Automatic alignment gluing machine

An automatic alignment and bonding machine technology, applied in thin material processing, folding thin materials, winding strips, etc., can solve problems such as delaying the construction period, affecting the fabric synthesis, and inconsistent flatness before and after the fabric, to improve processing efficiency, Easy to apply effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

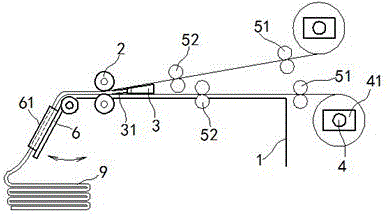

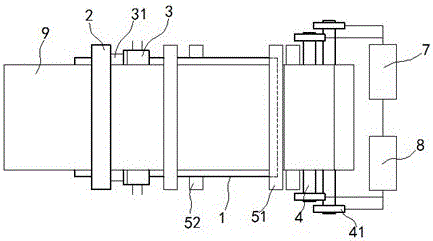

[0014] exist figure 1 , figure 2 In the illustrated embodiment, the automatic alignment bonding machine includes an organic bed 1, a cloth pressing roller 2 and a gluing brush 3; The spraying mouth of brush 3 is offered at the pointed end of wedge; The flat mouth cover 31 of matter soft elasticity is installed in the spraying mouth of described gluing brush 3, and the edge of described flat mouth cover 31 and pressure cloth roller 2 is tangent; The head of 1 is fixedly installed with two cloth winding rollers 4 for winding and placing cloth 9, and a weighing instrument 41 is installed on each of the cloth winding rollers 4; each of the weighing instruments 41 is electrically connected in turn An analyzer 7 and a controller 8; two groups of cloth adjusting rollers are also installed on the machine tool 1, and each group of cloth adjusting rollers is correspondingly matched with two of the cloth winding rollers 4; each group of cloth adjusting rollers includes a speed limiter ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com