Winding structure of unwinding box of grass mower

A pay-off box and lawnmower technology, which is applied to harvesters, agricultural machinery and implements, cutters, etc., can solve the problems of different degrees of wear and tear of the cutting wires, the inability to ensure the normal setting of the lawn mower, and large durability, etc., to achieve Reasonable arrangement, improve practicability and working stability, and avoid the effect of improper coordination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Preferred embodiment of the present invention:

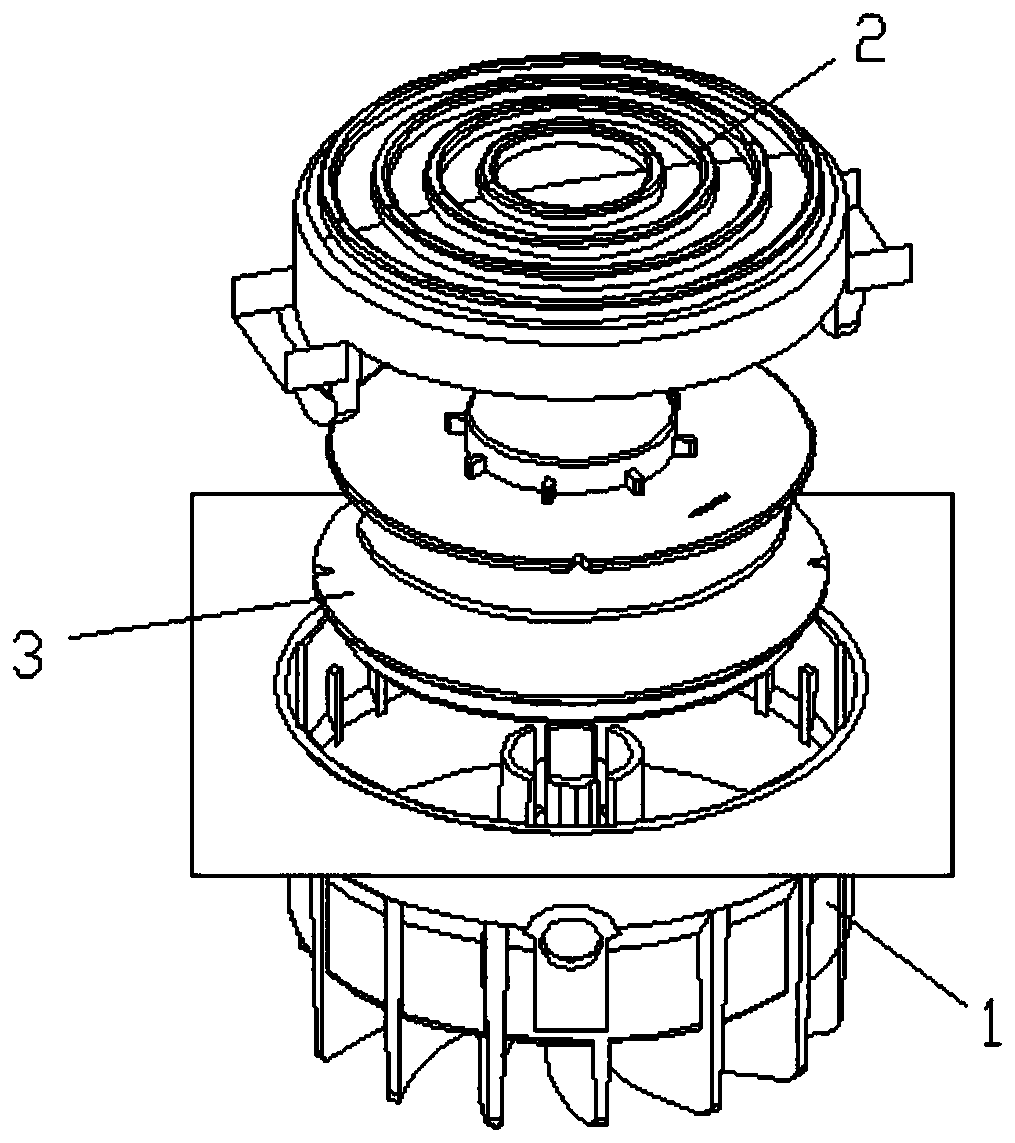

[0022] A wire take-up structure of a wire pay-off box for a grass trimmer, comprising a wire pay-off box 1, a wire pay-off cover 2, and a wire reel 3 arranged in the wire pay-off box. A supporting part 11 for rotating support is provided in the pay-off box 1, and the wire reel 3 is matched with the support part 11 through its shaft hole. Based on this cooperation, the wire reel 3 can rotate in the pay-off box 1 .

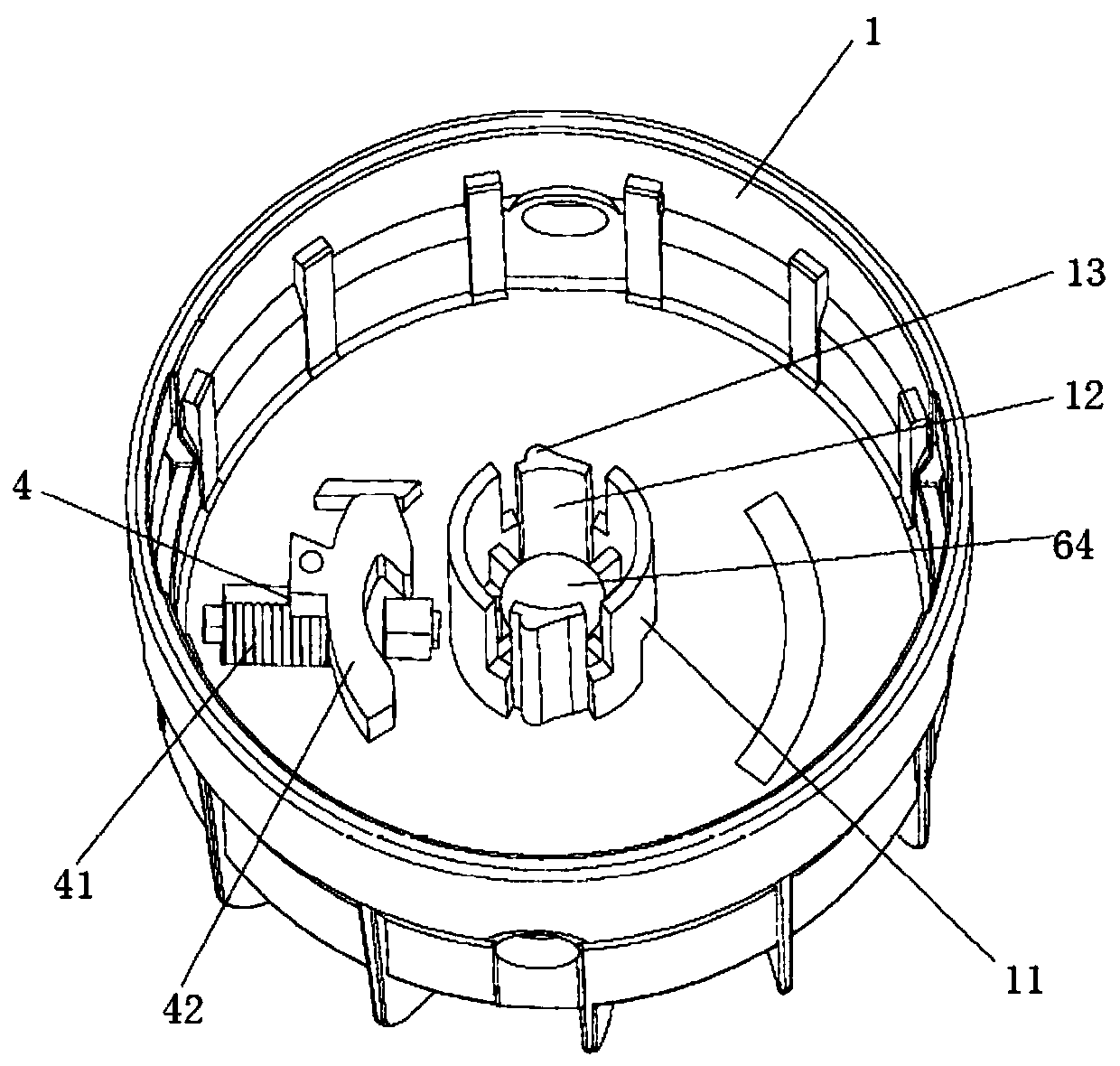

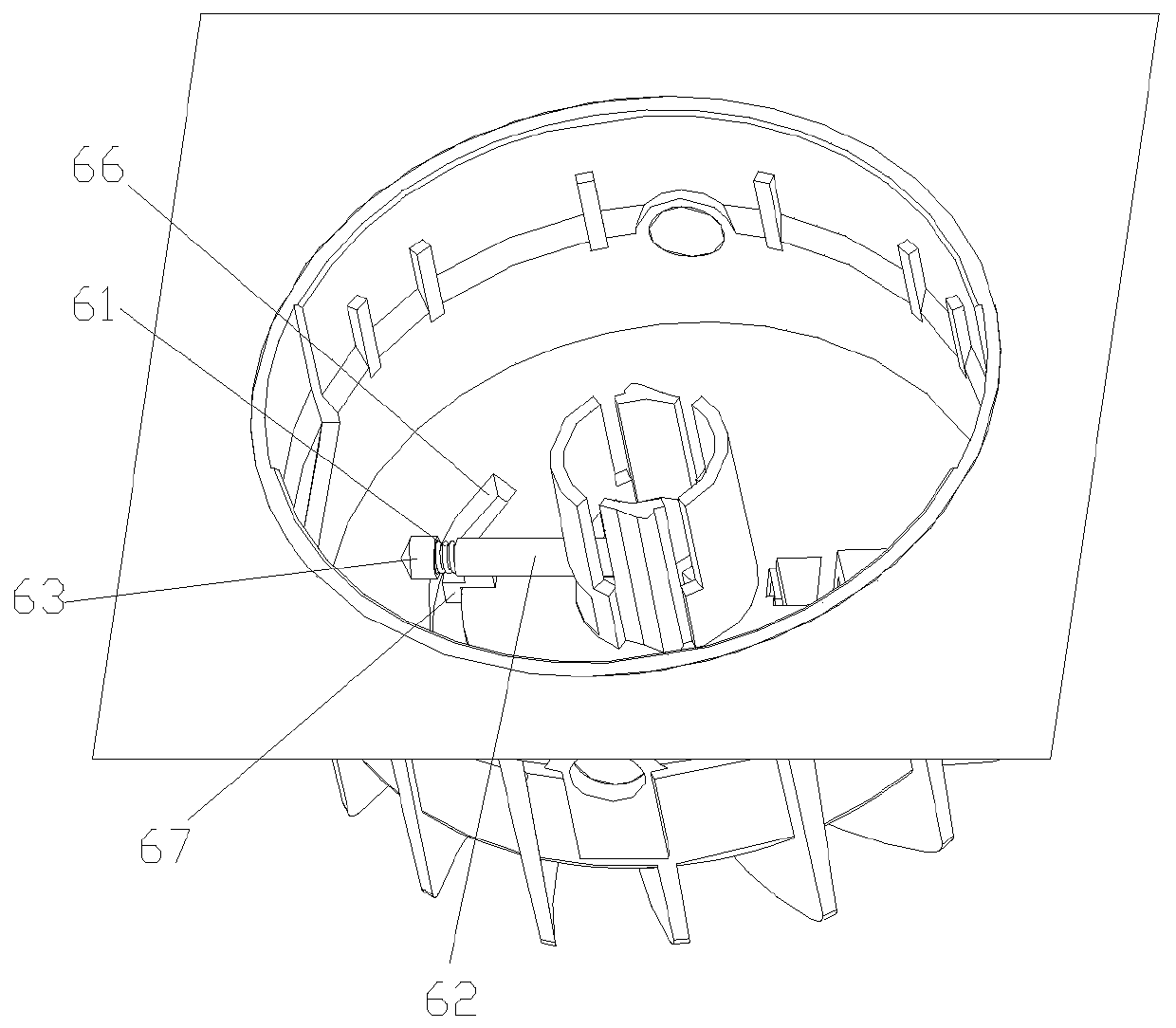

[0023] A pair of elastic ribs 12 are arranged on the peripheral wall of the support portion 11 , and the outer wall of the elastic ribs 12 has a first protruding rib 13 extending axially. A second rib 31 is arranged in the shaft hole of the wire reel 3 . When paying out, the elastic tendons 12 of the supporting part 11 spread out under the action of centrifugal force, and the first ribs 13 of the elastic ribs 12 frictionally cooperate with the second ribs 31 in the shaft hole of the reel to form damping.

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com