A double intermediate shaft dct structure and its gear ratio calculation method

A technology of double countershafts and countershafts, which is applied to the transmission device, transmission device parts, gear transmission device, etc., can solve the problems of unreasonable arrangement of gears in the gearbox and poor mechanical strength, so as to save layout space and reduce production The effect of cost and compact structure arrangement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

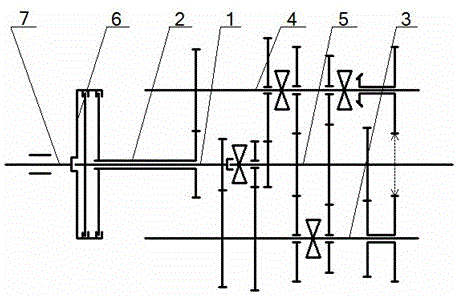

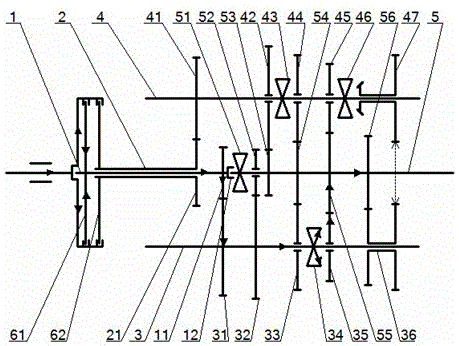

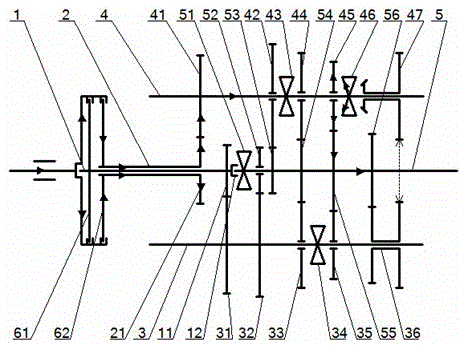

[0108] A double countershaft DCT structure, including a double clutch 6, a solid input shaft 1 and a hollow input shaft 2, the outer shell of the double clutch 6 is fixedly connected to the output end of the main input shaft 7, and the odd-numbered clutches in the double clutch 6 frictionally The plate 61 is fixedly connected with the coaxial solid input shaft 1, and the even-numbered clutch friction plate 62 in the dual clutch 6 is fixedly connected with the coaxially arranged hollow input shaft 2. The solid input shaft 1 is connected to the The output shaft 5 is driven and matched, and the hollow input shaft 2 is driven and matched with the output shaft 5 through the even-numbered intermediate shaft 4; the solid input shaft 1 is provided with a solid shaft constant mesh fixed gear 11, and the solid shaft constant mesh fixed gear 11 meshes with the odd-numbered intermediate shaft constant meshing fixed gear 31, the hollow input shaft 2 is provided with a hollow shaft constant ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com