Rework method for dual damascene through-hole technology

A through-hole process and process technology, applied in the direction of electrical components, semiconductor/solid-state device manufacturing, circuits, etc., can solve the problems of reduced process effect, long process time, and low efficiency, so as to improve rework efficiency, improve rework quality, reduce The effect of steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

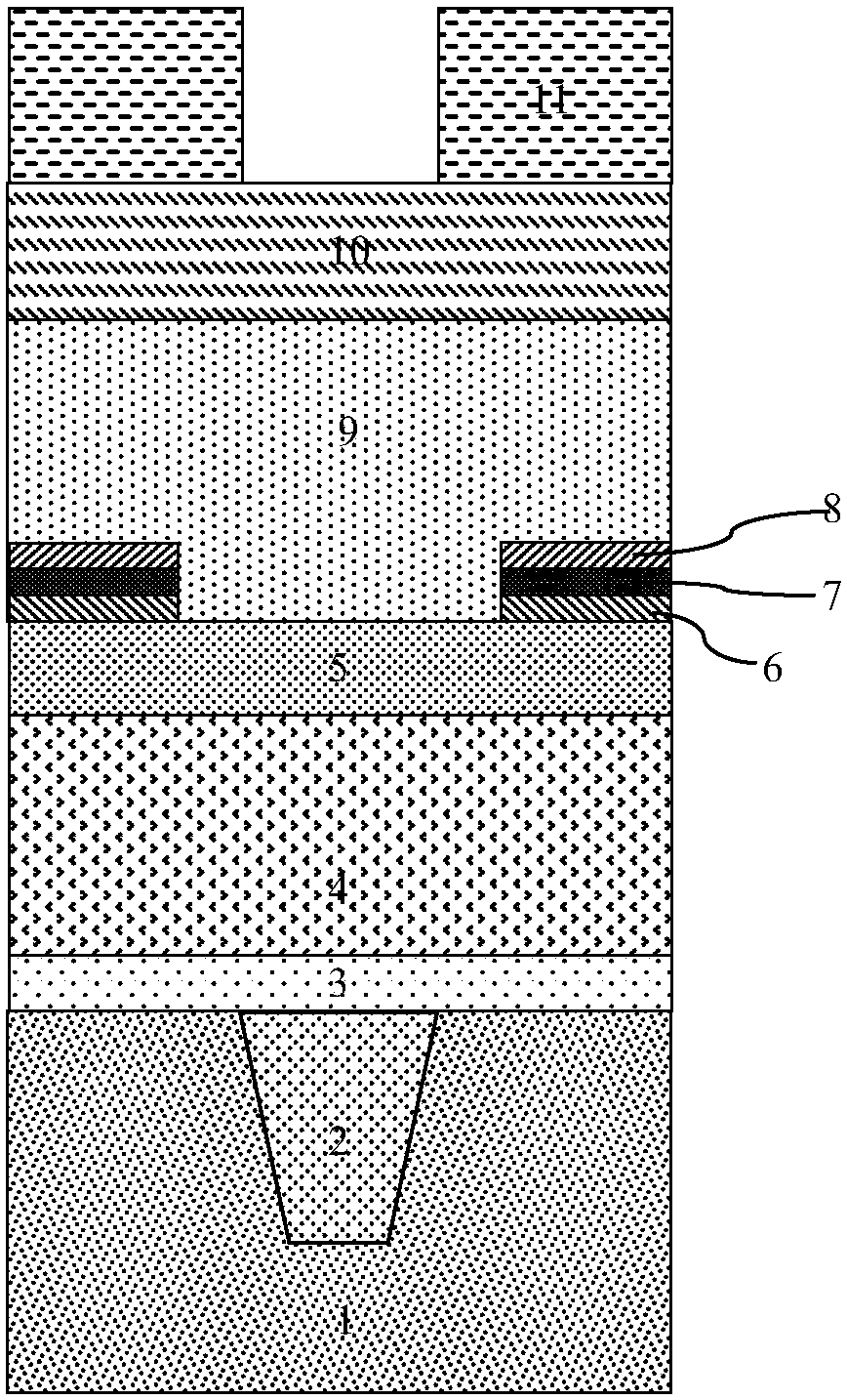

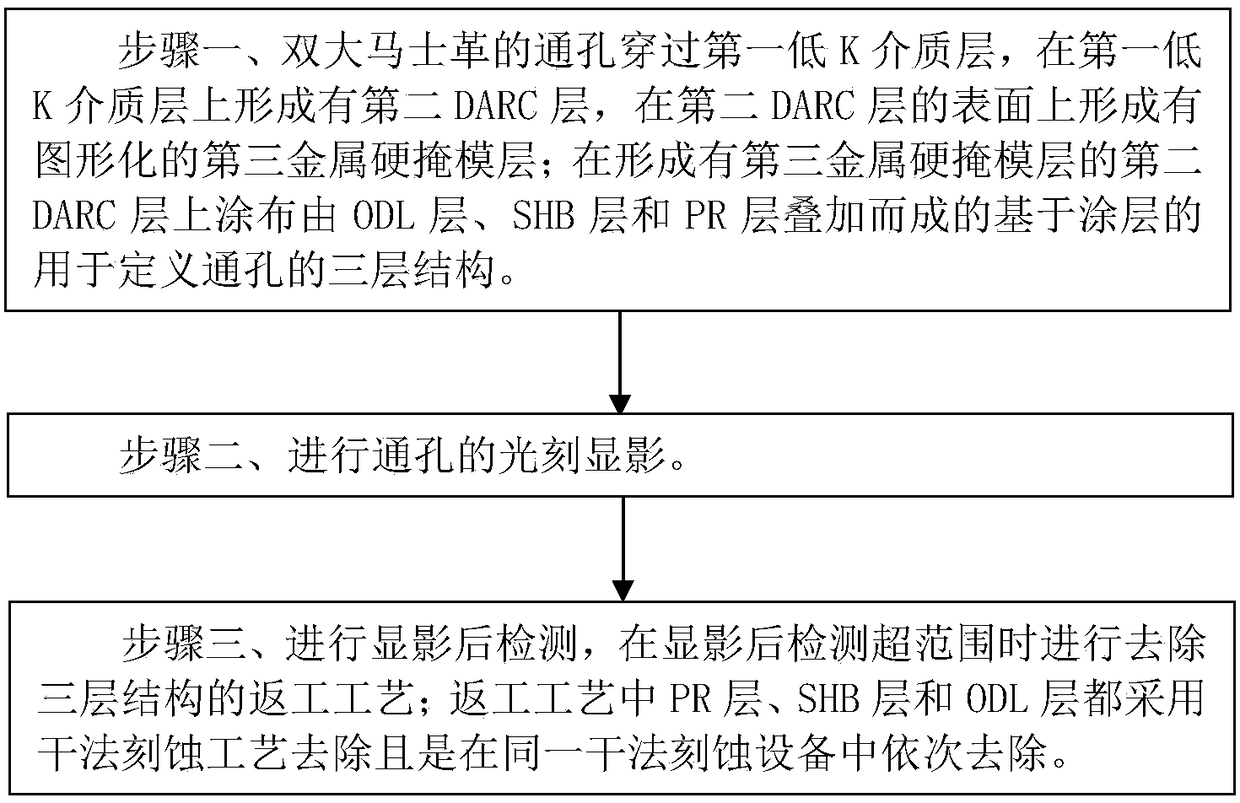

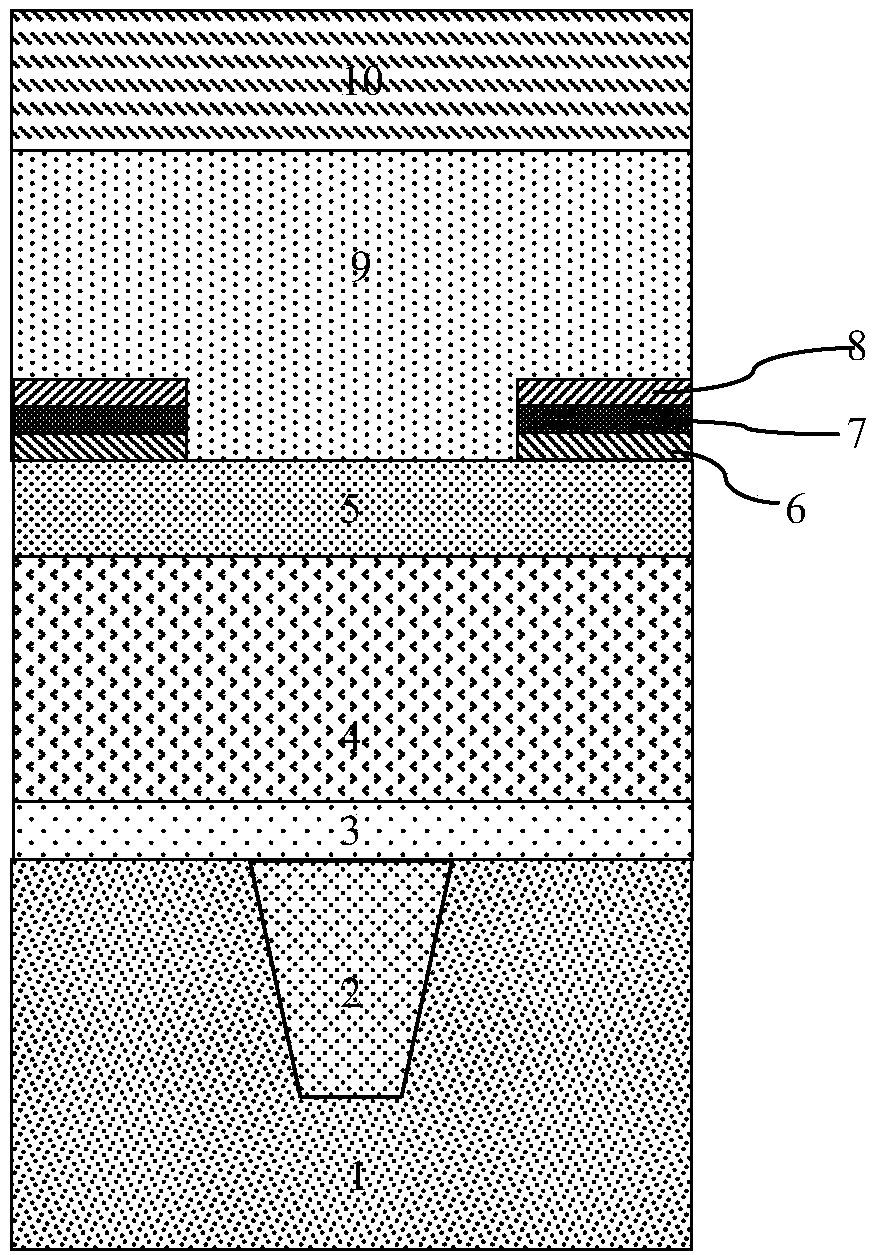

[0052] Such as figure 2 Shown is the flow chart of the rework method of the double Damascus via process in the embodiment of the present invention; please refer to the device structure before the rework process figure 1 shown; as Figure 3A to Figure 3C As shown, it is a schematic diagram of the device structure in each sub-step of the rework method of the embodiment of the present invention. The rework method of the double damascene through-hole process of the embodiment of the present invention includes the following steps:

[0053] Step 1, such as figure 1As shown, the through hole of the double damascene passes through the first low-K dielectric layer 4, a second DARC layer 5 is formed on the first low-K dielectric layer 4, and a second DARC layer 5 is formed on the surface of the second DARC layer 5 A patterned third metal hard mask layer 7.

[0054] The mask structure defining the via holes includes a coating-based three-layer structure, the three-layer structure bei...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com