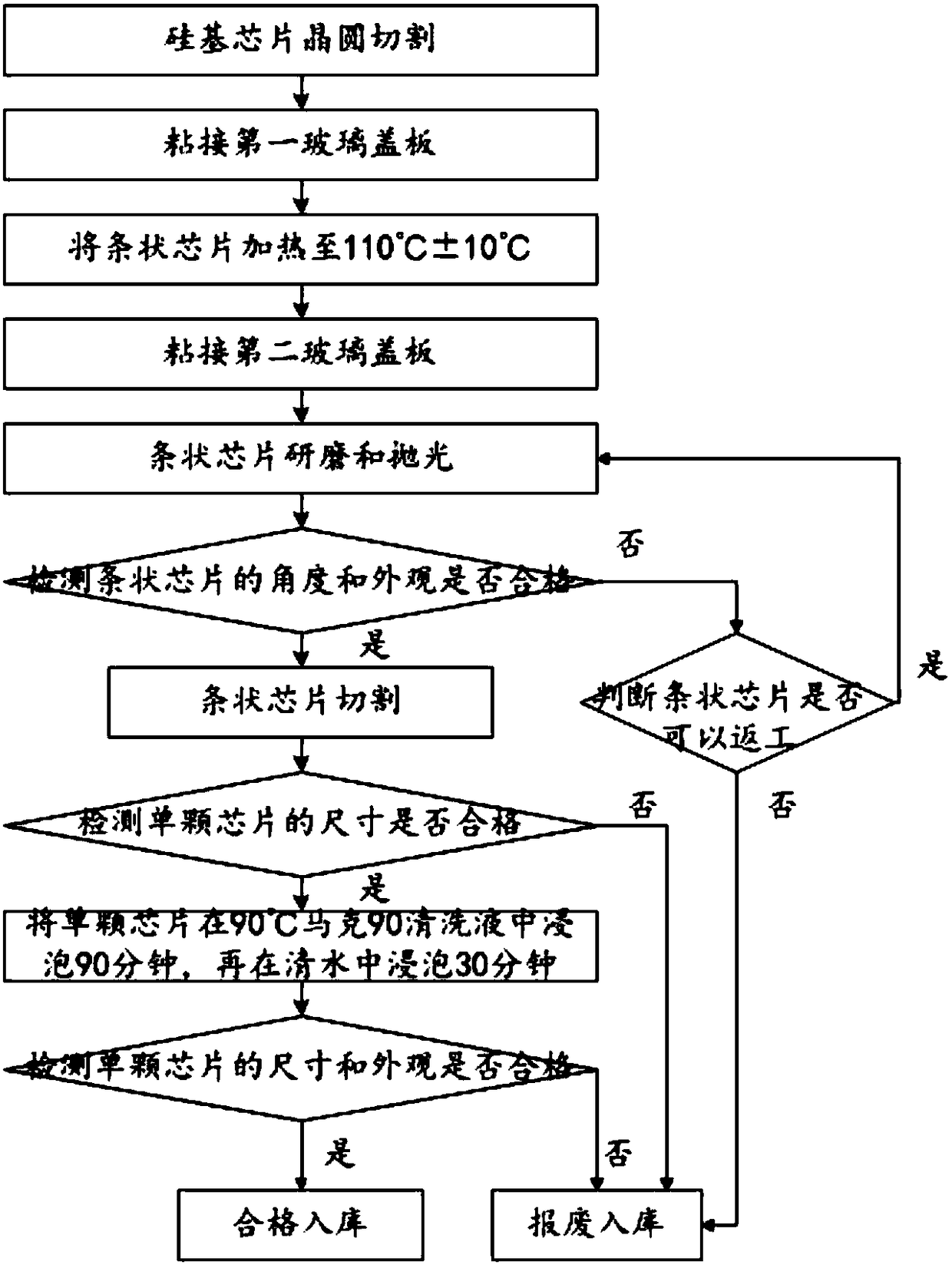

Grinding and cutting method for chip of low-channel arrayed waveguide grating wavelength division multiplexer

An arrayed waveguide grating and wavelength division multiplexer technology, applied in the field of optical communication, can solve the problems of high angle defect rate, high product scrap rate, low rework efficiency, etc., to facilitate grinding and polishing, improve detection efficiency, and rework efficiency. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0045] Example: Grinding and cutting of four-channel arrayed waveguide grating wavelength division multiplexer chip

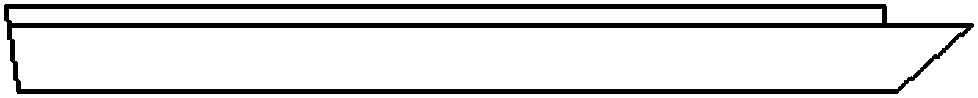

[0046] Step 1. Cut the silicon-based chip wafer into strip chips. The width of the strip chip is 8.6-9.2 mm, the length of a single four-channel arrayed waveguide grating wavelength division multiplexer chip. The length of the strip chip is The value is greater than or equal to twice the width of a single four-channel arrayed waveguide grating wavelength division multiplexer chip 1.4 ~ 1.75mm, and the height of the strip chip is equal to or greater than that of a single four-channel arrayed waveguide grating wavelength division multiplexer chip Including the height of the glass cover 1mm;

[0047] Step 2: Use UV glue to bond the first glass cover with the same length as the strip chip, less than 0.9-1.1mm in width, and 0.138-0.142mm in height to the left end of the upper surface of the strip chip, as shown in figure 2 shown;

[0048] Step 3, heating the stri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com