Jumper wire double-speed chain conveying line

A double-speed chain and conveyor line technology, applied in the field of conveyor lines, can solve problems such as conveyor line problems, and achieve the effects of improving rework efficiency, realizing automated operations, and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

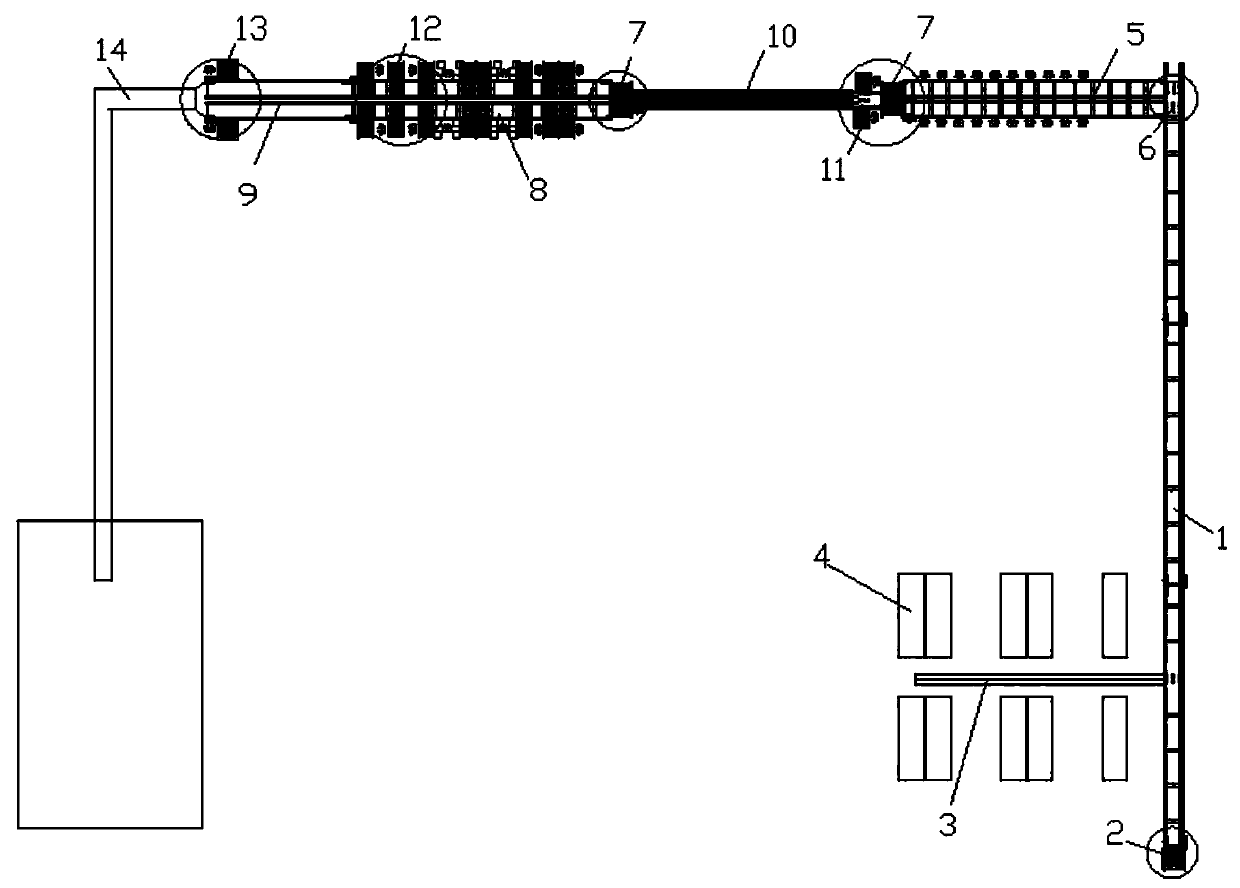

[0038] Preferred embodiment of the present invention:

[0039] A jumper double-speed chain conveying line includes: a first conveying part, a second conveying part and a third conveying part. The three conveying parts are formed by docking, and the forward conveying and reverse conveying are realized synchronously. A guardrail is set outside the conveyor line, and the guardrail surrounds the main body of the entire jumper double-speed chain conveyor line to play a role of safety protection.

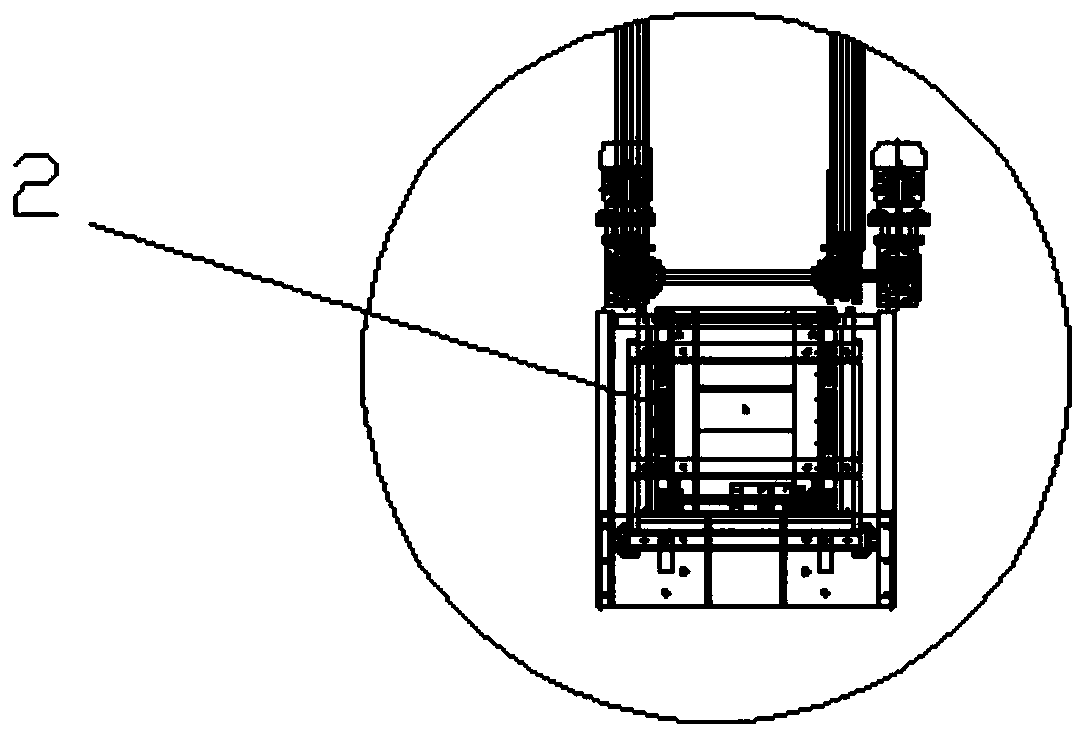

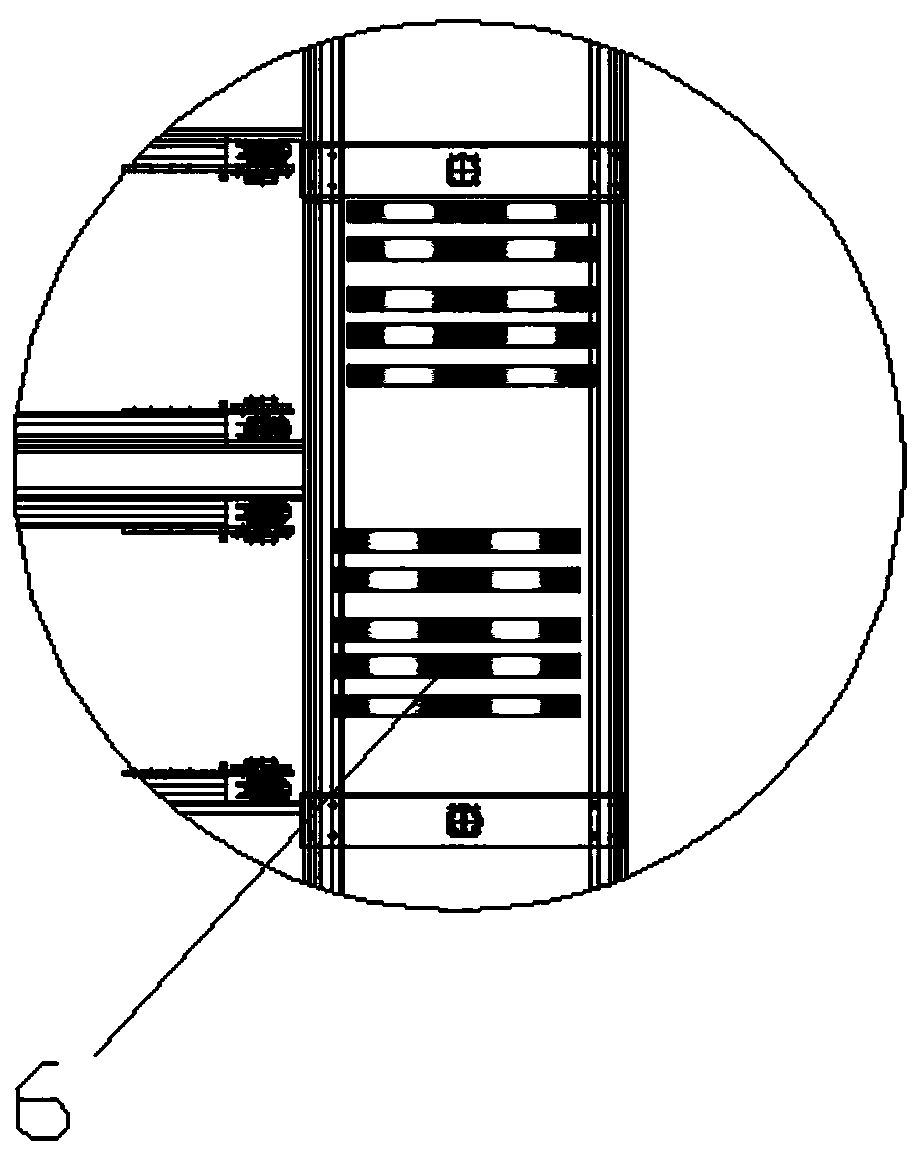

[0040] Each conveying part has a unit layer based on the forward direction of conveying or the reverse direction of conveying, and the unit layer is conveyed by a chain roller set on one side. Each conveying part has at least two unit layers, and the upper and lower unit layers are stacked to form a double-layer return conveyance. However, a diversion assembly is provided between the adjacent unit layers in the same layer, and the diversion assembly can realize the diversion of conveyin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com