packaging of products and cartons in combination with an automatic case unpacking machine and an automatic case packing machine. The box sealing module of the present invention can realize automatic bending and box sealing of the folded plate, thereby providing a basis for subsequent adhesive tape packaging. The adhesive tape module of the present invention can realize the automatic bonding of the adhesive tape to the crevice where the folded plates of the carton are folded in half, thereby realizing automatic packaging.

Owner:CHONGQING VOCATIONAL INST OF ENG

a spoon machine

ActiveCN112173308BEasy to operateRealize automatic bondingPackagingConveyor partsAdhesive glueWaste product

The invention relates to a scoop pointing machine, which comprises a frame, on which a cup cover conveyor belt and a spoon conveyor belt are respectively arranged, a glue spraying device, a manipulator, and a visual recognition waste discharge device are arranged on the frame along the conveying direction, and the frame is equipped with There is a spoon-dividing device; the advantage of the present invention is that the cup lid on the cup lid conveyor belt is sprayed with glue by the glue spraying device, and then the spoon conveyed on the spoon conveyor belt is put into the cup lid through the robot arm. Glue, so that the spoon can be automatically glued to the cup cover, and then the cup cover can be detected by the visual recognition waste discharge device, so as to effectively avoid the missing or overfilling of the spoon. Secondly, the visual recognition waste discharge device includes The detection mechanism and the push-out mechanism use the detection mechanism to detect the number of spoons in the cup lid. When the information detected by the detection mechanism does not match the set value, the waste product can be pushed out of the cup lid conveyor belt in time through the push-out mechanism, thus ensuring that the rack is released. The quality of the lid of the material.

Owner:JIAXING YANDANG PACKAGING

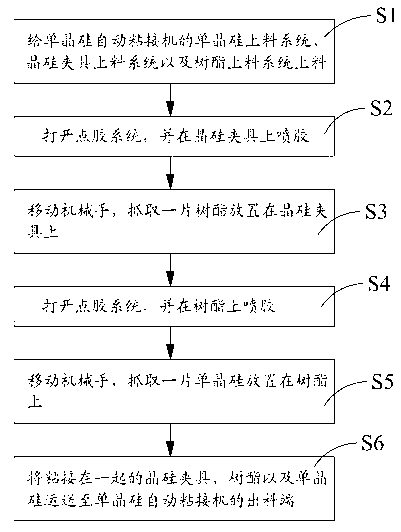

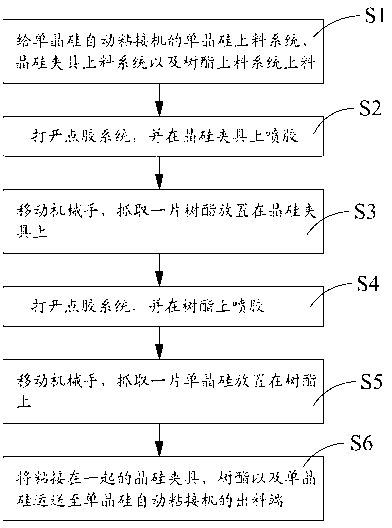

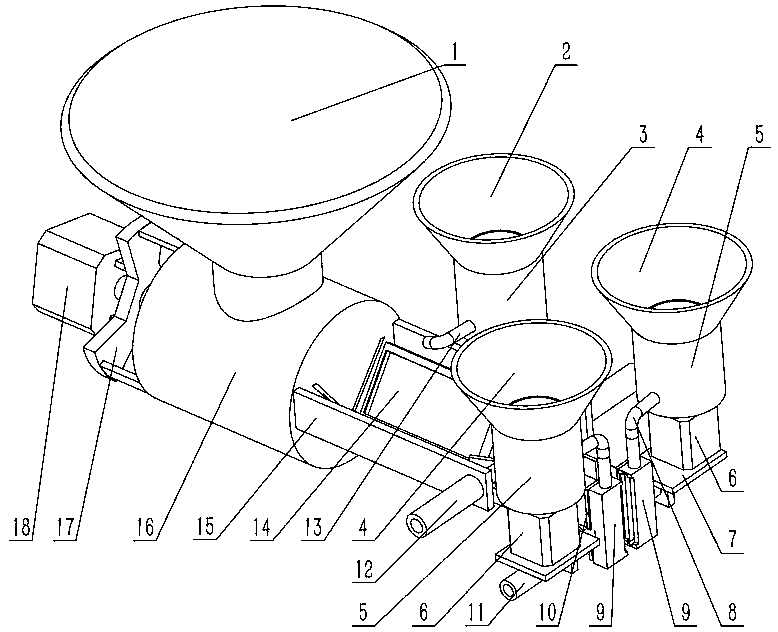

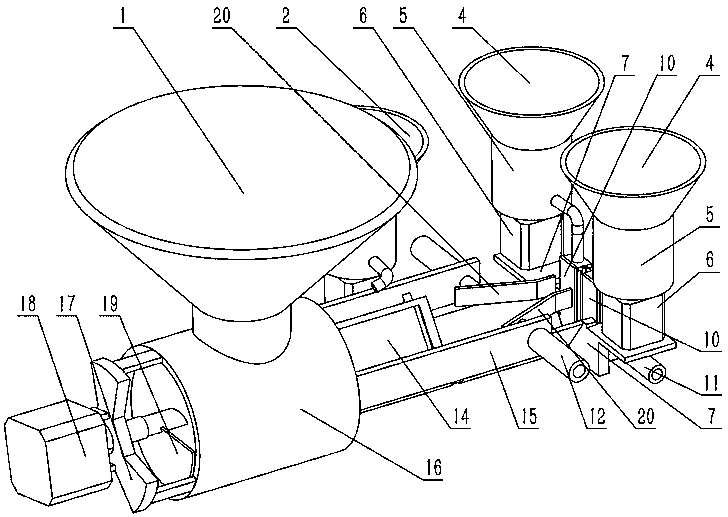

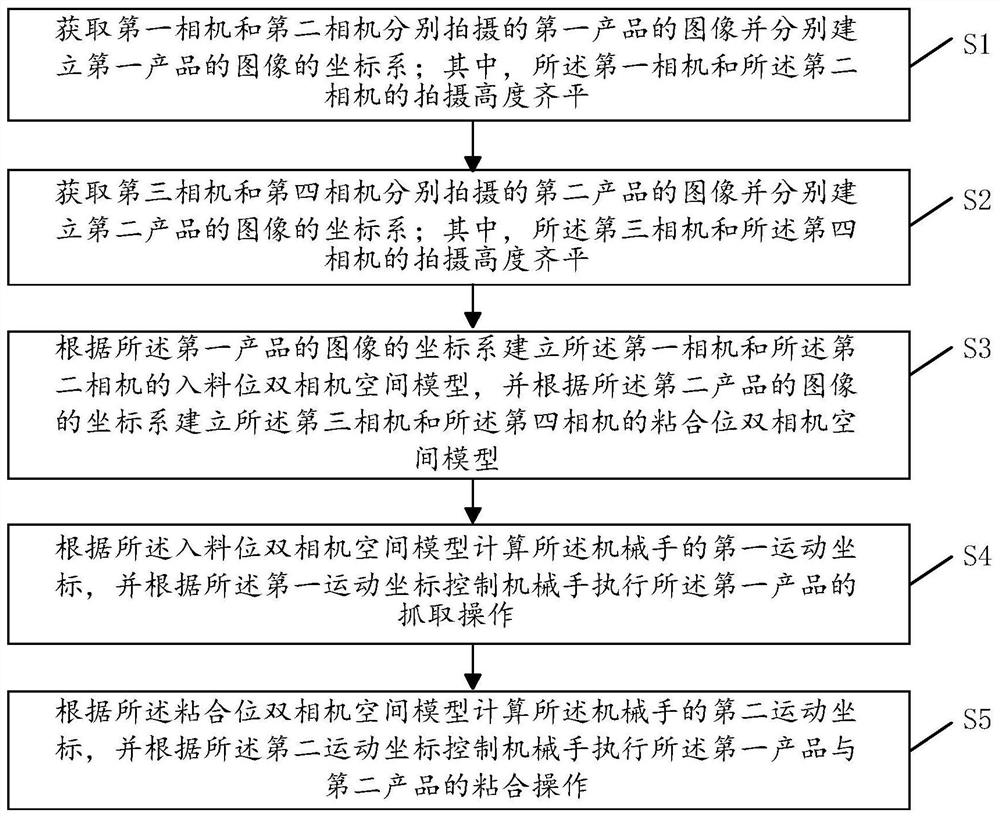

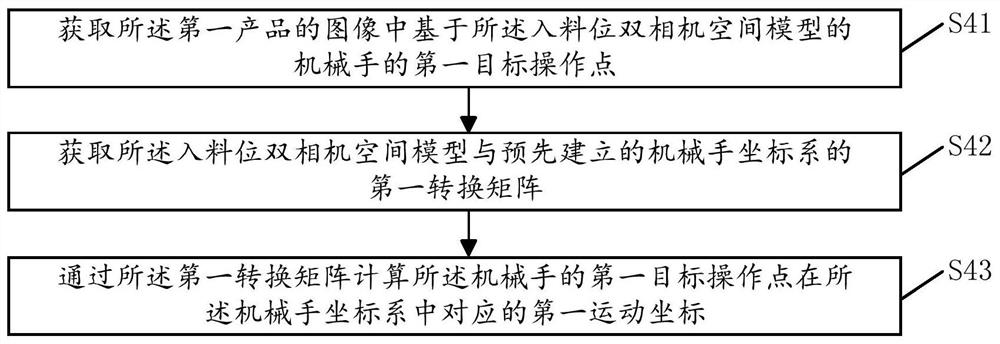

Monocrystalline silicon automatic bonding method

A monocrystalline silicon automatic bonding method is disclosed by the invention, and comprises the following steps: S1. feeding for a monocrystalline silicon feeding system, a crystal silicon clamp feeding system and a resin feeding system of a monocrystalline silicon automatic bonding machine; S2. opening a dispensing system and spraying a binder on the crystal silicon clamp; S3. moving a machinery hand to grab a sheet of resin and place on the crystal silicon clamp; S4. opening the dispensing system and spraying the binder on the resin; S5. moving the machinery hand to grab a sheet of monocrystalline silicon on the resine; S6. deliverying the crystal silicon clamp, the resin and monocrystalline silicon which are bonded together to a discharge end of the monocrystalline silicon automatic bonding machine. Compared with the prior art, the monocrystalline silicon automatic bonding method of the invention can help to achieve an automatic bonding of the crystal silicon clamp, the resin and the monocrystalline silicon.

Owner:SIP GOLDWAY TECH

Wine box base shell bonding device

ActiveCN109774239BRealize automatic bondingReduce labor intensityBox making operationsPaper-makingReciprocating motionStructural engineering

The invention discloses a wine box base shell bonding device comprising a base plate. The top face of the base plate is provided with a push plate, a pressing plate and a discharge outlet sequentially. The push plate does reciprocating motion facing or back on to the pressing plate along the top face of the base plate. A top plate is fixed above the base plate. The pressing plate does vertical reciprocating motion between the top plate and the base plate and perpendicular to the top face of the base plate. The pressing plate is matched with an inner opening of a wine box base shell. A discharge conveying belt is arranged below the base plate and at the discharge outlet. Known from the above structure, through the wine box base shell bonding device, automatic bonding of the wine box base shell is achieved, manual bonding is not needed, bonding efficiency is improved, labor intensity of operators is lowered, and bonding quality is ensured.

Owner:HUAIYIN INSTITUTE OF TECHNOLOGY

Wine box base shell bonding device

ActiveCN109774239ARealize automatic bondingReduce labor intensityPaper-makingBox making operationsReciprocating motionEngineering

The invention discloses a wine box base shell bonding device comprising a base plate. The top face of the base plate is provided with a push plate, a pressing plate and a discharge outlet sequentially. The push plate does reciprocating motion facing or back on to the pressing plate along the top face of the base plate. A top plate is fixed above the base plate. The pressing plate does vertical reciprocating motion between the top plate and the base plate and perpendicular to the top face of the base plate. The pressing plate is matched with an inner opening of a wine box base shell. A discharge conveying belt is arranged below the base plate and at the discharge outlet. Known from the above structure, through the wine box base shell bonding device, automatic bonding of the wine box base shell is achieved, manual bonding is not needed, bonding efficiency is improved, labor intensity of operators is lowered, and bonding quality is ensured.

Owner:HUAIYIN INSTITUTE OF TECHNOLOGY

Automatic adhesive tape pasting equipment

PendingCN114380121AReduce manual operation hoursLess fixed investmentArticle deliveryComposite materialEngineering

The invention relates to automatic adhesive tape pasting equipment which comprises an electrical cabinet, two pasting mechanisms are arranged in the electrical cabinet from left to right, each pasting mechanism comprises a black band moulding bed, an adhesive tape moulding bed is arranged at the bottom of the black band moulding bed, a plurality of pressure sensors are arranged at the bottom of the adhesive tape moulding bed, and the pressure sensors are connected with the adhesive tape moulding bed. A white film detector and an in-place sensor are arranged on the top of the rubber belt forming die, and the in-place sensor is arranged on one side of the white film detector. According to the automatic bonding device, automatic bonding of the 3M adhesive tape is achieved, the bonding accuracy rate of 98% or above is achieved, the manual operation time and the rework rate of parts are reduced, and automatic production is achieved.

Owner:SHENYANG MINGHUA MOULD & PLASTIC TECH CO LTD

Automatic adhesive tape bonding equipment

ActiveCN110293689ARealize automatic bondingRealize automatic supplyDomestic articlesEngineeringManufacturing line

The invention provides automatic adhesive tape bonding equipment for bonding adhesive tape to a product located on a production line and advancing along with the production line. The bonding equipmentcomprises a supply mechanism for outwards outputting the adhesive tape, a rack arranged along the production line, a following mechanism which is arranged on the rack and can follow the product, a robot connected to the following mechanism, and a bonding mechanism connected to the robot for adhesive tape bonding. According to the automatic adhesive tape bonding equipment, automatic adhesive tapesupply can be achieved through the supply mechanism, and synchronous advancing of the bonding part and the product can be achieved through the following mechanism; and through the bonding mechanism driven through the robot, the adhesive tape can be automatically bonded to the product, automatic bonding of the adhesive tape on products such as automobile skylight can be achieved, and good practicability is achieved.

Owner:精诚工科汽车系统有限公司

Semi-automatic catcher

The invention relates to a semi-automatic material catcher, which includes a feeding board and a lowering board. The lowering board is fixedly connected with a plurality of vertical guide rails. matched through holes, each of the guide rails is sleeved with a return spring, the return spring is located between the upper material plate and the lower material plate, and the lower side of the upper material plate is provided with a The housing chamber of the metal buckle, the housing chamber is located at the front of the feeding plate, the lower side of the feeding board is also provided with a chute arranged in the front and rear direction, the chute communicates with the housing chamber, A supporting block corresponding to the accommodating cavity is provided on the upper side of the blanking plate for fixing the material belt. The utility model has the characteristics of simple operation, high work efficiency, high degree of automation, and the material of the metal buckle is more economical.

Owner:广东南方职业学院

Spoon counting machine

ActiveCN112173308AEasy to operateRealize automatic bondingPackagingConveyor partsAdhesive glueWaste product

The invention relates to a spoon counting machine. The spoon counting machine comprises a rack, wherein a cup cover conveying belt and a spoon conveying belt are arranged on the rack; a glue sprayingdevice, a manipulator and a visual recognition waste discharging device are sequentially arranged on the rack in the conveying direction; and a spoon distributing device is arranged on the rack. The spoon counting machine has the advantages that cup covers on the cup cover conveying belt are subjected to glue spraying treatment through the glue spraying device, then the spoons conveyed on the spoon conveying belt are put into the cup covers through the manipulator, and the interiors of the cup covers are coated with glue, so that the spoons can be automatically glued to the cup covers; then, the cup covers are detected through the visual recognition waste discharging device, so that loading missing or excessive loading of the spoons can be effectively avoided; and secondly, the visual recognition waste discharging device comprises a detection mechanism and a push-out mechanism, the number of the spoons in the cup covers is detected through the detection mechanism, and waste can be pushed out of the cup cover conveying belt in time through the push-out mechanism when information detected by the detection mechanism is not in accordance with set information, so that the quality of thecup covers discharged by the rack is ensured.

Owner:JIAXING YANDANG PACKAGING

A fpc automatic bonding machine

ActiveCN110886751BRealize automatic bondingHigh bonding precisionMaterial gluingEmbedded systemElectrical mechanism

The present invention provides an FPC automatic bonding machine, comprising: a carrying device configured to carry FPC and products; a turning device including a first feeding mechanism, a turning mechanism and a first driving mechanism, and the first feeding mechanism is configured as The FPC is carried, the first feeding mechanism is arranged on the flipping mechanism, the first driving mechanism is connected with the flipping mechanism, and the first driving mechanism is configured to drive the flipping mechanism to flip, so that the bonding surface of the FPC is opposite to the surface to be bonded of the product; a connecting device configured to bond the FPC to the product; a transferring device configured to transfer the FPC on the carrier device to the flipping device and the FPC on the flipping device to the bonding device; the positioning device, including position acquisition A mechanism and a deviation correction mechanism; the position acquisition mechanism is configured to acquire position information of the FPC and the product, and the deviation correction mechanism corrects the position of the FPC and the product according to the position information. The turning mechanism can realize automatic bonding of FPC, and the positioning device can improve the bonding accuracy of FPC.

Owner:GOERTEK INC

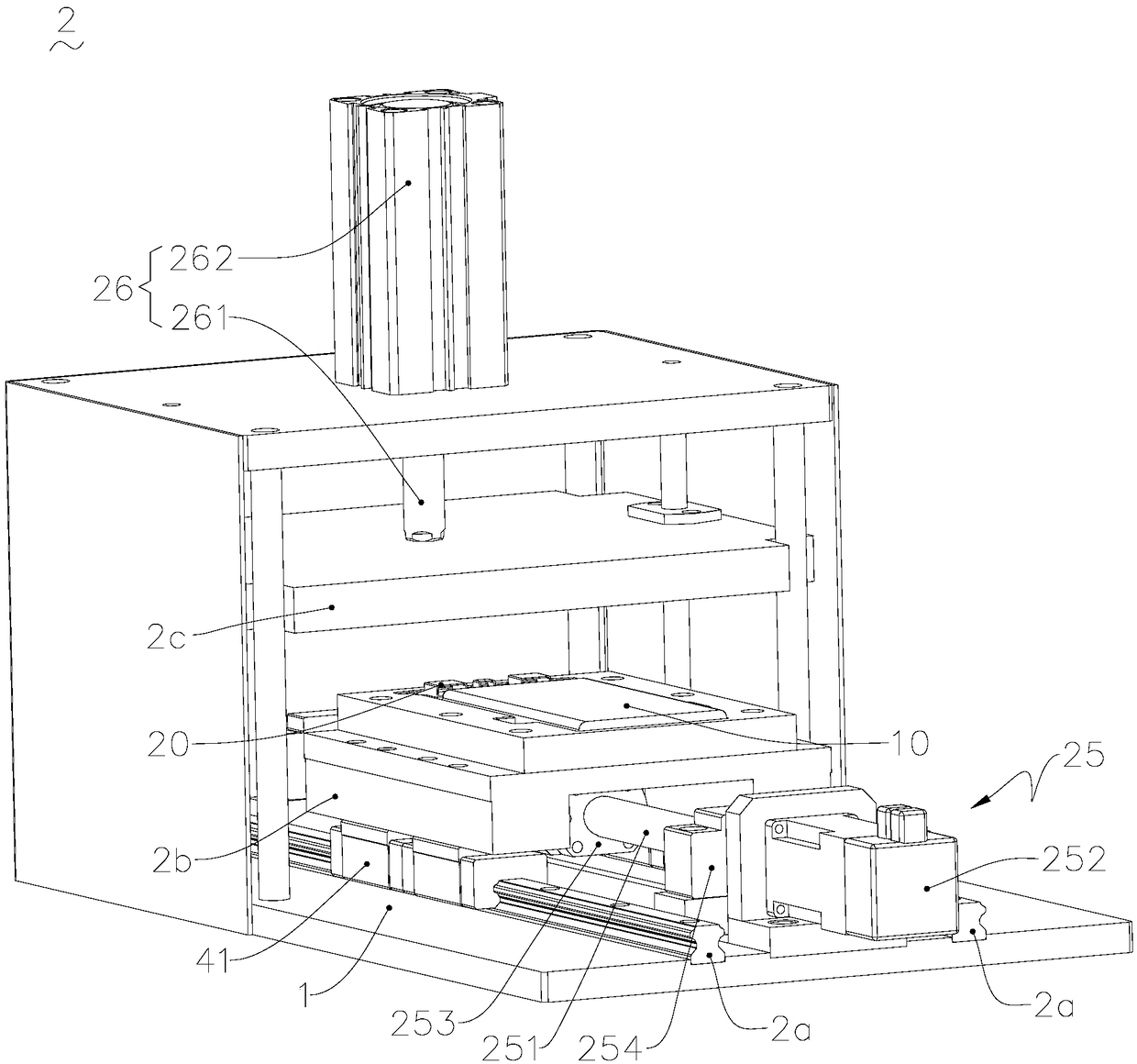

Automatic bonding device

PendingCN108723749AMeet flatness requirementsRealize automatic bondingLiquid surface applicatorsCoatingsElectricityAdhesive

The invention relates to the field of movable power supply production equipment and provides an automatic bonding device. The automatic bonding device comprises a base, an automatic laminating device,an automatic adhesive dispensing machine and a welding part mechanical arm; the automatic laminating device, the automatic adhesive dispensing machine and the welding part mechanical arm are arrangedon the base; the automatic laminating device is used for laminating an electricity core assembly, namely an electricity core and a circuit board assembly which are mutually welded; the automatic adhesive dispensing machine is used for bonding the electricity core assembly after being laminated by the automatic laminating device on a housing; and the welding part mechanical arm is used for transferring the electricity core assembly on the automatic laminating device into the housing born by a housing sliding device. With the adoption of the structure, the automatic laminating device, the automatic adhesive dispensing machine and the welding part mechanical arm are integrated so as to achieve automatic laminating of the electricity core and the circuit board assembly, and automatic adhesivedispensing of the housing, so that a welding part meets the requirement of smoothness, automatic bonding between the electricity core assembly and the housing is also achieved, manpower is not required in the operating process, the automation degree is high, and the working efficiency is high.

Owner:BESITER CO LTD

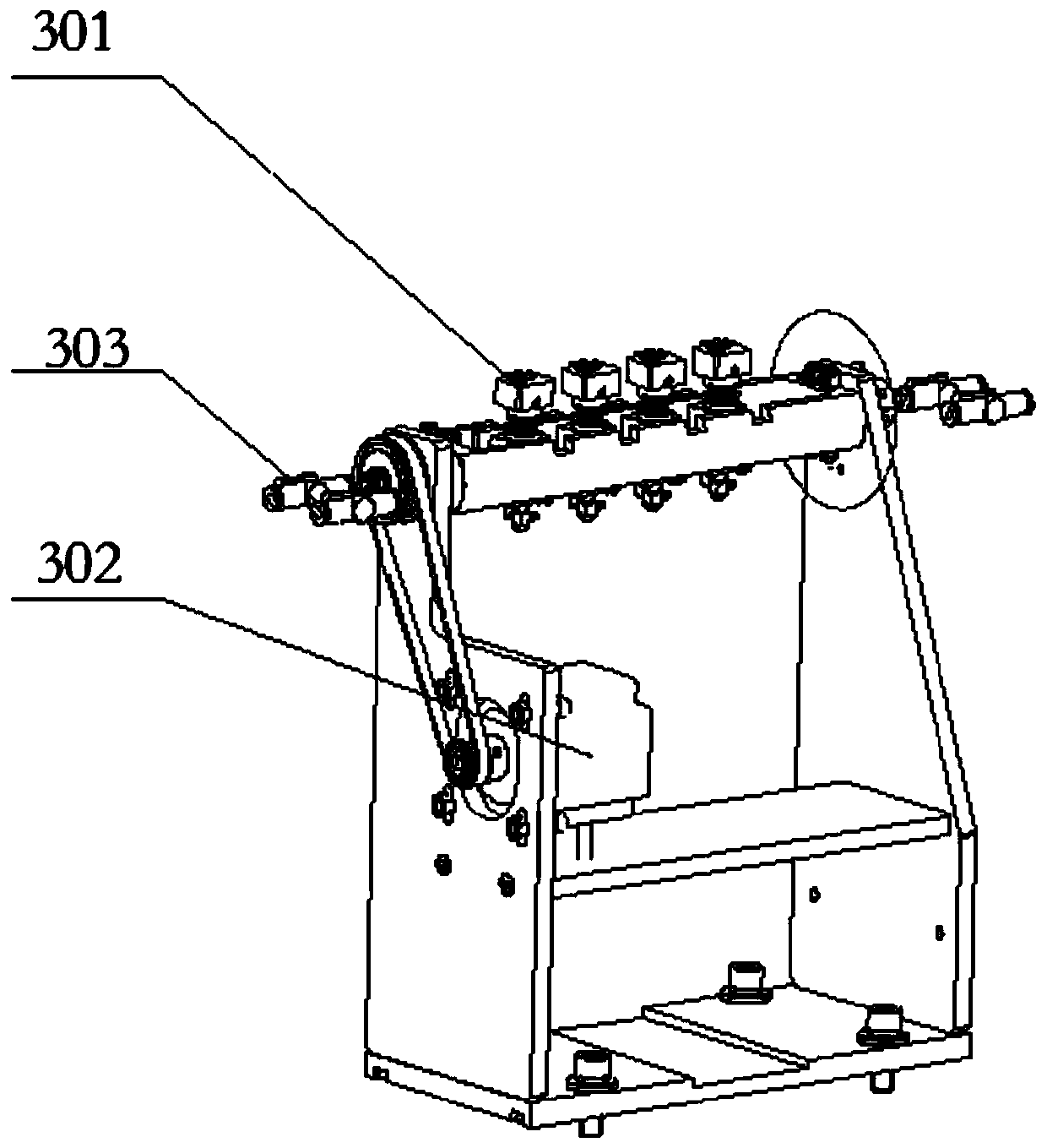

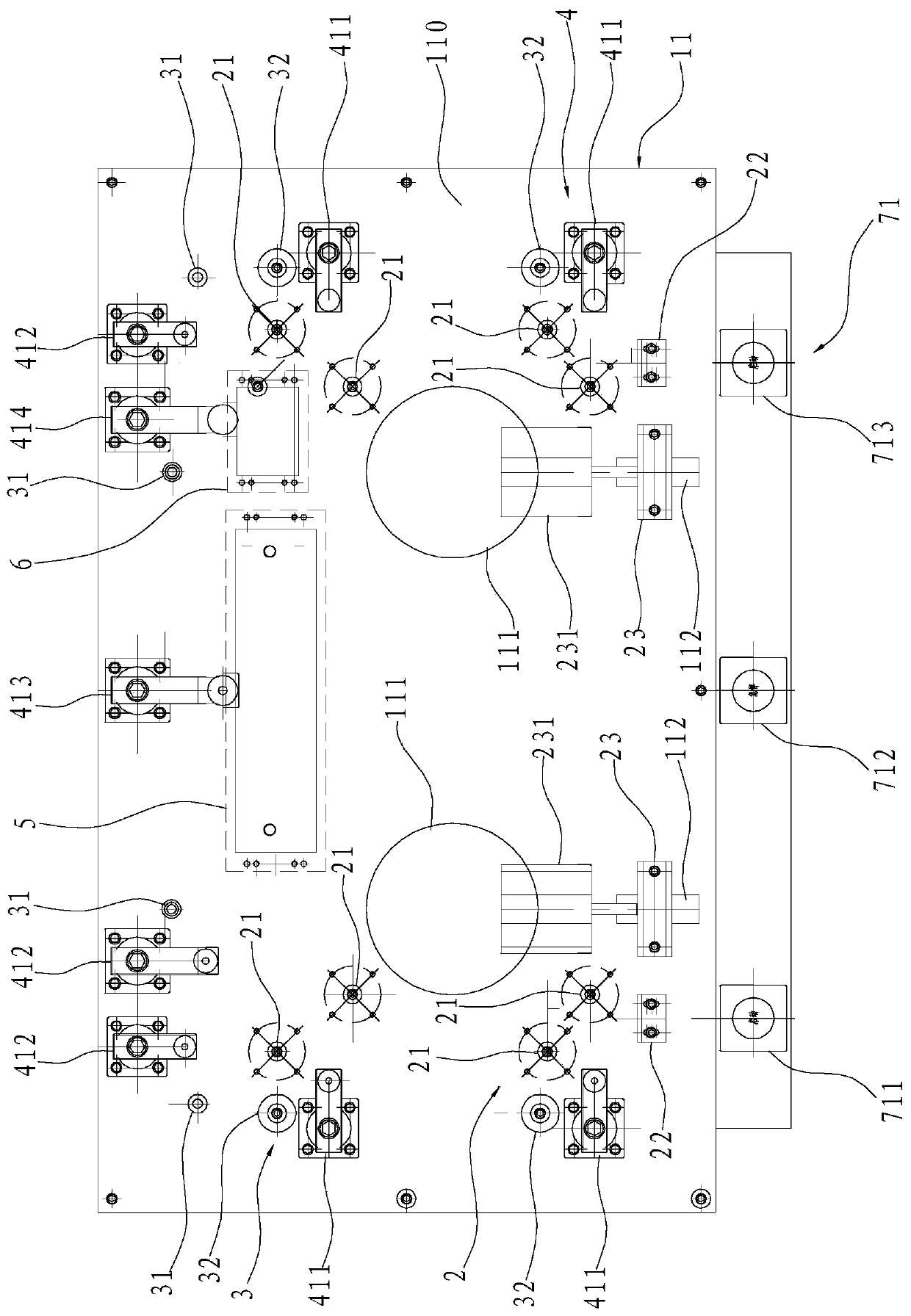

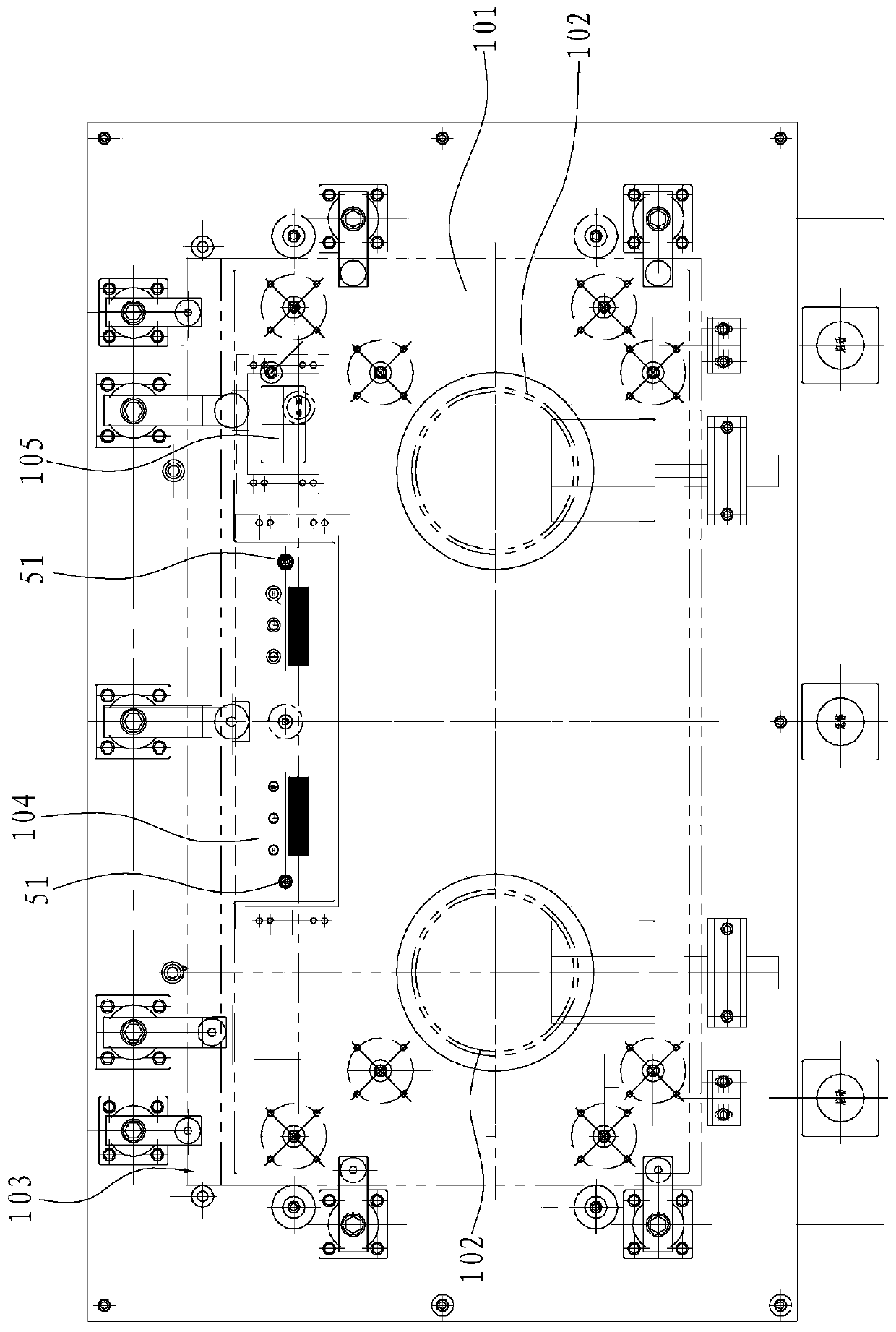

Automatic bonding machine for cooker panel components

ActiveCN109139637BAvoid displacementAvoid misalignmentMaterial gluingMetal working apparatusMetal stripsDisplay board

The invention relates to an automatic bonding machine for a kitchen range panel assembly. The automatic bonding machine comprises a machine frame with a table top, and further comprises a main positioning hole, a first positioning assembly, a second positioning assembly, a third positioning assembly and a tight pressing assembly; the main positioning hole is formed in the table top and correspondsto a furnace end hole in a panel; the first positioning assembly is used for positioning the panel; the second positioning assembly is used for positioning a metal strip; the third positioning assembly is used for positioning a display panel assembly; and the tight pressing assembly is arranged on the table top, and comprises a rotary tight pressing air cylinder fixed on the table top and a pressing column fixed on a piston rod of the rotary tight pressing air cylinder, and the pressing column can tightly press the panel, the metal strip and the display panel assembly. According to the automatic bonding machine, displacement and dislocation of the panel and other assemblies in the bonding process can be effectively avoided, and correctness of the bonding position of the product can be guaranteed so that the quality of the kitchen range panel product can be improved, in addition, the tight pressing assembly is further arranged, the tight pressing assembly can tightly press the panel, the metal strip and the display panel assembly, then automatic bonding of the panel assembly can be realized, and the processing efficiency is improved.

Owner:NINGBO FOTILE KITCHEN WARE CO LTD

An automated dumpling making robot

ActiveCN106805278BRealize automatic deliveryRealize automatic bondingFood coatingMechanical engineeringRobot

The invention discloses an automatic dumpling making robot which comprises a dumpling wrapper forming cylinder, a dumpling noodle conveying funnel, a forming motor, a forming motor mounting frame and the like, wherein the dumpling wrapper forming cylinder is cylinder-shaped; the forming motor mounting frame is arranged at one end of the dumpling wrapper forming cylinder, a baffle is arranged at the other end of the dumpling wrapper forming cylinder, and a V-shaped groove is formed in the baffle. The automatic dumpling making robot disclosed by the invention has the benefits that by arranging a plurality of spirally-conveyed auger structures, automatic conveying of dumpling flour sheets and dumpling stuffing is realized; through arranging an automatic bonding structure, automatic bonding of dumpling wrappers is realized; through arranging a cutting and flour filling structure, the purposes of automatic cutting and further flour filling are realized; the automatic dumpling making robot disclosed by the invention is reasonable in structure and high in working efficiency, and the productive forces are effectively liberated.

Owner:SHANGHAI QINGMEI GREEN FOOD

Semi-automatic material receiver

The invention relates to a semi-automatic material receiver. The semi-automatic material receiver comprises an upper material plate and a lower material plate. Multiple vertical guide rails are fixedly connected to the lower material plate. Through holes matched with the guide rails are correspondingly formed in the upper material plate. Each guide rail is sleeved with a reset spring. The reset springs are located between the upper material plate and the lower material plate. The lower side face of the upper material plate is provided with a containing cavity used for containing metal clasps. The containing cavity is located on the front portion of the upper material plate. The lower side face of the upper material plate is further provided with a sliding groove arranged in the front-back direction. The sliding groove is communicated with the containing cavity. The upper side face of the lower material plate is provided with supporting blocks, wherein the supporting blocks correspond to the containing cavity and are used for fixing a material strap. The semi-automatic material receiver has the advantages that operation is simple, the working efficiency and the automation degree are high, and more materials of the metal clasps are saved.

Owner:广东南方职业学院

Metal handicraft fixing and bonding device

The invention relates to the technical field of metal handicraft processing, in particular to a metal handicraft fixing and bonding device which comprises a first gear, a caterpillar band, a second gear, a first sliding plate, a channel, a glue box, a second sliding plate, a sliding rolling shaft, a plastic film and a rotating rod. The first gear is connected with the second gear through the caterpillar band, and the first sliding plate is connected to the left side of the second gear; the channel is connected to the left side of the first sliding plate; a channel sliding rolling shaft is arranged in the channel; the glue box is mounted on the side surface of the channel; the second sliding plate is arranged on the left side of the glue box; and the first gear is connected to one side of the second sliding plate and is connected with the second gear through the caterpillar band. By means of the metal handicraft fixing and bonding device, the effects of automatic bonding, automatic fixing and batch operation can be achieved.

Owner:浙江江山福鑫工艺品有限公司

A bonding method, system, device and device

ActiveCN108520538BSolve efficiency problemsReduce failure rateImage enhancementProgramme-controlled manipulatorRobot handEngineering

Owner:GUANGZHOU SHIYUAN ELECTRONICS CO LTD +1

A bonding mold and bonding method for tapered surface friction material of synchronizer inner ring

ActiveCN107225790BAvoid Adhesion EffectsRealization of heat and pressure bondingPressesBond qualityHeating effect

Owner:CHENGDU HAONENG TECH CO LTD

A magnetic steel automatic bonding device for snap switches

ActiveCN106208564BSolve the problem that small volume magnetic steel cannot be bondedRealize automatic bondingManufacturing stator/rotor bodiesSolenoid valveMagnetic poles

The present invention is an automatic bonding device for magnetic steel used for quick-action switches, which includes a working tank 1, which is a long strip structure with a U-shaped cross section, and a positioning component is arranged in the working tank 1 along the length direction. One side of the tank 1 is provided with dispensing parts and magnetic steel assembly parts. The beneficial effect of the invention is that it solves the problem that the existing magnetic steel bonding device cannot carry out small-volume magnetic steel bonding. The cooperation of the positioning part, the glue dispensing part and the magnetic steel assembly part can realize the adhesive assembly of the small volume magnetic steel used for the snap switch. The dispensing cylinder is equipped with a pressure regulating valve, which can control the dispensing amount by adjusting the air pressure to ensure uniform product quality. The early warning device on the outer wall of the dispensing cylinder can prompt to add glue in time. The pre-fixed magnets of the magnet base can distinguish the poles of the magnets and improve production efficiency. In addition, the device controls the operation of the cylinder through the PLC controller and the solenoid valve, and can realize the automatic bonding of the magnetic steel.

Owner:XIAN KAITIAN RAILWAY ELECTRICAL

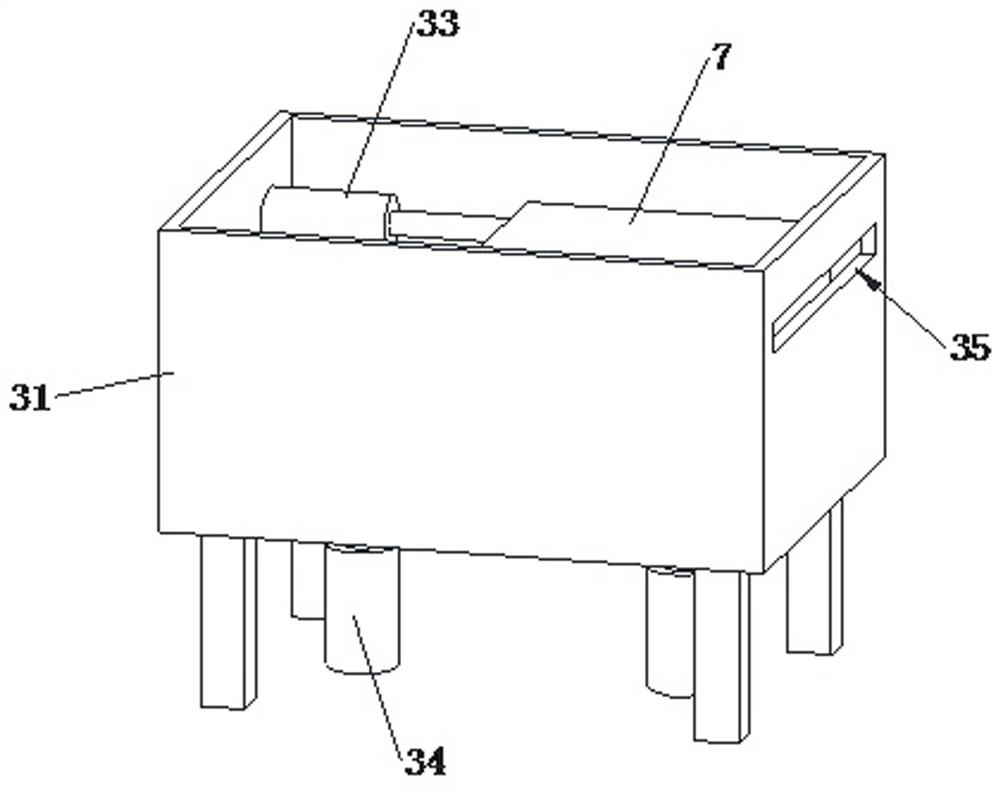

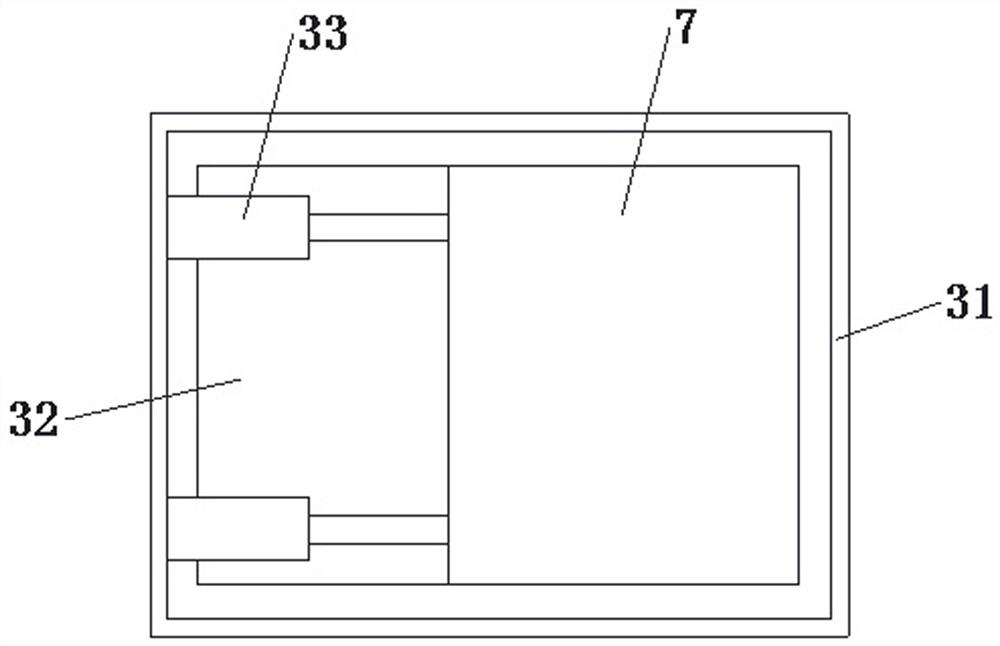

Automatic door plate feeding and discharging device

PendingCN113548449ASpray evenlyPrecise controlSpraying apparatusConveyor partsMachining processStructural engineering

The invention relates to an automatic door plate feeding and discharging device. The device comprises a first conveying belt, an automatic feeding device is arranged at the feeding end of the first conveying belt, and an automatic discharging device is arranged at the discharging end of the first conveying belt; a second conveying belt and a top plate feeding device are arranged at one side of the first conveying belt, and an automatic glue spraying device is arranged above the position, located between the automatic feeding device and the second conveying belt, of the first conveying belt; and the automatic feeding device comprises a box body with a support, a horizontal containing plate located in the box body, a horizontal pushing air cylinder fixedly connected to the side wall of the box body and a plurality of first jacking air cylinders vertically arranged under the box body. By arranging the automatic feeding device, the top plate feeding device and the automatic discharging device, automatic feeding and discharging of a door plate are achieved in the machining process of the door plate, operation is easy, and more time and labor are saved.

Owner:ZHENGZHOU TATA SONGYANG WOOD IND CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

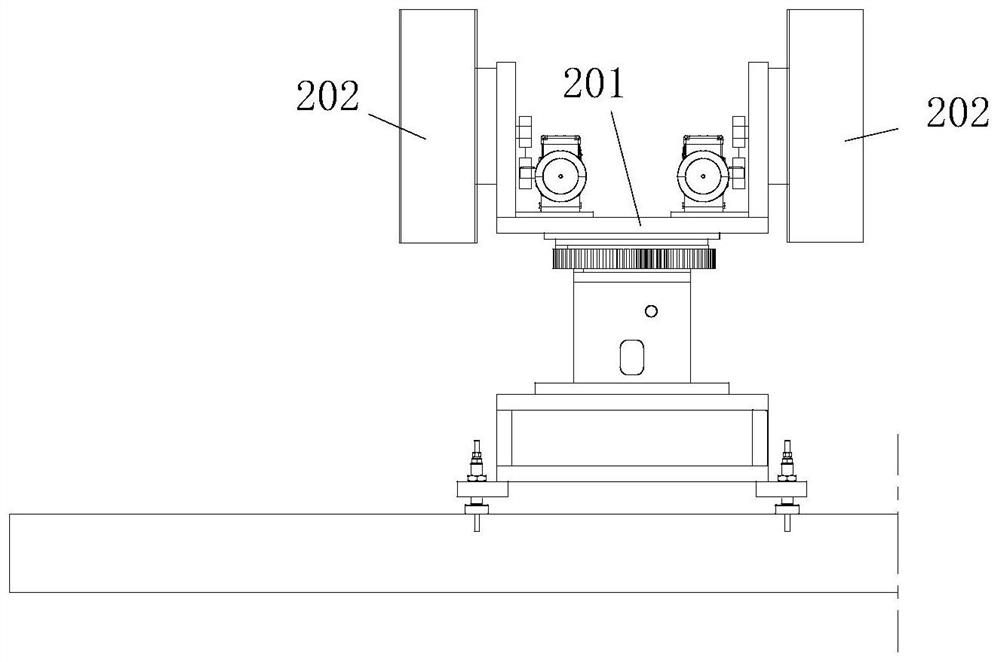

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com