Industrial-wastewater purifying treatment device

A technology for industrial waste gas, purification and treatment, applied in gas treatment, chemical instruments and methods, use of liquid separation agents, etc., can solve problems such as imperfect and unreasonable design, long purification process, and low purification efficiency, and achieve fast and efficient Removal, high purification rate, good purification effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

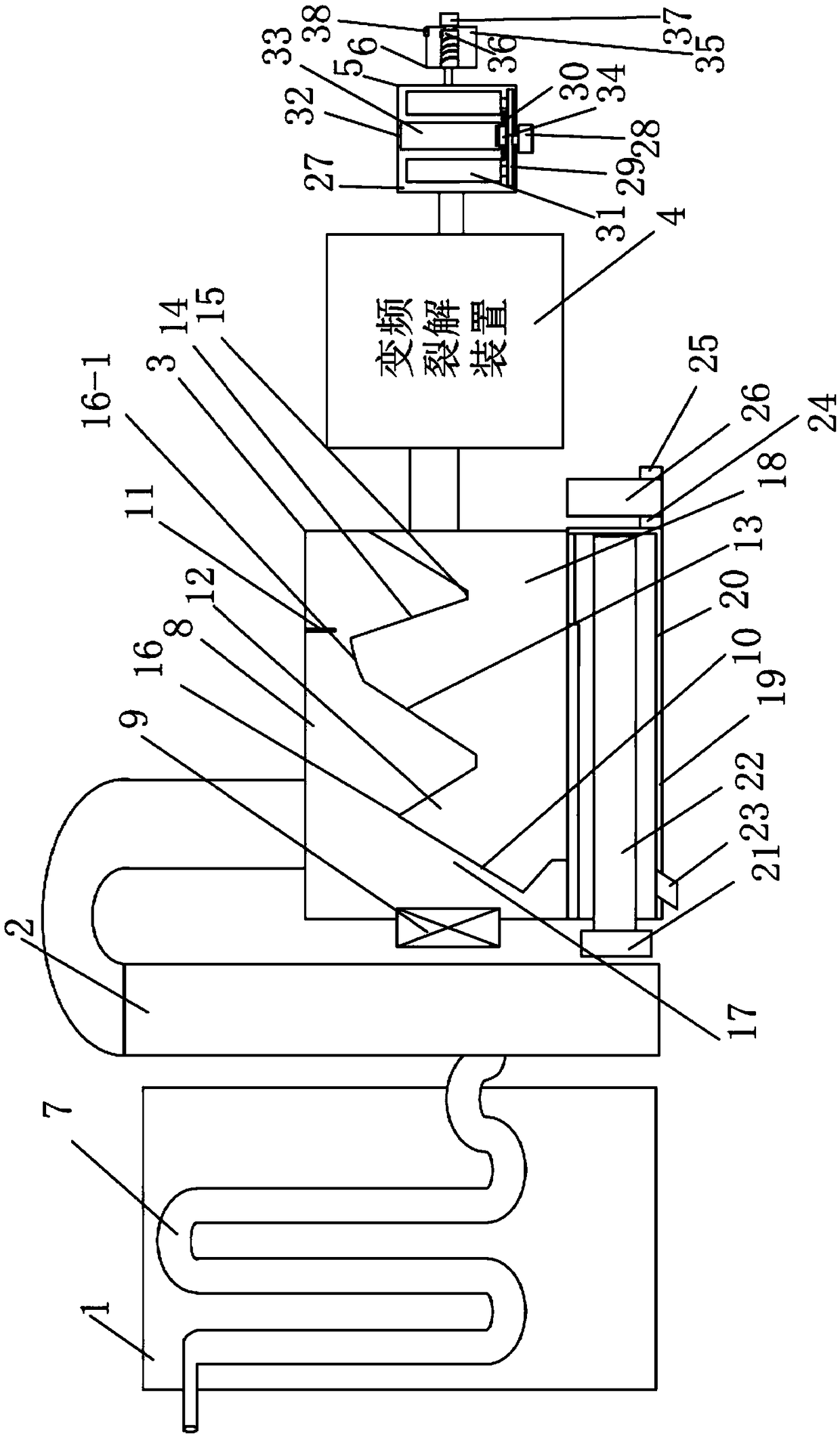

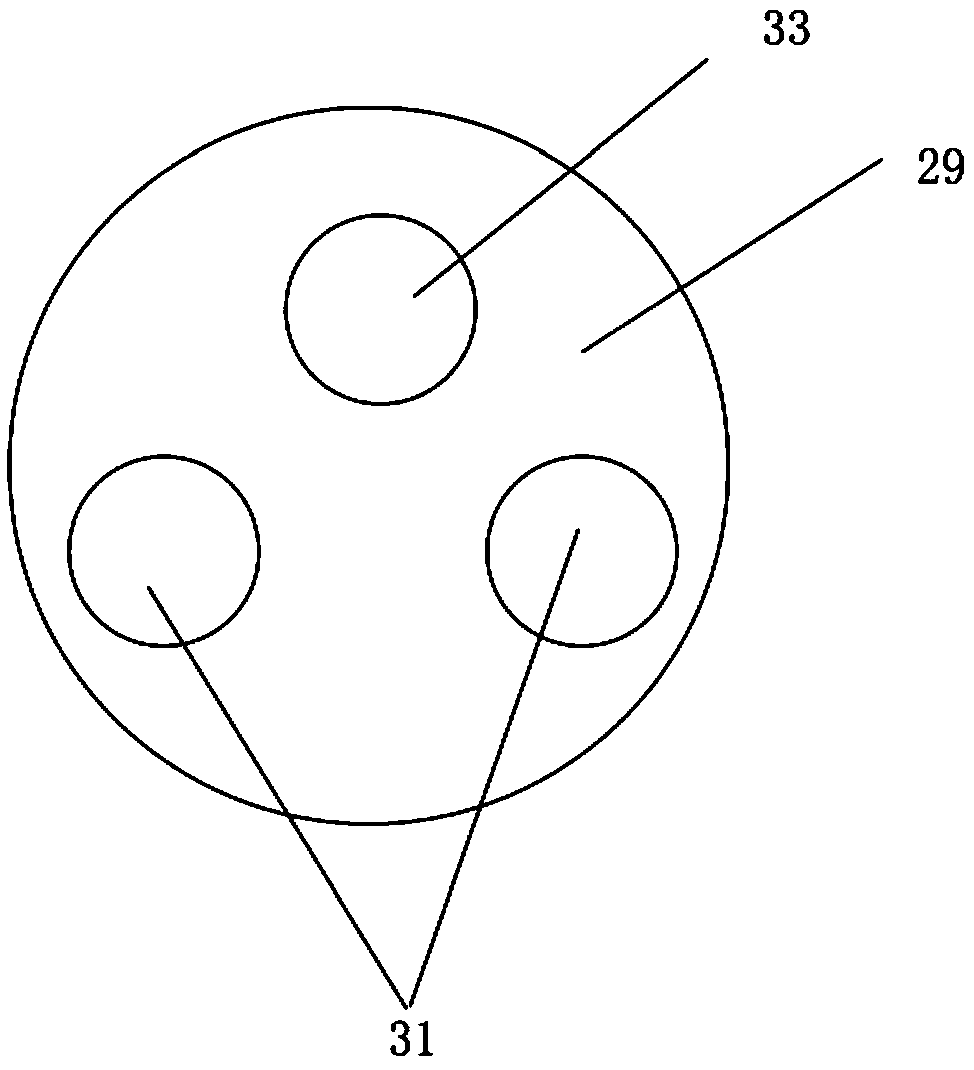

[0032] The following is attached Figure 1-2 The present invention is described in further detail.

[0033] An industrial waste gas purification treatment device, such as Figure 1-2 As shown, an industrial waste gas purification treatment device includes a cooling area 1, a spray tower 2, a water retaining part 3, a frequency conversion cracking device 4, a deodorizing device 5, and a drying device 6 connected in sequence through pipelines. Zone 1 includes a wavy heat dissipation pipeline 7 placed inside the zone. The output of the heat dissipation pipeline 7 is connected to the spray tower 2 through a pipeline. The blowing device 9, the water retaining frame 10 located inside the box body 8, and the water retaining plate 11 located on the top of the water retaining frame 10 and having a distance from the water retaining frame 10, wherein the water retaining frame 10 includes more than one peak-shaped structure 12, and the peak-shaped structure 12 includes a guiding baffle ...

Embodiment 2

[0036] An industrial exhaust gas purification treatment device, further, in order to improve the cooling effect, the heat dissipation pipeline 7 has a spiral structure.

[0037] By adopting the above technical solution, it is possible to reduce the temperature of the exhaust gas along the time when the exhaust gas is sent into the spray tower 2, and further improve the heat dissipation effect in the later stage.

Embodiment 3

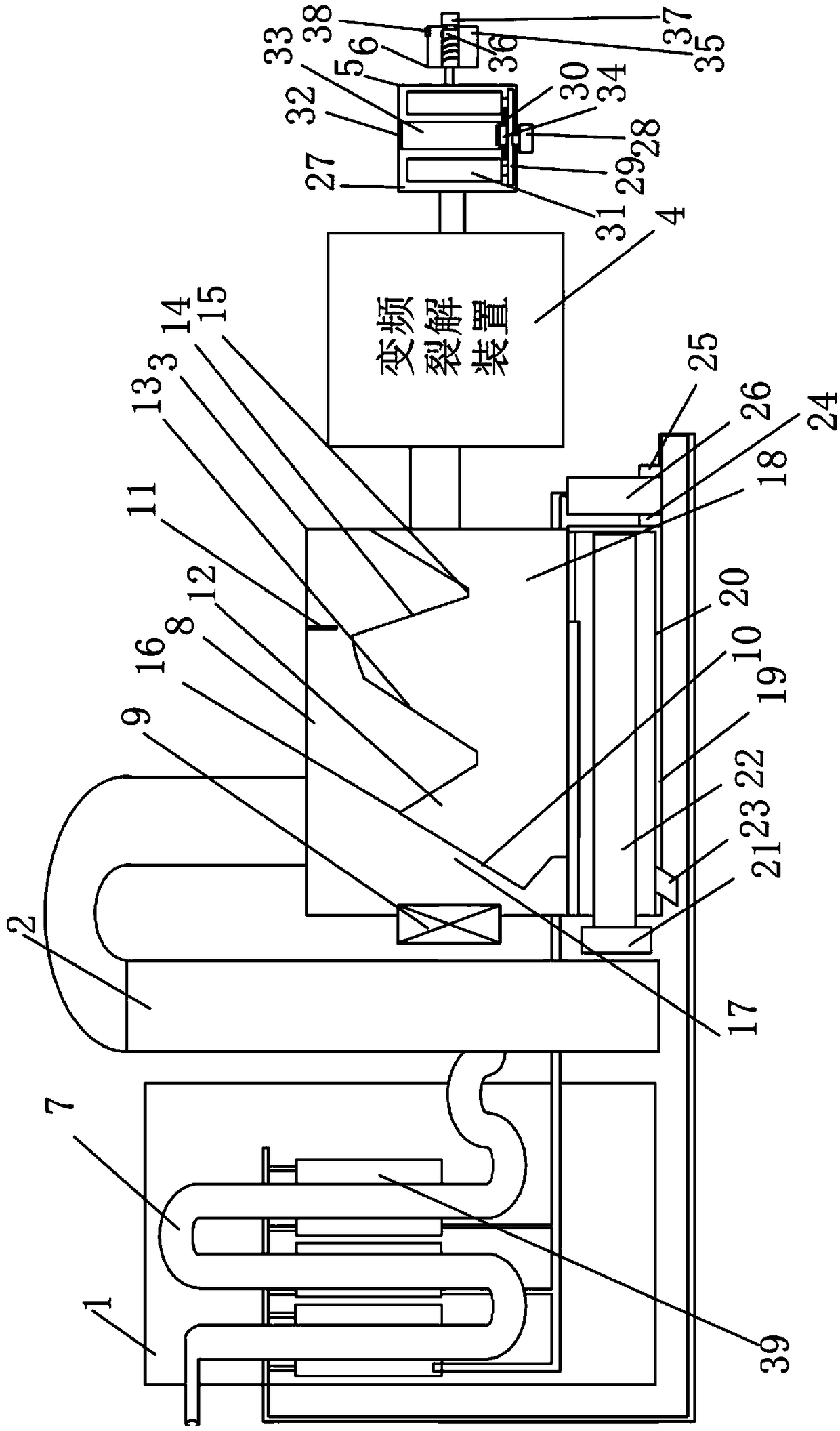

[0039] An industrial waste gas purification treatment device, such as image 3 As shown, further, in order to improve the rapid cooling of the exhaust gas and realize the effect of environmental protection and energy saving, a cooling pipeline 39 which is in circular communication with the water outlet pipe 25 is provided on the outside of the heat dissipation pipeline 7 .

[0040] By adopting the above technical solution, further, the treated clean water is used to further cool the waste gas sent in, and finally the treatment effect of the waste gas is improved.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com