Packaging equipment

A technology of packaging equipment and feeding device, which is applied in electrical components, semiconductor/solid-state device manufacturing, circuits, etc., and can solve the problems of single frame feeding method, inability to meet actual production capacity, and low installation efficiency of crystal components and frames.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention will be further described below in conjunction with the embodiments and drawings.

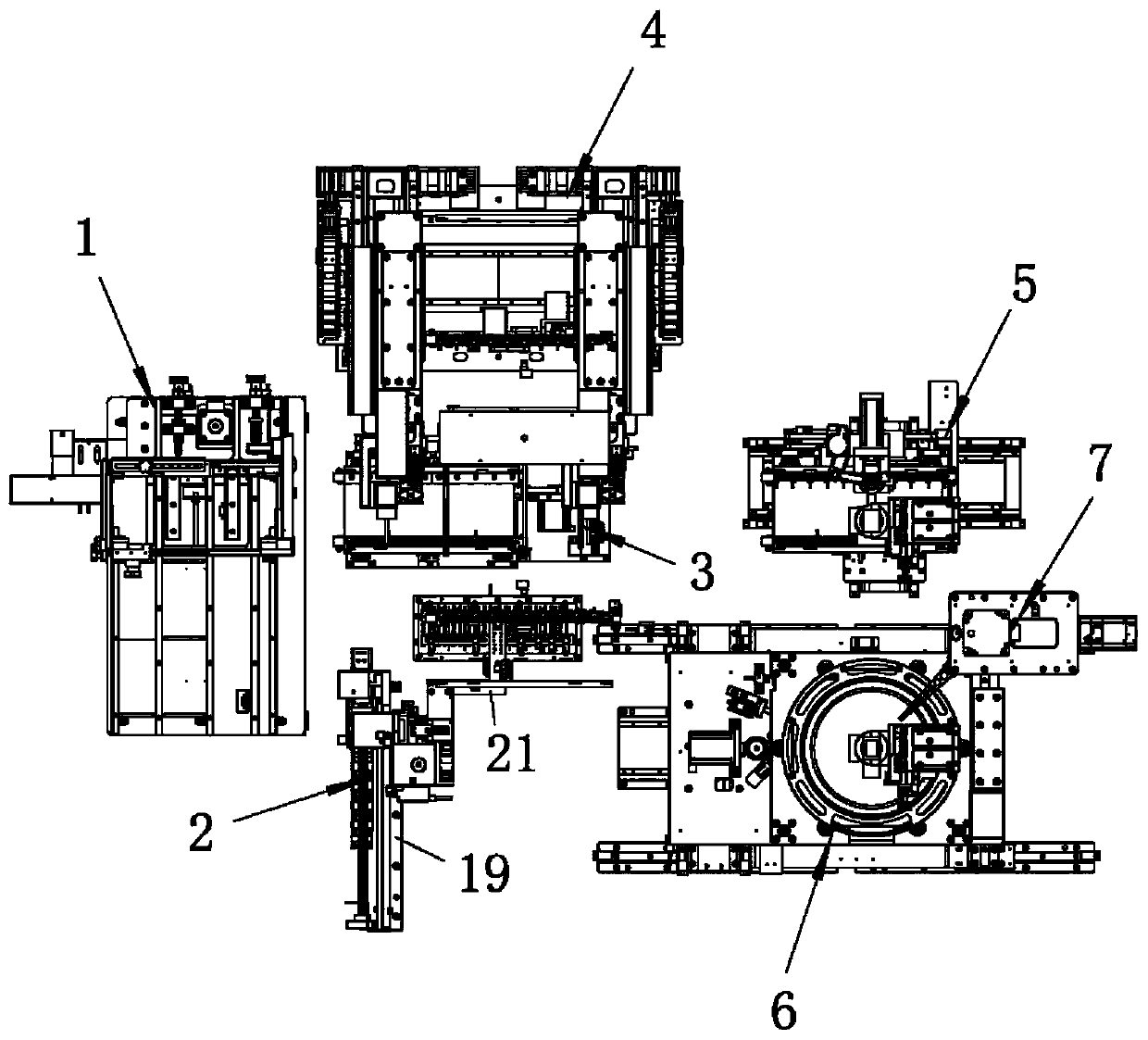

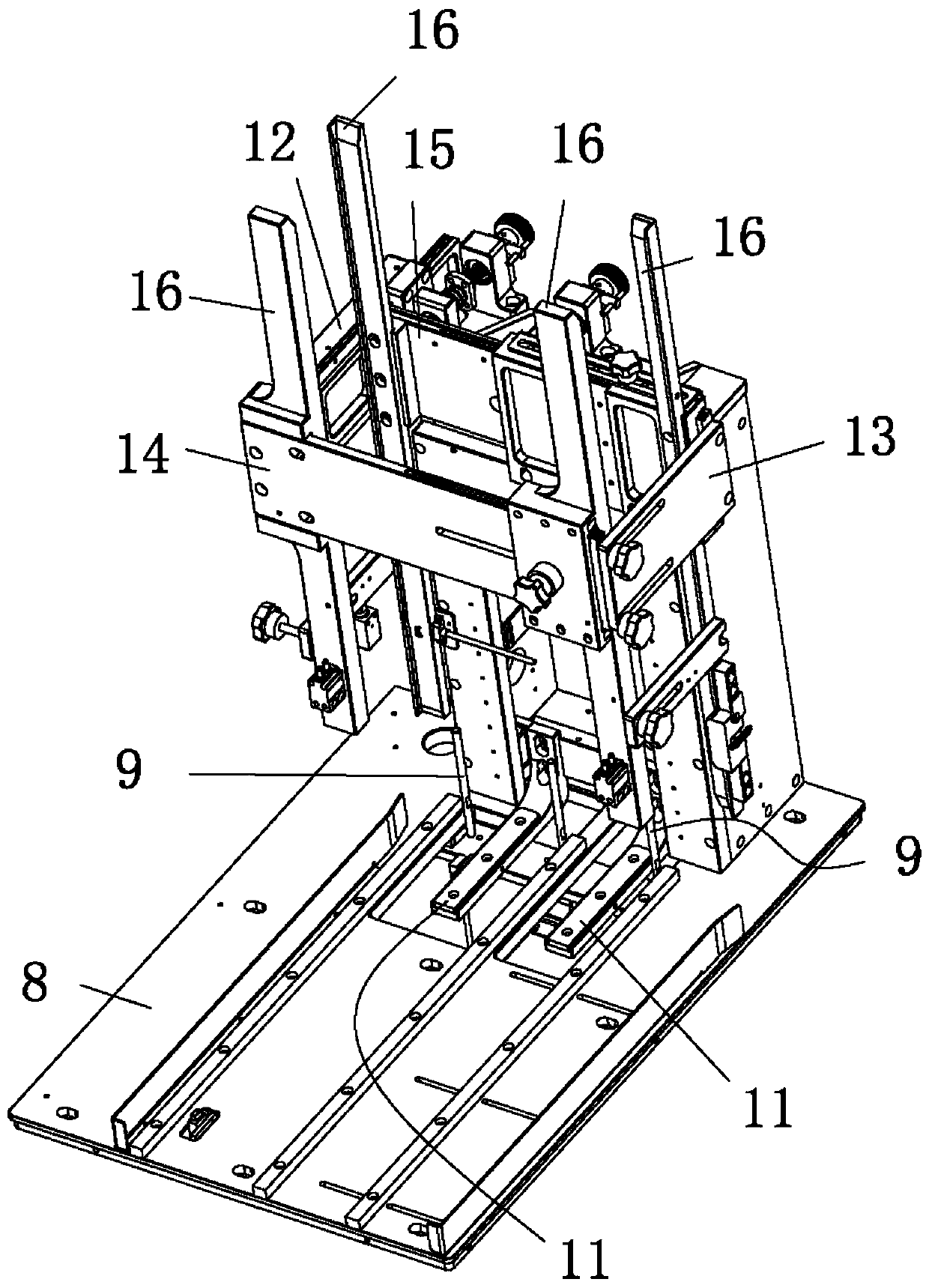

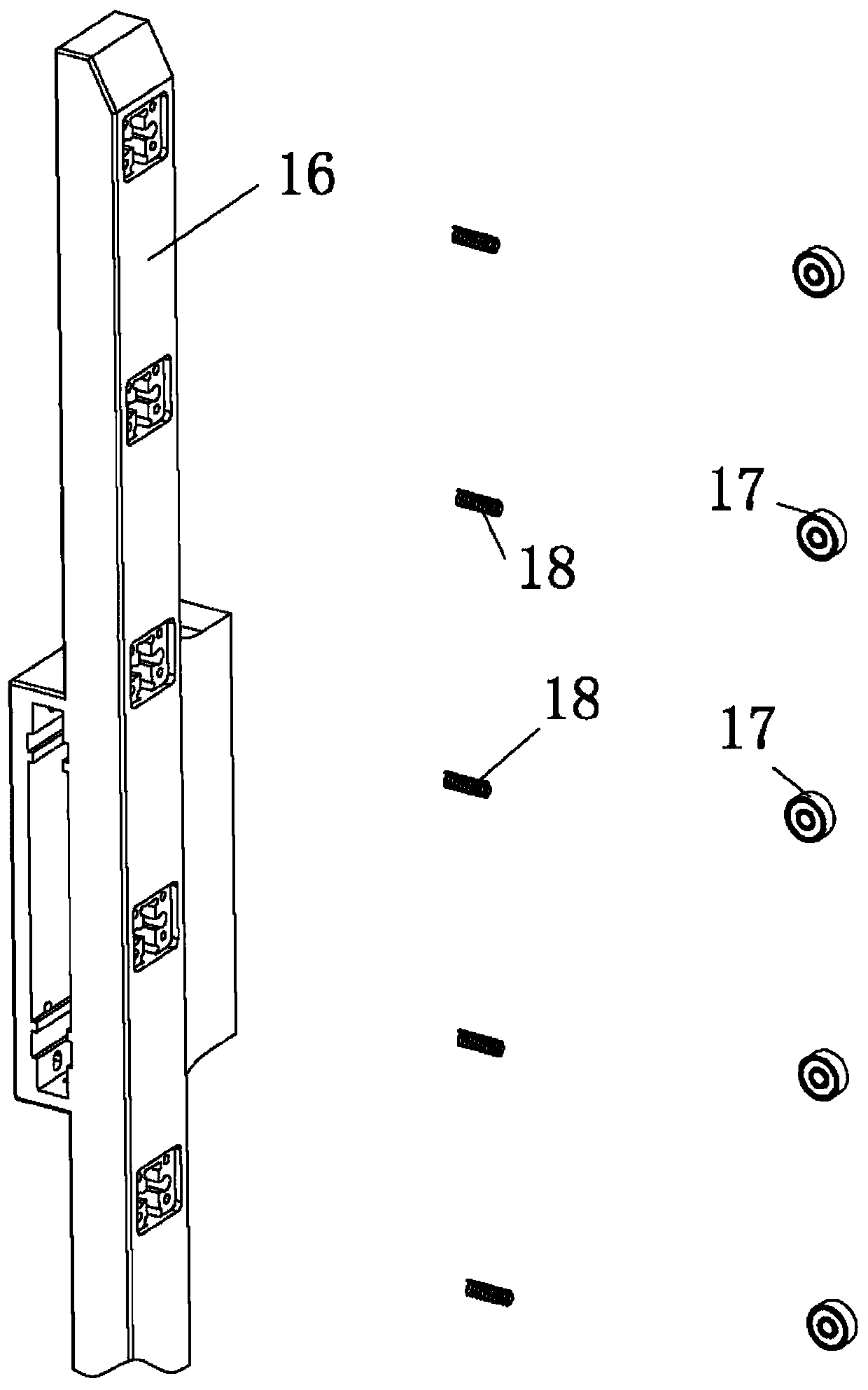

[0044] Reference figure 1 , The packaging equipment of the present invention includes a first feeding device 1, a second feeding device 2, a double-layer rolling device 3, a pneumatic dispensing device 4, an electric glue device 5, a crystal expansion device 6 and a bonding head Device 7; the first feeding device 1 is used to automatically supply a cassette carrying multiple frames, and the second feeding device 2 is used to automatically supply multiple stacked frames. Of course, according to actual needs, the manufacturer can choose to use only the first feeding device 1 or only the second feeding device 2.

[0045] The double-layer rolling device 3 has a first feeding unit and a second feeding unit. The first feeding unit is located above the second feeding unit. The first feeding unit is used to transfer the frame transferred by the feeding device; the pneumatic disp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com