Patents

Literature

84results about How to "Neatly folded" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

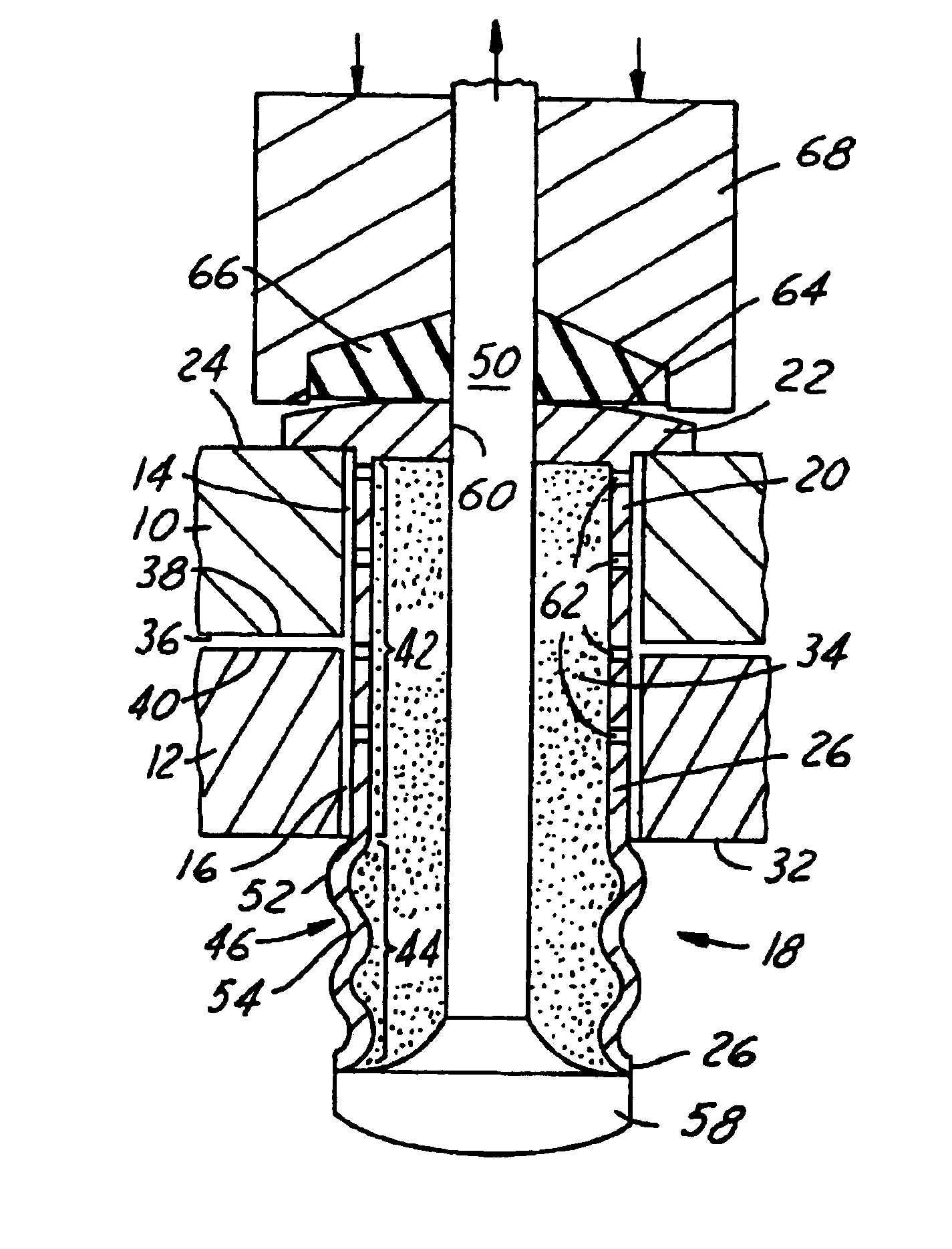

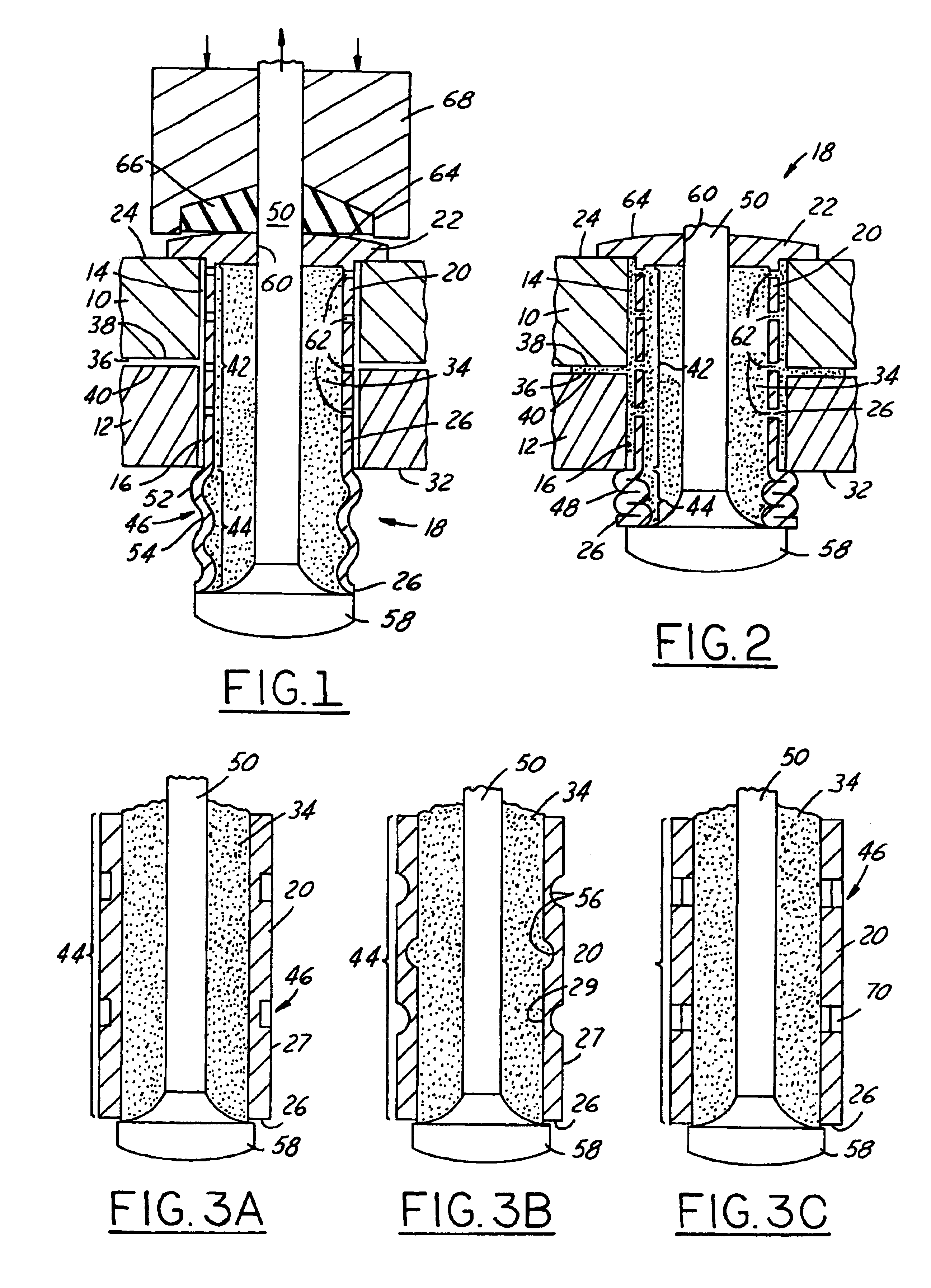

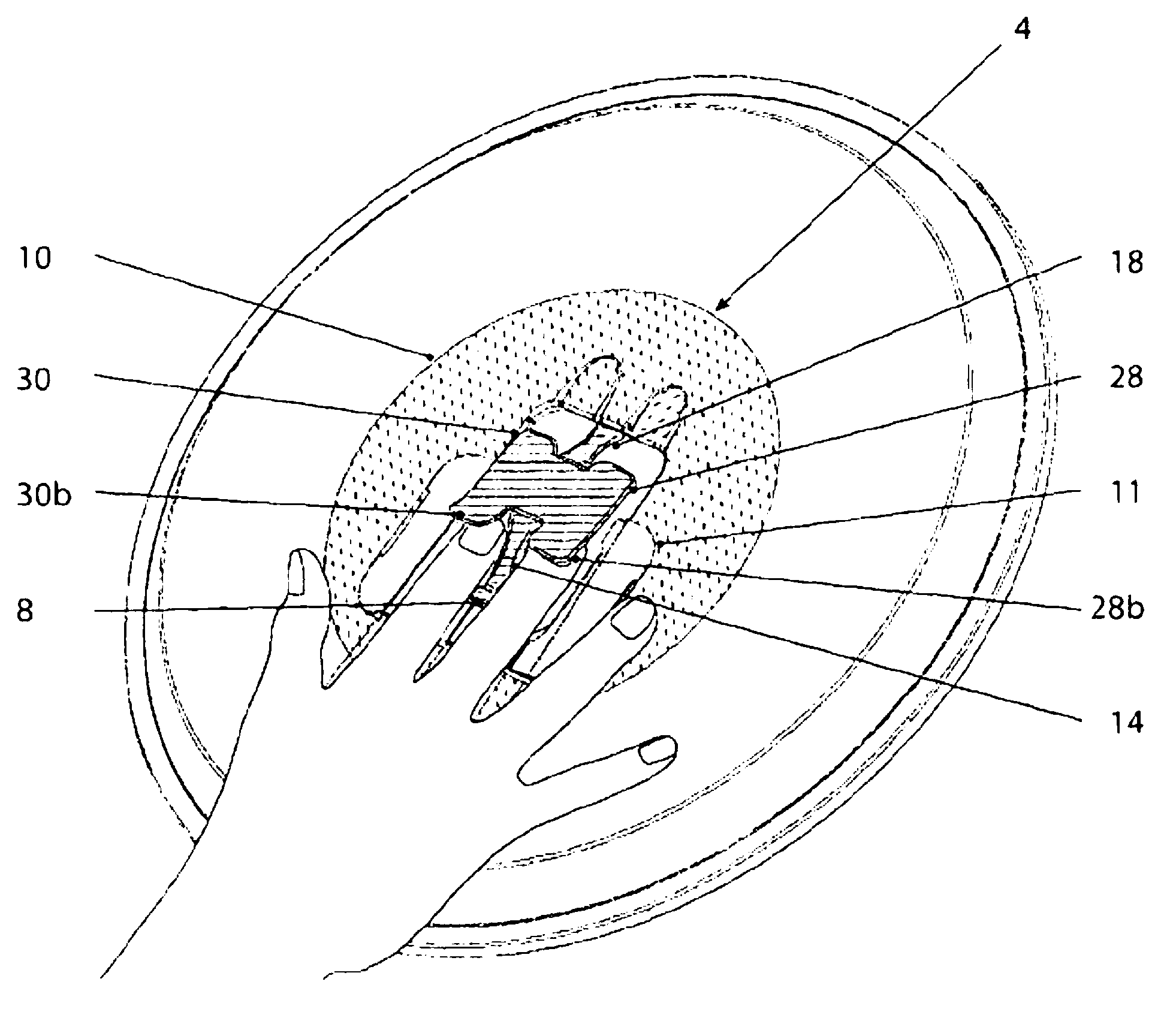

Blind rivet with extended adhesive reservoir

This invention provides a design of an adhesive encapsulated blind rivet for joining an assembly of overlying parts having an accessible side and an inaccessible side. The rivet comprises a rivet head and tubular rivet body. A mandrel is inserted through the open end of the tubular rivet body and through a mandrel hole in the rivet head. A mandrel head engages the end of the tubular body. The tubular body is filled with a mass of latent adhesive around the mandrel. The rivet body is longer than the thickness of the parts to be joined to accommodate a substantial amount of adhesive for expulsion through holes in the rivet body located within the thickness of the assembled parts. The portion of the rivet body extending beyond the blind side of the assembled parts is weakened in a pattern of corrugations or other bands for folding of the end of the tubular body in setting the blind side of the rivet and expelling the larger quantity of adhesive against and between the riveted parts.

Owner:GM GLOBAL TECH OPERATIONS LLC

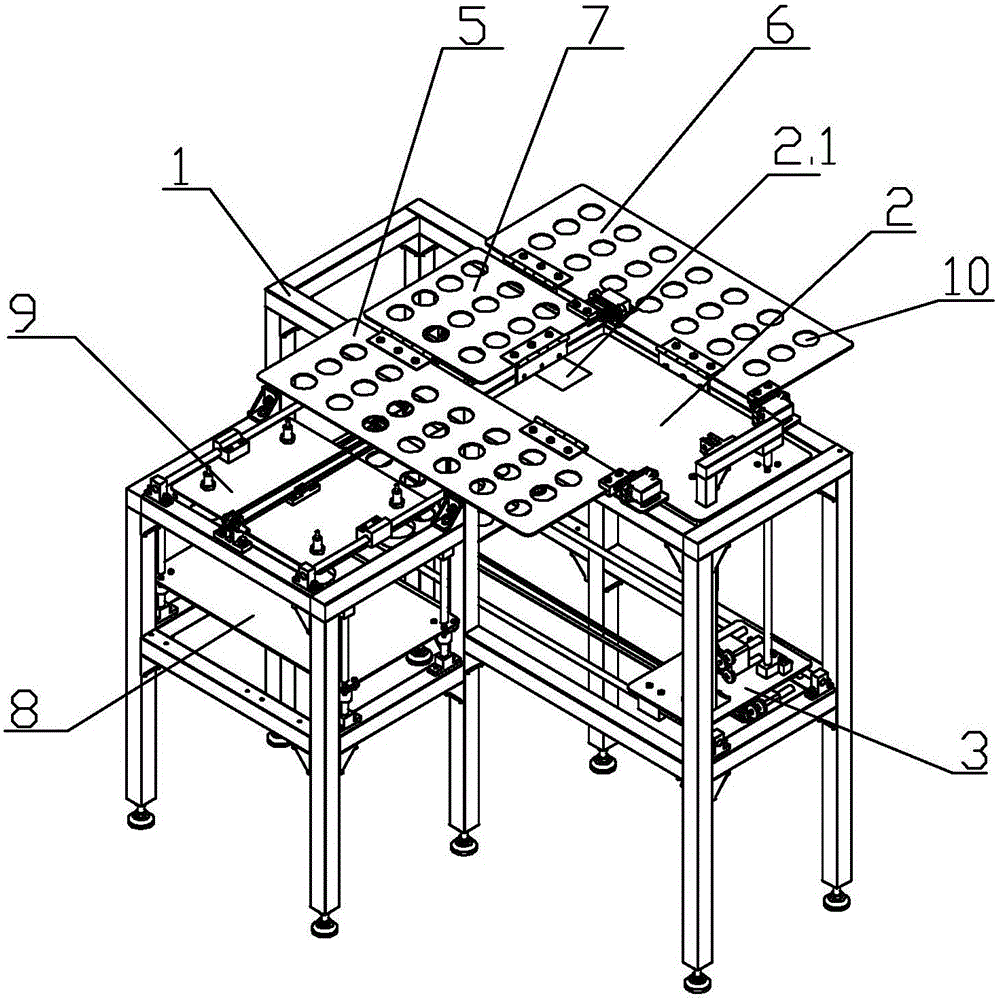

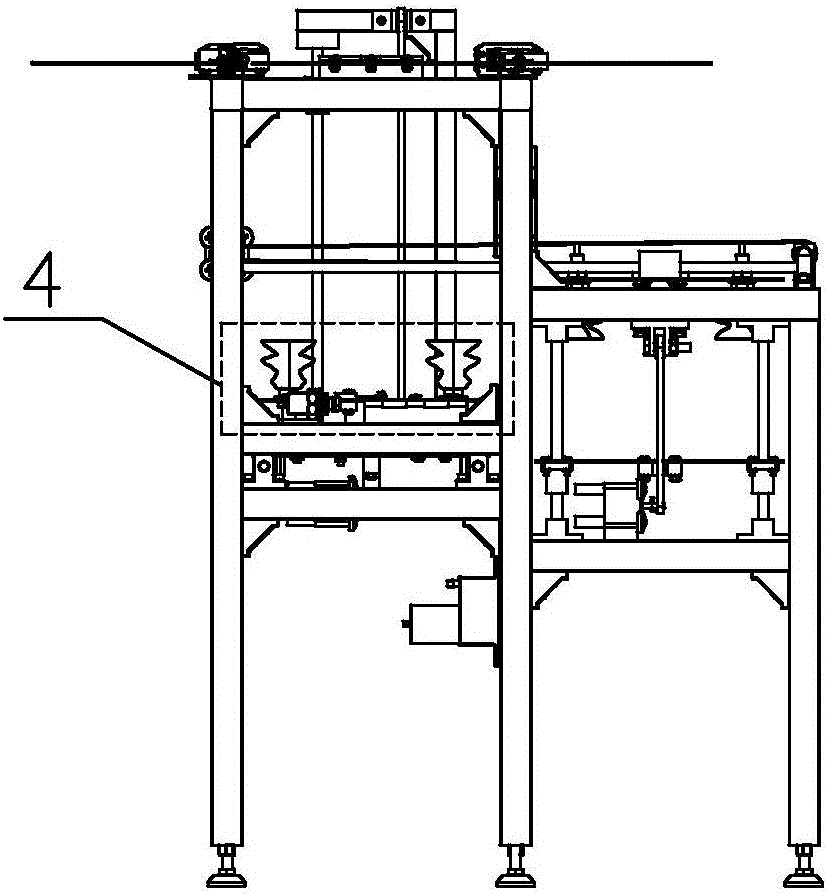

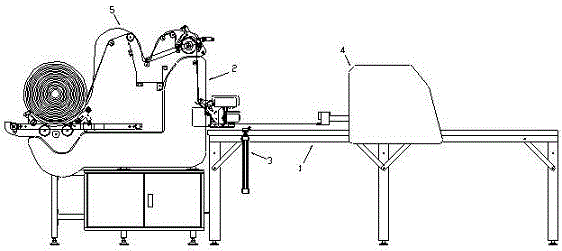

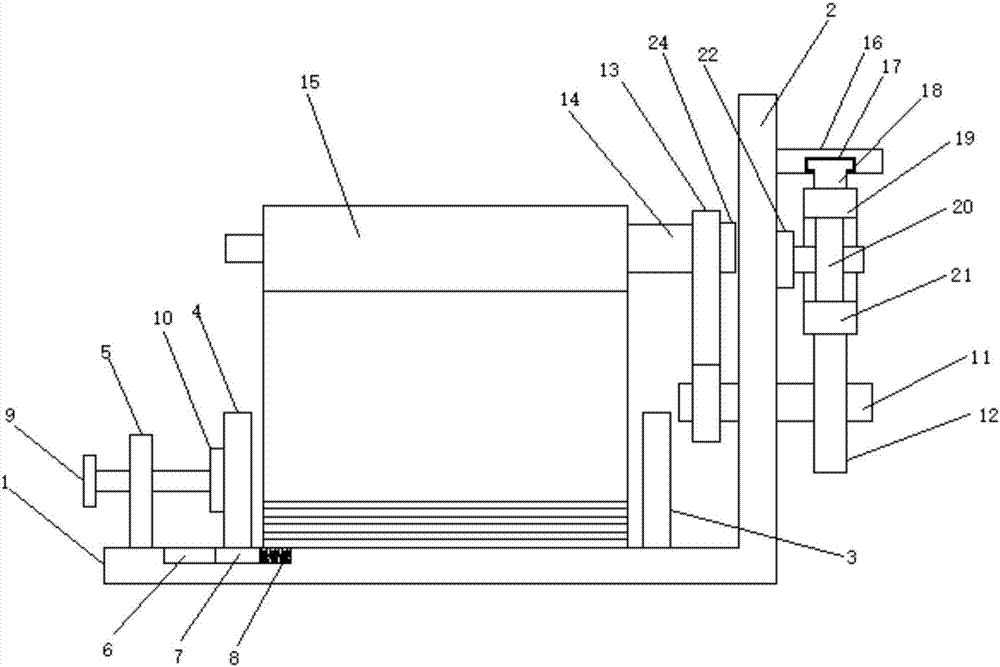

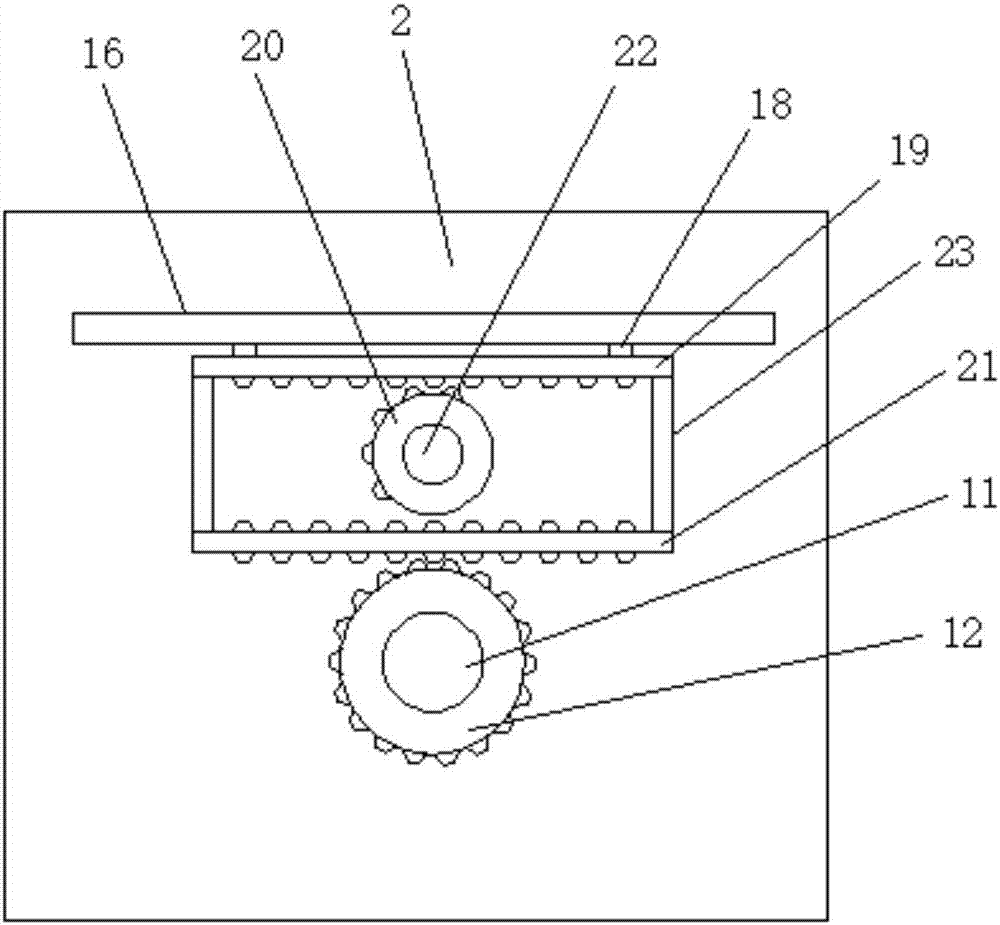

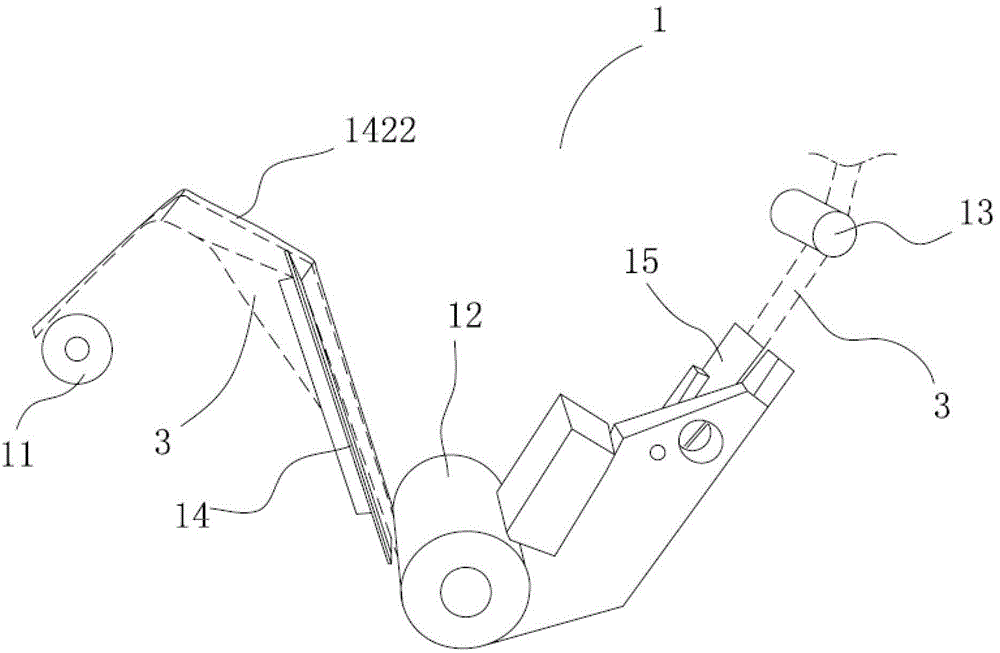

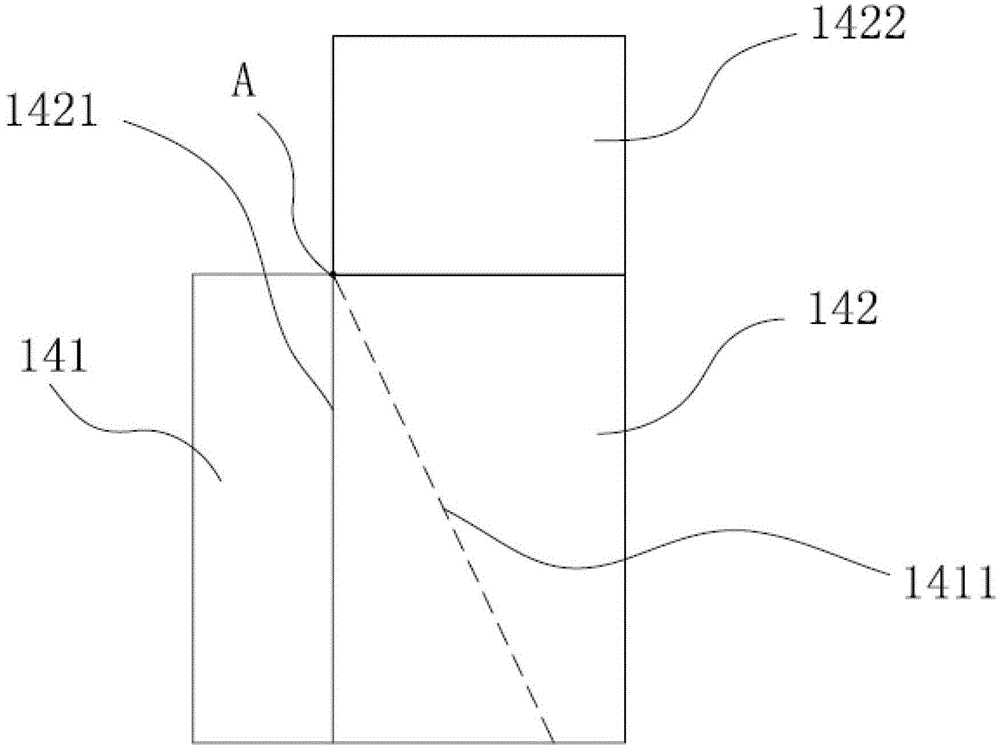

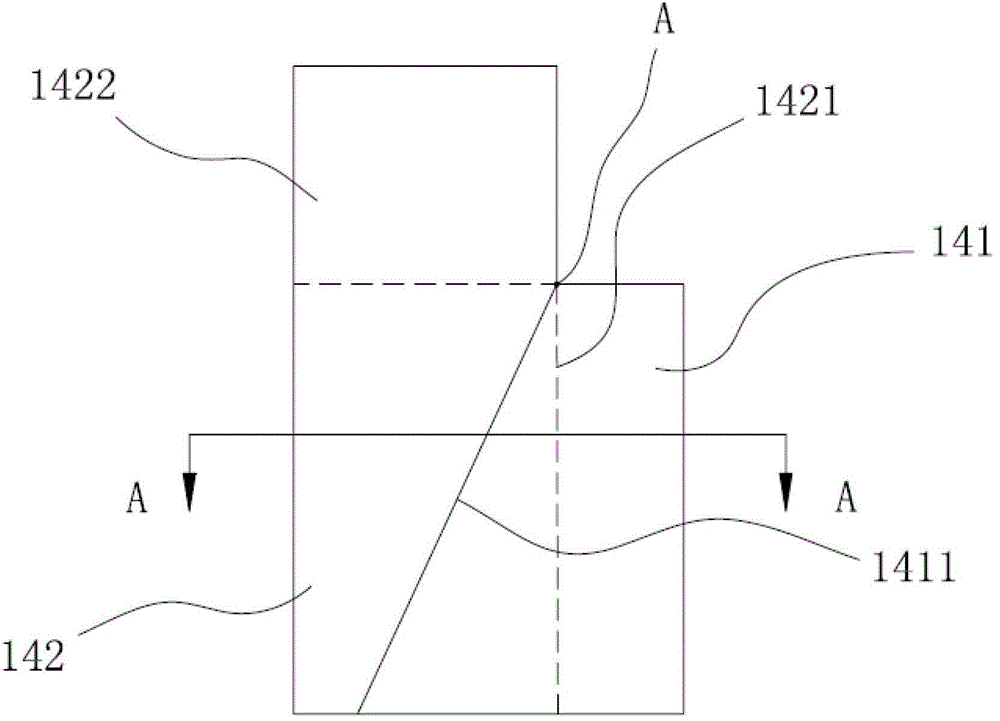

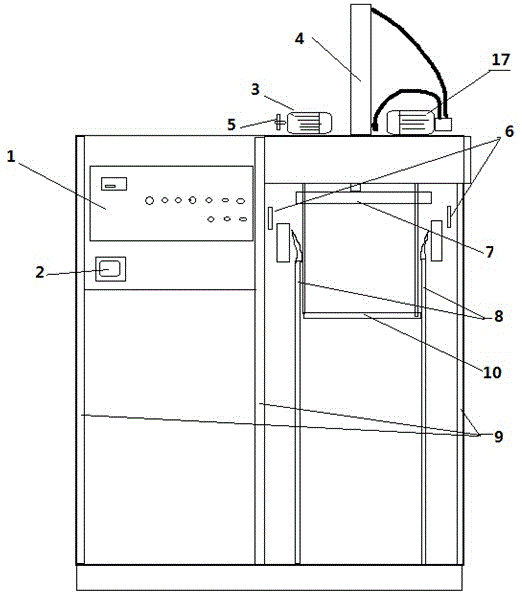

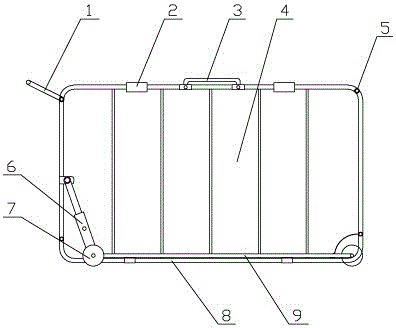

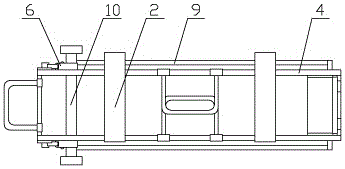

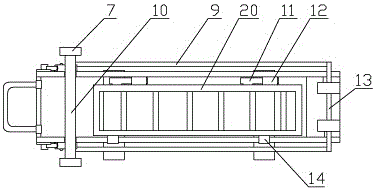

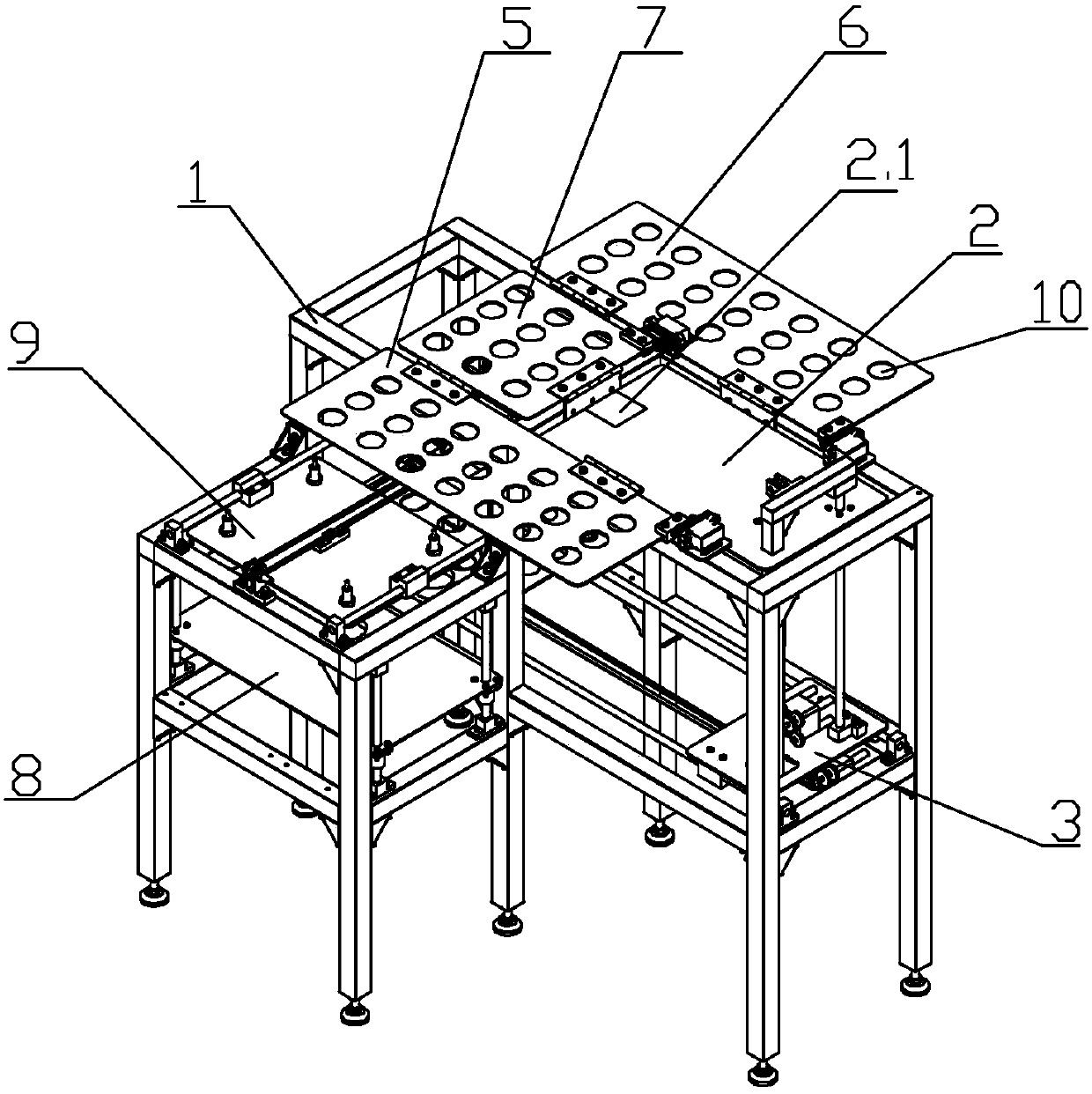

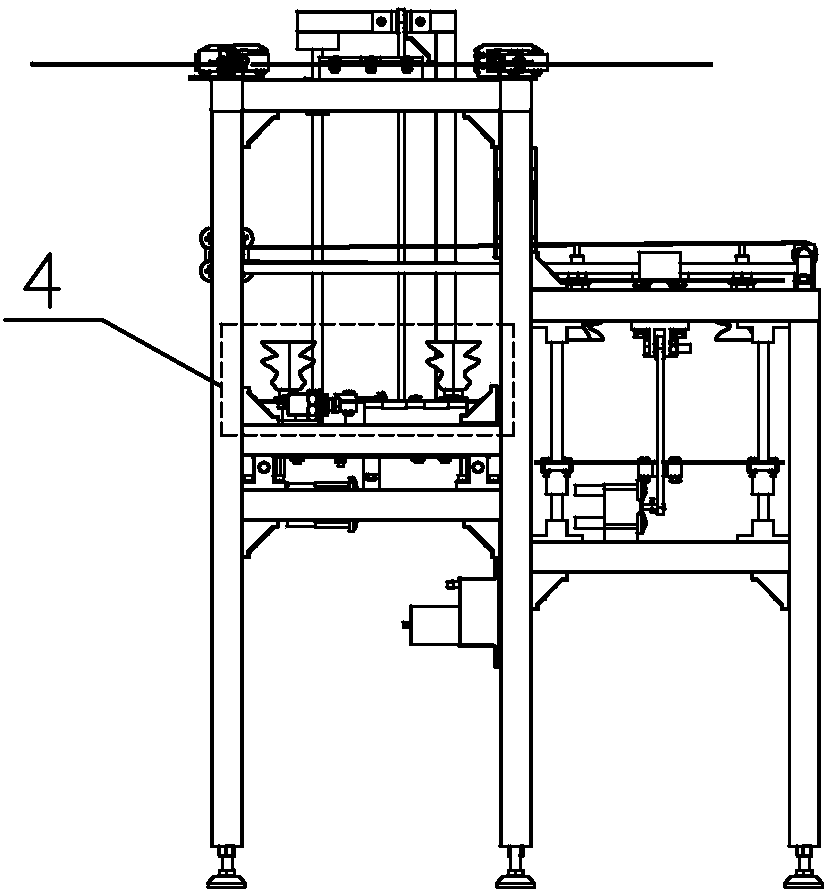

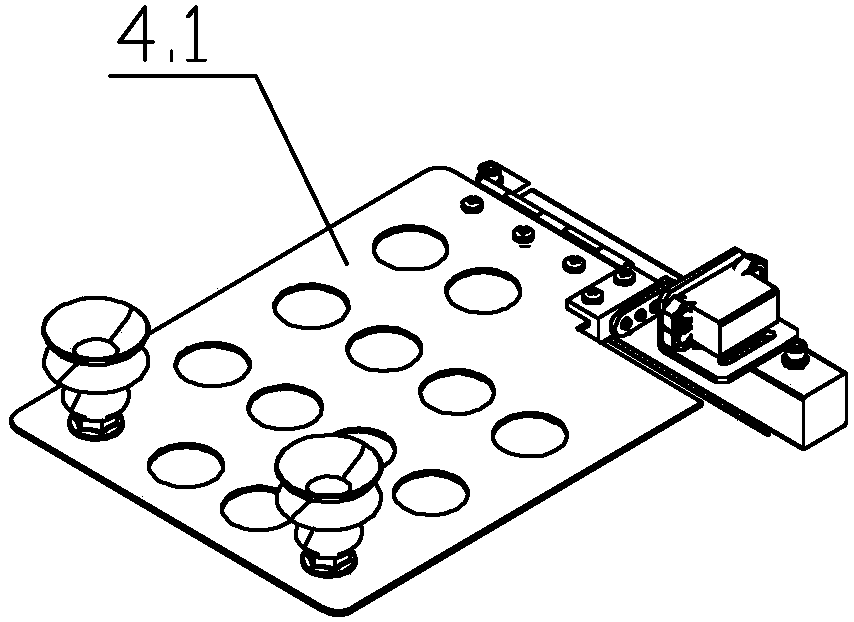

Automatic clothes folding packer and clothes folding and packing method

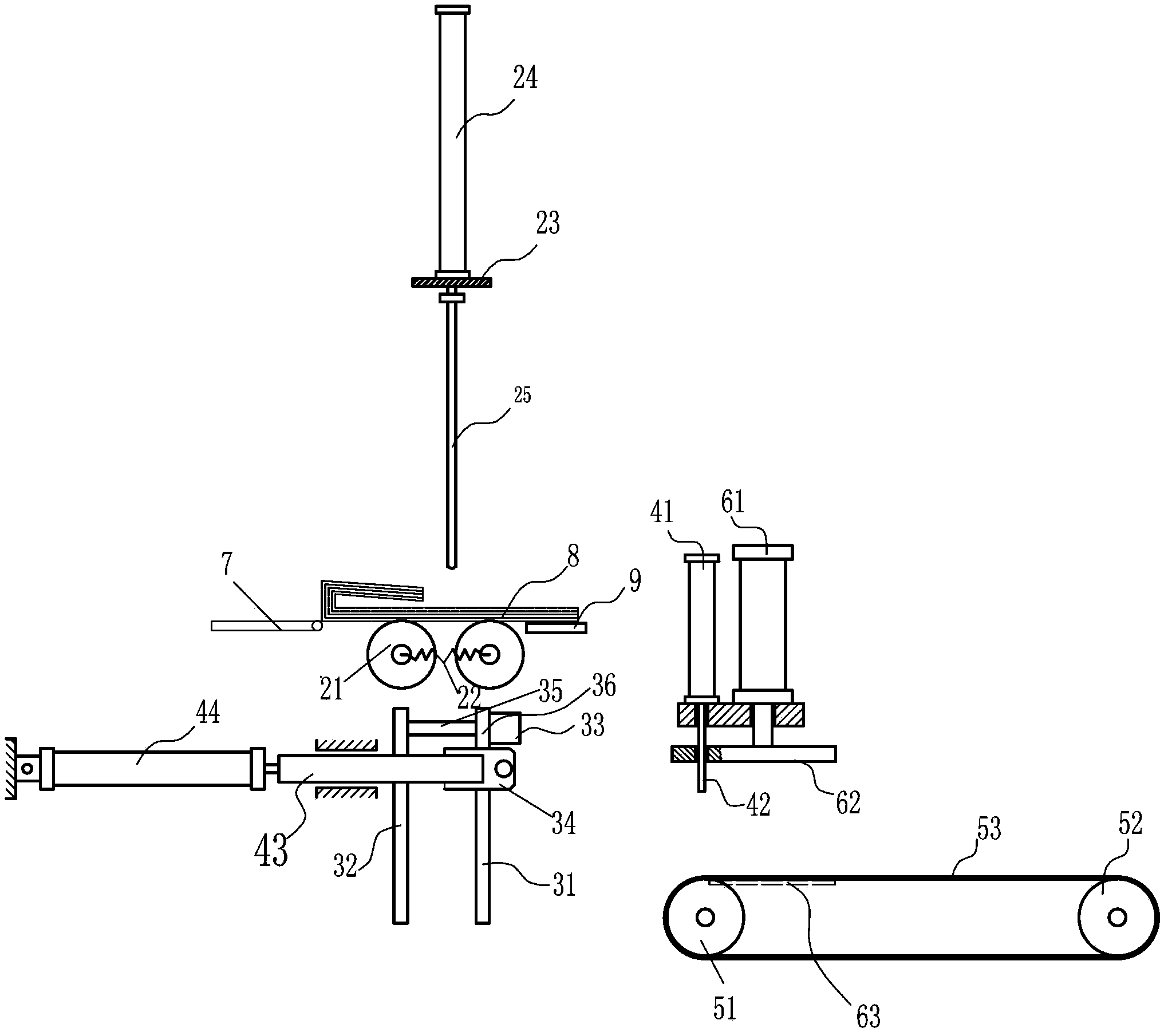

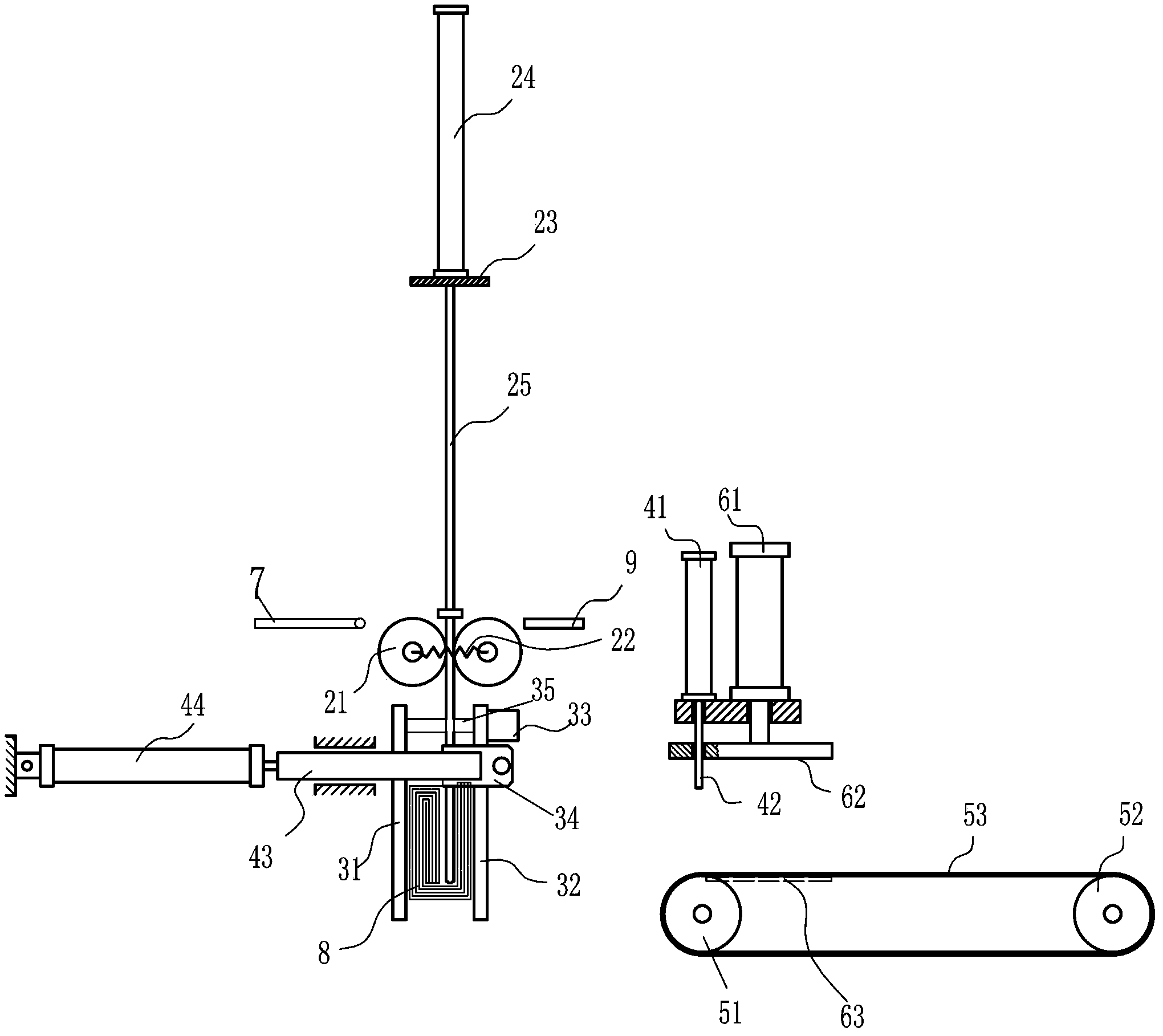

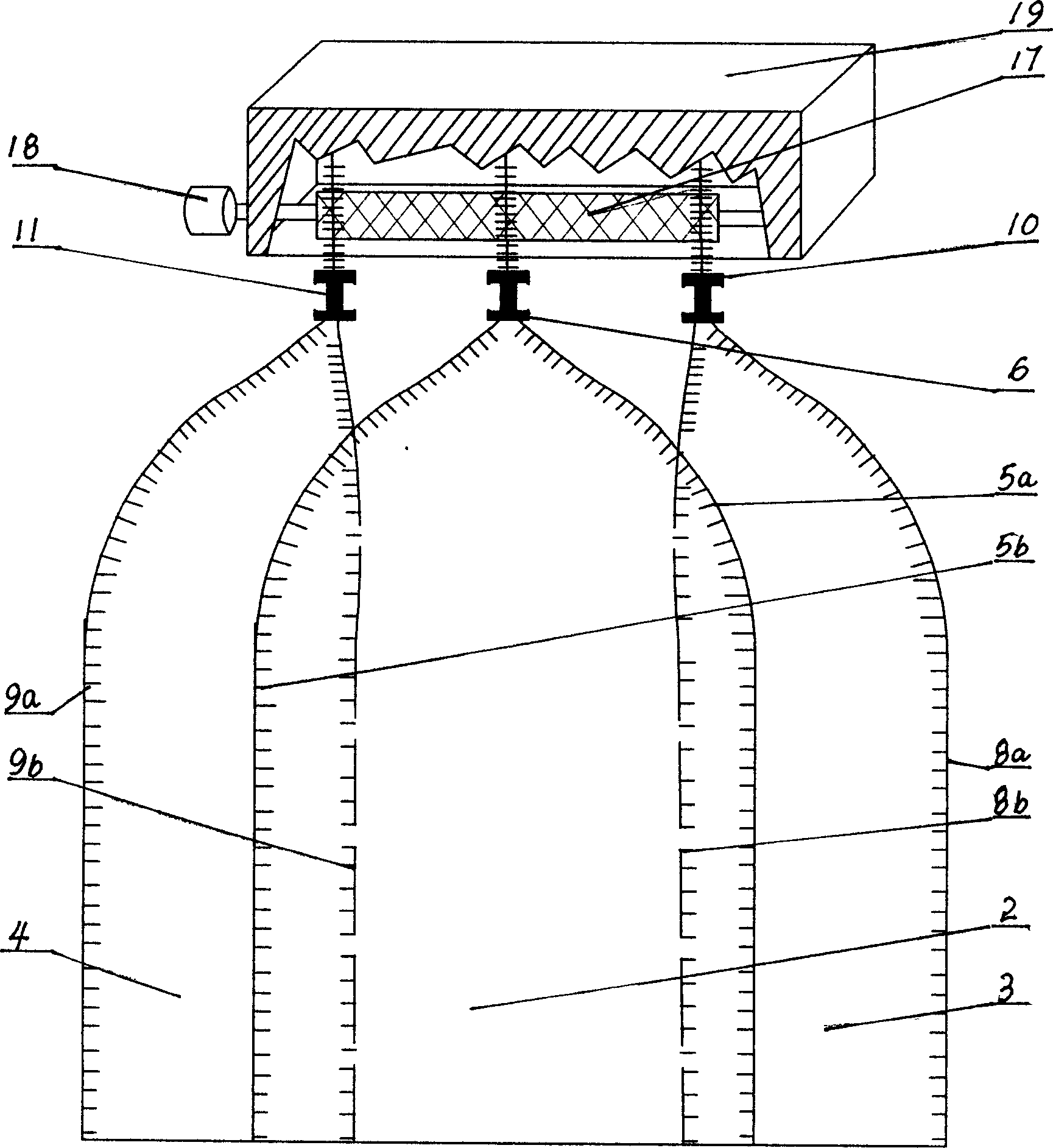

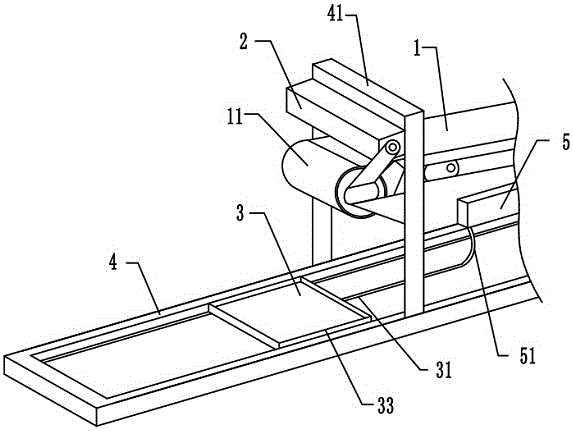

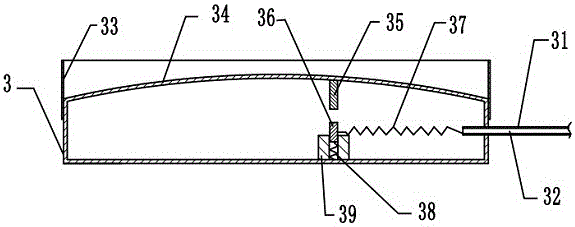

The invention discloses an automatic clothes folding packer. The automatic clothes folding packer comprises a rack and is characterized in that a main board and a folding component are arranged on the rack, the folding component is hinged to the rack (1), a transmission board (3) is arranged under the main board (2), a motor is arranged on the transmission board (3) or the rack (1), a packing station (4) and the motor used for driving the transmission board (3) to drive the main board (2) to reciprocate onto the packing station (4) are arranged on the rack (1), a transmission mechanism is arranged on the rack (1), and a clamping mechanism is arranged on the packing station (4). The invention further discloses a folding and packing method based on the automatic clothes folding packer. The automatic clothes folding packer provided by the invention can automatically finish clothes folding and packing, is high in integration performance, is motor-driven, eliminates noise, adopts a vertical structure and saves the working space.

Owner:NINGBO INST OF TECH ZHEJIANG UNIV ZHEJIANG

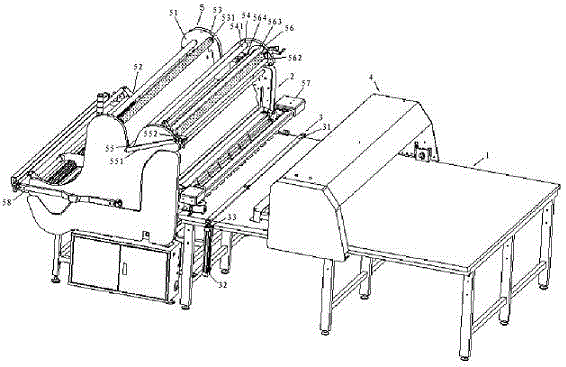

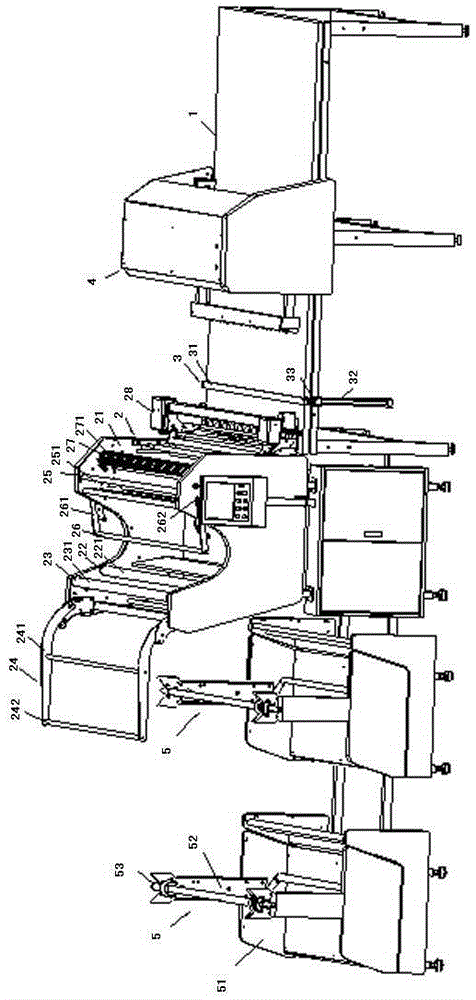

Cloth spreading machine with manipulator gripping mechanism

ActiveCN103342251BGuaranteed uptimeHigh precisionUnfolding thin materialsArticle deliveryManipulatorTextile

The invention provides a cloth spreading machine with a manipulator cloth clamping mechanism. The cloth spreading machine comprises a making bed, a main machine, a cloth pressing mechanism above the making bed, and the manipulator cloth clamping mechanism arranged on the making bed in a sliding mode. The main machine is provided with a cloth making mechanism, a cloth releasing mechanism is arranged on one side of the cloth making mechanism, a cloth spreading mechanism is arranged on the other side of the cloth making mechanism, a front-positioning cloth spreading mechanism is arranged in front of the cloth spreading mechanism, a cloth feeding mechanism is arranged in front of the front-positioning cloth spreading mechanism, and a cloth cutting device is arranged below the cloth feeding mechanism; cloth materials enter from the cloth releasing mechanism to the cloth cutting device through the cloth spreading mechanism, the front-positioning cloth spreading mechanism and the cloth feeding mechanism, and the manipulator cloth clamping mechanism arranged on the making bed in the sliding mode is matched with the cloth cutting device to cut off cloth materials with setting lengths. The cloth spreading machine has the advantages that the manipulator cloth clamping mechanism is adopted to carry out single-pulling cloth folding, positioning is accurate, precision is high, the cloth is tidily folded, neatness of the two ends of the cloth can be effectively controlled, accuracy of cloth cutting is improved, and working efficiency is high.

Owner:YYC IND CO LTD CHINA

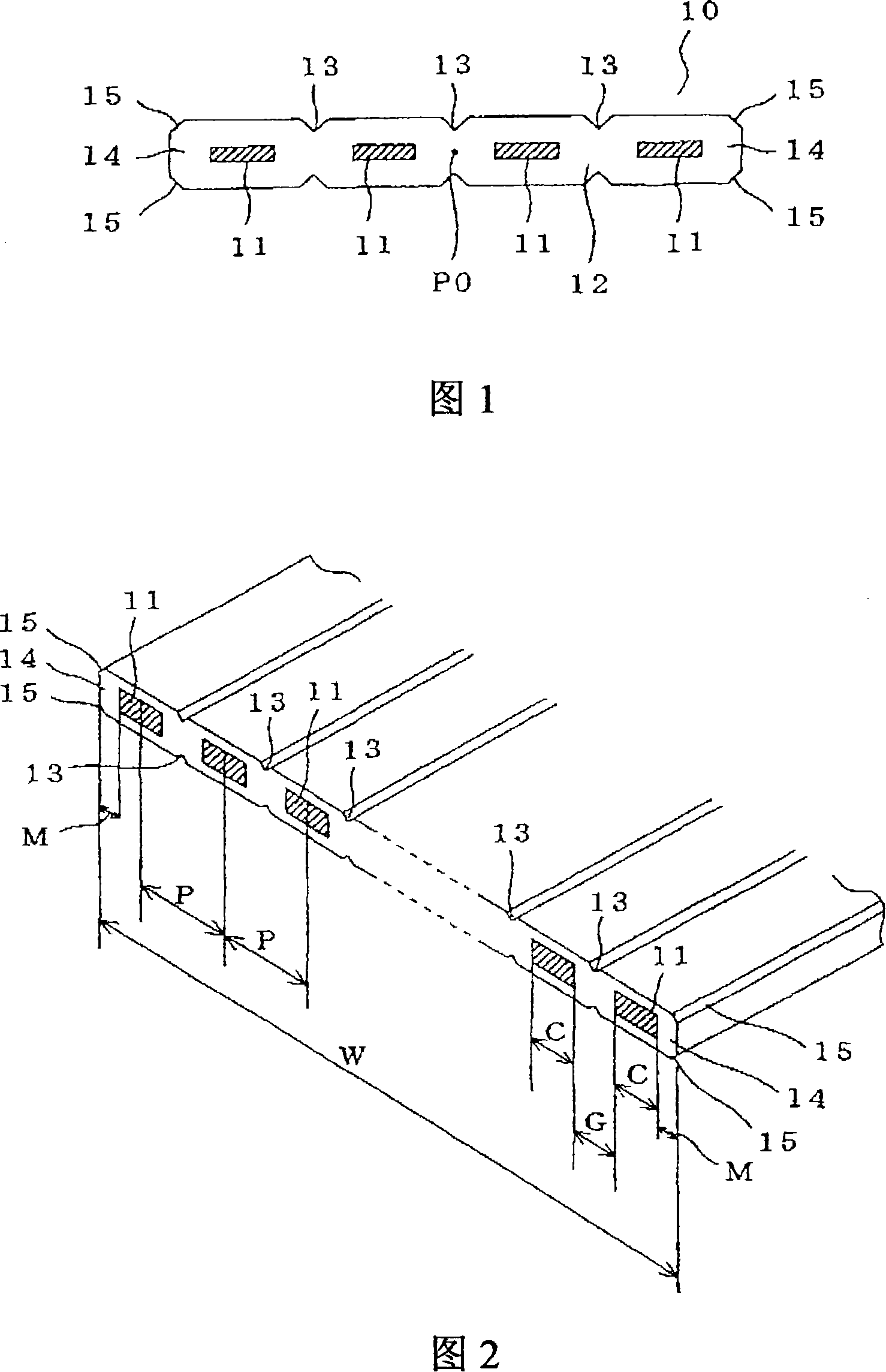

Flexible flat cable

InactiveCN101174491AImprove flame retardant performanceImprove flexibilityPlastic/resin/waxes insulatorsFlat/ribbon cablesElectrical conductorHeat resistance

A flexible flat cable is provided to facilitate division or branching into a plurality flexible flat cables with a predetermined number of straight angle conductors by including cutting grooves on both surfaces of an insulating coating along a longitudinal direction. A flexible flat cable(10) is formed by insulating coating of a plurality of straight angle conductors(11) arranged in parallel with an insulating coating material(12) at once. The insulating coating material is composed of a flame-retardance resin composition including a resin component 100 parts by weight and a metal hydroxide 40~250 parts by weight. The resin component includes a thermoplastic polyurethane elastomer with a JIS hardness of below A97 measured according to JIS K 7311 and an ethylene acetic vinyl copolymer with an acetic vinyl unit 50~90 wt% at a ratio of 40:60 to 90:10.

Owner:SUMITOMO ELECTRIC IND LTD

Swing-type protecting film folding device

ActiveCN107381201ANeatly foldedImprove folding efficiencyFolding thin materialsTectorial membraneTransverse axis

Owner:山东菏益科技有限公司

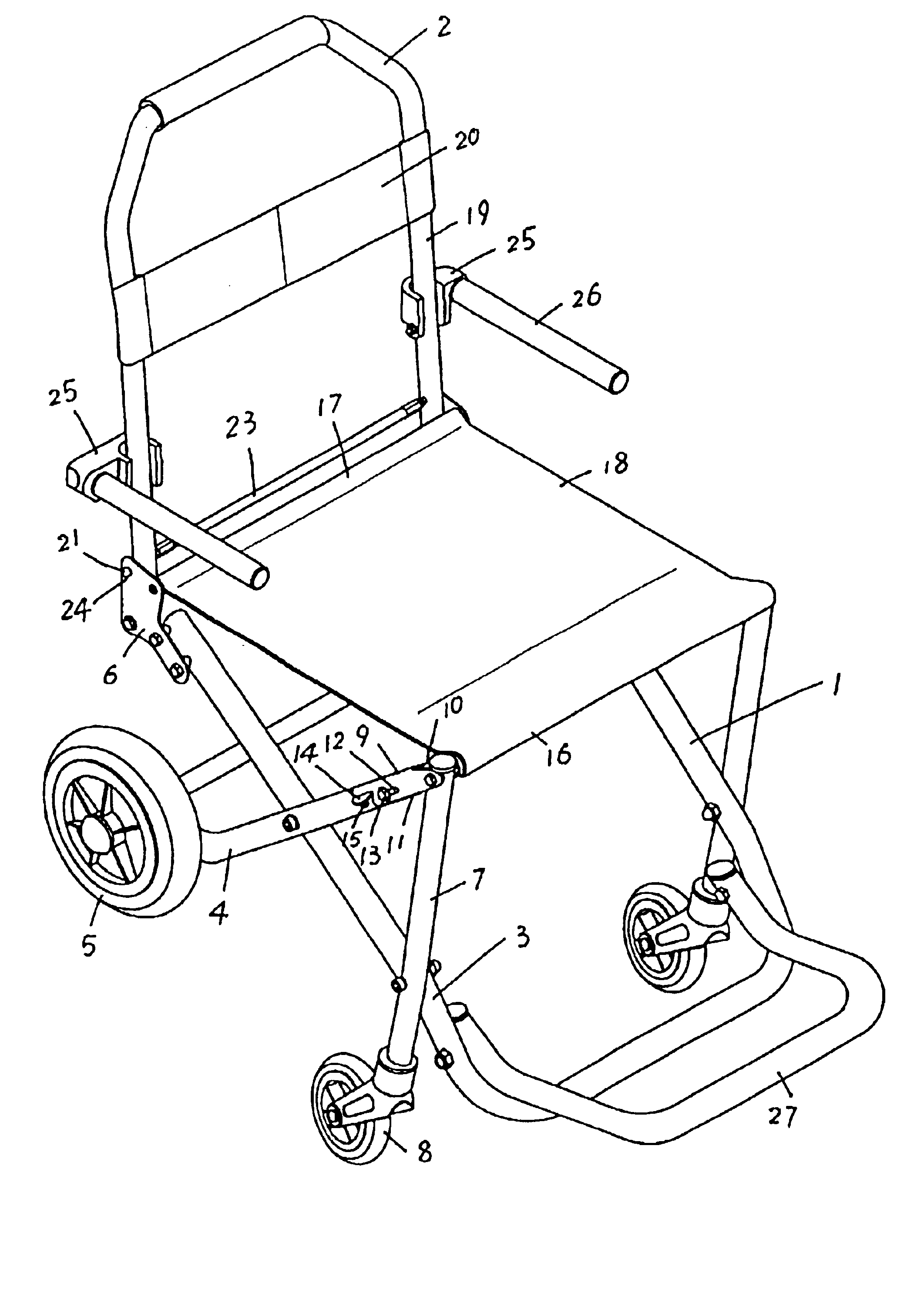

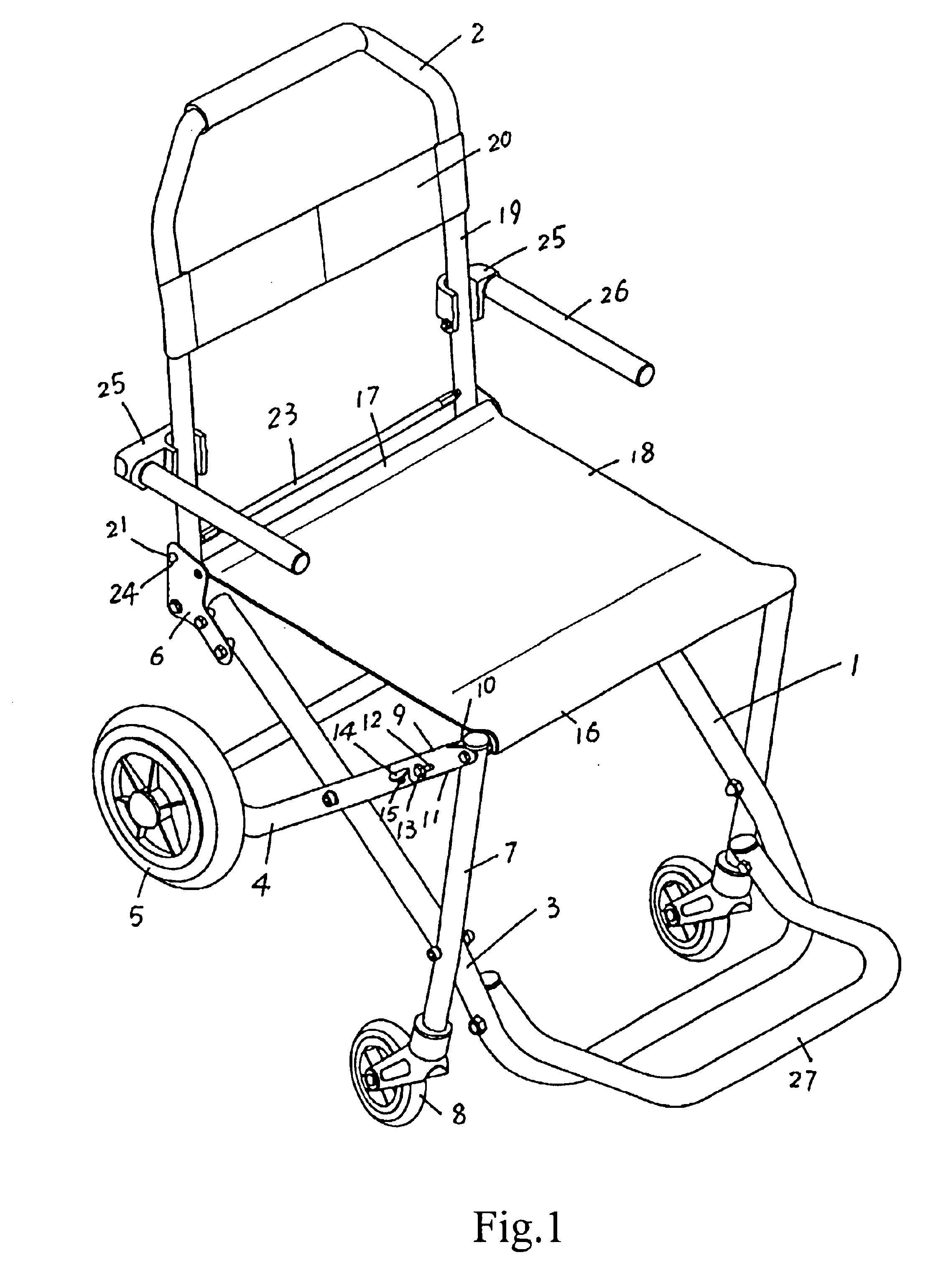

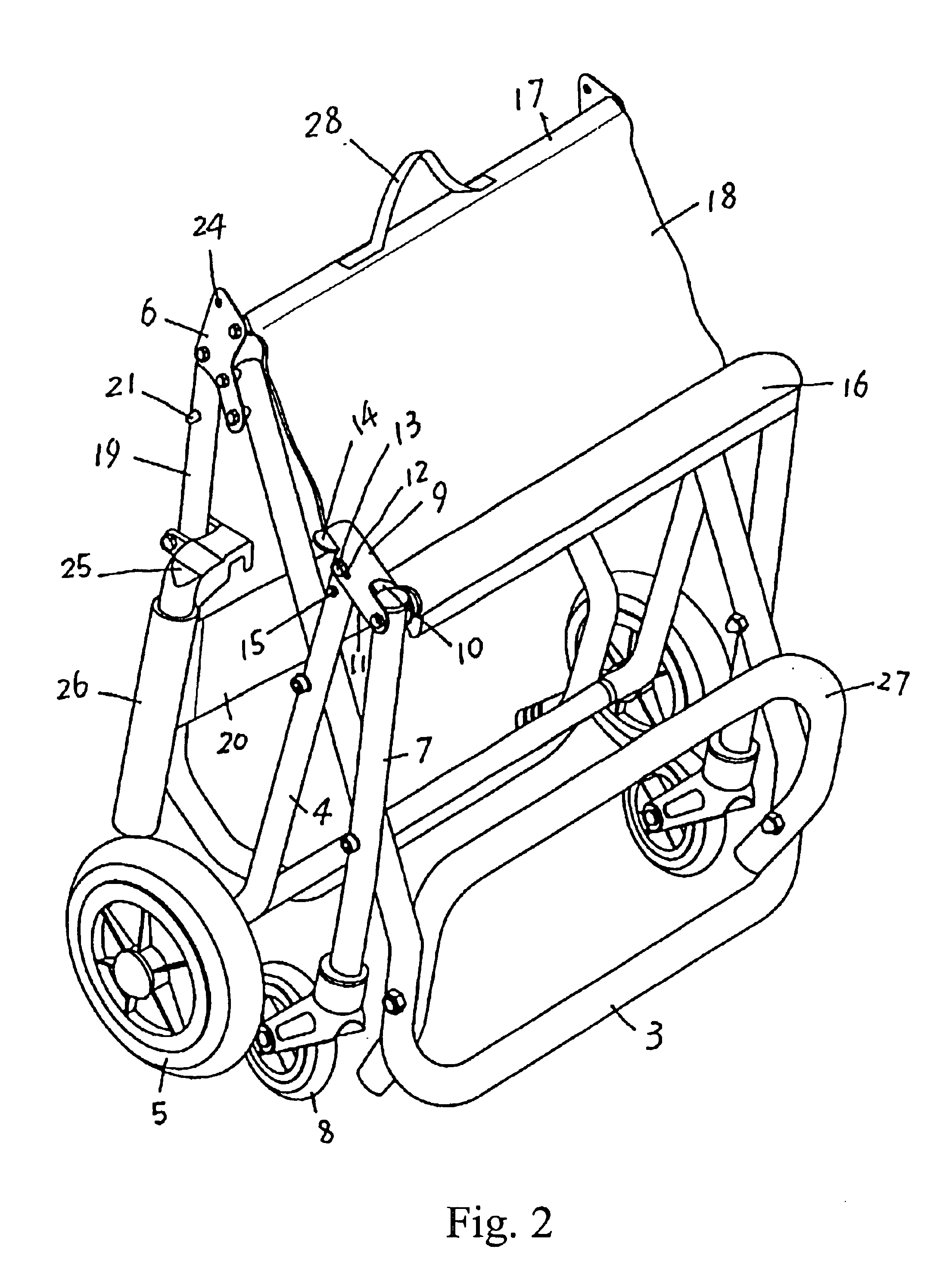

Portable folding wheelchair

A portable folding wheelchair includes a front U-shaped tube and a rear U-shaped tube pivotally coupling with each other through a pin to form a X-shape. The front U-shaped tube has an upper end on two sides to fasten to a connection plate. The connection plate connects to a backrest. The front U-shaped tube has a lower section on two sides to pivotally engage with an upright tube. The upright tube and the rear U-shaped tube have an upper end bridging a sleeve. The wheelchair has a simple structure and may be folded in forward, rearward, upward and downward directions to become a smaller size to facilitate carrying or storing in a car to enable disabled people to use in travels and trips.

Owner:LI MAO SHUN

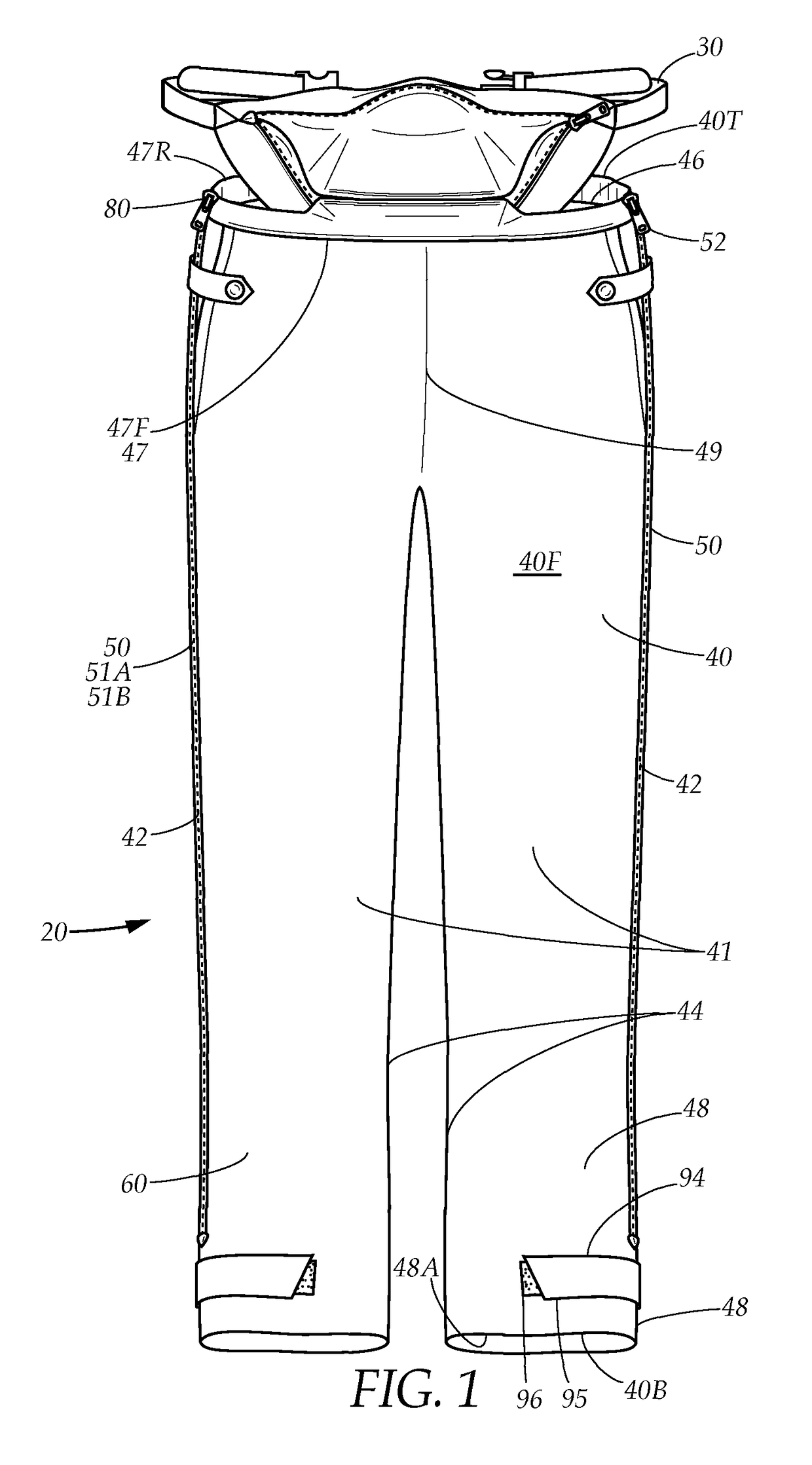

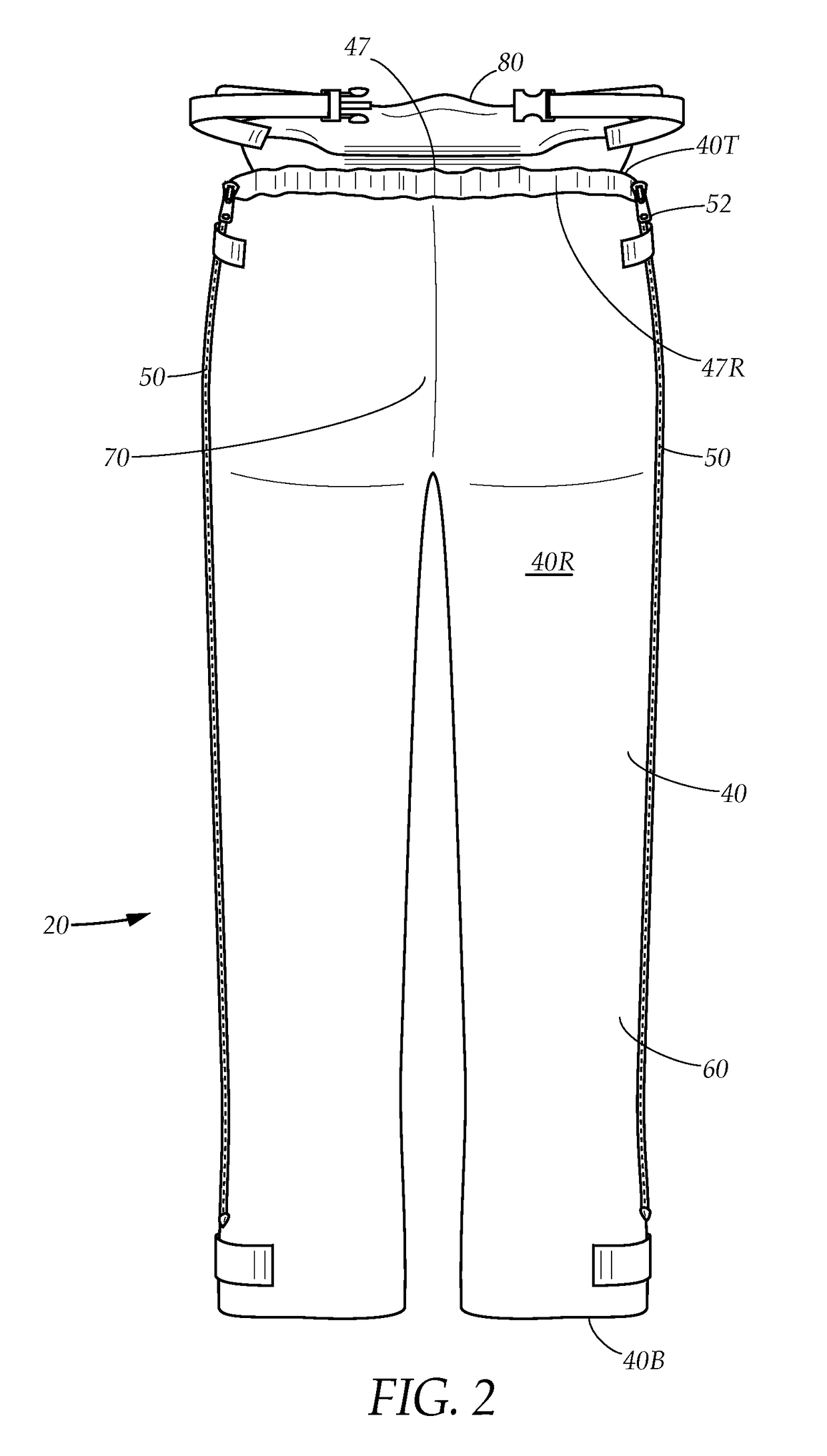

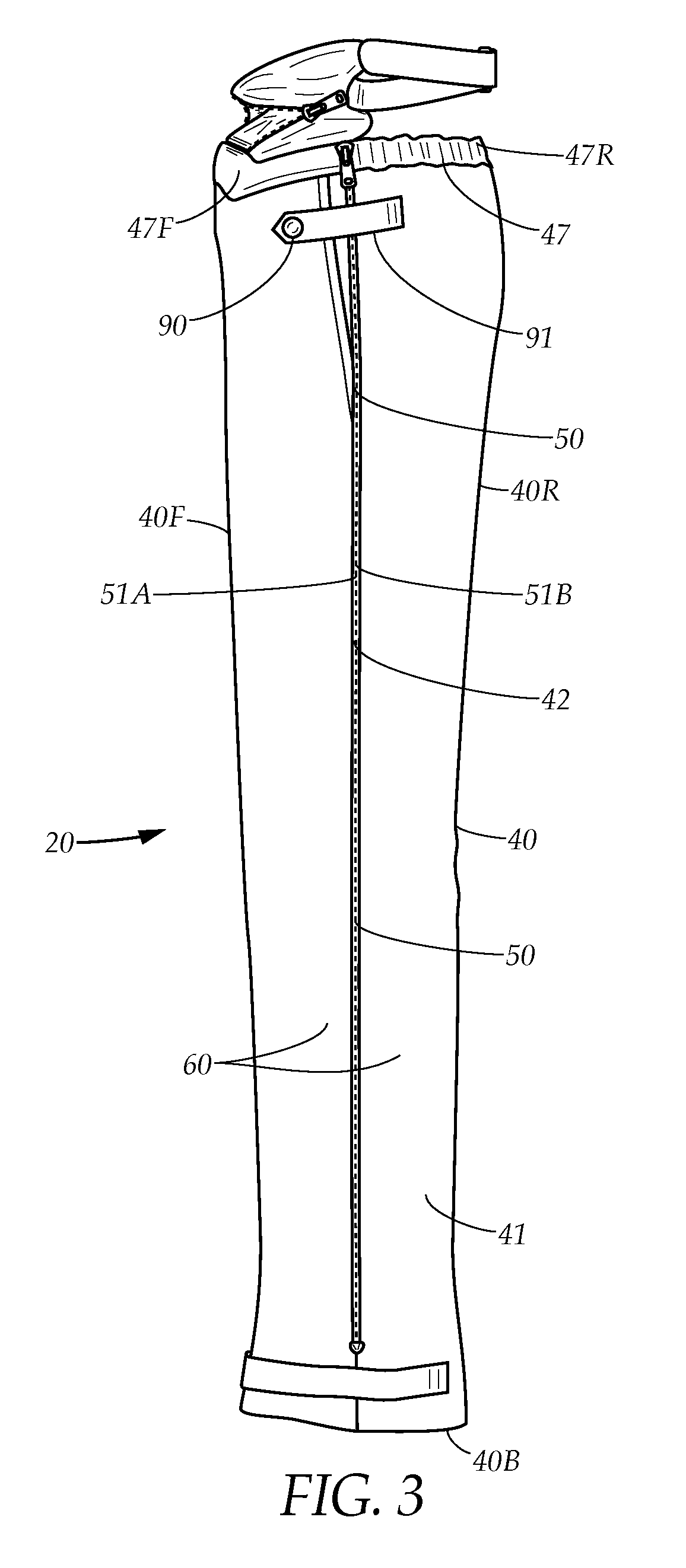

Deployable rain pants

ActiveUS10231496B1Easy to deployEasy to useGarment special featuresConvertible garmentEngineeringAnkle

A deployable rain pants assembly, for use by a user having a waist and legs in protecting everyday pants from the rain, including a belt and a pants portion. The pants portion is initially stored near the belt, which is worn around the waist until needed. The pants portion has a top edge, a bottom edge having ankle openings, a pair of pant leg portions, and a waist band having a waist band front and a waist band rear. A pair of main seams extend from near the bottom edge to the waistband and selectively join the pant leg parts, and join the waist band front and waist band rear. Once the pants portion is deployed downwardly from the belt, the waist band rear is tucked between the legs, the user steps through the ankle openings, and main seams are joined to encase and cover the everyday pants.

Owner:GLASSNER DOVID LEIB

Multi-functional charger

ActiveUS20170229890A1Easy to useEasy to carryElectric powerArrangements for several simultaneous batteriesElectricityUSB

The multi-functional charger includes a charger body, a circuit board and an external charging plug, wherein the circuit board is arranged in the charger body and electrically connected with the external charging plug; the external charging plug is detachably connected with one end of the charger body and electrically connected with the circuit board through a connecting cable; a containing cavity is formed in the charger body and used for containing the connecting cable; the charger body is further provided with at least one mounting groove, the interiors of all the mounting grooves are respectively and detachably connected with a functional assembly and each functional assembly are in electric connection with the circuit board; the functional assembly includes a retractable USB assembly for the cable connection and a charging power assembly for electric energy storage.

Owner:LU NINGYUAN

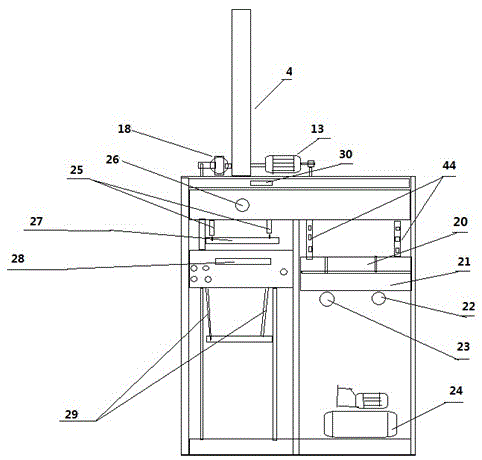

Paper handkerchief folding machining device

ActiveCN103332525AQuality improvementEasy to operateFolding thin materialsArticle deliveryPulp and paper industry

The invention discloses a paper handkerchief folding machining device. The paper handkerchief folding machining device comprises a longitudinal folding machine set, a transverse folding machine set and a flower plate machine set, wherein the longitudinal folding machine set, the transverse folding machine set and the flower plate machine set are sequentially jointed on a machine platform. Paper webs are sequentially arranged on the longitudinal folding machine set and the transverse folding machine set in a tensioning and penetrating mode. A paper handkerchief is folded into three folding surfaces in a Z-shaped mode in the width direction through a longitudinal folding machine, and refolded twice in the length direction to form four folding surfaces through a transverse folding machine. The paper handkerchief folding machining device is high in production efficiency and in speed and capable of reducing production cost. The size of produced paper can be adjusted, and products are convenient to carry and exquisite.

Owner:中顺洁柔(云浮)纸业有限公司

Plastic body folding machine

InactiveCN103359339BNot easy to deform and disperseNeatly foldedPaper article packagingRelative motionEngineering

Owner:王秀来

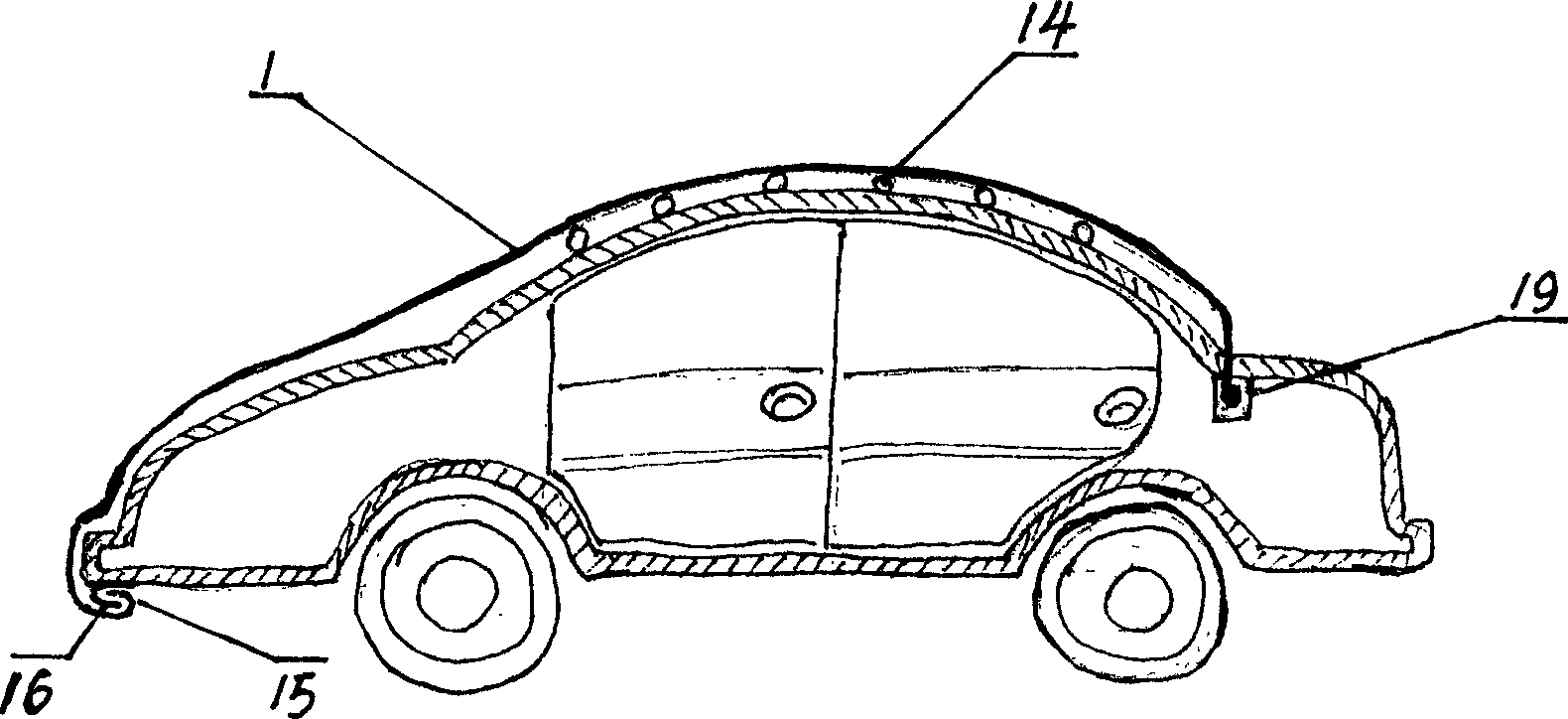

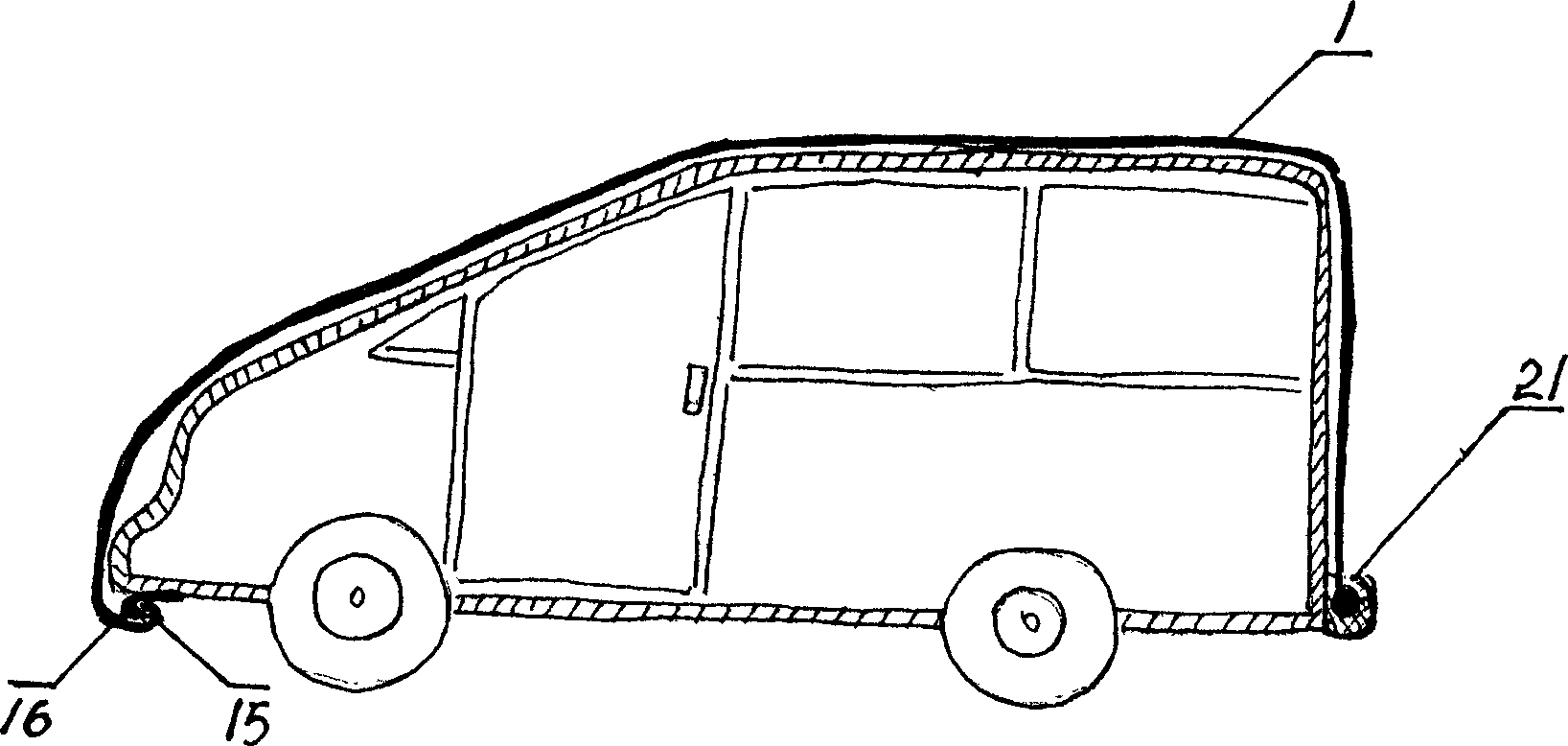

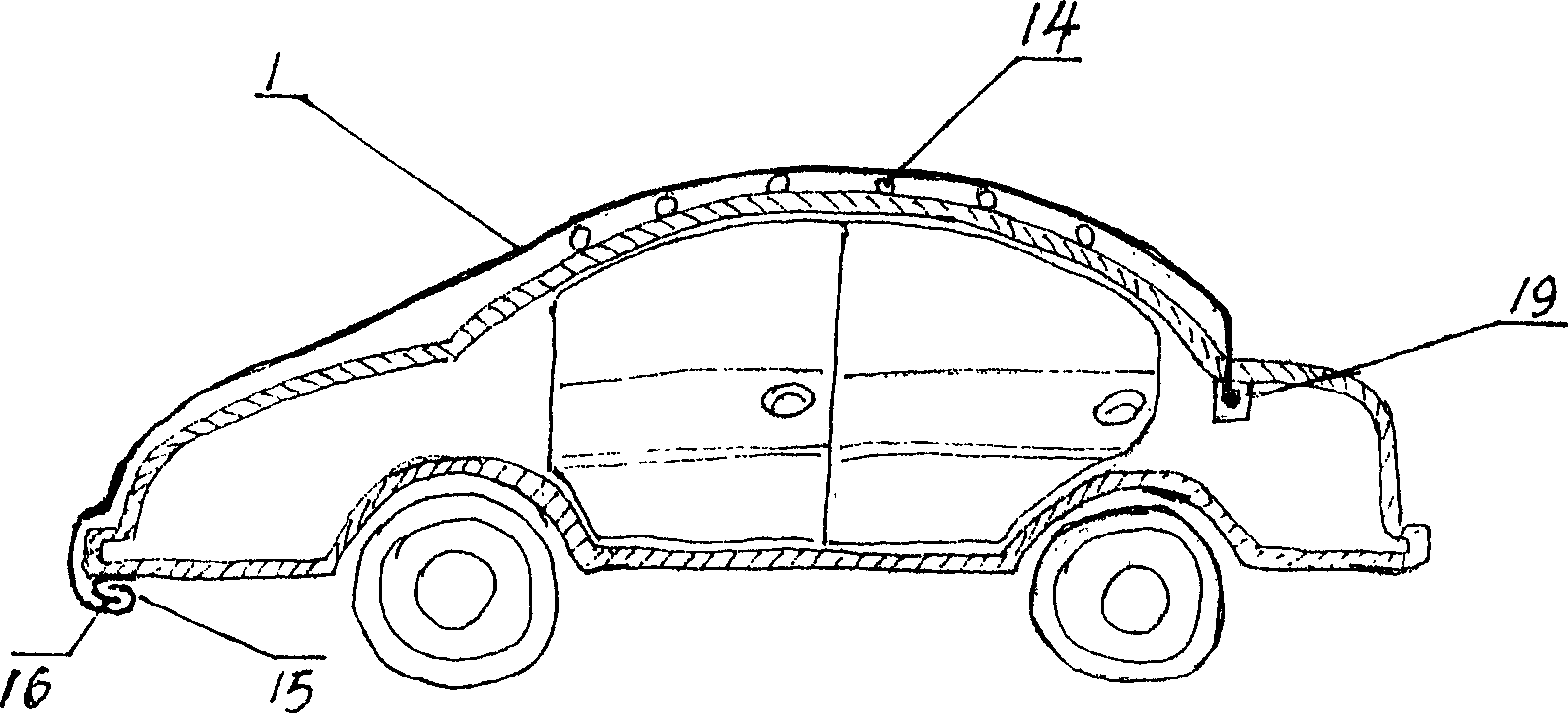

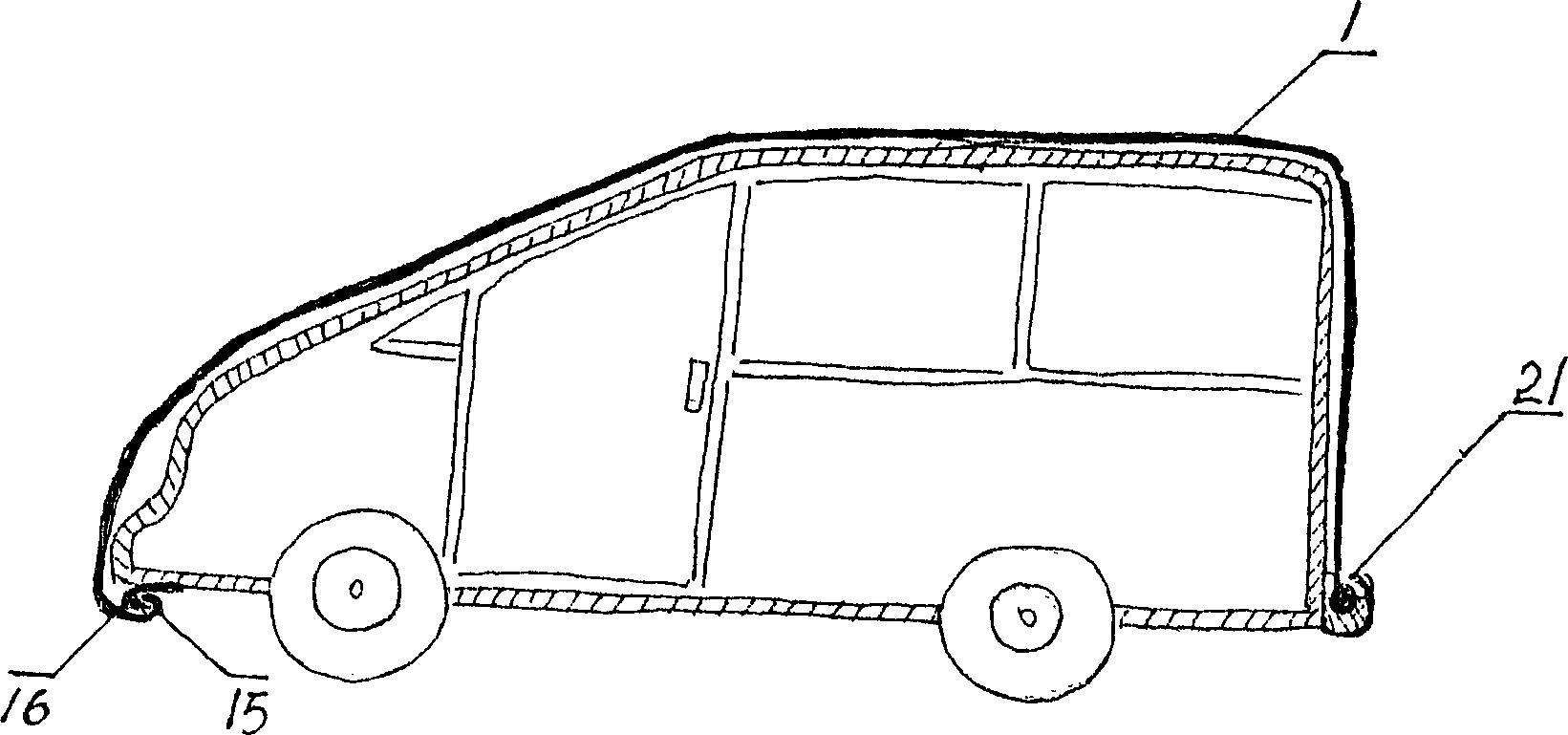

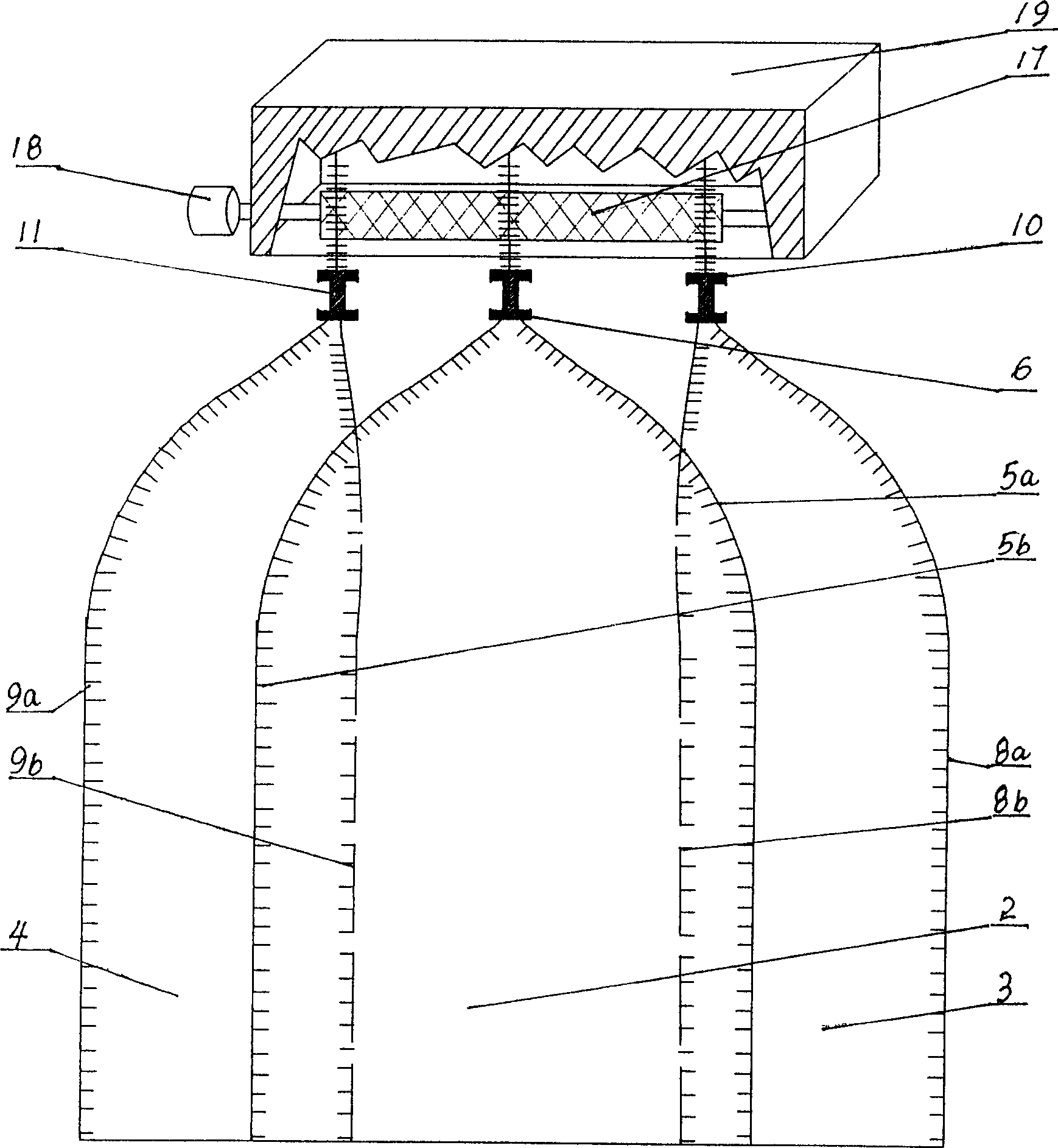

Reeling type automobile sunshade inclosure

InactiveCN1590148ANeatly foldedEasy to useRemovable external protective coveringsAutomotive engineering

Owner:王峻

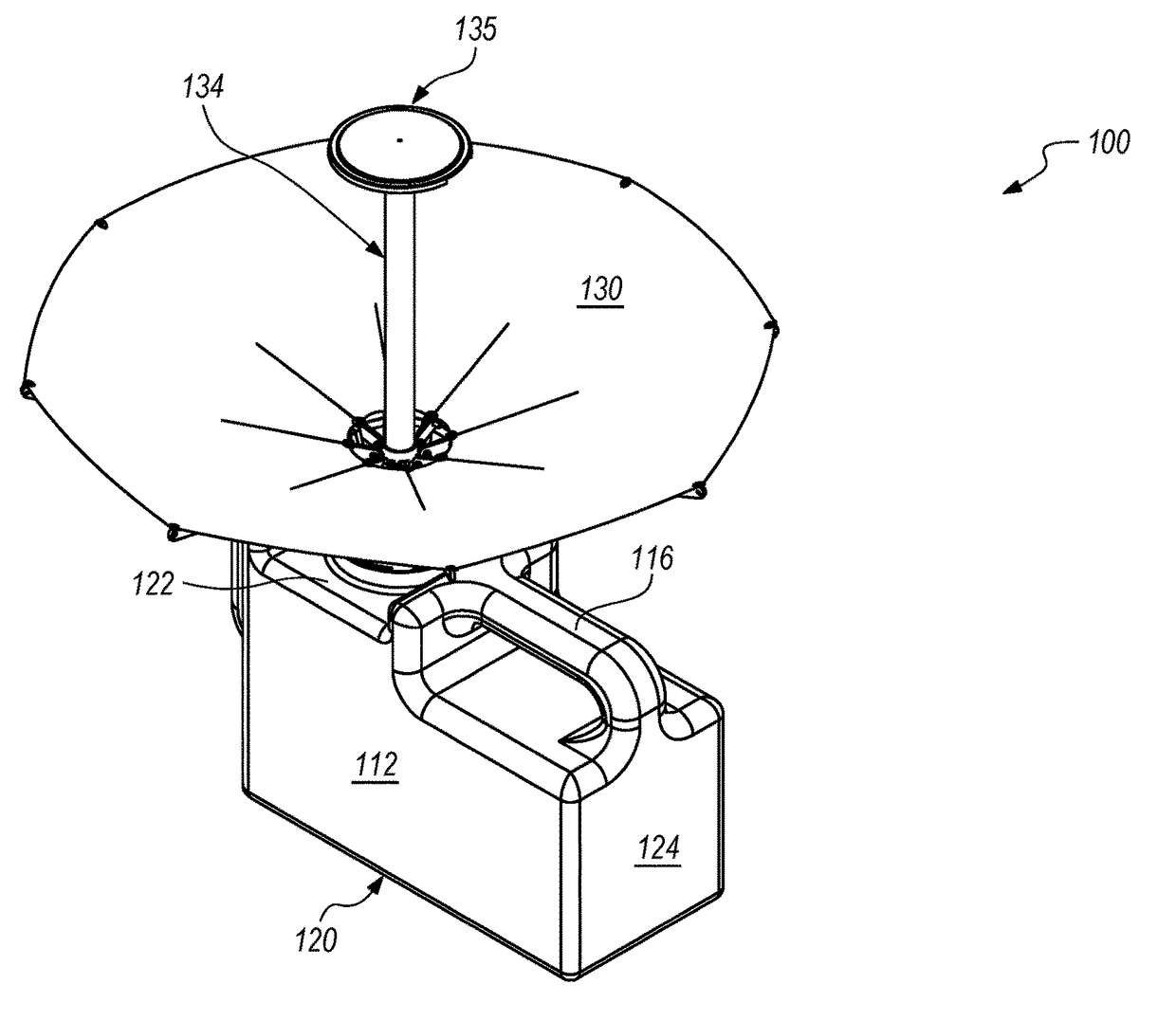

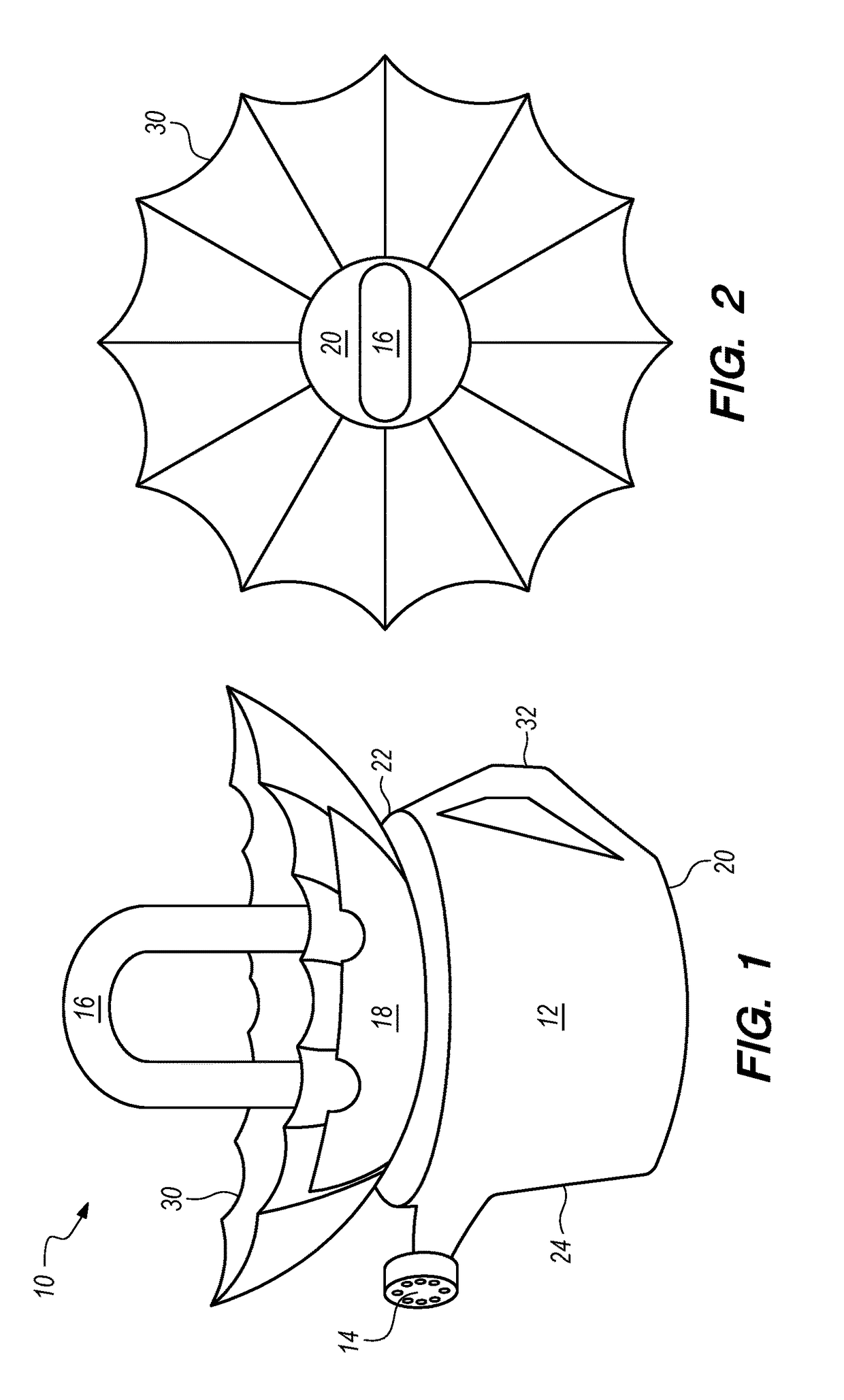

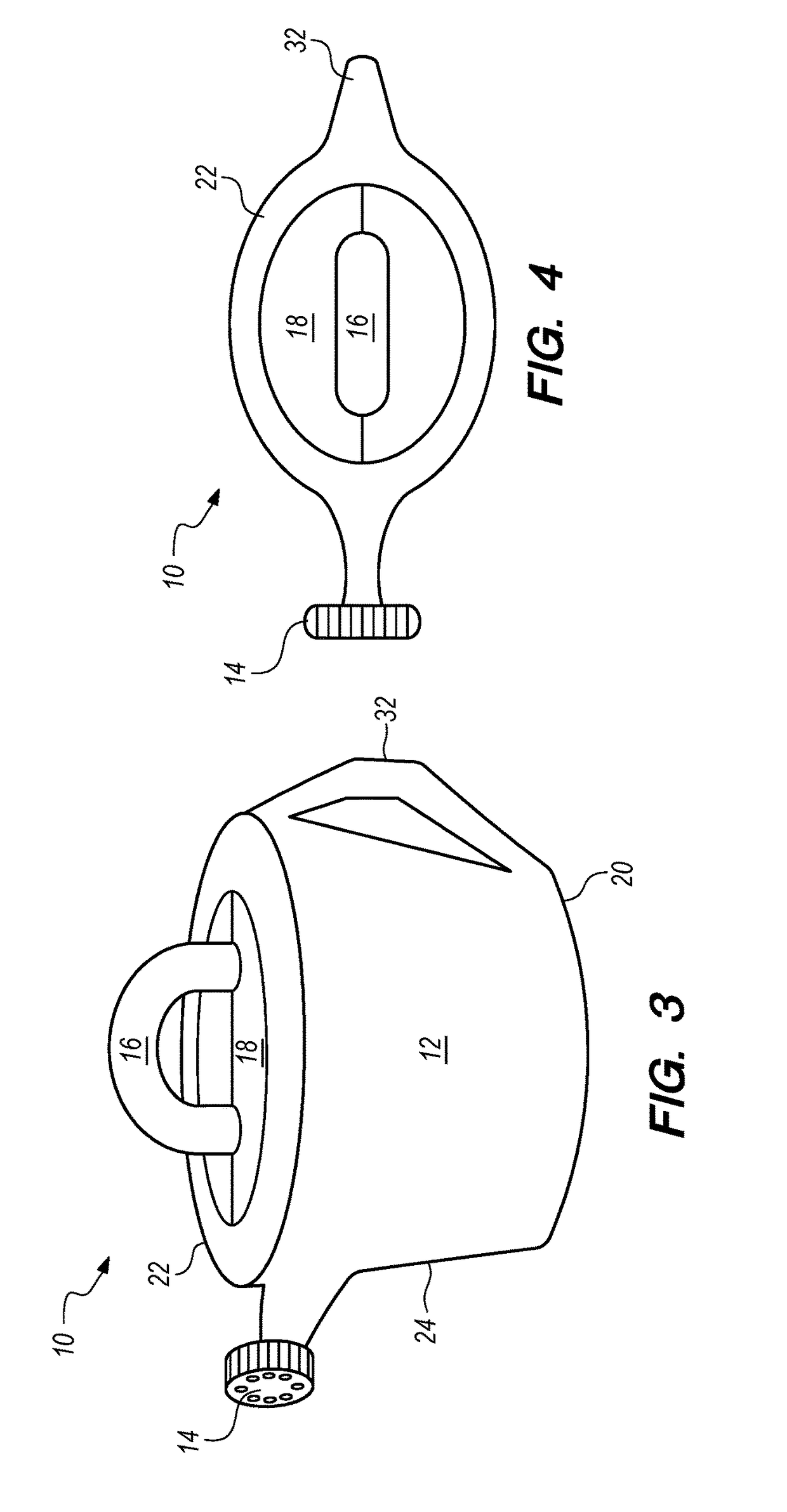

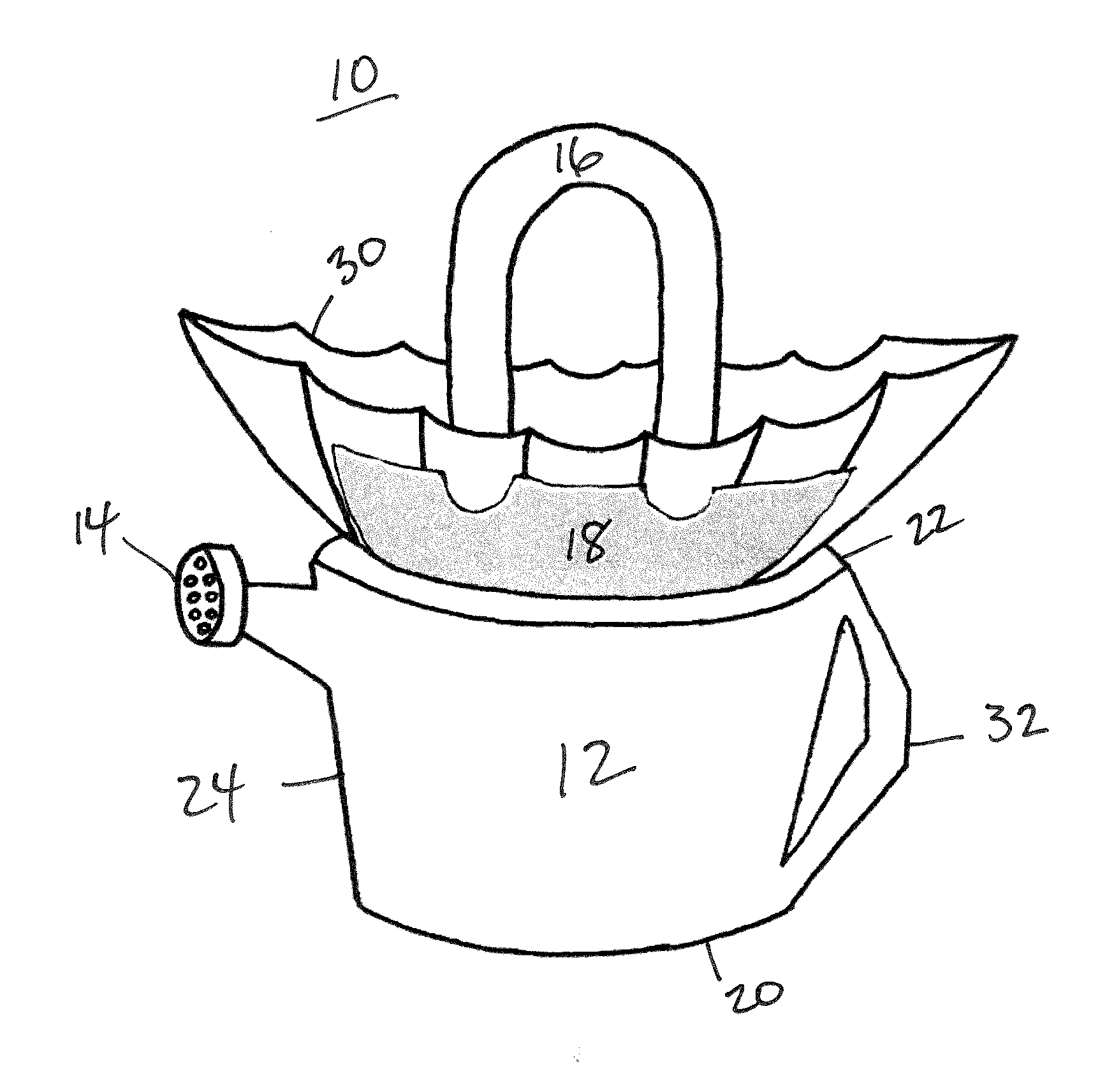

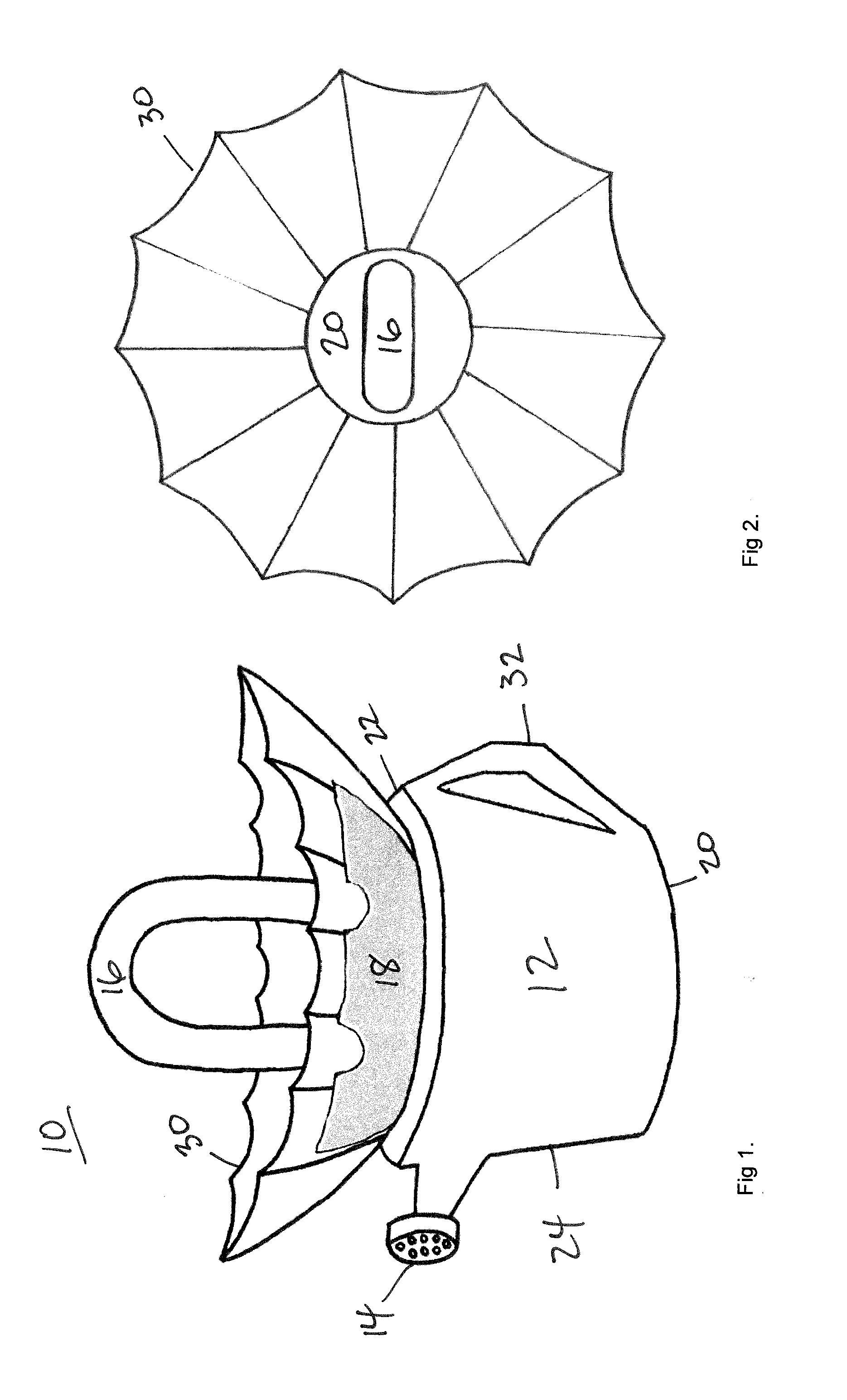

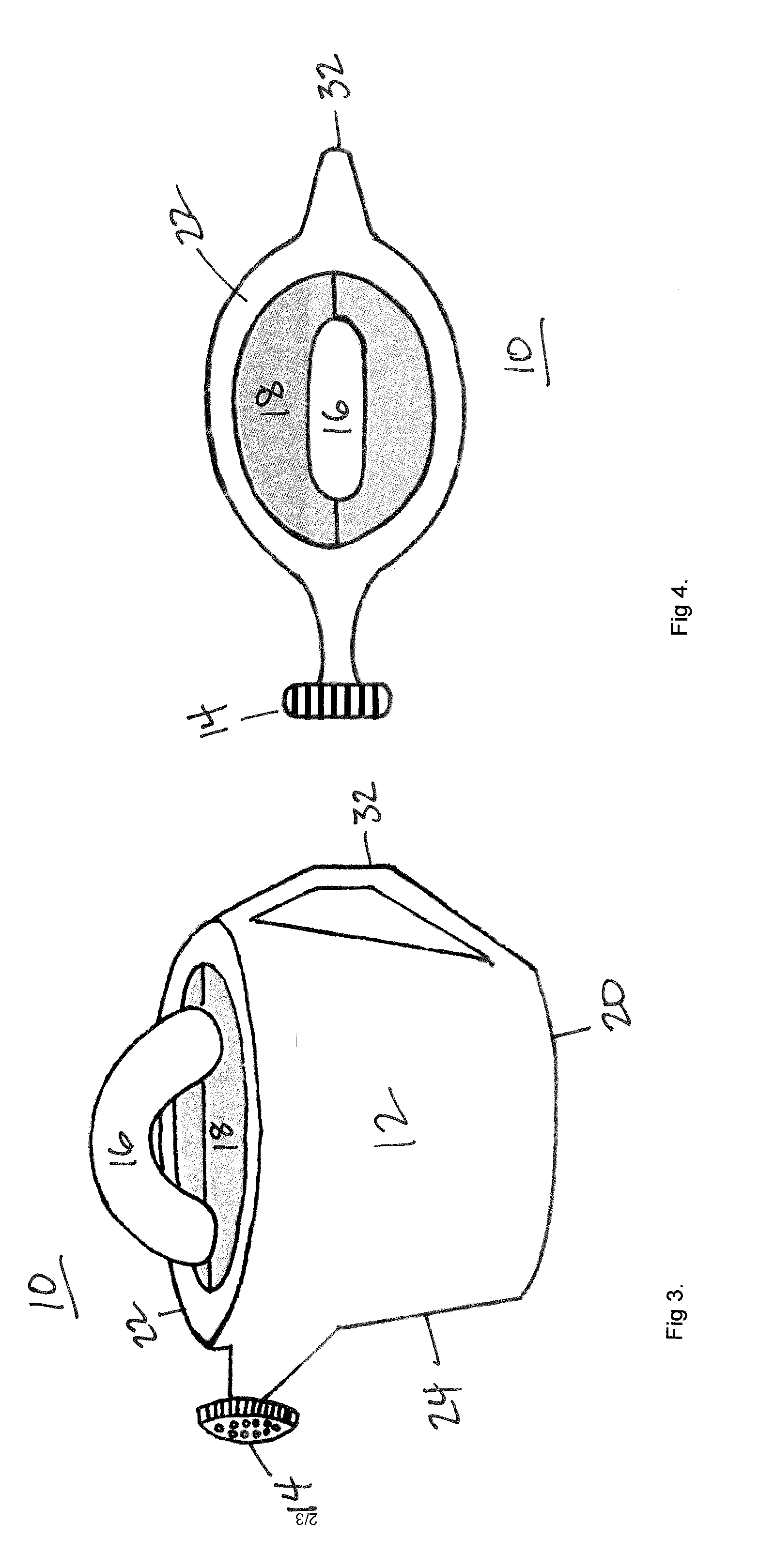

Shower Flower Water Collection Device

A shower water collection device configured to capture pre-shower water which once full may easily be sealed to prevent contamination of the collected water until the water can be used for another purpose. A shower water collection device further including an inverted umbrella type funnel for increased surface area and enhanced water collection.

Owner:WALES WILLIAM FIELD

Reeling type automobile sunshade inclosure

InactiveCN1295092CNeatly foldedEasy to useRemovable external protective coveringsAutomotive engineering

Owner:王峻

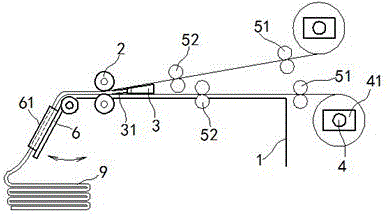

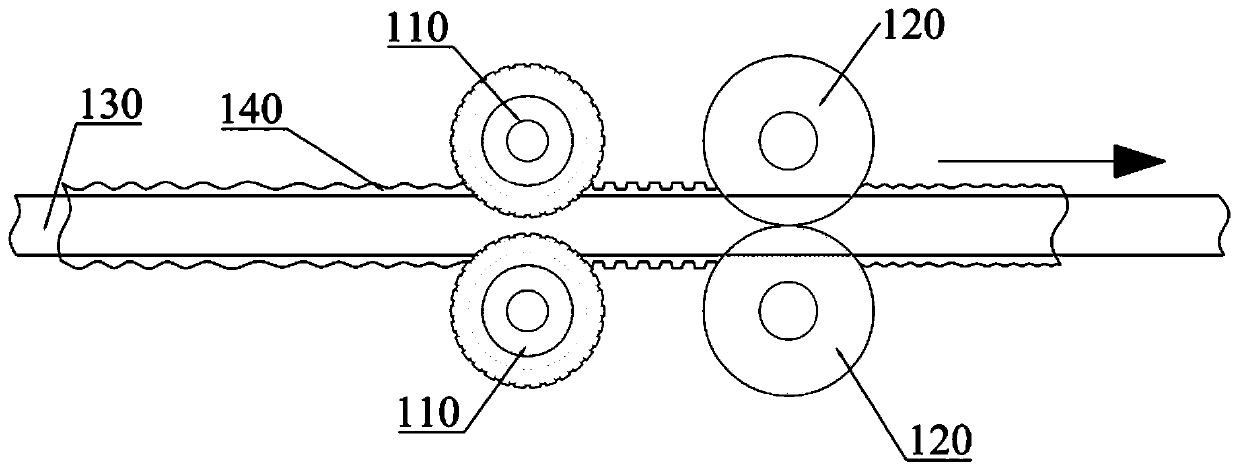

Automatic alignment gluing machine

InactiveCN105752738AImprove processing efficiencyAvoid unevennessFunction indicatorsFolding thin materialsSpray coatingEngineering

The invention relates to an automatic alignment gluing machine. The automatic alignment gluing machine comprises a machine tool, cloth pressing rollers and a gluing brush; the gluing brush is of a wedge shape, and a spray-coating opening of the gluing brush is formed in the tip of the wedge shape; two cloth winding rollers for winding and placing cloth are fixedly mounted at the head part of the machine tool; a weighing instrument is mounted on each cloth winding roller; each weighing instrument is sequentially and electrically connected with an analyzer and a controller; two groups of cloth regulating rollers are also mounted on the machine tool; each group of cloth regulating rollers further comprises speed limiting rollers and cloth drawing rollers; rotating speeds of both the speed limiting rollers and the cloth drawing rollers are regulated by the controller; the cloth pressing rollers and the cloth drawing rollers rotate at the same speed; a rotating speed of the cloth drawing rollers is higher than that of the speed limiting rollers. According to the automatic alignment gluing machine, cloth can be flatly glued, and meanwhile, the condition that tail edges of the cloth are aligned can be guaranteed, so that a tail edge cutting process is avoided, cloth processing efficiency is improved, and meanwhile, texture, aesthetics and flatness of the cloth are ensured.

Owner:马根昌

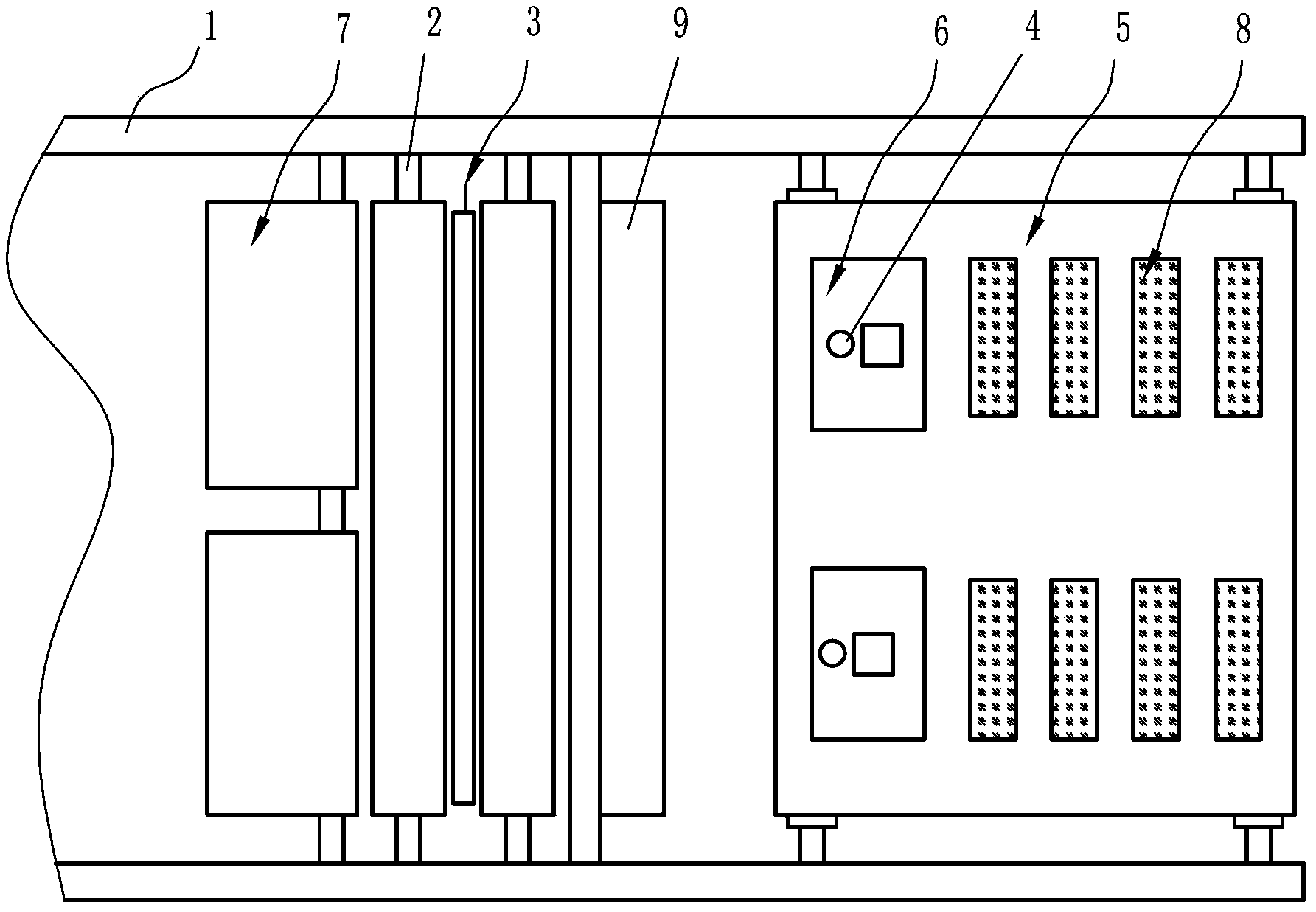

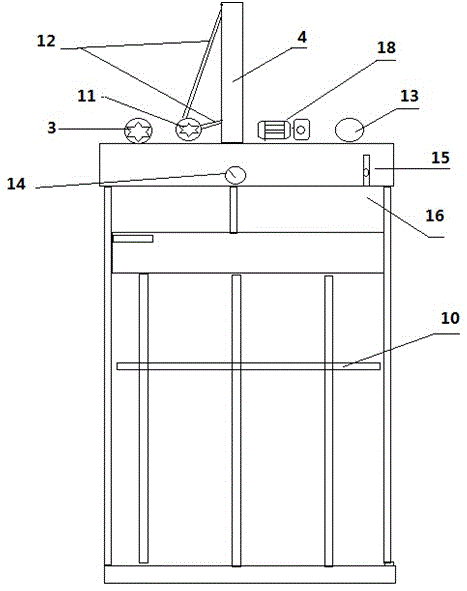

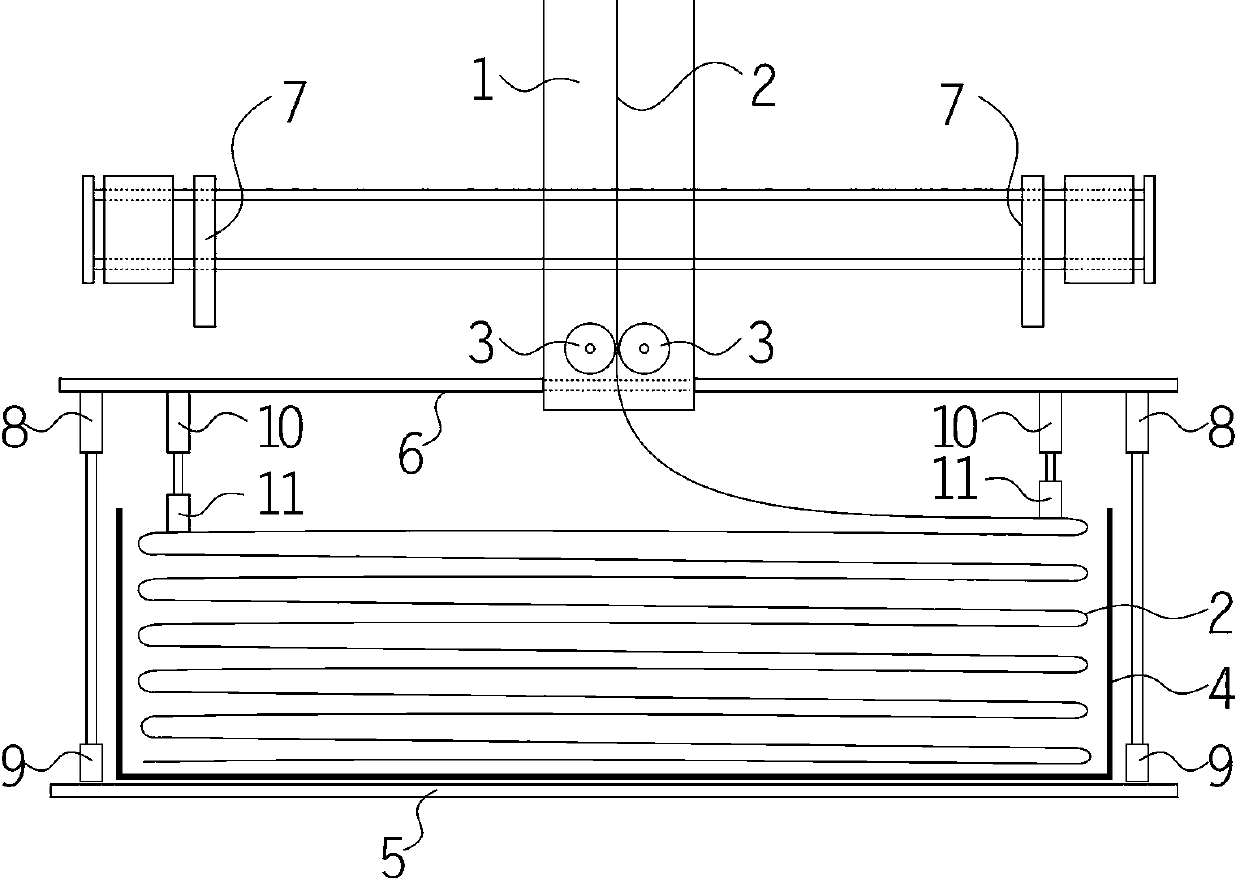

Automatic net folding and packaging all-in-one machine

ActiveCN105564746ANeatly foldedReasonable structure arrangementBinding material applicationEngineeringUltimate tensile strength

The invention discloses an automatic net folding and packaging all-in-one machine. The automatic net folding and packaging all-in-one machine is composed of a bar inserting mechanism, a first bar drawing mechanism, a bar pulling mechanism, a second bar drawing mechanism, a bar conveying mechanism, a net bearing mechanism, a net pressing mechanism and a controller which are mounted on a machine frame, wherein the machine frame is halved; one side of the machine frame is provided with the bar inserting mechanism, the first bar drawing mechanism, the second bar drawing mechanism and the bar conveying mechanism, the bar inserting mechanism and the first bar drawing mechanism are located at one end of the same side, the second bar drawing mechanism is located at the other end, and the bar conveying mechanism is mounted in the position, between the first bar drawing mechanism and the second bar drawing mechanism, of the machine frame horizontally; the bar pulling mechanism, the net bearing mechanism and the controller are mounted on the other side of the machine frame, the bar pulling mechanism is mounted on the machine frame horizontally, the net bearing mechanism is mounted in the position, below the bar pulling mechanism, of the machine frame, the net pressing mechanism is mounted in the position, above the bar pulling mechanism, of the machine frame, and the controller is mounted on the lateral face of the machine frame. The structural layout of the automatic net folding and packaging all-in-one machine is reasonable, nets are folded in order automatically at a time, no labor operation is needed during folding, so that the production efficiency is high, the labor intensity is high, and the folding effect is good.

Owner:滨州宏愿化纤制品有限公司

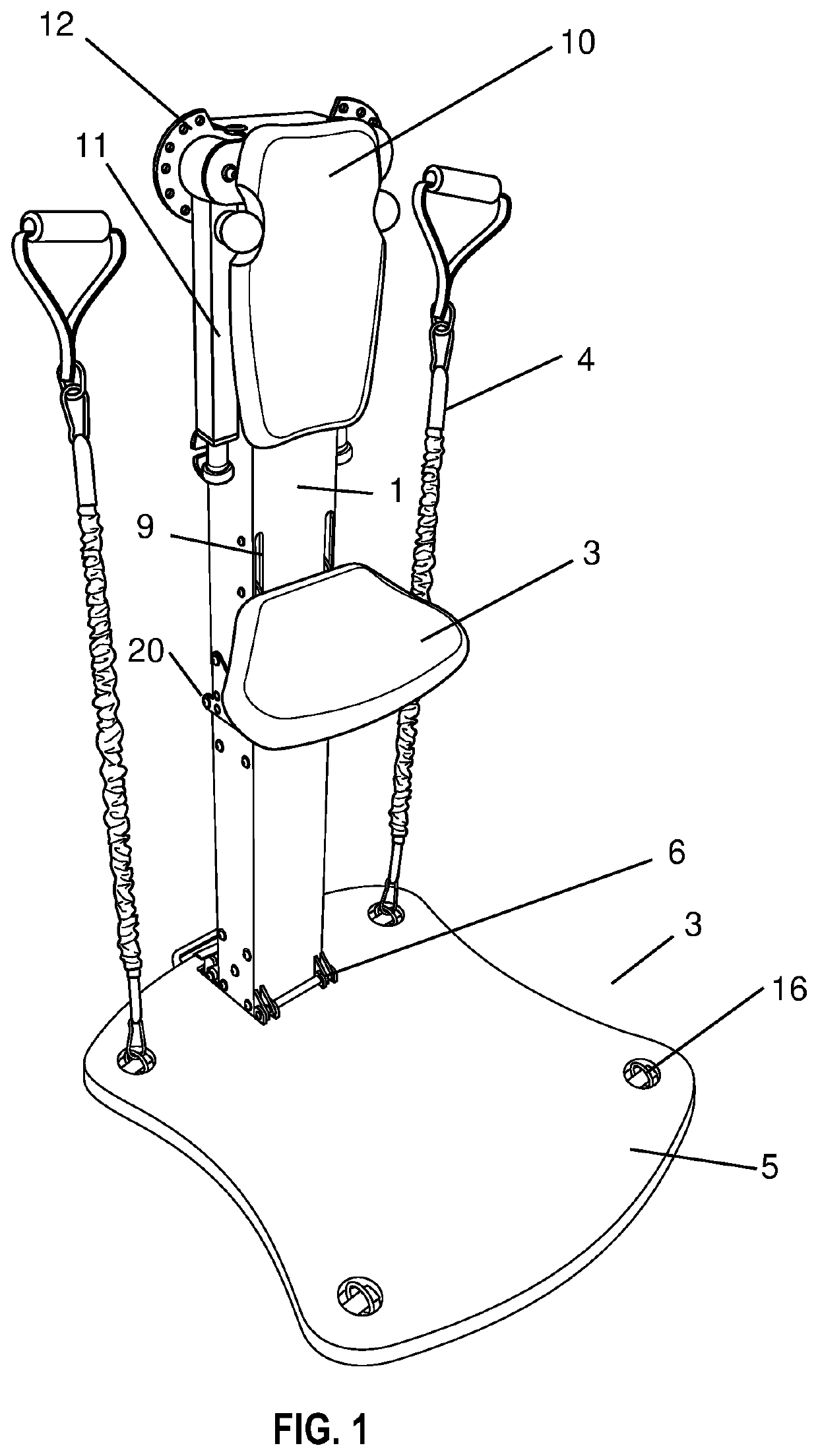

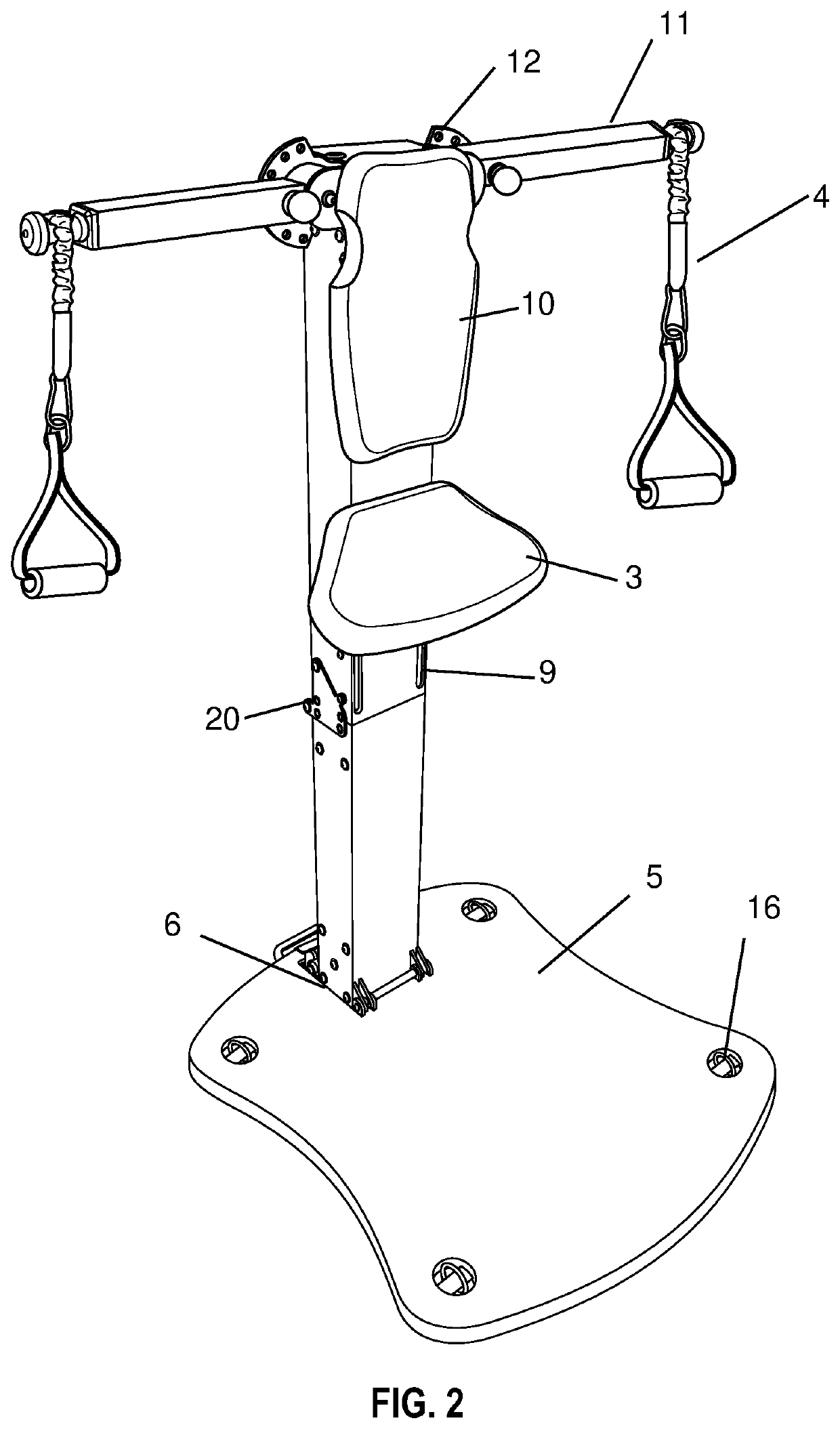

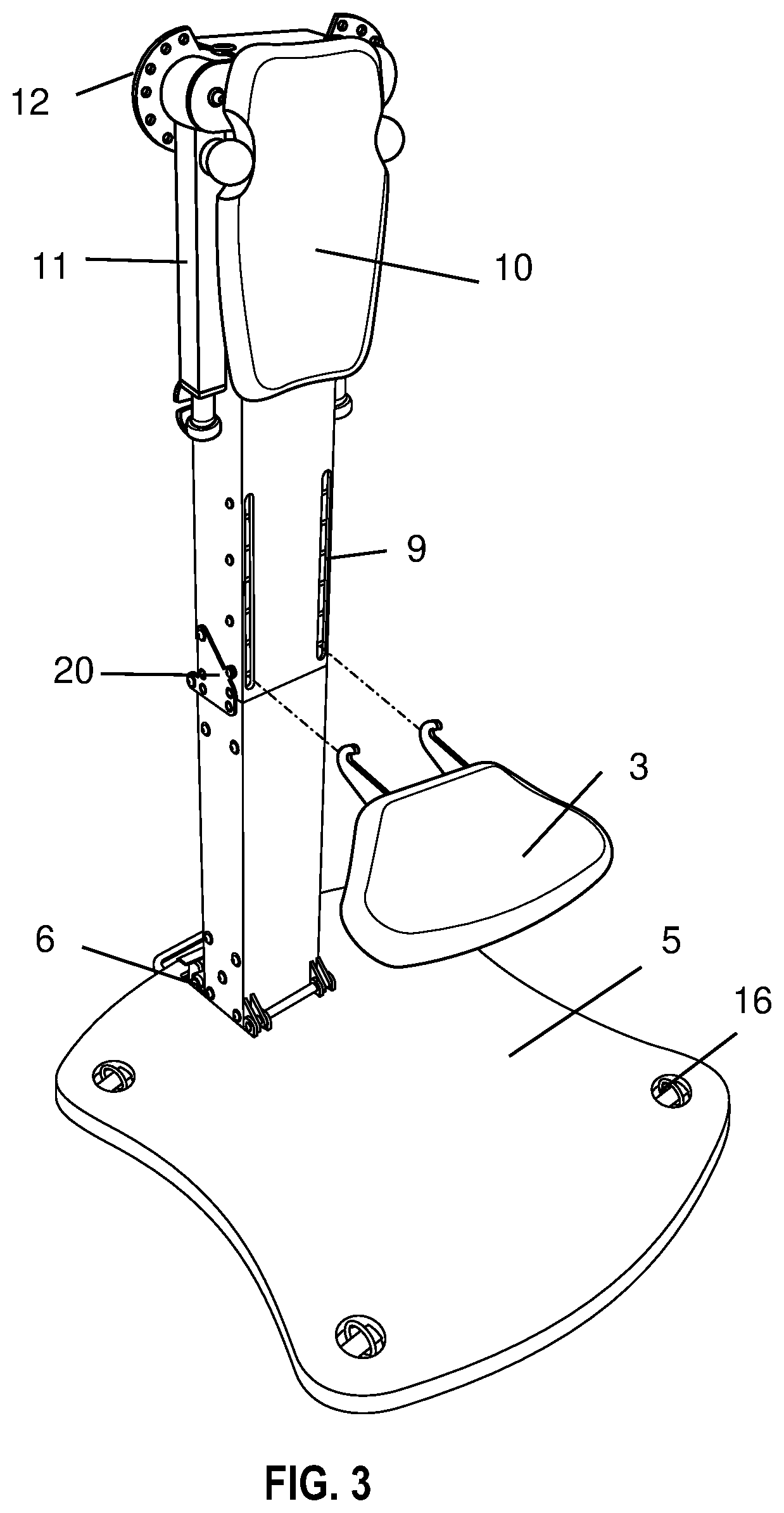

Portable, multi-function fitness device.

PendingUS20210402248A1Quick and easy adjustmentEasily travelSpace saving gamesMuscle exercising devicesStructural engineeringMechanical engineering

Owner:CLARK JEFF

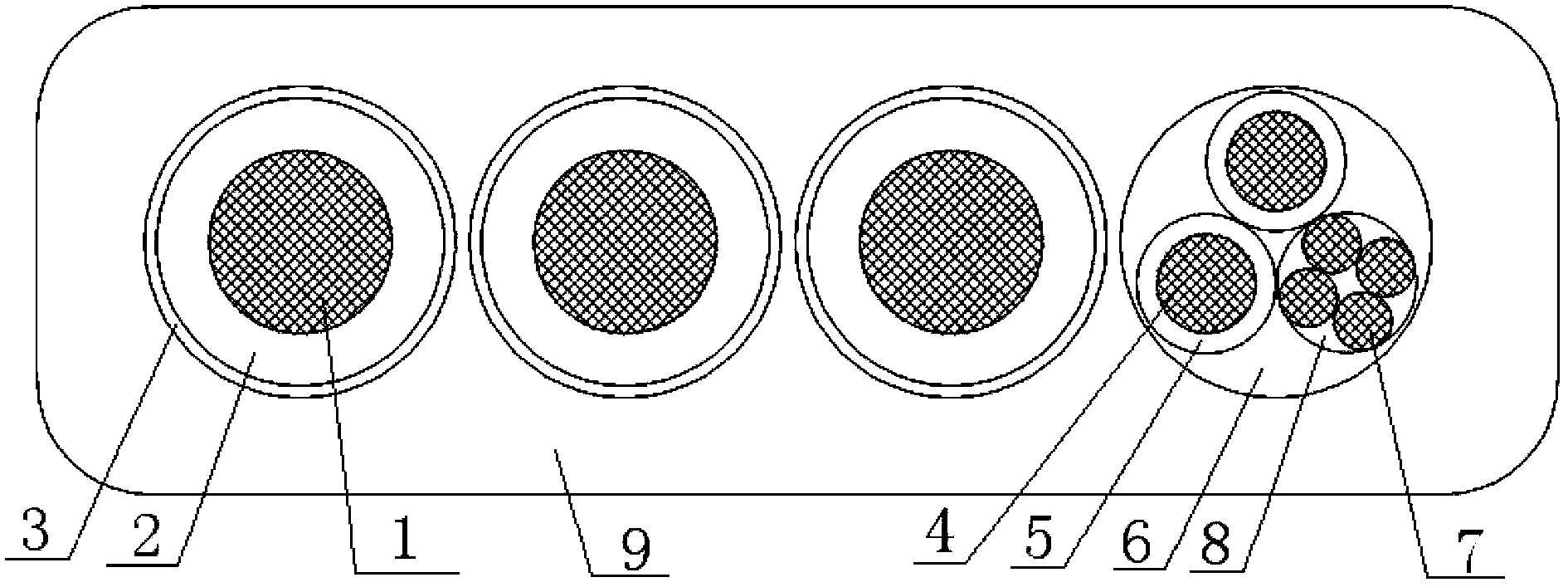

Flat insulating rubber jacketed flexible cable

InactiveCN104078115AEasy to useNeatly foldedFlat/ribbon cablesFlexible cablesInsulation layerElectrical conductor

The invention discloses a flat insulating rubber jacketed flexible cable. The flat insulating rubber jacketed flexible cable comprises a control core, at least one power line core and at least one ground line core, wherein each power line core comprises a conductor, an insulation layer in which the conductor is wrapped and adhesive tape in which the insulation layer is wrapped, each ground line core comprises conductors and an insulation layer in which the conductors are wrapped, the control core comprises at least one conductor and an insulation layer in which the conductors are wrapped, a combined core is formed by twisting the ground line cores and the control core, the combined core and the power line cores are arranged side by side, and the combined core and the power line cores are wrapped in a sheath. The flat insulating rubber jacketed flexible cable is applied to various hoisting and transportation machines which are moved outdoors frequently or electrical devices and is convenient to use. Due to the fact that the insulating rubber jacketed flexible cable is flat, the flat insulating rubber jacketed flexible cable is particularly suitable for occasions where frequent bending is needed, is not prone to knotting and can be folded orderly. The flat insulating rubber jacketed flexible cable is used for connecting movable electrical devices under the severe environments such as the power generation environment, the metallurgical environment, the chemical engineering environment and the port environment.

Owner:无锡市金正电缆有限公司

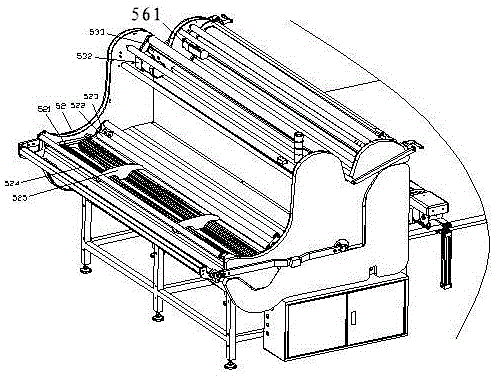

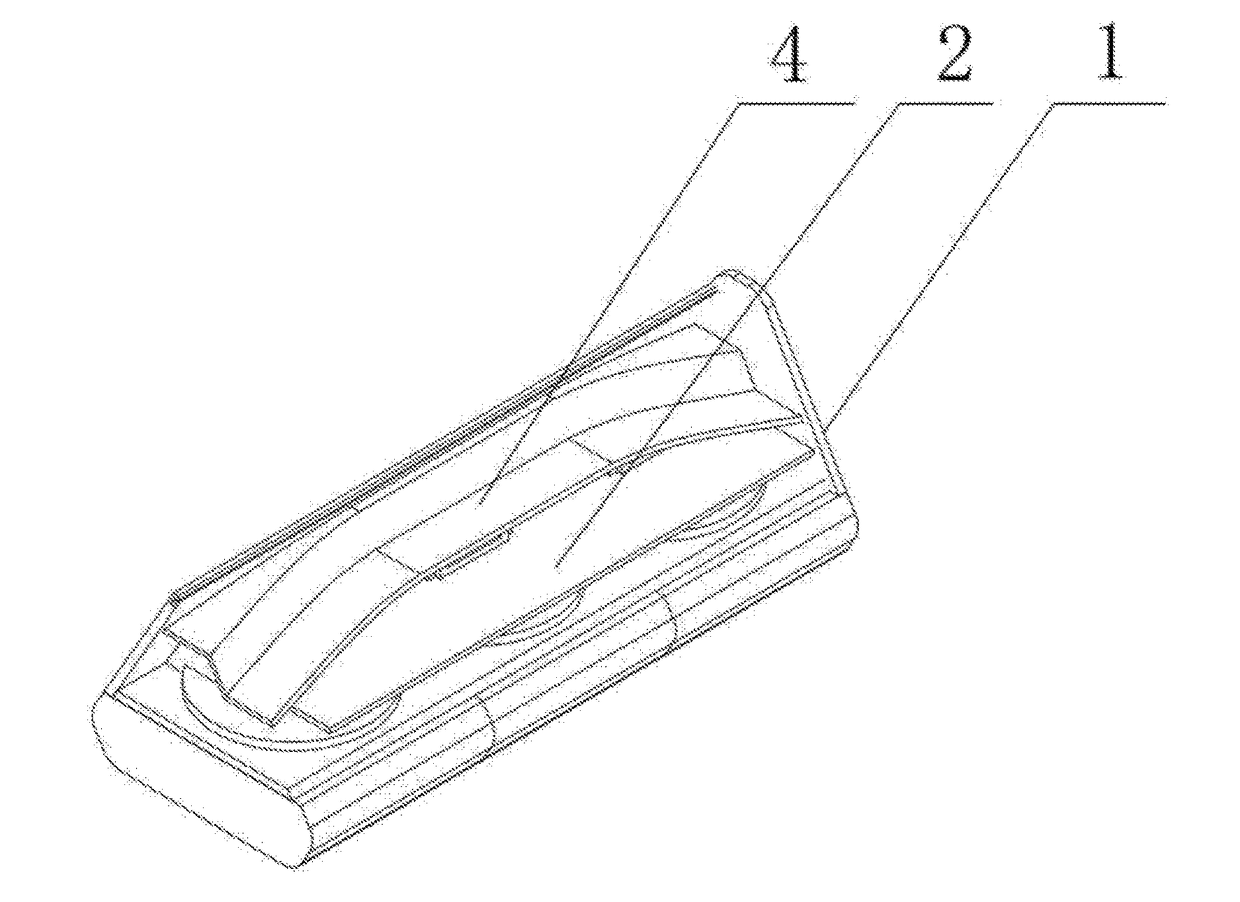

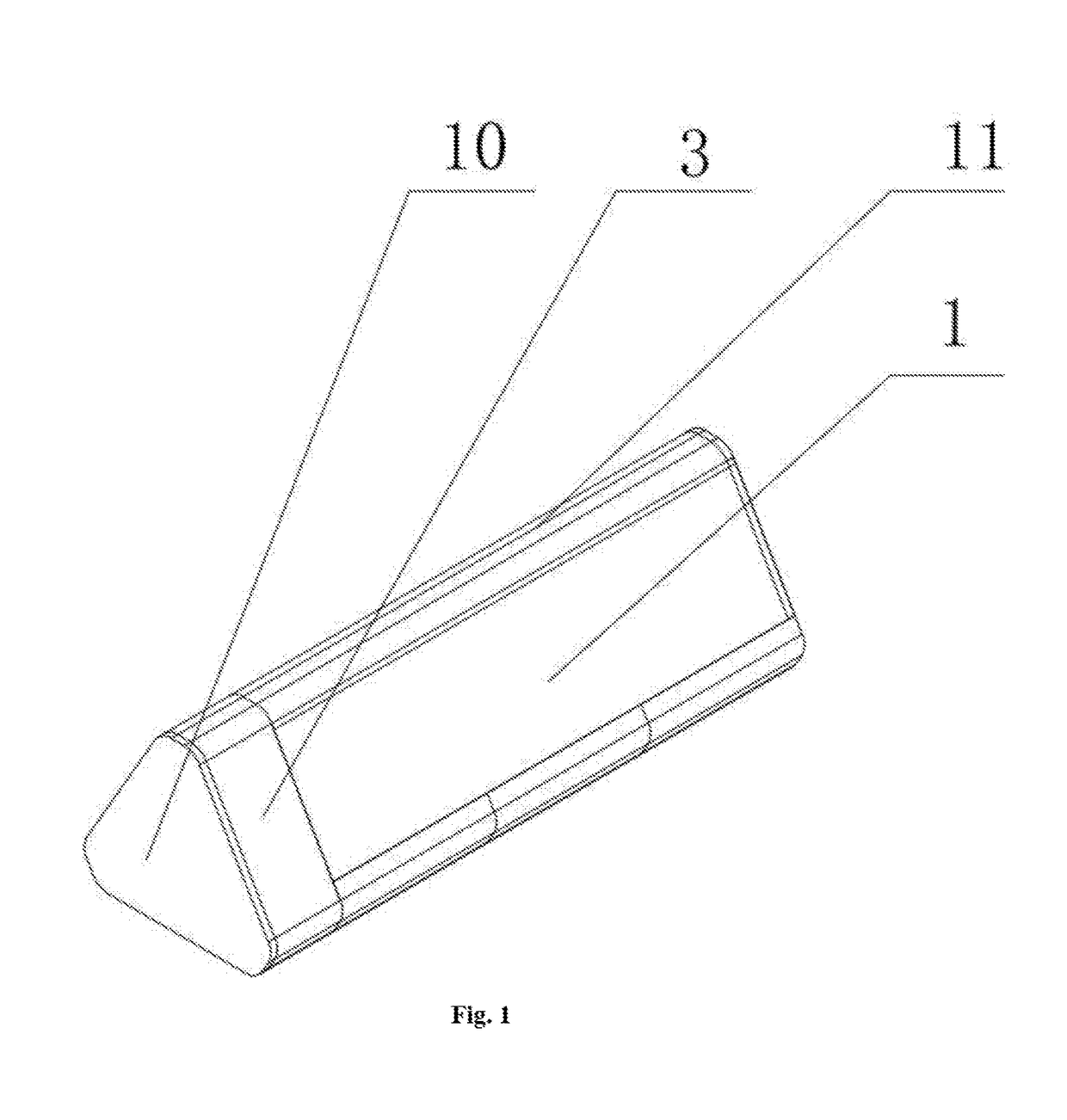

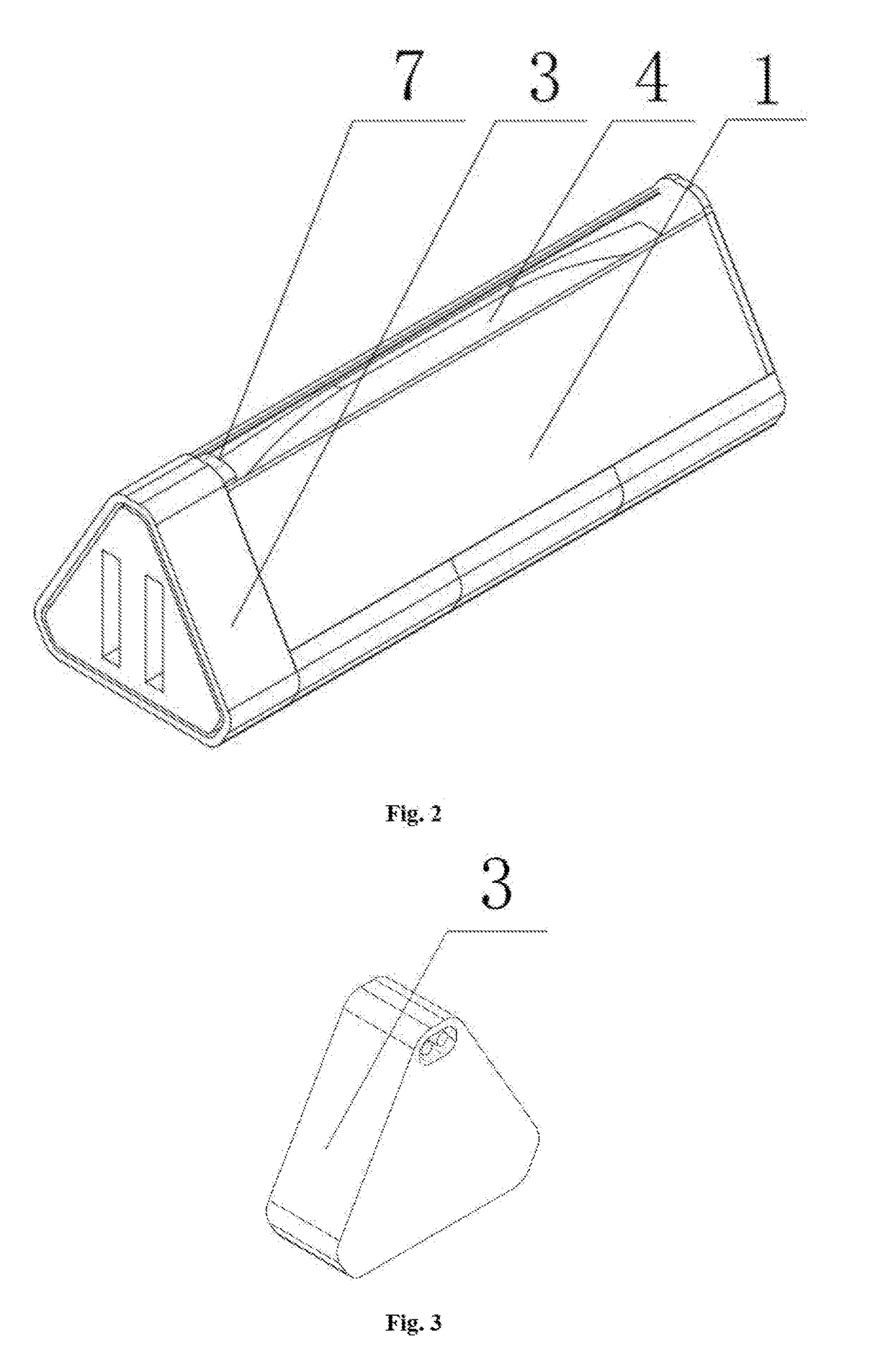

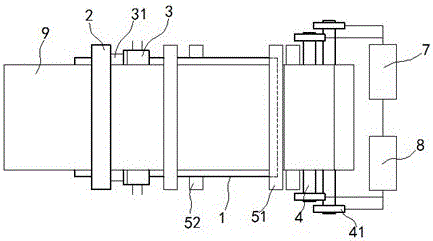

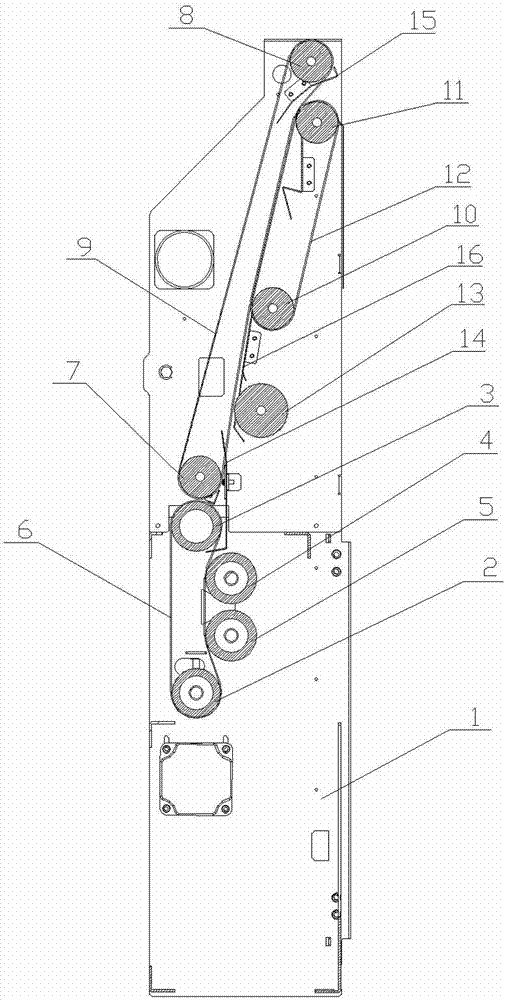

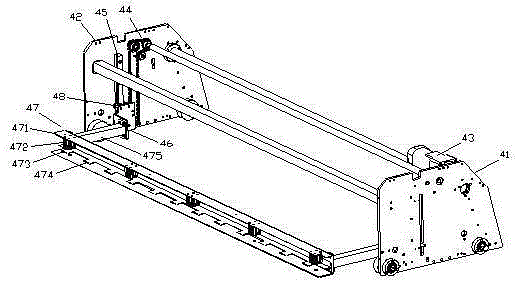

Vertical folding mechanism of drawing folding machine

InactiveCN103612943ALess likely to shiftNot prone to flatnessFolding thin materialsArticle deliveryStructural engineeringMachine

The invention provides a vertical folding mechanism of a drawing folding machine. The vertical folding mechanism comprises a base (1), a driving rolling barrel (2), a driven rolling barrel (3), an upper subshaft (4), a lower subshaft (5) and belts (6). The driving rolling barrel (2) and the driven rolling barrel (3) are symmetrically arranged relative to a straight line, the upper subshaft (4) and the lower subshaft (5) are symmetrically arranged relative to the same straight line, the multiple belts (6) are arranged in parallel and are closely arranged to the periphery of the driving rolling barrel (2) and the periphery of the driven rolling barrel (3) in a matched mode, one side of the upper subshaft (4) and one side of the lower subshaft (5) are pressed on the belts (6), the driving rolling barrel (2) is driven by a servo motor, and the axis distance of the upper subshaft (4) and the lower subshaft is smaller than that of the driving rolling barrel (2) and the driven rolling barrel (3). When the vertical folding mechanism of the drawing folding machine is used for folding drawings, the operation is simple, human cost is low, locating is good, folds are clear and linear, and folding widths are consistent.

Owner:NINGBO RONGHUA OFFICE EQUIP

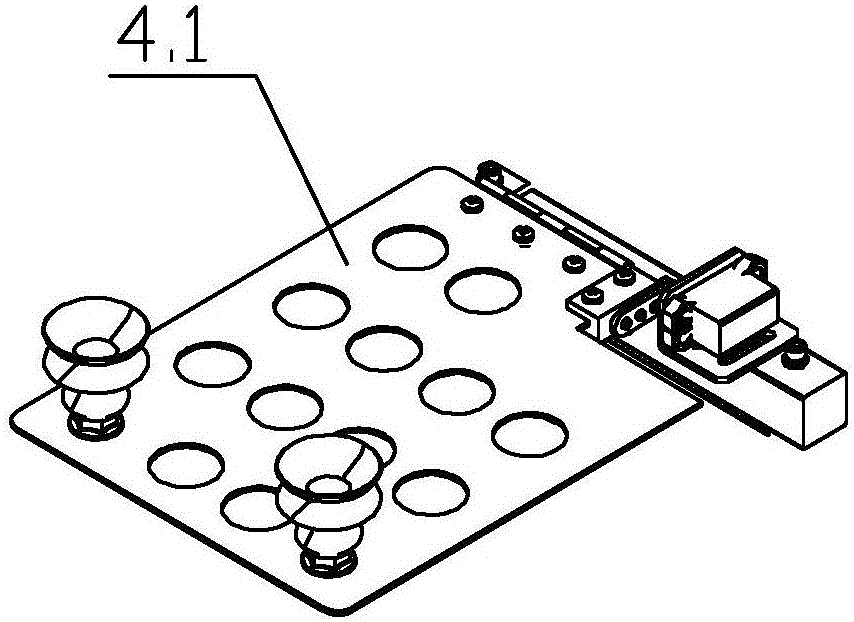

Automatic tape folding mechanism

The invention discloses an automatic tape folding mechanism. The automatic tape folding mechanism comprises a feeding plate, a resistance adhesive tape, a tape discharging servo motor roller, a tape loading pot, a tray support, a guide rail, a guide rail sensor, a tray cylinder, a tray ejection rod, a tape pressing cylinder and a tape pressing ejection rod, wherein the lower end of the feeding plate is provided with the tape discharging servo motor roller and the guide rail, the guide rail sensor is arranged above the guide rail, the tape loading pot is arranged under the guide rail, the tray cylinder and the tape pressing cylinder are arranged at two ends of the guide rail, the tape pressing cylinder is connected with the tape pressing ejection rod, the tray cylinder is connected with the tray ejection rod, and the tray is connected at the lower end of the tray ejection rod. The automatic tape folding mechanism can realize automatic folding and packing of the resistance adhesive tape.

Owner:太仓吉井机械有限公司

Tray and device for stabilising a tray

Owner:SAFETRAY PRODS

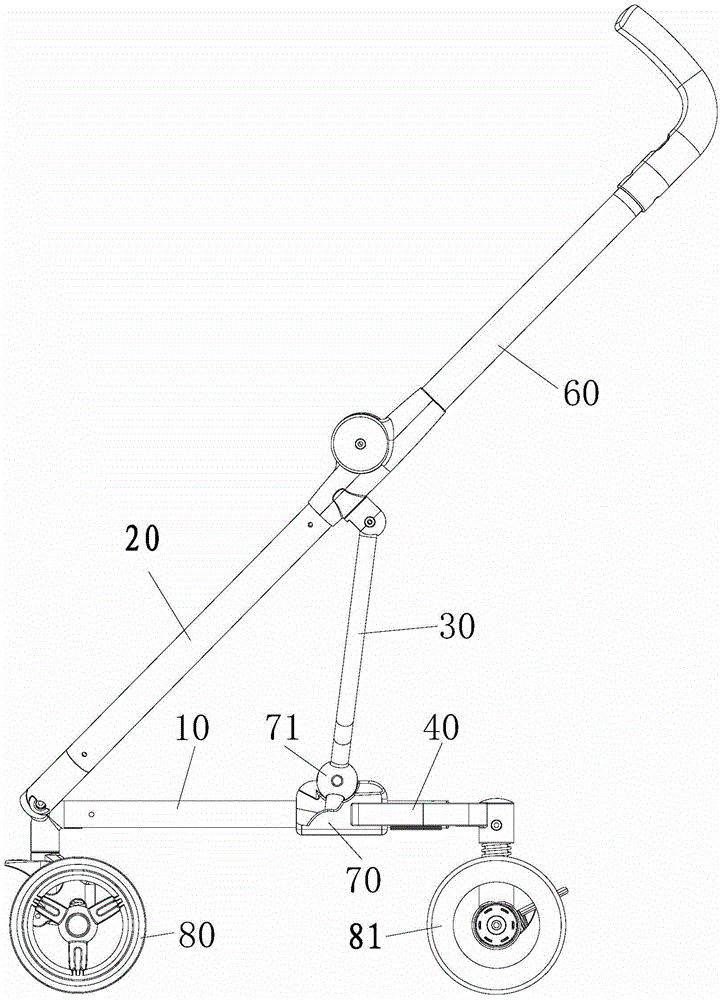

Portable fire hose laying vehicle

The invention relates to a portable fire hose laying vehicle. The portable fire hose laying vehicle comprises a vehicle body, wherein the top surface and the bottom surface of the vehicle body are of unenclosed structures; a wheel shaft A and a wheel shaft B are respectively arranged at the two sides of the unenclosed structure of the bottom surface of the vehicle body and are connected together through two connecting rods; idler wheels are arranged at the end parts of the wheel shaft A and the wheel shaft B; two sets of vehicle body jacking devices are respectively and symmetrically arranged at the two ends of the wheel shaft A; a hinge type water hose bottom supporting door is arranged on the unenclosed structure of the bottom of the vehicle body; a ferrule is arranged at one side of the water hose bottom supporting door; a latch is arranged at the other side of the water hose bottom supporting door; a movable handle which rotates towards front and back is arranged on the unenclosed structure of the top surface of the vehicle body; two sticking tapes are respectively arranged at the left side and right side of the movable handle; and an oblique-pulling handle and a water hose idler wheel are respectively arranged at the left side and right side of the top surface of the vehicle body. According to the portable fire hose laying vehicle, the transportation is convenient, the occupying space is small, water hoses can be expanded quickly and conveniently without knot tying, the efficiency is high, the labor can be saved, and due to existence of the water hose idler wheels, the friction is small when the water hose is expanded, and therefore, the damage of the water hose is small.

Owner:王敬忠

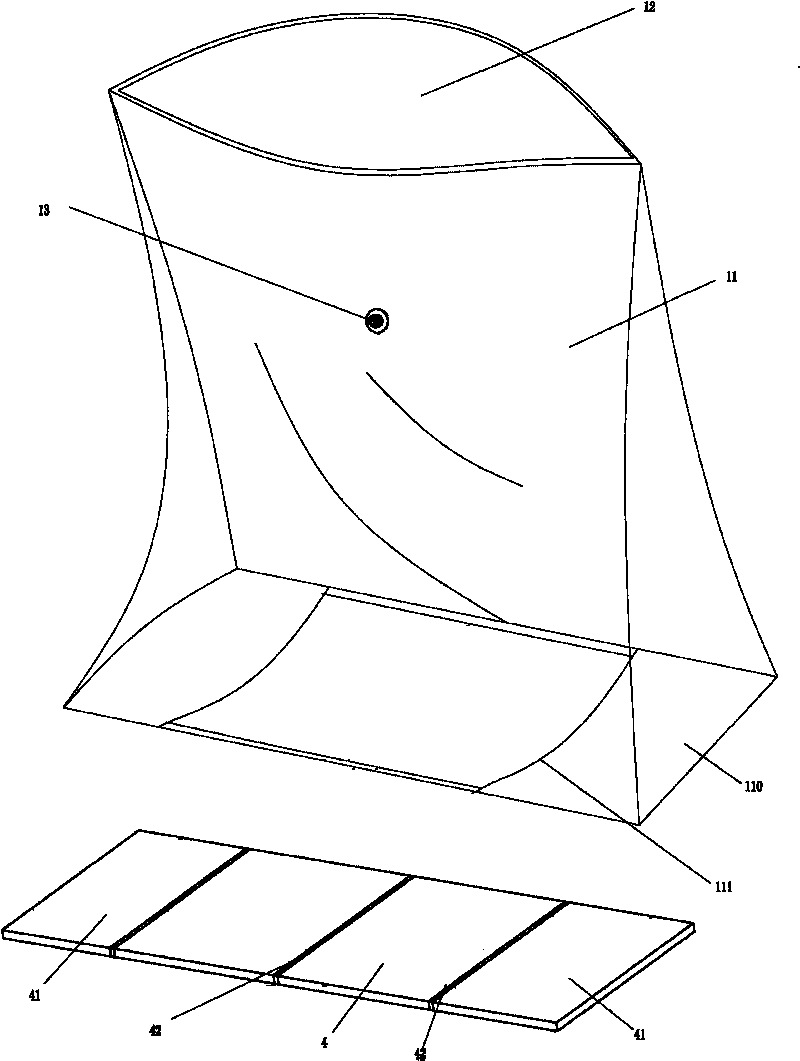

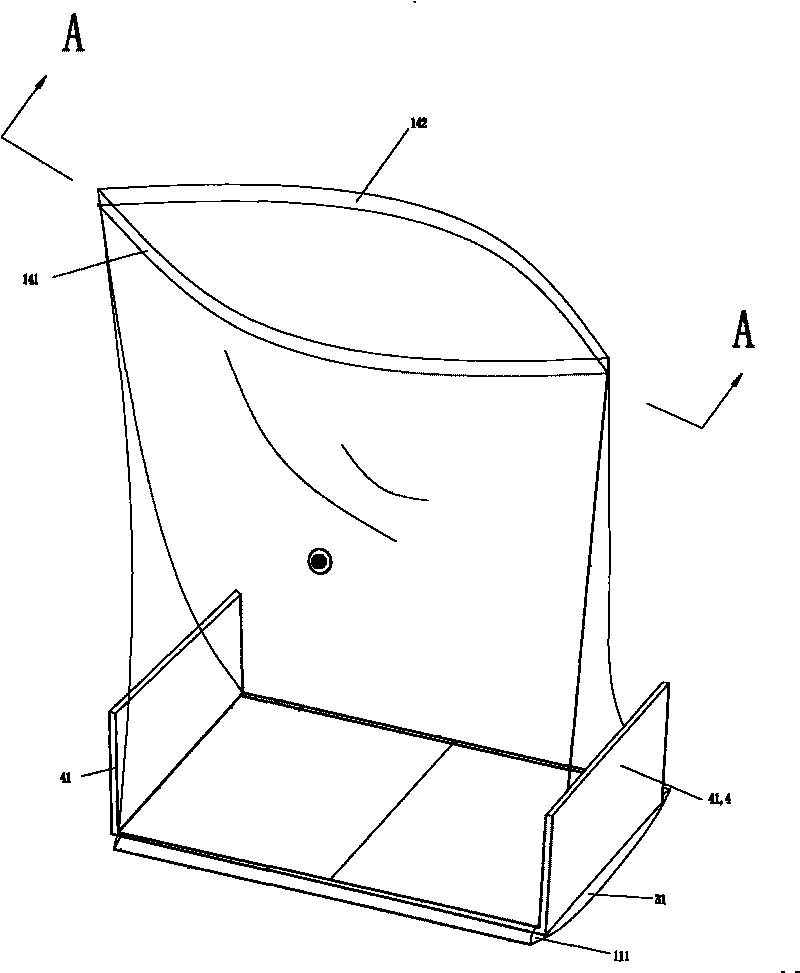

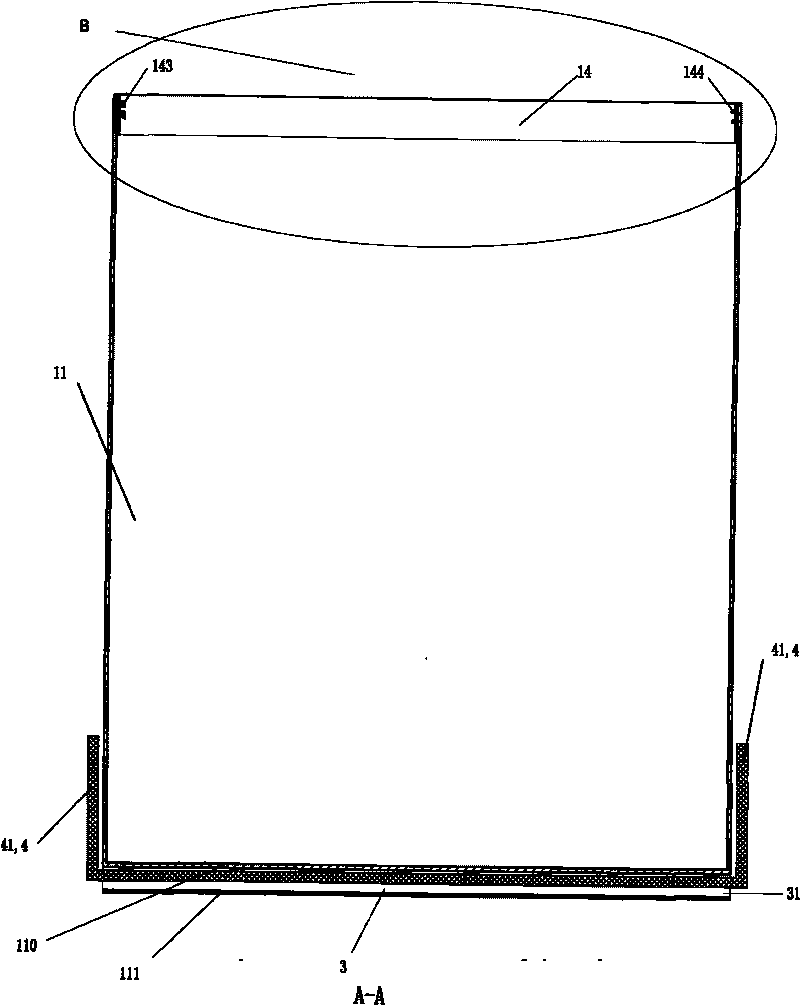

Vacuum bag and combination device of vacuum bag and stuff bag

The invention relates to a vacuum bag, which comprises a bag body and a bag mouth, wherein the bag body is provided with an air sucking faucet and a sealing device on the bag mouth. The vacuum bag is characterized in that an interlayer is arranged on the lower side of the bag bottom of the bag body; the bag bottom and the interlayer form an accommodation space with an opening; and a supporting board which can be separated from the bag body is inserted into the accommodation space and extends out of the opening of the accommodation space, and the extending segment can be folded. The invention relates to a combination device of the vacuum bag and a stuff bag; the stuff bag is arranged outside the bag body; and the size of the stuff bag is matched with the size of the bag bottom. The invention aims to overcome the defect that the existing vacuum bag has difficulty in combining with the supporting board at the bottom, and provides the vacuum bag with simple structure, easy combination of the vacuum bag and bottom supporting board and convenient transportation and storage, and the combination device of the vacuum bag and the stuff bag.

Owner:HUBEI TAILI HOUSEHOLD ARTICLE MFG

An automatic clothing folding packaging machine and a clothing folding packaging method

The invention discloses an automatic clothes folding packer. The automatic clothes folding packer comprises a rack and is characterized in that a main board and a folding component are arranged on the rack, the folding component is hinged to the rack (1), a transmission board (3) is arranged under the main board (2), a motor is arranged on the transmission board (3) or the rack (1), a packing station (4) and the motor used for driving the transmission board (3) to drive the main board (2) to reciprocate onto the packing station (4) are arranged on the rack (1), a transmission mechanism is arranged on the rack (1), and a clamping mechanism is arranged on the packing station (4). The invention further discloses a folding and packing method based on the automatic clothes folding packer. The automatic clothes folding packer provided by the invention can automatically finish clothes folding and packing, is high in integration performance, is motor-driven, eliminates noise, adopts a vertical structure and saves the working space.

Owner:NINGBO INST OF TECH ZHEJIANG UNIV ZHEJIANG

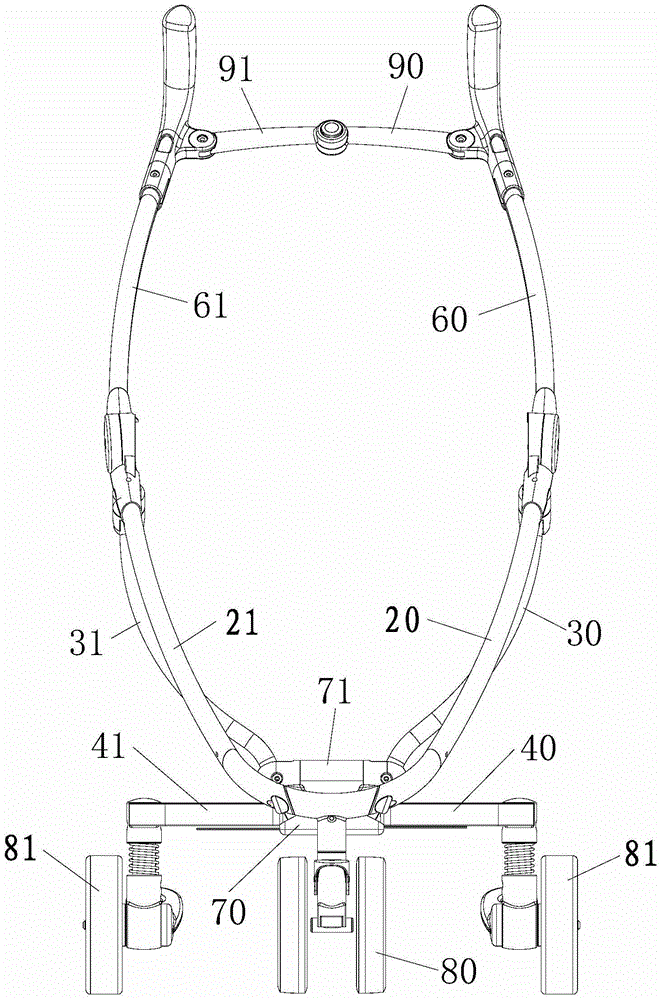

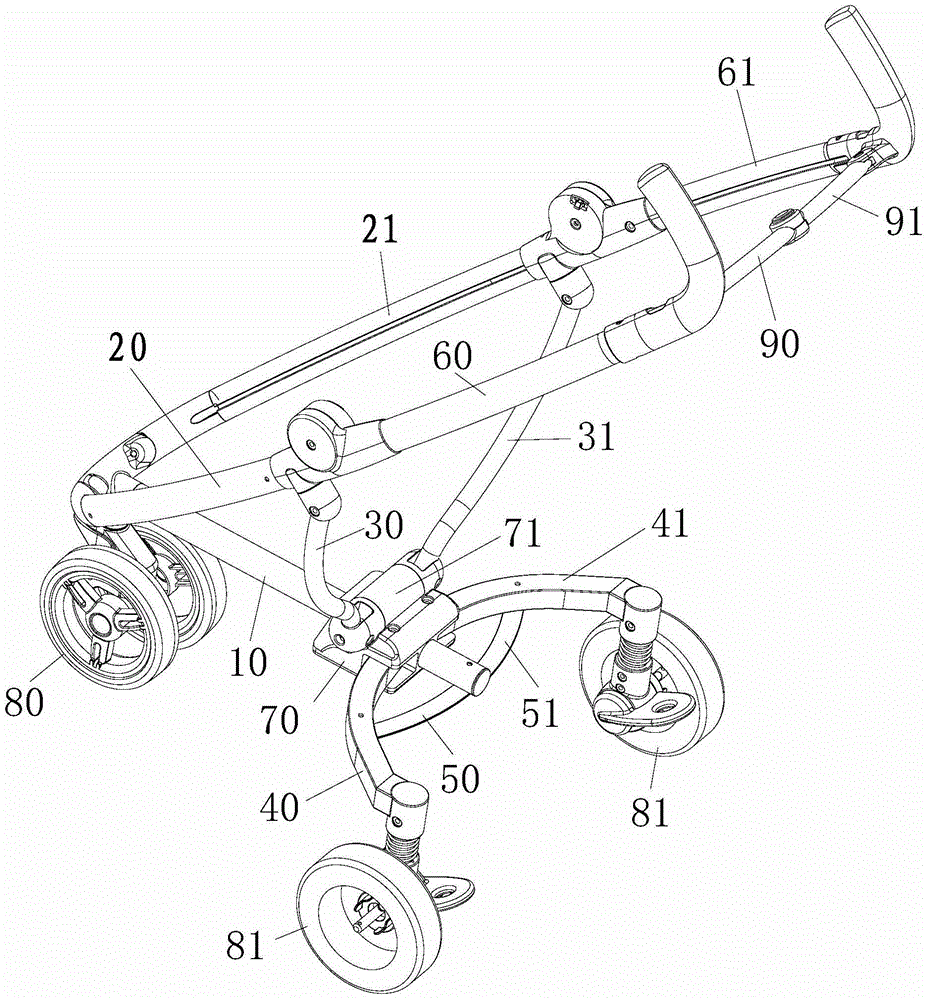

Folding child stroller

The invention discloses a folding child stroller. The folding child stroller comprises a foldable stroller frame, front wheels and rear wheels which are arranged below the stroller frame as well as a locking mechanism for locking the stroller frame at the opening state; the stroller frame comprises a bottom rod of which the front part is connected with the front wheels, a first front support of which the lower part is rotationally connected with the front part of the bottom rod, a first support rod of which the lower part is rotationally connected with the middle of the bottom rod in a front and back movable mode, a first rear support of which the front part is rotationally connected with the middle of the bottom rod in a front and back movable mode, and a first rear support connection rod of which one end part is rotationally connected with the rear part of the bottom rod; wherein the upper part of the first support rod is rotationally connected with the upper part of the first front support; the rear wheels are connected to the rear part of the first rear support; the other end part of the first rear support connection rod is rotationally connected with the middle of the first rear support.

Owner:GOODBABY CHILD PROD CO LTD

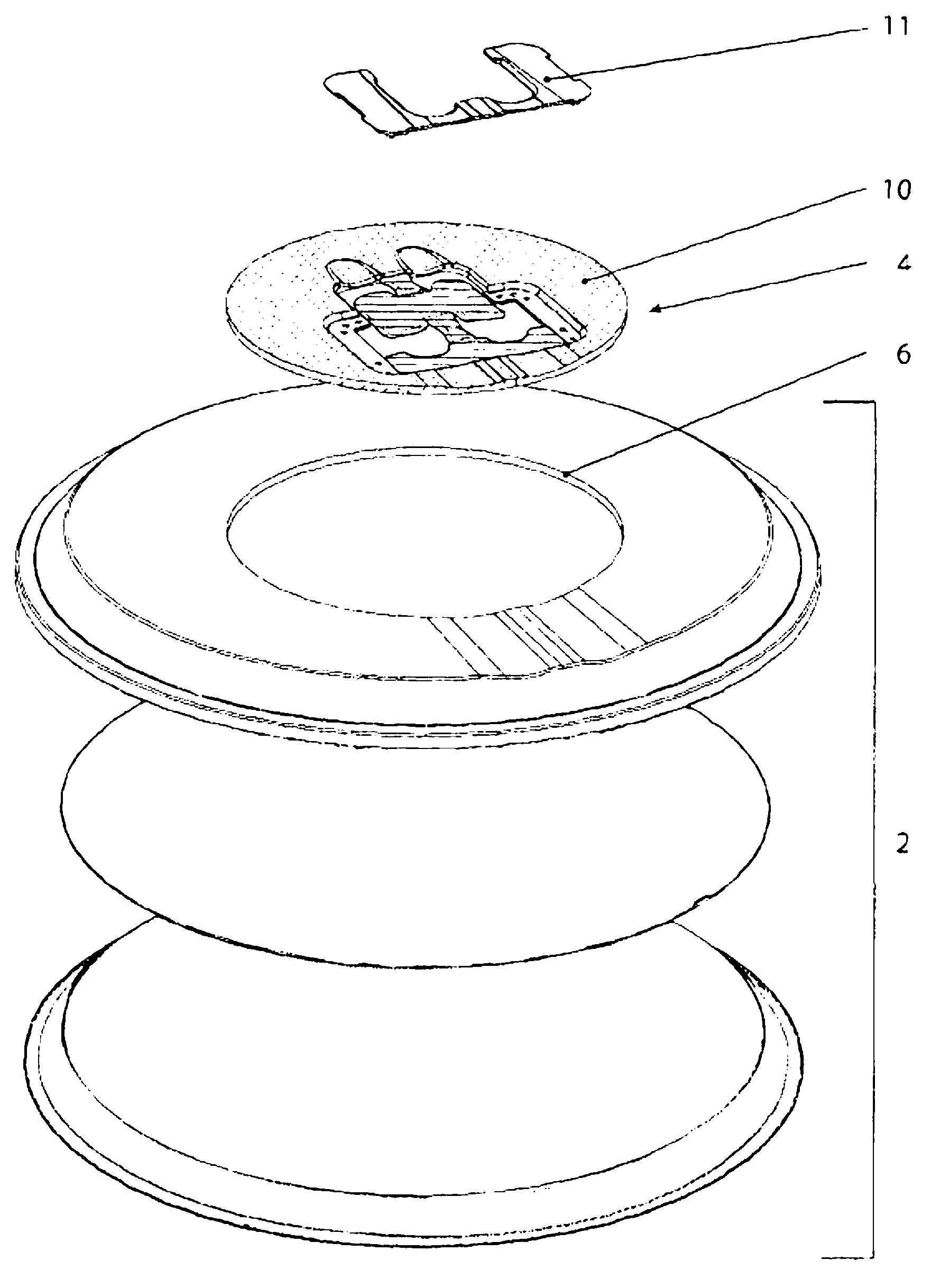

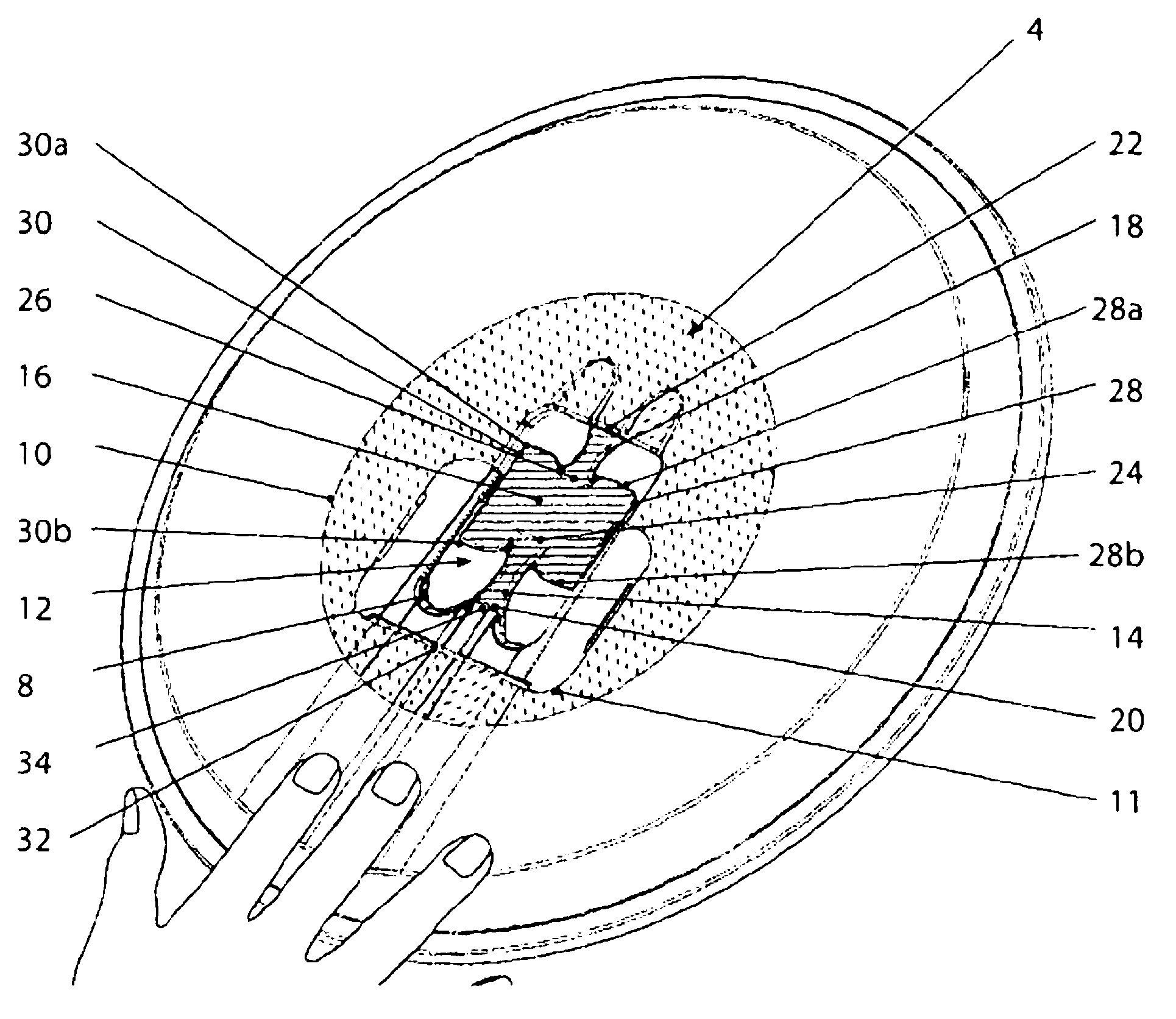

Shower Flower Water Collection Device

InactiveUS20150136275A1Prevent contaminationAvoid pollutionWatering devicesFunnelsEngineeringWater collection

A shower water collection device configured to capture pre-shower water which once full may easily be sealed to prevent contamination of the collected water until the water can be used for another purpose. A shower water collection device further including an inverted umbrella type funnel for increased surface area and enhanced water collection.

Owner:WALES WILLIAM FIELD

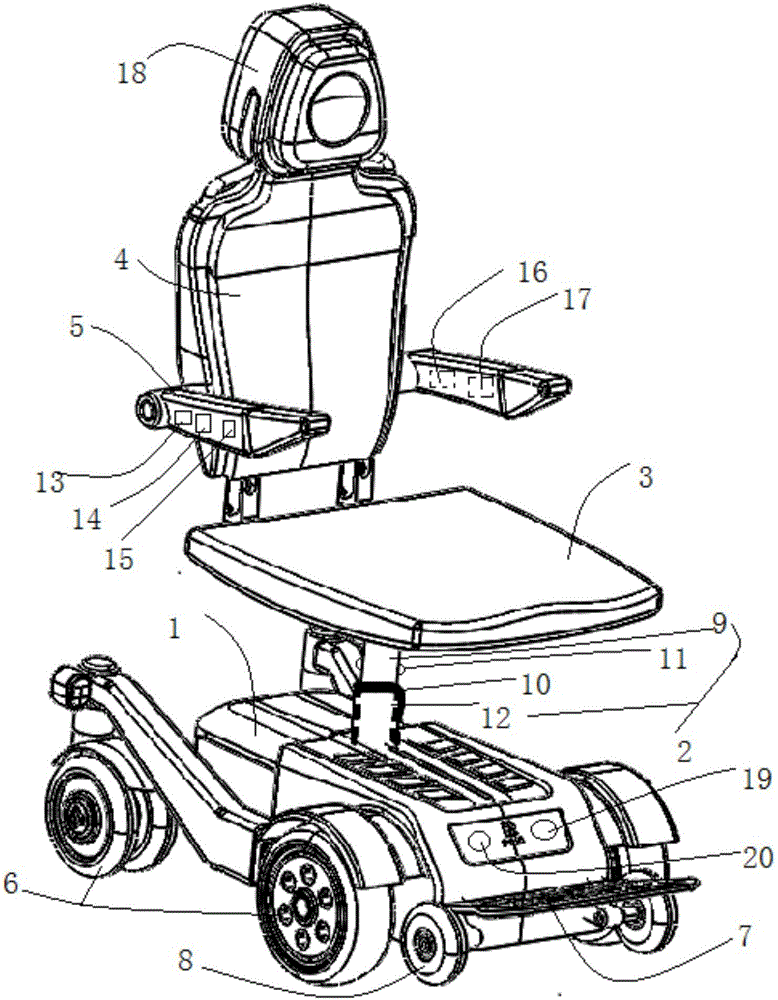

Folding electric wheelchair

InactiveCN106726202ANeatly foldedEasy to carryWheelchairs/patient conveyanceWheelchairRechargeable cell

The invention discloses a folding electric wheelchair. The folding electric wheelchair comprises a base and a driving mechanism arranged in the base. The base is connected with a seat body through a telescopic supporting column, the rear end of the seat body is connected with a backrest in a turnable folding mode, the lower portions of the two sides of the backrest are connected with armrests in a rotatable folding mode, the sides of the base are connected with front and rear wheels, the lower portion of the front end of the base is connected with a pedal plate, the side ends of the pedal plate are connected with braking wheels, and a rechargeable battery electrically connected with the driving mechanism is arranged in the rear portion of the base. Compared with the prior art, the folding electric wheelchair has the advantages of being simple in folding process, high in operability, regular in folding, convenient to carry, small in size, low in weight, low in cost and the like.

Owner:东莞产权投资有限公司 +1

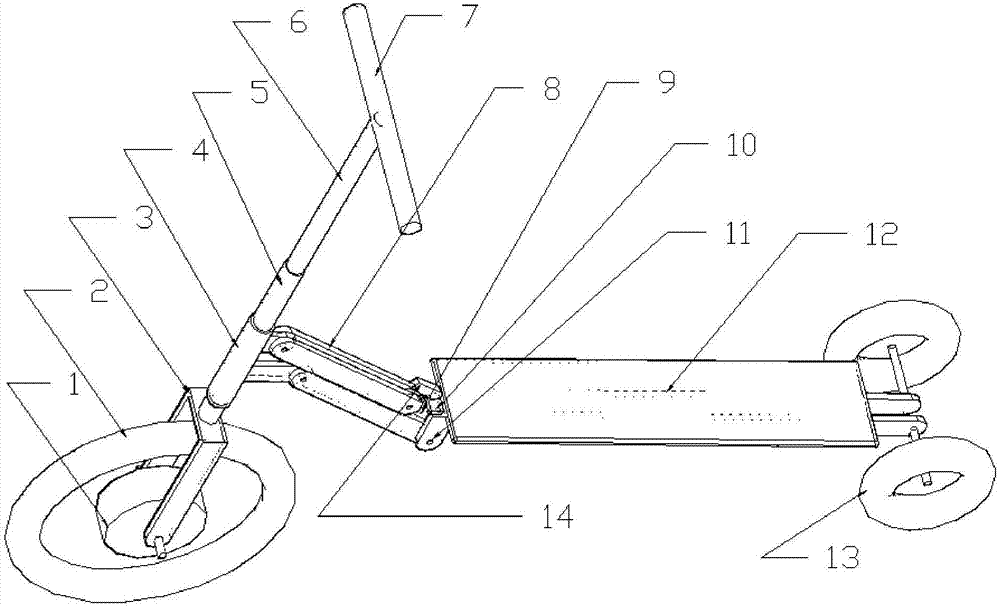

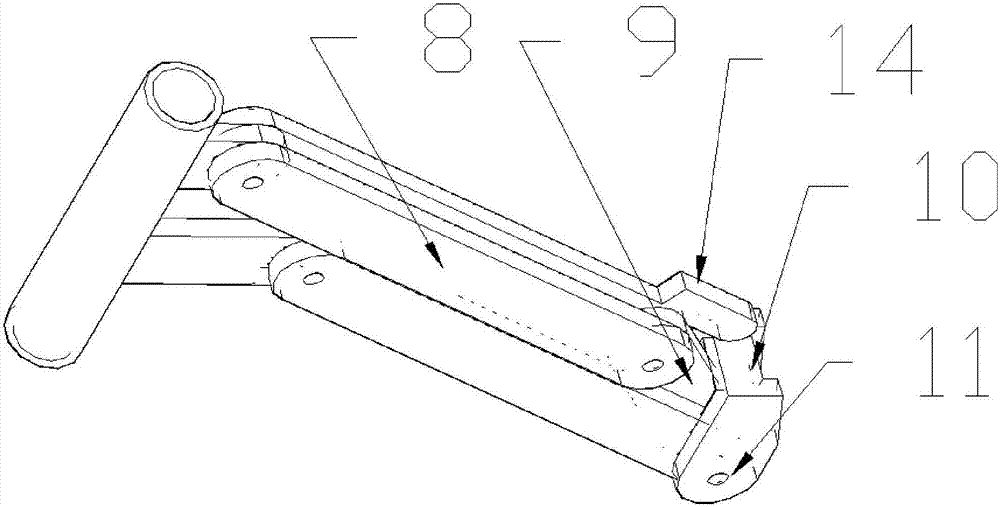

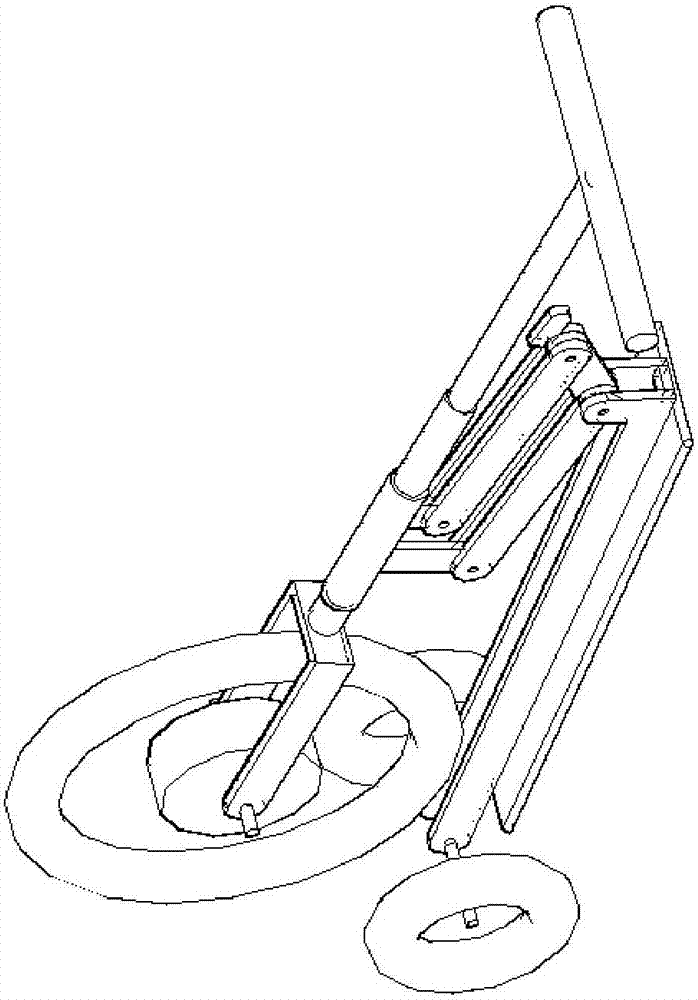

Foldable scooter

The invention aims to provide a foldable scooter. A foldable rear plate is parallel to a head pipe; front and rear wheels are gathered at one end; a handle is arranged at the other end; in a carrying process, a user can hold the handle by hand and can pull the wheels to move on the ground, so that the clothes can be prevented from being dirty, the weight of the scooter can be overcome and the scooter can be easily carried. The technical scheme adopted for solving the technical problem is that a self-limiting hinge is adopted for realizing the quick folding and unfolding of the scooter. The foldable scooter is composed of a faucet assembly, a foldable hinge, a plate body and a rear wheel; the front part of the foldable hinge is connected with a faucet head pipe while the rear part is connected with the front end of a plate bracket; the rear wheel is arranged at the rear end of the plate bracket; the foldable hinge is the key point for realizing the folding function thereof; a connecting corner point of the foldable hinge and the plate bracket is downward self-limited on the horizontal position of the plate body and is capable of upward freely moving; an unfolding angle of the foldable hinge and the faucet head pipe is self-limited on a fixed position of 'front wheel end of the head pipe located on forward vertical position within 0-15 degrees'; the front and rear wheels are gathered at one end under a folded state.

Owner:吴结华

Food folding device

InactiveCN106697452AAvoid damageNo delays in the production processPackagingProduction lineReciprocating motion

The invention relates to the field of matched devices of a food processing production line, in particular to a food folding device. The food folding device comprises a slideway, a support rack on the slideway, a motor fixed on the support rack, a roller driven by the motor to rotate, a conveying belt winding the roller and an air pump, wherein the air outlet of the air pump is connected with a telescopic pipe, the telescopic pipe is detachably provided with a hollow push rod, the push rod is connected with a folding plate, which can reciprocate on the slideway, in an insertion manner, the folding plate is driven by an air cylinder to reciprocate, a cavity is arranged in the folding plate, the top wall of the cavity of the folding plate is a soft film, a pressing pin is fixed on the soft film in the cavity, a soft clamp pin facing directly to the pressing pin is fixed on the bottom wall in the cavity, a sleeve is arranged outside the clamp pin, a pressure spring is clamped in the sleeve, one end of the pressure spring is fixed at the bottom of the sleeve, the other end of the pressure spring is fixed at the bottom of the clamp pin, and the push rod inserted into the cavity is connected with a tension spring which sleeves the clamp pin in a tensile manner. The food folding device has the advantages that material taking is performed without device shutdown, a production process is not delayed, and production efficiency can be increased.

Owner:襄阳一根山药食品有限公司

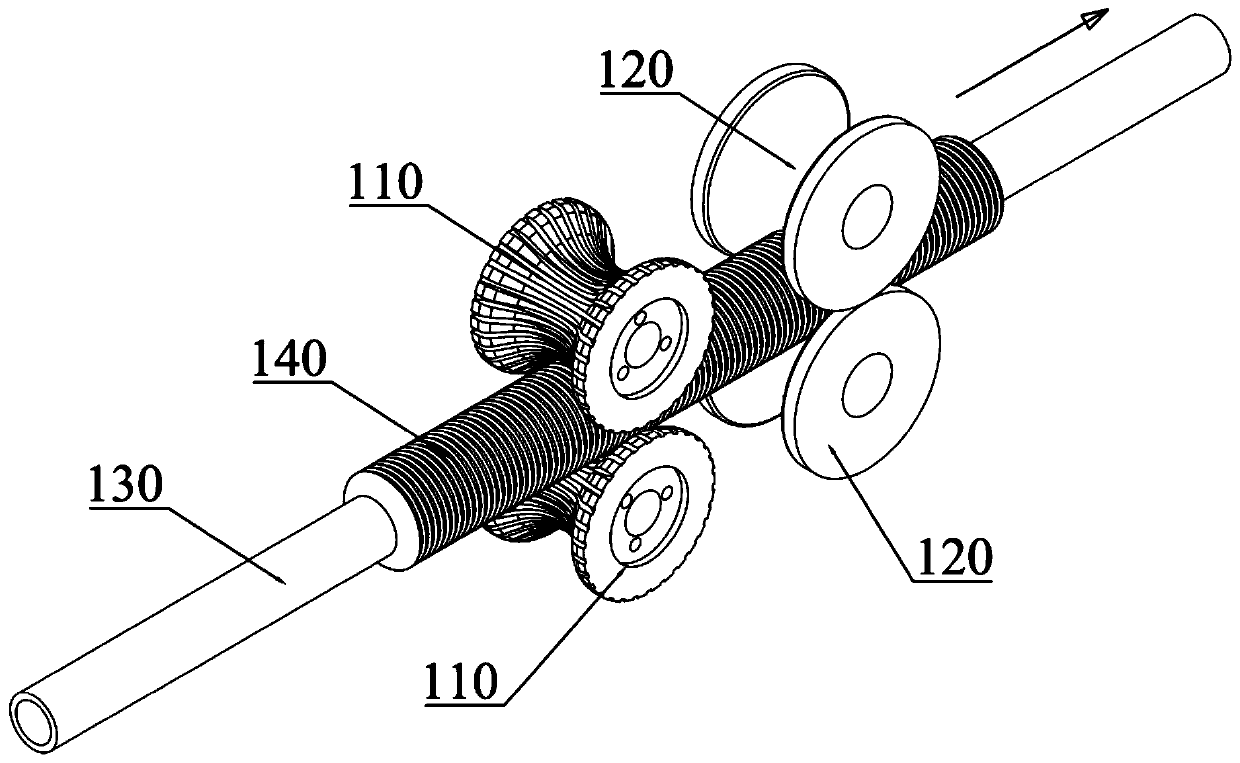

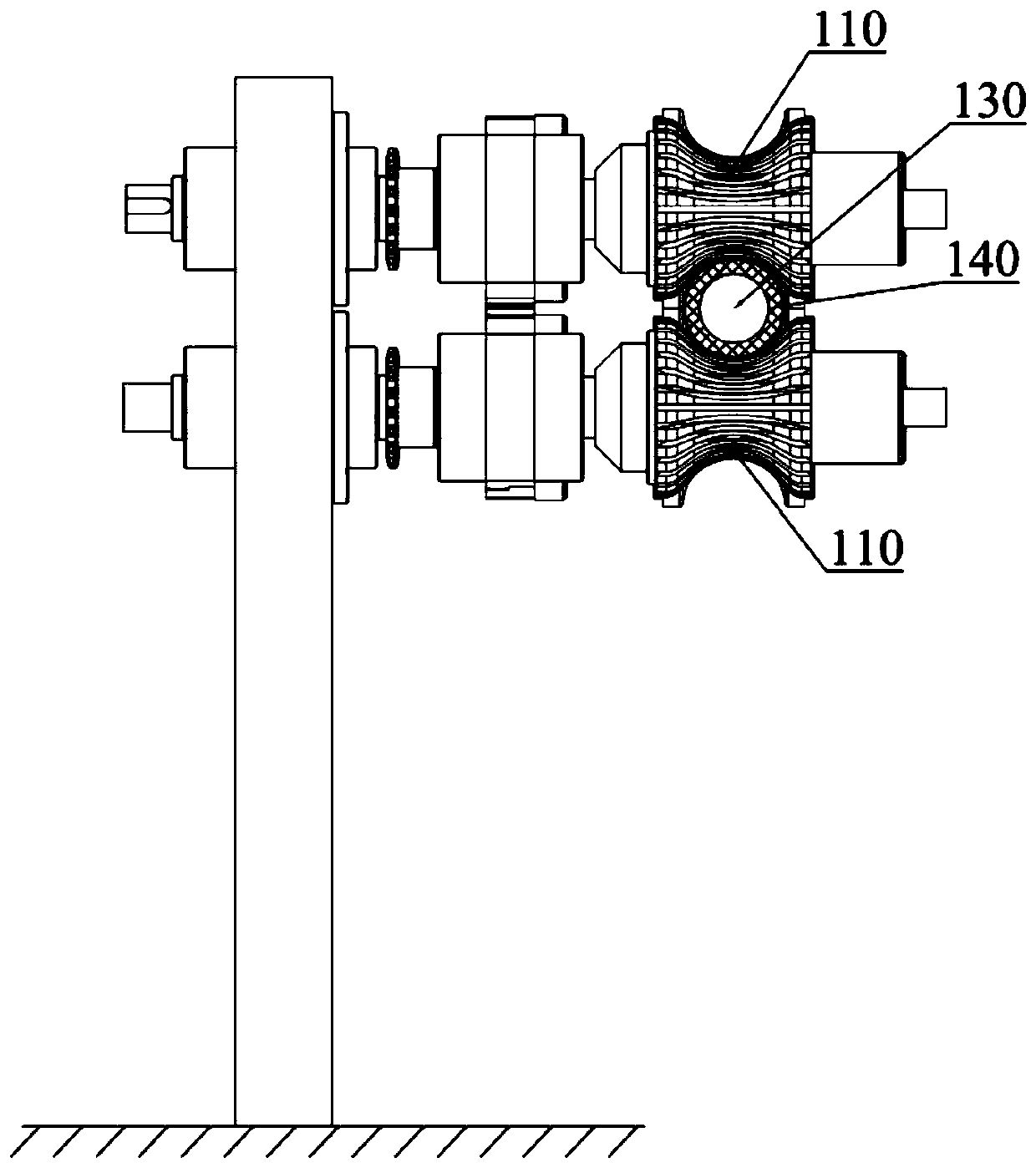

Casing feeding device and casing shrinking device with casing feeding device

ActiveCN108378117BEasy qualityNeatly foldedSausage filling/stuffing machinesStructural engineeringMechanical engineering

Owner:佛山磐砻智能科技有限公司

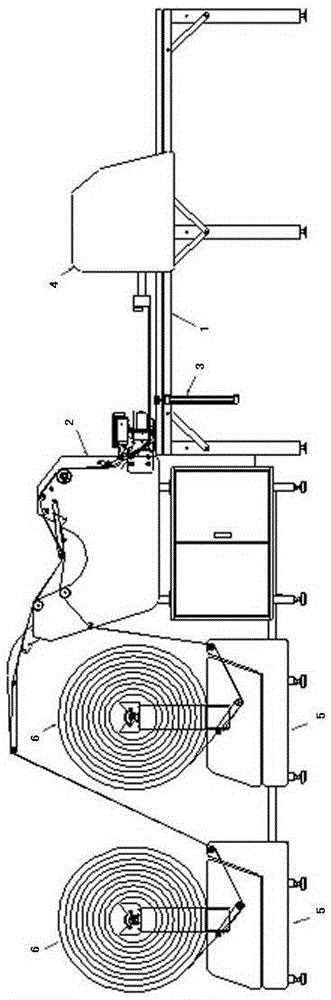

Double roll cloth cloth machine

ActiveCN103318691BImprove work efficiencyImprove spreading qualityUnfolding thin materialsArticle deliveryMechanical engineeringCotton material

This double-roll cloth cloth machine includes a bed, a main machine, a cloth pressing mechanism on the bedding bed, and a manipulator clamping mechanism slid on the bedding bed. On the side of the main machine, there are two roll fabric supports arranged in front and rear. Mechanism, implements double-roll roll cloth feeding. There are two spreading mechanisms on the main machine, which respectively spread the fabric on the two roll fabric support mechanisms. Behind the two spreading mechanisms, there is a rear rack to support A reel cloth supporting mechanism is installed at the rear to feed the cloth, and a front spreading mechanism is set in front of the two spreading mechanisms, and a pressing bar is set between the two spreading mechanisms and the front spreading mechanism, and the two spreading mechanisms send The cloth is overlapped under the pressure bar and then sent to the front spreading mechanism; there is a cloth feeding mechanism in front of the front spreading mechanism, and a cloth cutting device is installed under the feeding mechanism. The advantage is that it can carry out double-roll roll cloth spreading at the same time, and it uses the manipulator to clamp the cloth for single pulling and folding, with accurate positioning, high precision, neat folding and high work efficiency.

Owner:YYC IND CO LTD CHINA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com