Photovoltaic cell string reworking device

A photovoltaic cell and repair technology, applied in photovoltaic power generation, circuits, electrical components, etc., can solve the problems of high scrapping cost, waste, damage of several pieces, etc., and achieve the effect of reliable repair quality, enhanced welding stability, and improved repair efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

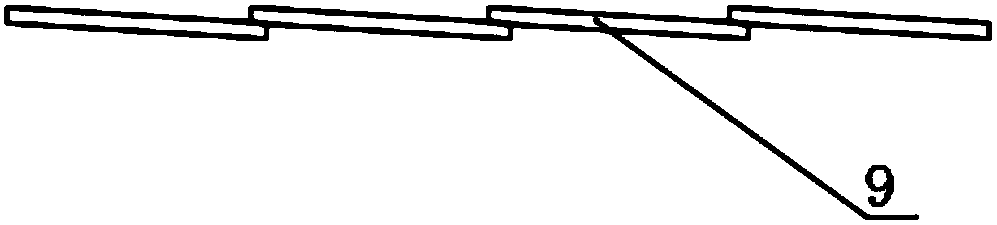

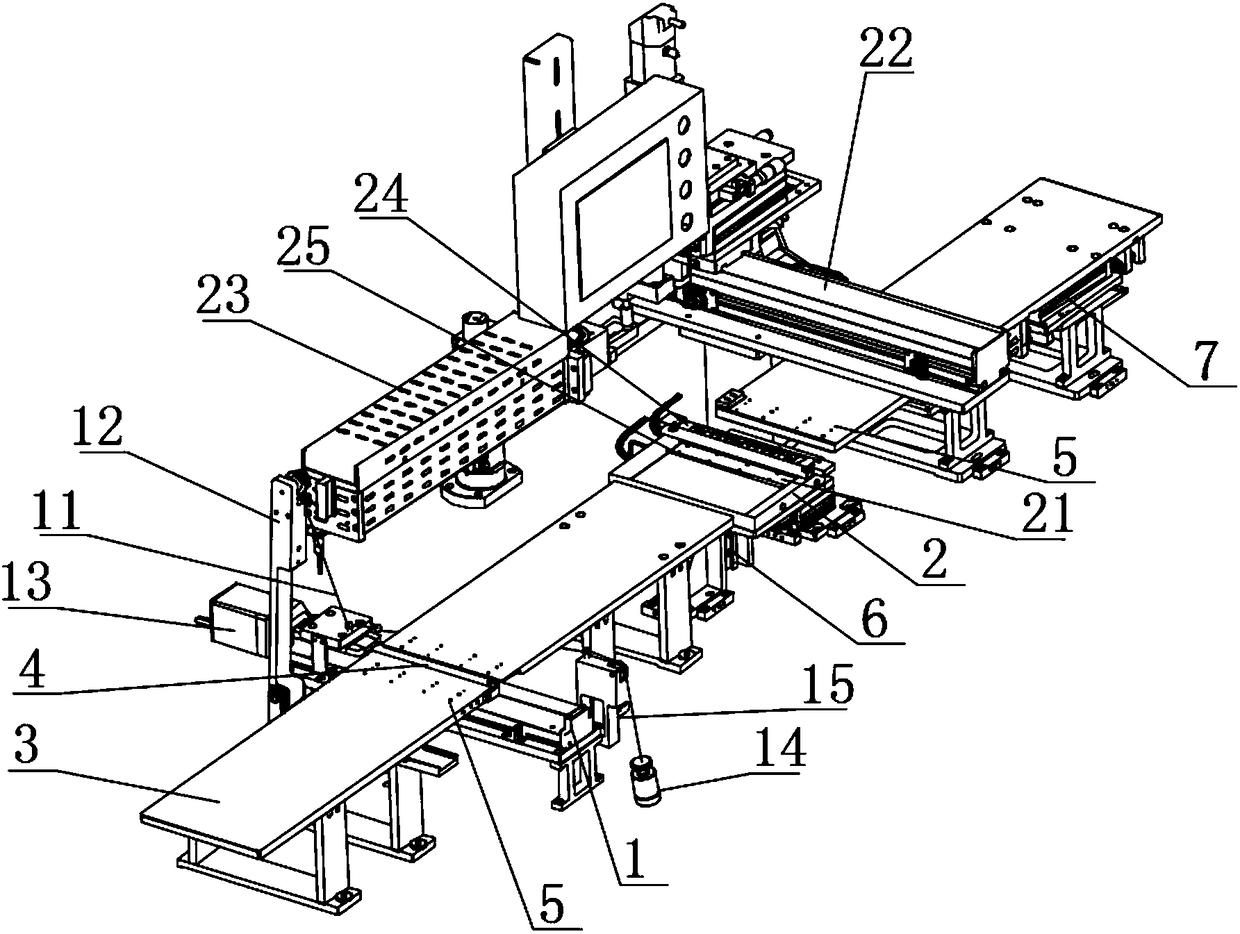

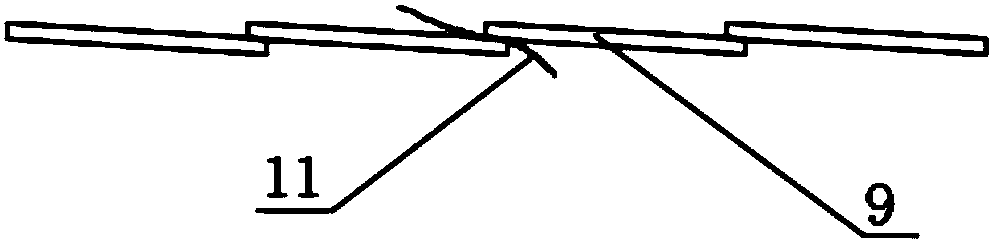

[0042] In order to achieve the purpose of the present invention, as Figure 2-4 As shown, an embodiment of the present invention is: a photovoltaic cell string rework device, including a desoldering device 1, a working platform 3, the working platform 3 is used to place a photovoltaic cell string 8, and a wire slit is opened on the working platform 3 4. The desoldering device 1 includes a cutting wire 11 that can move along the wire slit 4 .

[0043] Such as image 3 As shown, the cutting wire 11 is desoldered and separated along the welding seam of the battery sheet 9, and the welding part of the bad battery sheet is set at the wire-feeding seam 4, and the cutting wire 11 is dialed into the edge welding seam of the battery sheet. The movement of the cutting wire 11 can remove the battery slice from the battery string. The beneficial effects of adopting the above technical solution are: fast and convenient, reliable repair quality, and greatly improved repair efficiency.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com