Double roll cloth cloth machine

A cloth cloth machine and cloth feeding mechanism technology, which is applied in the direction of winding strips, sending objects, and spreading thin soft materials, etc., which can solve the problems of inability to spread cloth at the same time, low work efficiency, and poor quality of cloth spreading and other problems, to achieve the effect of improving the quality of spreading, improving work efficiency, and neatly stacking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

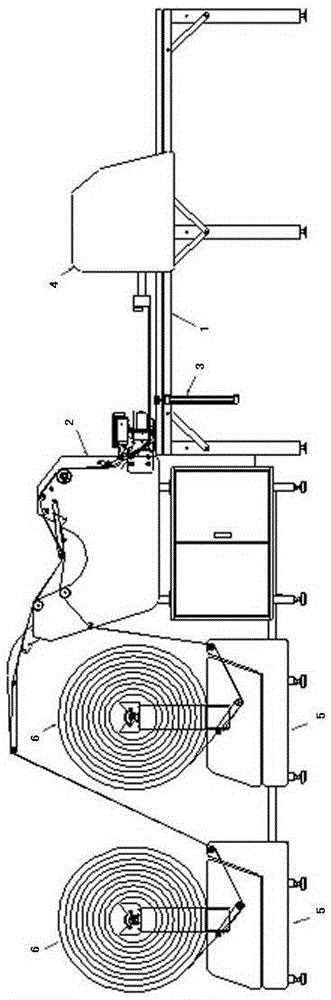

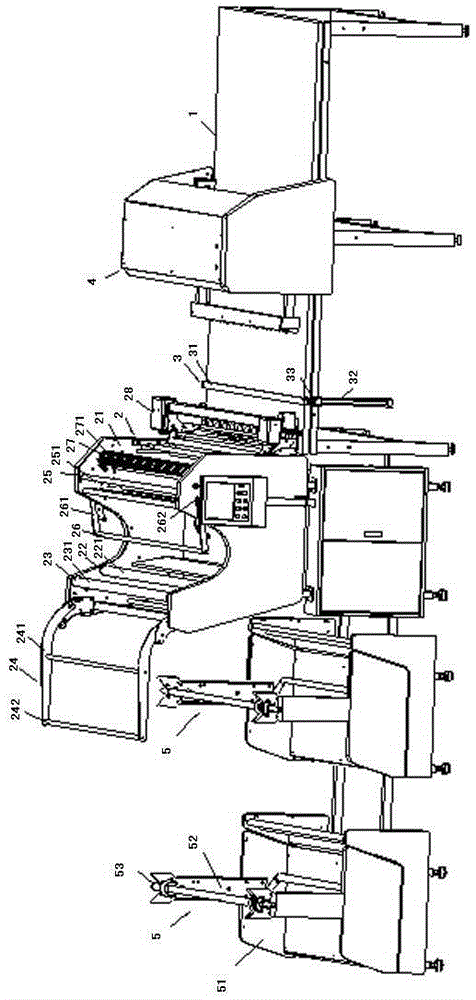

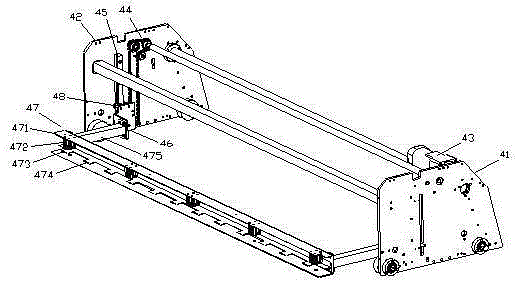

[0022] Please refer to the attached figure 1 — Figure 5 Shown, the present invention is further described.

[0023] The present invention includes bed making 1, main machine 2, cloth pressing mechanism 3 arranged on bed making 1, and manipulator cloth clamping mechanism 4 slidably arranged on bed making 1. On one side of main machine 2, two reels arranged in front and rear are arranged. The cloth support mechanism 5 implements double-roll reel cloth feeding, and two spreading mechanisms 22 and 23 are arranged on the host machine 2 to spread the cloth on the two reel cloth supporting mechanisms 5 respectively. The two spreading mechanisms 22 , 23 rears, be provided with rear frame 24, support a reel cloth supporting mechanism 5 that rear is provided with cloth feeding, two spreading mechanisms 22,23 fronts are provided with front spreading mechanism 25, in two spreading mechanisms 22,23 Between the front spreading mechanism 25, there is a pressing bar 26, and the cloth sent ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com