Patents

Literature

42results about How to "Reasonable structure arrangement" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

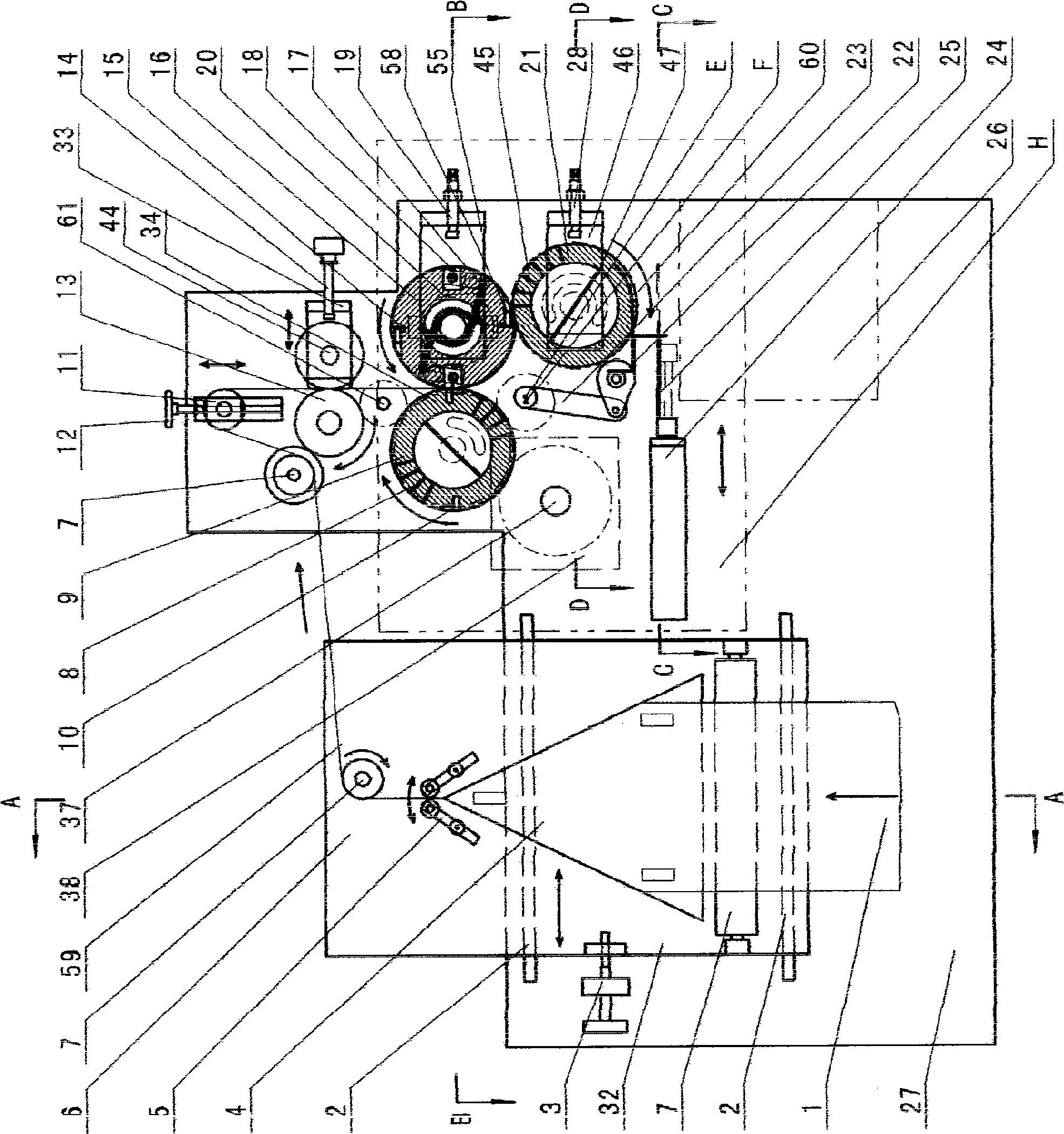

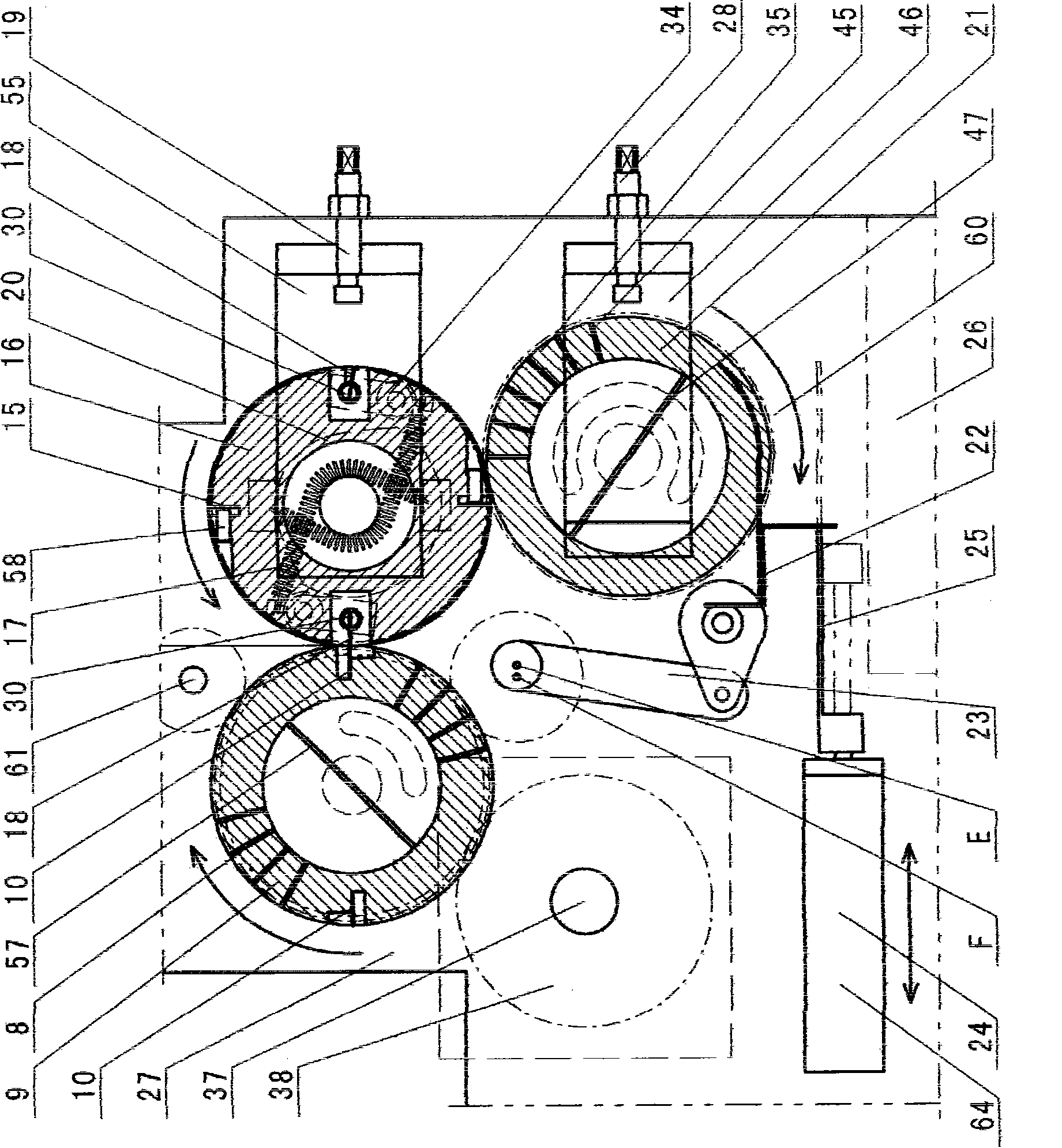

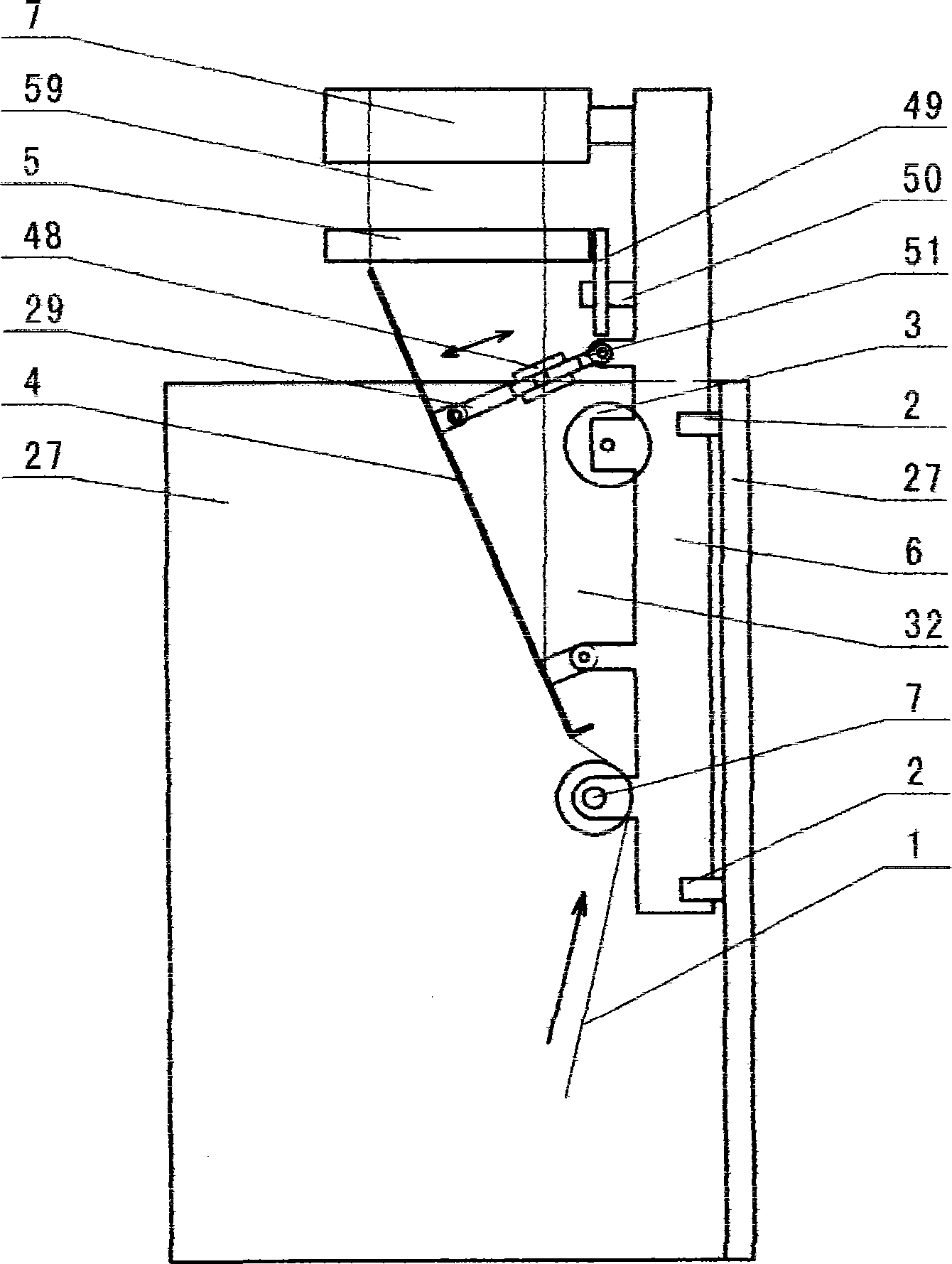

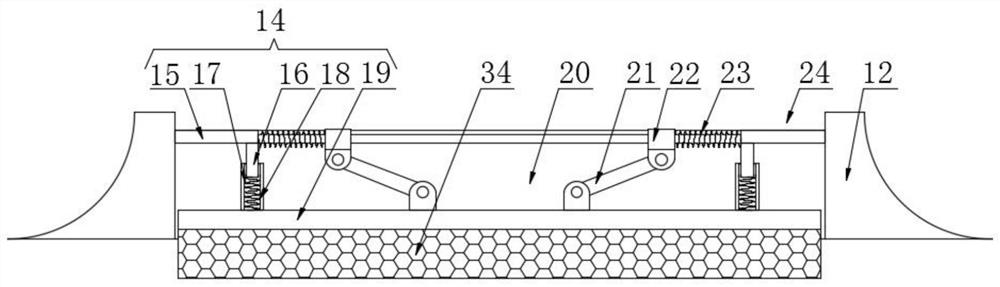

Technique for folding and producing adsorption type napkin paper and device thereof

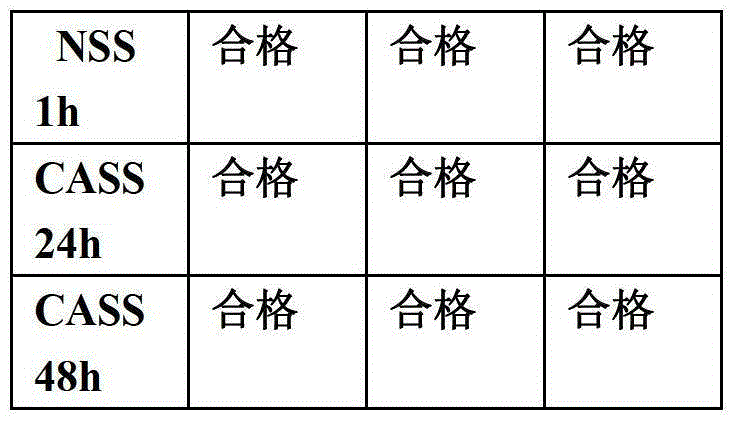

InactiveCN101474891ARealize in-line printingRealize the collectionPaper/cardboard articlesHigh ratePulp and paper industry

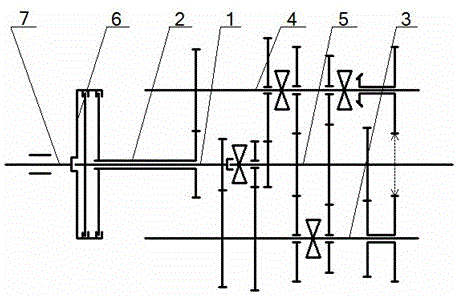

The invention relates to a high-speed adsorption napkin paper folding and manufacturing process and device needing wire printing and folding. The prior adopted mechanical linkage vertical folding structure has the defects of complex structure, low folding accuracy, more fault points, low rate of finished products, low production efficiency, and the like. Therefore, the invention designs the adsorption napkin paper folding and manufacturing process and device. The process comprises that: the napkin paper is pulled by a traction mechanism, aligned and longitudinally folded by a longitudinal folding mechanism, smoothed by a compression roller and then aligned by an aligning mechanism, fed into an adsorption transversely folding mechanism through the traction mechanism and then aligned and transversely folded; and then the longitudinally folded paper is cut by a cutting knife roll, and manufactured into finished products by an adsorption counting mechanism and a collecting and packaging mechanism. The process and the device achieve wire printing and folding of the napkin paper conveniently and reliably, have the advantages of high folding accuracy, few fault points, high rate of finished products, high production efficiency, stable quality of the products and low production cost, and are suitable for large-scale industrialized production.

Owner:李玉龙

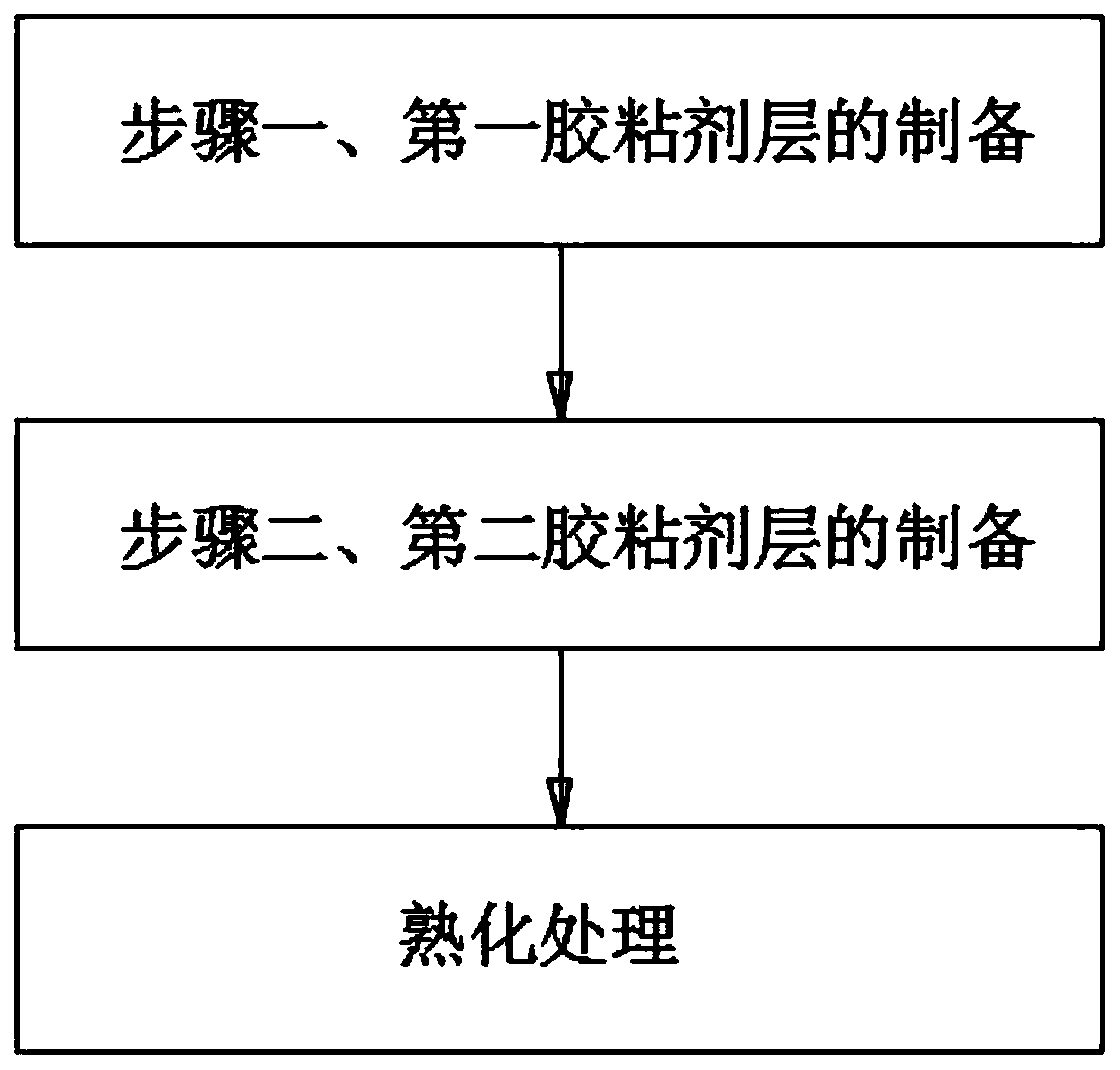

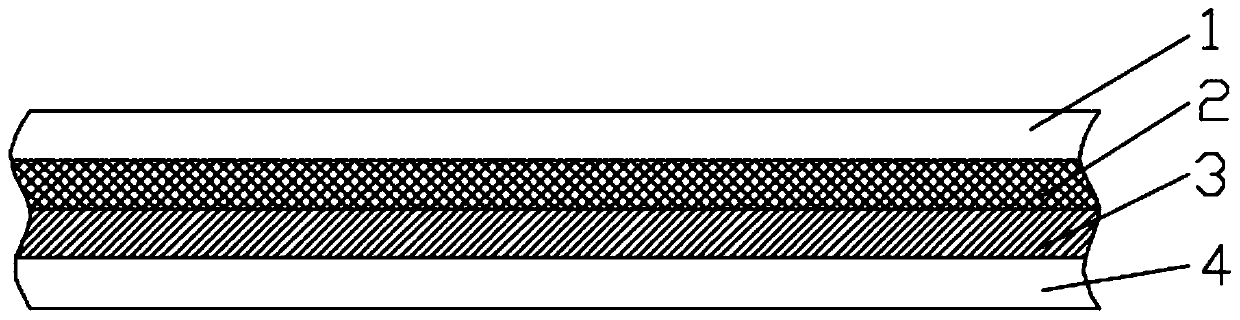

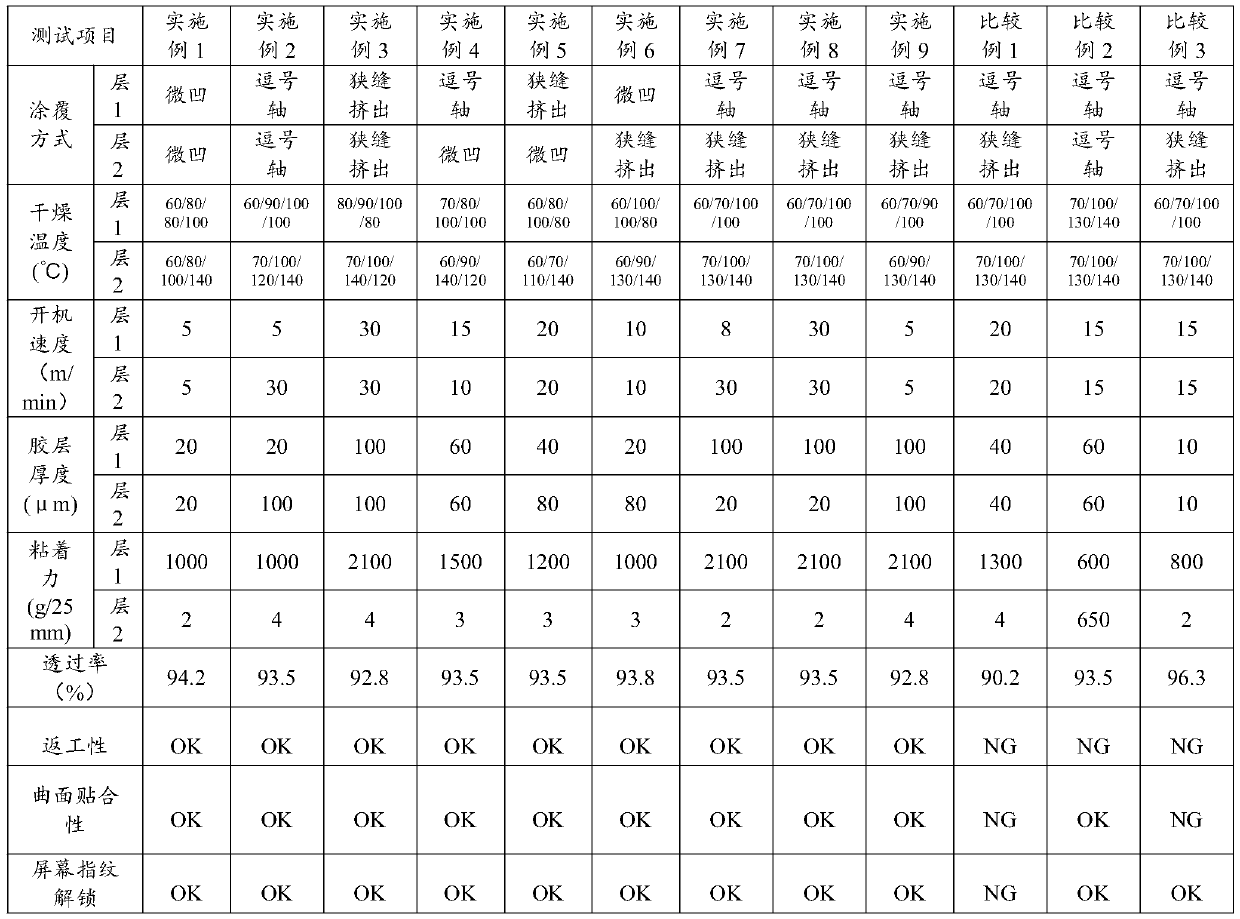

Preparation method of novel AB adhesive film

PendingCN110982437AUniform thicknessGood lookingEster polymer adhesivesFilm/foil adhesives without carriersAdhesive cementPolymer science

The invention discloses a preparation method of a novel AB adhesive film. The novel AB adhesive film comprises a first release layer, a first adhesive layer, a second adhesive layer and a second release layer, wherein the first adhesive layer and the second adhesive layer are arranged up and down and directly bonded together, the first release layer is bonded on the upper side of the first adhesive layer, and the second release layer is bonded on the lower side of the second adhesive layer. The preparation method comprises the steps: 1, preparation of the first release layer; 2, preparation ofthe second adhesive layer, and bonding of the first release layer, the first adhesive layer, the second adhesive layer, and the second release layer. The preparation method is ingenious in conception, reasonable in structural arrangement, softer in material, good in following performance, better in consistency and fitness of electronic product protection and better in sensitivity for fingerprintunlocking products.

Owner:宁波启合新材料科技有限公司

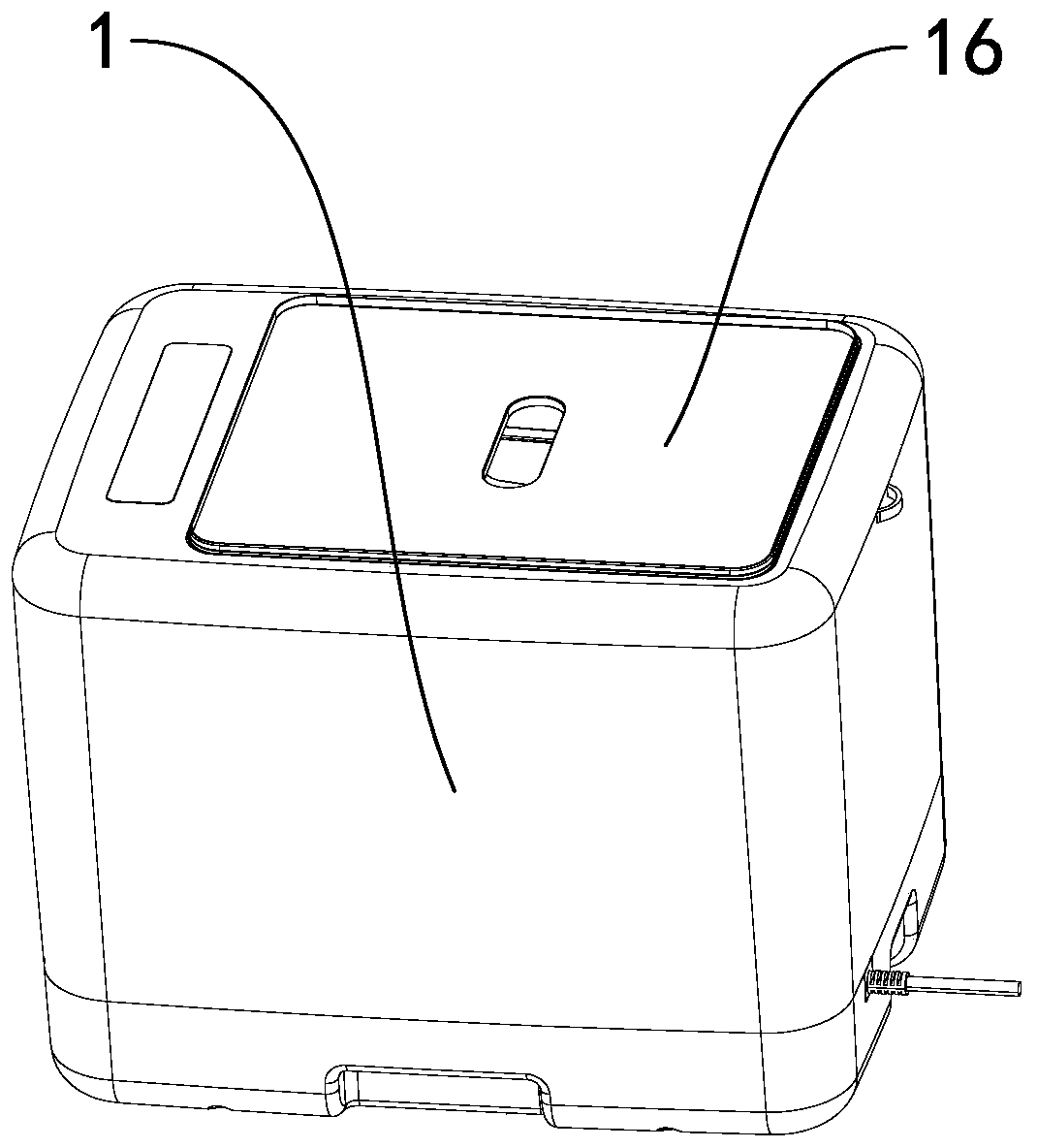

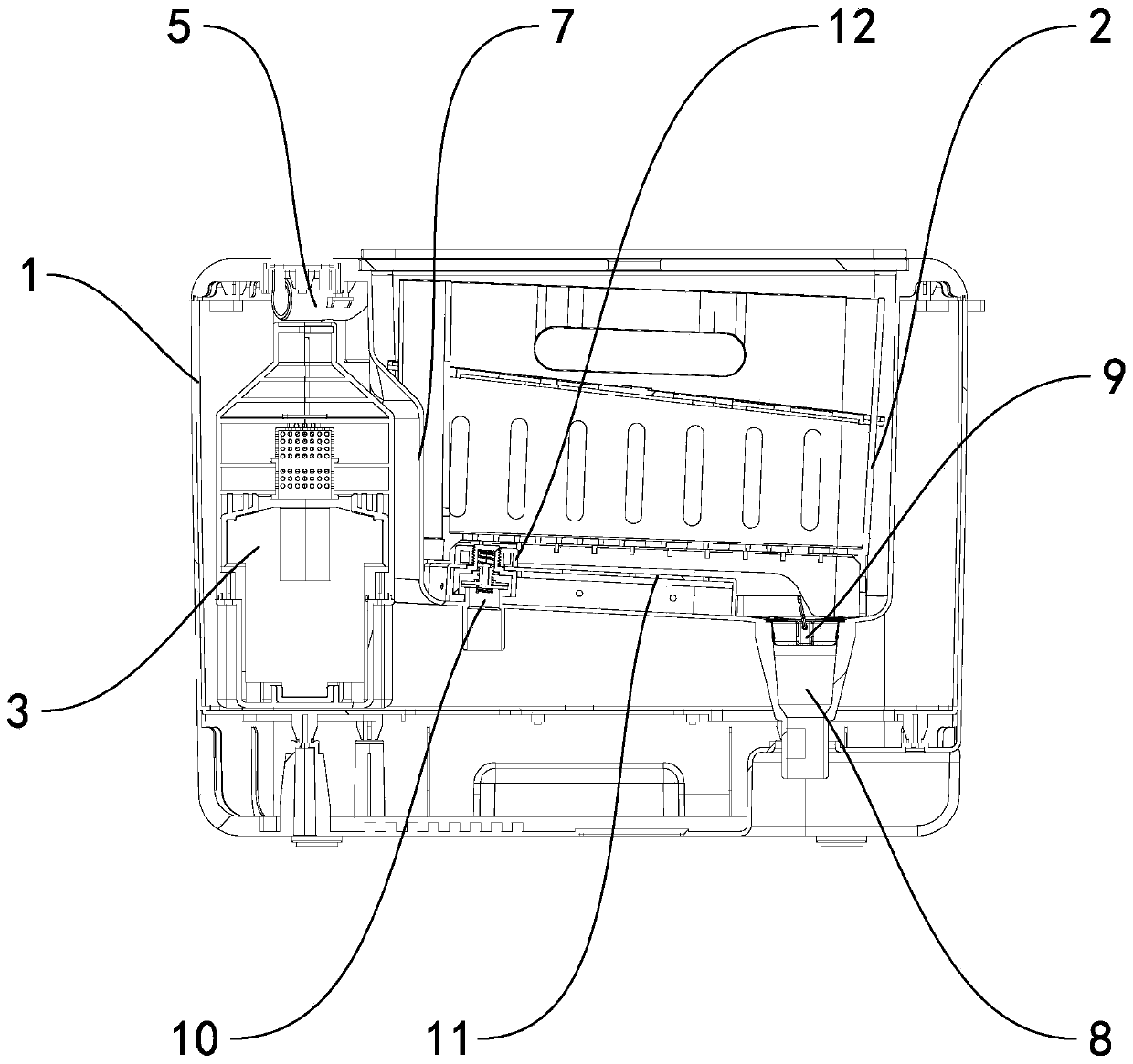

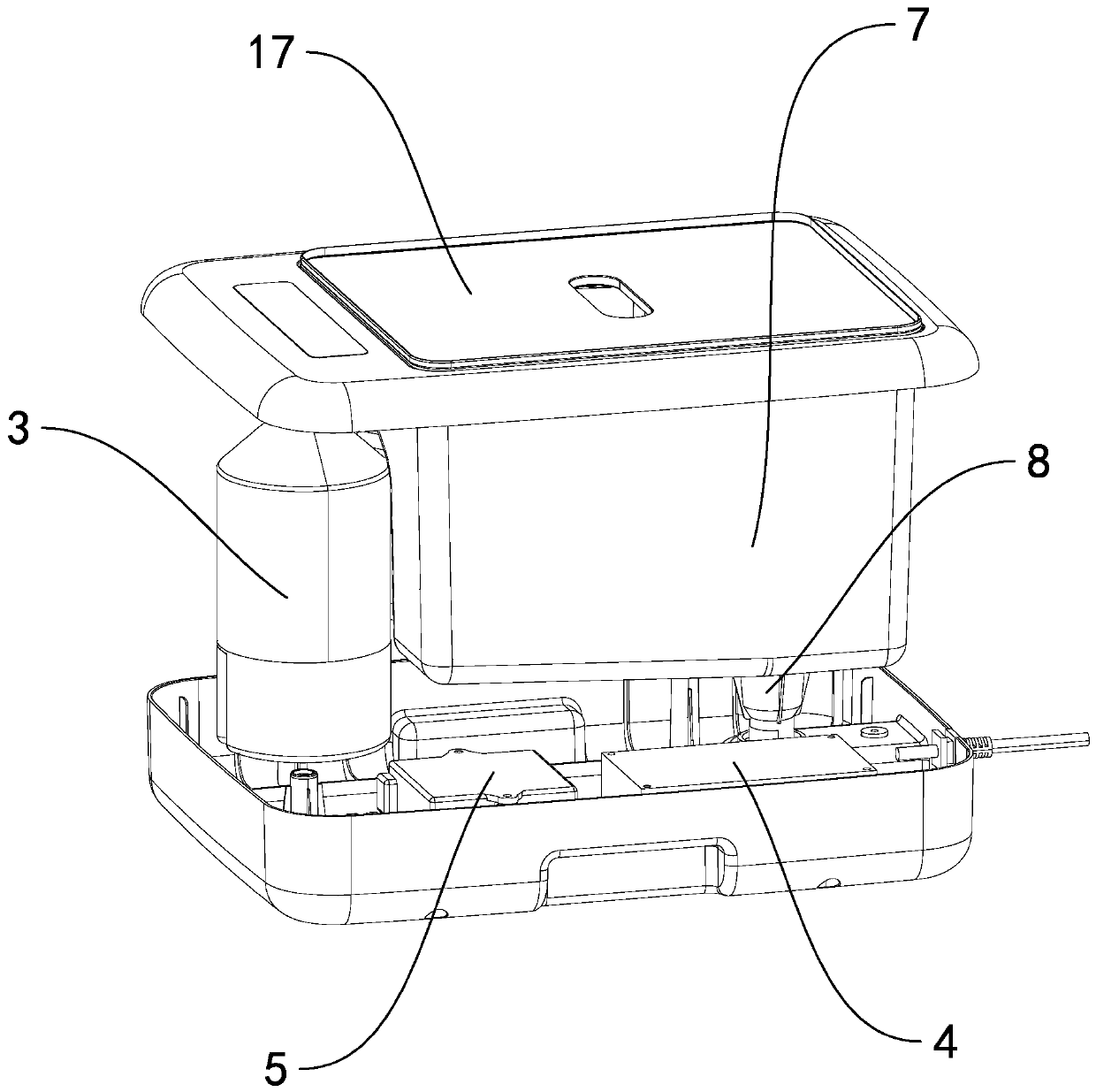

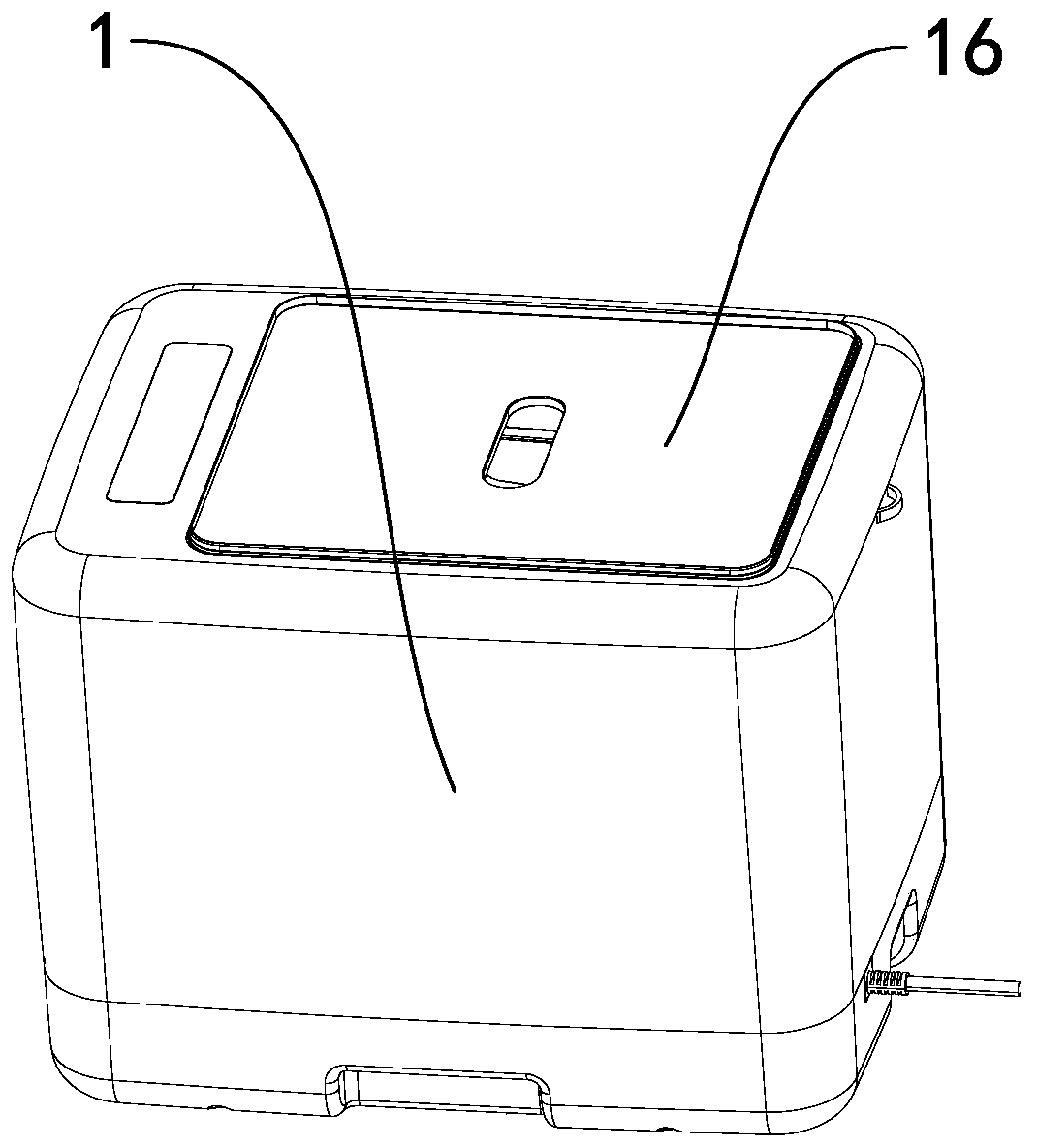

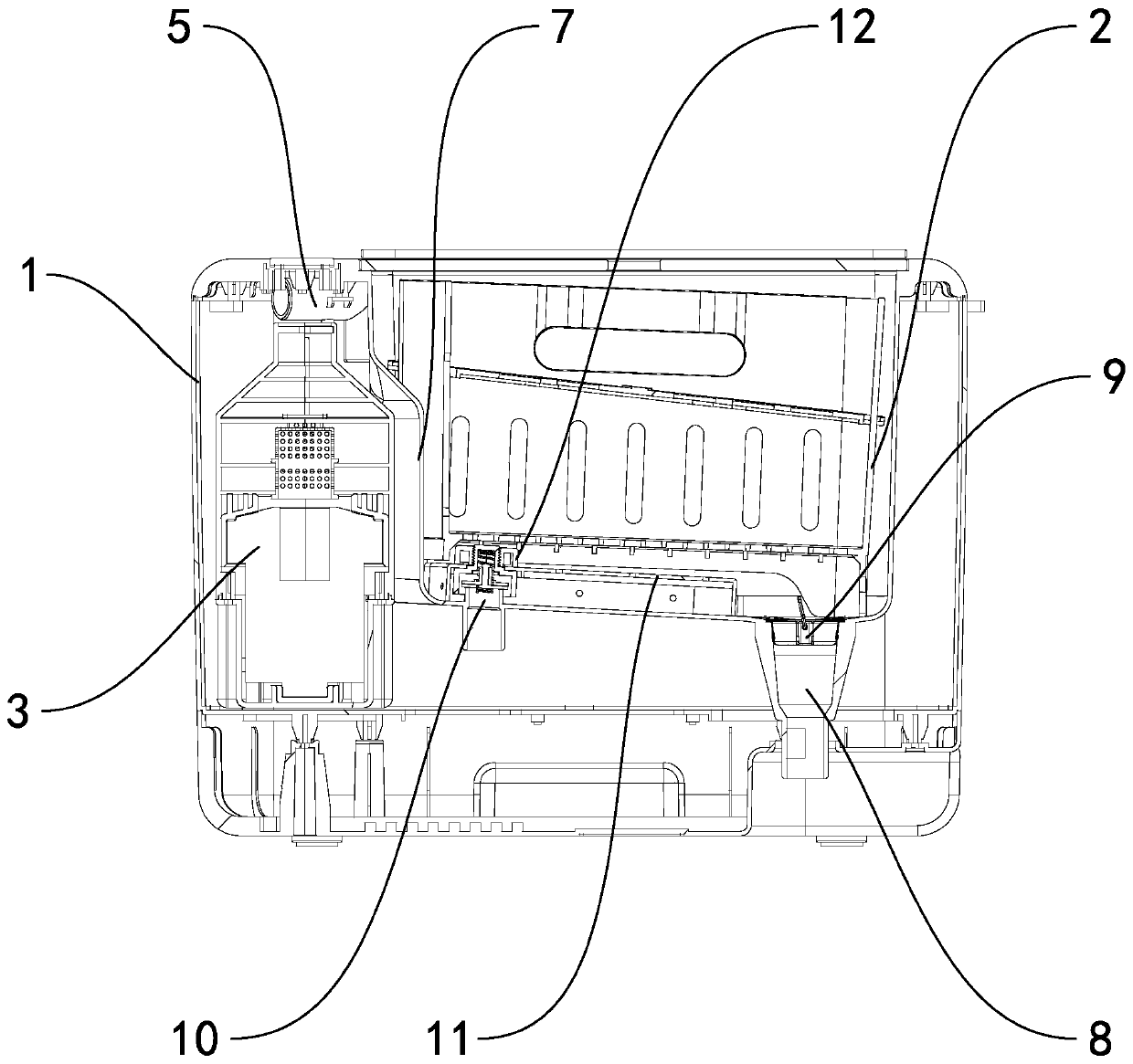

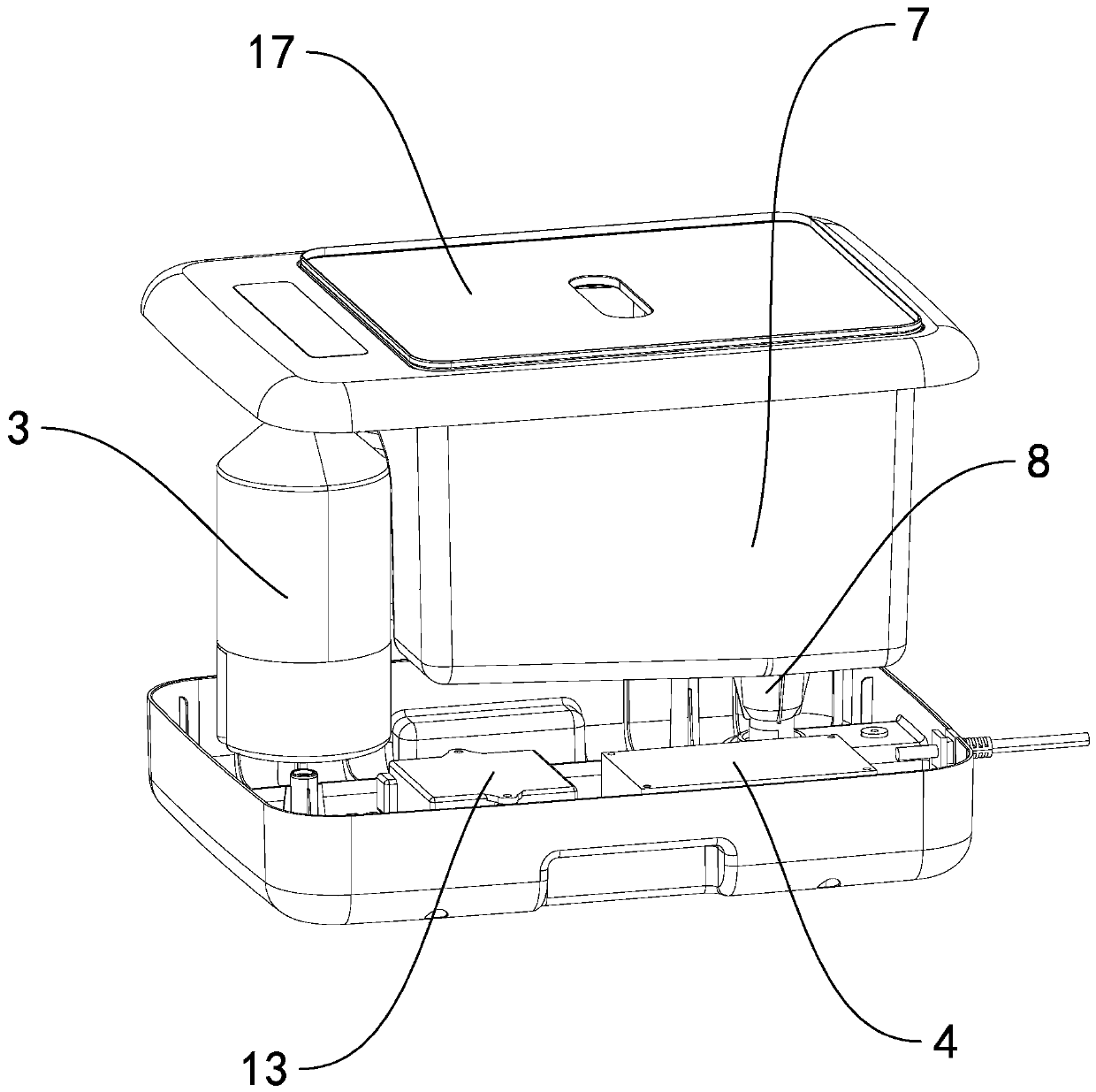

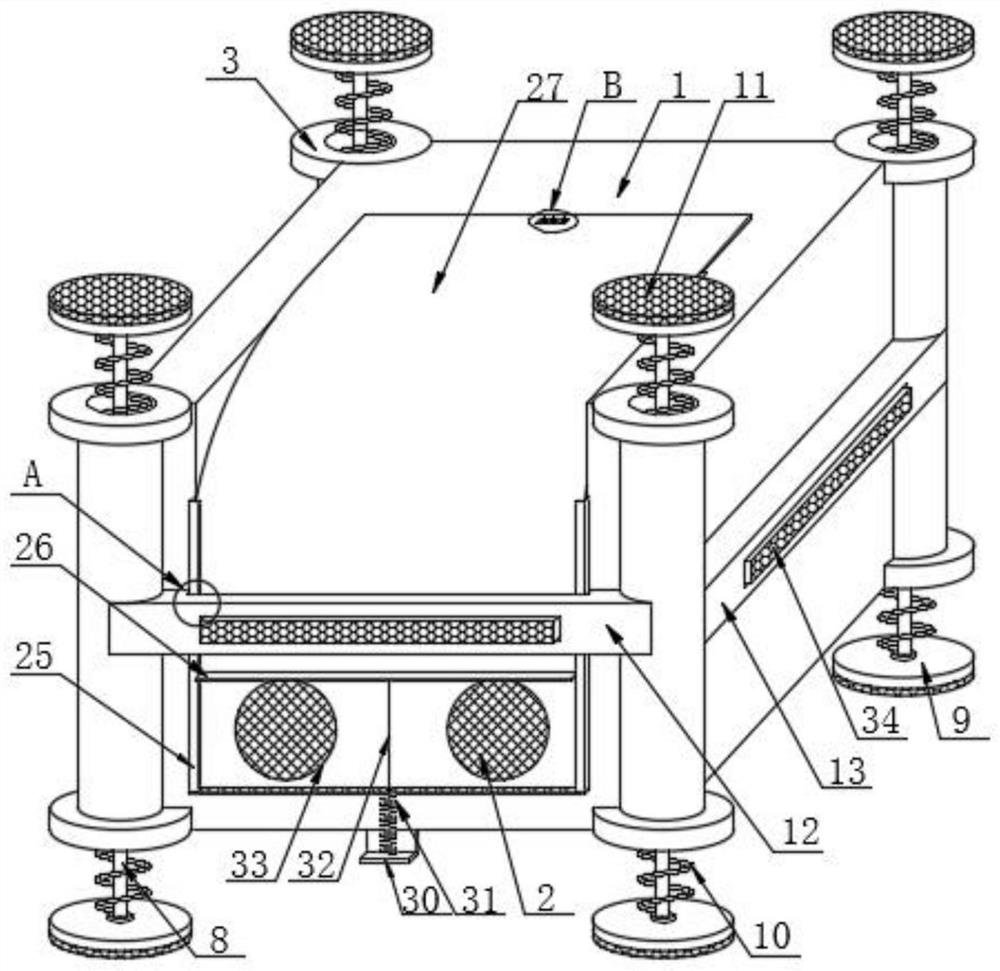

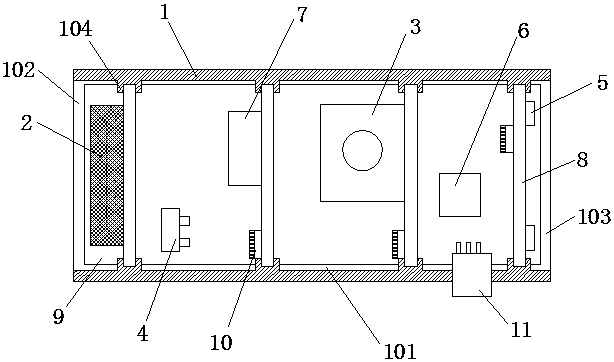

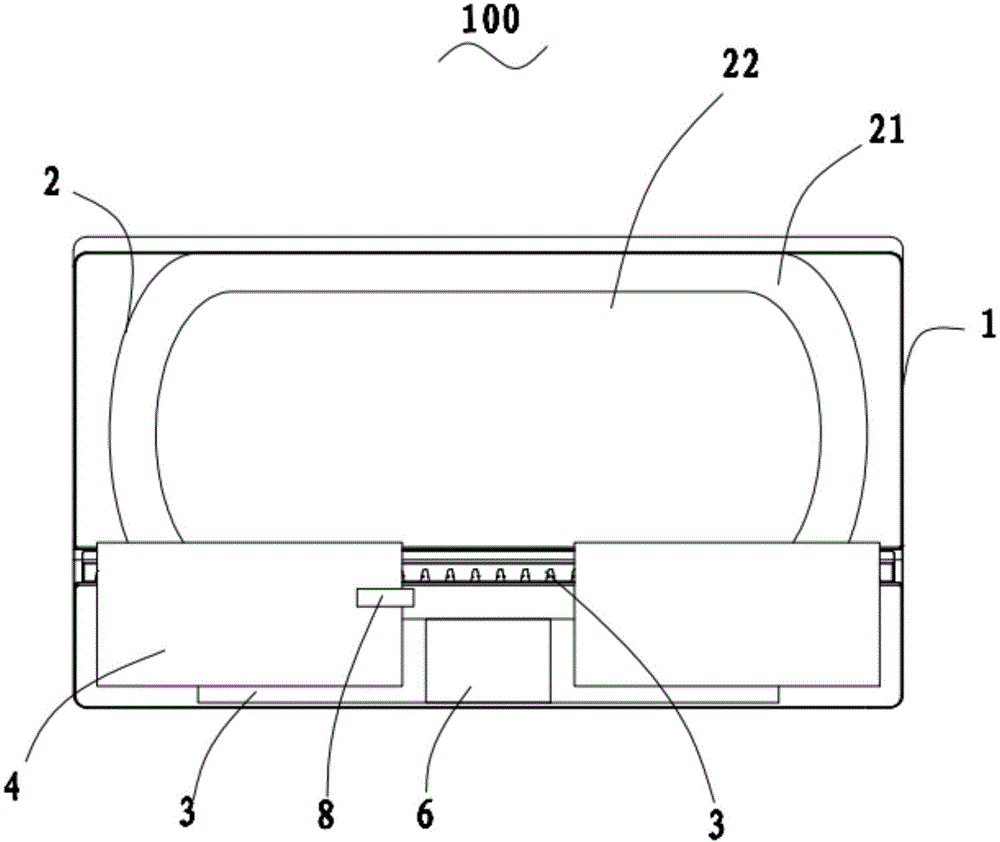

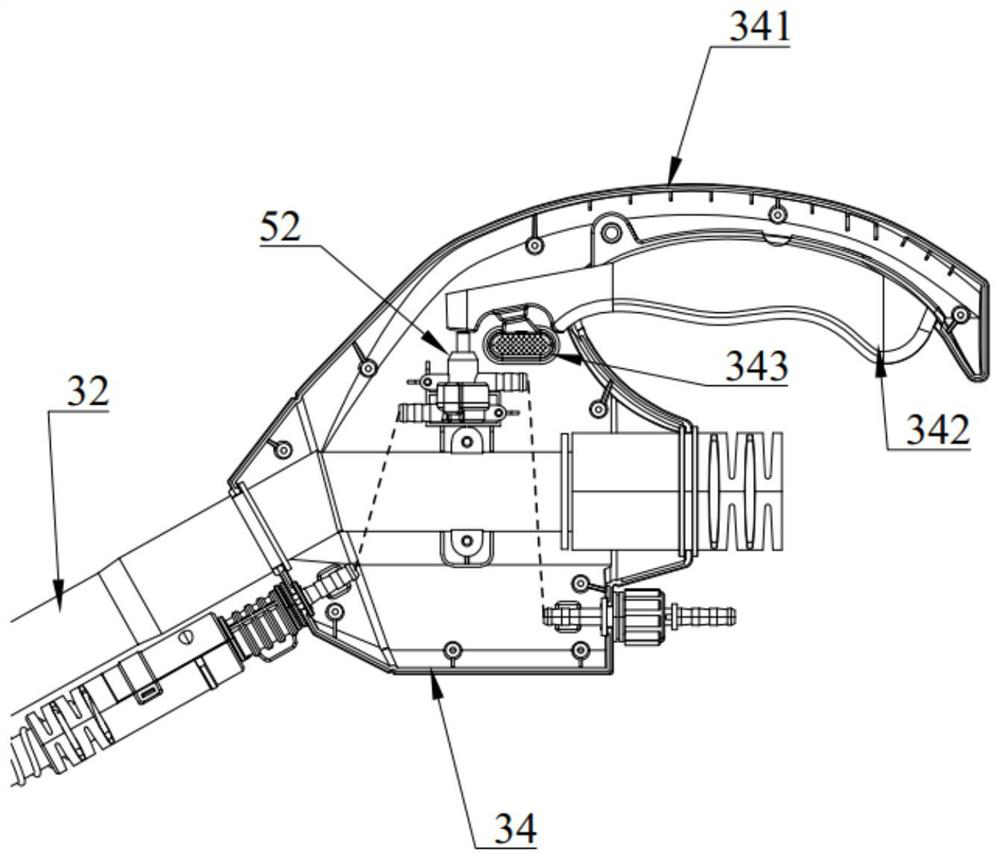

Fruit and vegetable cleaning machine

PendingCN111265125AReasonable structure arrangementReduce volumeKitchen equipmentAir pumpEnvironmental engineering

The invention discloses a fruit and vegetable cleaning machine, which comprises an outer housing, and a cleaning tank, a gas generation device and an ozone generator which are arranged in the outer housing. The gas generating device is arranged at the side of the cleaning tank, a pipeline connecting piece is arranged on the upper portion of the outer housing, the gas generating device and the ozone generator are connected to a gas inlet of the pipeline connecting piece, and a gas outlet of the pipeline connecting piece is connected with a gas outlet pipe and communicated to the bottom of the cleaning tank. The internal structure is reasonably arranged, and clean water is prevented from flowing back into an air pump.

Owner:NINGBO MEIGAO KITCHENWARE CO LTD

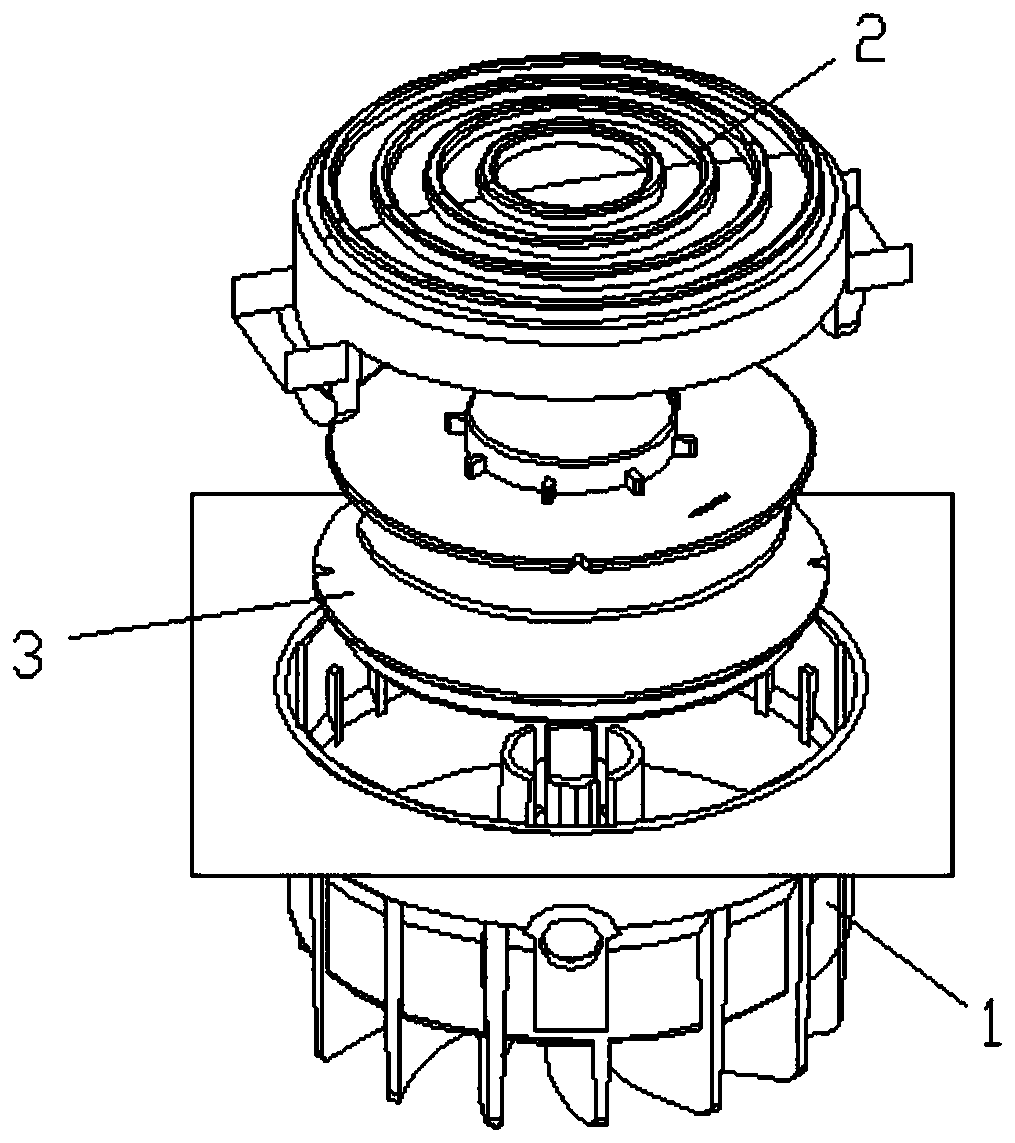

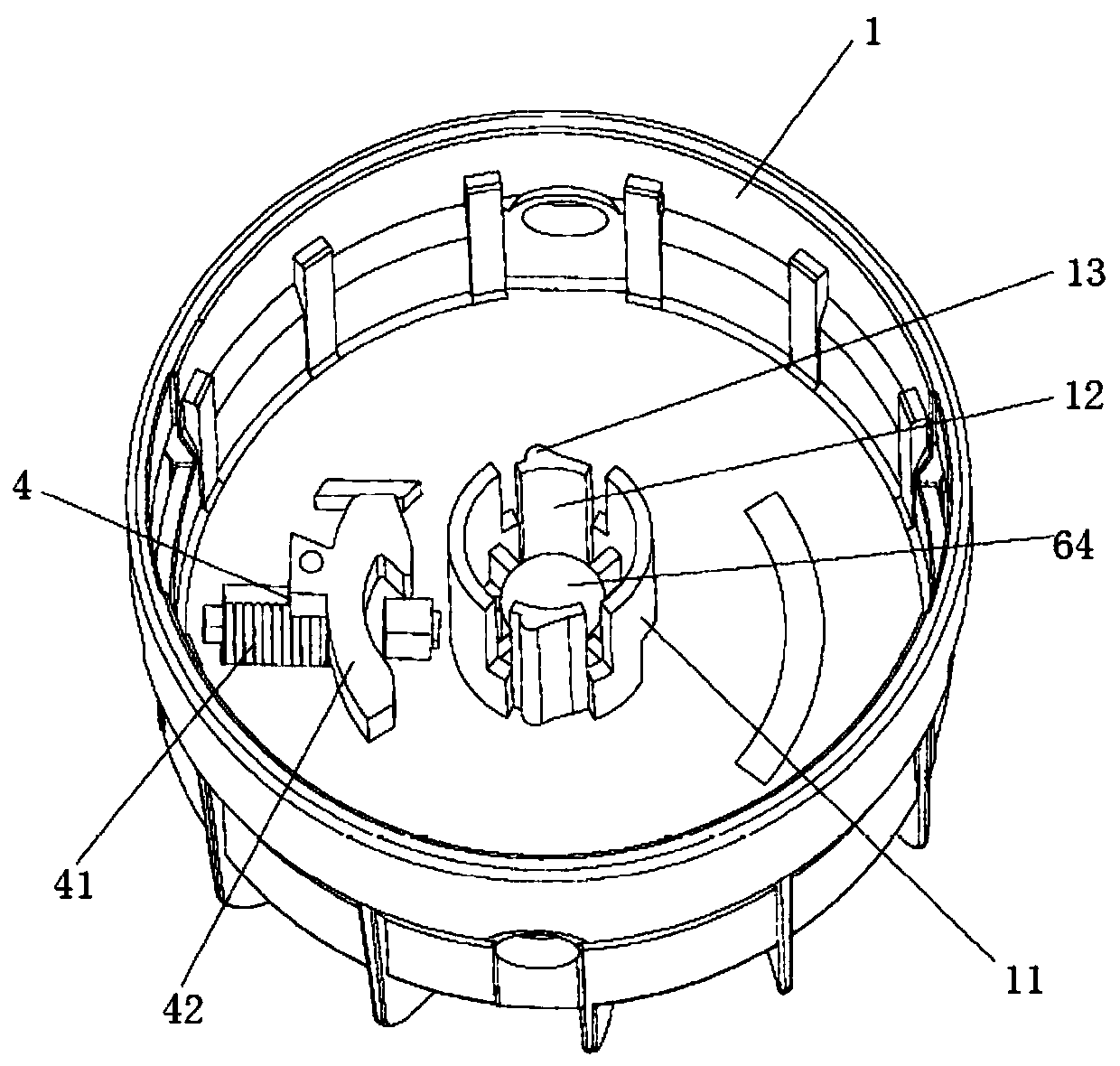

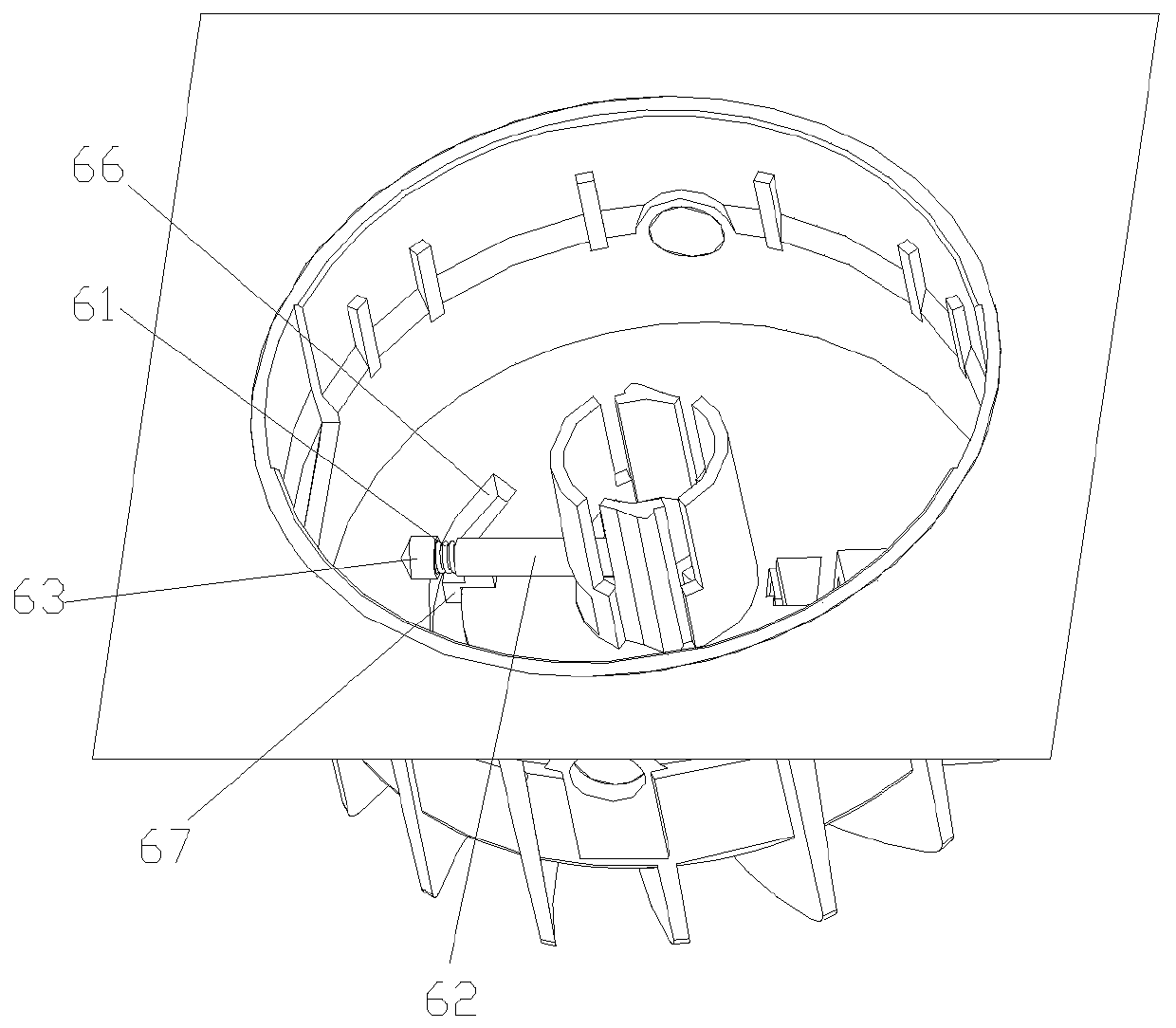

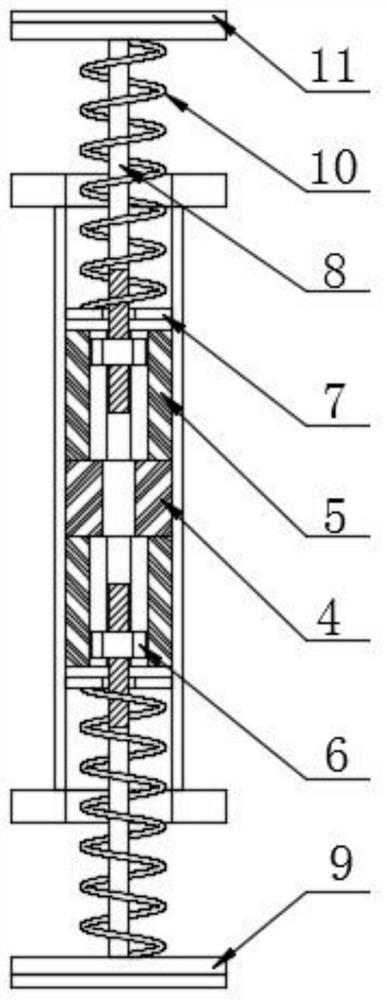

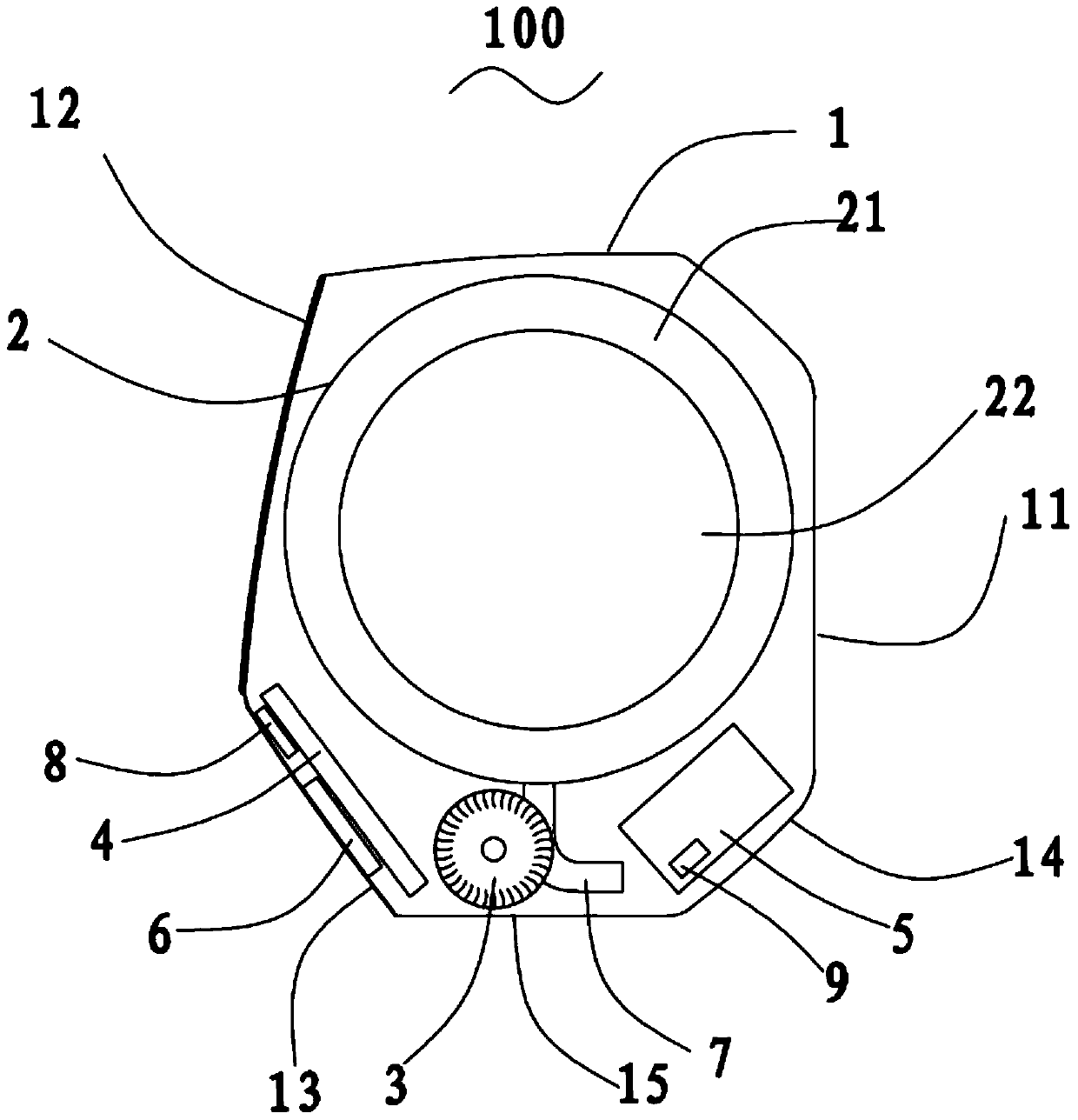

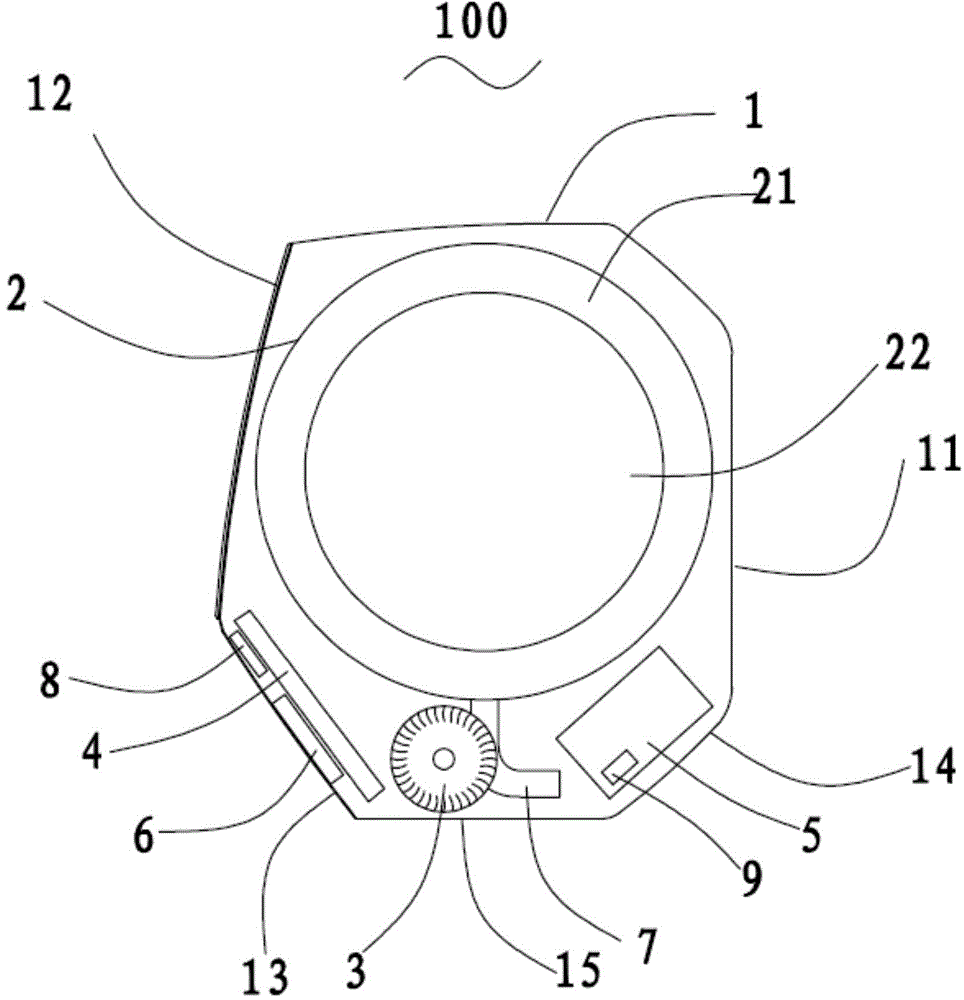

Winding structure of unwinding box of grass mower

The invention discloses a winding structure of an unwinding box of a grass mower. The structure comprises the unwinding box and a wire coil arranged in the unwinding box; a supporting part for rotating and supporting is arranged in the unwinding box, the wire coil is matched with the supporting part through a shaft hole of the wire coil, and a ratchet assembly is arranged between the wire coil and the unwinding box and comprises an automatic unwinding assembly and a manual unwinding assembly; an inner gear ring and an outer gear ring are coaxially arranged on the wire coil. The automatic unwinding assembly includes a first spring pressing a first pawl towards the outer gear ring; the manual unwinding assembly includes a second spring pressing a second pawl towards the inner gear ring. The structure is reasonable in arrangement, and the axial relative rotation is based on a damping force, so that reduction of friction is facilitated, the unwinding moment is shortened, and the service life of an automatic unwinding device is prolonged. Meanwhile, due to the arrangement of two unwinding structures, more unwinding modes can be provided, the problem of improper matching caused by automatic unwinding is avoided, and the practicability and working stability of the winding structure are improved.

Owner:SUZHOU YUYUAN MASCH CO LTD

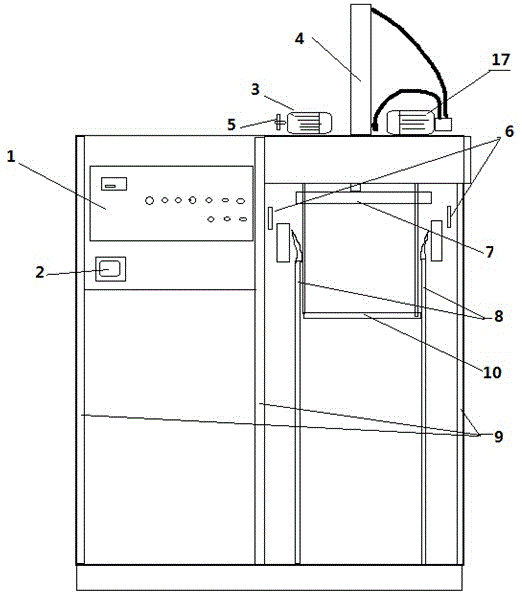

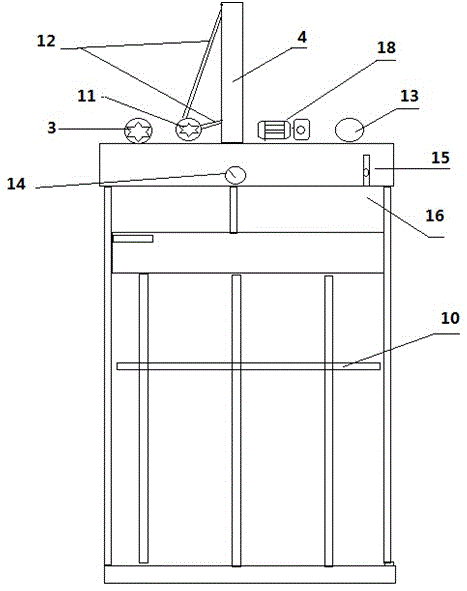

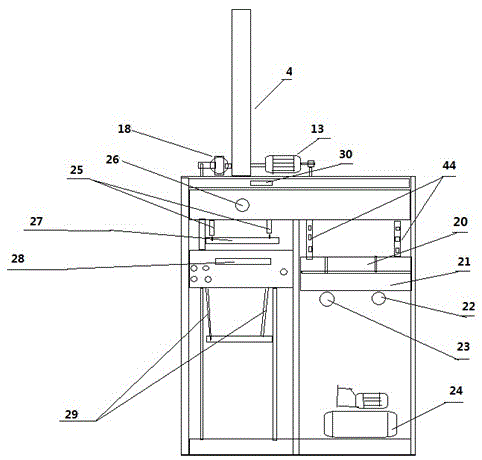

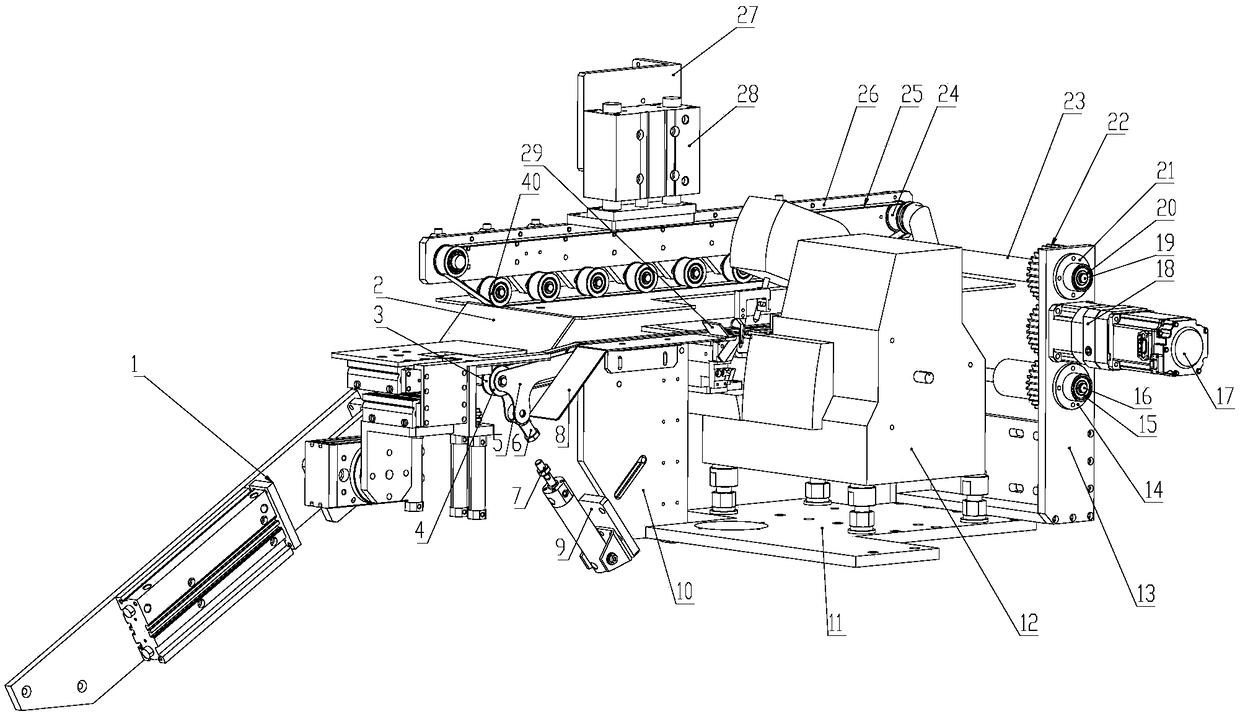

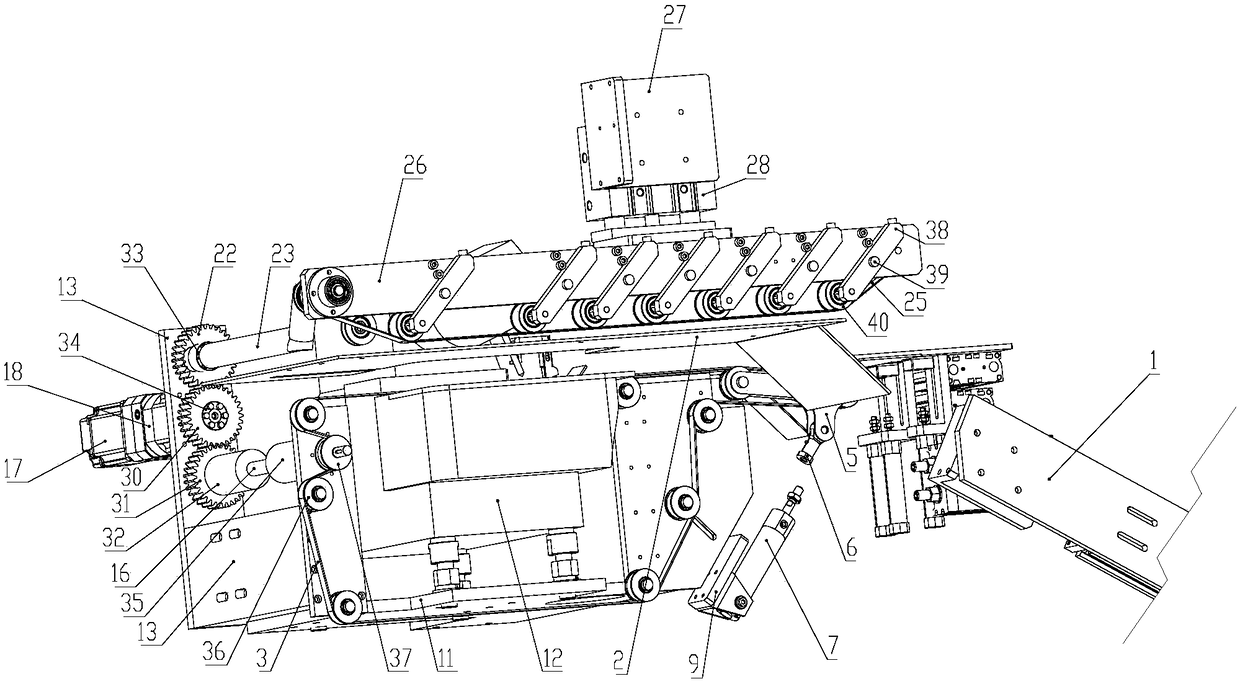

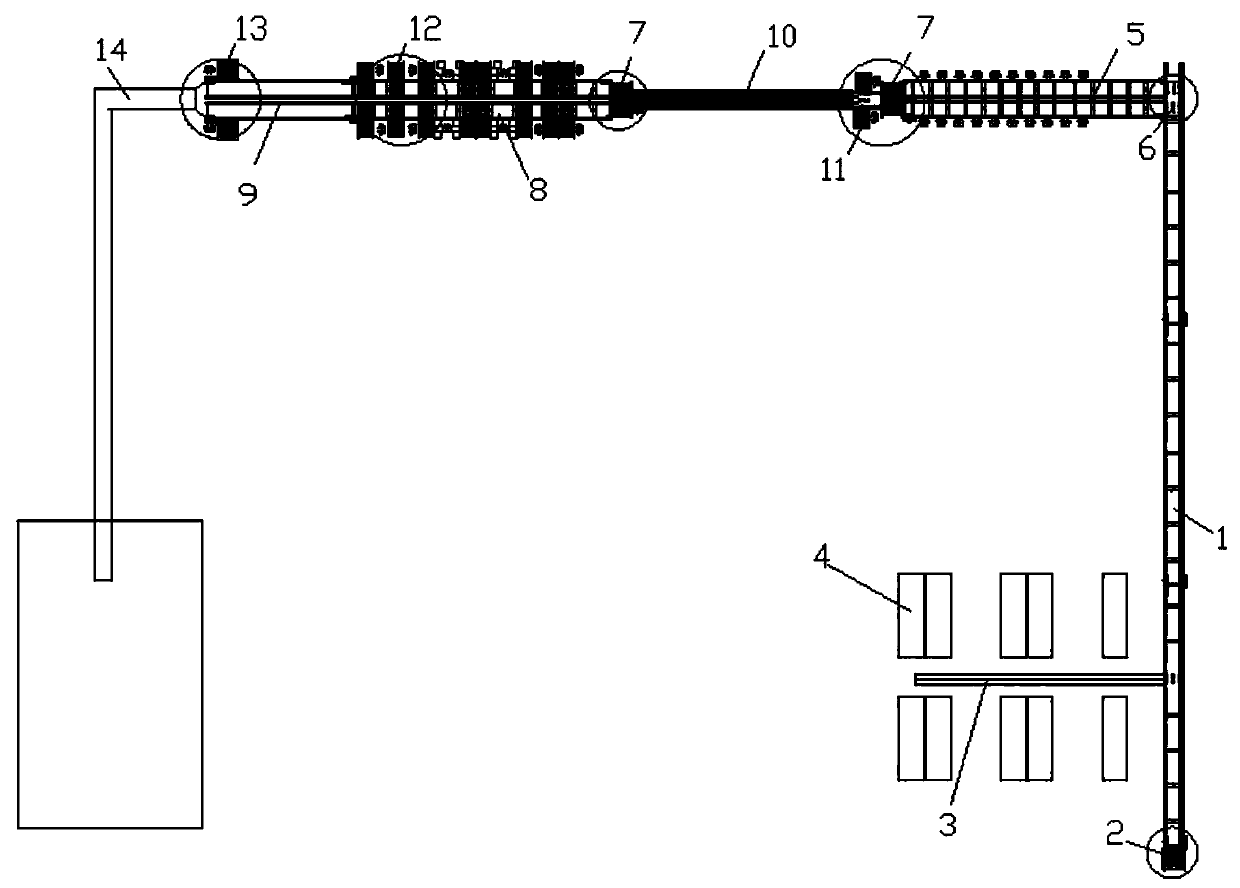

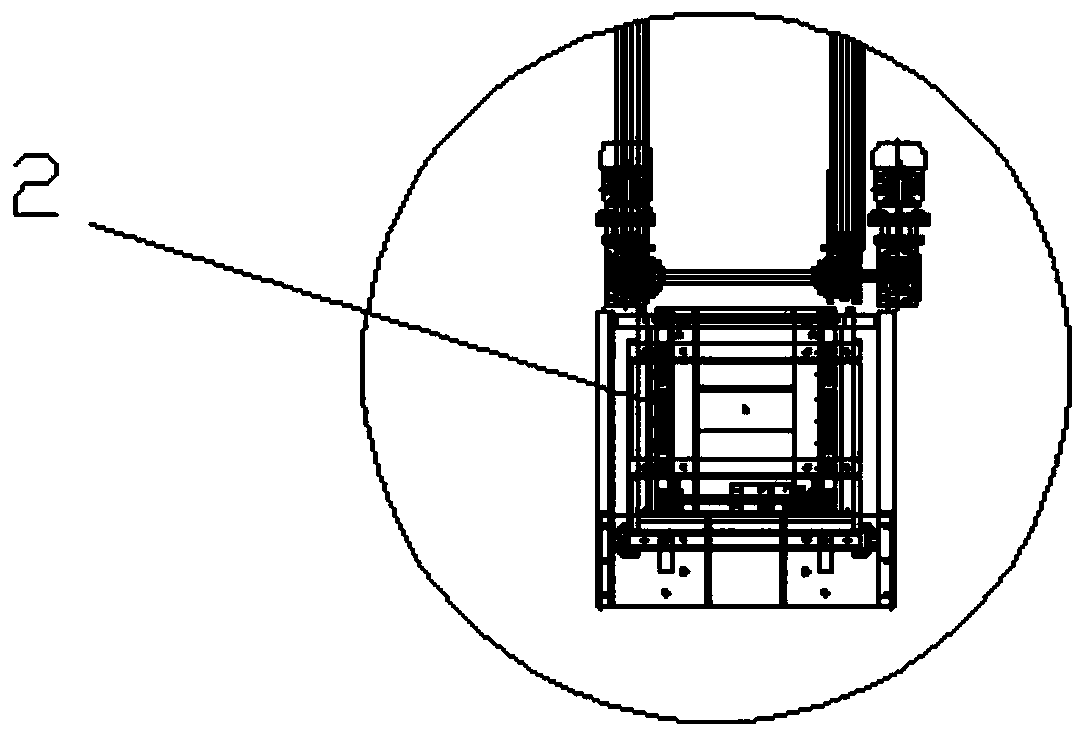

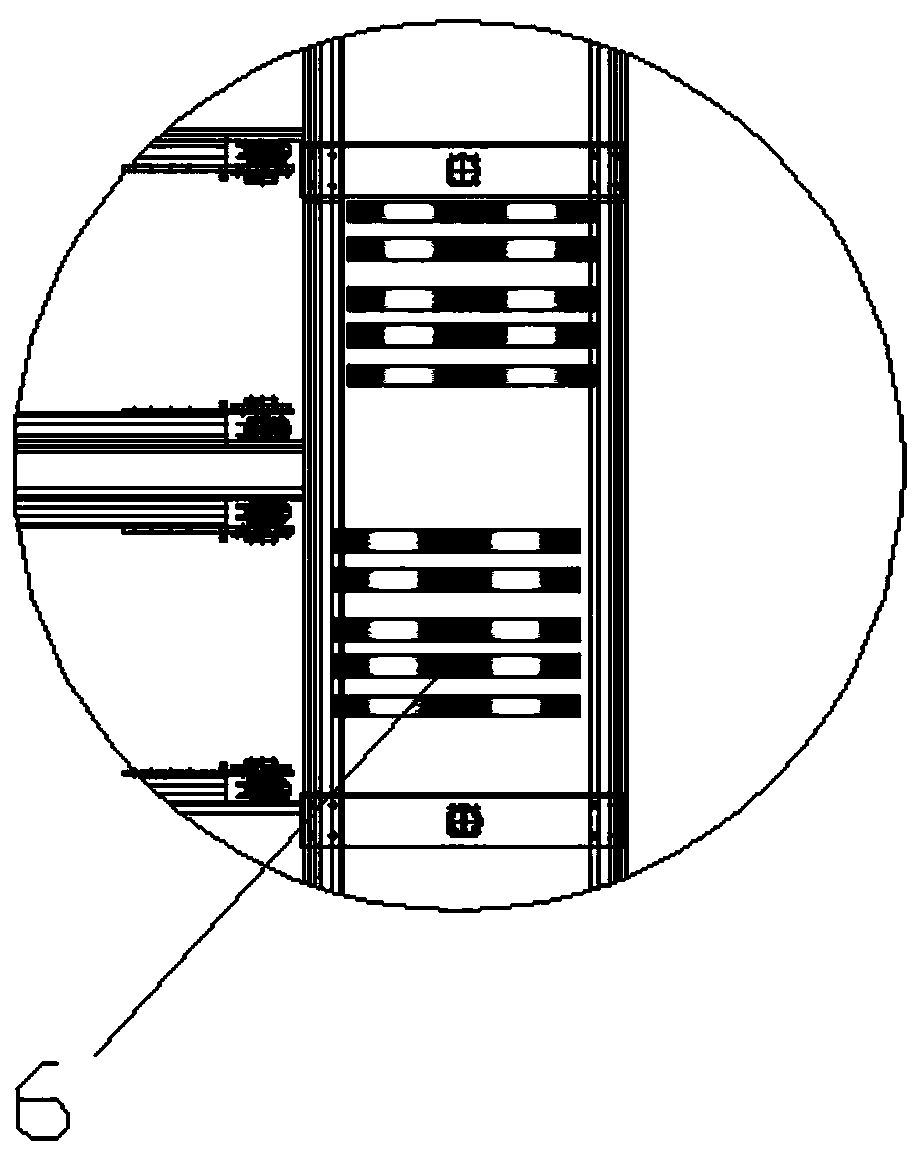

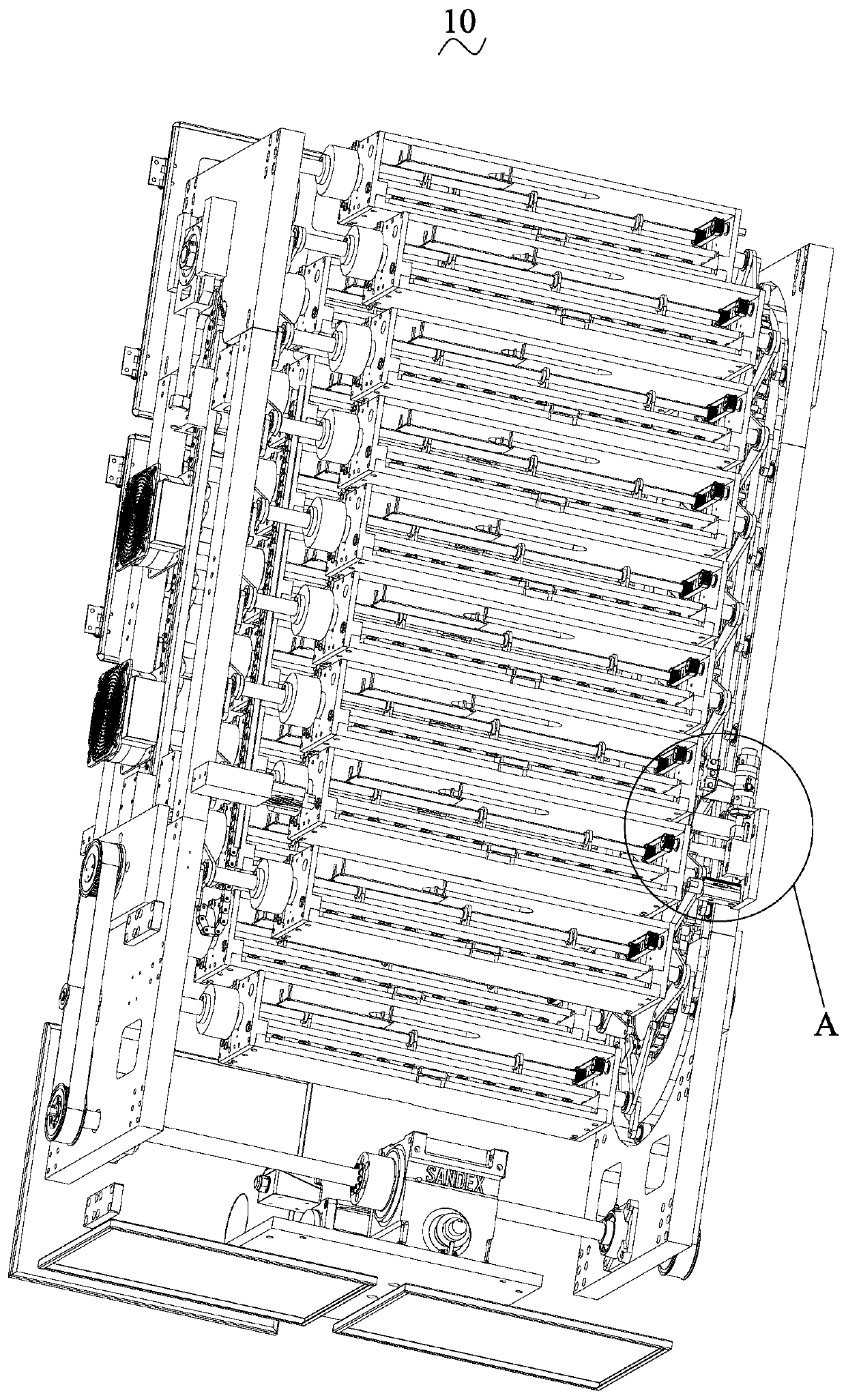

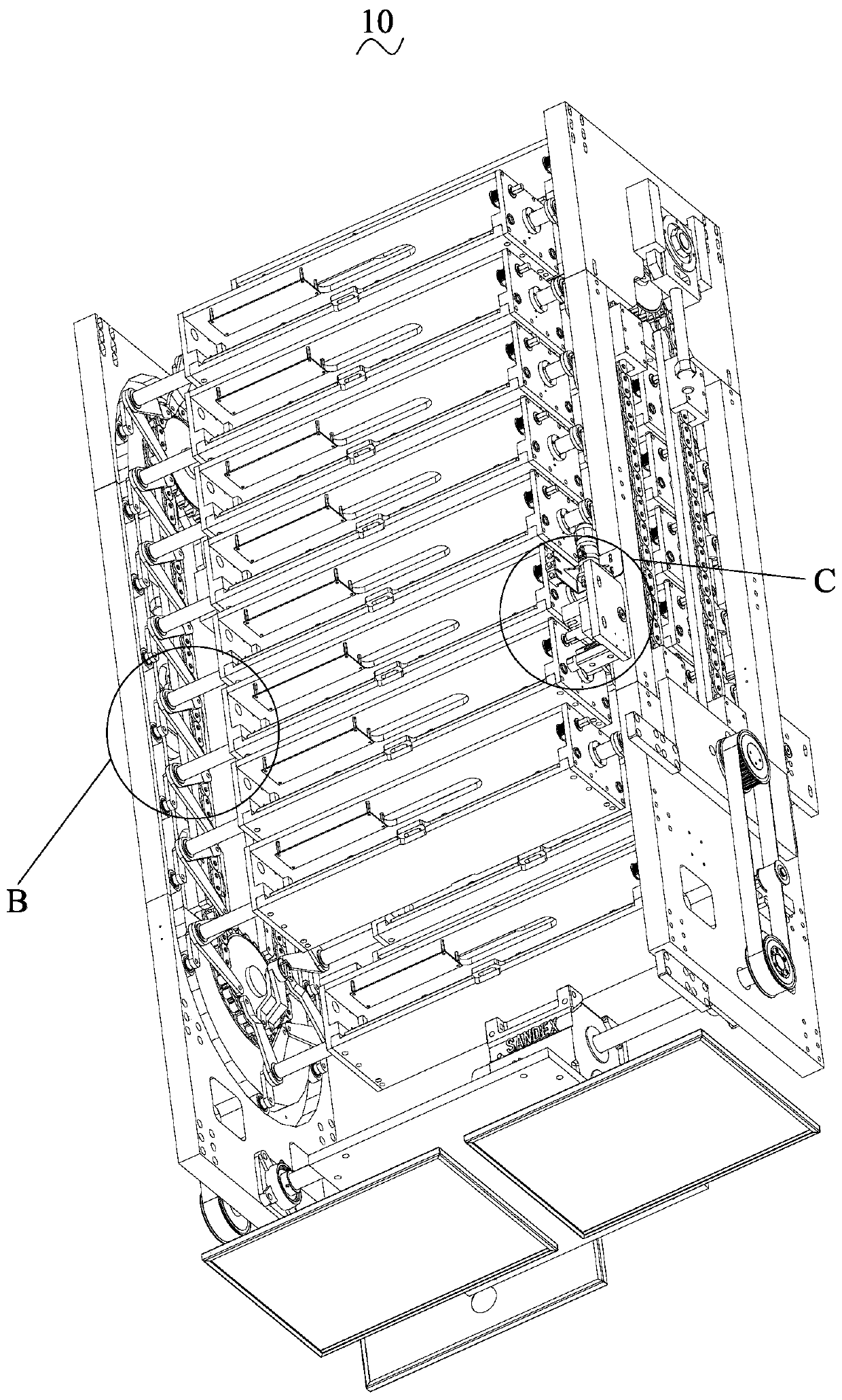

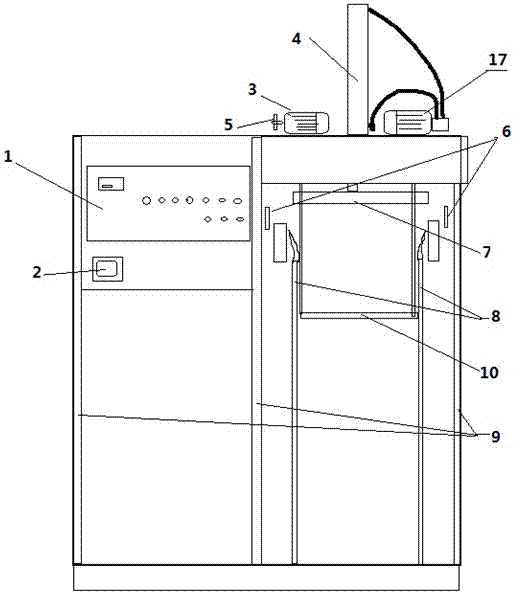

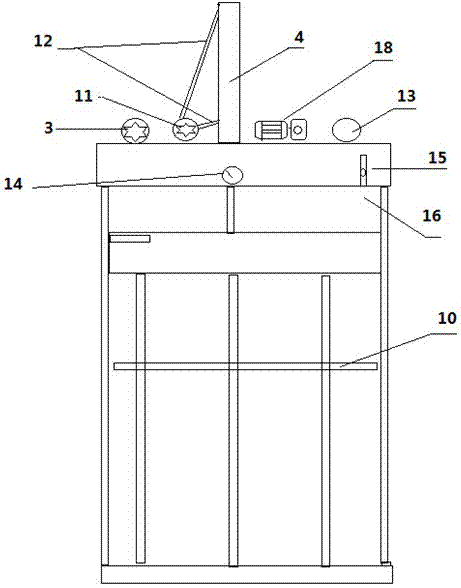

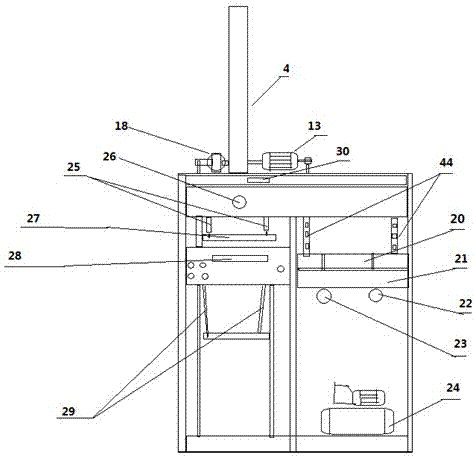

Automatic net folding and packaging all-in-one machine

ActiveCN105564746ANeatly foldedReasonable structure arrangementBinding material applicationEngineeringUltimate tensile strength

The invention discloses an automatic net folding and packaging all-in-one machine. The automatic net folding and packaging all-in-one machine is composed of a bar inserting mechanism, a first bar drawing mechanism, a bar pulling mechanism, a second bar drawing mechanism, a bar conveying mechanism, a net bearing mechanism, a net pressing mechanism and a controller which are mounted on a machine frame, wherein the machine frame is halved; one side of the machine frame is provided with the bar inserting mechanism, the first bar drawing mechanism, the second bar drawing mechanism and the bar conveying mechanism, the bar inserting mechanism and the first bar drawing mechanism are located at one end of the same side, the second bar drawing mechanism is located at the other end, and the bar conveying mechanism is mounted in the position, between the first bar drawing mechanism and the second bar drawing mechanism, of the machine frame horizontally; the bar pulling mechanism, the net bearing mechanism and the controller are mounted on the other side of the machine frame, the bar pulling mechanism is mounted on the machine frame horizontally, the net bearing mechanism is mounted in the position, below the bar pulling mechanism, of the machine frame, the net pressing mechanism is mounted in the position, above the bar pulling mechanism, of the machine frame, and the controller is mounted on the lateral face of the machine frame. The structural layout of the automatic net folding and packaging all-in-one machine is reasonable, nets are folded in order automatically at a time, no labor operation is needed during folding, so that the production efficiency is high, the labor intensity is high, and the folding effect is good.

Owner:滨州宏愿化纤制品有限公司

Independent fruit and vegetable cleaning machine

PendingCN111588286AReasonable structure arrangementReduce volumeKitchen equipmentAgricultural engineeringBiology

The invention discloses an independent fruit and vegetable cleaning machine which comprises an outer shell, a cleaning tank, a gas generation device and an ozone generator, the cleaning tank, the gasgeneration device and the ozone generator are arranged in the outer shell, the gas generation device is arranged on the side of the cleaning tank, the gas generation device and the ozone generator areboth communicated with the cleaning tank, and the gas generating device is a high-speed fan or a compressor. The internal structure of the fruit and vegetable cleaning machine is reasonably arranged,so that the size of the fruit and vegetable cleaning machine is reduced.

Owner:NINGBO MEIGAO KITCHENWARE CO LTD

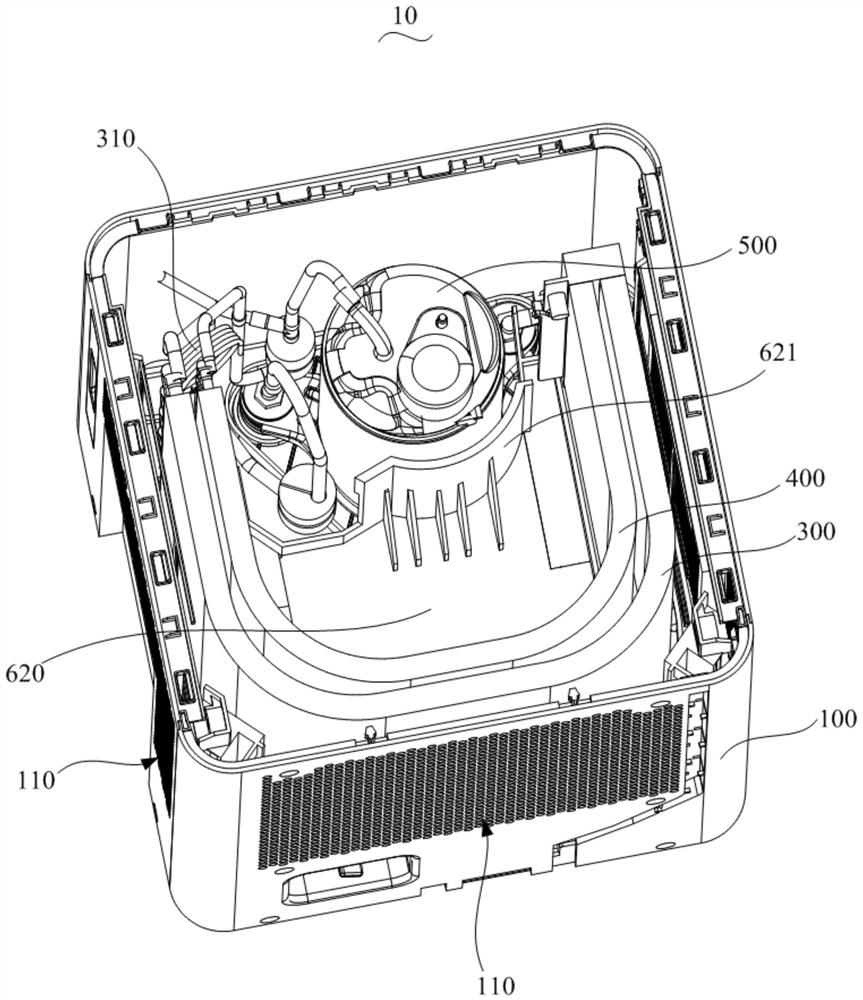

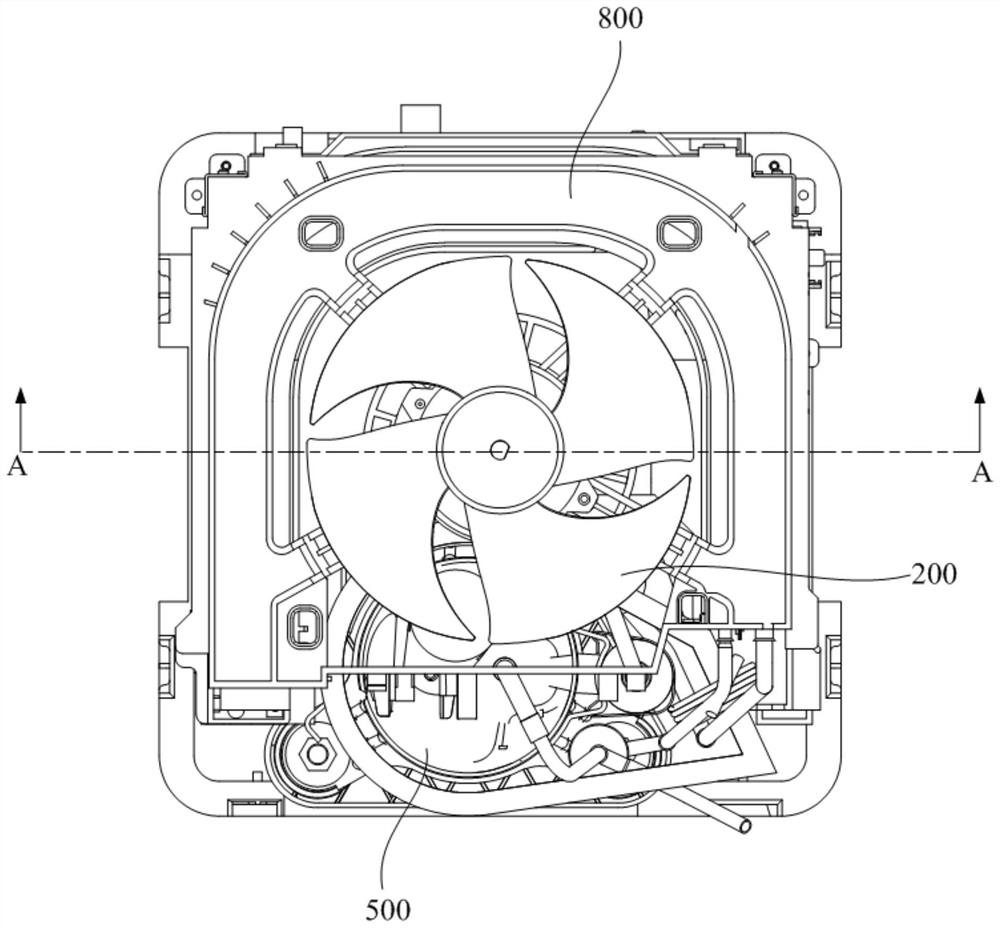

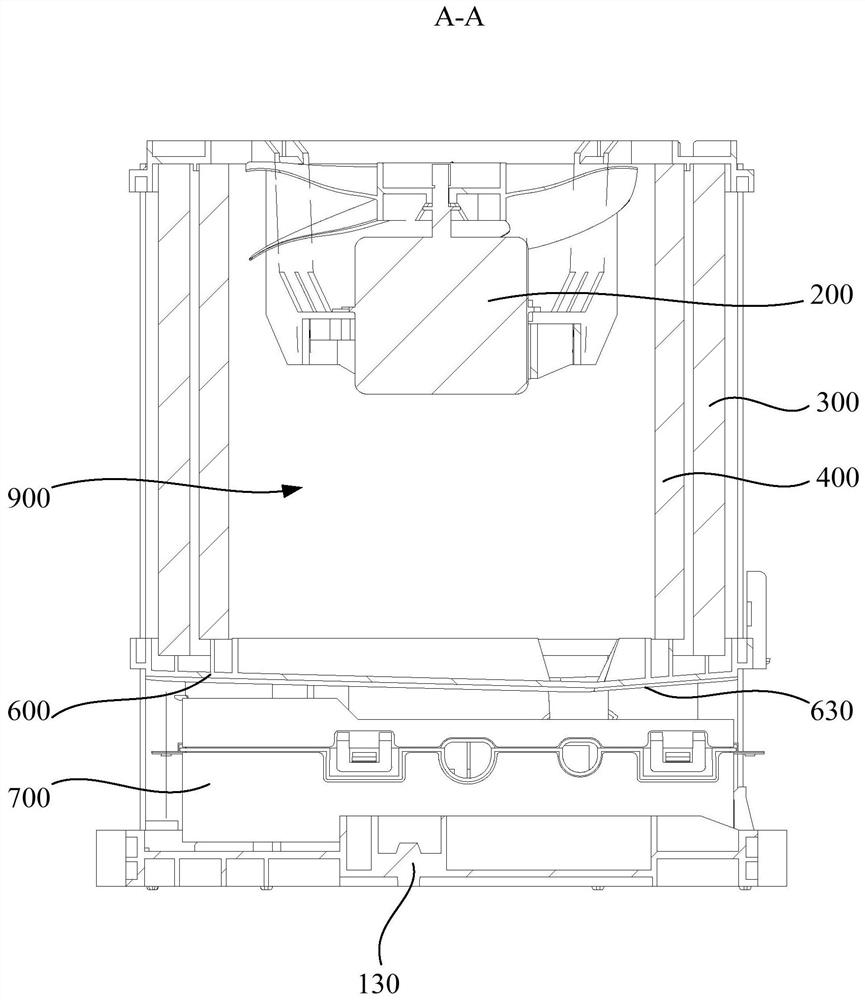

Machine body and dehumidifier

PendingCN111735194ACompact structureReduce horizontal widthMechanical apparatusCondensate preventionInterior spaceEngineering

The invention provides a machine body. The machine body comprises a shell, a water pan, an evaporator, a condenser and an electric control assembly. An air inlet and an air outlet are formed in the shell; the water pan is arranged in the shell so as to divide the inner space of the shell into a dehumidification air duct and an accommodating cavity, and the air inlet and the air outlet both communicate with the dehumidification air duct; the evaporator and the condenser are arranged in the dehumidification air duct in a stacked mode; and the electric control assembly is arranged in the accommodating cavity. The invention further provides a dehumidifier comprising the machine body. According to the technical scheme, the interior of the machine body is divided into an upper-layer space and alower-layer space through the water pan, the inner structure of the machine body is compact, space is saved, and the transverse width of the machine body is reduced; and meanwhile, the internal structure of the machine body is reasonable and safe in arrangement, so that the evaporator and the electric control assembly are separated up and down, and condensation on the surface of the evaporator isprevented from dropping to the electric control assembly to affect an electric control circuit of the dehumidifier.

Owner:GD MIDEA AIR-CONDITIONING EQUIP CO LTD +1

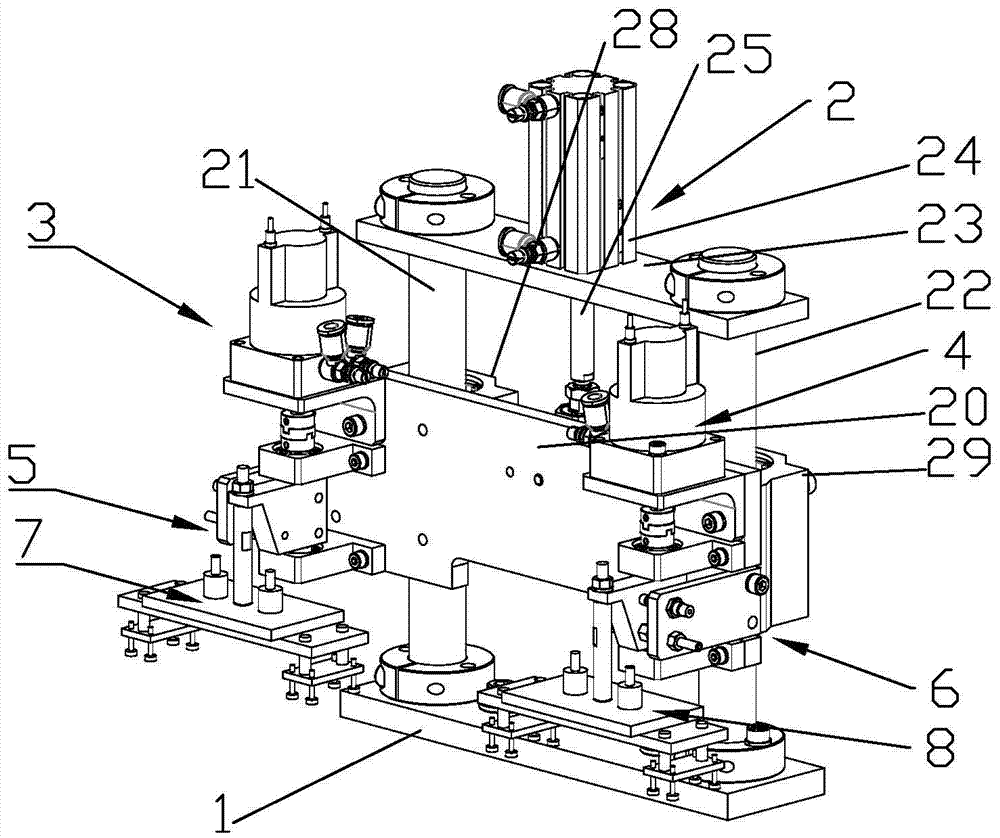

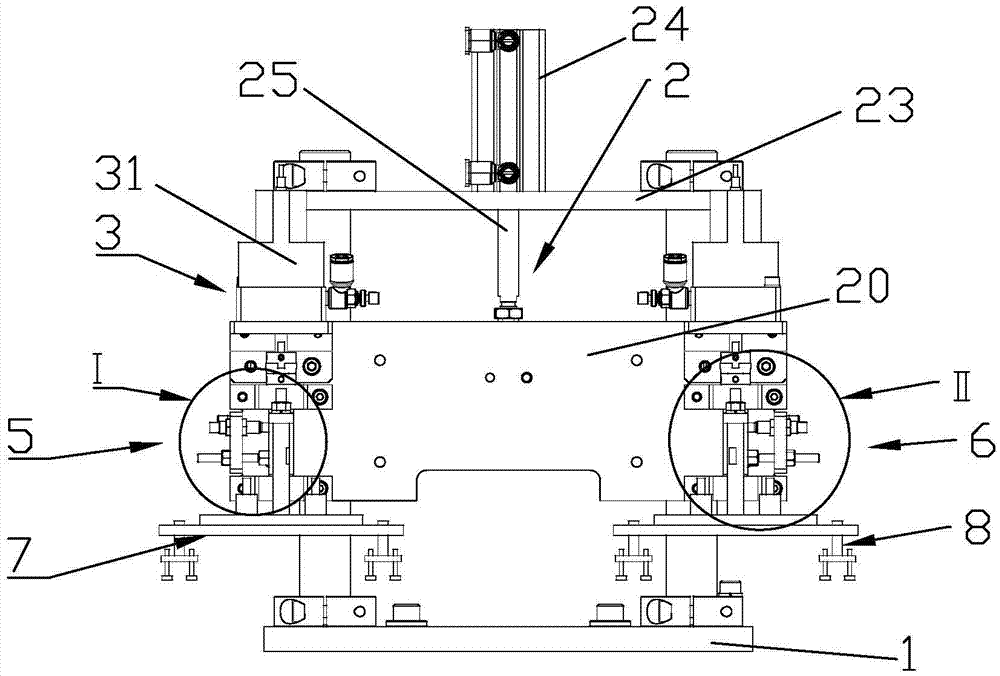

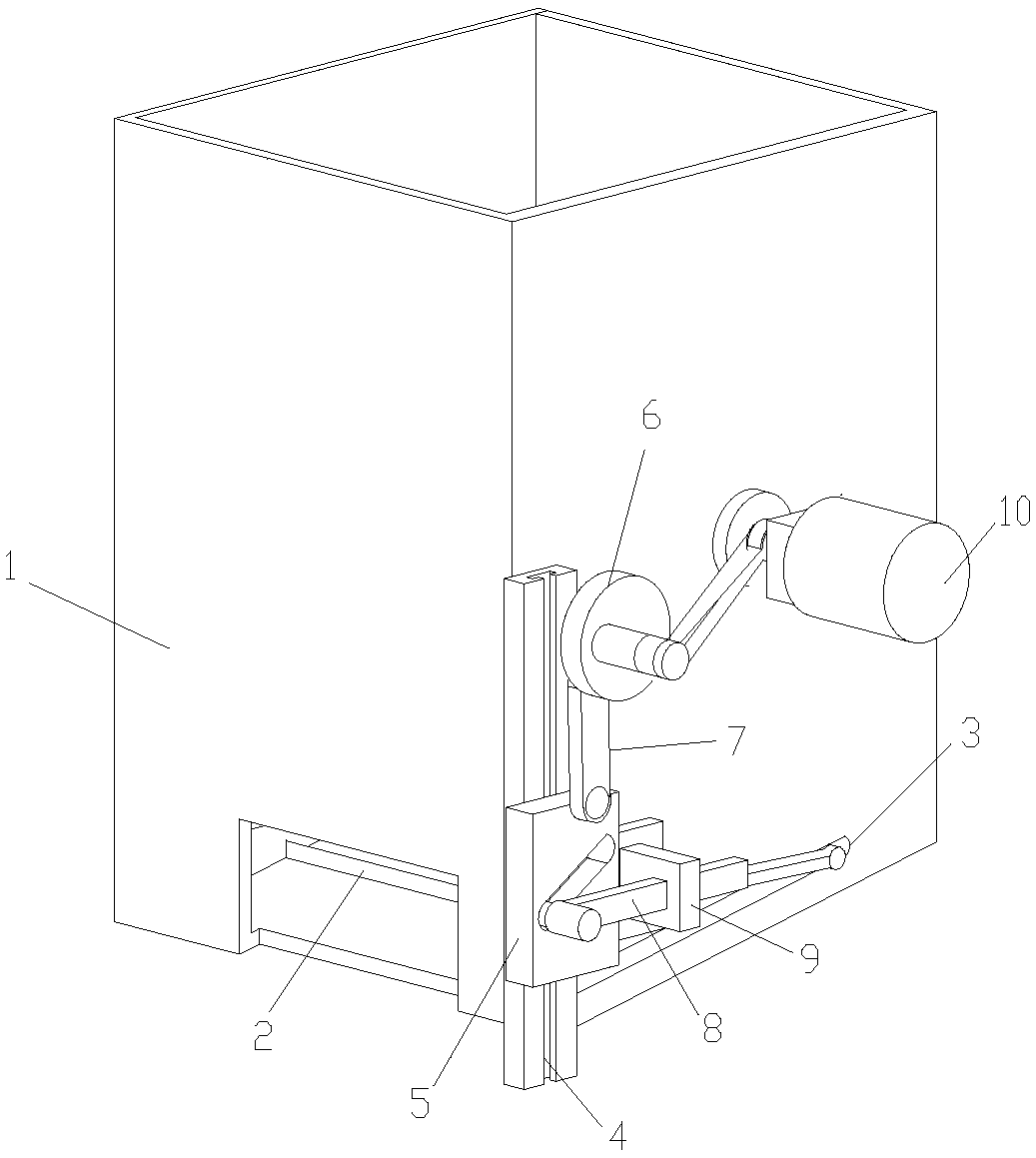

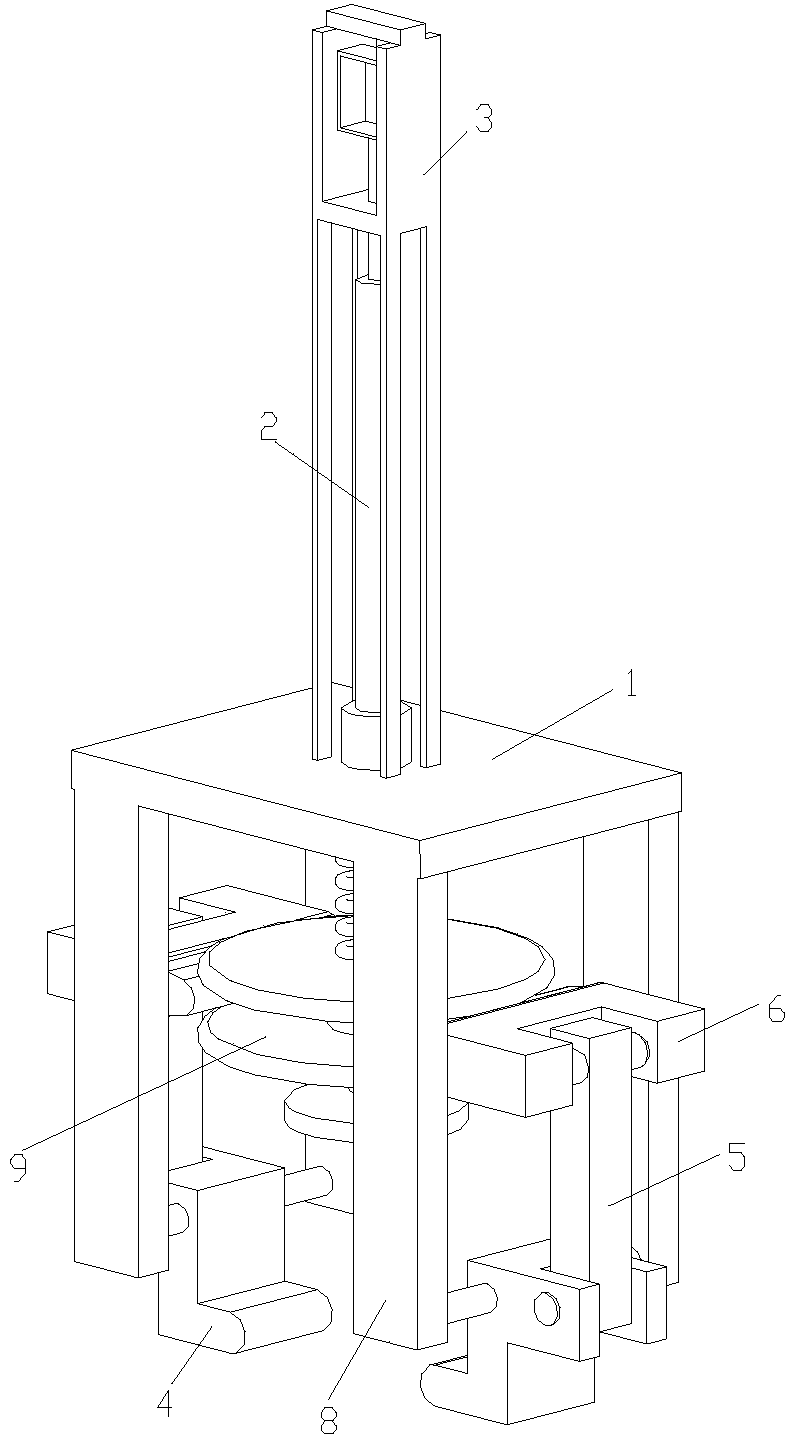

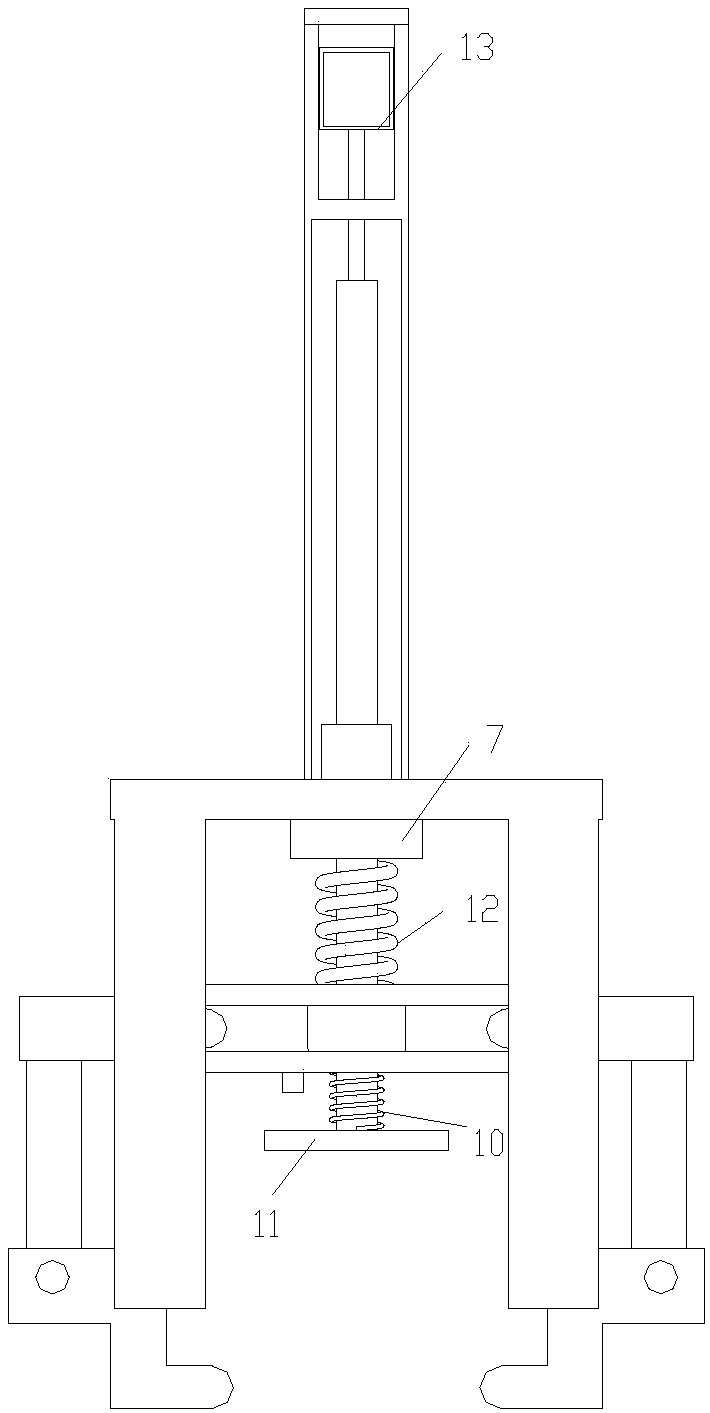

Lifting pick-up equipment for mechanical production

InactiveCN105436341ASolve the picking problemSimple structureMetal-working feeding devicesStripping-off devicesEngineeringMechanical engineering

The invention discloses lifting pick-up equipment for mechanical production. The lifting pick-up equipment comprises a base, a lifting device and pick-up devices, wherein the lifting device is installed on the base and is provided with the pick-up devices; the pick-up devices comprise the first pick-up device and the second pick-up device; the first pick-up device comprises a first pick-up motor and a first rotating assembly; the first pick-up motor is connected to a first pick-up shaft; the first pick-up shaft is provided with the first rotating assembly; the first rotating assembly is connected to a first pick-up assembly; the second pick-up device comprises a second pick-up motor and a second rotating assembly; the second pick-up motor is connected to a second pick-up shaft; the second pick-up shaft is provided with the second rotating assembly; and the second rotating assembly is connected to a second pick-up assembly. The pick-up equipment can be used for picking up various materials needing mechanical producing and machining such as stator and rotor sheets of motors, sheet metal parts, stamping sheets, punching parts and other sheet mechanical work-pieces, and is wide in application range, high in work efficiency and easy to operate.

Owner:SHENGZHOU YIHAI MOTOR PARTS FACTORY

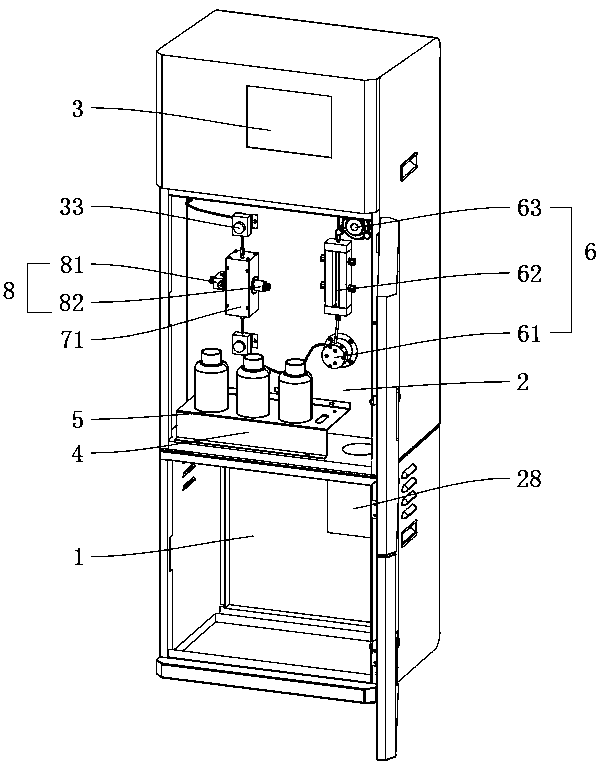

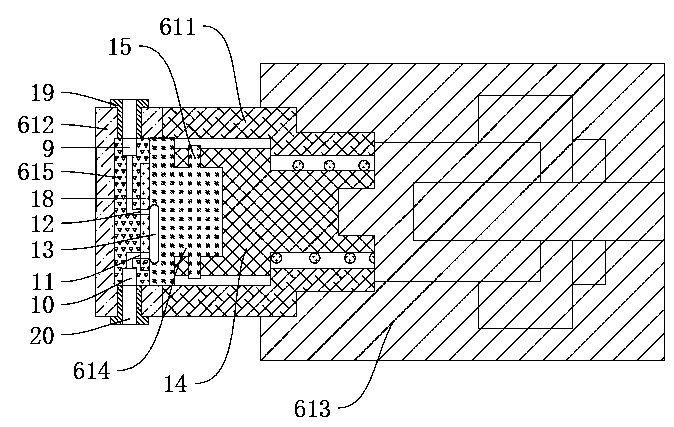

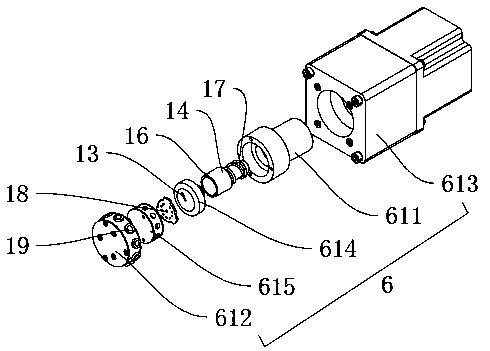

Water quality monitor

PendingCN110672595AUniform temperatureEliminate the effects ofMaterial analysis by observing effect on chemical indicatorColor/spectral properties measurementsPeristaltic pumpWater quality

The invention provides a water quality monitor, and relates to the technical field of water quality monitoring equipment. The water quality monitor comprises a shell; a sample introduction device, a reaction device, a detection device and a control terminal are arranged in the shell; the sample introduction device comprises a ten-way valve, a metering bottle and a peristaltic pump; a main branch of the ten-way valve communicates with the metering pump through a conduit; the peristaltic pump communicates with the metering bottle through a conduit; the reaction device comprises a reaction bottle; a heating wire is wound on the peripheral side of the reaction bottle; a temperature sensor is arranged in the reaction bottle; and the detection device comprises a light source emitter and a primary light sensor. The water quality monitor has the advantages of high measurement precision, simple operation and reasonable structure.

Owner:XIAMEN BLUE OCEAN SCI INSTR

Anti-falling waterproof Bluetooth sound box structure used on desktop

ActiveCN112511930APlace stableImprove drop resistanceMicrophonesLoudspeaker transducer fixingAcousticsMechanical engineering

The invention discloses an anti-falling waterproof Bluetooth sound box structure used on a desktop, which comprises a sound box body and sound outlet holes formed in the front surface of the sound boxbody, and is characterized in that four corners of the sound box body are respectively and fixedly connected with a mounting cylinder, and relates to the technical field of Bluetooth sound boxes. According to the anti-falling waterproof Bluetooth sound box structure used on the desktop, the distance between the fixing plate and the sound box body is adjusted by rotating the fixing plate, a certain distance is formed between the sound box body and the desktop while stable placement of the sound box body is guaranteed, and therefore water on the desktop is prevented from directly entering the interior of the device; with the arrangement of the anti-collision mechanism, the sound box body is comprehensively protected in the upper, lower, left, right, front and back directions, the anti-falling performance of the sound box body is effectively improved, and when the sound box body vibrates, the water retaining cloth enables the water retaining plate to be attached to the transverse plate under the acting force of the contraction spring, so that the waterproof effect of the device is improved. And the condition that the sound outlet hole is blocked by dust can be effectively prevented.

Owner:湖北一杰电子股份有限公司

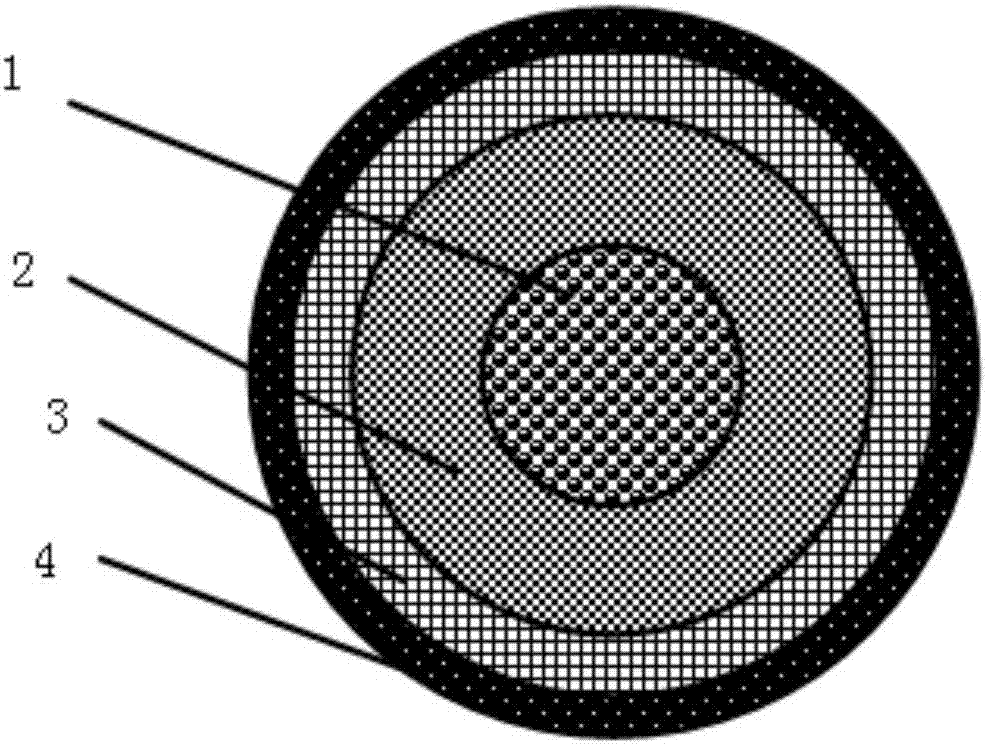

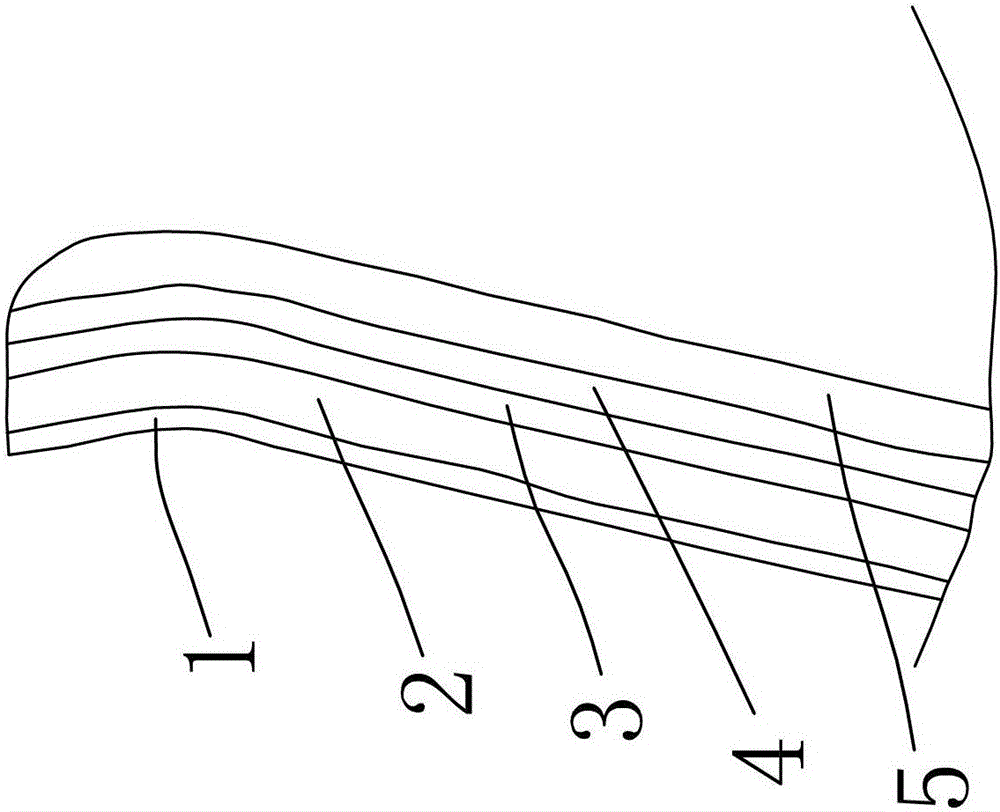

A high-toughness anti-split carbon fiber composite wire mandrel and preparation method thereof

ActiveCN106298010BHigh tensile strengthGuaranteed anti-deformation effectFlexible cablesCable/conductor manufactureFiberGlass fiber

The invention discloses a high-toughness splitting-resistant carbon fiber composite wire core rod and a preparation method. The wire core rod is made of a plurality of kinds of fiber hybrid composite materials, wherein carbon fibers are adopted as main body reinforcing fibers. The wire core rod is composed of a rigid core, a flexible layer, an anti-splitting layer and a surface wear-resistant layer which are distributed from inside to outside sequentially; the rigid core is made of a high-performance carbon fiber composite material, so that the deformation resistance of the overall core rod can be ensured; the flexible layer is made of a glass fiber composite material, so that the toughness of the core rod can achieve winding of a certain curvature; the anti-splitting layer is made of a hybrid fiber helical winding structure, so that the splitting problem of the wire core rod in a winding process can be solved; and the surface wear-resistant layer is made of a carbon fiber surface felt or a two-dimensional braided high-performance fiber mixture, so that the surface wear-resistant characteristic of the wire core rod can be ensured, and the stability of the internal structural of the wire core rod can be effectively protected. With the multi-layer structured carbon fiber composite wire core rod of the invention adopted, the comprehensive mechanical properties of a current wire steel core or a traditional composite material wire core rod can be improved, and the service life of the current wire steel core or the traditional composite material wire core rod can be effectively prolonged.

Owner:SHANDONG UNIV

Scraping plate linkage structure

InactiveCN108273600AReasonable structure arrangementEasy production and assemblyGrain treatmentsMechanical engineeringEngineering

The invention discloses a scraping plate linkage structure which comprises a box body. The bottom face of the box body is a slope face, and an outlet of the box body is formed in the bottom of the slope face. A scraping plate is arranged in the box body. A sliding groove parallel to the slope face is formed in the side face of the box body. One end of the scraping plate penetrates the sliding groove to be connected to a transmission assembly outside the box body. The transmission assembly comprises a guide strip, a sliding block, an eccentric wheel, a connecting rod, a guide rod and a supporting plate. The guide strip is arranged vertically and sleeved with the sliding block. A guide groove is formed in the surface of the sliding block. One end of the guide rod is in sliding fit in the guide groove, and the other end of the guide rod is hinged to the scraping plate. The guide rod is further sleeved with a supporting plate. The supporting plate is fixed to the side face of the box body.The sliding block is connected to the eccentric wheel through the connecting rod. A rotating shaft of the eccentric wheel is driven by a motor.

Owner:SUZHOU JU SHENG ELECTROMECHANICAL EQUIP ENG CO LTD

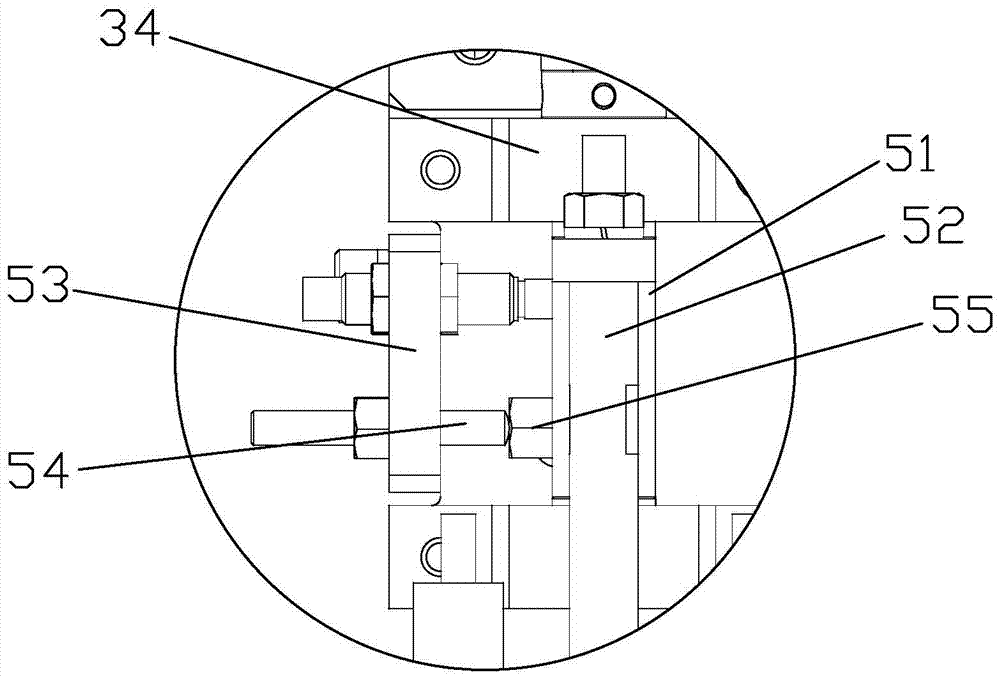

Manual clamping structure

InactiveCN108326890AReduce surface damageEasy to controlGripping headsEngineeringMechanical engineering

The invention provides a manual clamping structure. A bottom plate is provided with a guide sleeve matched with a guide rod, the lower surface of the bottom plate is fixedly provided with claw heads through supporting pillars, and folding corners on the claw heads are fixed to the supporting pillars on the two sides of the claw heads through rotating shafts. The two claw heads oppositely arrangedclamp workpieces through clamping ends rotating in the opposite directions, and connection ends are hinged to transmission blocks through connection rods. The transmission blocks are matched with a transmission head at the lower end of the guide rod. The rotative surface of the transmission head is provided with grooves matched with the transmission blocks, one ends of the transmission blocks areprovided with protrusions, the protrusions are inserted into the grooves, and the transmission head rotates with the protrusions in the grooves as the axes. The lower end face of the transmission headis further provided with a limiting plate supported by a first spring. The guide rod is further provided with a second spring, and the second spring is arranged between the transmission head and thebottom plate in a supported manner. The upper end of the guide rod is provided with a hand shank. The hand shank comprises an outer frame arranged on the upper end face of the bottom plate in a supported manner, and the upper end face of the guide rod is provided with a handle to be held. The handle is lifted opposite to the outer frame, and the guide rod slides along the guide sleeve in an oppositely stretching and contracting manner.

Owner:苏州鸣人金属制品有限公司

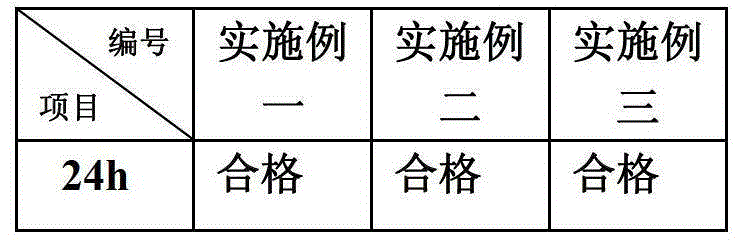

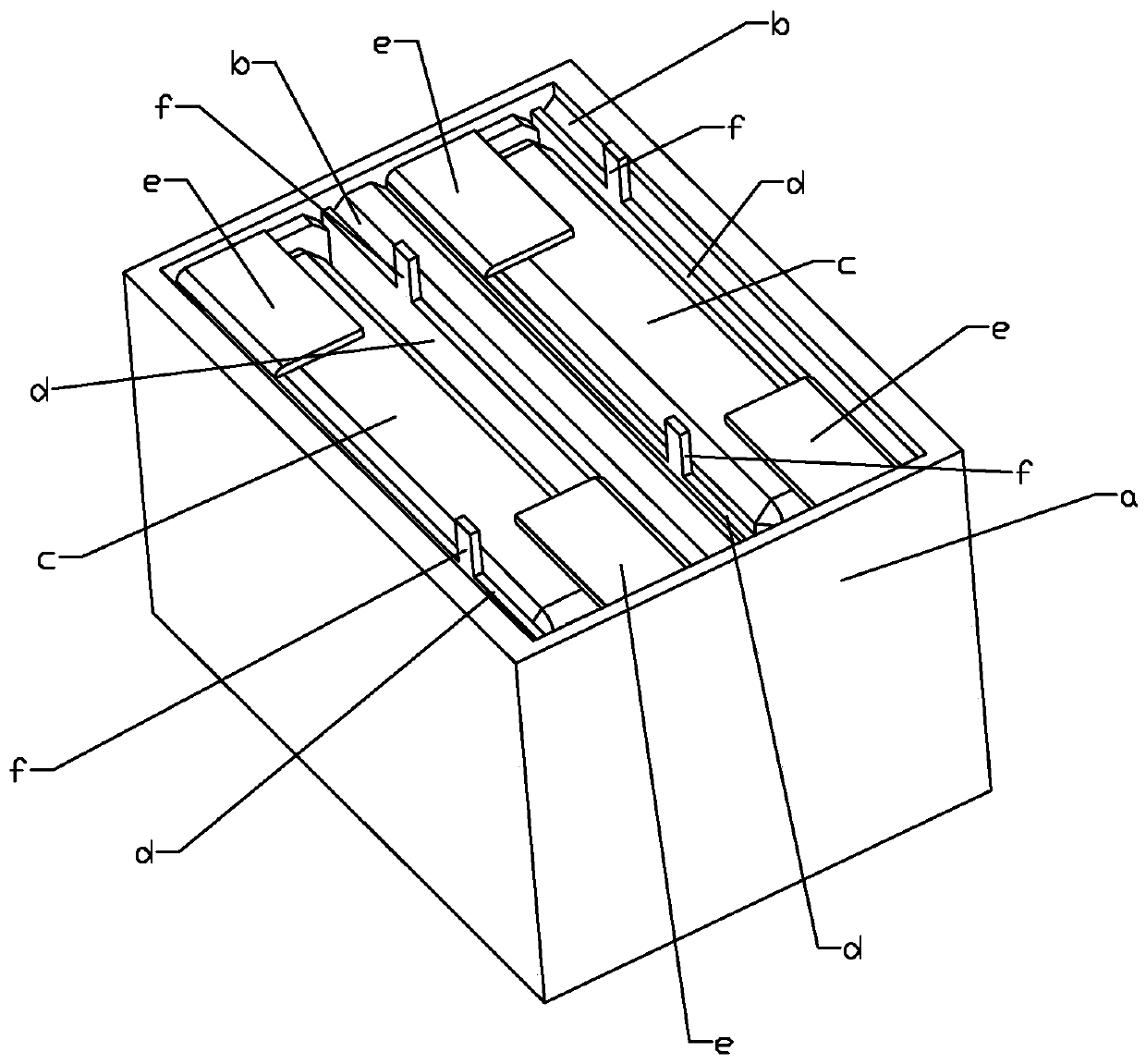

Layer structure and layer structure treatment process for automobile decoration

ActiveCN103318102BReasonable structure arrangementNice appearanceAnodisationLayered productsWaxFiber

The invention belongs to the technical field of automobile accessories and provides an automobile decorative sheet layer structure and the layer structure processing technology of the automobile decorative sheet layer. The automobile decorative sheet layer structure structurally comprises a non-woven layer, an aluminum part layer, a beech layer, a fiberboard layer and a walnut layer from inside to outside. The fiberboard layer is formed by wood fibers, a bonding formula, a flame-retarding formula and a waterproof formula. According to the processing technology, firstly, electrolytic oxidation is performed on the surface of the aluminum part layer, wax removing is performed before electrolytic oxidation, and a mixture of the flame-retarding formula, a gluing formula and the bonding formula is sprayed on the wood fibers which undergo hot grinding, and the fiberboard layer is formed through the procedures of drying, paving, hot pressing and sanding. The automobile decorative sheet layer structure and the layer structure processing technology of the automobile decorative sheet layer have the advantages that the technology processing process is green and safe and protects the environment; all the technology procedures are simple, therefore, yield is improved, a qualification rate is improved, production cost is reduced, and maintenance is easy; the layer structure after being processed is reasonable in layout, beautiful in appearance, and good in corrosion resistance, and the defects such as cracking and rusting are overcome; meanwhile, a high-quality film layer is formed on the outer surface of the layer structure, and therefore the corrosion resistance performance is enhanced.

Owner:宁波劳伦斯汽车内饰件有限公司

An air quality detector

ActiveCN105547950BReduce detection errorReasonable structure arrangementAnalysing gaseous mixturesParticle suspension analysisMass parameterData treatment

The invention discloses an air quality detector, and belongs to the field of detecting equipment. The air quality detector comprises a shell, a particle detector, a gas component detector, an environment condition detector, an indicating device and a data processor; the shell comprises an accommodating part, a detecting part and an indicating part; the particle detector is arranged in the detecting part; the indicating part is arranged in the indicating device; the gas component detector, the environment condition detector and the data processor are all arranged in the accommodating part; the gas component detector is arranged behind the particle detector. According to the air quality detector, the spatial positions of the various different detectors are reasonably arranged, so that the air quality detector which can detect a plurality of air quality parameters is implemented.

Owner:ZHEJIANG ZHIYUAN OFFICE EQUIP MFG

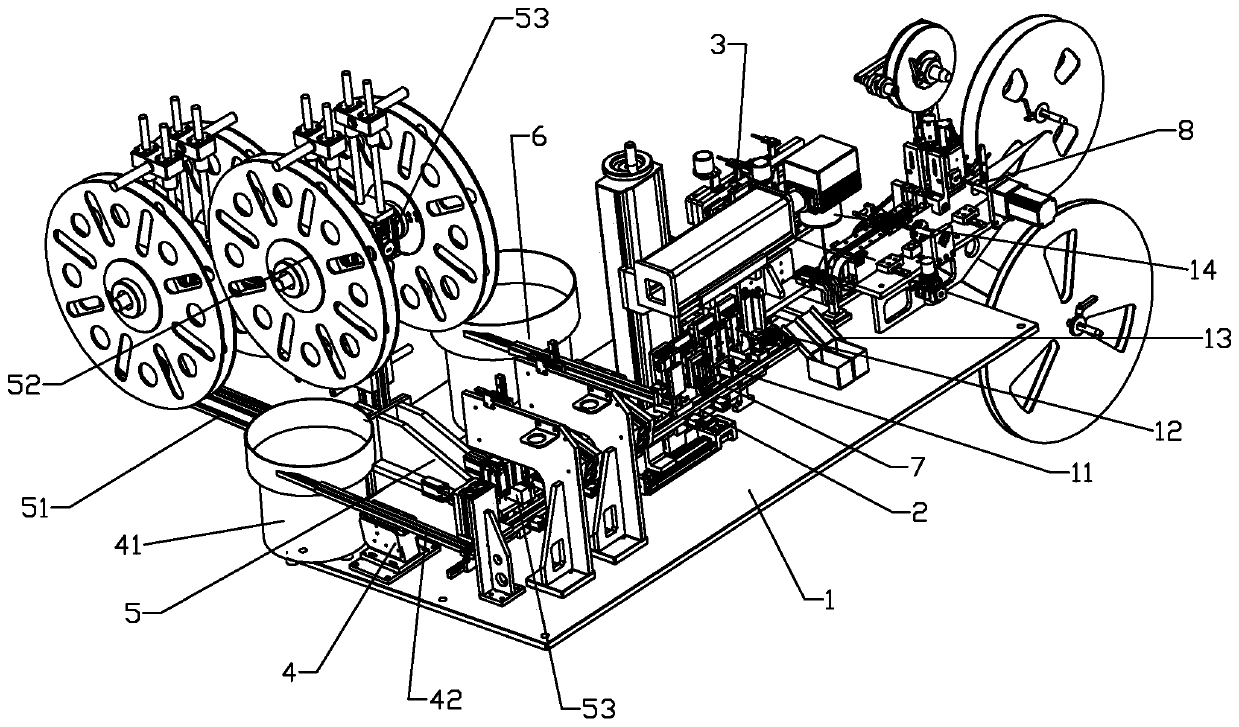

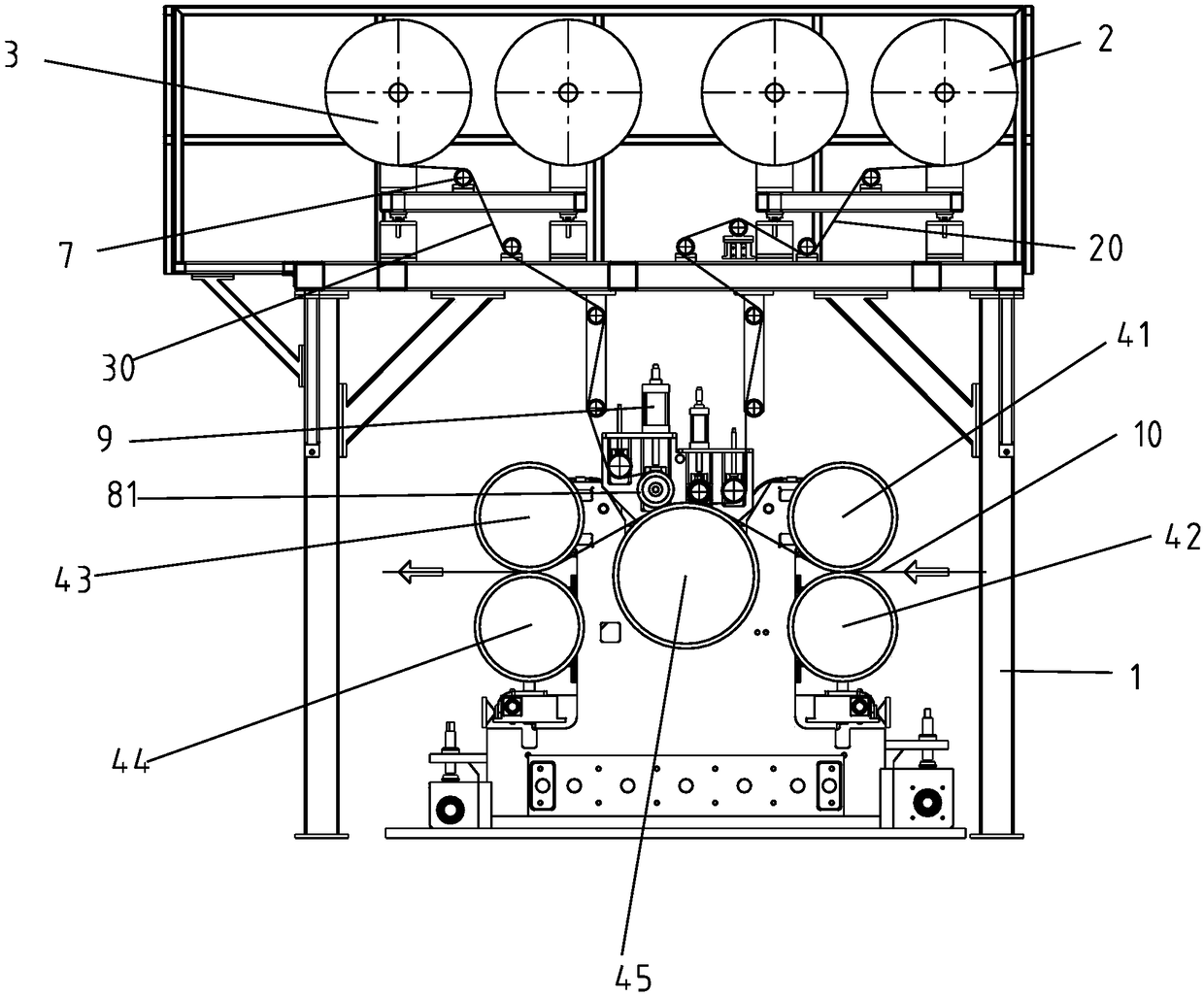

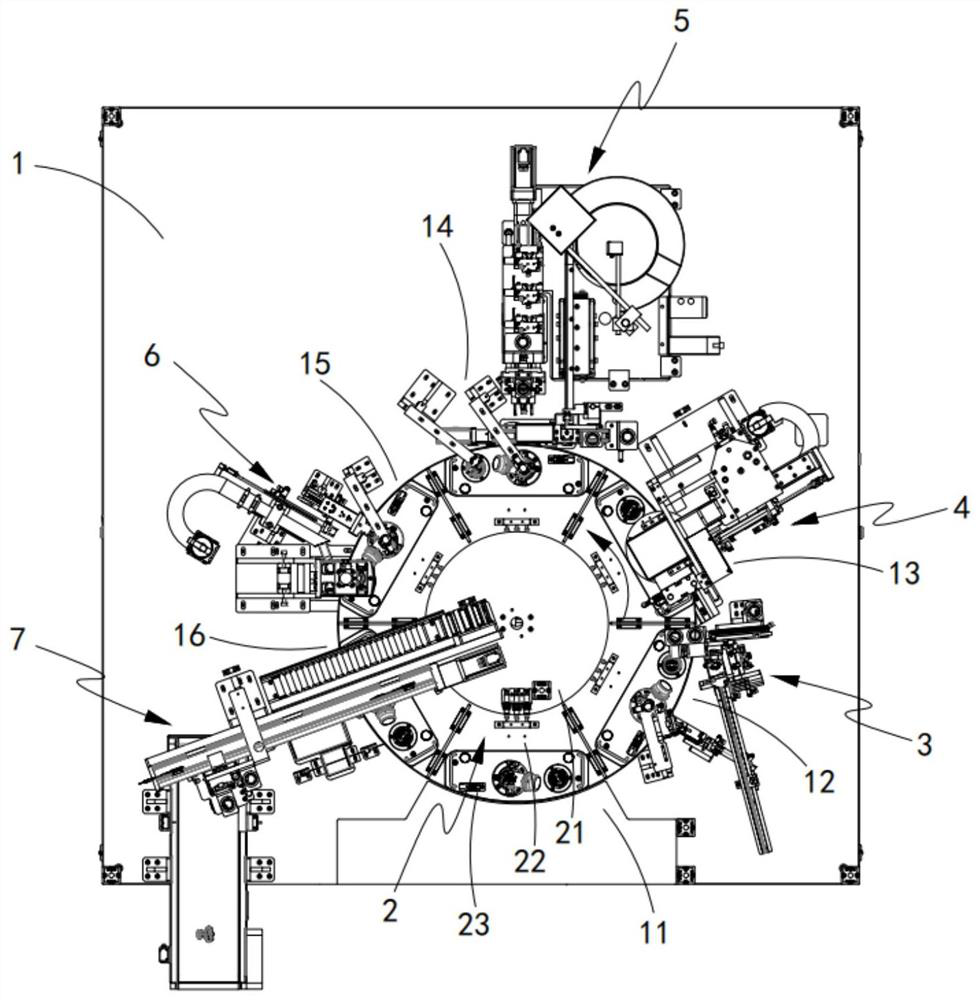

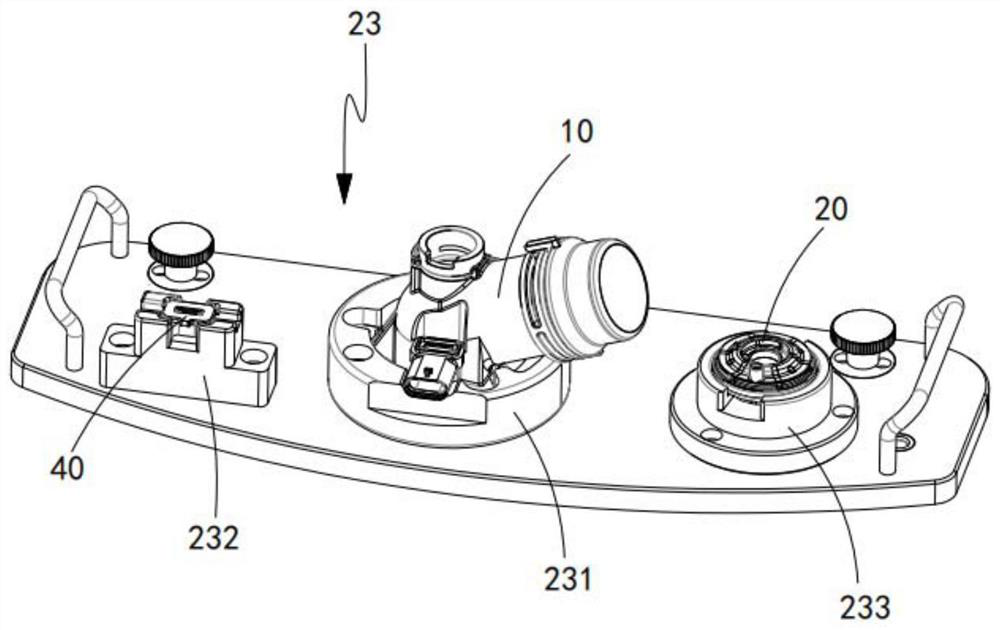

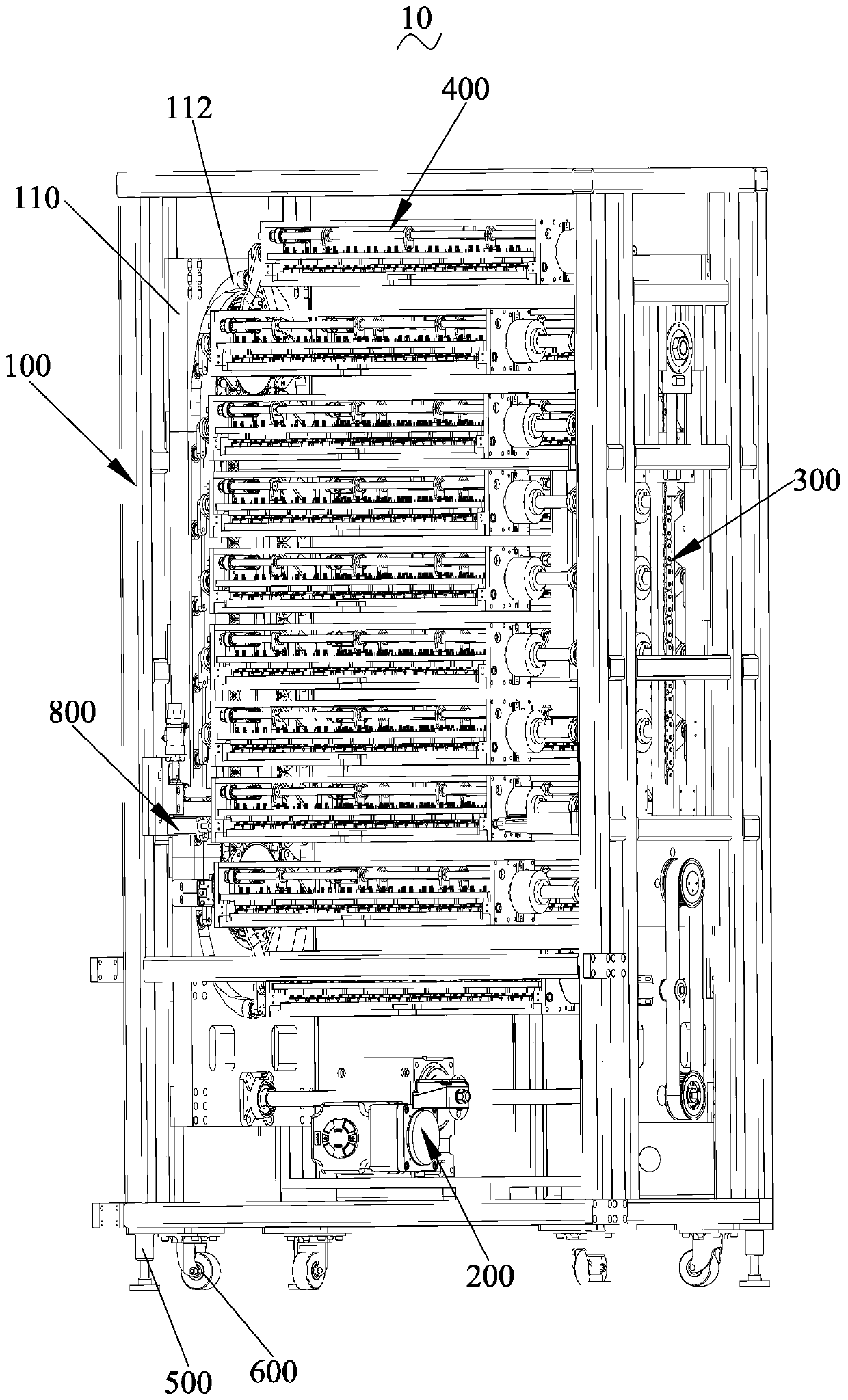

Customized inductor assembly detection equipment

ActiveCN111243841AAvoid artificial disadvantagesImprove assembly efficiencyElectrical testingInductances/transformers/magnets manufactureStructural engineeringInductor

The invention relates to customized inductor assembly detection equipment. A shell feeding device is used for placing an insulating shell on a main transmission device in an opening facing manner; thenumber of elastic sheet feeding devices is four, and elastic sheets are inserted into an insulating shell. A magnetic sheet feeding device inserts a magnetic sheet into the insulating shell. A bending device is used for bending limiting lugs of the elastic sheets. An electrical detection device is used for performing electrical detection on an inductor. A specification detection device detects whether the bent limiting lugs are located on a same plane or not. A transferring device transfers the unqualified inductors subjected to electrical detection and appearance specification detection tothe waste discharging device. Meanwhile, qualified inductors are rotated and then transferred to the marking device to be marked, and finally the marked inductors are transferred to the packaging device to be packaged into braids. By adopting the scheme, the customized inductor assembly detection equipment provided by the invention improves the assembly efficiency and improves the qualified rate.

Owner:WENZHOU POLYTECHNIC

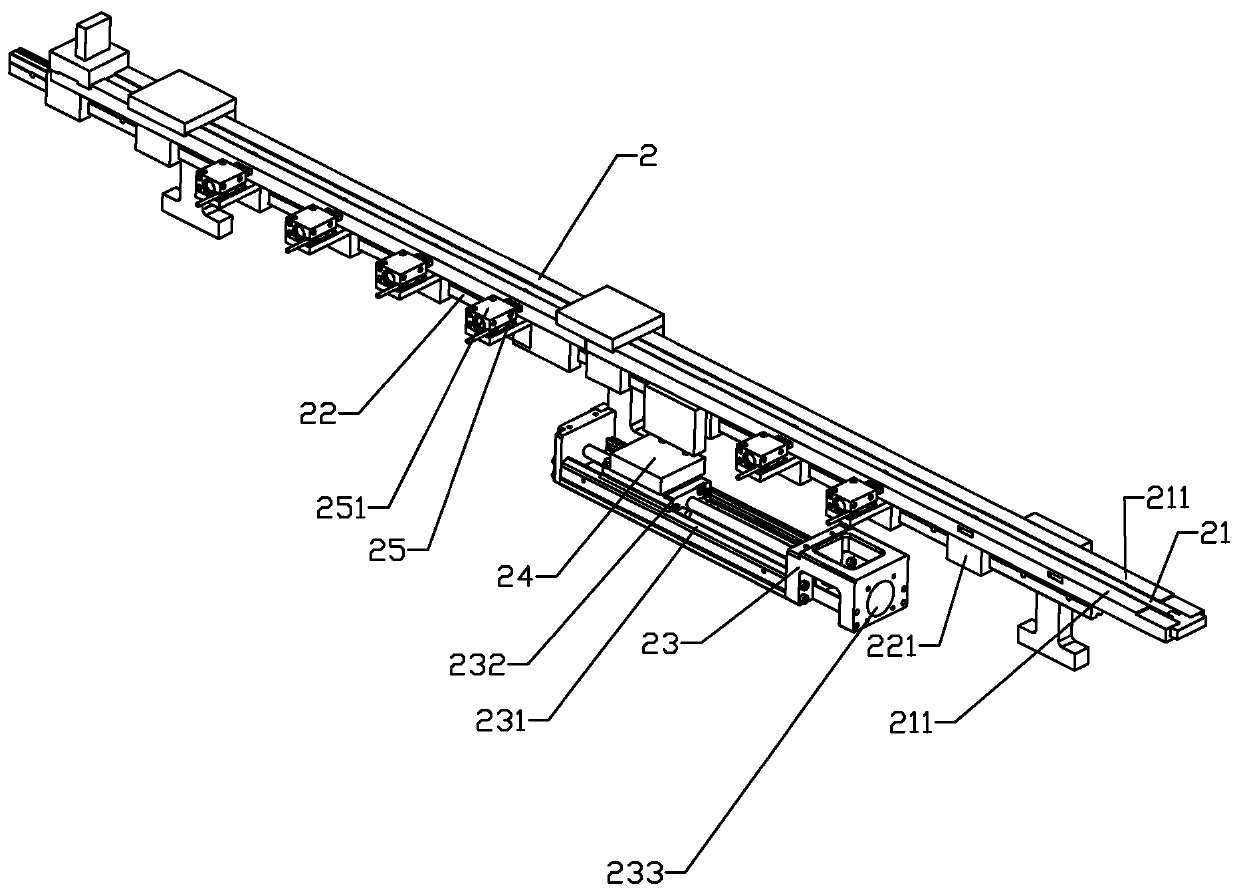

Label conveying mechanism

PendingCN108179555APrecise feeding controlAvoid misalignmentWork-feeding meansDrive wheelEngineering

Provided is a label conveying mechanism. The label conveying mechanism comprises a label conveying machine, a first label guiding platform, a second label guiding platform and a sewing machine; the second label guiding platform is horizontally disposed and passes through the head of the sewing machine; the first label guiding platform is horizontally disposed on the upper side of the second labelguiding platform; the label conveying machine is arranged at the beginning position of the second label guiding platform; the label conveying machine comprises at least a pneumatic jaw; an upper wheelset-linked upper belt is arranged on the upper side of the first label guiding platform; the upper belt rolls in the feeding direction of the sewing machine; an upper wheel set connecting plate for fixing the upper belt and the roller thereof is driven by a vertically telescopic cylinder; a lower belt is arranged at the second label guiding platform; the lower belt and the upper belt are arrangedin the same direction; the lower belt is coordinated by a lower wheel set in a linkage mode; the lower wheel set is provided with a linkage block; the linkage block is located at the beginning position of the lower wheel set; one end of the linkage block is fixed, and the other end is provided with a driven wheel matched with the lower belt; an air cylinder is also connected to the linkage block,and the air cylinder pushes the linkage block to drive the driven wheel to rotate around the fixed point.

Owner:苏州匠博智能科技有限公司

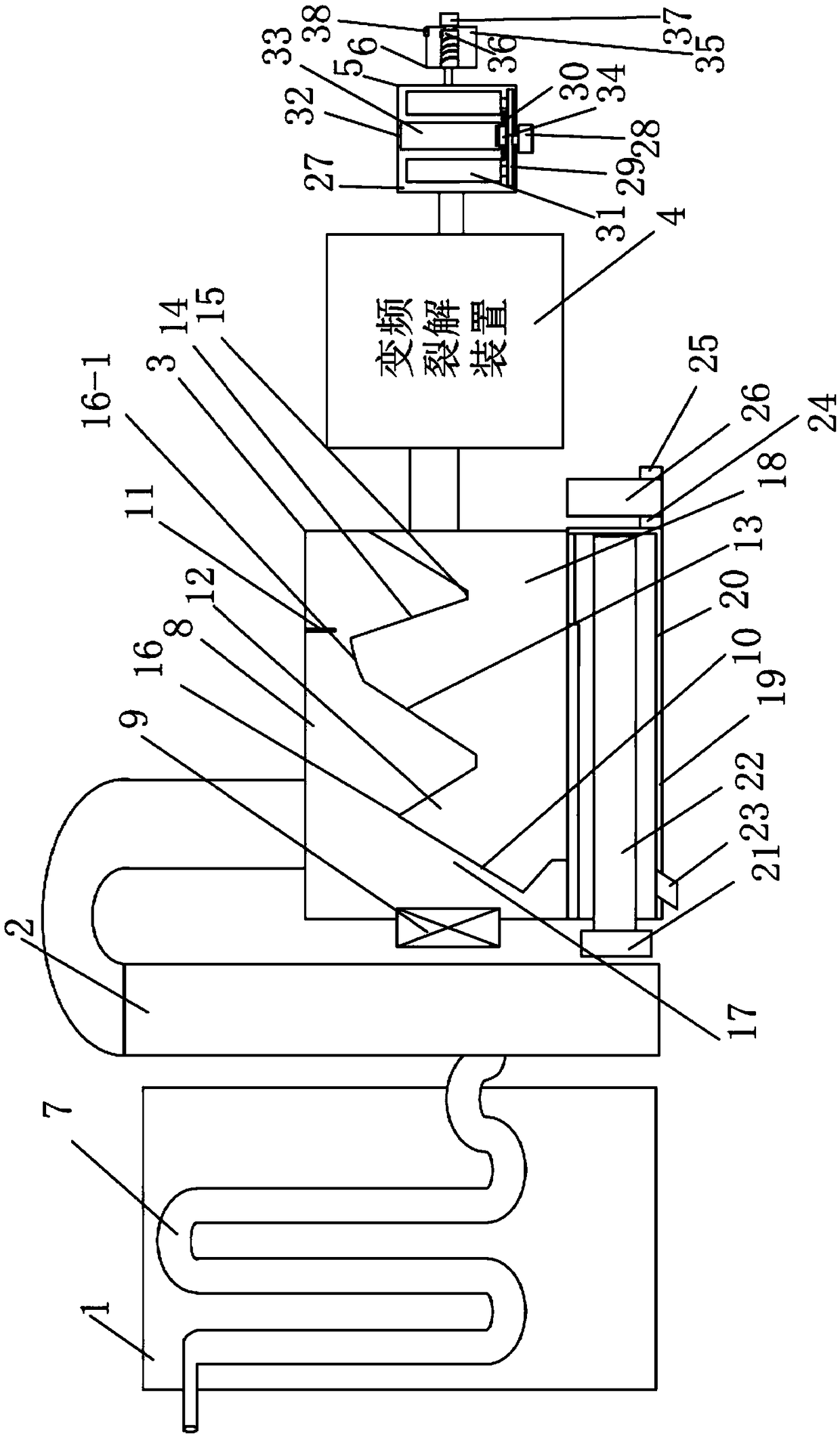

Industrial-wastewater purifying treatment device

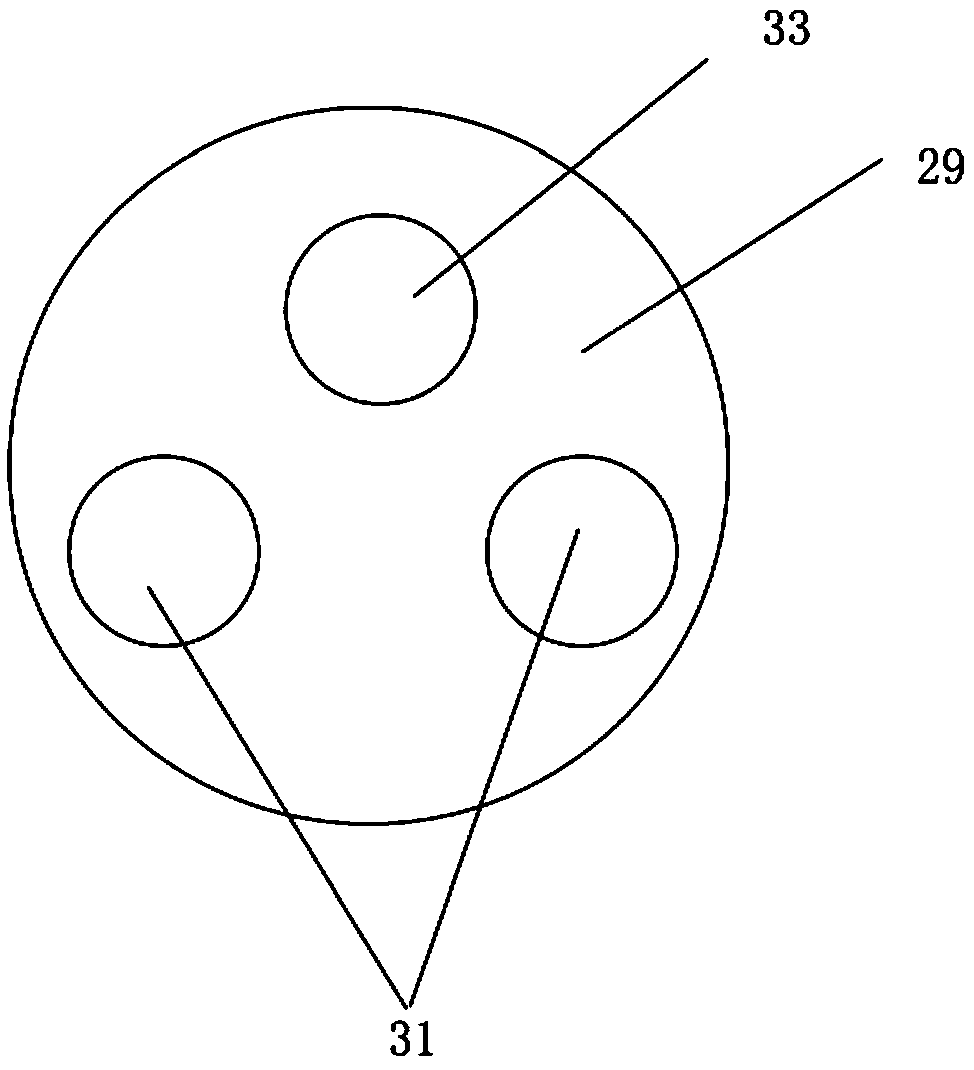

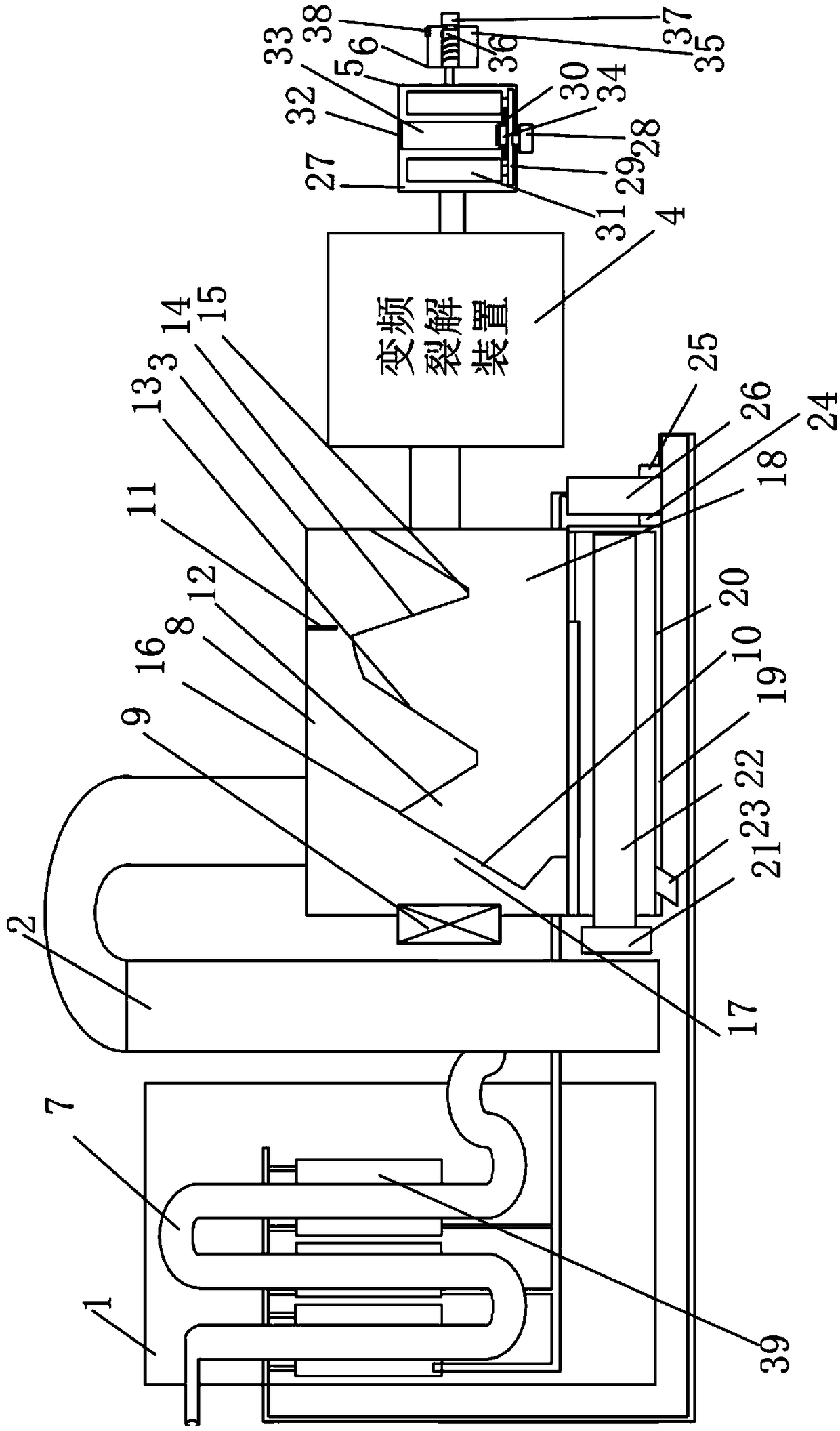

PendingCN108744809AEasy to handleReduce power consumptionGas treatmentUsing liquid separation agentWater storageFrequency conversion

The invention discloses an industrial-wastewater purifying treatment device. The industrial-wastewater purifying treatment device comprises a heat dissipation area, a spraying tower, a water stoppingpart, a frequency conversion pyrolysis device, a deodorization device and a drying device, wherein the heat dissipation area, the spraying tower, the water stopping part, the frequency conversion pyrolysis device, the deodorization device and the drying device are sequentially connected; the heat dissipation area comprises a heat dissipation pipe which is arranged inside the area and is wavy; thewater stopping part comprises a box body, a blowing device, a water stopping frame and a water stopping plate, the water stopping frame comprises more than one peak-shaped structure, the peak-shaped structures comprise guiding baffles, following baffles, baffle tops and baffle bottoms, the baffle tops and the baffle bottoms extend between the guiding baffles and the following baffles, the baffle top of one peak-shaped structure is an arc surface formed when arc extending is carried out from the corresponding guiding baffle to the connection portion of the corresponding following baffle, the box body is divided by the water stopping frame into a water stopping area and a water storage area which are distributed up and down, and the baffle bottoms are communicated with the water storage area. The industrial-wastewater purifying treatment device has the advantages of being low in running cost, easy to operate, free of secondary pollution, good in purifying effect, short in purifying process and high in recovery utilization rate.

Owner:江苏瀚珹工程咨询有限公司

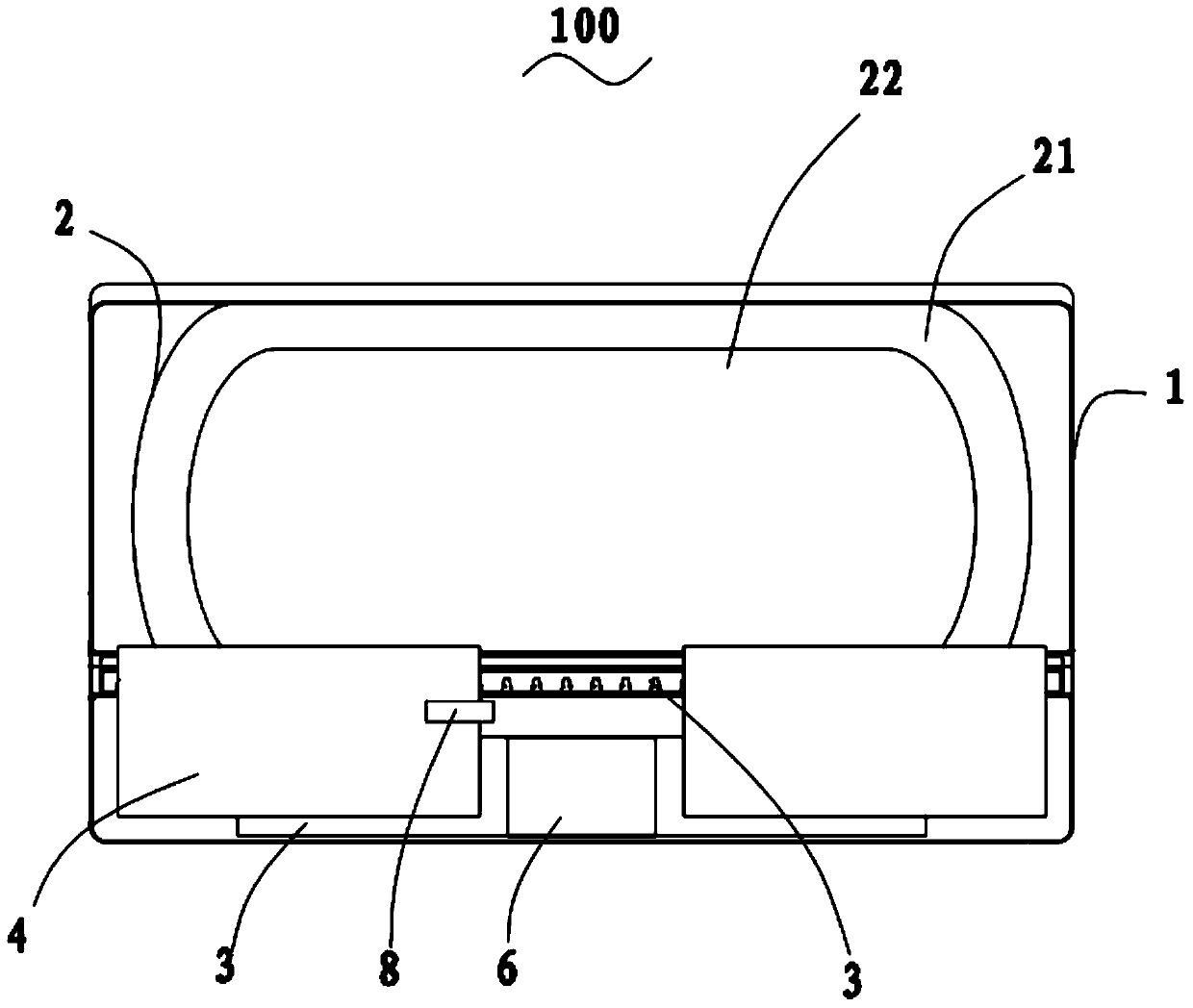

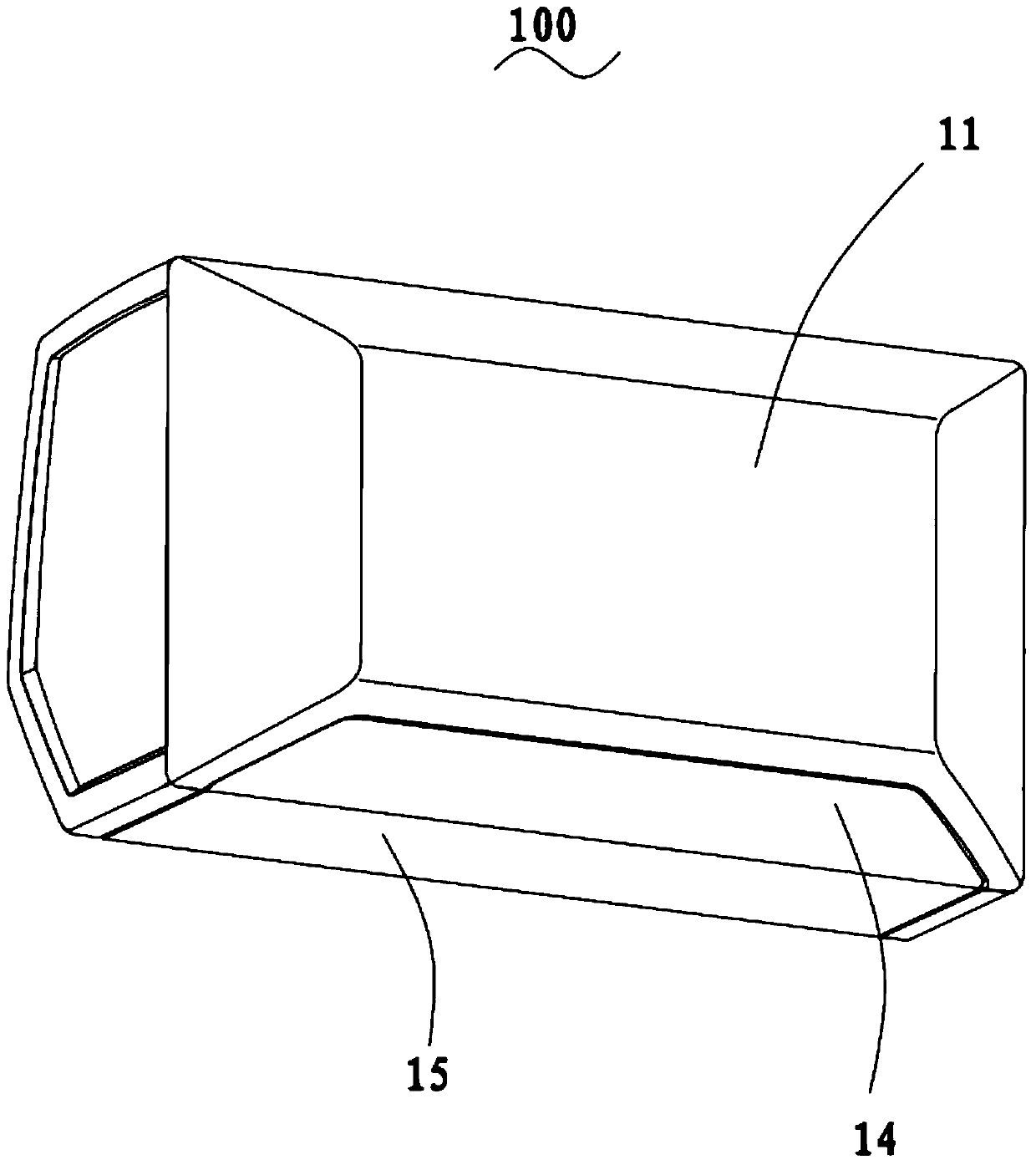

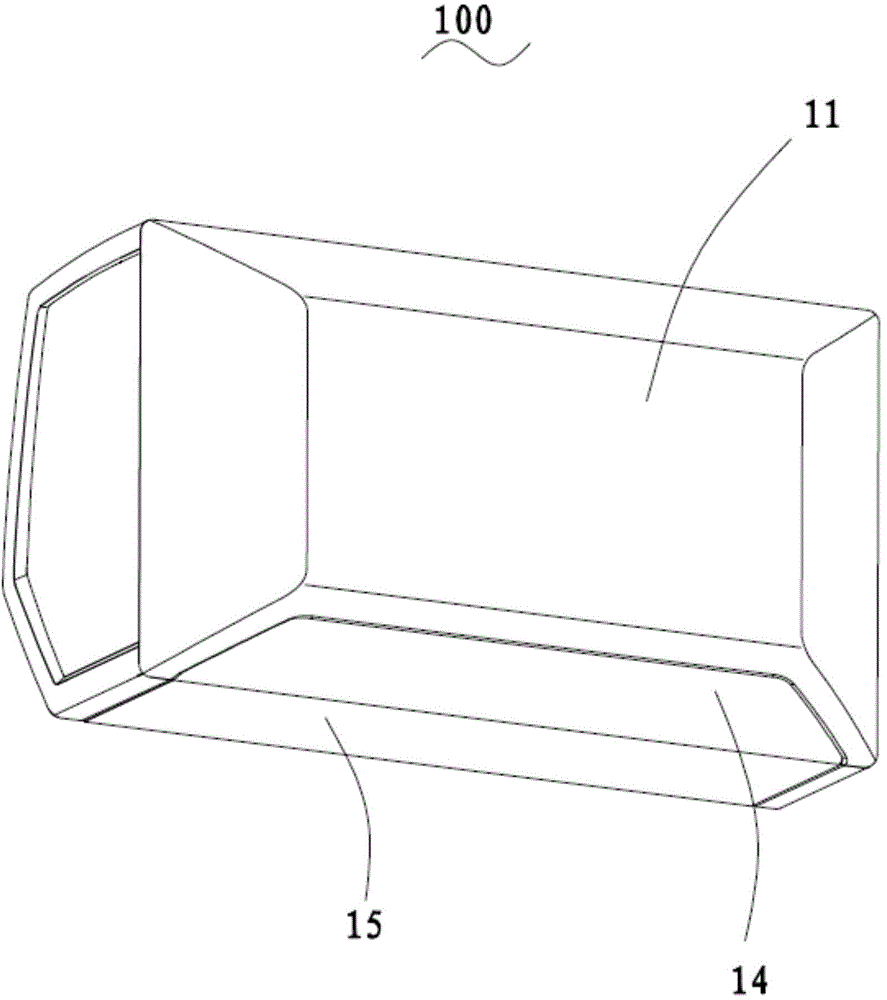

Air source heat pump water heater

ActiveCN105987505BReduce volumeReasonable structure arrangementFluid heatersEngineeringAir source heat pumps

The invention provides an air source heat pump water heater. The air source heat pump water heater comprises a box, a water tank, a fan, an evaporator and a compressor, wherein the water tank is arranged in the box and is columnar; the fan, the evaporator and the compressor are arranged in the box; and the compressor, the fan and the evaporator are arranged between the inner wall of the box and the water tank along the radial direction of the water tank, and are successively arrayed along the periphery direction of the water tank. By the air source heat pump water heater, a novel arrangement mode of the air source heat pump water heater is provided, space between the box and the water tank is utilized fully, a special cavity for accommodating the compressor, the fan, the evaporator and the like is not required, overall size of the air source heat pump water heater is reduced, and the air source heat pump water heater can be placed by a user conveniently.

Owner:QINGDAO HAIGAO DESIGN MFG CO LTD

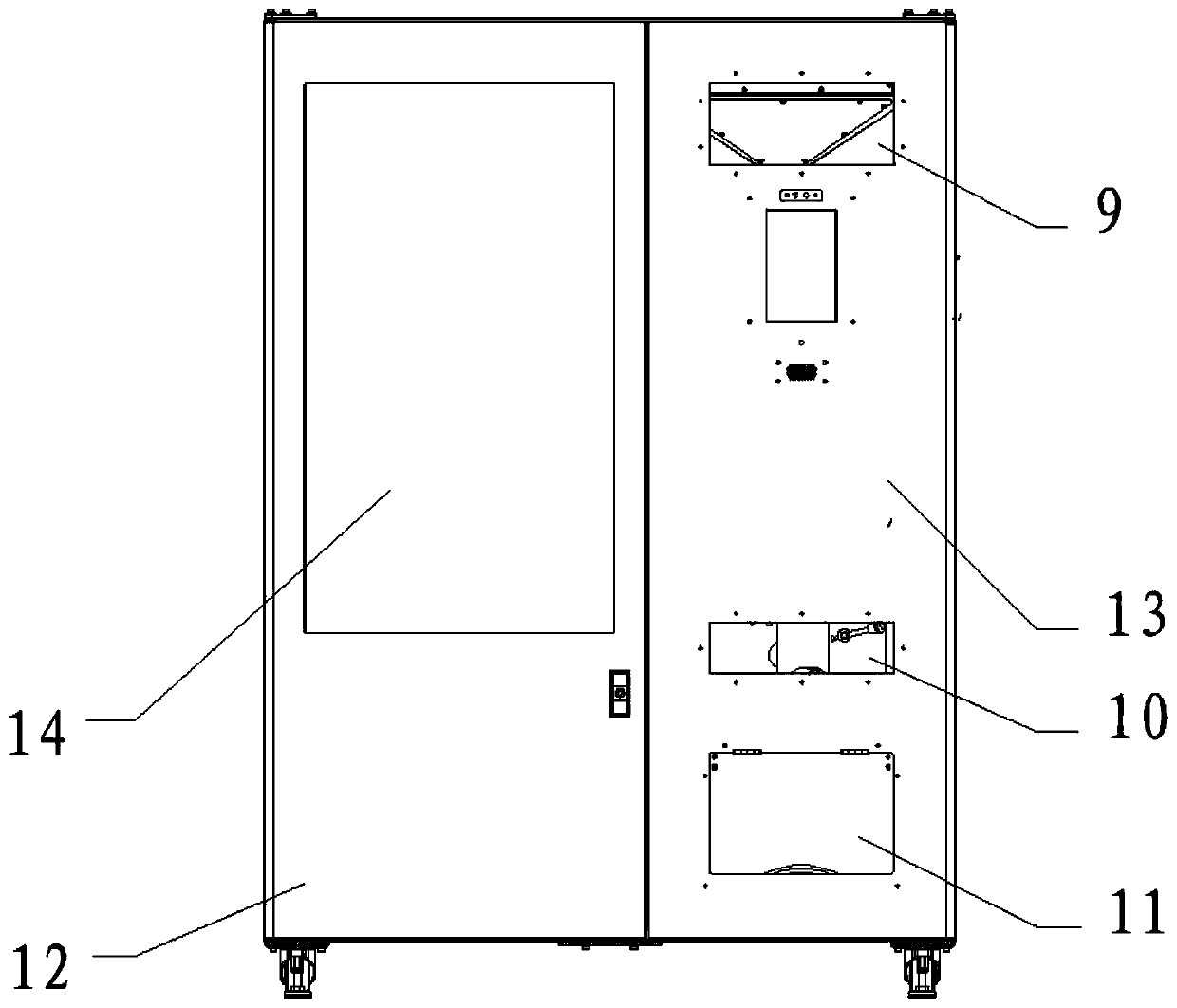

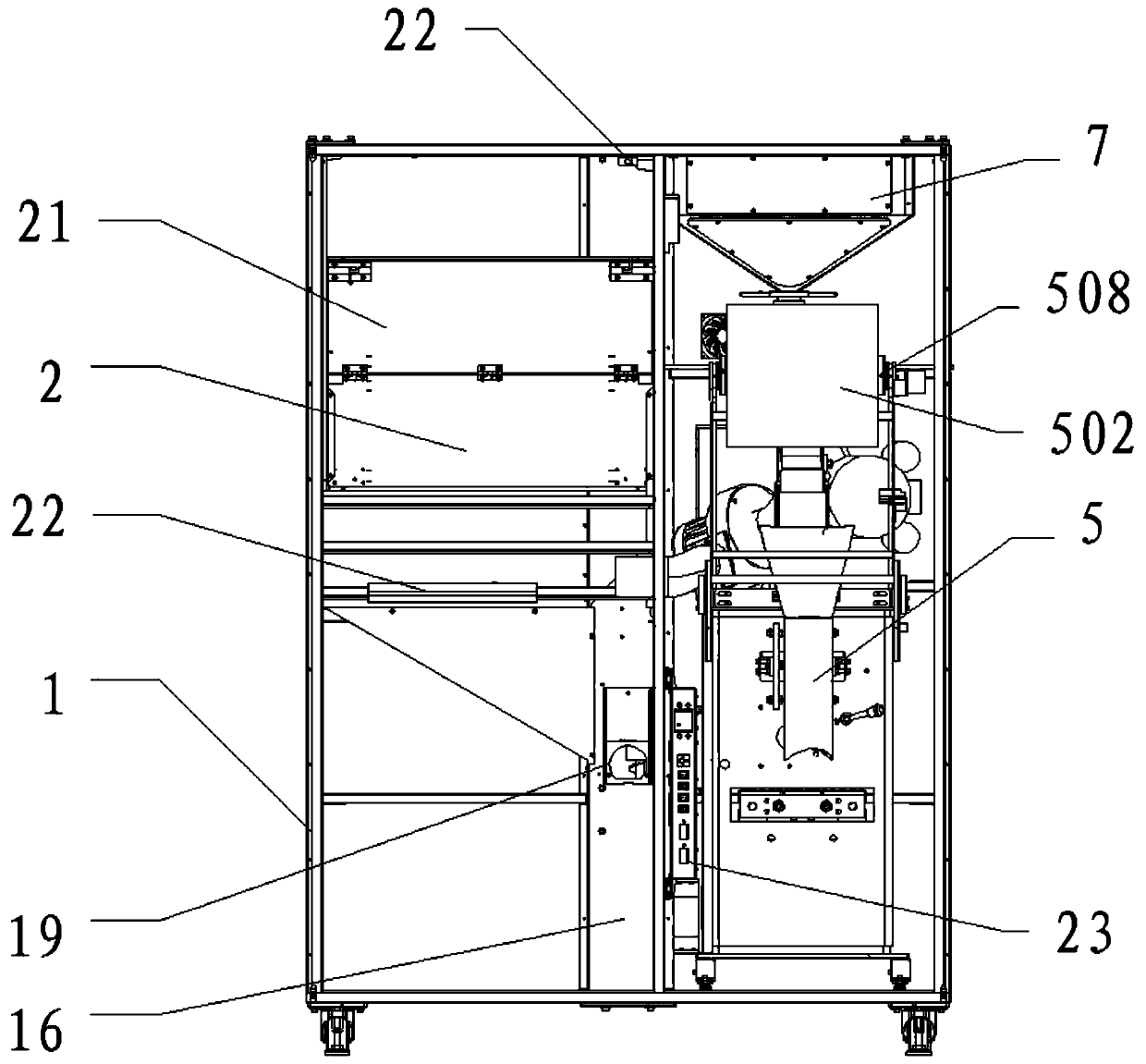

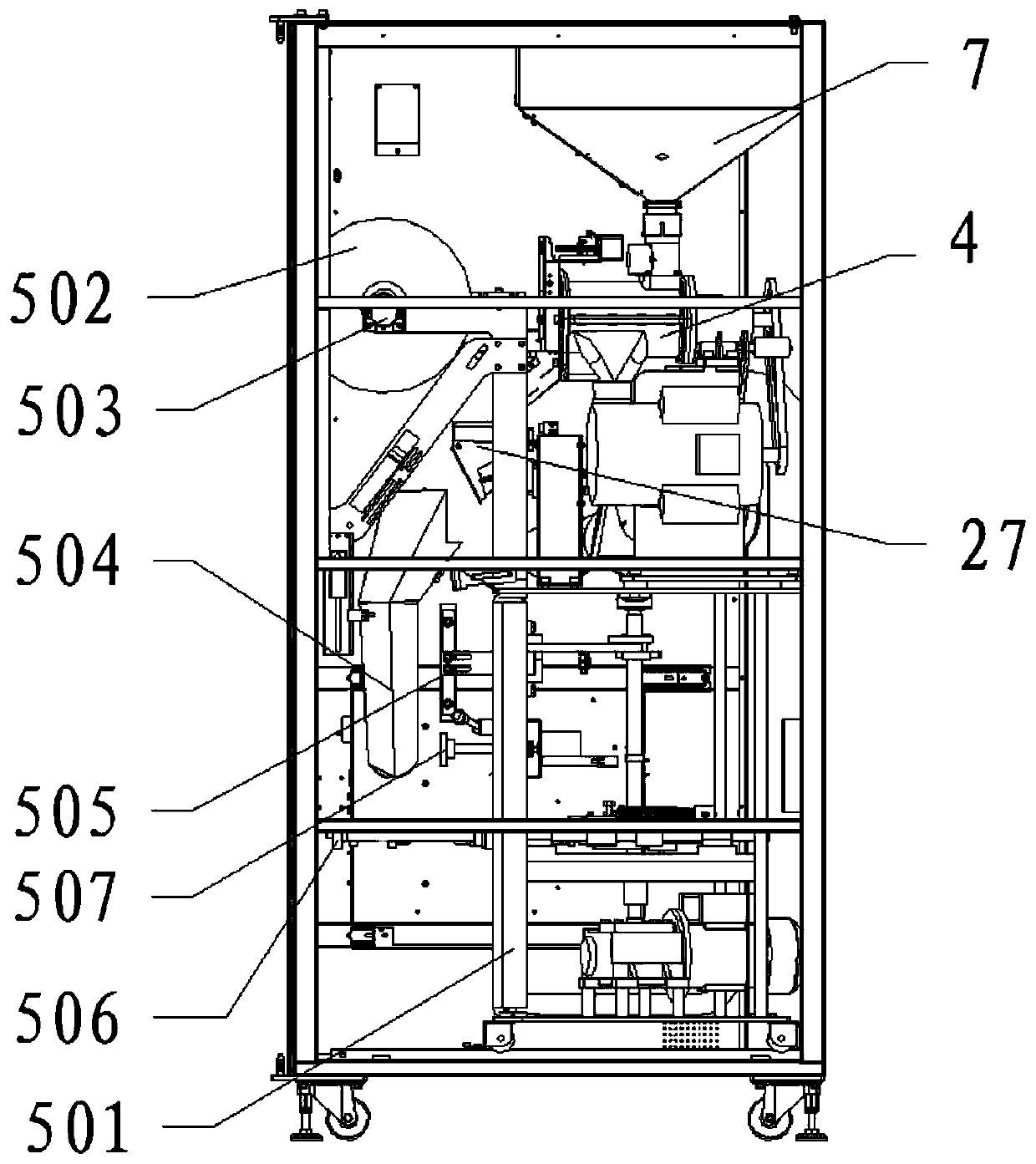

Rice milling machine

The invention relates to a rice milling machine. A first-level rice bin is located on the upper portion of one side of a case, the first-level rice bin is communicated with a second-level rice bin located on the upper portion of the other side of the case through a feeding device, the second-level rice bin is communicated with an inlet of a rice milling mechanism located under the second-level rice bin, an outlet in the front side of the rice milling mechanism is provided with a packing machine, a chaff outlet of the rice milling mechanism is communicated with a chaff collection bag located under the first-level rice bin, and a case door is provided with a first visual window and a second visual window. The rice milling machine has the advantages that the first-level rice bin and the chaffcollection bag are arranged at one side of the case, the rice bins have enough space to store a large amount of unhusked rice, and the chaff collection bag is separated from the rice milling mechanism and the packing machine, which avoids the situation that dust affects normal operation of the rice milling mechanism and the packing machine; the inner structure of the rice milling machine is arranged compactly, the structure is reasonable, and consumers can visually watch the process of rice from the second-level rice bin to packing through the first visual window and the second visual window,so that the consumers are more trustful in the product.

Owner:日照先农氏物联网科技有限公司

Air source heat pump water heater

The invention provides an air source heat pump water heater, which comprises a box body, a columnar water tank arranged in the box body, a fan, an evaporator and a compressor arranged in the box body, and the compressor, the fan and the evaporator are along the diameter of the water tank They are arranged between the inner wall of the box and the water tank, and are arranged in sequence along the circumferential direction of the water tank. The air source heat pump water heater in the present invention provides a new arrangement of the air source heat pump water heater, which makes full use of the space between the tank and the water tank, and does not need to specially set up a cavity to accommodate compressors, fans, evaporators, etc. , reducing the overall volume of the air source heat pump water heater, convenient for users to place.

Owner:QINGDAO HAIGAO DESIGN MFG CO LTD

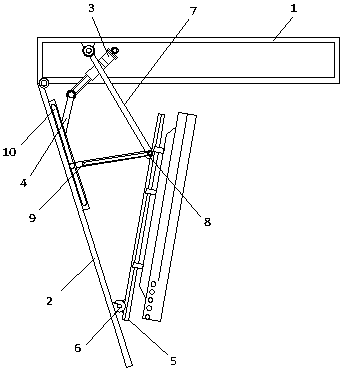

Suspended television cabinet

PendingCN107928206AReasonable structure arrangementEasy to operateFurniture partsCabinetsEngineeringCable television

The invention discloses a suspended television cabinet. The cabinet includes a cabinet body formed by splicing wooden plates, the surface of the cabinet body is open, and a covering plate which can beopened downward is arranged on the open surface; through a damping gas supporting component, a supporting force can be supplied for opening and closing the covering plate and the cabinet body; a planar frame is installed on the inner side surface of the covering plate; the lower end of the planar frame is fixed to the inner side surface of the covering plate through a rotating shaft; a movable hinging point is arranged at the upper end of the planar frame; the movable hinging point is connected to the upper wall of the cabinet body through a connecting rod, and the connecting rod is fixedly hinged to the upper wall of the cabinet body; the movable hinging point is also connected to the inner side surface of the covering plate through a sliding rod; the matching end of the sliding rod is installed on a guiding strip on the inner side surface of the covering plate; the guiding strip is provided with a sliding groove parallel to the covering plate; the included angle between the slidingrod and the connecting rod is not larger than 90 degrees; multiple clamping grooves are also formed in the sliding groove; the matching end of the sliding rod is limited by the clamping grooves.

Owner:浙江花景木业有限公司

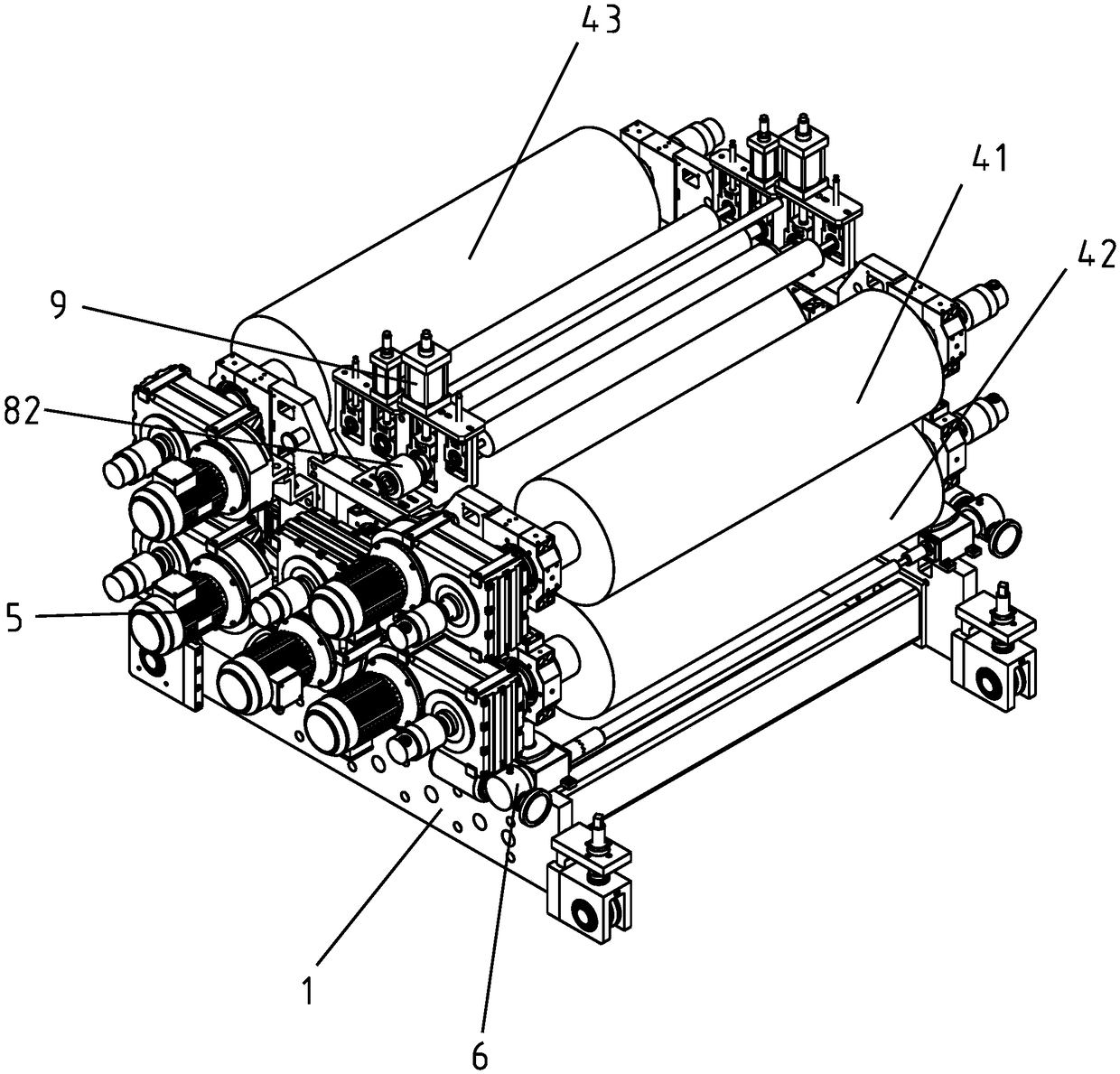

Five roller moulding machine for composite floors

PendingCN109203497AGood molding effectImprove composite effectFlat articlesWear resistantEngineering

The invention discloses a five roller moulding machine for composite floors. The five roller moulding machine comprises a frame, a printed film unreeling device, a wear resistant film unreeling device, a pair of front rollers, a pair of rear rollers, a moulding cooling roller, and five rotation driving members. The front rollers are an upper moulding roller and a lower moulding roller, which are parallelly arranged in the vertical direction and rotatingly arranged on the frame. A feeding channel is formed between the upper moulding roller and the lower moulding roller. The rear rollers are a patterned roller and a shaded roller, which are parallelly arranged in the vertical direction and rotatingly arranged on the frame. A discharging channel is formed between the patterned roller and theshaded roller. The moulding cooling roller is rotatingly arranged on the frame and is between the feeding channel and the discharging channel so that a floor substrate can conveniently go through thefeeding channel, the moulding cooling channel and the discharging channel in sequence. A printed film, a wear resistant film, and a floor substrate are compounded on the outer surface of the mouldingcooling roller. The provided moulding machine improves the moulding effect and compound effect of composite floors, the quality of composite floors is guaranteed, the structure is reasonable, and theoperation is easy.

Owner:常州金纬片板设备制造有限公司

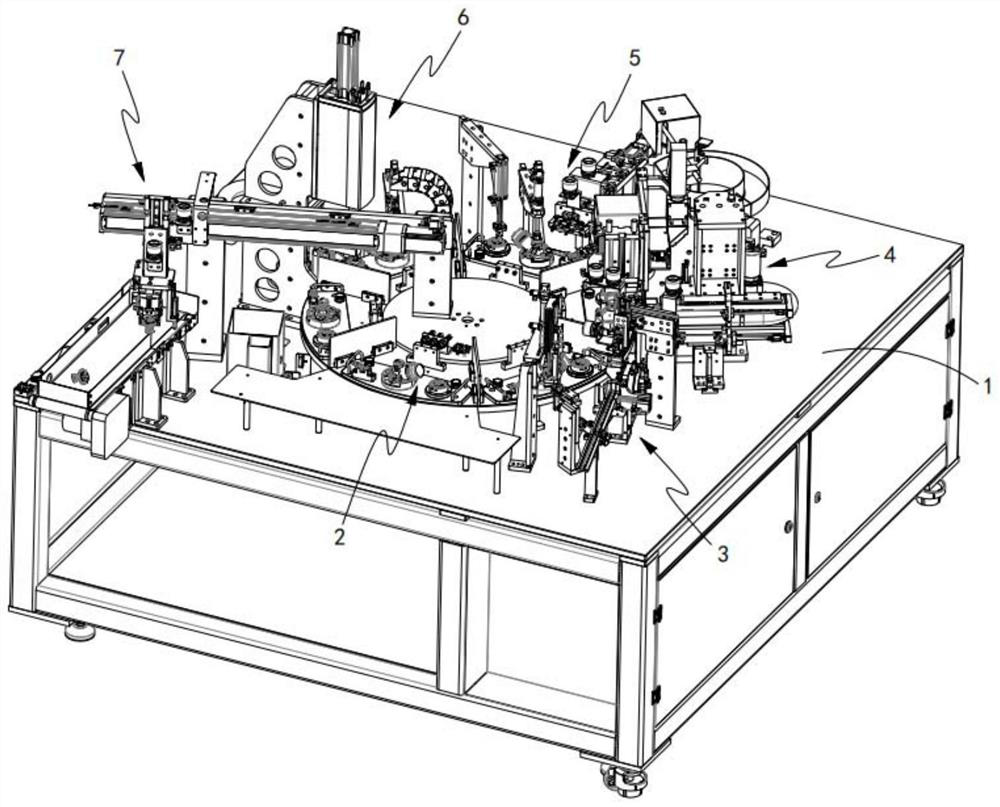

Automatic assembling device for upper shell of engine thermostat

InactiveCN112276548AQuality improvementImprove assembly efficiencyAssembly machinesMetal working apparatusEngineeringPhysics

The invention relates to an automatic assembling device for an upper shell of an engine thermostat. The automatic assembling device comprises a workbench and further comprises a turntable moving assembly, a magnet feeding assembly used for conveying magnets to wax package pieces on wax package positioning blocks, a first welding assembly used for grabbing cover plates from cover plate positioningblocks and welding the cover plates into upper shells on shell positioning blocks, a wiring pin feeding assembly used for conveying wiring pins to the upper shells and installing the wiring pins, a second welding assembly used for welding the magnets and the wax package pieces, and a discharging assembly grabbing the assembled upper shells and wax package pieces from a shell tool and discharges the assembled upper shells and the wax package pieces. The thermostat shell is driven to sequentially pass through the magnet feeding assembly, the first welding assembly, the wiring pin feeding assembly, the second welding assembly and the discharging assembly to be assembled by arranging a rotary plate moving assembly, the assembling efficiency is high, positioning is accurate, manpower is saved,the quality of finished products is improved, and the cost is saved.

Owner:LIANYUNGANG GOLD MTECH PRECISION MACHINERY

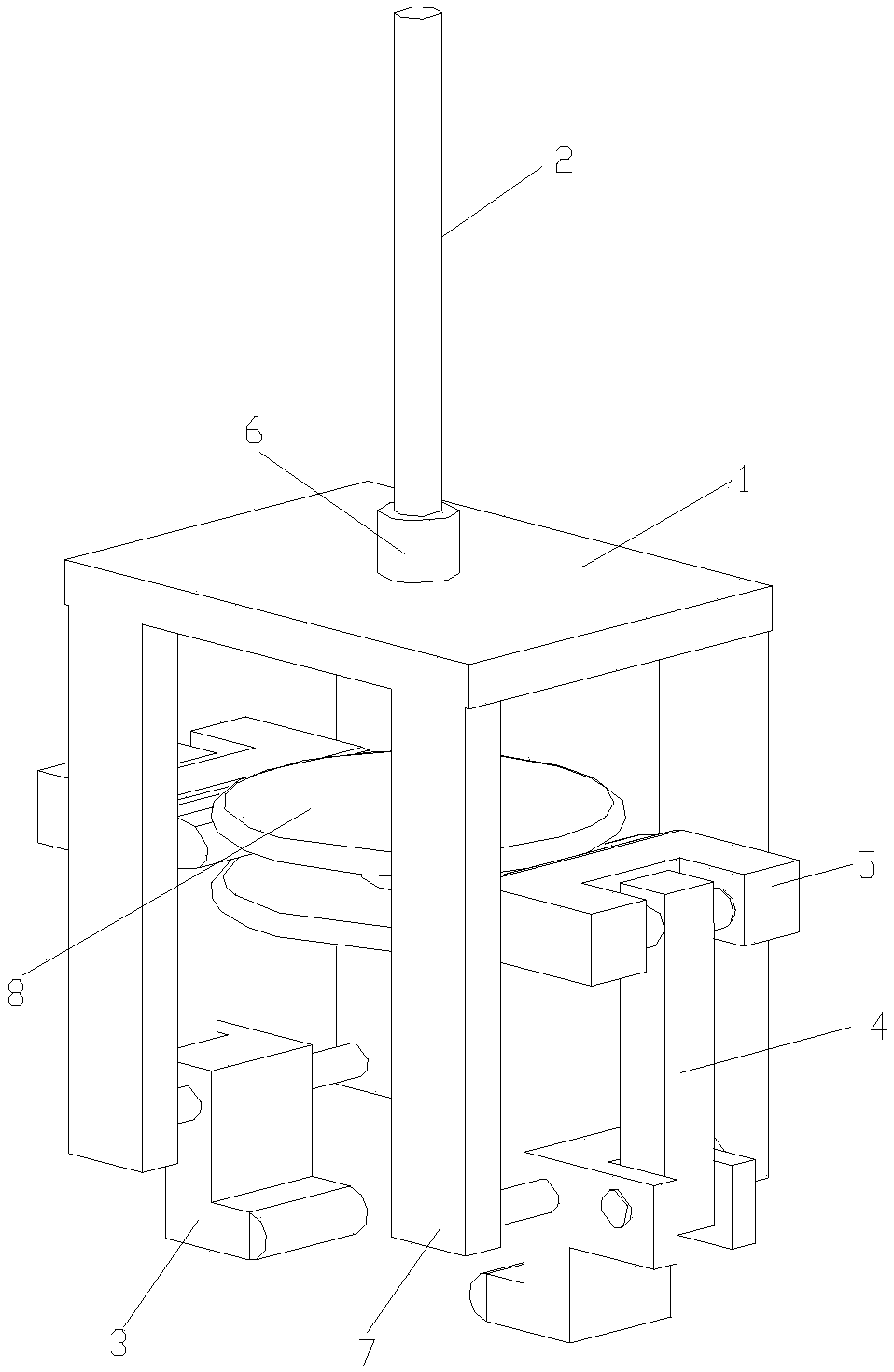

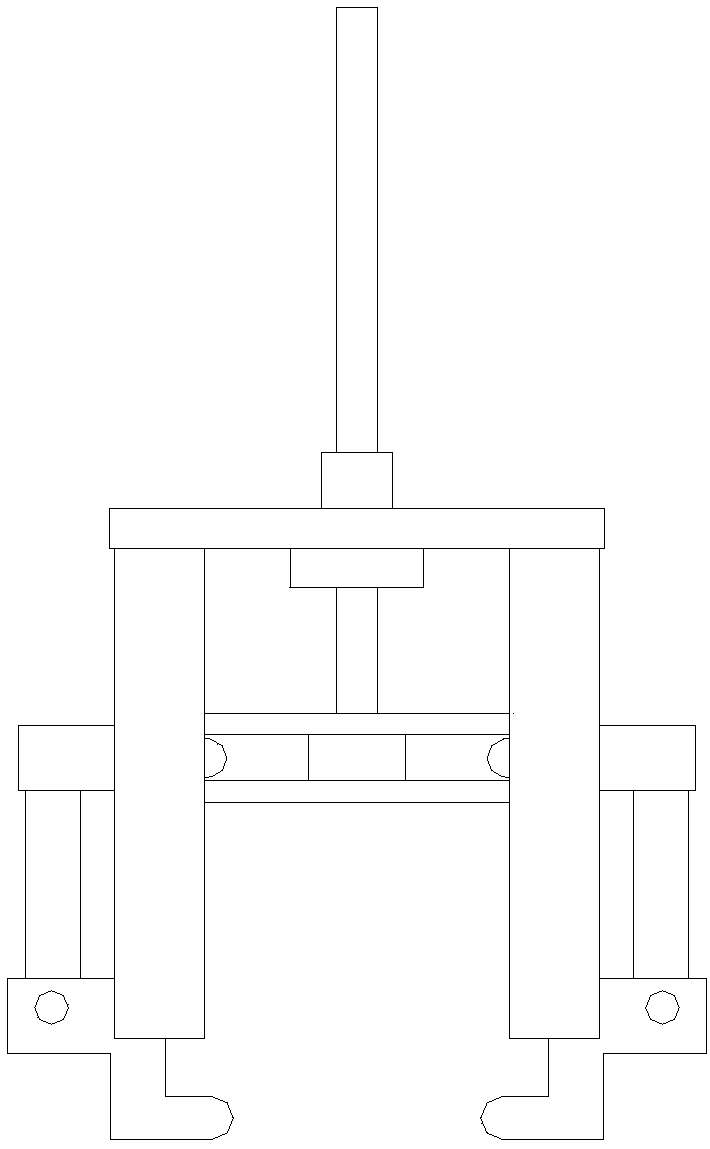

Mechanical clamping jaw

The invention relates to a mechanical clamping jaw. The mechanical clamping jaw comprises a bottom plate, a guide rod, claw heads, connecting rods and a transmission block; a guide sleeve matched withthe guide rod is arranged on the bottom plate, and the guide rod is sleeved with the guide sleeve; the two claw heads are fixed to the lower surface of the bottom plate through supporting columns, arranged oppositely, and each in a Z shape; the break angle positions of the claw heads are fixed to the supporting columns on the two sides of the claw heads through rotating shafts, and the lower endsof the claw heads serve as clamping ends, and the upper ends of the claw heads serve as connecting ends; the two oppositely-arranged claw heads clamp a workpiece through the clamping ends rotating inthe opposite direction, and the connecting ends are hinged to the transmission block through the connecting rods; the transmission block is matched with a transmission head on the guide rod, and thetransmission head is in a disc body shape; the transmission head and the guide rod are coaxially fixed, and a revolving face of the transmission head is provided with a groove matched with the transmission block; and one end of the transmission block is machined into a semi-circular protrusion, the protrusion is inserted into the groove, and the transmission head rotates by taking the protrusion in the groove as the axis.

Owner:苏州鸣人金属制品有限公司

Jumper wire double-speed chain conveying line

PendingCN109941720AReasonable structure arrangementAutomate operationsWrappers shrinkageControl devices for conveyorsEngineeringPatch cable

The invention discloses a jumper wire double-speed chain conveying line. The jumper wire double-speed chain conveying line comprises a first conveying part, a second conveying part and a third conveying part which are used for synchronously realizing forward conveying and reverse conveying, wherein the first conveying part comprises a double-layer double-speed chain line which is formed by stacking two unit layers in different conveying directions, the second conveying part comprises double-sided double-layer double-speed chain lines which are formed by combining four unit layers, the conveying direction in the same layer is the same, the third conveying part comprises an operation line based on the double-sided double-layer double-speed chain lines, a curing line is arranged between the two double-sided double-layer double-speed chain lines, the curing line comprises a current collecting device arranged in a heat preservation shell, the operation line comprises a plurality of machining stations arranged on the double-sided double-layer double-speed chain lines, the machining station are of bidirectional roller conveying assemblies composed of rollers, steering assemblies corresponding to the machining stations are arranged on the double-sided double-layer double-speed chain lines, a bundling packaging station is further arranged at the tail end of the operation line, and lifting machines used for transferring materials on the upper layer and the lower layer are correspondingly arranged at the starting end of the first conveying part and the tail end of a detection part.

Owner:JIANGSU XINDA COMM TECH

Relay Sophistication Testing Organization

ActiveCN107045102BSophisticated Test SmoothSophisticated testing in orderCircuit interrupters testingTest frameSoftware engineering

The invention discloses a relay sophistication test mechanism which comprises a test stand, a drive device, a transmission chain and a transfer test device. The drive device drives the transfer test device to circulate along a guide rail groove through the transmission chain. The transfer test device comprises a transfer test frame, a rotating shaft, a test lifting plate, a test fixture plate and a jig plate drive part. The rotating shaft is rotationally arranged on the transfer test frame. The rotating shaft is provided with a cam. The cam abuts against or is separated from the test lifting plate. An elastic part is arranged between the test lifting plate and the transfer test frame. The rotating shaft is arranged outside the transfer test frame. The rotating shaft is provided with a connecting rod and a roller. The connecting rod is hinged on the transmission chain. The roller is accommodated in the guide rail groove in a rolling manner. According to the invention, the relay sophistication test mechanism is capable of transporting a relay in the movement form of a ferris wheel and occupies a small space; the relay is moved from the starting position on one side of the test stand to the end position on the other side, and the sophistication test is completed; the test time is fully used.

Owner:HUIZHOU JINYUAN PRECISION AUTOMATION EQUIP

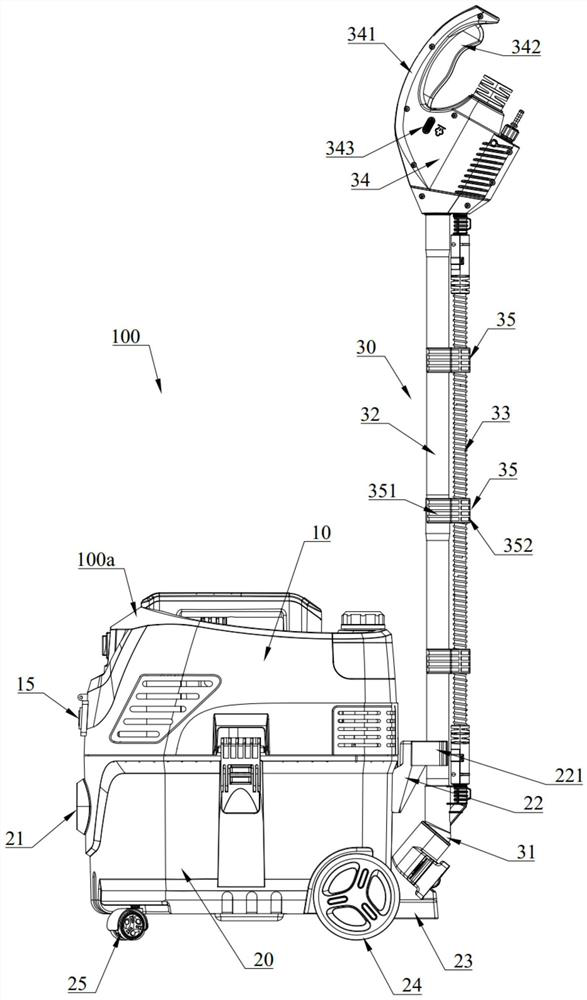

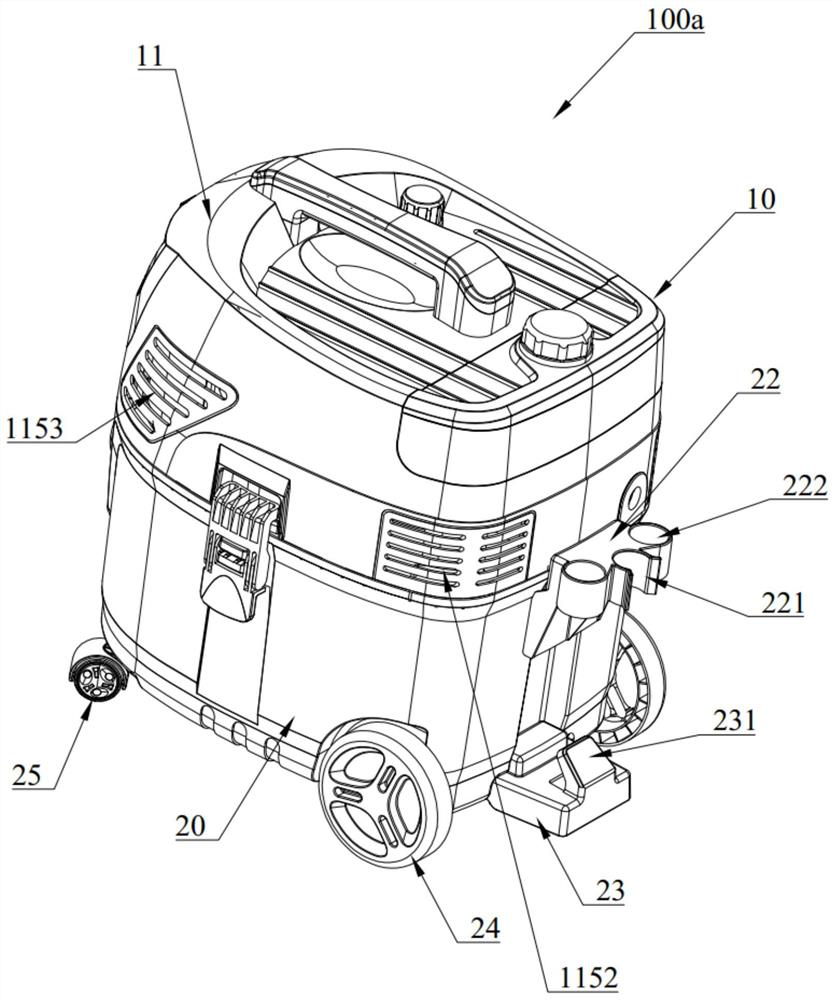

Steam dust collector

PendingCN111956123AShort pathReduces the possibility of high temperature meltingSuction cleanersThermodynamicsEngineering

The invention discloses a steam dust collector which comprises a dust collection box and a box cover. The box cover is mounted at the top of the dust collection box; the box cover comprises a box cover shell, a dust collection fan, a water tank and a steam generator; the dust collection fan, the steam generator and the water tank are mounted on the tank cover shell; the steam dust collector defines a central axis; the front end and the rear end of the steam dust collector are defined in the direction of the central axis; the central axis is perpendicular to the axis of the dust collection fan;the front end of the dust collection box is provided with a dust collection pipeline connecting structure used for being connected with a dust collection pipeline. A steam pipeline connecting structure for connecting a steam pipeline is arranged at the front end of the box cover; the water tank is arranged at the rear end of the tank cover; a generator containing cavity used for containing a steam generator is formed in the front end of the box cover shell. The steam generator is located in the generator containing cavity. The collector has the beneficial effect that the internal structure arrangement is reasonable.

Owner:永康市超锐电器有限公司

Automatic stacking and packing all-in-one machine

ActiveCN105564746BNeatly foldedReasonable structure arrangementBinding material applicationEngineeringLabor operations

The invention discloses an automatic net folding and packaging all-in-one machine. The automatic net folding and packaging all-in-one machine is composed of a bar inserting mechanism, a first bar drawing mechanism, a bar pulling mechanism, a second bar drawing mechanism, a bar conveying mechanism, a net bearing mechanism, a net pressing mechanism and a controller which are mounted on a machine frame, wherein the machine frame is halved; one side of the machine frame is provided with the bar inserting mechanism, the first bar drawing mechanism, the second bar drawing mechanism and the bar conveying mechanism, the bar inserting mechanism and the first bar drawing mechanism are located at one end of the same side, the second bar drawing mechanism is located at the other end, and the bar conveying mechanism is mounted in the position, between the first bar drawing mechanism and the second bar drawing mechanism, of the machine frame horizontally; the bar pulling mechanism, the net bearing mechanism and the controller are mounted on the other side of the machine frame, the bar pulling mechanism is mounted on the machine frame horizontally, the net bearing mechanism is mounted in the position, below the bar pulling mechanism, of the machine frame, the net pressing mechanism is mounted in the position, above the bar pulling mechanism, of the machine frame, and the controller is mounted on the lateral face of the machine frame. The structural layout of the automatic net folding and packaging all-in-one machine is reasonable, nets are folded in order automatically at a time, no labor operation is needed during folding, so that the production efficiency is high, the labor intensity is high, and the folding effect is good.

Owner:滨州宏愿化纤制品有限公司

A double intermediate shaft dct structure and its gear ratio calculation method

ActiveCN103032528BShorten the lengthIncrease load capacityToothed gearingsGearing detailsEngineeringCalculation methods

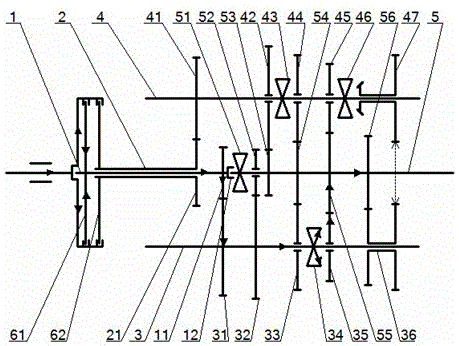

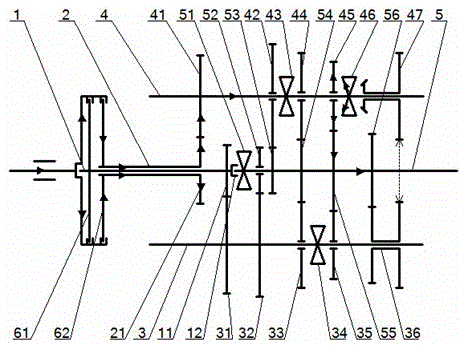

The invention relates to a double-intermediate-shaft DCT (Dual Clutch Transmission) structure and a computing method of a gear transmission ratio thereof. The double-intermediate-shaft DCT structure comprises dual clutches, a solid input shaft and a hollow input shaft, wherein one ends of the solid input shaft and the hollow input shaft which are coaxially arranged are connected with the dual clutches, and a normally engaged gear is respectively arranged at each of the other end of the solid input shaft and the other end of the hollow input shaft; the hollow input shaft is matched with an even-number gear intermediate shaft through a normally engaged gear set, and the even-number gear intermediate shaft is matched with an output shaft through a gear set; the solid input shaft is matched with an odd-number gear intermediate shaft through the normally engaged gear set, the odd-number gear intermediate shaft is matched with the output shaft through a gear set; and the tail end of the solid input shaft is matched with the head end of the output shaft sequentially through an embedded bearing and five-gear seven-gear synchronizers, and the total transmission ratios of all the gears are distributed in a geometric progression manner from the seventh gear to the first gear. The double-intermediate-shaft DCT structure not only achieves a structure of four synchronizers and eight speed-variable gears, but also is compact in layout and shortened in lengths of the input shafts.

Owner:DONGFENG MOTOR CORP HUBEI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com