Automatic adhesive tape bonding equipment

A technology of automatic bonding and glue strips, which is applied to household components, household appliances, and other household appliances, etc., can solve problems such as low production efficiency, poor vehicle adaptability, and high manual labor intensity, and achieve good practical results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] It should be noted that the embodiments of the present invention and the features in the embodiments can be combined with each other if there is no conflict.

[0055] Hereinafter, the present invention will be described in detail with reference to the drawings and in conjunction with the embodiments.

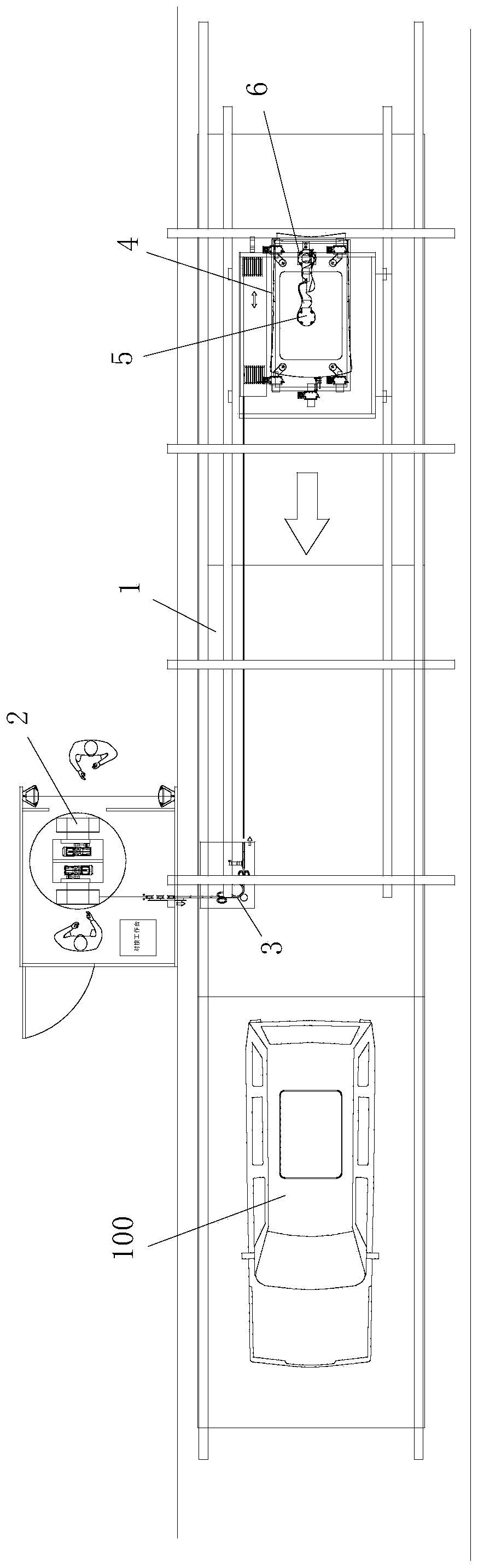

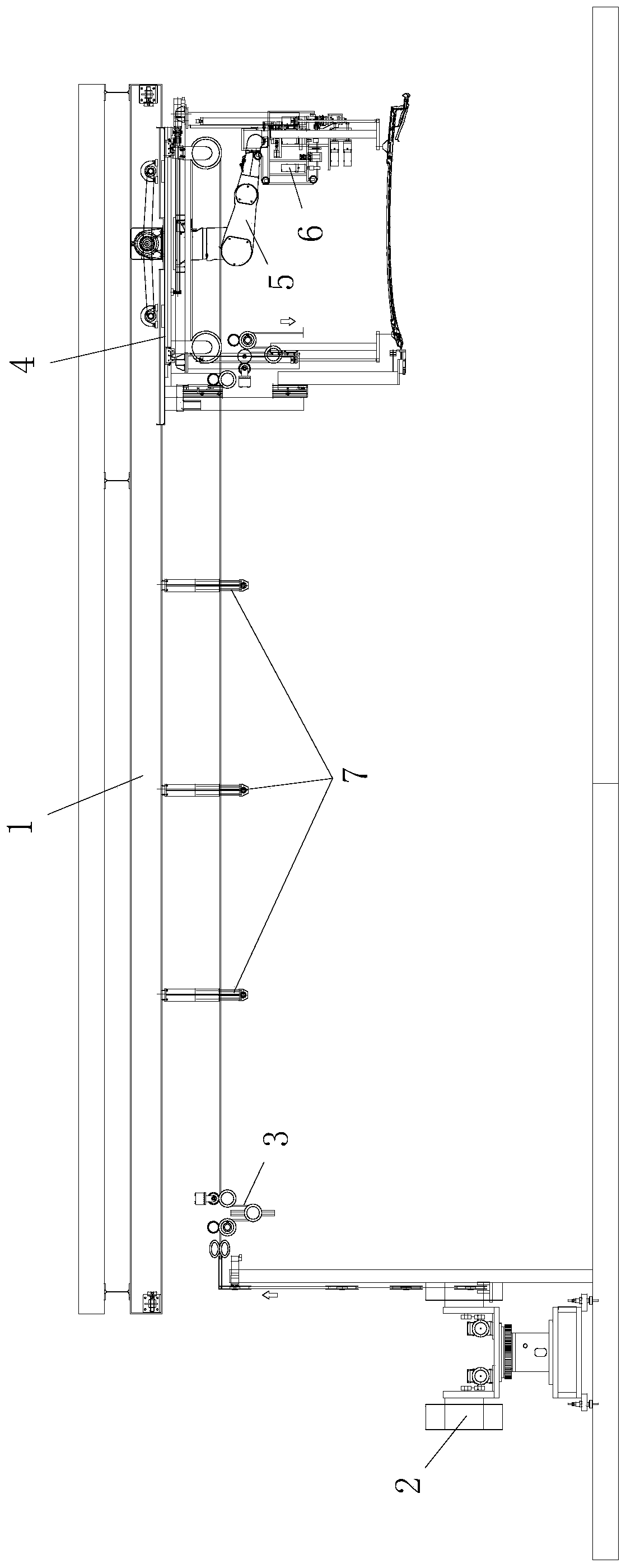

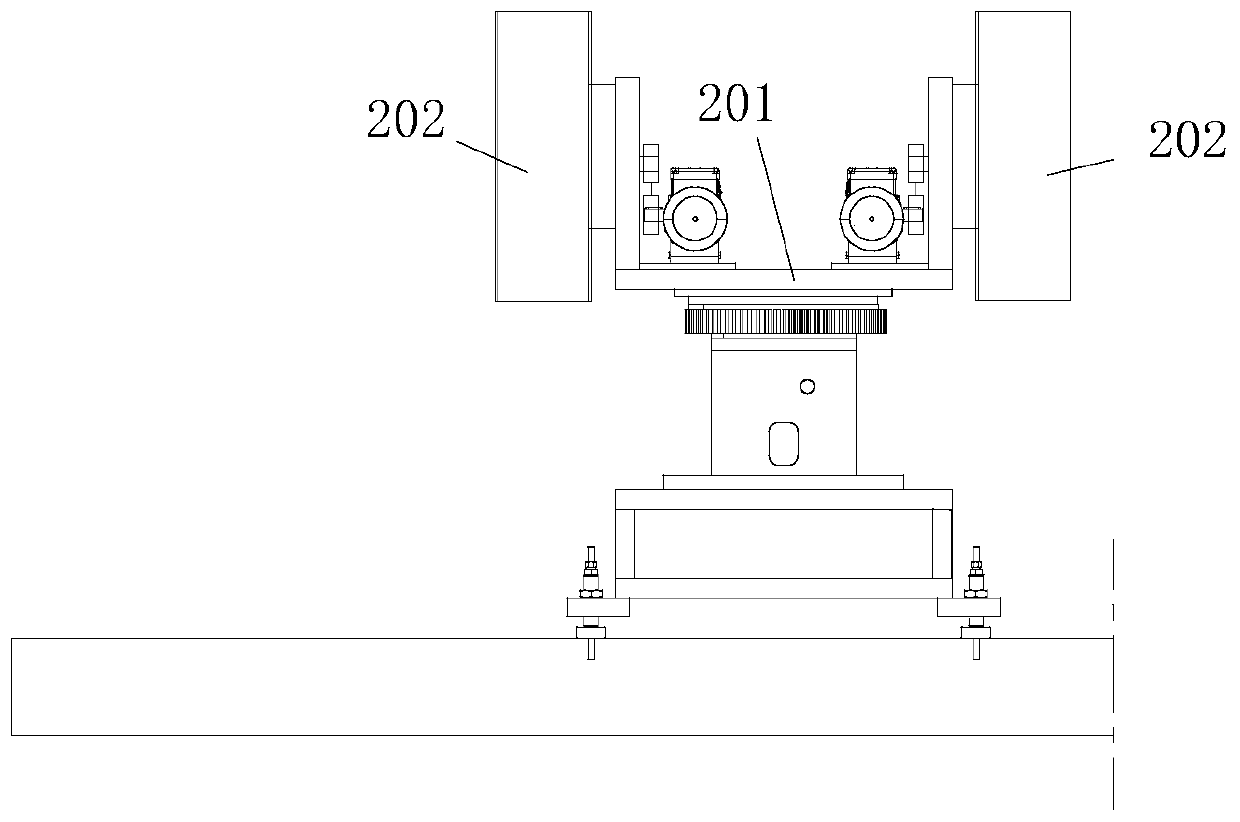

[0056] This embodiment relates to an automatic adhesive tape bonding equipment for bonding adhesive tape to a product located on a production line and traveling along the production line. The product may be, for example, a product on the production line that will be used as an example in this embodiment. For automobiles, the sunroof sealing tape is bonded at the sunroof on the roof of the car. Of course, in addition to being used for the bonding of automotive sunroof rubber strips, the automatic bonding equipment of this embodiment can also be used for bonding the sealing rubber strips on other products, which is not limited.

[0057] by figure 1 And combine figure 2 As shown ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com