TR module vertical interconnecting structural member

A technology of vertical interconnection and structural parts, which is applied in the structural connection of printed circuits, the structural connection of antenna grounding switches, electrical components, etc., can solve the problems of low yield, low production efficiency, poor productivity, etc. High yield, high rework efficiency, and improved reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described in detail below in combination with specific embodiments. However, it should not be understood that the scope of the above subject matter of the present invention is limited to the following embodiments, and all technologies realized based on the content of the present invention belong to the scope of the present invention.

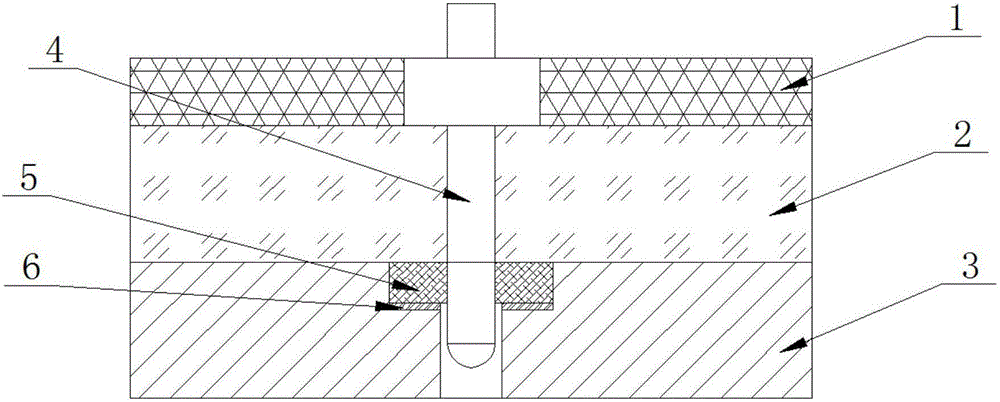

[0019] Such as figure 1 The structure schematic diagram of the embodiment of the present invention is shown; wherein, the TR module vertical interconnection structure of the present invention includes a PCB board 1 , a dielectric board 2 and a substrate 3 , and the dielectric board 2 is located between the PCB board 1 and the substrate 3 . In the vertical interconnection structure of the TR module of the present invention, the PCB board 1 , the dielectric board 2 and the base board 3 are fixed together by external clips.

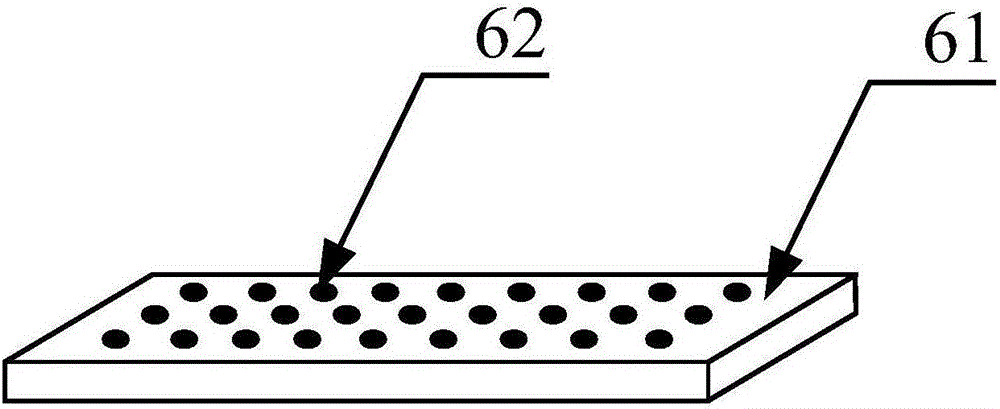

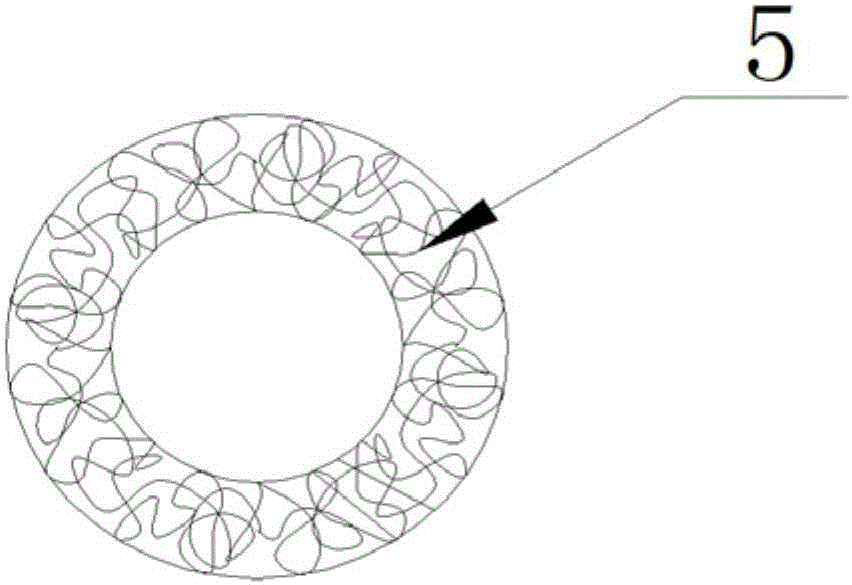

[0020] Specifically, the PCB board 1 is provided with a metallized hole for we...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com