Patents

Literature

99results about How to "Improve rework efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

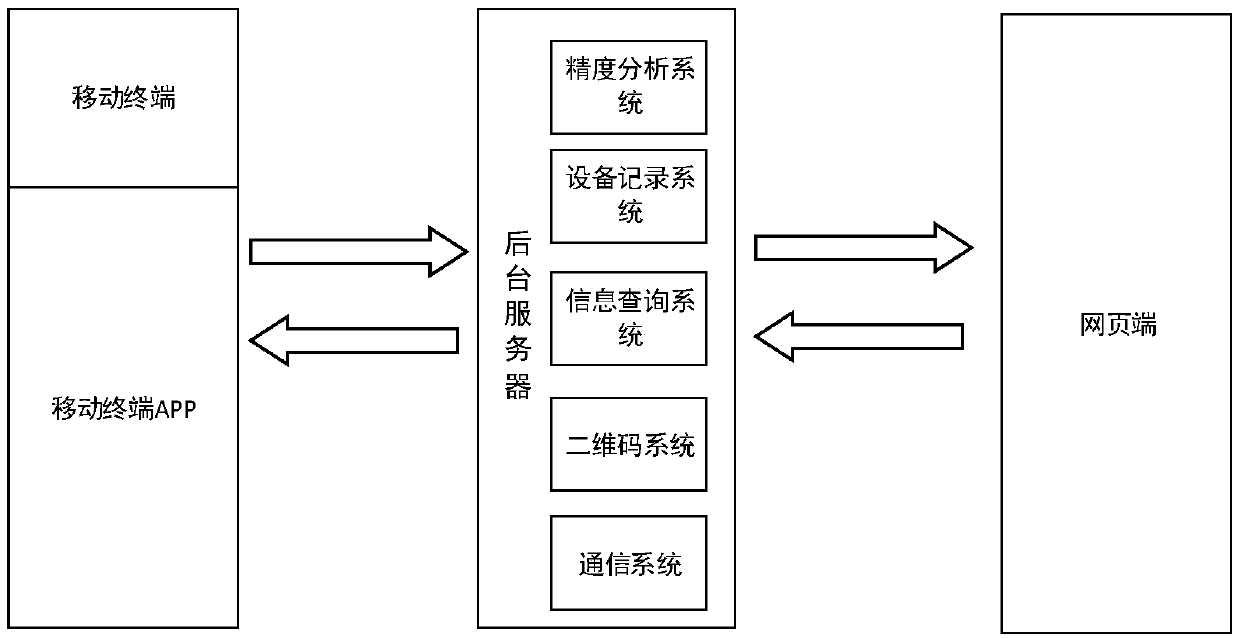

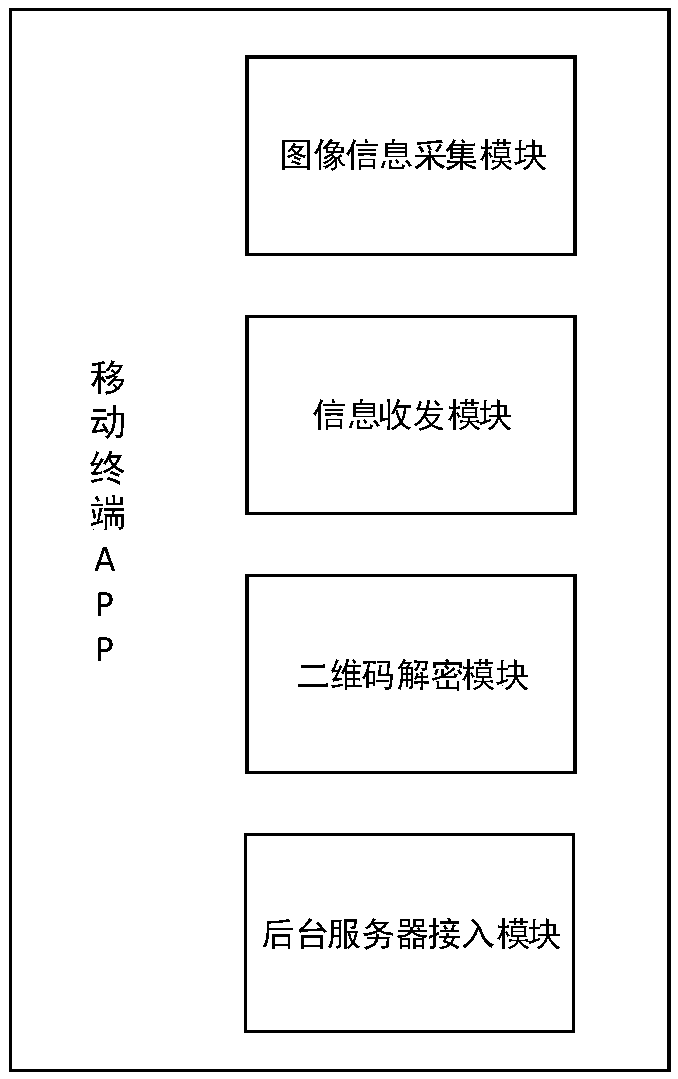

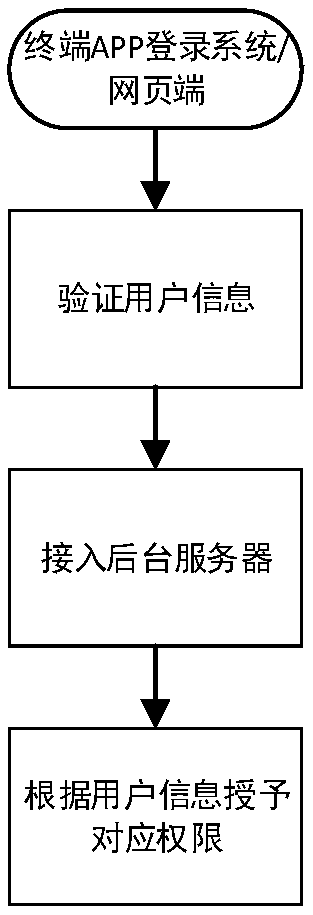

A two-dimensional code device management system

InactiveCN109255083AImprove management efficiencyPrecise positioningCo-operative working arrangementsWeb data retrieval using information identifiersRelevant informationSoftware engineering

The technical scheme of the invention comprises a two-dimensional code device management system, To implement: the device information is stored and analyzed by the background server, a corresponding two-dimensional code is generated to be bound with the corresponding device, a staff member scans the two-dimensional code displayed on the device with the mobile terminal with the mobile terminal APP,obtains the decrypted two-dimensional code information through a decryption module, and performs data exchange with a background server. The invention has the advantages that: by scanning the two-dimensional code corresponding to the device, the related information of the device can be inquired, and can directly carry out fault warranty and other operations through APP, The background server monitors the equipments in real time, which can quickly check the equipments to locate the equipments problems accurately and quickly, speed up the repairing efficiency, improve the equipment utilizationrate, register safely, check quickly, speed up the repairing efficiency, improve the equipment utilization rate, improve the enterprise management efficiency, save a lot of manpower and material resources, and realize the paperless equipment management.

Owner:精英制模实业(深圳)有限公司

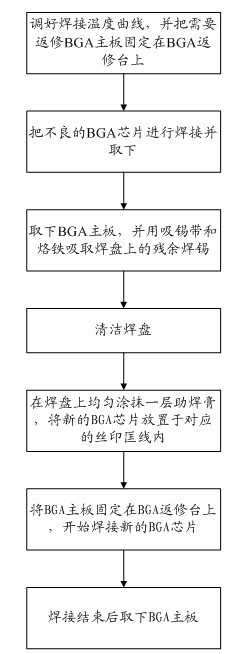

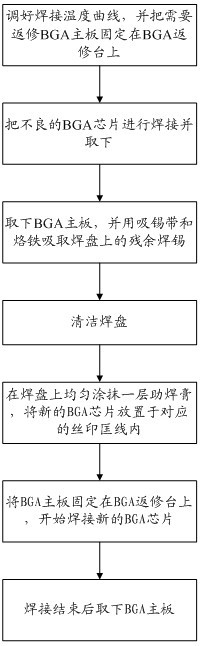

Method for removing residual solder tin from soldering-pan during repair and replacement of ball grid array (BGA) chip

InactiveCN102686044AImprove rework efficiencyImprove yield ratePrinted circuit assemblingScreen printingTemperature curve

The invention discloses a method for removing residual solder tin from a soldering-pan during the repair and replacement of a ball grid array (BGA) chip. The method comprises the following steps of: (a) well regulating a soldering temperature curve, and fixing a BGA mainboard to be repaired on a BGA repair station; (b) soldering a poor BGA chip, and taking the poor BGA chip down; (c) taking the BGA mainboard down, and sucking the residual solder tin from the soldering-pan by using a soldering wick and soldering iron; (d) cleaning the soldering-pan; (e) uniformly smearing a layer of flux paste on the soldering-pan, and placing a new BGA chip in a corresponding silk-screen printing frame wire; (f) fixing the BGA mainboard on the BGA repair station, and starting soldering the new BGA chip; and (g) after the soldering is finished, taking the BGA mainboard down. According to the method for removing the residual solder tin from the soldering-pan during the repair and replacement of the BGA chip, the residual solder tin can be effectively removed from the soldering-pan, the repair efficiency of the BGA chip is greatly improved, and the yield is also greatly improved.

Owner:JIANGSU LEMOTE TECH CORP

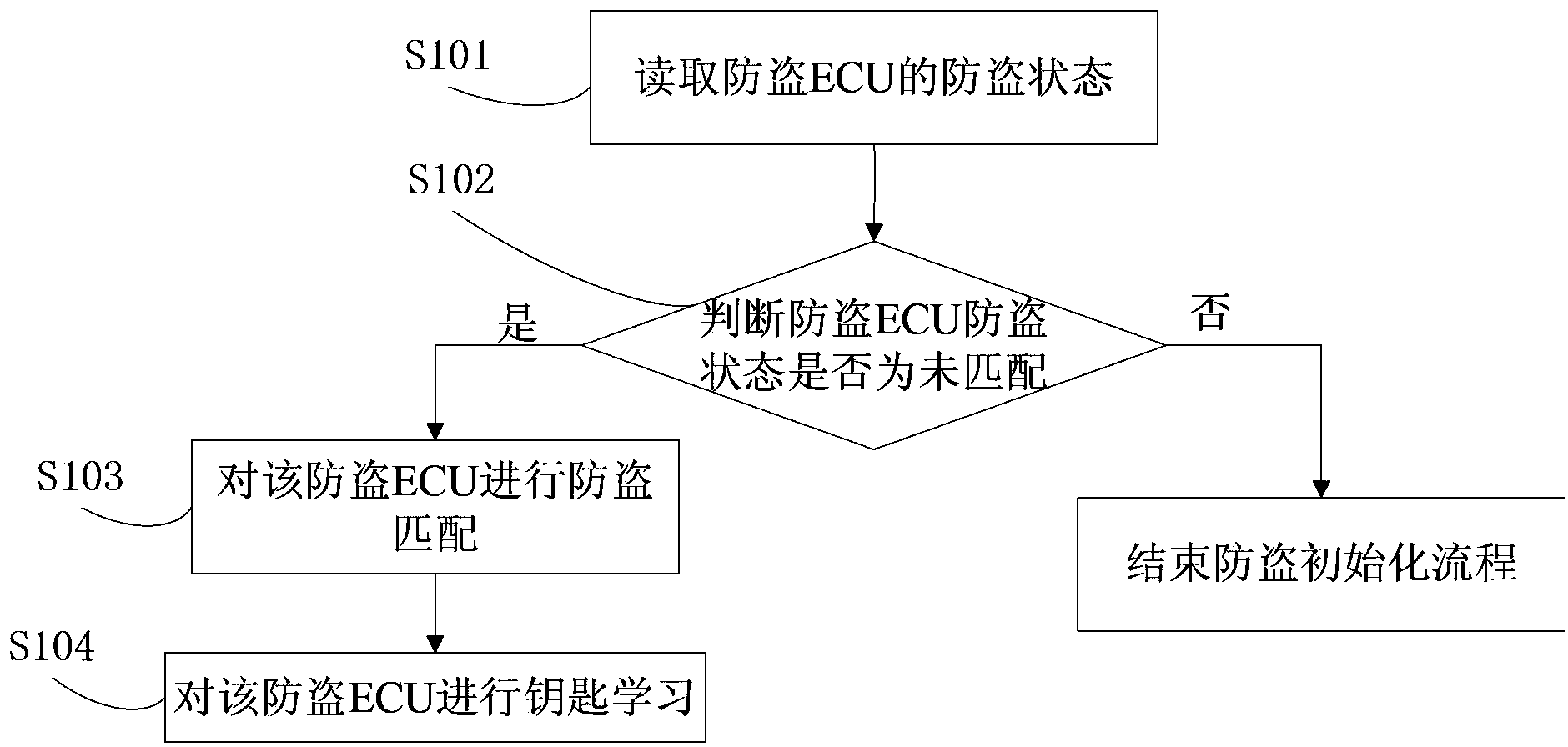

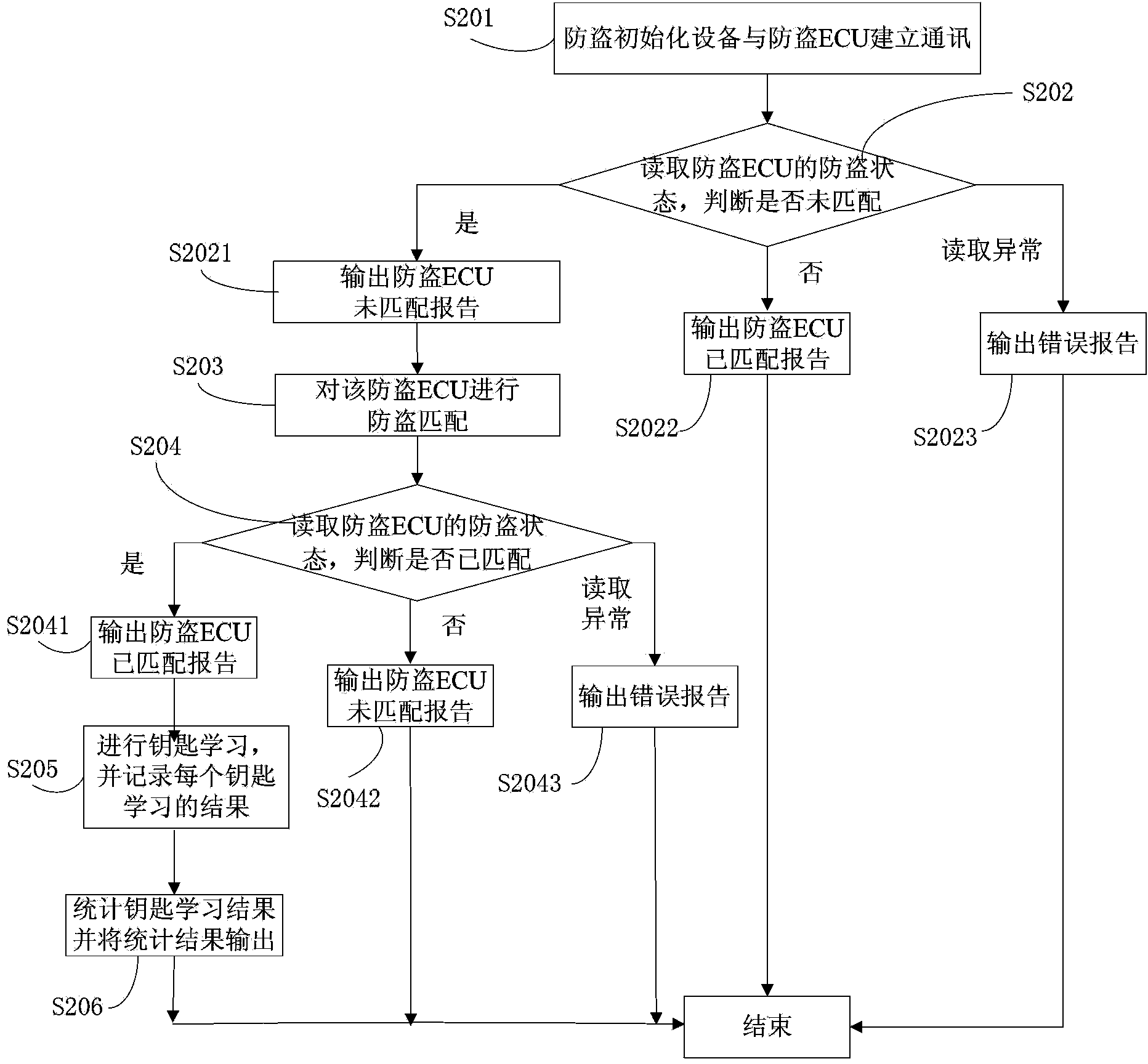

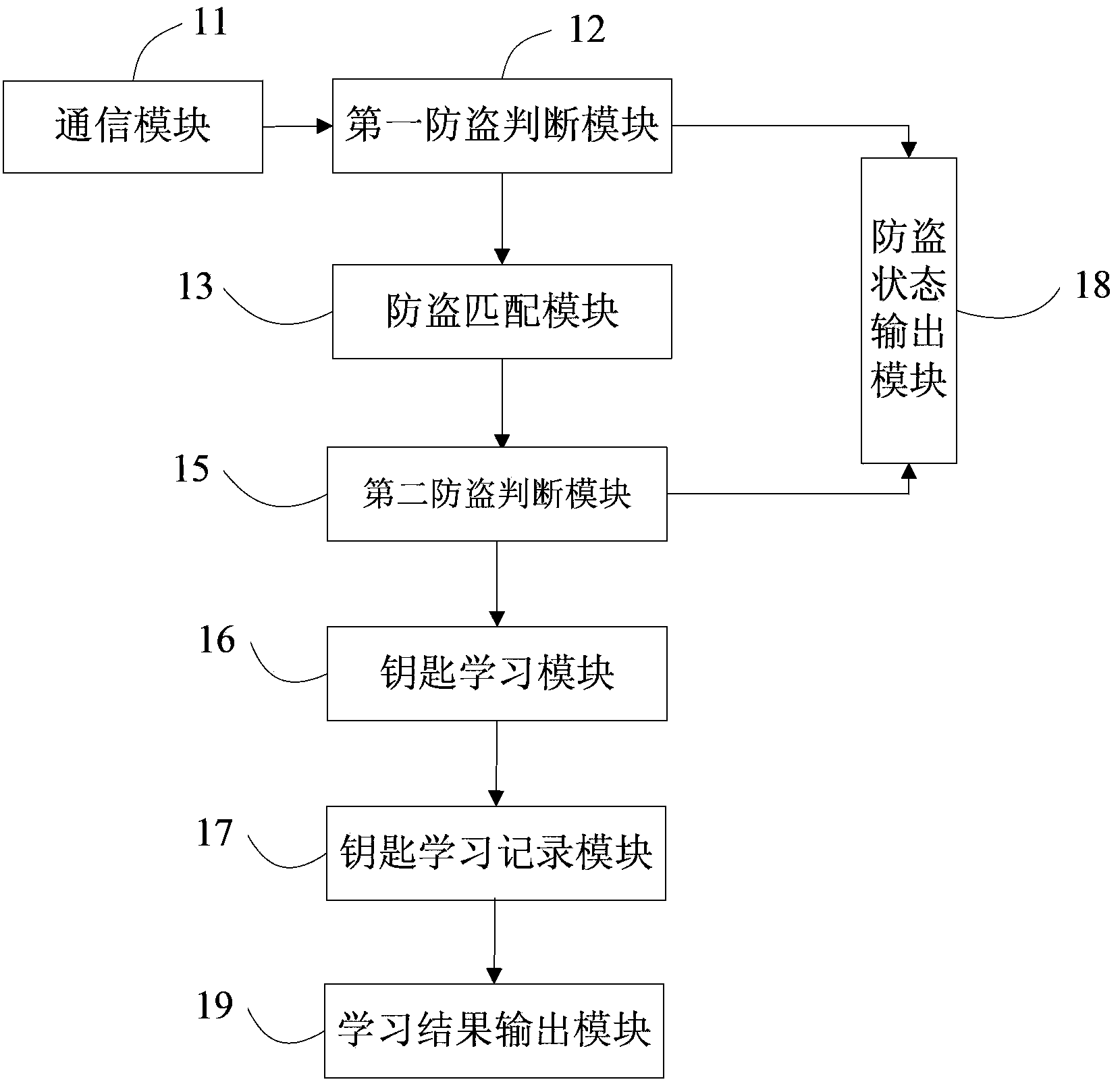

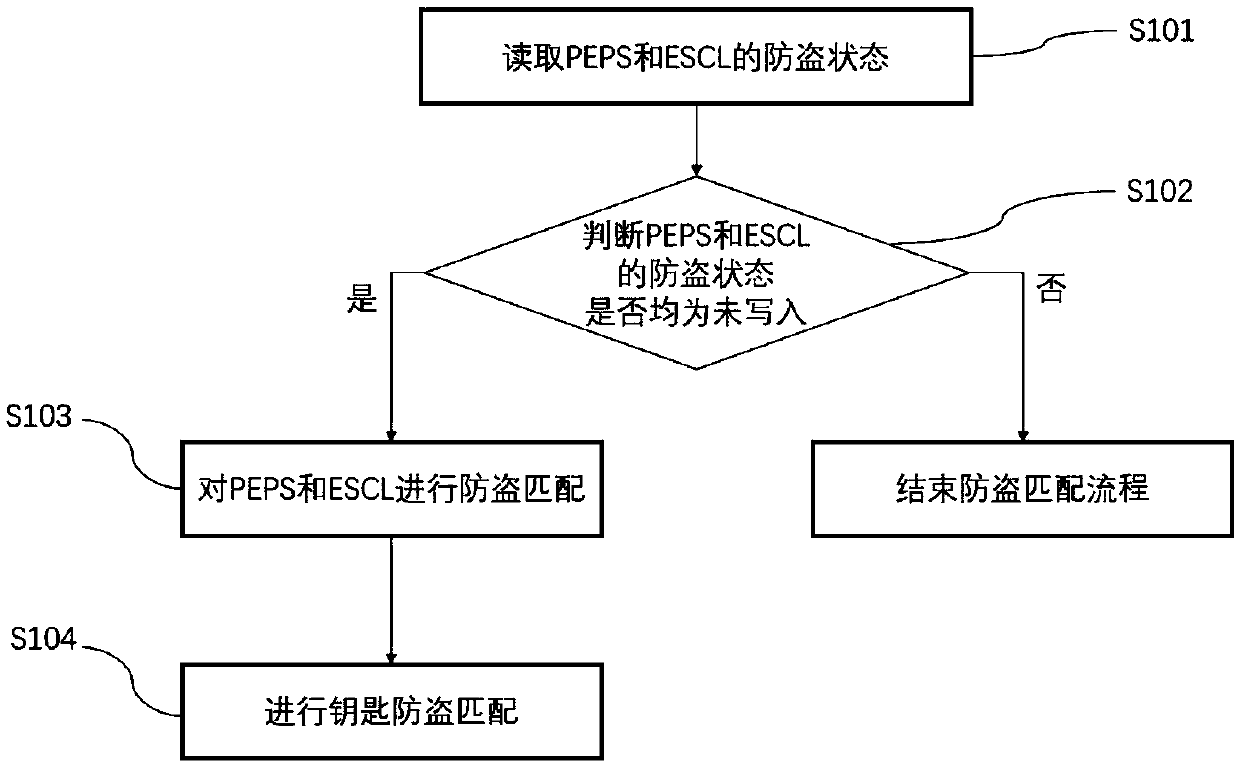

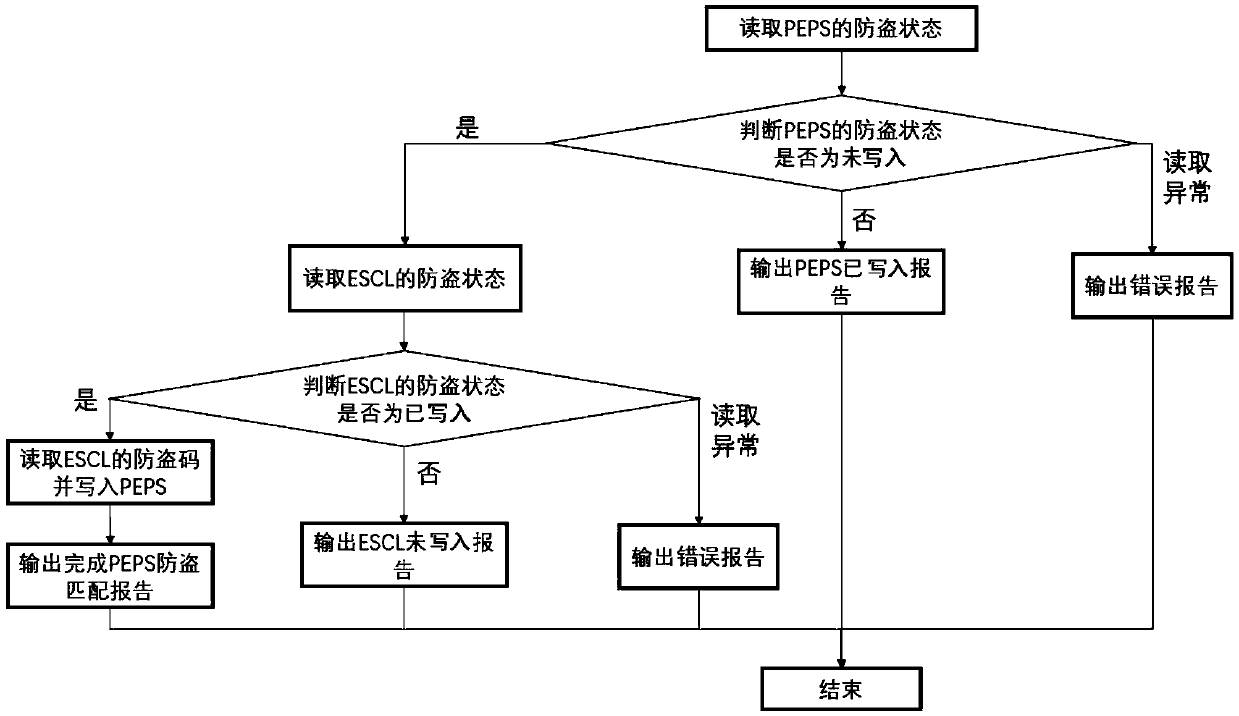

Anti-theft system initialization method, equipment and anti-theft ECUs

ActiveCN104249705APrevent mis-matchAvoid wastingAnti-theft devicesCharacter and pattern recognitionAnti theftComputer security

The invention provides an anti-theft system initialization method, equipment and anti-theft ECUs. Before the anti-theft matching is performed for the anti-theft ECUs, matching states of the anti-theft ECUs are judged; the anti-theft ECUs after the anti-theft matching or from bad sources are separated out, and the blank anti-theft ECUs without performing the anti-theft matching are matched to generate and write in anti-theft codes so as to prevent wrong learning and wrong matching of keys due to repeated matching of the anti-theft ECUs. Before the key learning is performed, the anti-theft states of the anti-theft ECUs are judged again, and the anti-theft ECUs unsuccessful in anti-theft matching or having faults in the matching are separated out, so that part waste caused by incapability of use and recovery after the key learning can be prevented effectively. The whole anti-theft and key learning process is monitored, and error and failure factors generated in the anti-theft initialization process are recorded and output to provide reliable basis for repair, so that the repair efficiency and the success rate are improved.

Owner:GUANGZHOU AUTOMOBILE GROUP CO LTD

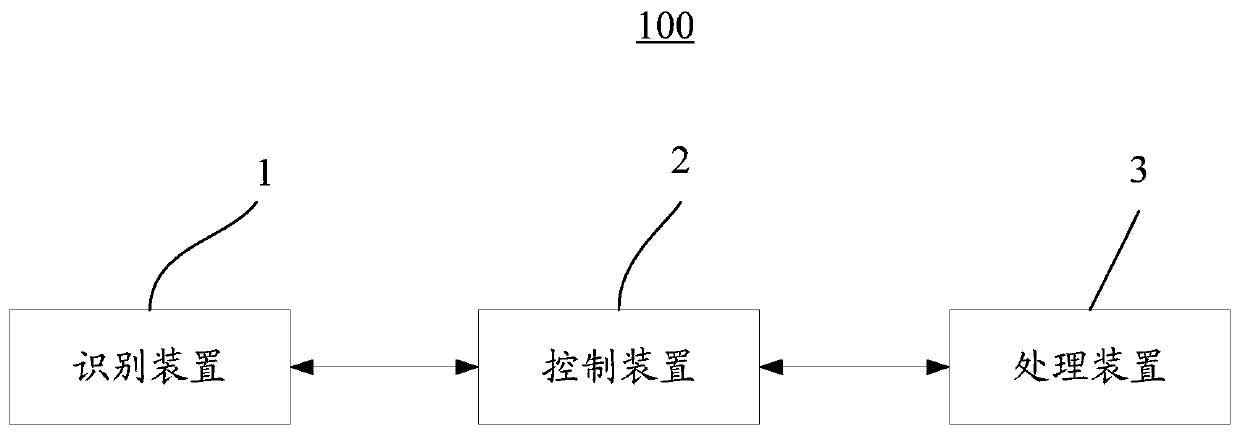

AI intelligent process abnormality recognizing and processing system and solar battery piece welding machine

InactiveCN109759755AIncrease productivityReduce human involvementWelding/cutting auxillary devicesAuxillary welding devicesProduction lineState dependent

The invention discloses an AI intelligent process abnormality recognizing and processing system and a solar battery piece welding machine. The AI intelligent process abnormality recognizing and processing system comprises multiple recognizing devices, a control device and a processing device. The multiple recognizing devices are used for being installed on a machine base and are used for collecting state related data of solar battery pieces located on multiple stations. The control device obtains the state related data of the solar battery pieces collected by the recognizing devices, comparesthe state related data with normal state data, and judges the abnormal state of the solar battery pieces. Corresponding processing information is generated according to the abnormal state. The processing device is used for receiving the processing information and carrying out related processing, manual participation is reduced, the production efficiency of the solar battery module production lineis improved, the yield of products is increased, and the system has a better effect.

Owner:WUHAN SUNIC INTELLIGENT EQUIP MFG CO LTD

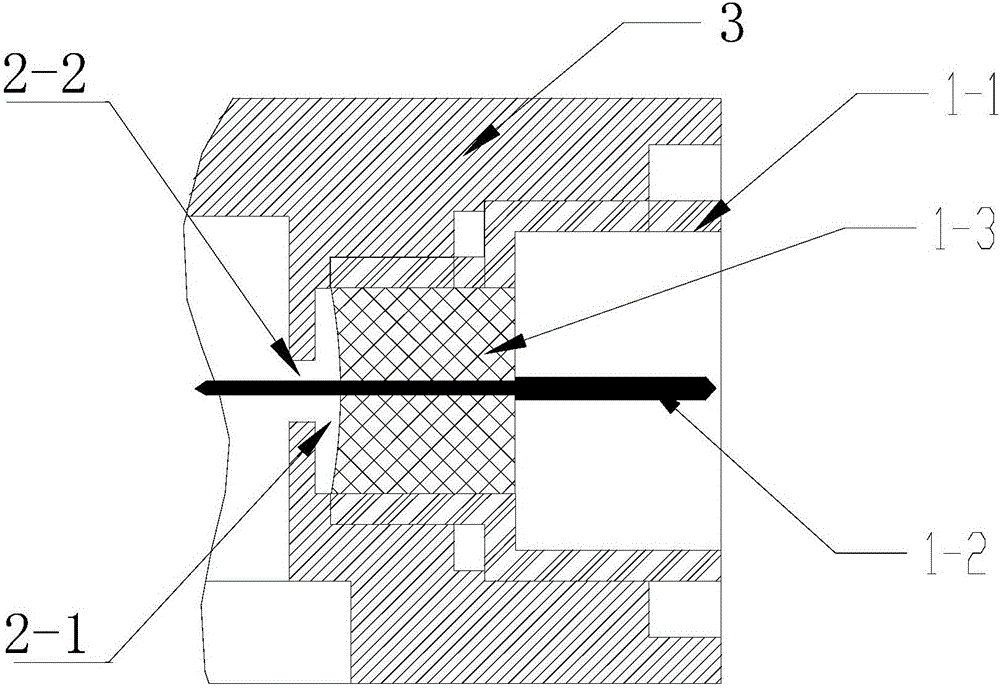

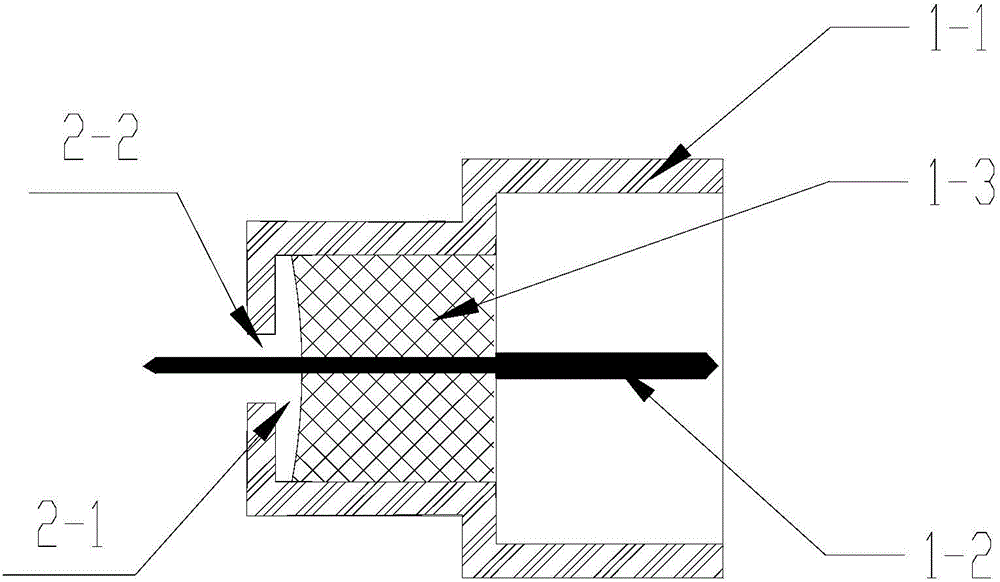

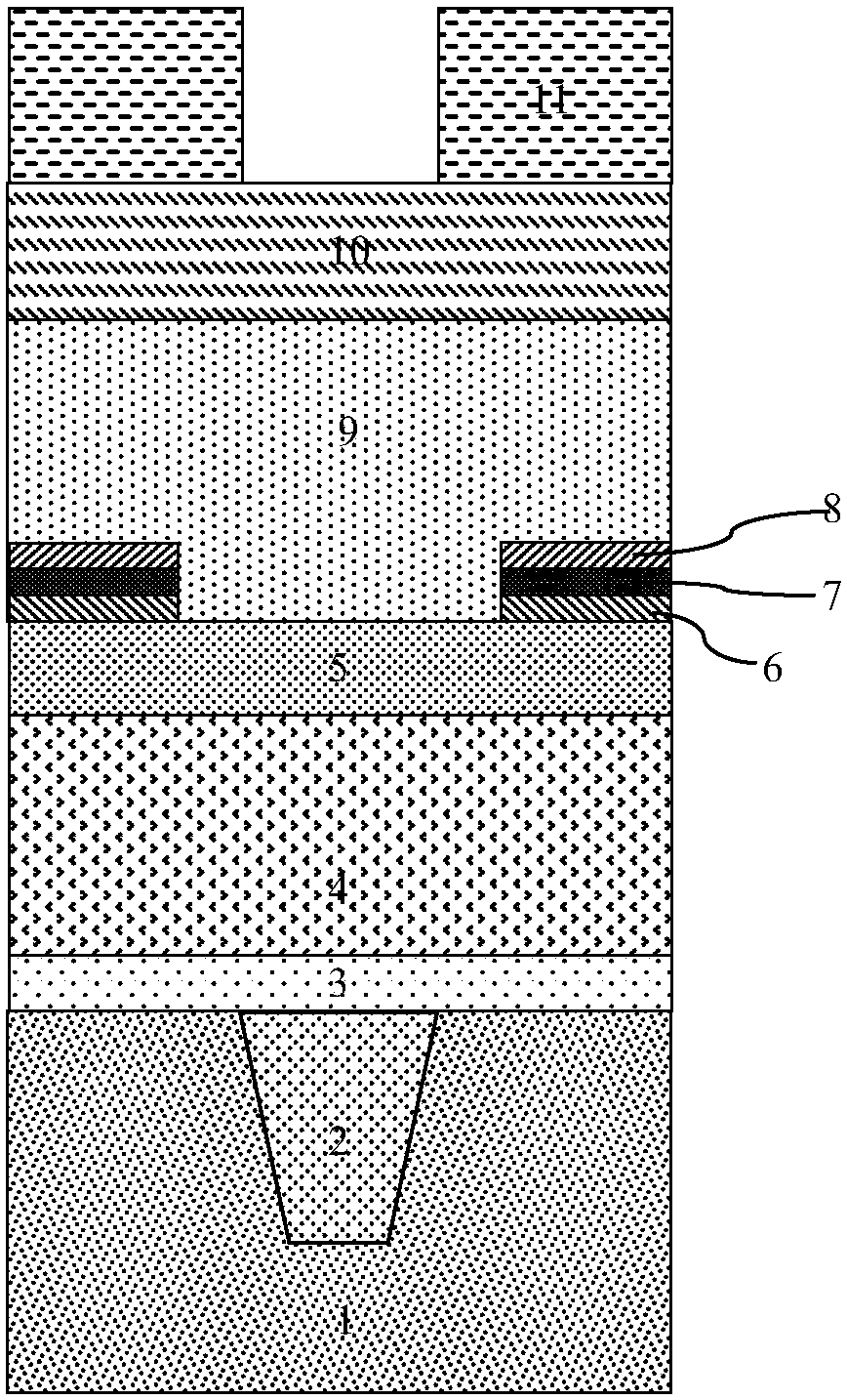

Radio frequency coaxial connector and microwave transmission structure

InactiveCN106785739AReduce welding difficultyImprove standing wave characteristicsSecuring/insulating coupling contact membersTwo-part coupling devicesImpedance matchingEngineering

The invention discloses a radio frequency coaxial connector. The radio frequency coaxial connector comprises a radio frequency coaxial connector body and air cavity structures for impedance matching required when the radio frequency coaxial connector body is transited to a microstrip line, and the air cavity structures which are generally designed and processed in connector mounting holes are directly designed at the end part of the end, connected with the microstrip line, of the radio frequency coaxial connector body. Compared with the prior art, the radio frequency coaxial connector has the advantages that quantitative measurement of standing waves after impedance matching between the radio frequency coaxial connector body and the air cavities can be realized, the machining difficulty of millimeter waveband connector mounting holes is particularly reduced, and deterioration of the standing waves, caused by tolerance accumulation of the mounting holes and the radio frequency coaxial connector body, is avoided; the welding difficulty of the radio frequency coaxial connector body and the mounting holes is greatly lowered, and deterioration of the standing waves, caused by mismatching of the air cavity structures due to welding of the radio frequency coaxial connector body, is also avoided; the standing wave performance after installation of the radio frequency coaxial connector body is guaranteed, and the radio frequency coaxial connector is particularly suitable for transmitting such high-frequency signals as millimeter waves.

Owner:CHINA ELECTRONIC TECH GRP CORP NO 38 RES INST

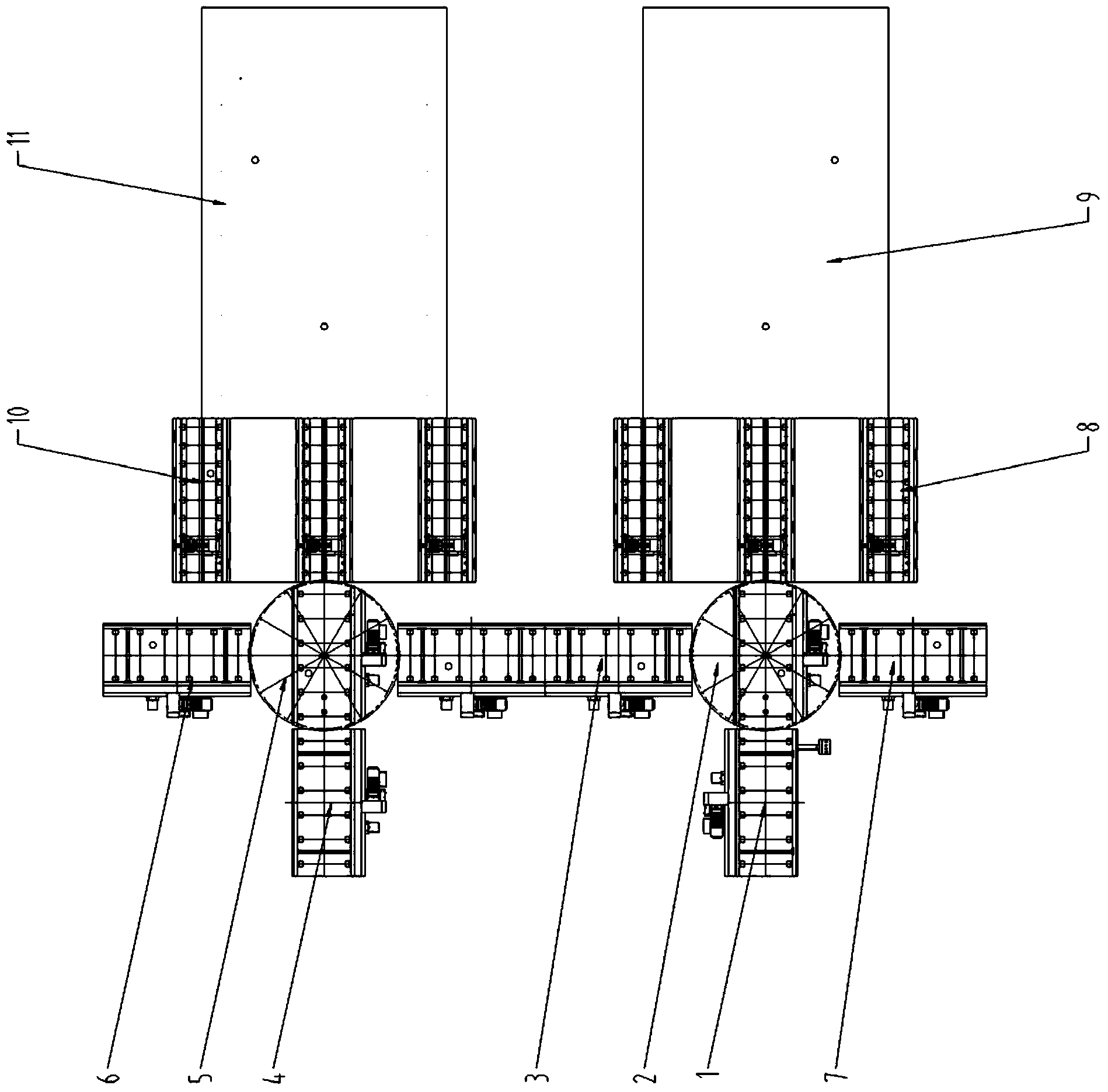

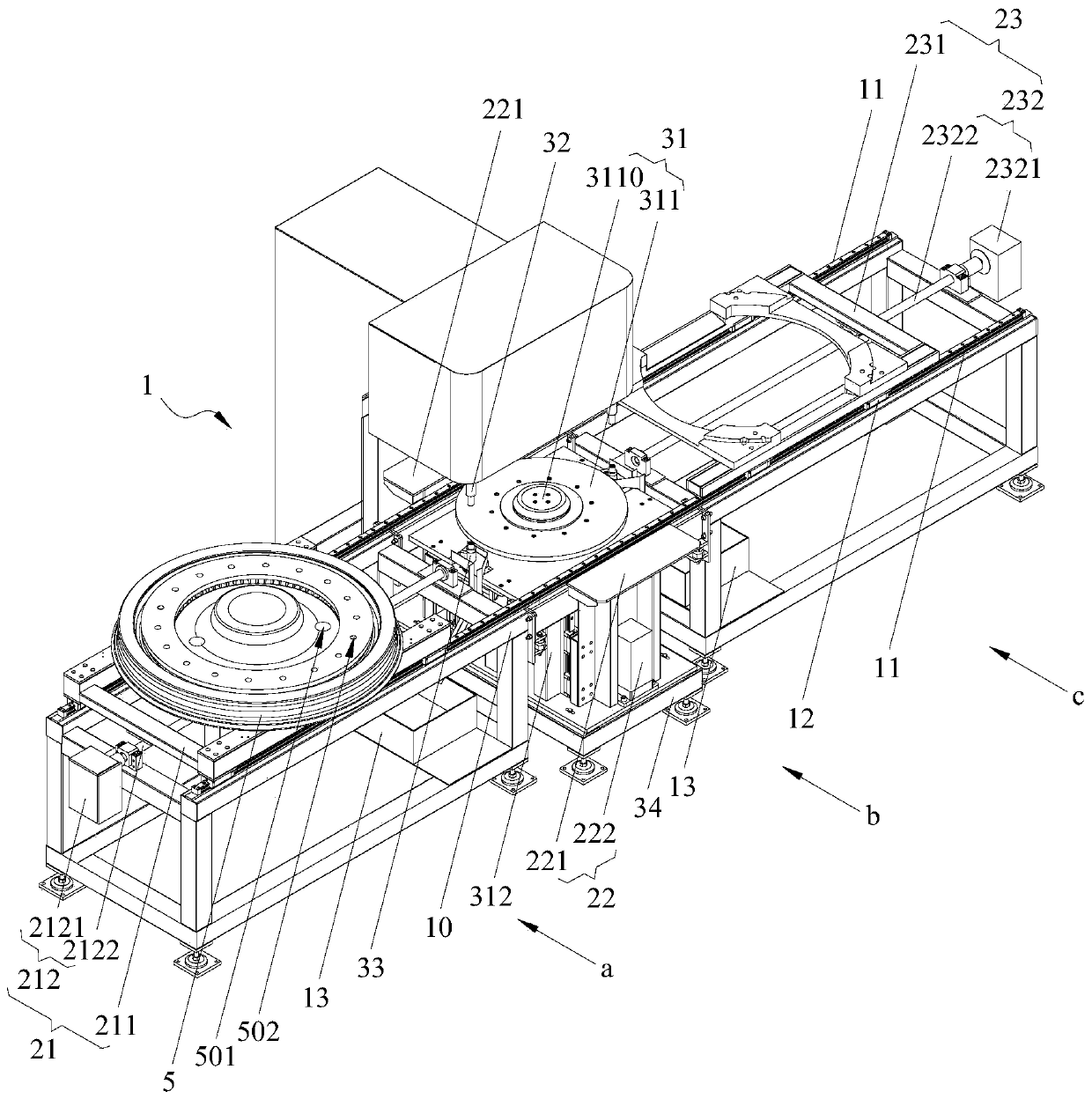

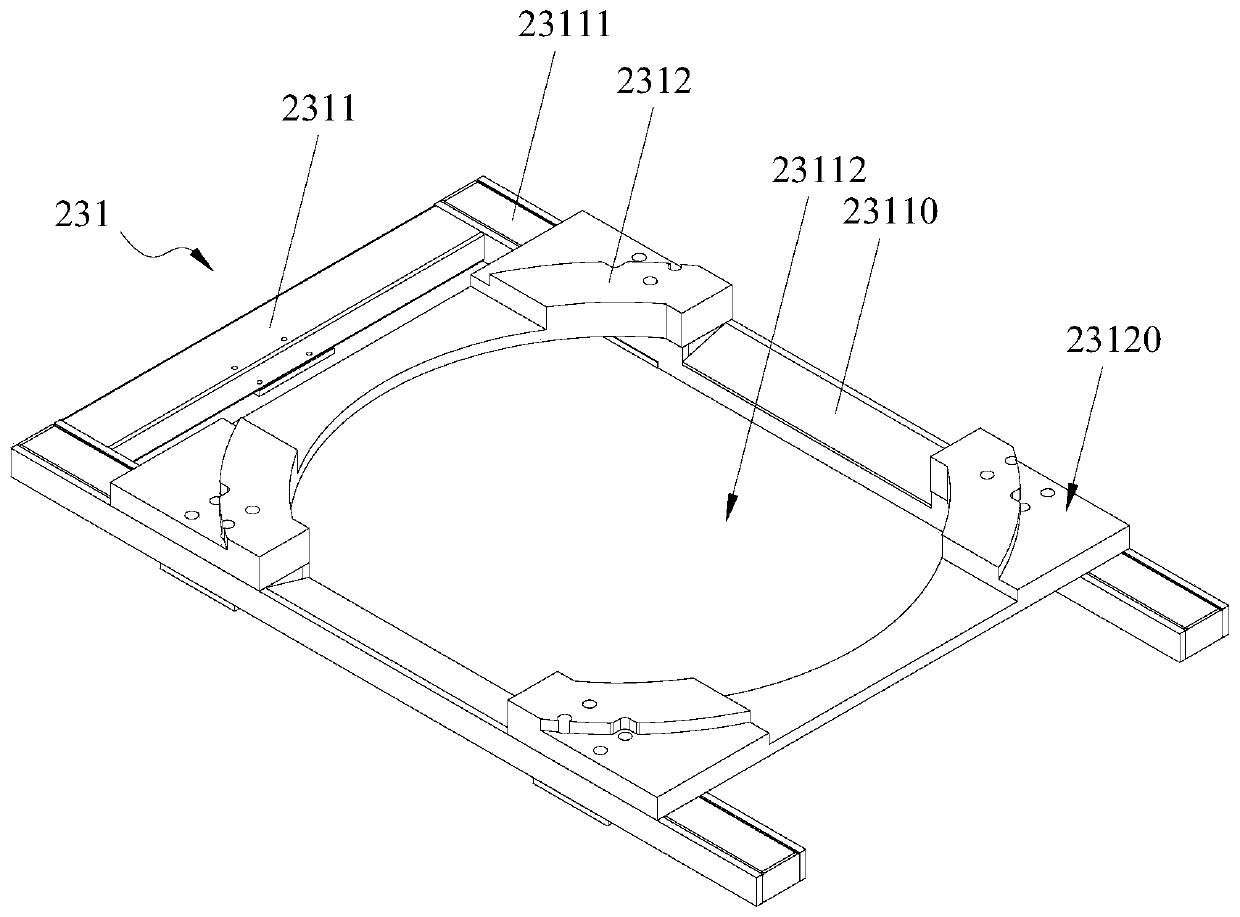

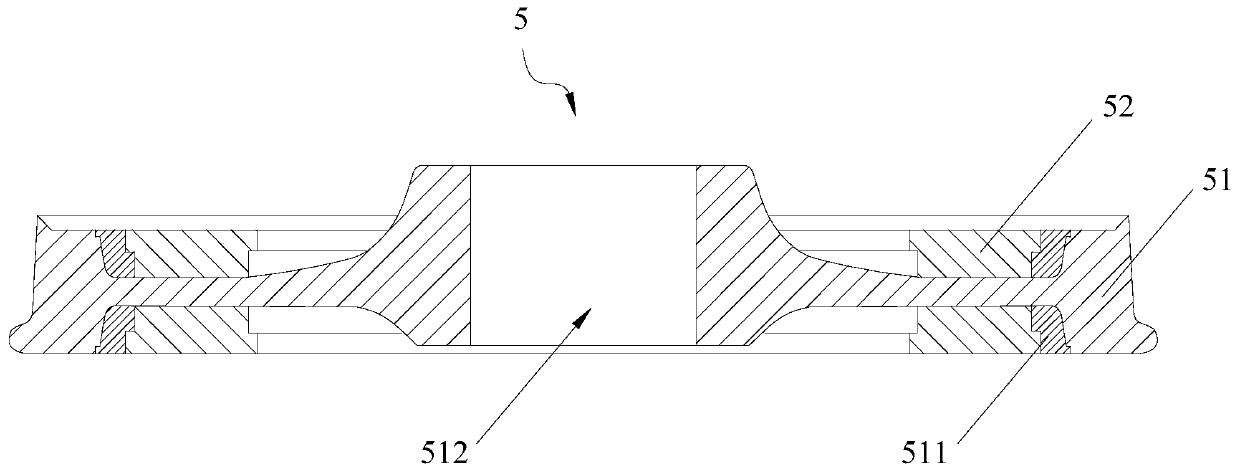

Production line for cold test of diesel engine

ActiveCN103934683AReduce rework costsImprove rework efficiencyInternal-combustion engine testingAssembly machinesCold testDiesel engine

The invention relates to a production line for a diesel engine, in particular to the production line for cold test of the diesel engine and belongs to the field of the diesel engine production technology. The production line comprises a first rotary table and a second rotary table, wherein a cold test conveying line body is arranged between the first rotary table and the second rotary table, a first repair section line body is arranged on other side of the first rotary table and opposite to the side where the cold test conveying line body is positioned, and a second repair section line body is arranged on other side of the second rotary table and opposite to the side where the cold test conveying line body is positioned. A last process conveying line body is arranged on one side of the first rotary table, and a first front transitional machine and a first cold test rack are arranged on the other side of the first rotary table. A next process conveying line body is arranged on one side of the second rotary table, and a second front transitional machine and a second cold test rack are arranged on the other side of the second rotary table. By means of the production line, online cold test can be performed during assembly of the diesel engine, repair is facilitated, and the production line is reasonable in integral layout, attractive and capable of facilitating production organization and logistics arrangement.

Owner:CHINA FIRST AUTOMOBILE

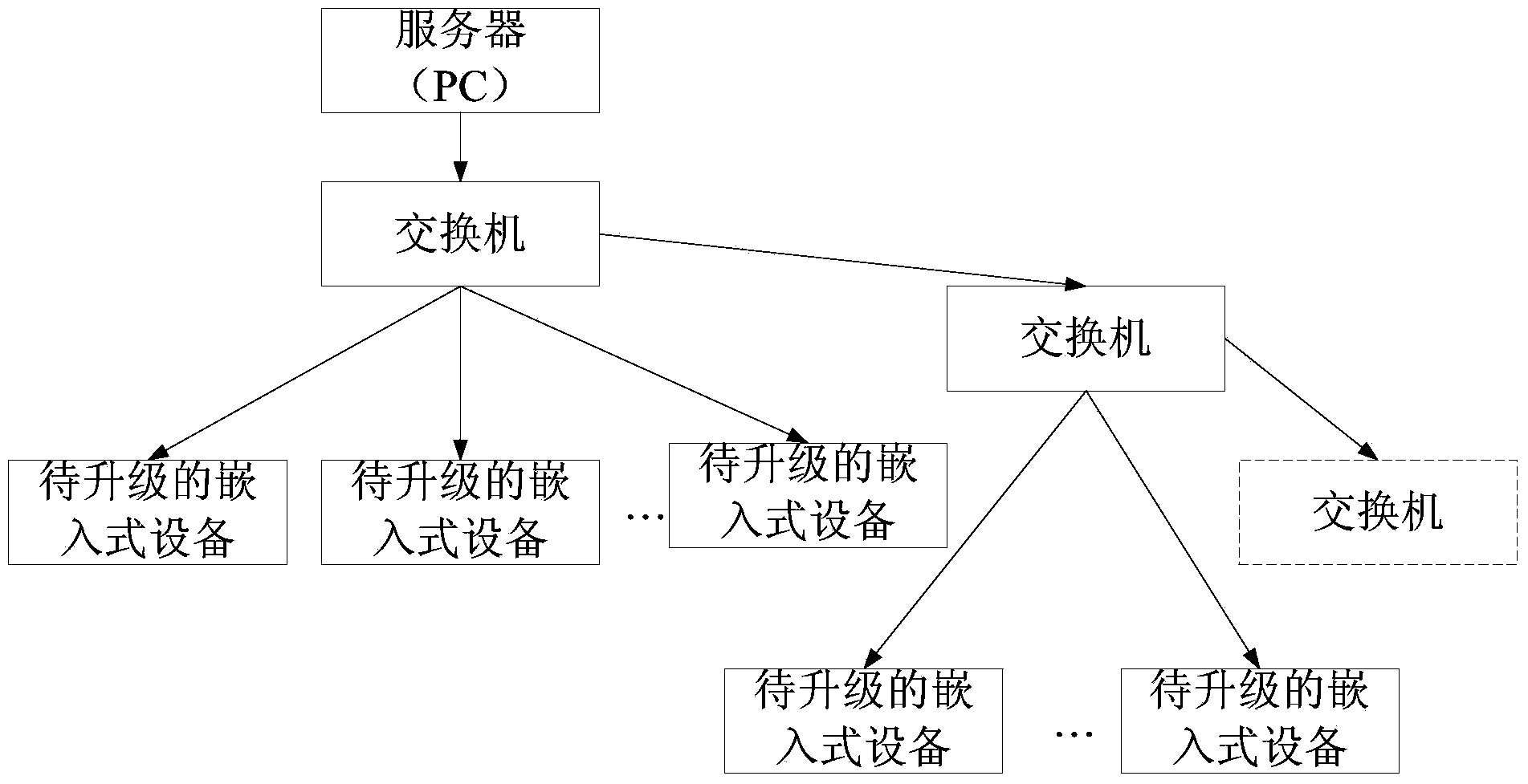

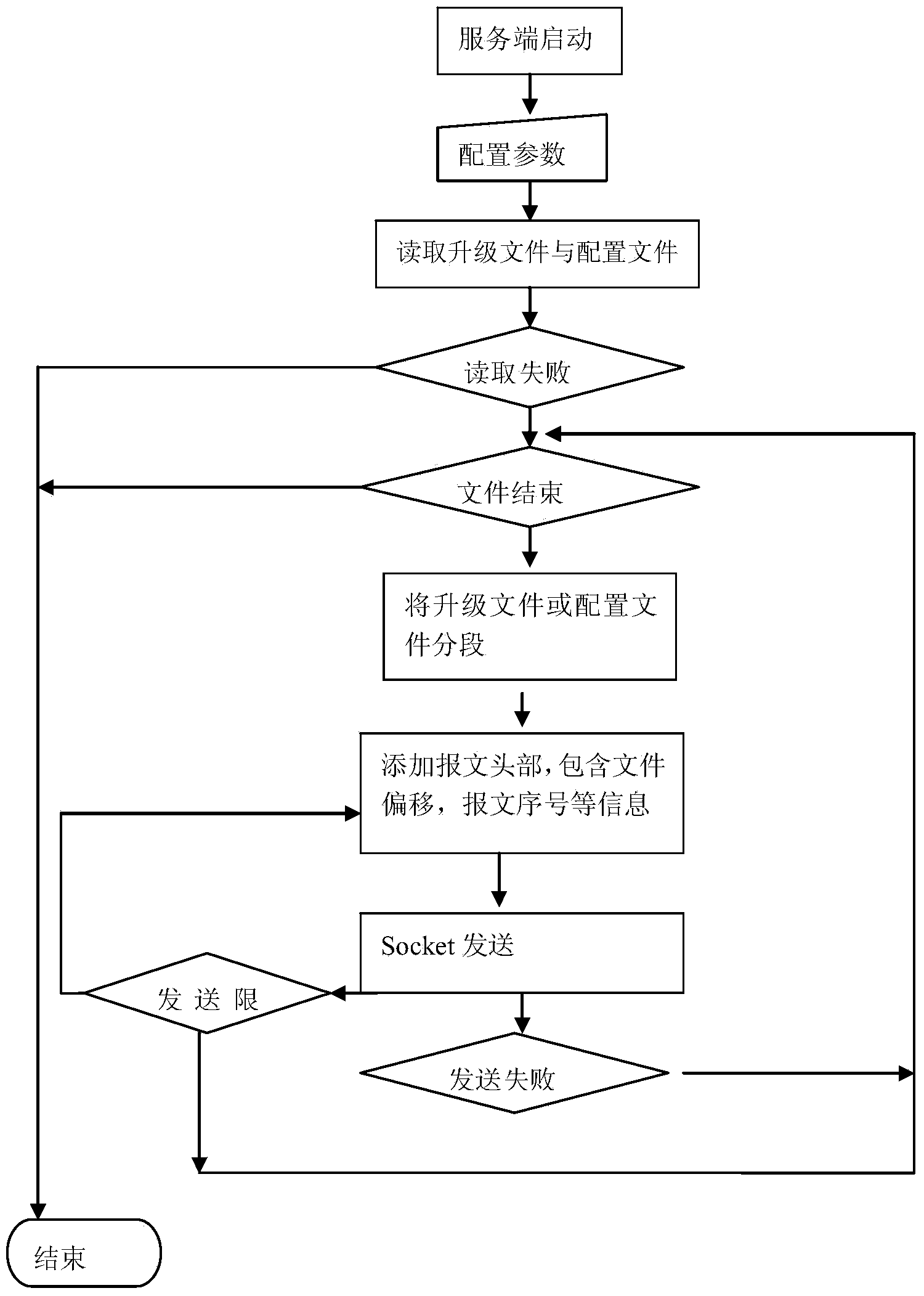

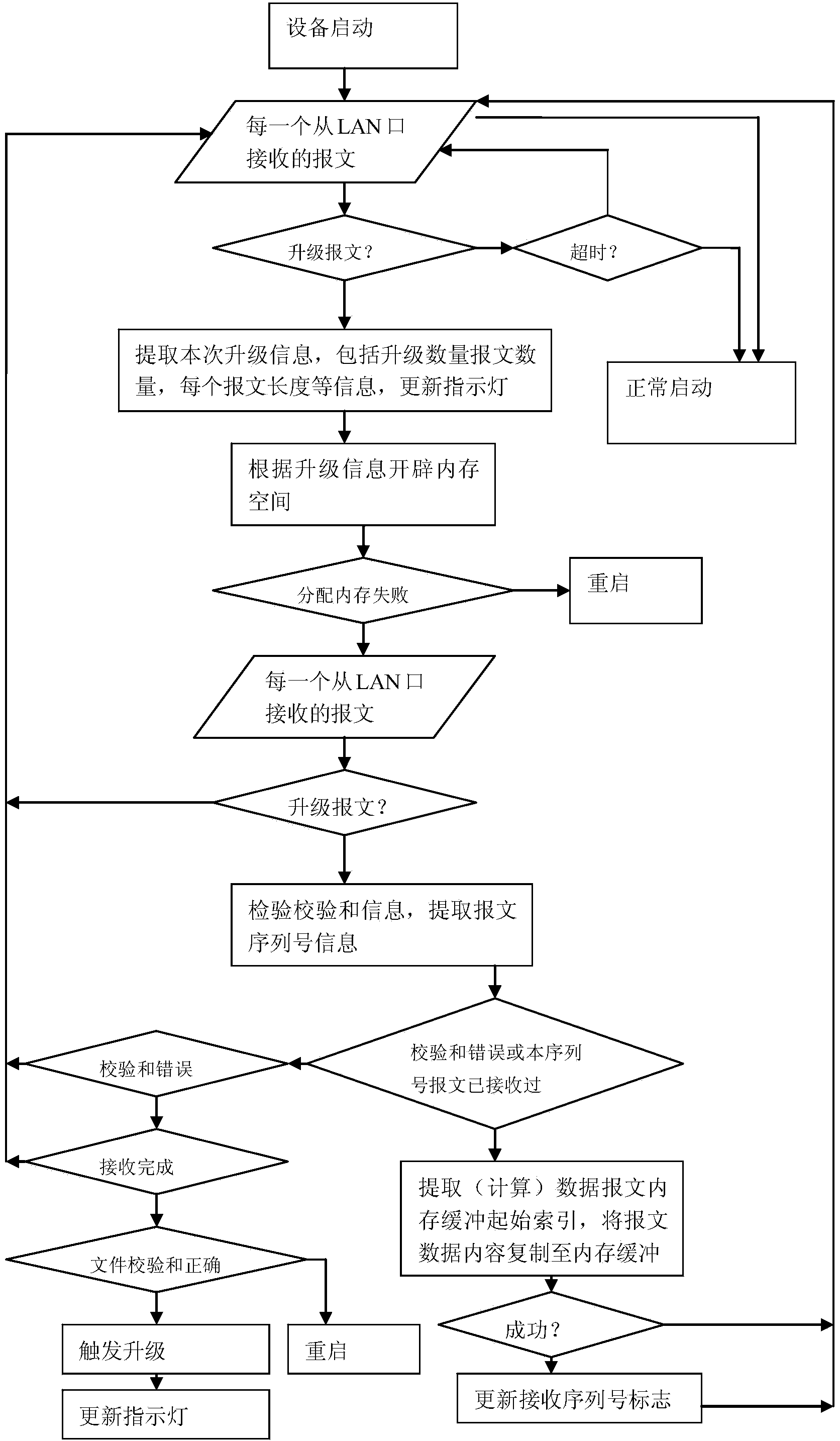

Embedded device batch upgrading method and system

InactiveCN103514020AApplicable to a wide range of platformsEasy to implementProgram loading/initiatingNetwork packetMaterial resources

The invention provides an embedded device batch upgrading method and system. The embedded device batch upgrading method includes the step of adopting a server to continuously transmit related upgrading data packets to the to-be-upgraded embedded devices. The embedded device batch upgrading system is specially used for carrying out software upgrading on embedded devices, the upgrading data server continuously and circularly transmits the upgrading packets to the to-be-upgraded embedded devices having access to the system, and after having access to the system, the to-be-upgraded embedded devices receive complete upgrading data to complete upgrading. The method and system are wide in application platform and convenient to implement, have the remarkable effects in the aspects of improving device production of factory enterprises and the repairing efficiency, saving manpower and material resources and controlling cost, have the good application effect under the background that a user does not have corresponding professional knowledge, and are suitable for being promoted in enterprises where the intelligent embedded devices are produced and maintained.

Owner:SHENZHEN GONGJIN ELECTRONICS CO LTD

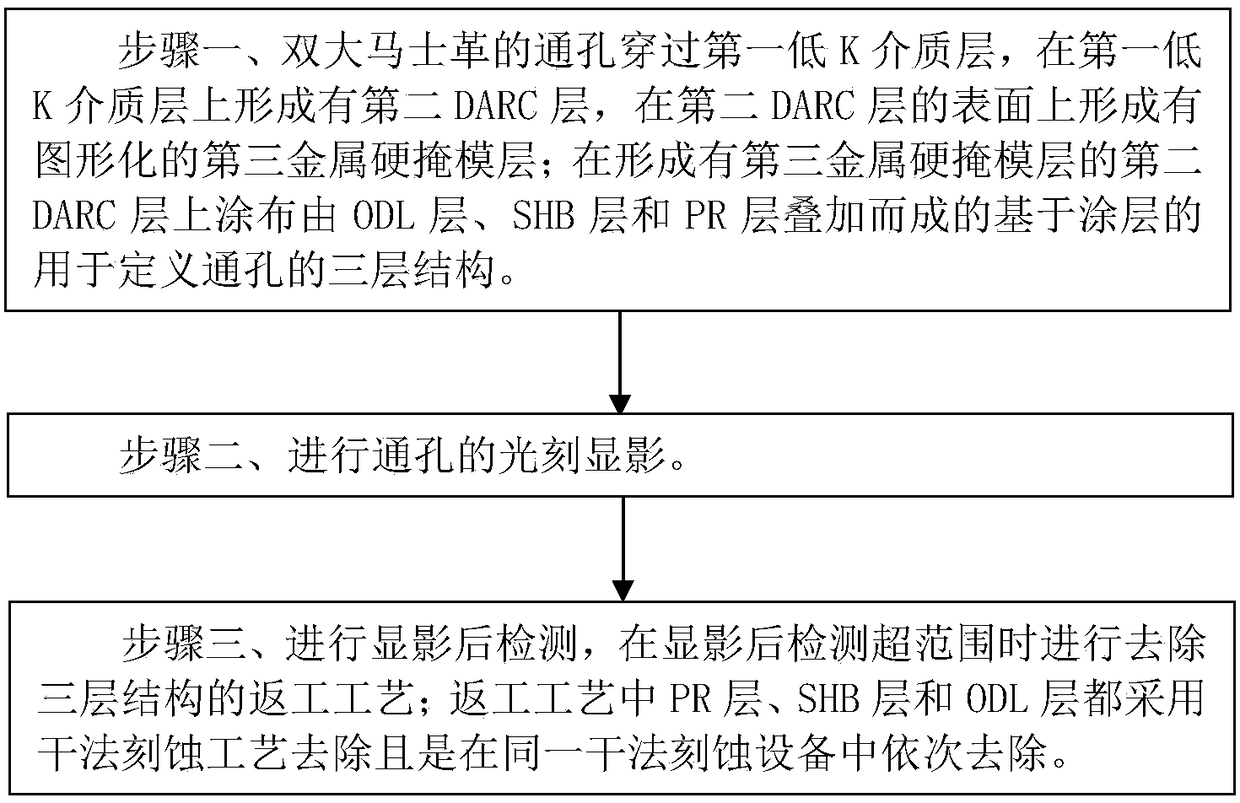

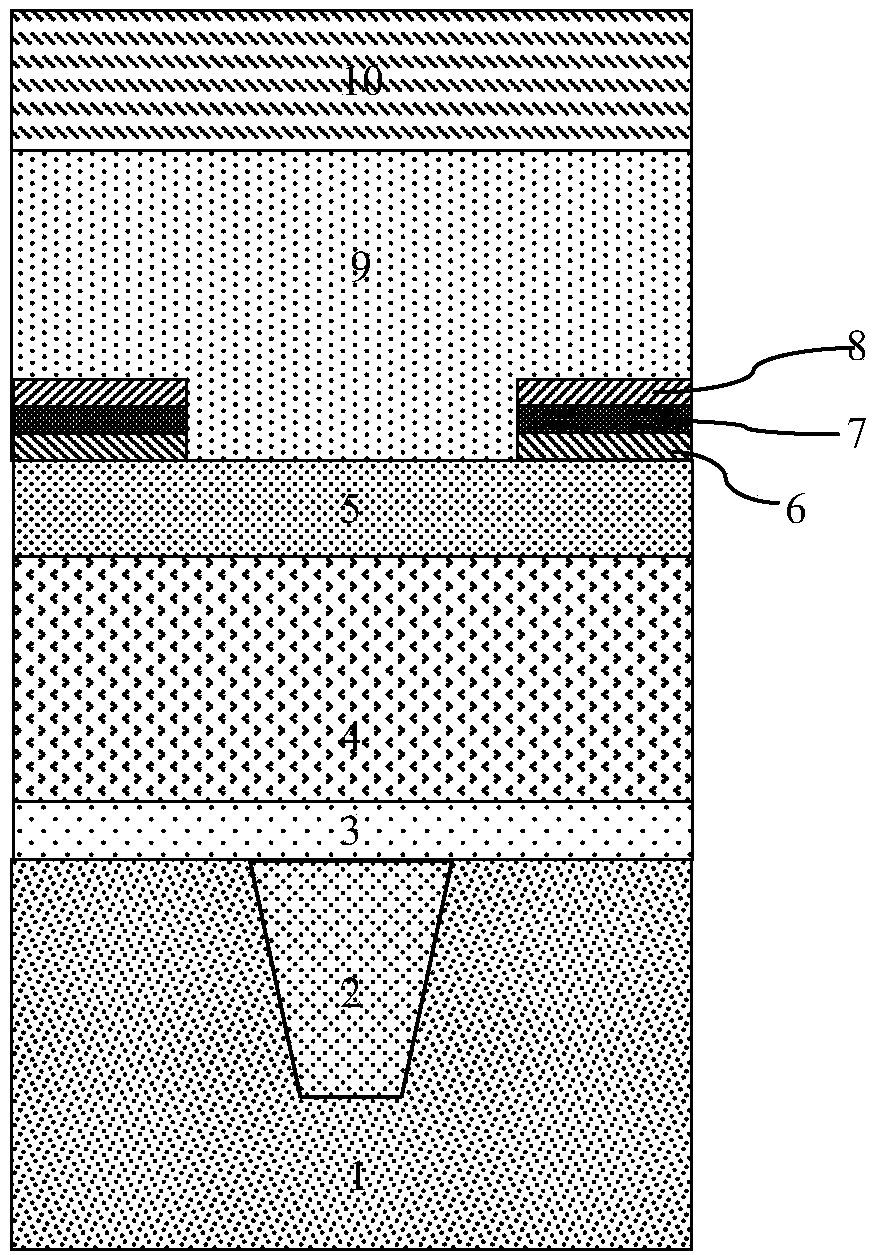

Rework method for dual damascene through-hole technology

ActiveCN108565216AEasy to monitorReduce rework processSemiconductor/solid-state device manufacturingLithographic artistDry etching

The invention discloses a rework method for a dual damascene through-hole technology. The method comprises the following steps that 1, a through hole of the damascene runs through a first low K dielectric layer, a second DARC layer is formed on the first low K dielectric layer, and a graphical third metal hard mask layer is formed on the surface of the second DARC layer; the second DARC layer withthe third metal hard mask layer is coated with a coating-based three-layer structure which is formed by overlaying an ODL layer, an SHB layer and a PR layer and used for defining the through hole; 2,lithography development of the through hole is performed; 3, detection is preformed after development is performed, after development is performed, when detection is out of the range, the rework technology of removing the three-layer structure is performed; in the rework technology, the PR layer, the SHB layer and the ODL layer are removed by adopting a dry etching technology and sequentially removed in the same dry etching equipment. Accordingly, the steps of the rework technology can be reduced, and the rework efficiency and quality are improved.

Owner:SHANGHAI HUALI INTEGRATED CIRCUTE MFG CO LTD

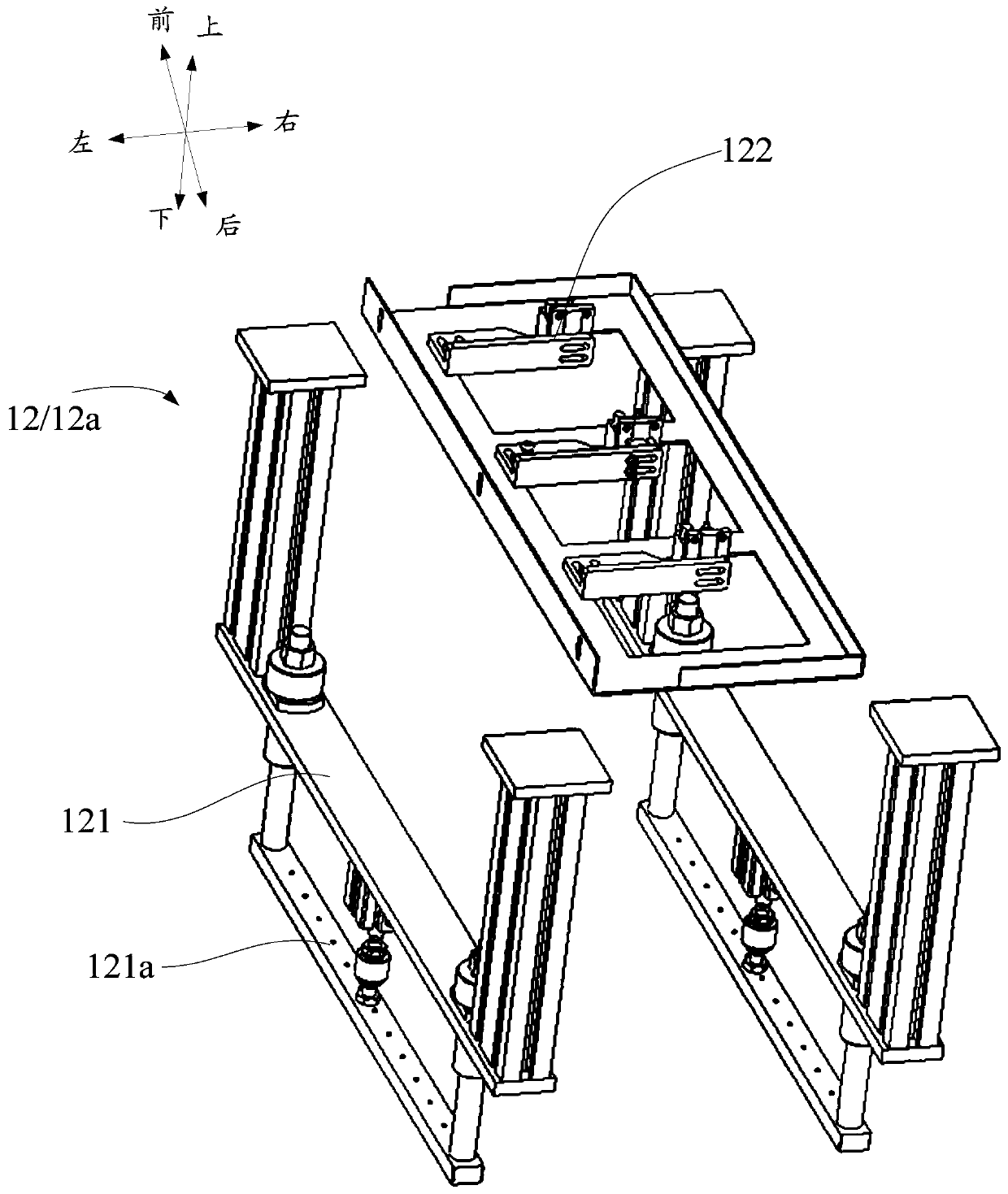

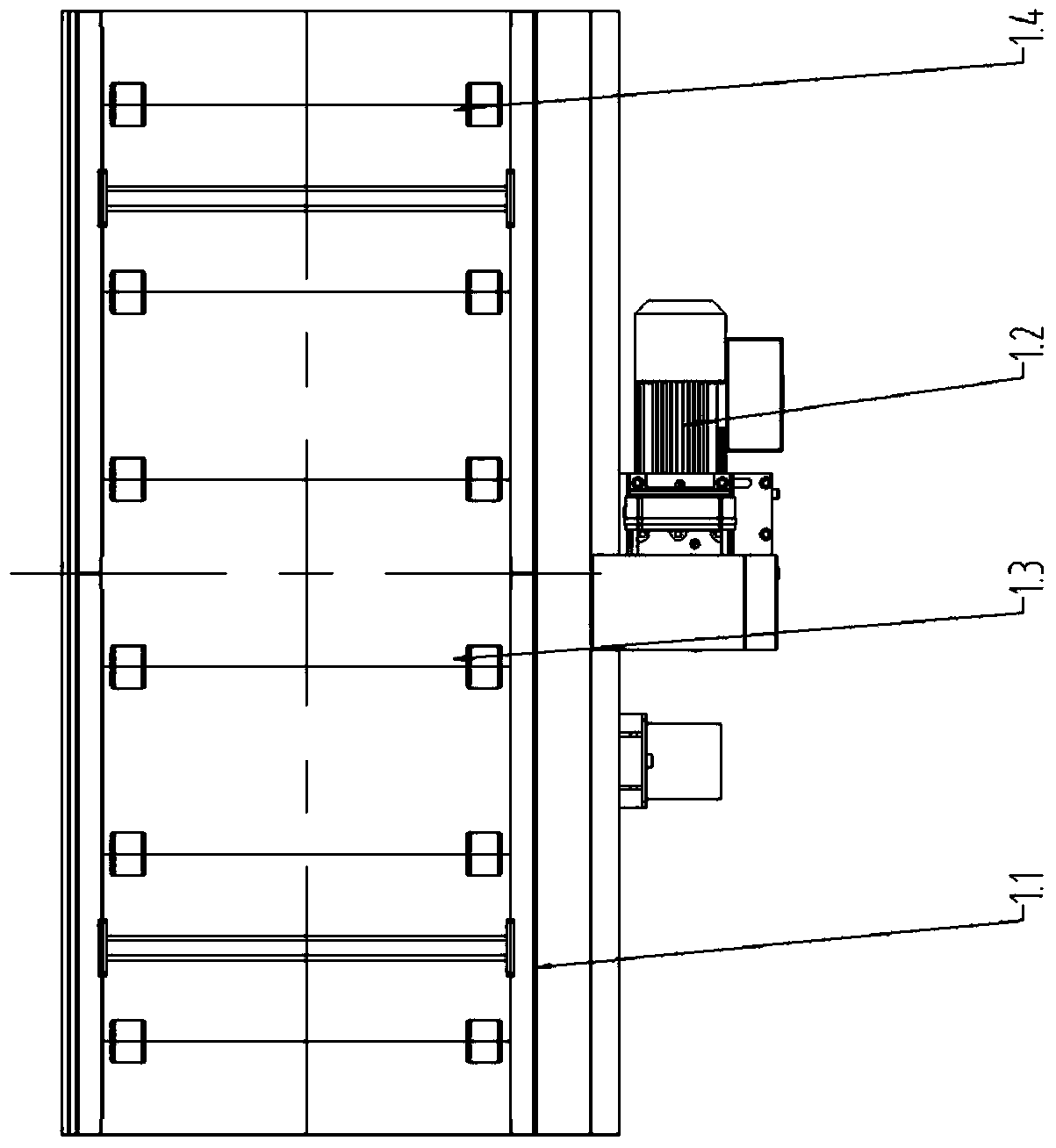

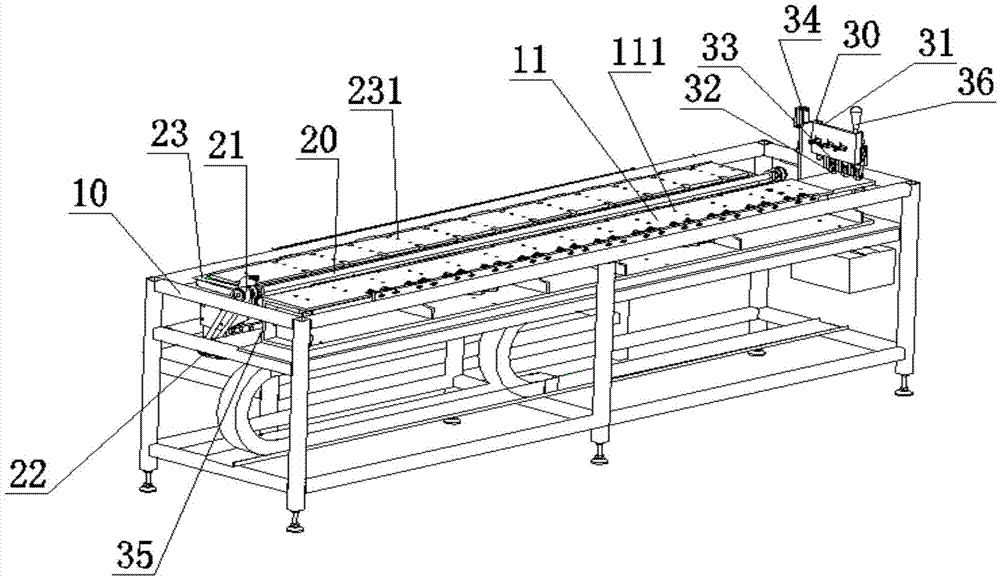

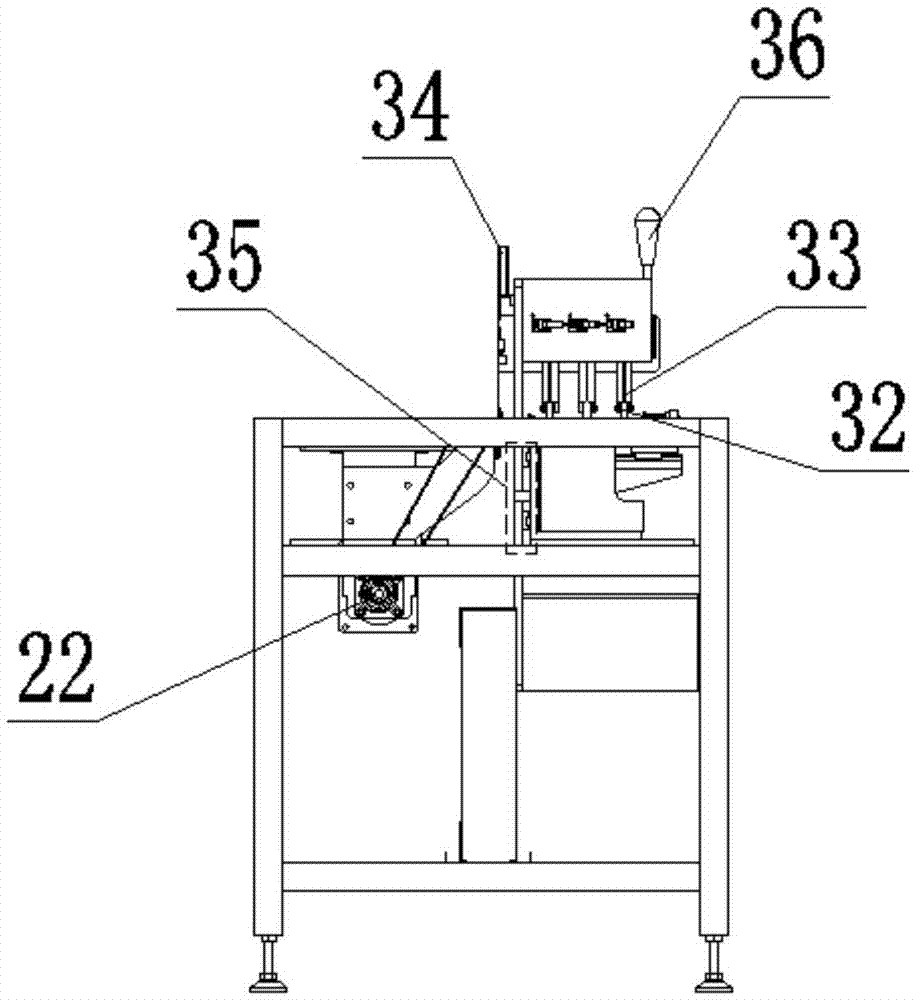

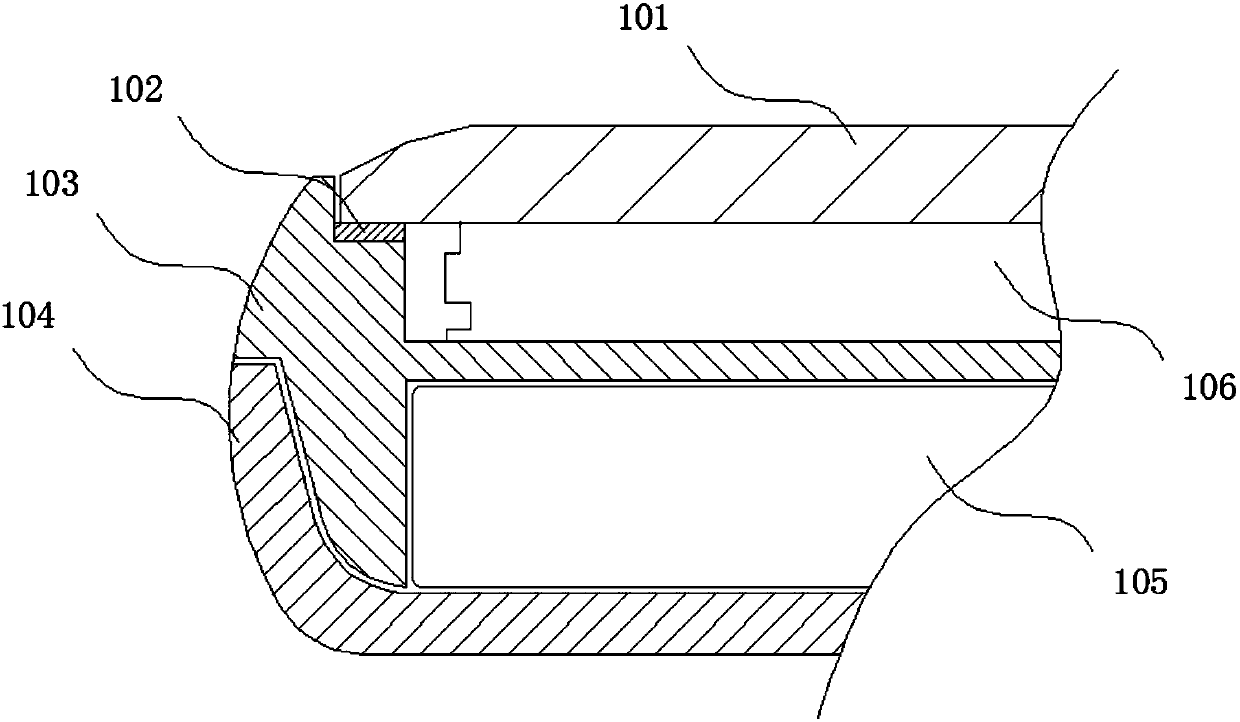

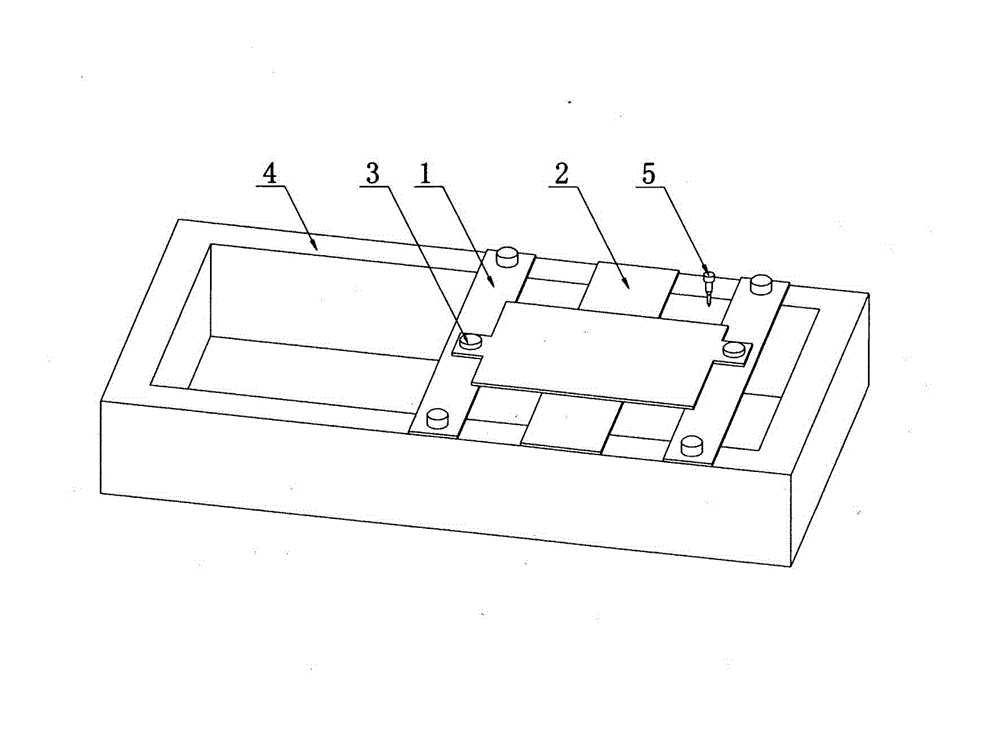

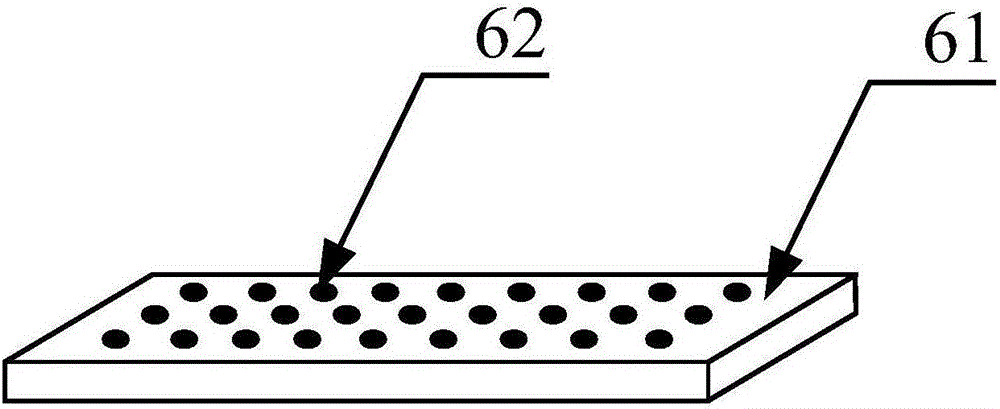

Assembly repairing device

InactiveCN105449047AReduce the chance of occurrenceImprove rework efficiencyFinal product manufactureSemiconductor devicesEngineeringVertical displacement

The invention provides an assembly repairing device, which comprises a rack, a reversal mechanism and a lamination mechanism, wherein the reversal mechanism and the lamination mechanism are arranged on the rack; the reversal mechanism comprises a reversal shaft, two bearing pedestals, a reversal motor and a reversal table top; the two bearing pedestals are independently arranged on two ends of the rack; the reversal shaft passes through the two bearing pedestals; one end of the reversal shaft is connected with the reversal motor; the reversal shaft is also connected with the reversal table top; the reversal table top is provided with a plurality of vacuum suction nozzles; the vacuum suction nozzles are connected with a vacuum system; the rack is also provided with an operating table top; the operating table top is arranged on one side which is opposite to the reversal table top; the lamination mechanism comprises a longitudinal frame and a lateral frame, wherein the lateral frame is arranged on the longitudinal frame and realizes vertical displacement through a lifting motor arranged on the upper part of the lateral frame; the bottom of the lateral frame is provided with a lamination roller; the longitudinal frame is arranged in a slideway; and the slideway penetrates through two ends of the rack.

Owner:TIANJIN YINGLI NEW ENERGY RESOURCES

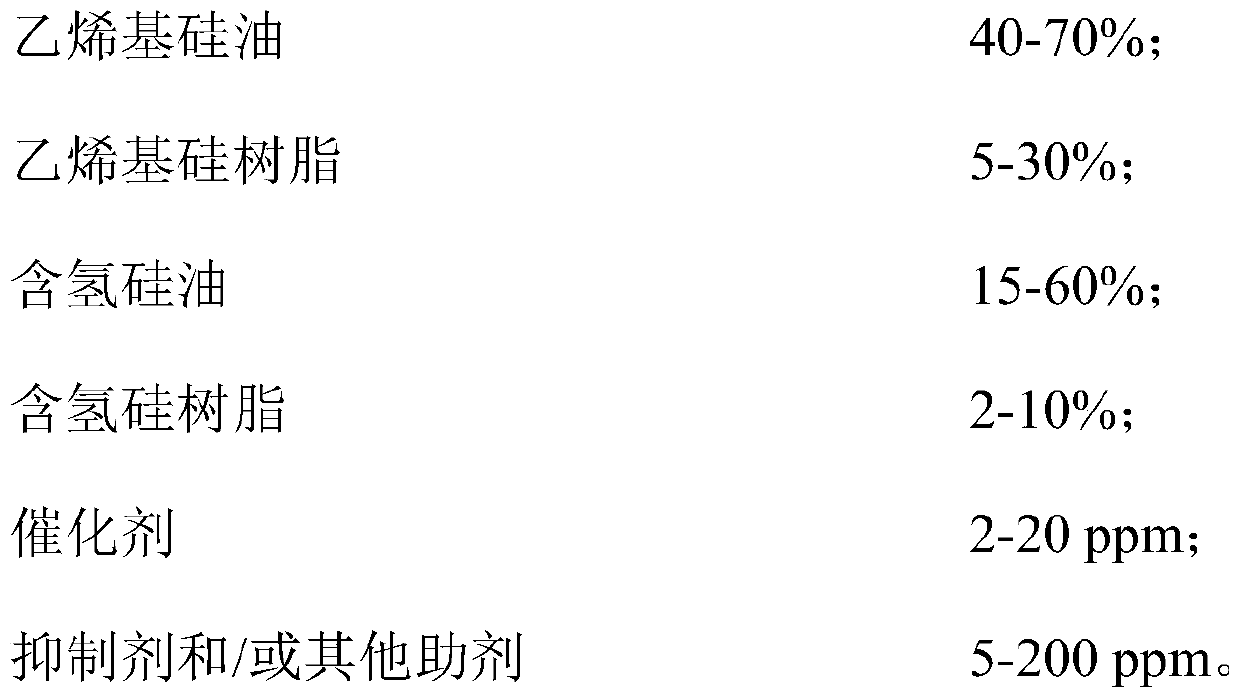

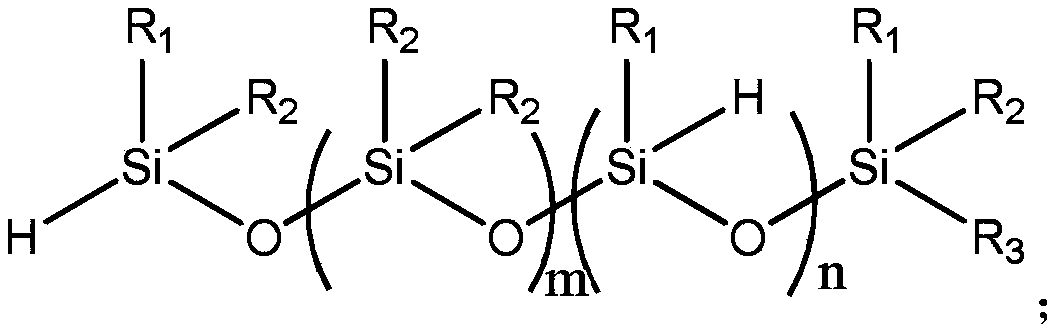

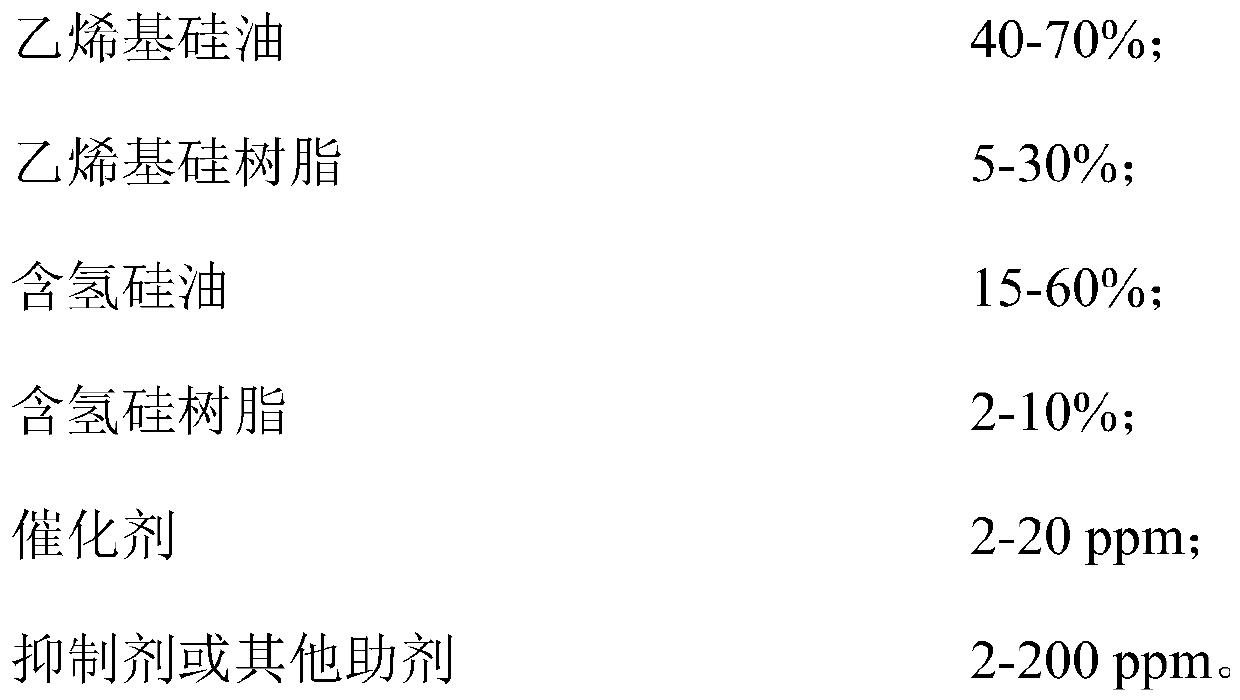

Thermosetting liquid optical adhesive composition and application thereof

ActiveCN111154451AStable PenetrationImprove heat stabilityNon-macromolecular adhesive additivesNeedle penetrationPolymer science

The invention provides a thermosetting liquid optical adhesive composition and an application thereof; the thermosetting liquid optical adhesive composition is tested according to a GB / T 4509-2010 asphalt needle penetration determination method, and the needle penetration of the thermosetting liquid optical adhesive composition is 160-250 mm. The thermosetting liquid optical adhesive provided by the invention has proper needle penetration after being cured, is easy to repair, does not greatly fluctuate along with the influence of temperature, humidity, UV aging irradiation and the like, and has higher cohesion strength, better binding power and excellent binding power for a binding material of a display module.

Owner:DONGGUAN POWERBOND NEW MATERIALS TECH DEV

Mobile terminal

InactiveCN107891263AImprove rework efficiency and rework qualityEvenly meltedClimate change adaptationMetal working apparatusEngineeringAdhesive

The invention provides a mobile terminal. The mobile terminal comprises a display module, a middle frame connected with the display module through an adhesive, a groove formed along an adhesive dispensing path, and a heating structure which is arranged in the groove and makes contact with the adhesive. When the display module and the middle frame need to be disassembled, the adhesive is uniformlymelted by activating the heating structure, accordingly, disassembling of the display module is achieved easily, and the repair efficiency and repair quality of the mobile terminal are improved.

Owner:VIVO MOBILE COMM CO LTD

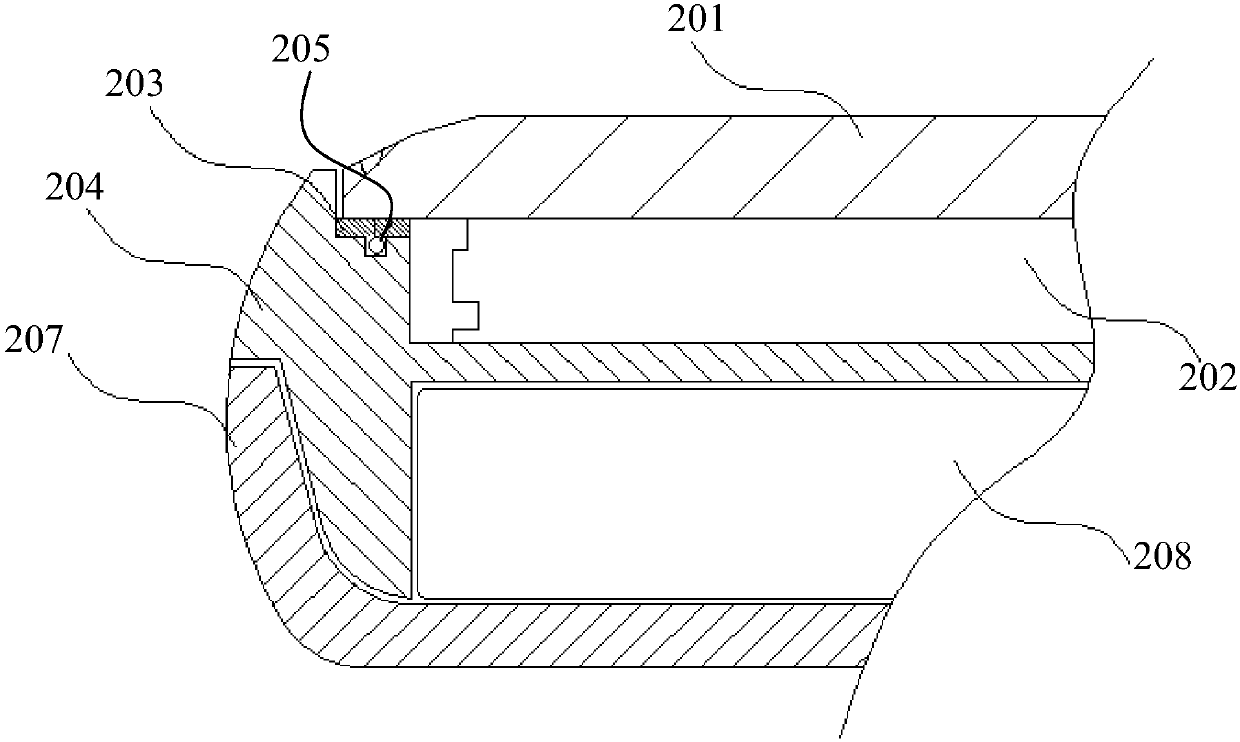

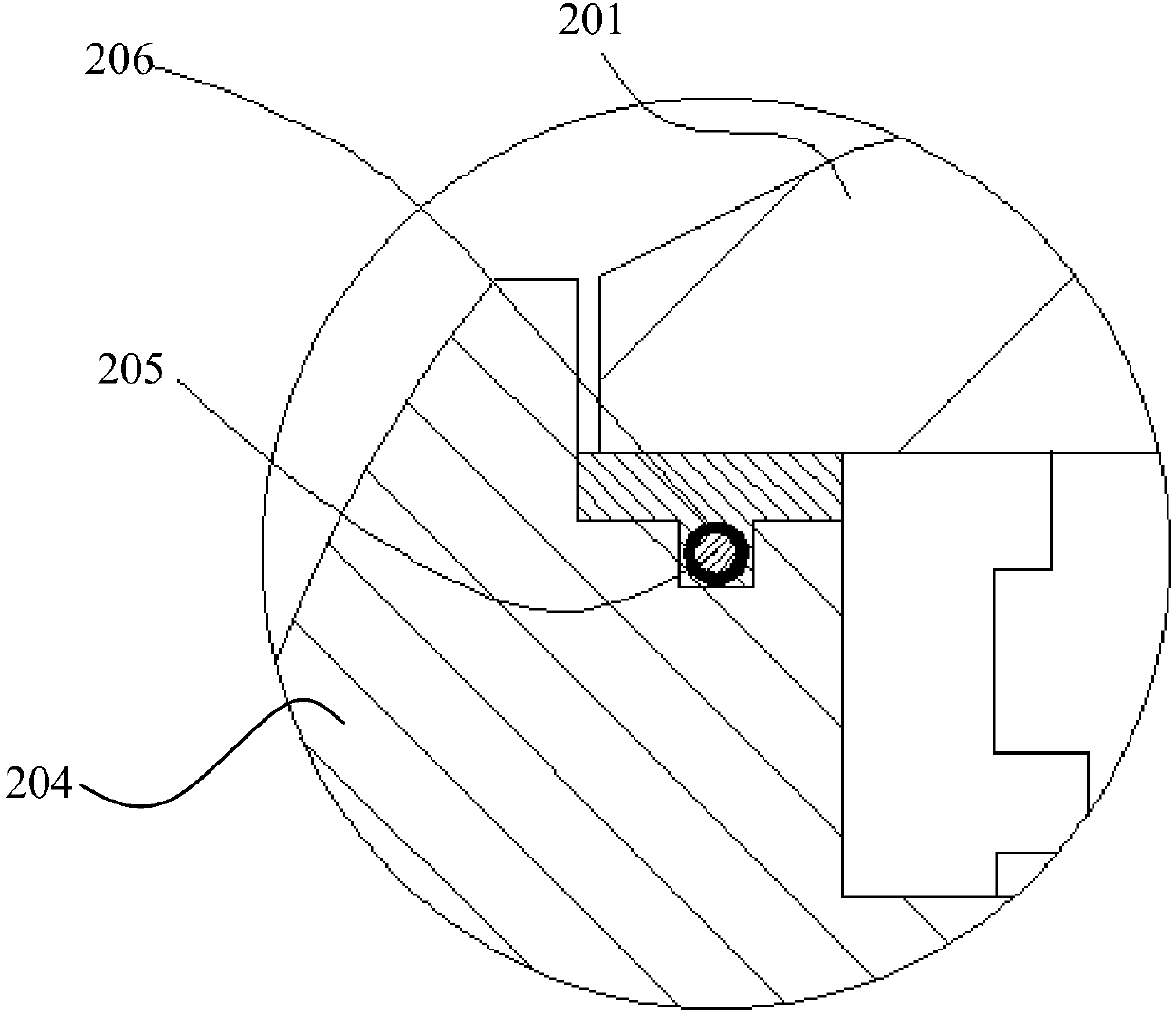

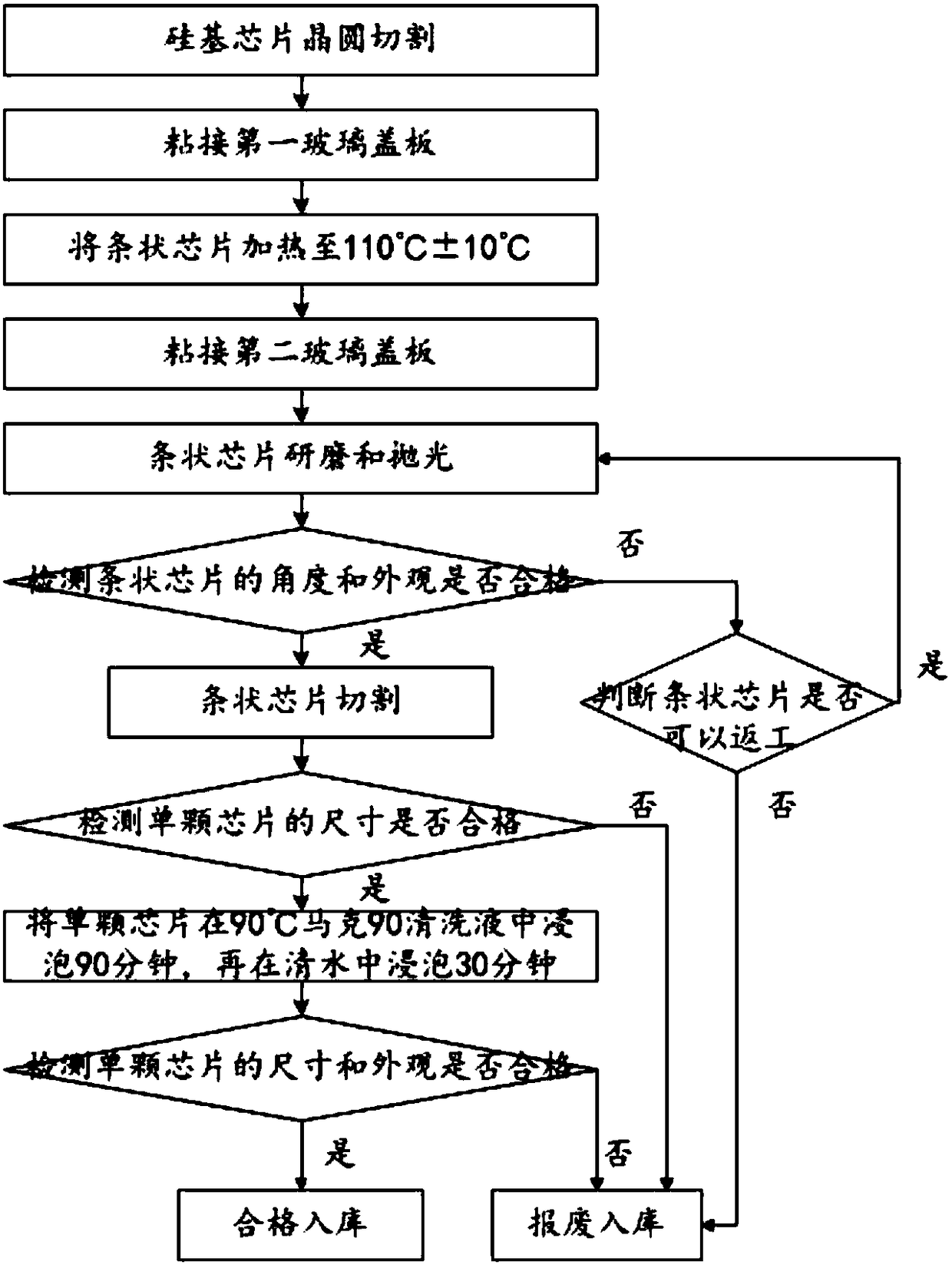

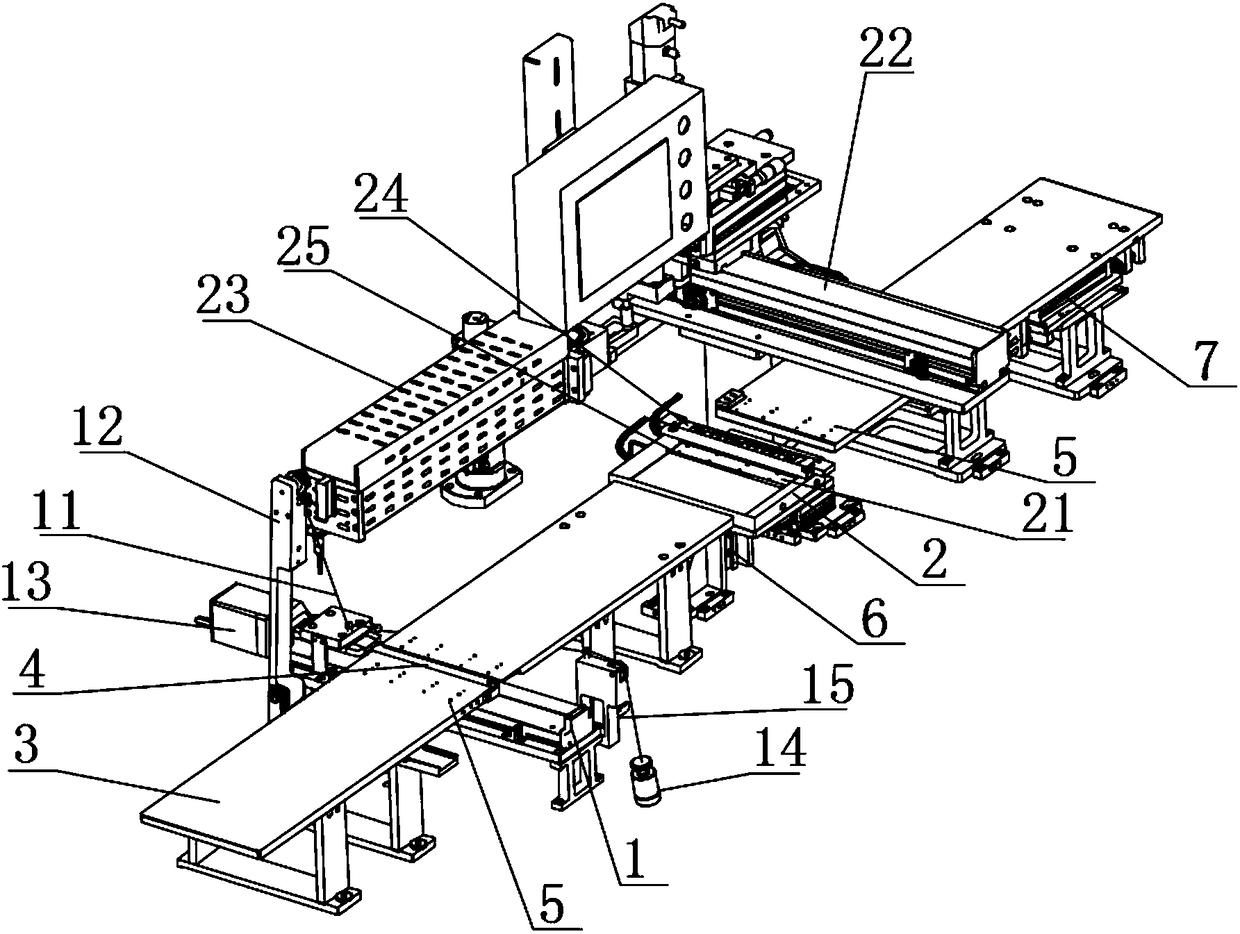

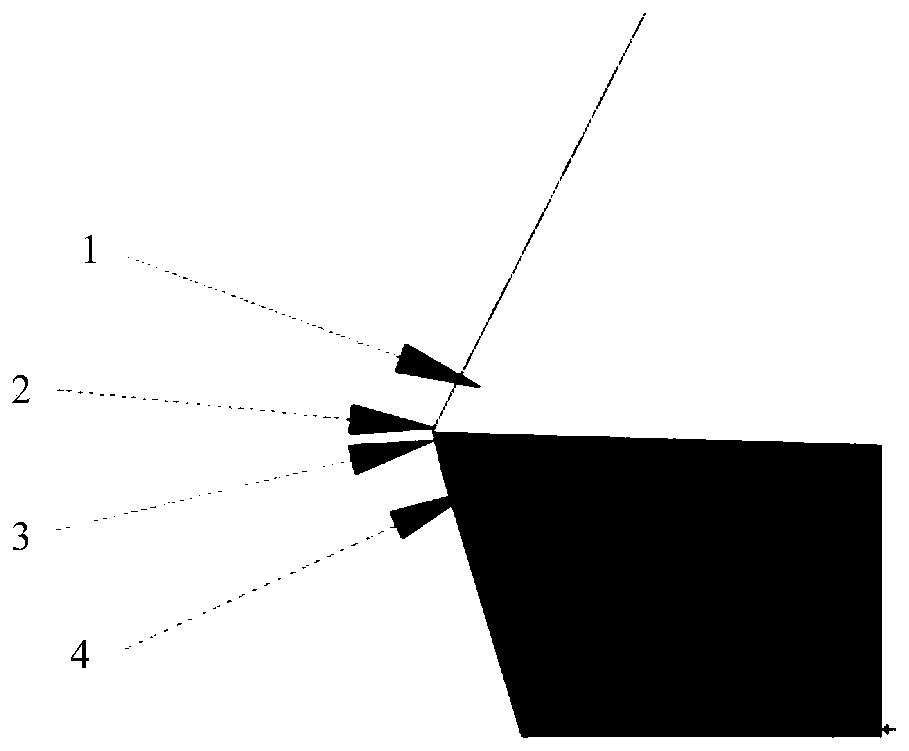

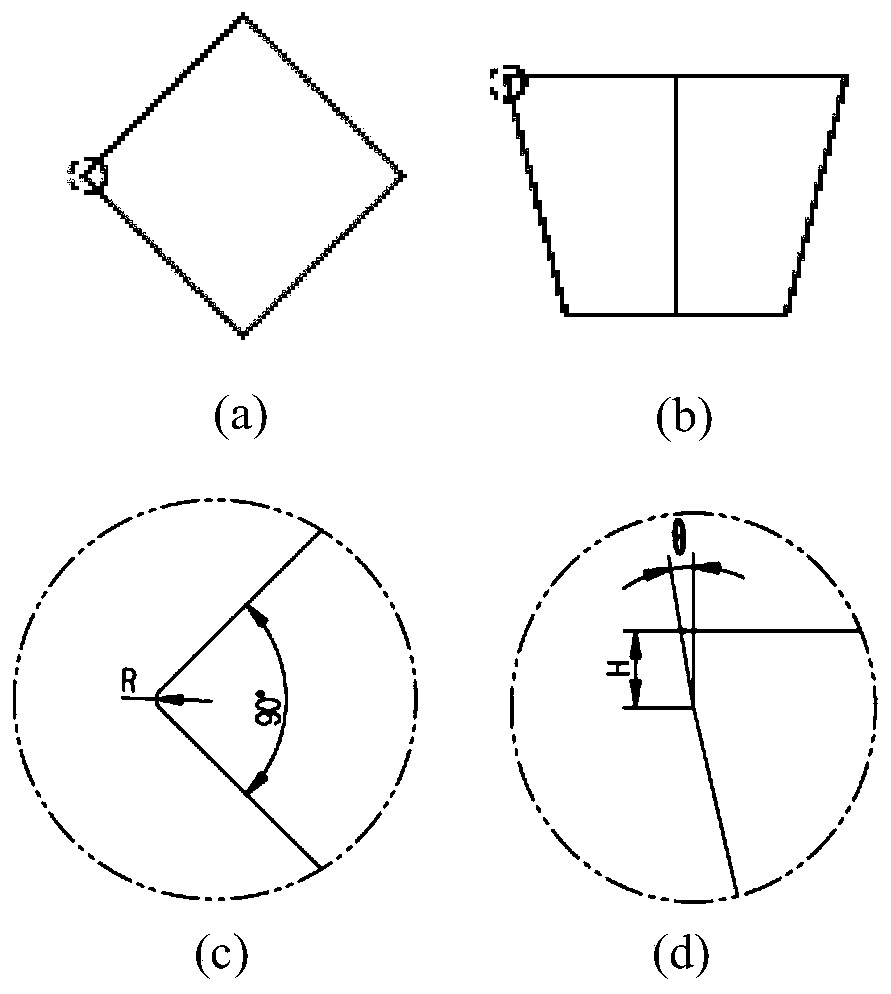

Grinding and cutting method for chip of low-channel arrayed waveguide grating wavelength division multiplexer

ActiveCN108372457ASmall sizePlay a protective effectLapping machinesFine working devicesGlass coverMultiplexer

The invention relates to a grinding and cutting method for a chip of a low-channel arrayed waveguide grating wavelength division multiplexer. According to the method, the two end surfaces in the widthdirection of strip-shaped chips are ground and polished on a grinding machine until different preset angles are formed between the two end surfaces of each strip-shaped chip and the upper surface ofa first glass cover plate, and therefore the different preset angles can be formed between the input end surface and the output end surface of one chip and the upper surface of one first glass cover plate; the size of each strip-shaped chip is relatively large, so that grinding and polishing are facilitated, and in addition, angle detection is carried out on the two end surfaces in the width direction of the strip-shaped chips, namely, angle detection can be simultaneously carried out on the input end surfaces and the output end surfaces of the multiple chips, so that the detection efficiencycan be improved; in addition, if the strip-shaped chips are unqualified in angle detection, reworking is needed, the overall reworking can be carried out, and the reworking efficiency is high; and inthe grinding process of the strip-shaped chips, the upper surfaces of the silicon-based chips are covered with the glass cover plates, the glass cover plates play a certain protection role on the silicon-based chips, and therefore the reject ratio caused by edge breakage, cracks and the like in the grinding process can be effectively lowered.

Owner:WUHAN YILUT TECH CO LTD

Method for return repairing image sensing mould set and clamp therewith

InactiveCN1983535AReduce damage rateReduce eye fatigueTelevision system detailsSemiconductor/solid-state device manufacturingCamera lensEyestrain

The invention is concerned with the reworking method for image inducting module, including the following steps: 1) removes the clamp to separate the camera lens module group of the camera module group and PCB board fixing with the camera wafer; 2) fixes the PCB on the clamp and emerges the wafer; 3) blows the dust on the wafer inducting area by the blowing equipment; 4) sets the camera lens on the PCB board. The invention can improve the reworking effect efficiently, and reduce the eye tire of the operator.

Owner:深圳市合力泰光电有限公司

Method for positioning mold line sample plate with positioning hole in repairing process

ActiveCN103143843AHigh positioning accuracyImprove rework efficiencyLaser beam welding apparatusLaser cuttingEngineering

The invention relates to a method for positioning a mold line sample plate with a positioning hole in a repairing process. The method comprises the steps that 1) the mold line sample plate is leveled; 2) a laser cutting program A is programmed; 3) a laser cutting program B is programmed; 4) the height of a laser head of a laser cutter is heightened, the laser cutter runs the laser cutting program A in an idling mode, when the laser head is positioned at a first positioning hole, the laser cutter is stopped, and a first positioning steel plate is put down and fixed; then the laser cutter runs in the idling mode continuously, when the laser head is positioned at a second positioning hole, the laser cutter is stopped, and a second positioning steel plate is put down and fixed; 5) the height of the laser head of the laser cutter is realigned; 6) and the laser cutter runs the laser cutting program B to machine the repaired part of the mold line sample plate. According to the method, the positioning holes in the mold line sample plate are utilized, the laser cutter can locate the accurate position of the mold line sample plate and carries out laser cutting on the repaired part, so that the machining accuracy is improved, and the working efficiency of sample plate repairing is also improved.

Owner:SHENYANG AIRCRAFT CORP

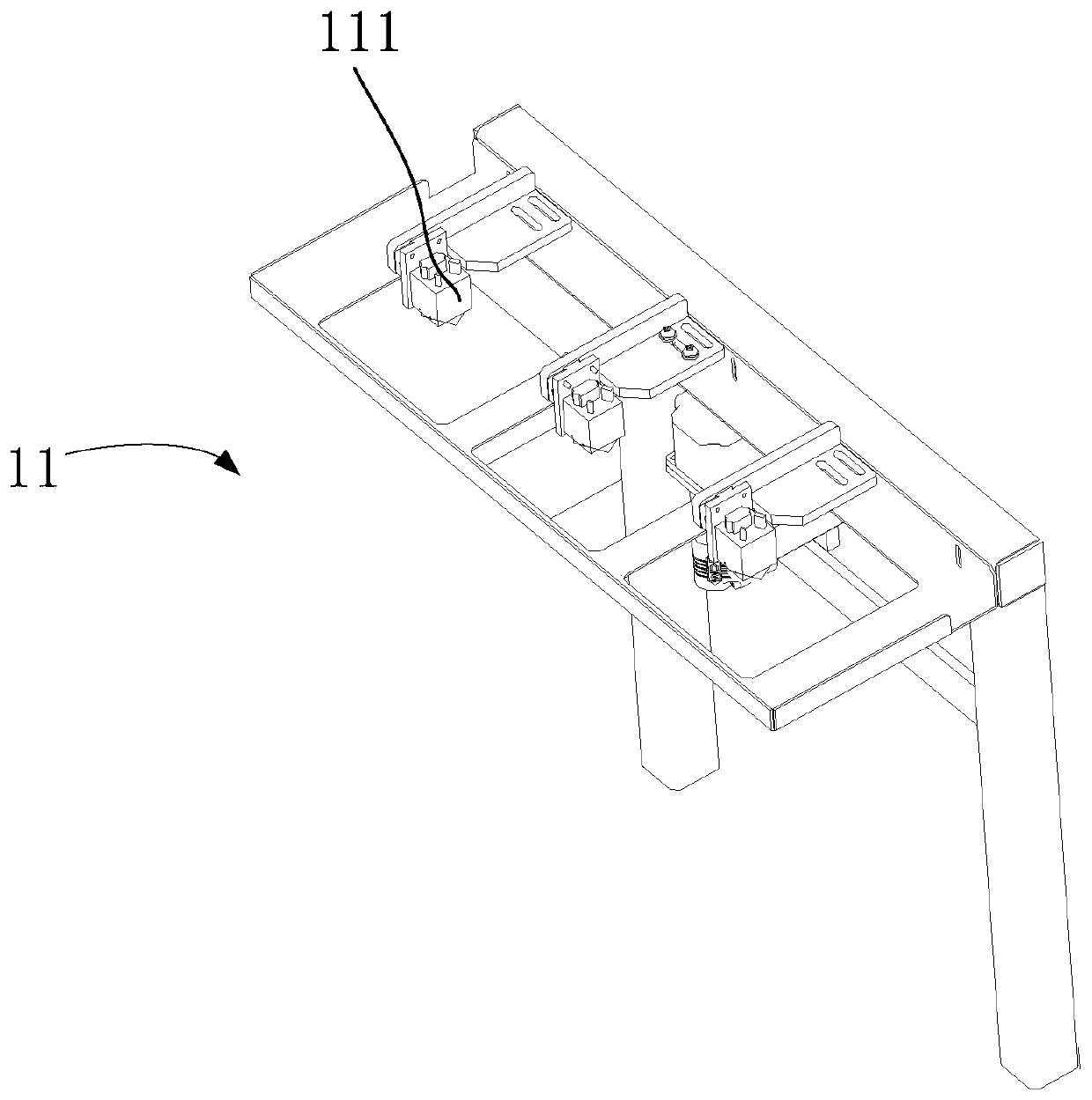

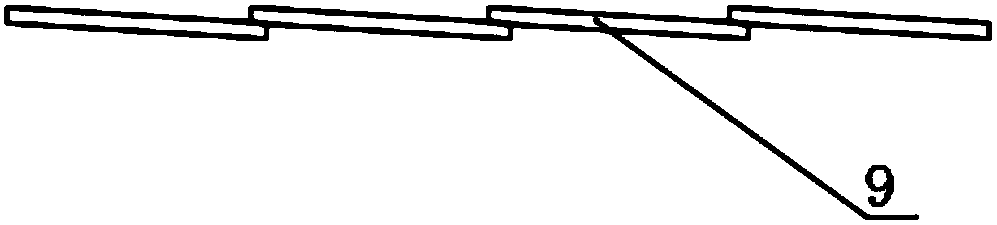

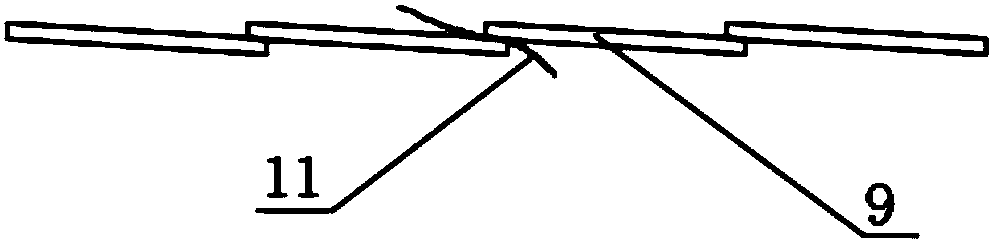

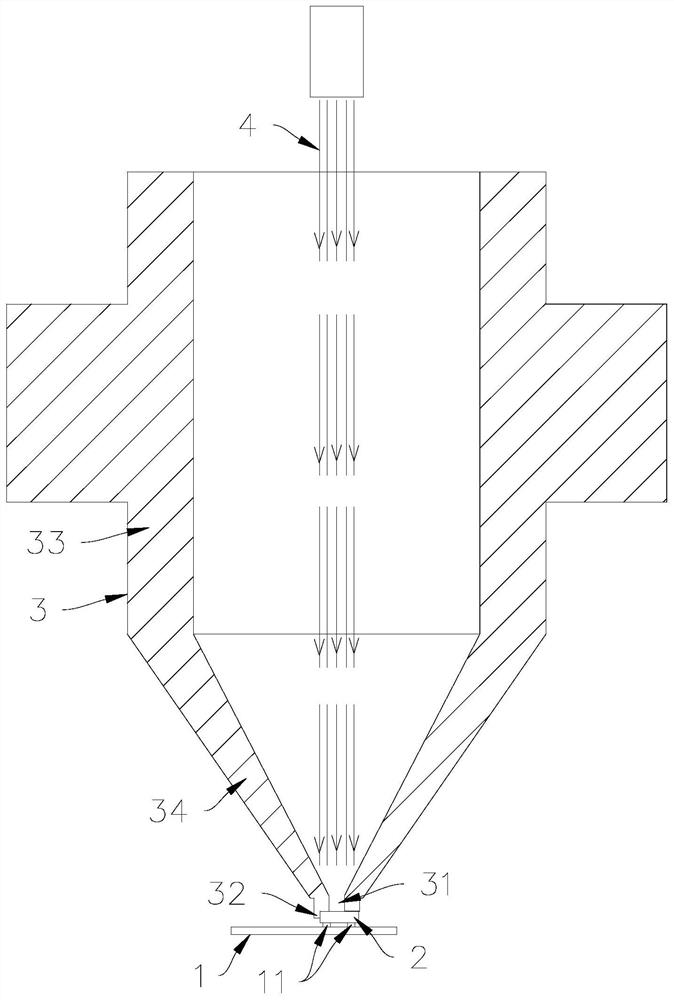

Photovoltaic cell string reworking device

ActiveCN108574023ARework quality is reliableImprove rework efficiencyFinal product manufacturePhotovoltaic energy generationEngineeringMechanical engineering

The invention provides a photovoltaic cell string reworking device. The device includes a desoldering device and a working platform; the desoldering device includes a cutting wire; the working platform is used for placing a photovoltaic cell string and is provided with a wire moving gap; and the cutting wire and the wire moving gap are in matching arrangement. The welding part of an undesirable cell sheet is placed along the wire moving gap, so that the undesirable cell sheet can be dismounted from the cell string with the movement of the cutting wire; and the device is fast and convenient, and is reliable in reworking qualities, and therefore, reworking efficiency can be greatly enhanced.

Owner:SUZHOU AUTOWAY SYST

Non-principle test device for general digital plug-ins and test method thereof

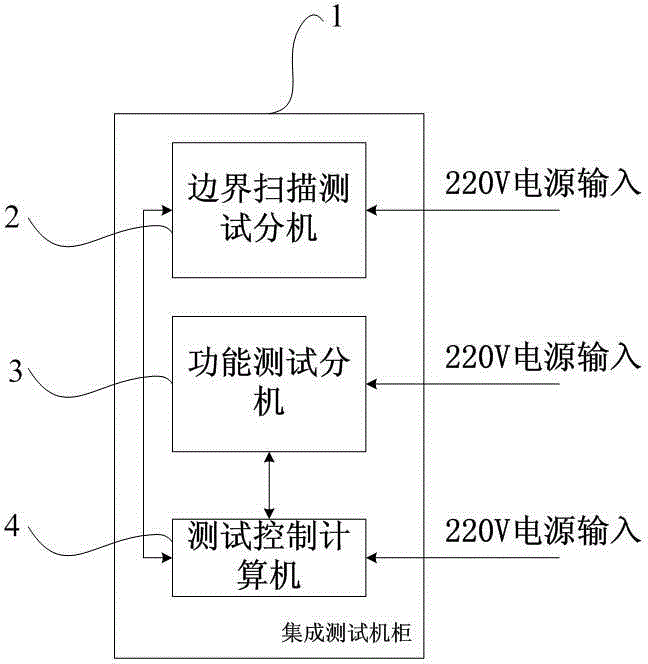

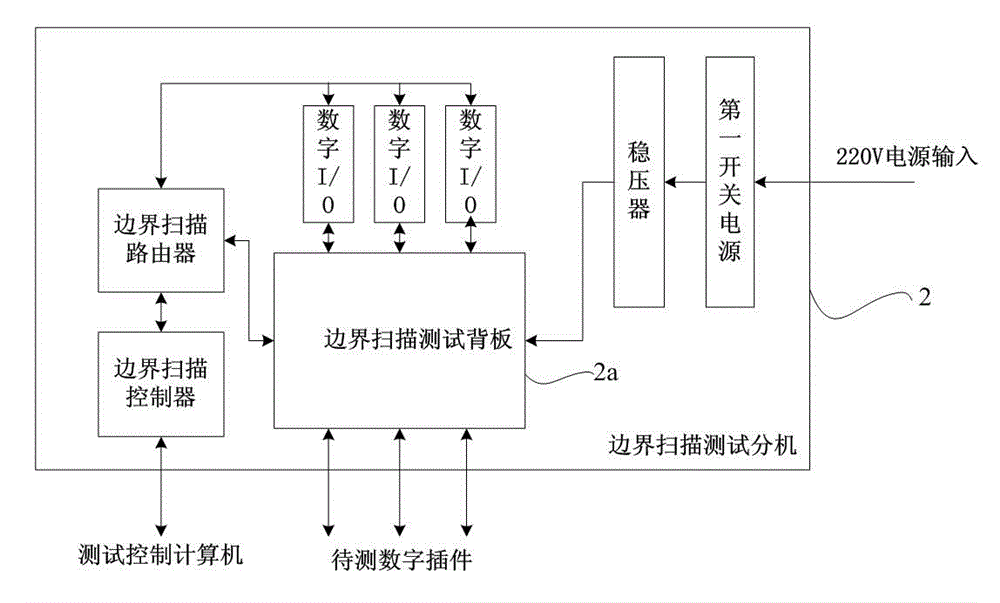

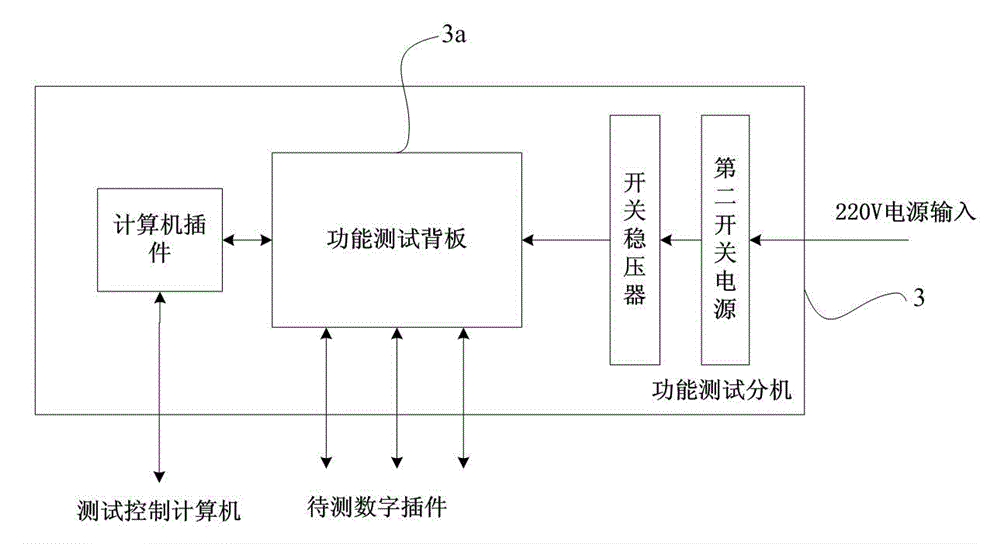

ActiveCN104914346AImprove fault detection rateImprove fault isolationWave based measurement systemsElectrical testingBoundary scan testingTraining set

The invention relates to a non-principle test device for general digital plug-ins, comprising a test control computer, a function test branch computer and a boundary scanning test branch computer which are arranged in an integrated test cabinet. The power input ends of the test control computer, the function test branch computer and the boundary scanning test branch computer are connected with a 220 mains supply through power lines. The test control computer is connected with the boundary scanning test branch computer through a USB cable, and the test control computer is connected with the function test branch computer through a network cable. The test control computer and the boundary scanning test branch computer communicate in a two-way mode, and the test control computer and the function test branch computer communicate in a two-way mode. The invention further discloses a test method of the non-principle test device for general digital plug-ins. The fault detection rate and fault isolation rate of digital plug-in boards are improved, the technical requirement for maintenance technicians is lowered, and the efficiency of digital plug-in test and repair is improved. The non-principle test device can assist in testing and debugging digital plug-ins in radar products, and especially, a testing and debugging platform is provided for separate plug-ins unable to build a whole system.

Owner:CHINA ELECTRONIC TECH GRP CORP NO 38 RES INST

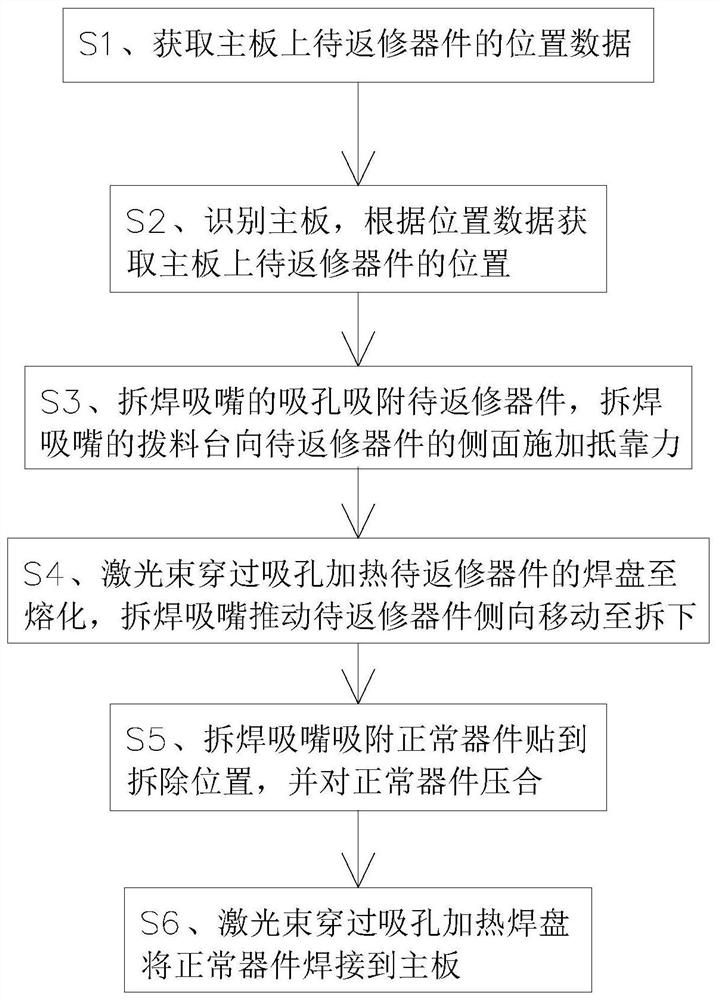

Mainboard repairing method

ActiveCN111785752AImprove rework efficiencyHigh precisionSolid-state devicesLaser beam welding apparatusMicro devicesStructural engineering

The invention relates to a mainboard repairing method. The mainboard repairing method comprises the following steps: S1, acquiring position data of a to-be-repaired device on a mainboard; S2, identifying the mainboard, and obtaining the position of the to-be-repaired device on the mainboard according to the position data; S3, enabling a light hole of a desoldering suction nozzle to adsorb the to-be-repaired device, and enabling a material stirring table of the desoldering suction nozzle to apply an abutting force to the side face of the to-be-repaired device; S4, enabling a laser beam to passthrough the light hole to heat a bonding pad of the to-be-repaired device until the bonding pad is molten, and enabling the desoldering suction nozzle to push the to-be-repaired device to move laterally until the to-be-repaired device is dismounted; S5, enabling the desoldering suction nozzle to suck the normal device to be attached to the desoldering position, and pressing the normal device; S6,enabling the laser beam to pass through the light hole to heat the bonding pad to weld the normal device to the mainboard. When the repair technology is used for repairing damaged lamp beads or Mini IC chips on the Mini LED backlight mainboard to wait for repair devices, the repair efficiency is high, the precision is high, the adaptability to small and micro devices is good, the heat influence issmall, no damage is caused to a repair target, and the high yield of products is ensured.

Owner:深圳市微组半导体科技有限公司

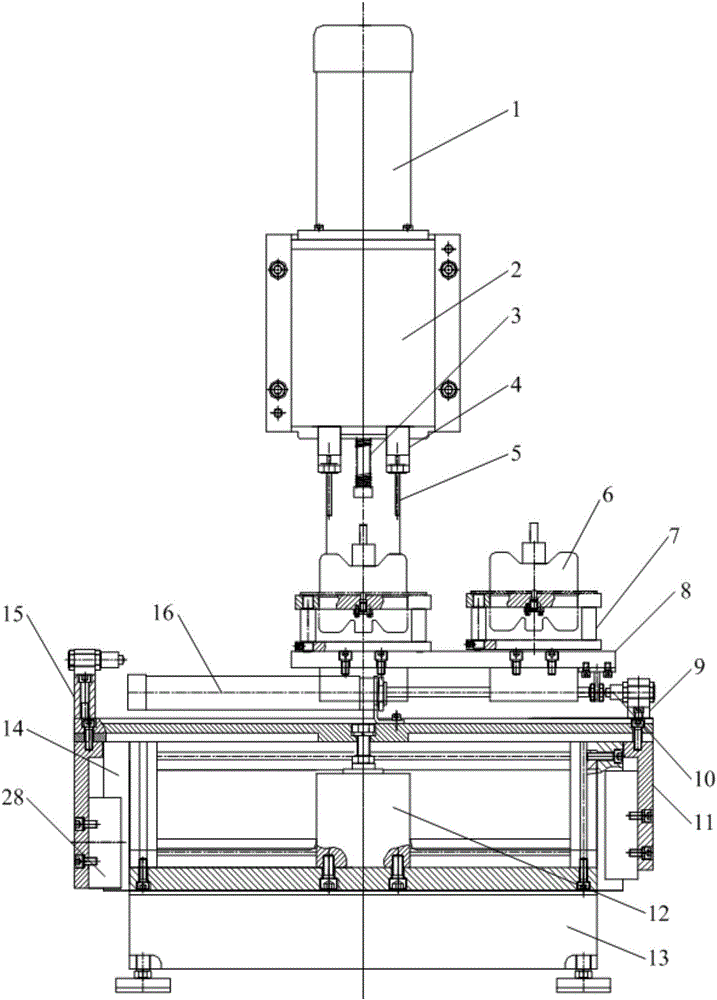

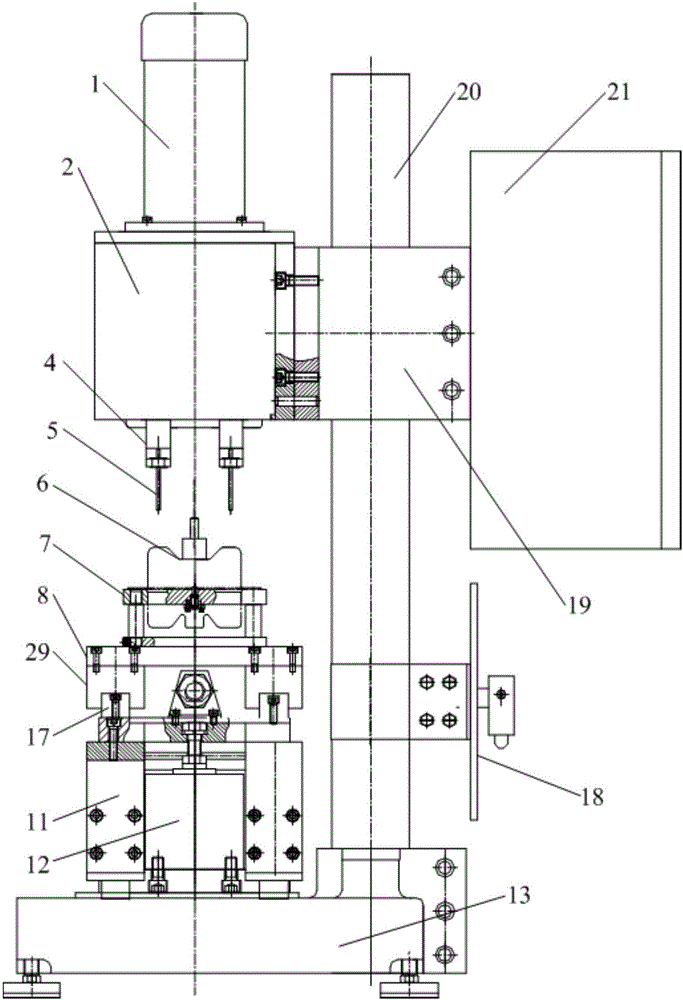

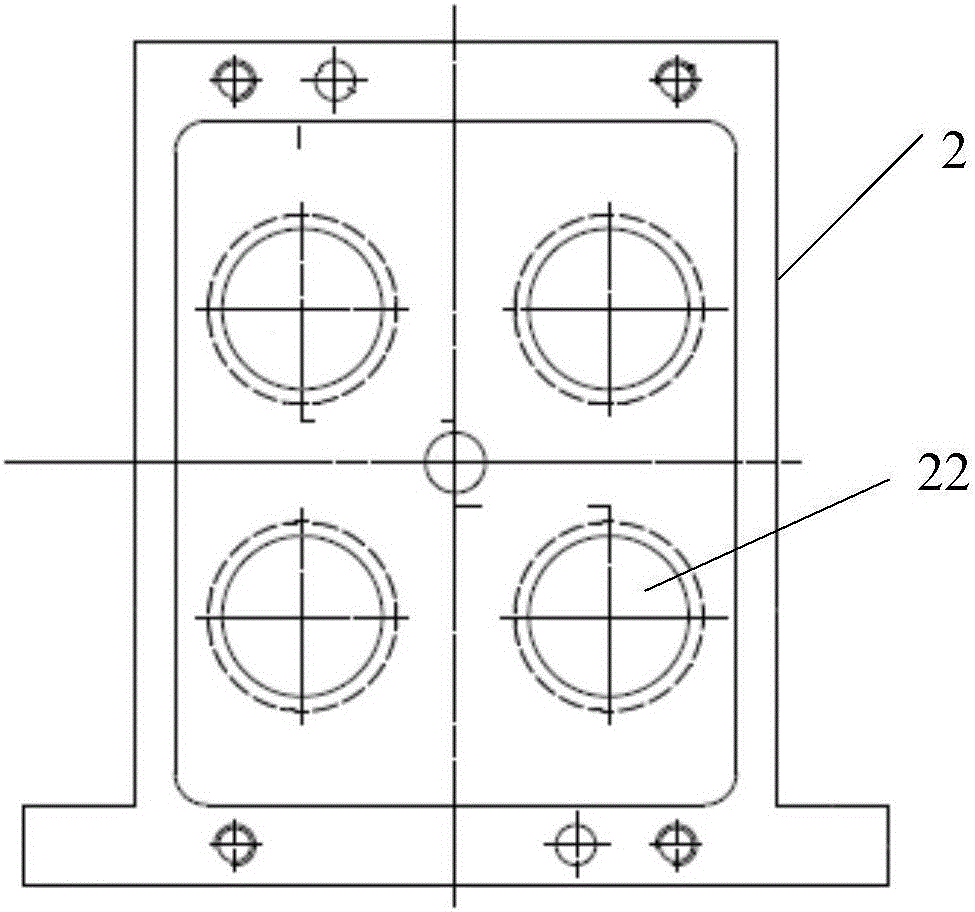

Drilling machine

InactiveCN105750582AReduce alignment timeReduce labor intensityBoring/drilling machinesEngineeringDrilling machines

The invention discloses a drilling machine.The drilling machine comprises a work table used for installing a motor to be repaired, a spindle box, at least two spindles positioned on the spindle box, drill bits fixed to the spindles, a first driving component driving the spindles to rotate, and a second driving component driving the work table or spindle box to move so as to make end cover rivets of the motor to be repaired located under the drill bits, wherein the drill bits are fixed to the spindles, and the drill bits are distributed in the same way as the end cover rivets of the motor to be repaired.Due to the fact that the at least two spindles are positioned in the spindle box and the drill bits are distributed in the same way as the end cover rivets of the motor to be repaired, alignment of the at least two drill bits and the end cover rivets can be achieved simply by moving the spindle box or work table, time for alignment of the drill bits and the end cover rivets is effectively shortened, alignment efficiency is improved, and then repair efficiency is improved and the labor intensity of workers is relieved.

Owner:CHONGQING KAIBANG MOTOR +2

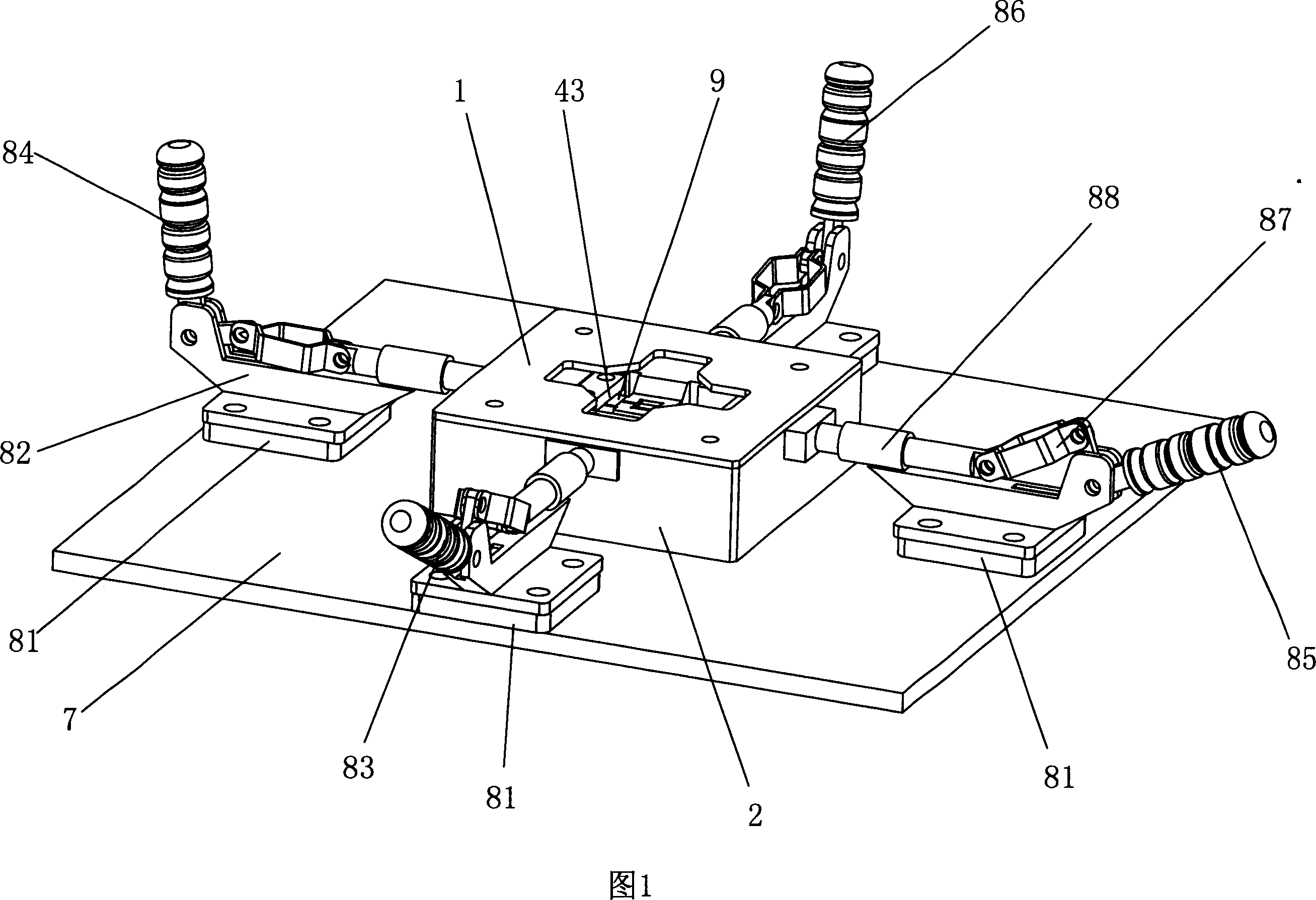

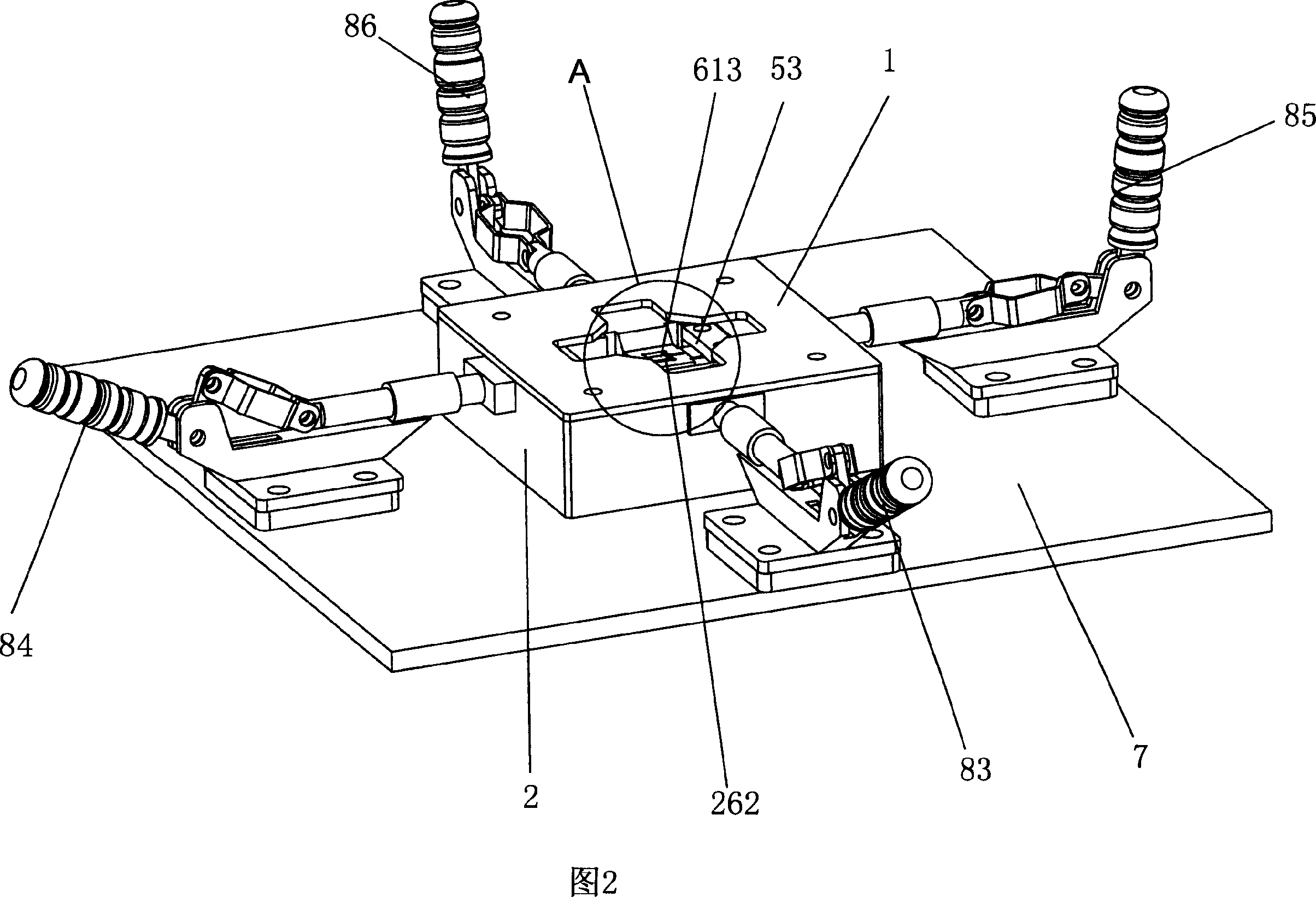

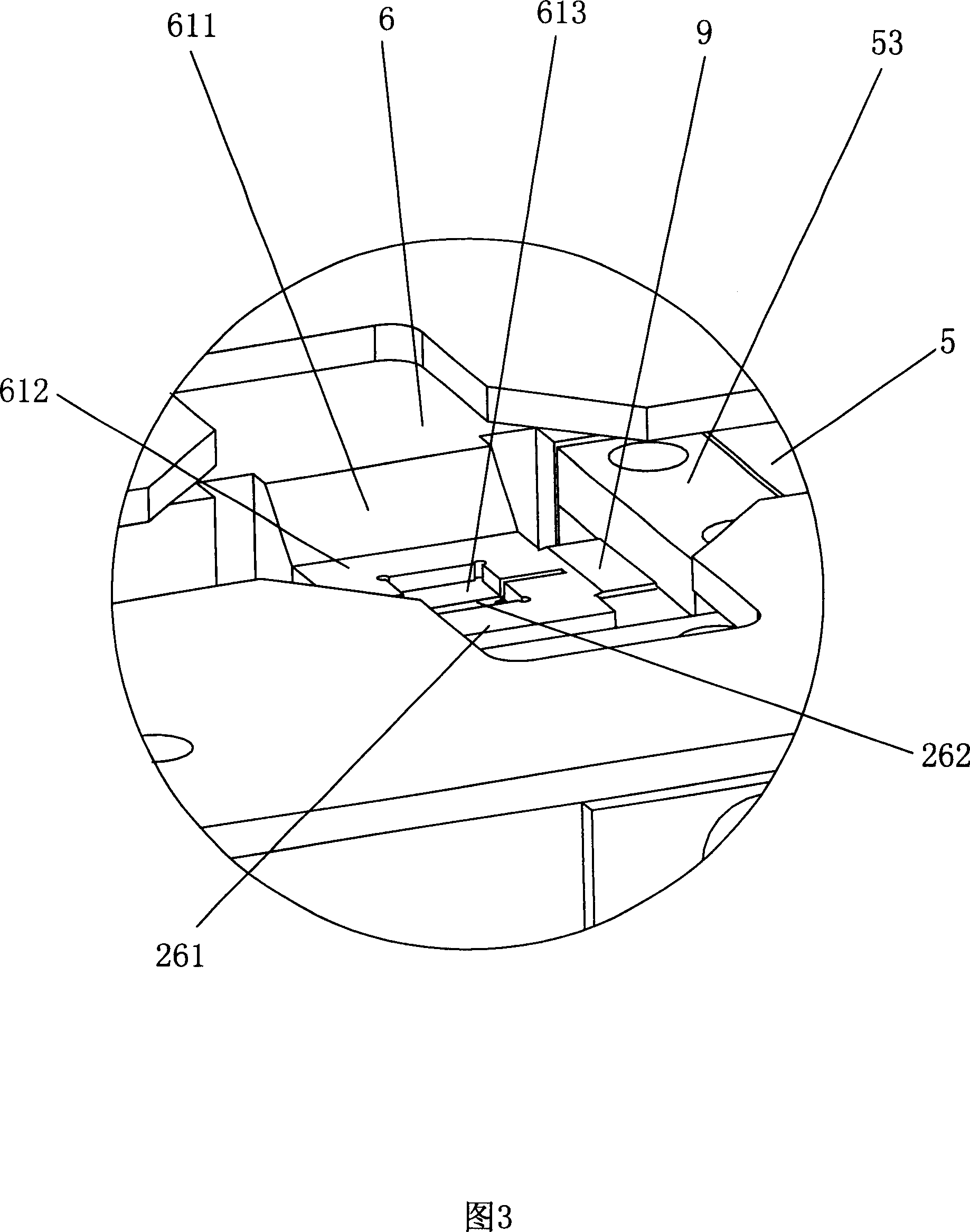

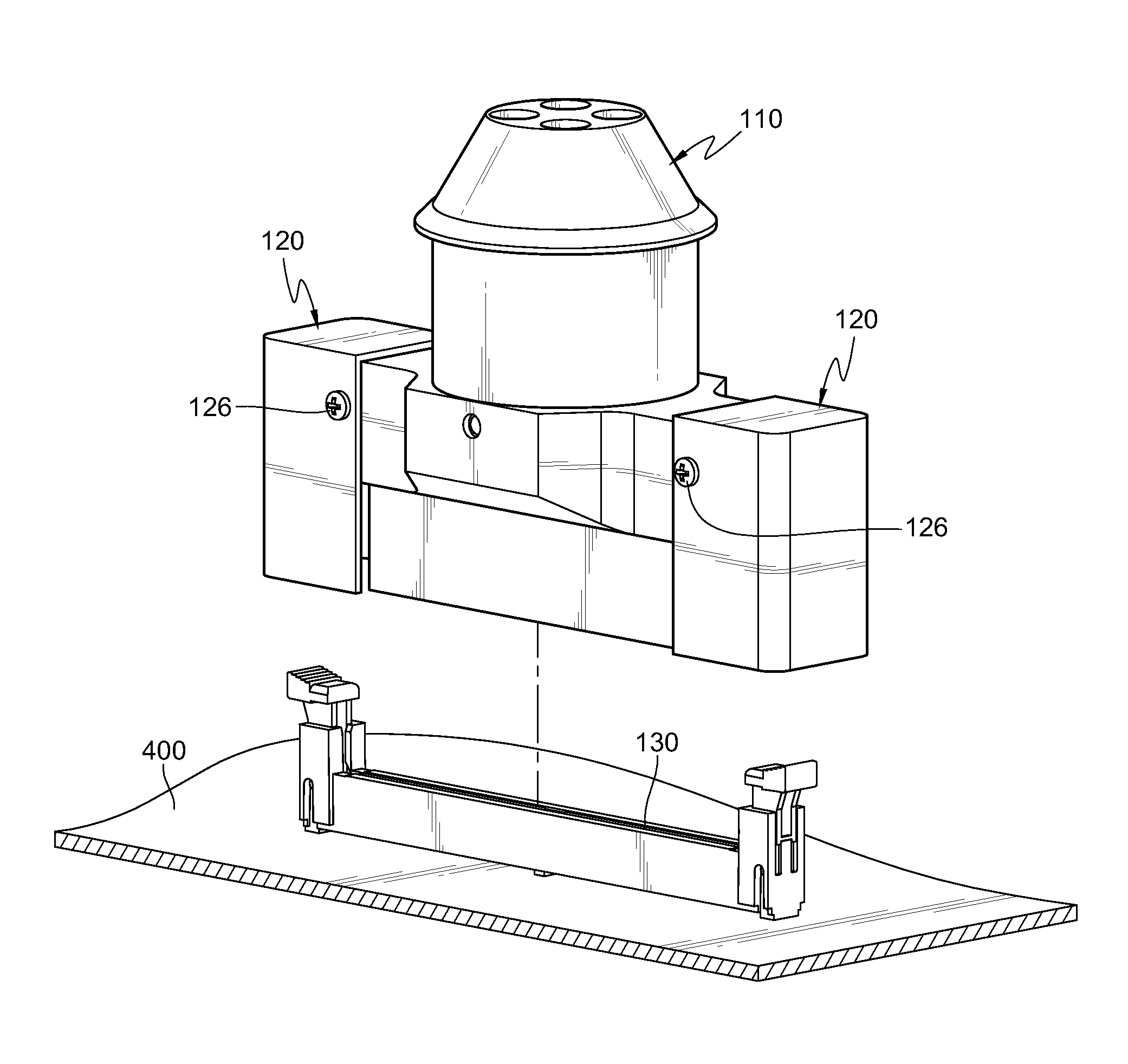

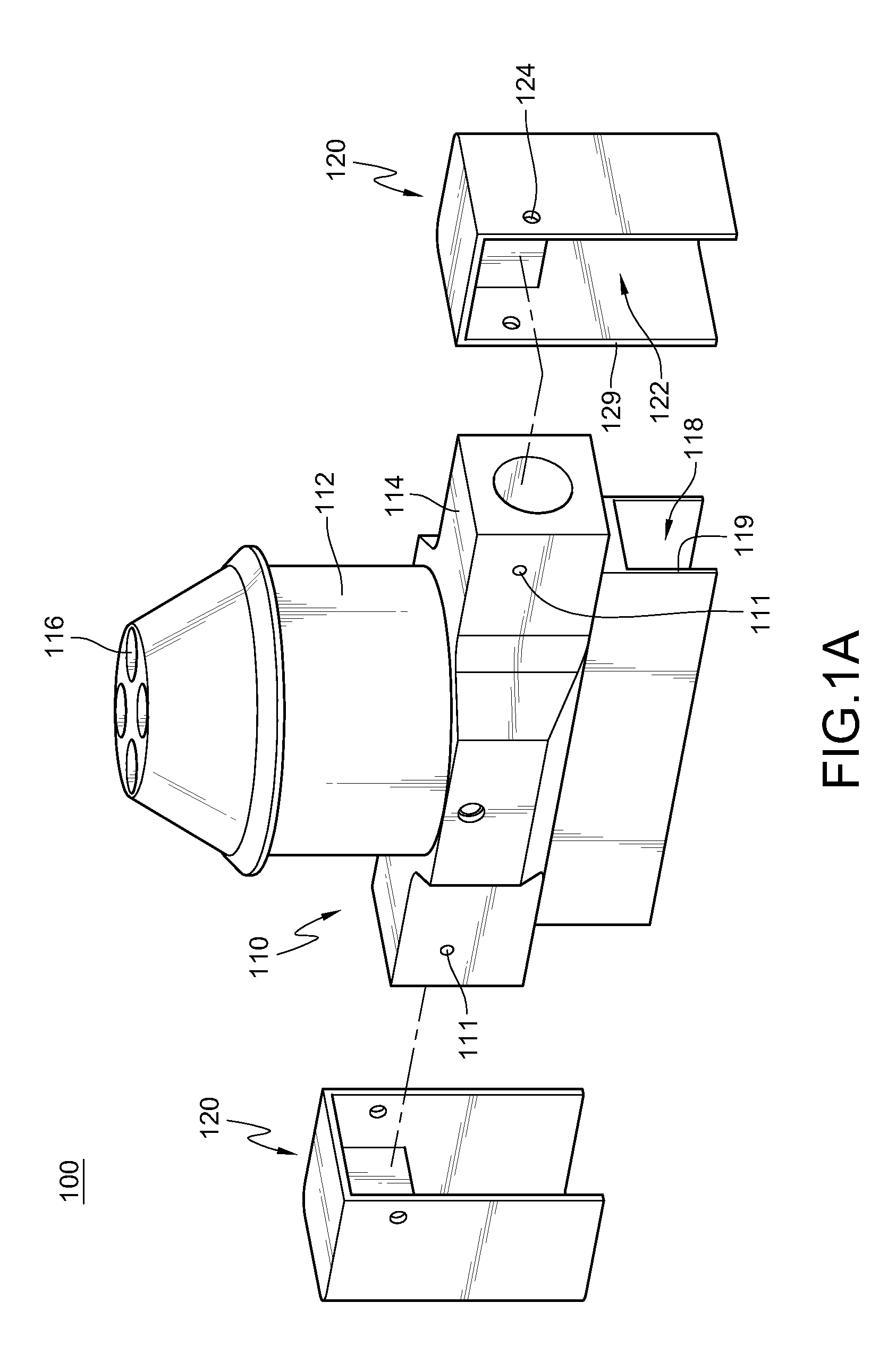

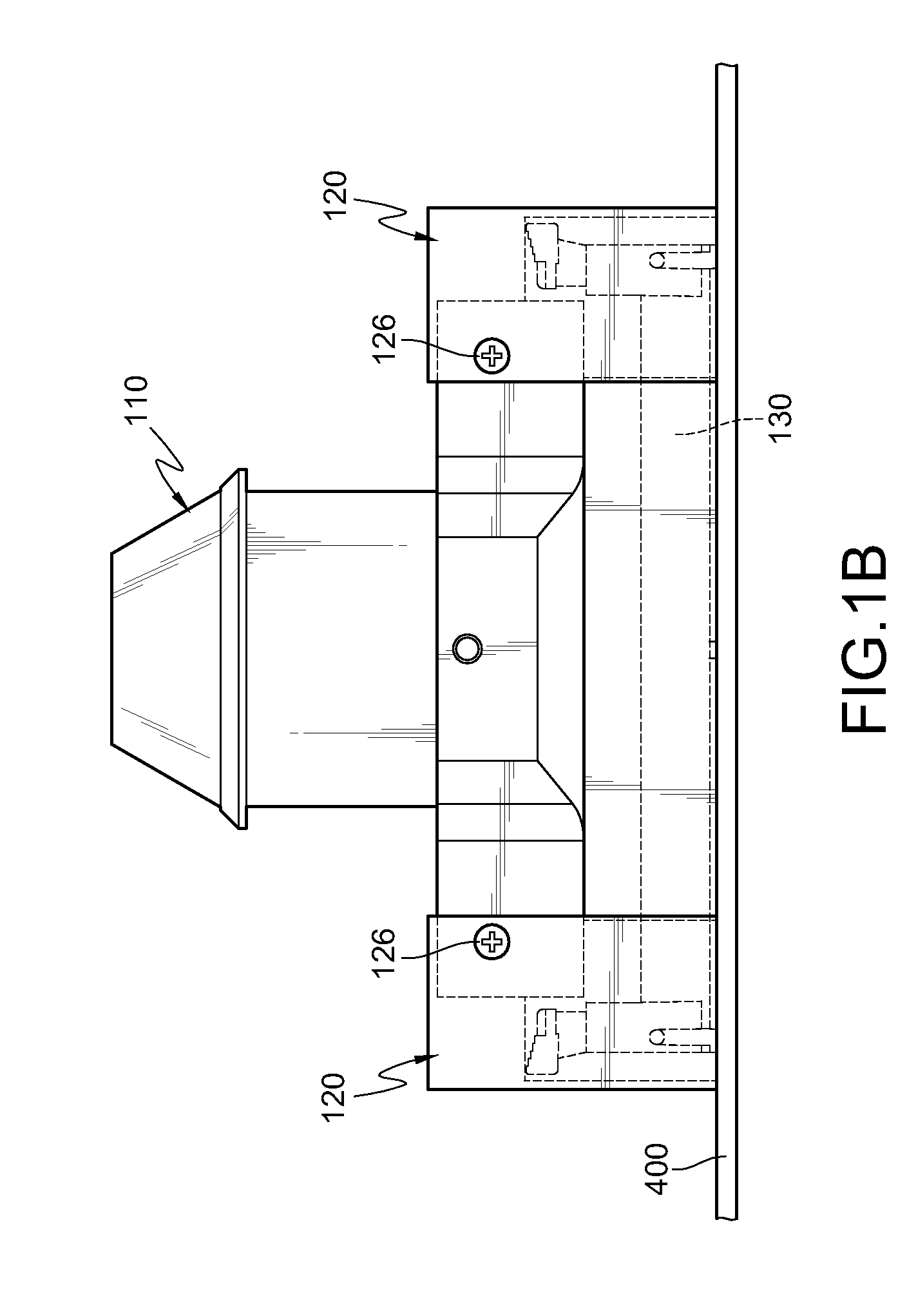

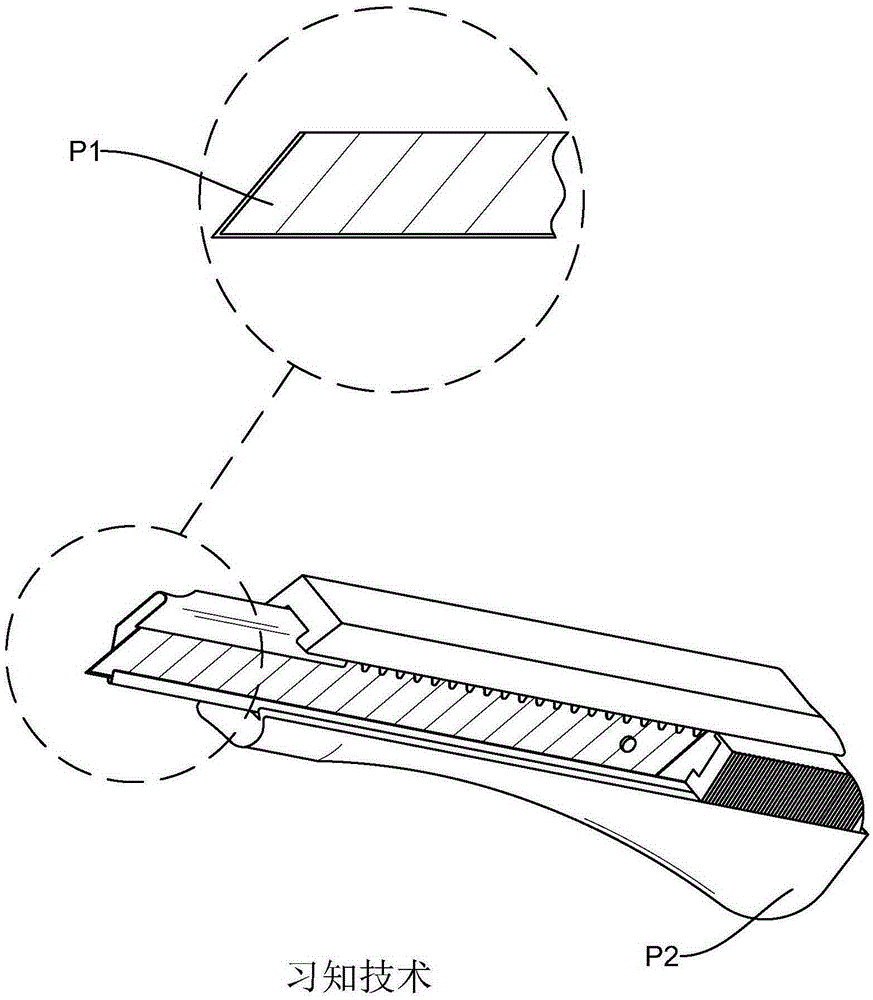

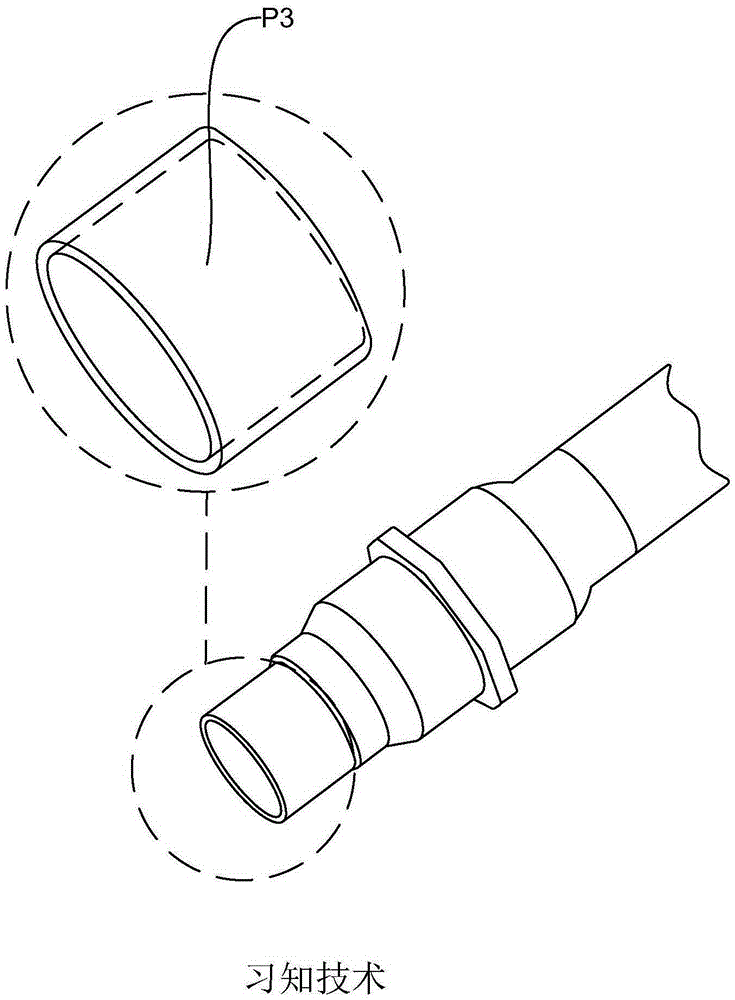

Rework soldering jig

InactiveUS20110296677A1Improve rework efficiencyChange shapeWorkpiece holdersContact member assembly/disassemblySurface mountingEngineering

A rework soldering jig is used for heating a surface mounted slot. The rework soldering jig includes a body and an assembly frame. The assembly frame is detachably disposed on the body. The body and the assembly frame together wrap the surface mounted slot. Since the rework soldering jig has the detachable assembly frame, a size thereof can be adjusted according to different forms of slots.

Owner:INVENTEC CORP

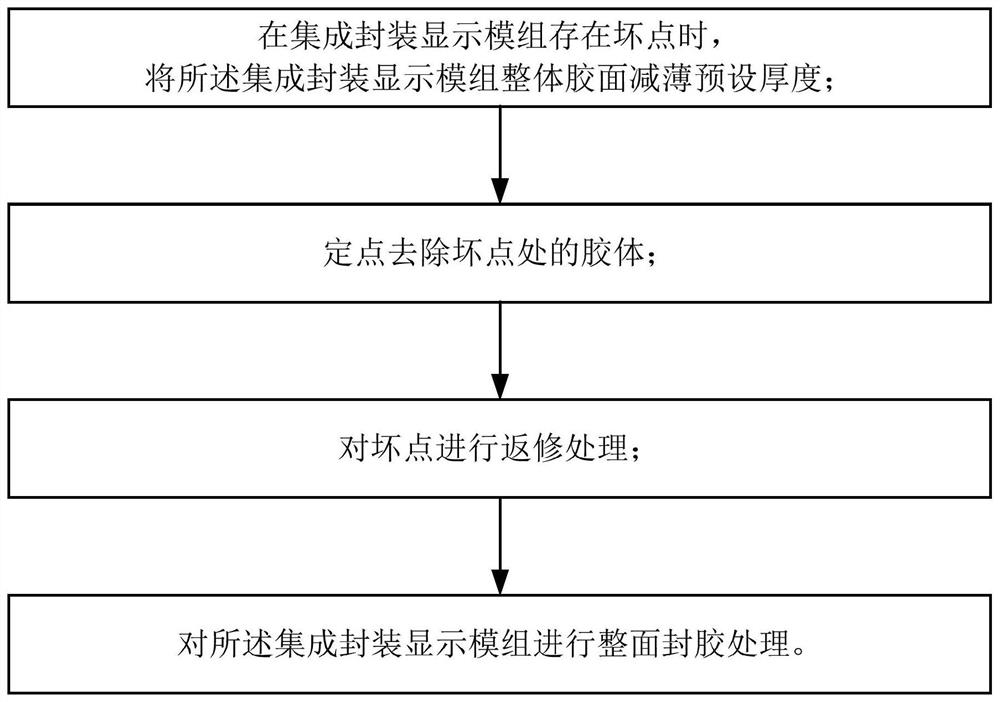

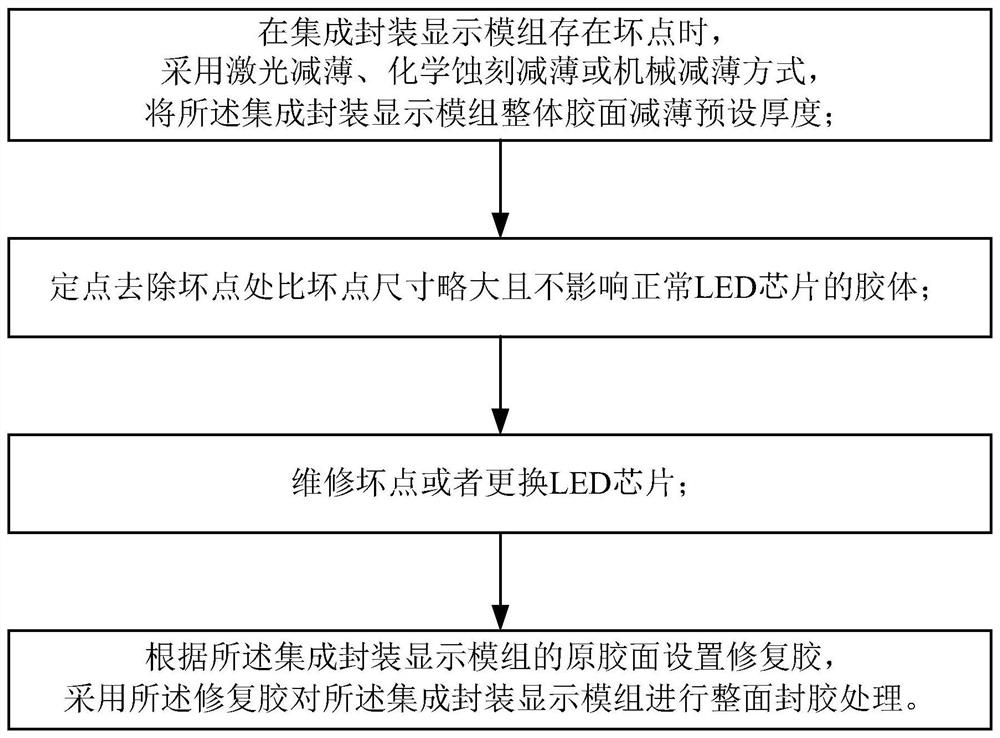

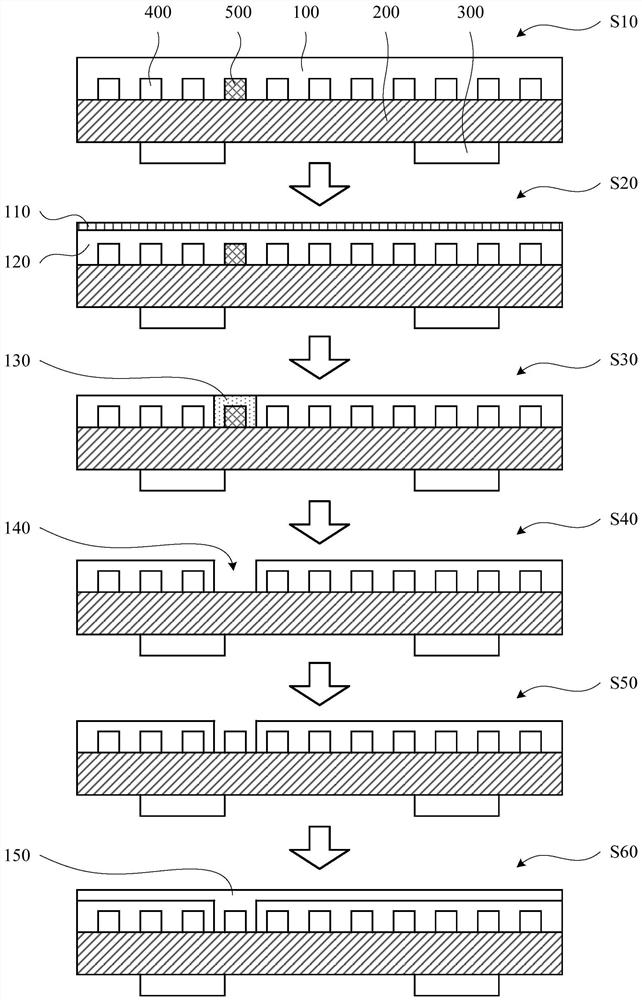

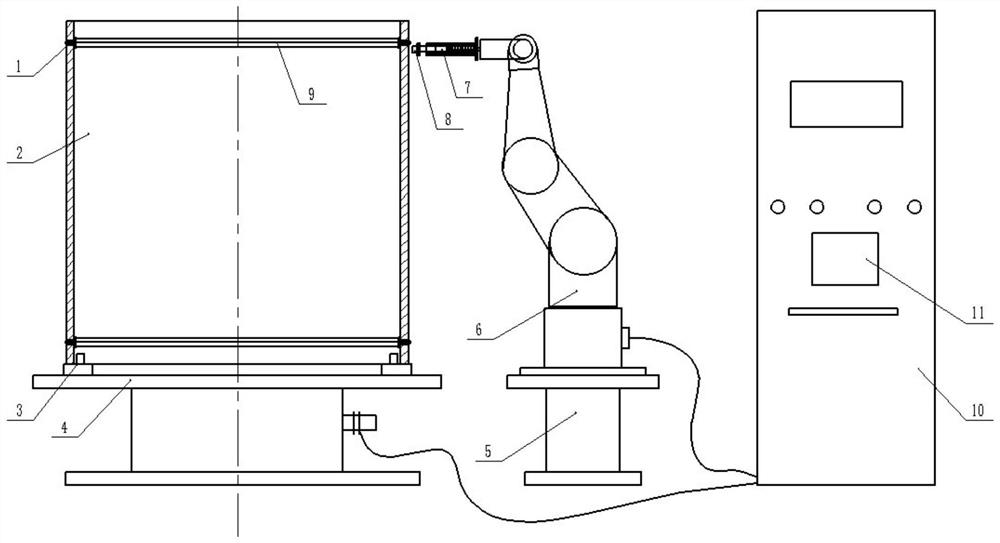

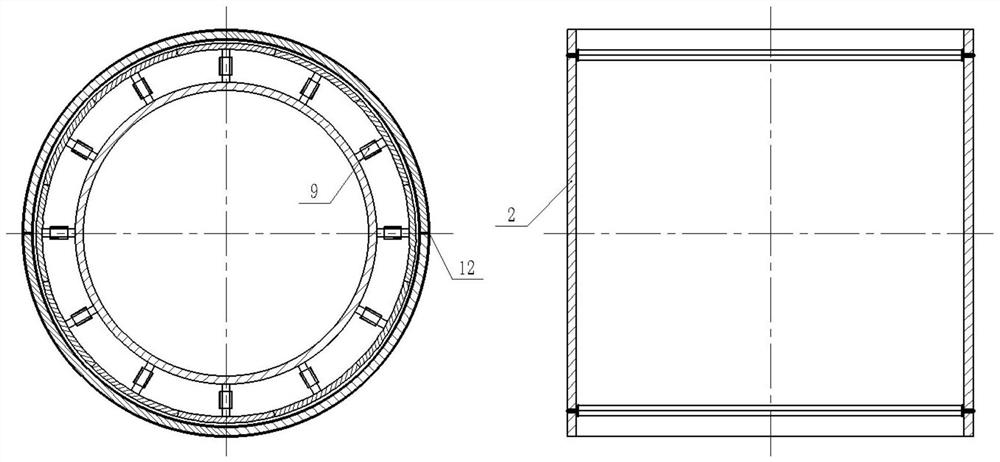

Integrated packaging display module, repair method thereof and display device

ActiveCN113054070AGuaranteed display effectAchieve mass productionSolid-state devicesIdentification meansDisplay deviceProcess engineering

The invention relates to an integrated packaging display module, a repair method thereof and a display device. The repair method of the integrated packaging display module comprises the following steps: thinning the overall glue face of the integrated packaging display module by a preset thickness; removing the colloid at the dead pixel at a fixed point; carrying out repair processing on the dead pixel; and carrying out glue sealing treatment on the whole surface of the integrated packaging display module. A repairing three-step method of first thinning, then hole filling and finally restoring is ingeniously designed, the method is particularly suitable for the integrated packaging display module which is more and more dense and even has the dot spacing smaller than 1 mm, repairing treatment is achieved in a very small limited space, and the overall display effect of the integrated packaging display module can be better guaranteed in cooperation with glue sealing on the whole face after thinning is conducted, so the problem of integrated packaging repair feasibility is solved, the repair reliability and the consistency of appearance color after repair are ensured, the repair efficiency and the overall display stability are improved, and reparable and large-scale mass production of the integrated packaging display module is realized.

Owner:UNILUMIN GRP

Automatic system for friction stir welding internal defect on-line detection

PendingCN113155970AImprove detection and repair efficiencySolving inefficienciesAnalysing solids using sonic/ultrasonic/infrasonic wavesProcessing detected response signalImaging processingImage manipulation

The invention discloses an automatic system for friction stir welding internal defect on-line detection, which comprises a mechanical scanning motion subsystem, a phased array ultrasonic instrument, an electric control subsystem and a control unit, and is characterized in that the mechanical scanning motion subsystem is used for realizing movement of a phased array probe along a welding seam and clamping and coupling of the probe; the phased array ultrasonic instrument is used for acquiring and processing ultrasonic data, and the control unit is used for performing data communication, instruction issuing and defect image processing with the phased array ultrasonic instrument and the electric control subsystem by taking Ethernet as a medium based on an industrial personal computer; and the electric control subsystem receives an instruction of the control unit to drive the mechanical scanning motion subsystem to drive the probe to realize full-automatic scanning detection on the friction stir welding seam of the cylindrical or conical workpiece. The system has the advantages of high automation degree, visual imaging, high detection efficiency and capability of automatically identifying, counting and analyzing defects.

Owner:NANJING CHENGUANG GRP

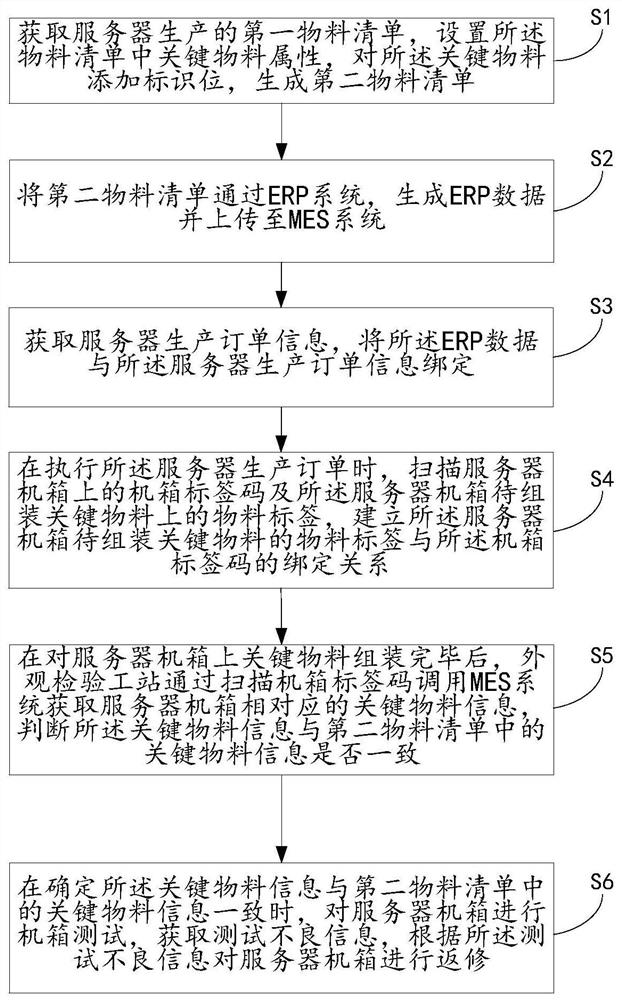

Automatic inspection and repair method for server production

InactiveCN112348530ASource traceableControllable assembly processResourcesCommerceProduction lineBill of materials

The invention discloses a server production automatic inspection and repair method, which comprises the steps of obtaining a first bill of materials produced by a server, adding an identification bitto a key material, generating a second bill of materials, uploading the second bill of materials to an MES system, and binding the second bill of materials with server production order information; scanning a case label code and a material label on the key material; calling an MES system by scanning the case label code to obtain key material information corresponding to the server case; and when it is determined that the key material information is consistent with the key material information in the second bill of materials, performing case test on the server case, obtaining test bad information and performing repair. The method realizes traceability of key material sources of server products, controllability of an assembly process and a repair process, automatic collection and arrangementof test data of the server products, automatic provision of reason countermeasures for part of bad items, assistance of production line repair, improvement of repair efficiency and reduction of potential quality hazards caused by repair.

Owner:INSPUR SUZHOU INTELLIGENT TECH CO LTD

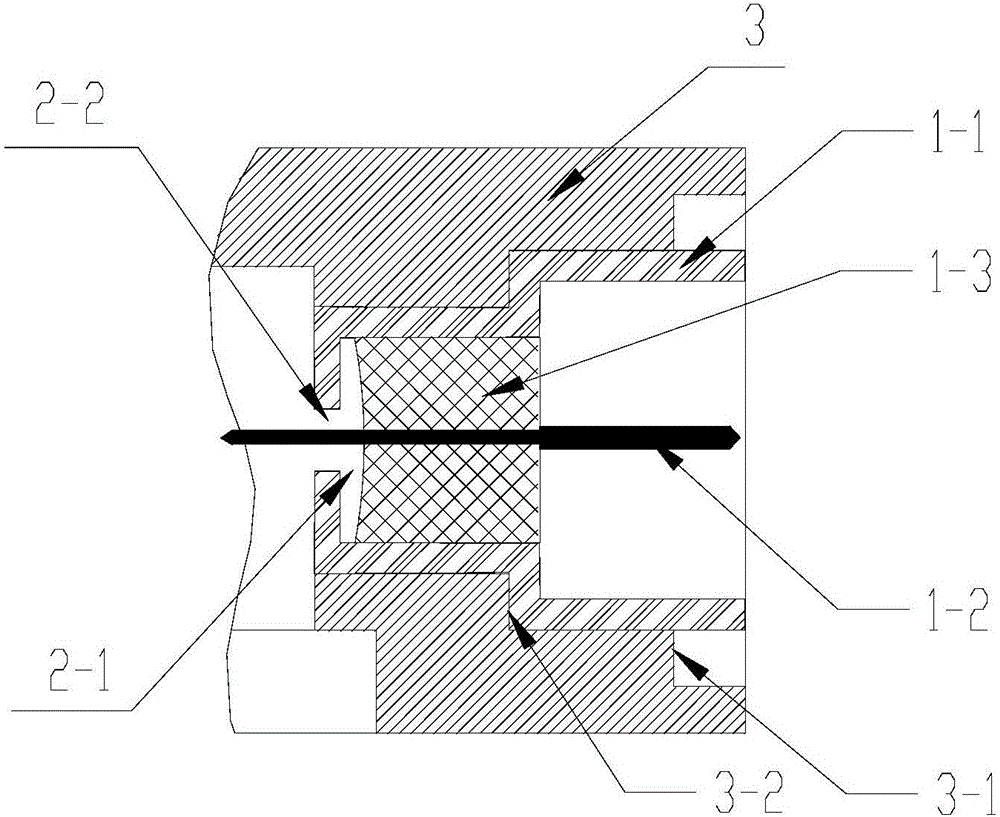

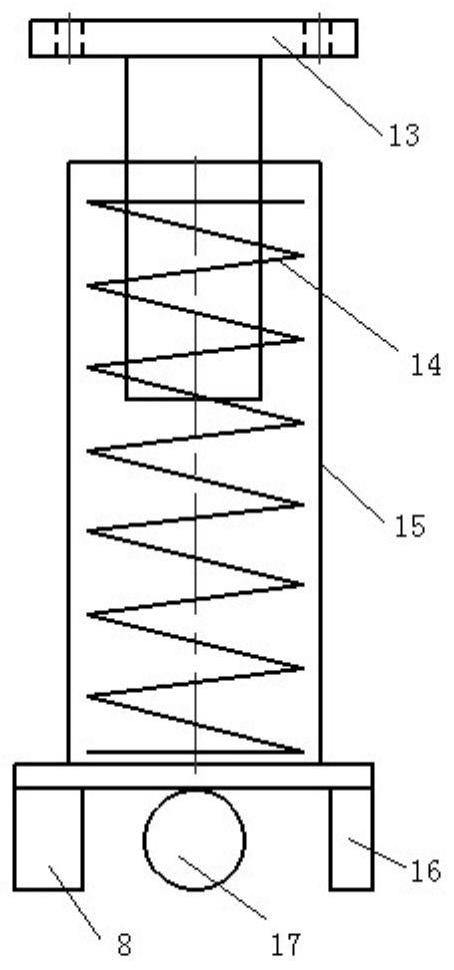

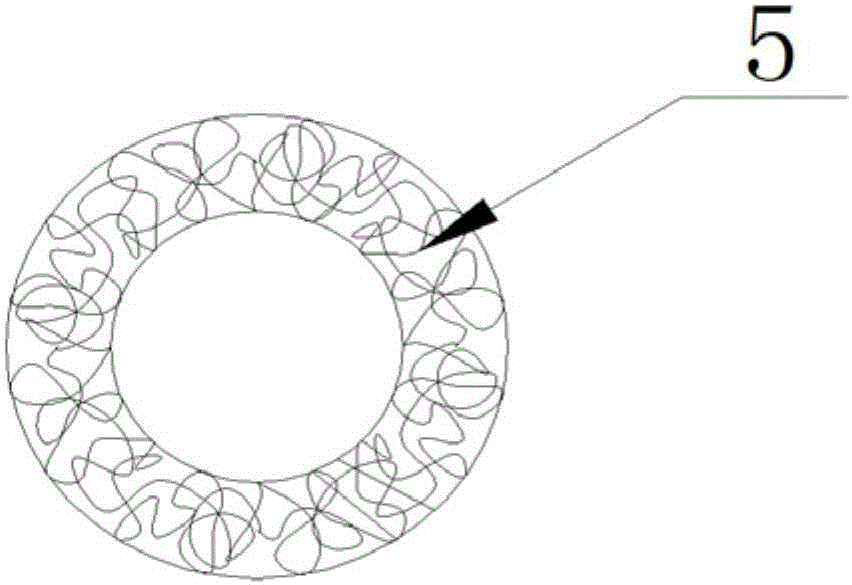

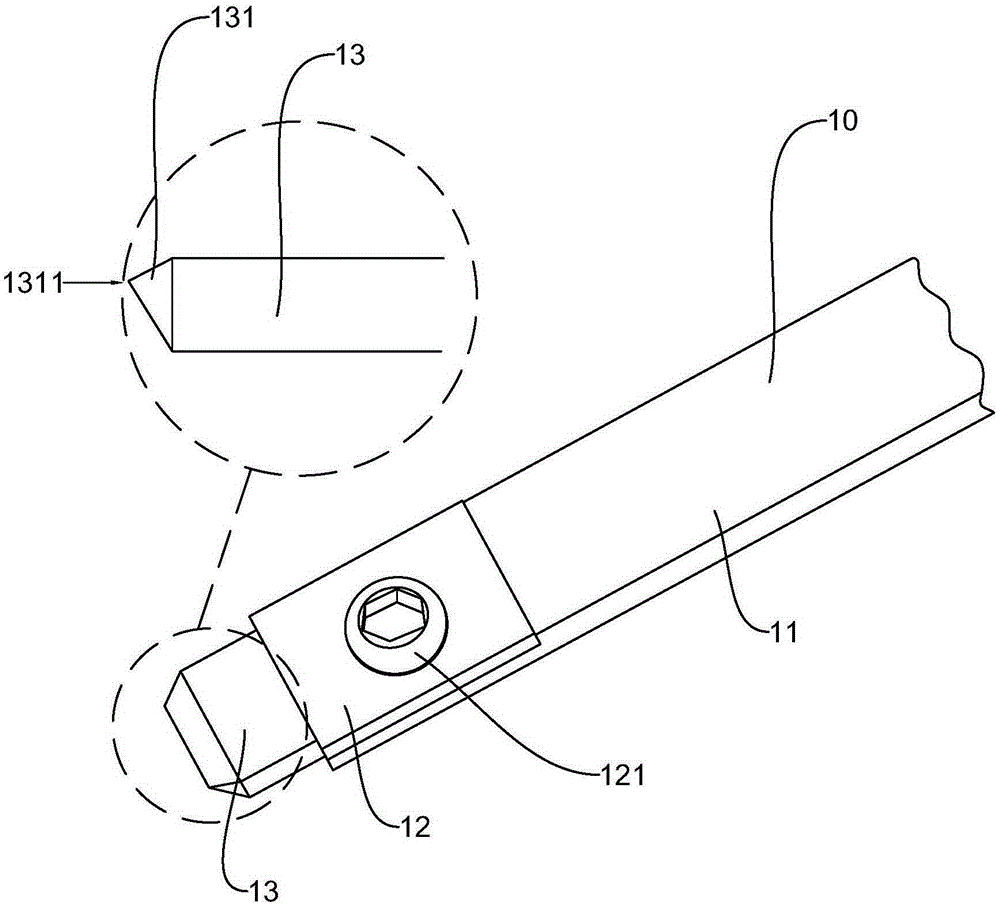

TR module vertical interconnecting structural member

ActiveCN106785435AImprove reliabilityIncrease productivityAntenna arraysAntennas earthing switches associationDielectricHigh density

The invention discloses a TR module vertical interconnecting structural member. An annular fuzz button is mounted in a mounting groove of a substrate and fixedly connected with a conductive thin film on the undersurface of the mounting groove, and a needle head of an insulator mounted on a PCB (printed circuit board) passes a positioning hole of a dielectric board and then is inserted into an inner hole of the annular fuzz button; hole diameter of the inner hole of the annular fuzz button is smaller than outer diameter of the needle head of the insulator, the annular fuzz button has elasticity, and after the needle head of the insulator is inserted into the inner hole of the annular fuzz button, the annular fuzz button elastically deforms, compresses the needle head of the insulator and closely contacts with the same, so that interconnecting reliability is improved. Elastic deformation is caused by when the needle head of the insulator is inserted into the annular fuzz button and not caused by extrusion of the PCB and the substrate, so that producibility is better during high-density interconnecting, production efficiency and yield are higher, repair efficiency is high, and damage to or falling loss of the fuzz button caused by separation of upper and lower boards is avoided.

Owner:成都雷电微力科技股份有限公司

LED lamp photoelectric composite packaging method

InactiveCN106783823ADoes not affect luminescent exposureEasy to operateSolid-state devicesSemiconductor devicesEpoxyPlastic packaging

The invention discloses an LED lamp photoelectric composite packaging method. The method comprises four steps of LED bead die-bonding and wire-bonding, LED bead plastic packaging, driving chip die-bonding and plastic-packaging, flash removing and finished product tendon cutting, wherein the bead and the driving chip are respectively bonded on front and back surfaces of a bracket, and are subjected to plastic package through epoxy resin. According to the method, the operation is simple, the yield is high, frequent reworking requirement is not needed, the efficiency is high, and the brightness display effect is relatively good since the chip does not influence luminescence and irradiation of the bead.

Owner:厦门天微电子有限公司

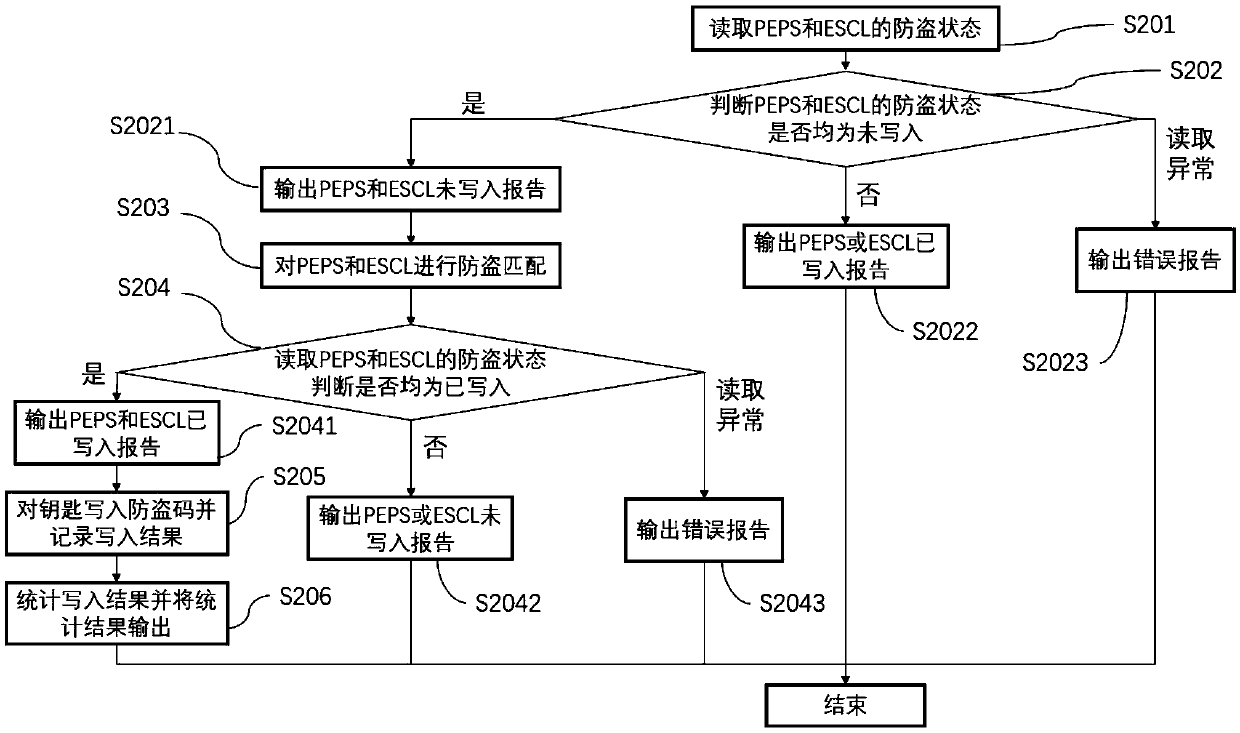

Vehicle anti-theft matching method and system

ActiveCN111196246AAvoid wastingAnti-theft matching preventionAnti-theft devicesComputer scienceReliability engineering

The invention provides a vehicle anti-theft matching method and system. According to the vehicle anti-theft matching method and system of the invention, the anti-theft states of PEPSs and ESCLs are judged; PEPSs and ESCLs which are subjected to anti-theft matching and have poor incoming parts are screened out, so that it is guaranteed that anti-theft matching equipment only carries out anti-theftmatching on blank PEPSs and ESCLs. The situation that repeated matching generates a plurality of anti-theft codes can be effectively prevented; the anti-theft matching errors of the PEPSs and ESCLs and key mismatching anti-theft codes are avoided. Besides, a detection result is output, so that an operator can visually see the reason why an anti-theft matching process is interrupted according to anoutput report, and therefore, the anti-theft repair efficiency and success rate of a vehicle are improved.

Owner:GUANGZHOU AUTOMOBILE GROUP CO LTD

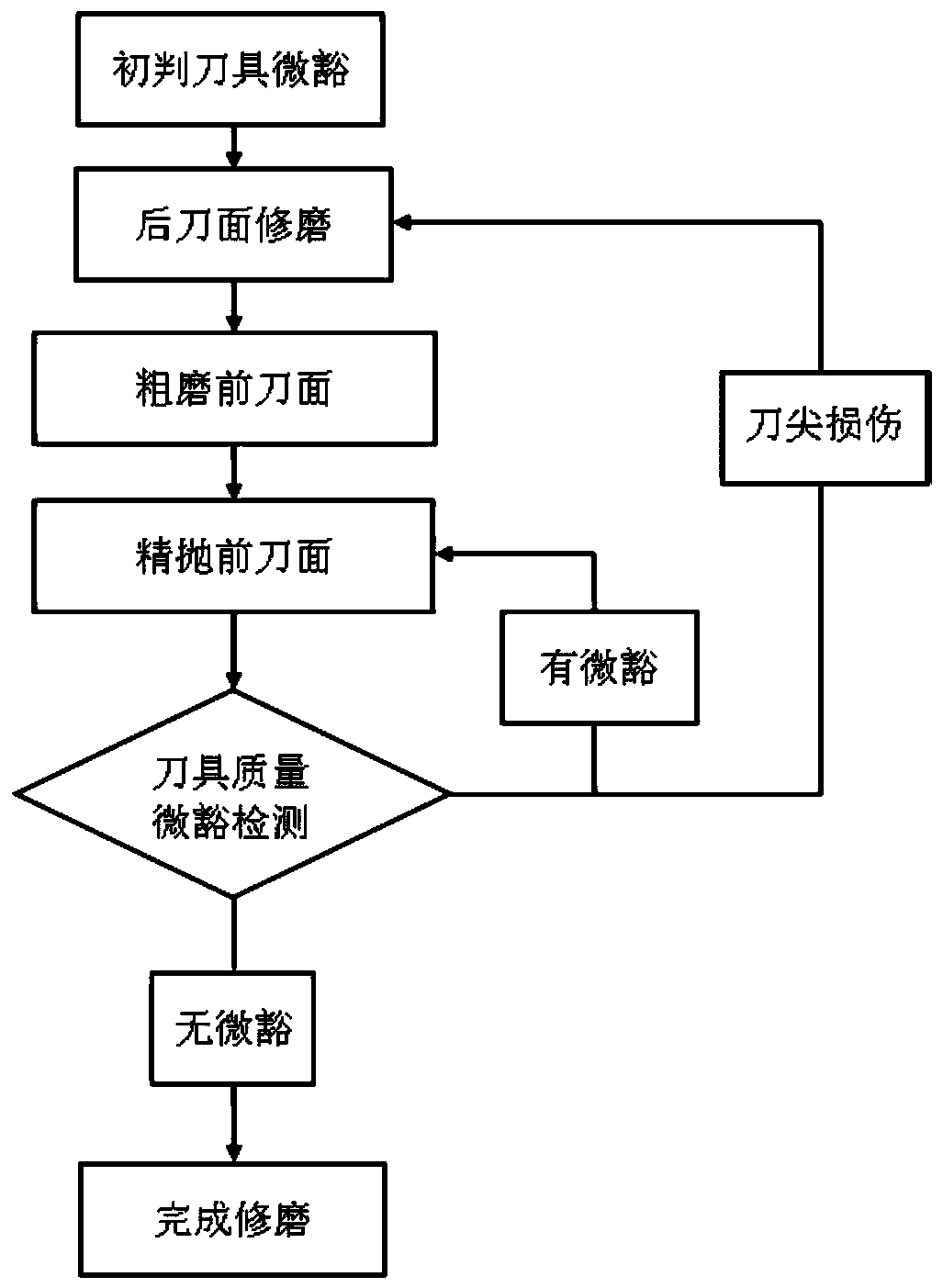

Micro-arc edge diamond cutter micro-notch control method based on mechanical grinding method

ActiveCN110757263AImprove rework efficiencyIncrease the number of repeated useGrinding feed controlOther manufacturing equipments/toolsEngineeringStructural engineering

The invention discloses a micro-arc edge diamond cutter micro-notch control method based on a mechanical grinding method. The method sequentially comprises the step 1 of determining the position and size of micro-notches of a cutting edge of a cutter; step 2, grinding the rear cutter face of the cutter, removing micro-gaps on the rear cutter face of the cutter, and meanwhile controlling the arc size of the cutter; step 3, roughly grinding the front cutter face of the cutter, and removing micro-notches near the front cutter face and a cutter tip of the cutter; step 4, finely polishing the frontcutter face of the cutter, removing fine micro-notches and defect areas, and controlling the roughness of the front cutter face and the contour of the cutting edge; and step 5, detecting the qualityof the cutter, determining whether the cutting edge of the cutter is damaged, and if so, returning to the step 2; if the micro-notches of the cutting edge of the cutter are reduced, but the micro-notches still exist, performing the step 4 again until the micro-notches of the cutter disappear and the arc size reaches the required value. The phenomena of cracking, micro-notch recurrence and the likecan be effectively avoided, so that the diamond repair efficiency is improved; and the removal amount is reduced, the repeated utilization frequency of the cutter is increased, and the use cost of the cutter is reduced.

Owner:INST OF MACHINERY MFG TECH CHINA ACAD OF ENG PHYSICS

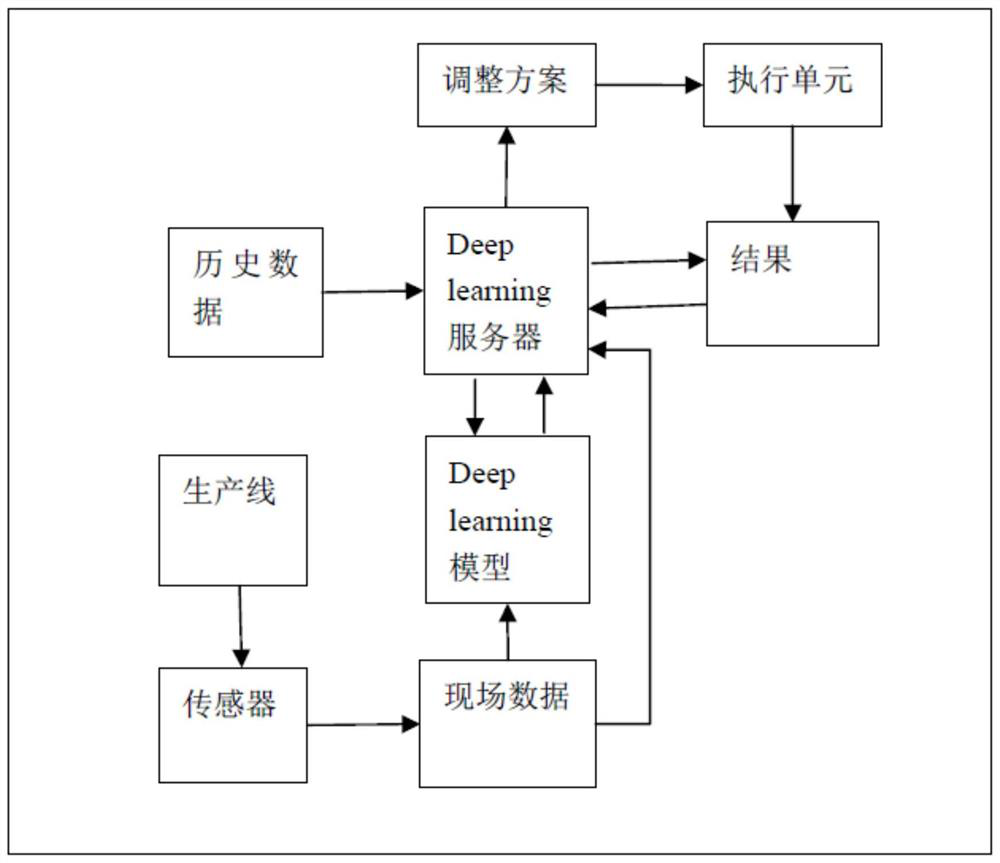

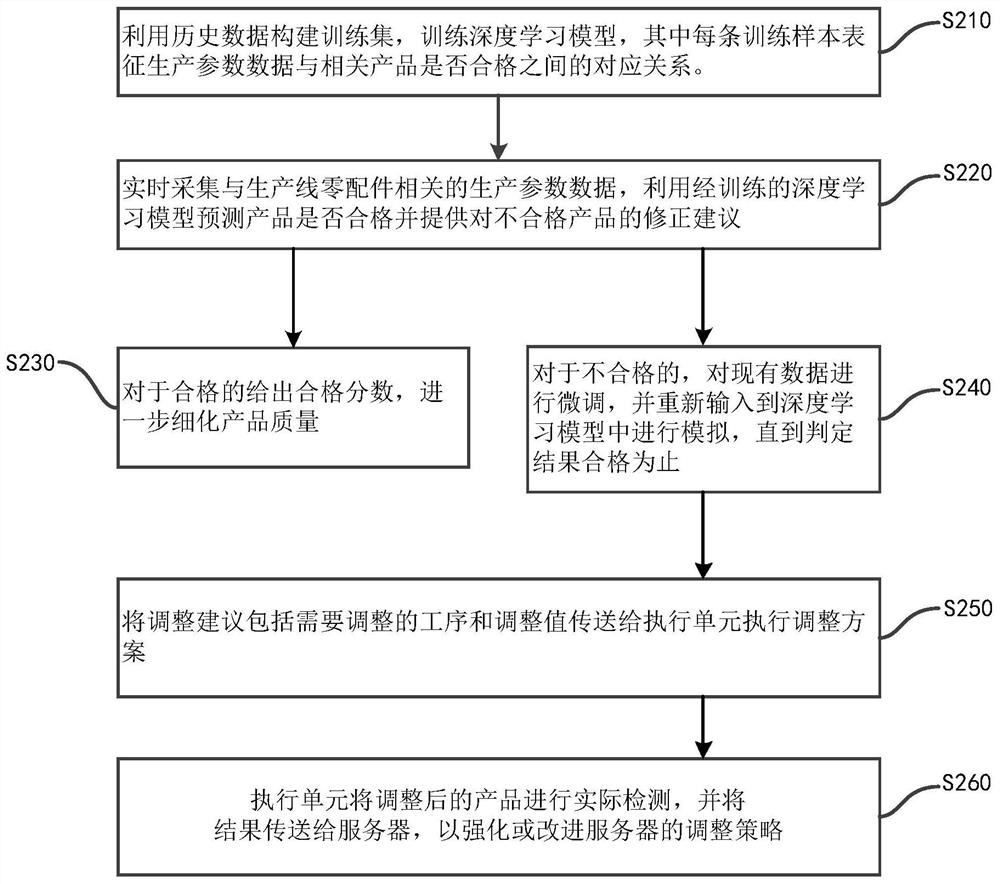

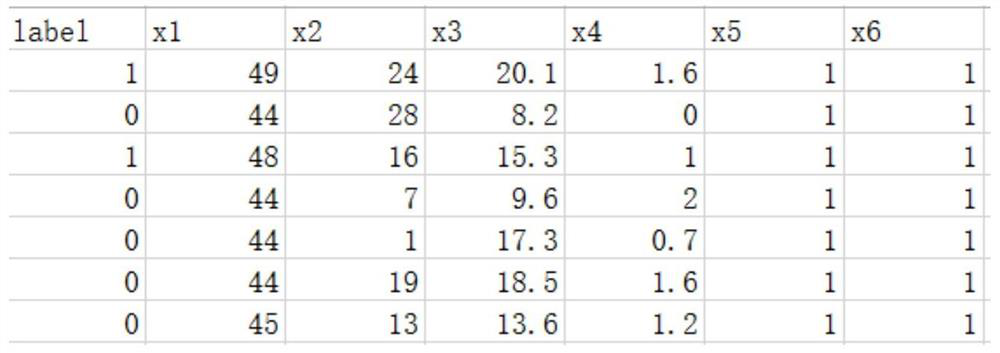

Intelligent quality control method and system

InactiveCN113435699AStrengthen or improve adjustment strategiesImprove quality control abilityForecastingResourcesProduction lineQuality control system

The invention discloses an intelligent quality control method and system. The method comprises the following steps: collecting production parameter data related to parts of a production line; inputting the production parameter data into a deep learning model, predicting whether products produced on site are qualified or not and outputting the result, giving qualified scores for the qualified products, refining the product quality further, giving correction suggestions for the unqualified products and transmitted to an execution unit for execution, conducting actual detection on the corrected products by the execution unit, and transmitting the result to the server so as to strengthen or improve the adjustment strategy of the server, wherein the deep learning model is obtained through training by taking a set loss function as a target, and each training sample represents a corresponding relation between the production parameter data and whether the related product is qualified or not. The method can be applied to actual production, predicts and guides a production result, enables a quality control system to be integrated and intelligent, and solves problems which cannot be solved by manpower.

Owner:SHENZHEN UNIV

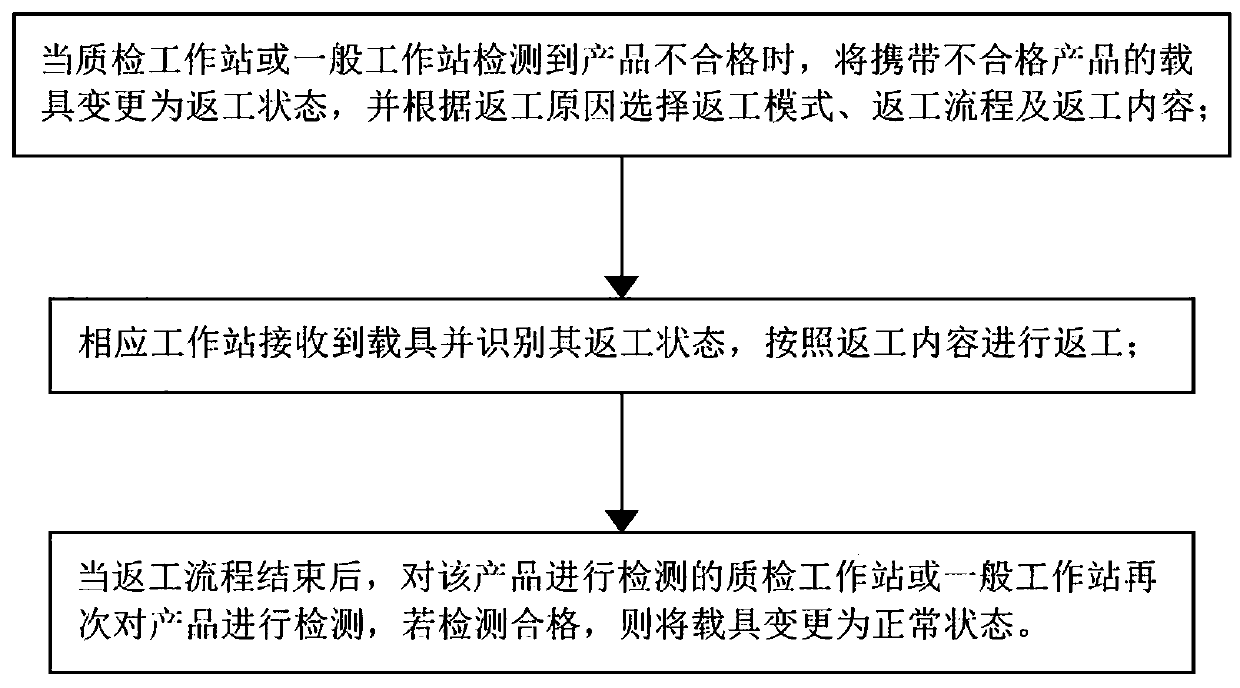

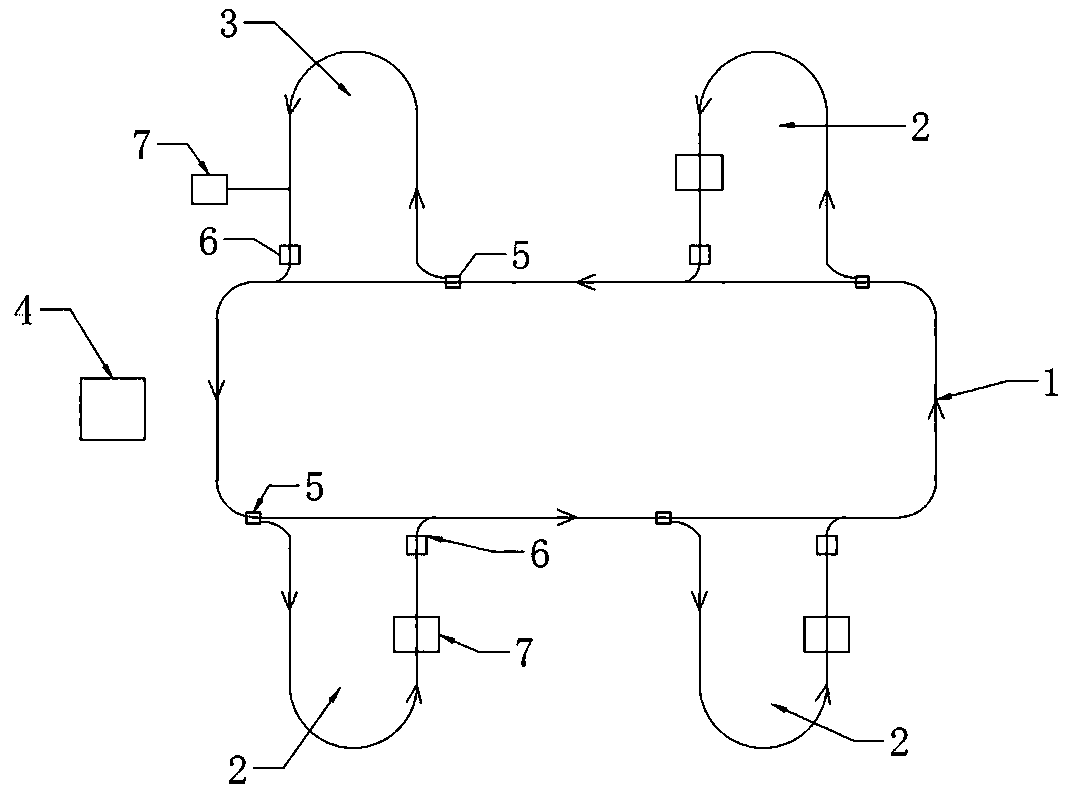

Clothing hanging system and a rework control method thereof

InactiveCN111559625AImprove efficiencyRealize real-time monitoringControl devices for conveyorsMechanical conveyorsIndustrial engineeringManufacturing engineering

The invention discloses a clothing hanging system and a rework control method thereof, and belongs to the technical field of clothing hanging systems. The rework control method of the clothing hangingsystem includes the steps that when a quality inspection workstation or a general workstation inspects that a product is unqualified, a carrier carrying the unqualified product is changed into a rework state, and a rework mode, a rework process and rework content are selected according rework reason; a corresponding workstation receives the carrier and recognizes the rework status of the carrier,and reworking is performed according to the rework content; and when the rework process is over, the quality inspection workstation or the general workstation that inspects the product inspects the product again, and if the inspection is qualified, the carrier is changed into a normal state. The efficiency of the rework process in a clothing assembly linen can be effectively improved, and the workload of staff is reduced.

Owner:INA INTELLIGENT TECH (ZHEJIANG) CO LTD

Loose wire flow equipment for wheel

The invention provides loose wire flow equipment for wheels. The loose wire flow equipment for the wheels comprises a first rack, a conveyor and a bolt and nut separator, wherein the first rack is used for connecting a feeding station, a loosening station and a discharging station which are sequentially arranged; the conveyor is disposed on the first rack and used for transporting to-be-repaired wheels in sequence between the feeding, loosening and discharging stations; the bolt and nut separator is arranged on the loosening station and used for positioning the to-be-repaired wheels and separating the bolts and nuts of the to-be-repaired wheels. With a three-station segmentation design adopted, and with the conveyor to sequentially connect the feeding, loosening and discharging stations and to conveniently transfer the to-be-repaired wheels from the previous station into the bolt and nut separator for loosening operation and continue to flow to the next station for further transfer, the loose wire flow equipment for the wheels has the advantages of allowing the bolt and nut separator to be well linked with a first and spreader and a second and spreader to become part of a wheel maintenance flow line, and thus solving the technical problem that the bolt and nut separator can not be linked with various equipment such as spreaders.

Owner:哈尔滨乾行达科技有限公司

Repair jig assembly for image module provided with integrated motor and application method of repair jig assembly

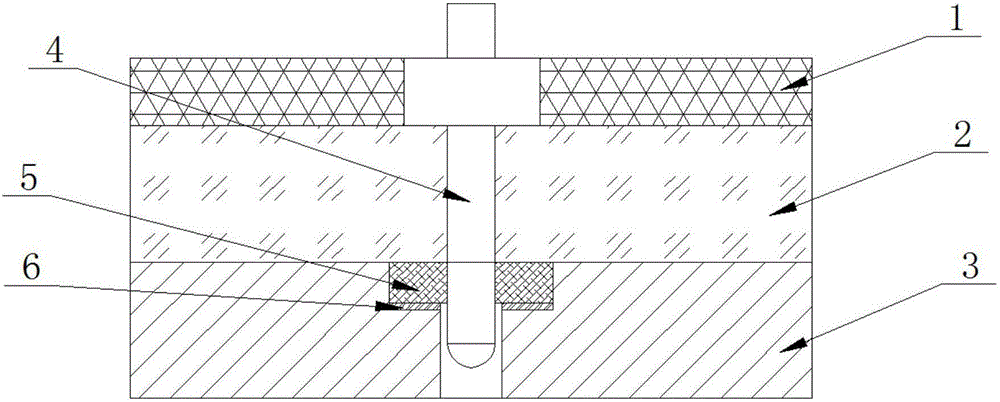

ActiveCN106733742AShorten heating timeImprove rework efficiencyCleaning using toolsAdhesiveIndustrial engineering

The invention provides a repair jig assembly for an image module provided with an integrated motor and an application method of the repair jig assembly. By means of the repair jig assembly for the image module provided with the integrated motor, adhesive located on an image module element can be linearly removed and specifically molten. The repair jig assembly is characterized in that the repair jig assembly comprises an adhesive removal device and an air flow device, wherein the adhesive removal device is used for removing the adhesive stuck to the image module element, and the air flow device is used for heating and melting the adhesive stuck to the image module element; the adhesive removal device comprises a handle, an adhesive removal component and a connecting component, wherein the handle is used for holding the adhesive removal device, the adhesive removal component is used for removing the adhesive, and the handle is detachably connected with the adhesive removal component through the connecting component; and the air flow device is provided with a replaceable air outlet head, wherein the air outlet head is used for changing the air outlet mode and preventing air from being output from the center of the air outlet head.

Owner:NINGBO SUNNY OPOTECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com