Patents

Literature

87results about How to "Improve quality control ability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

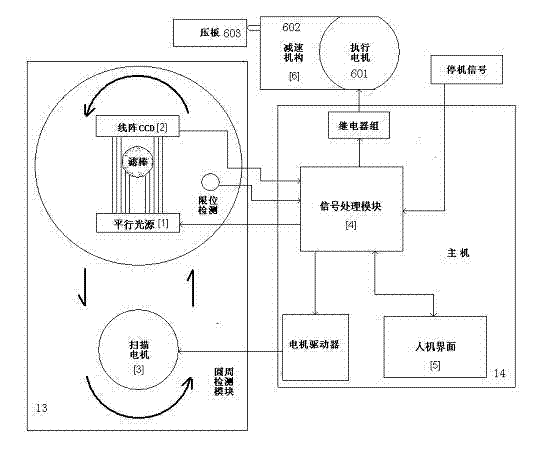

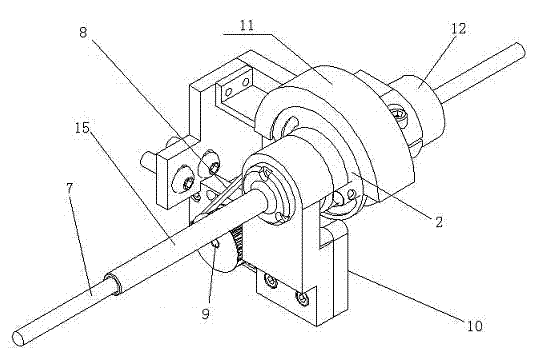

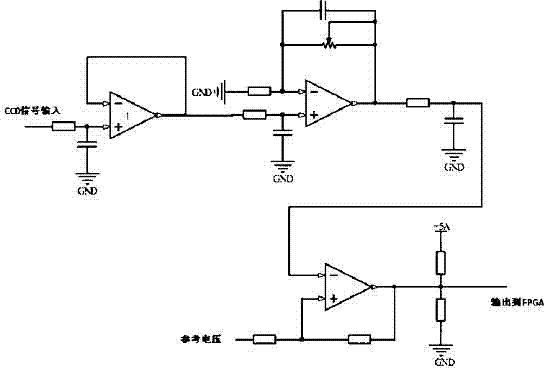

Online detection and control method and device of periphery of filtering rod

ActiveCN102160690AGuaranteed high precision controlImprove quality control abilityCigarette manufactureUsing optical meansControl signalInterference factor

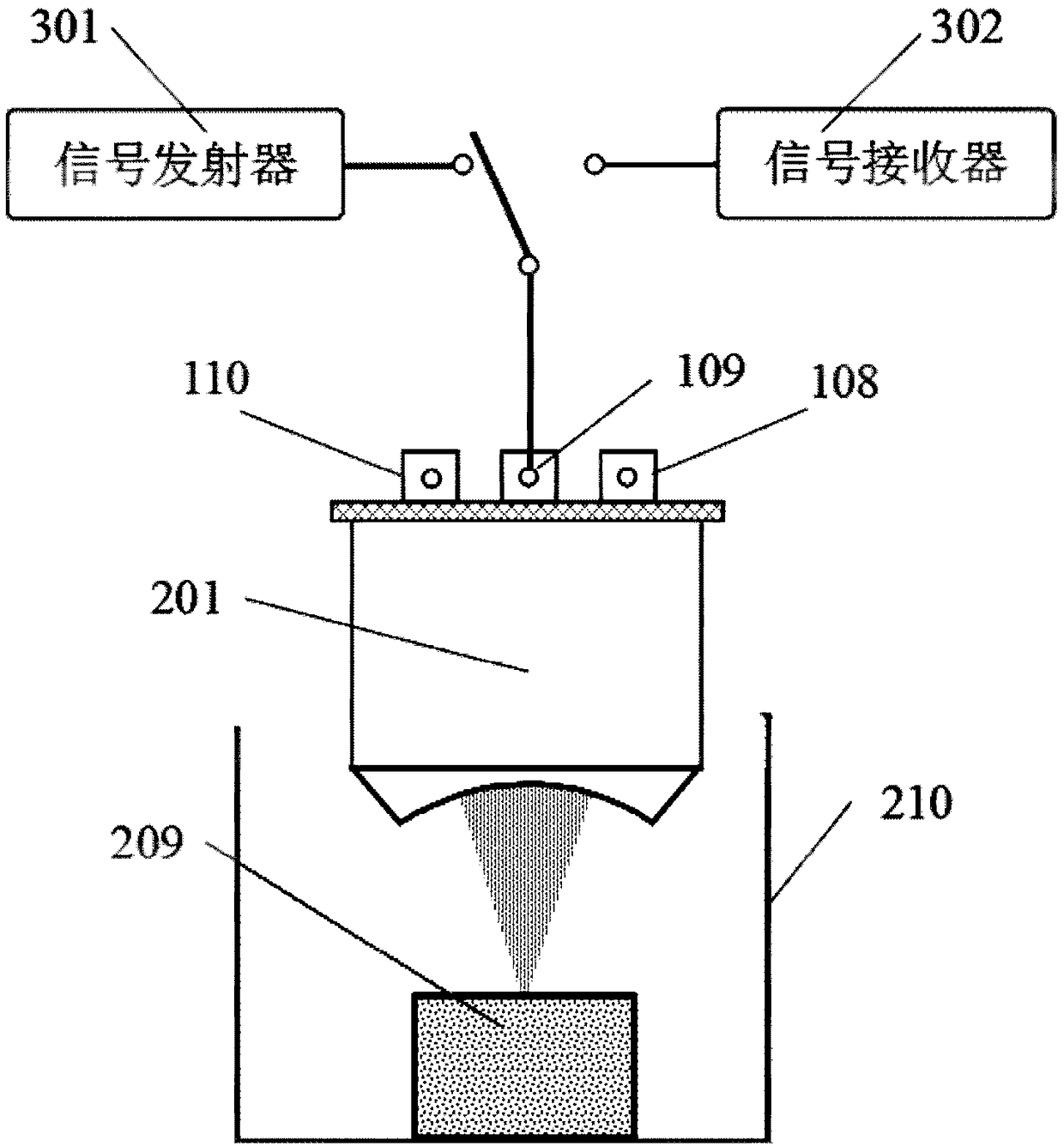

The invention relates to an online detection and control method of the periphery of a filtering rod and a device. The device is characterized by mainly comprising a parallel light source (1), a linear array CCD (Charge Coupled Device) detector (2), a scanning motor (3), a signal processing module (4) and an executing mechanism (6), wherein the parallel light source (1) and the linear array CCD detector (2) are respectively positioned at the two opposite sides of the filtering rod; the scanning motor (3) drives the parallel light sources (1) and the linear array CCD detector (2) to rotate around the filtering rod; the signal input end of the signal processing module (4) is connected with the signal output end of the linear array CCD detector (2); and the signal output end of the signal processing module (4) is connected with the control end of the parallel light source (1), the control signal input end of a motor driver of the scanning motor and the signal input end of the executing mechanism (6) simultaneously. The invention has the advantages that the accuracy is high (the size of the received image element is 10mum), no influence is caused by various interference factors such asvibration, noise, temperature, dust and barometric fluctuation and the like on a site, and the detection result is accurate, stable and reliable.

Owner:NANJING DASHU INTELLIGENT SCI & TECH CO LTD

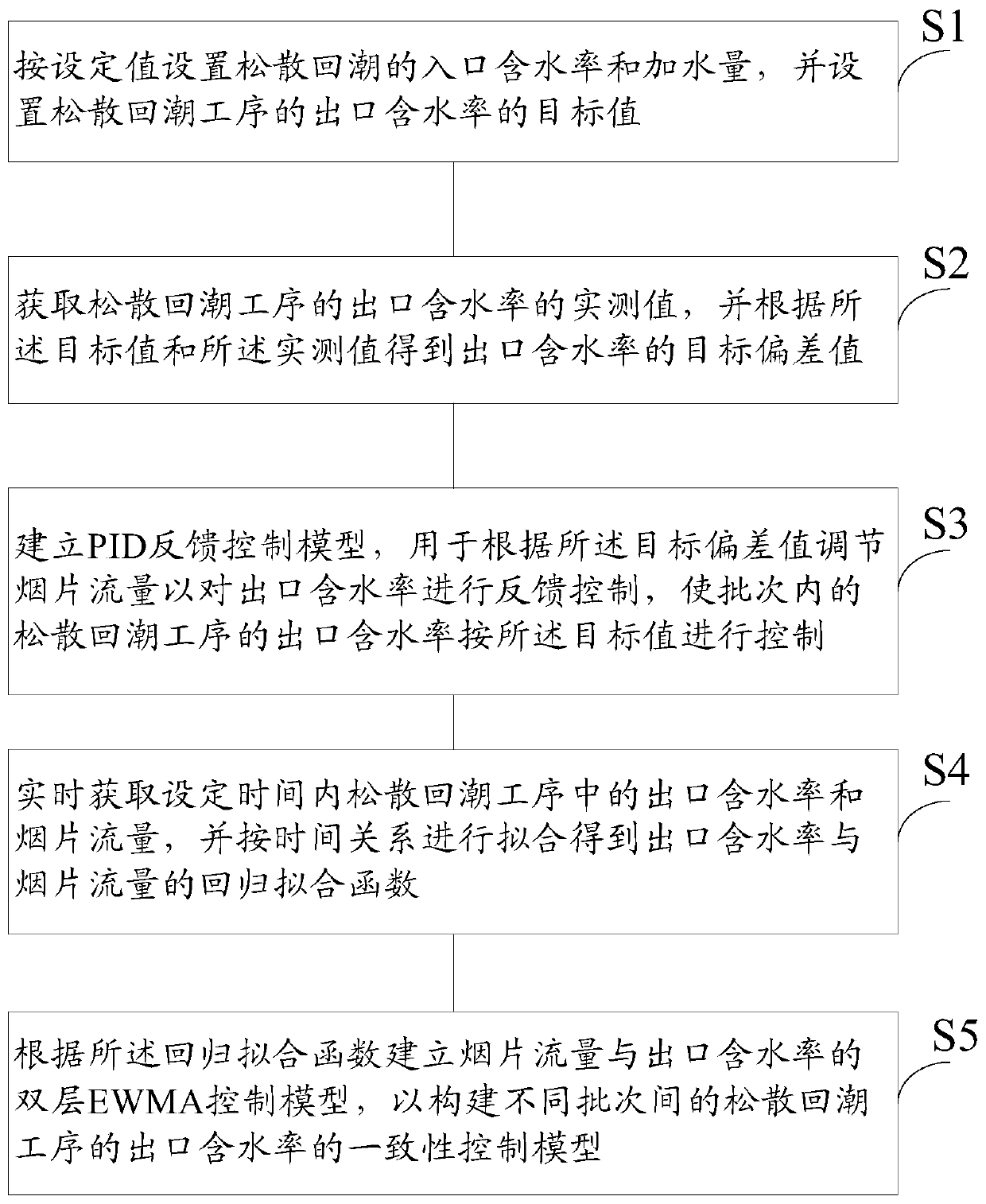

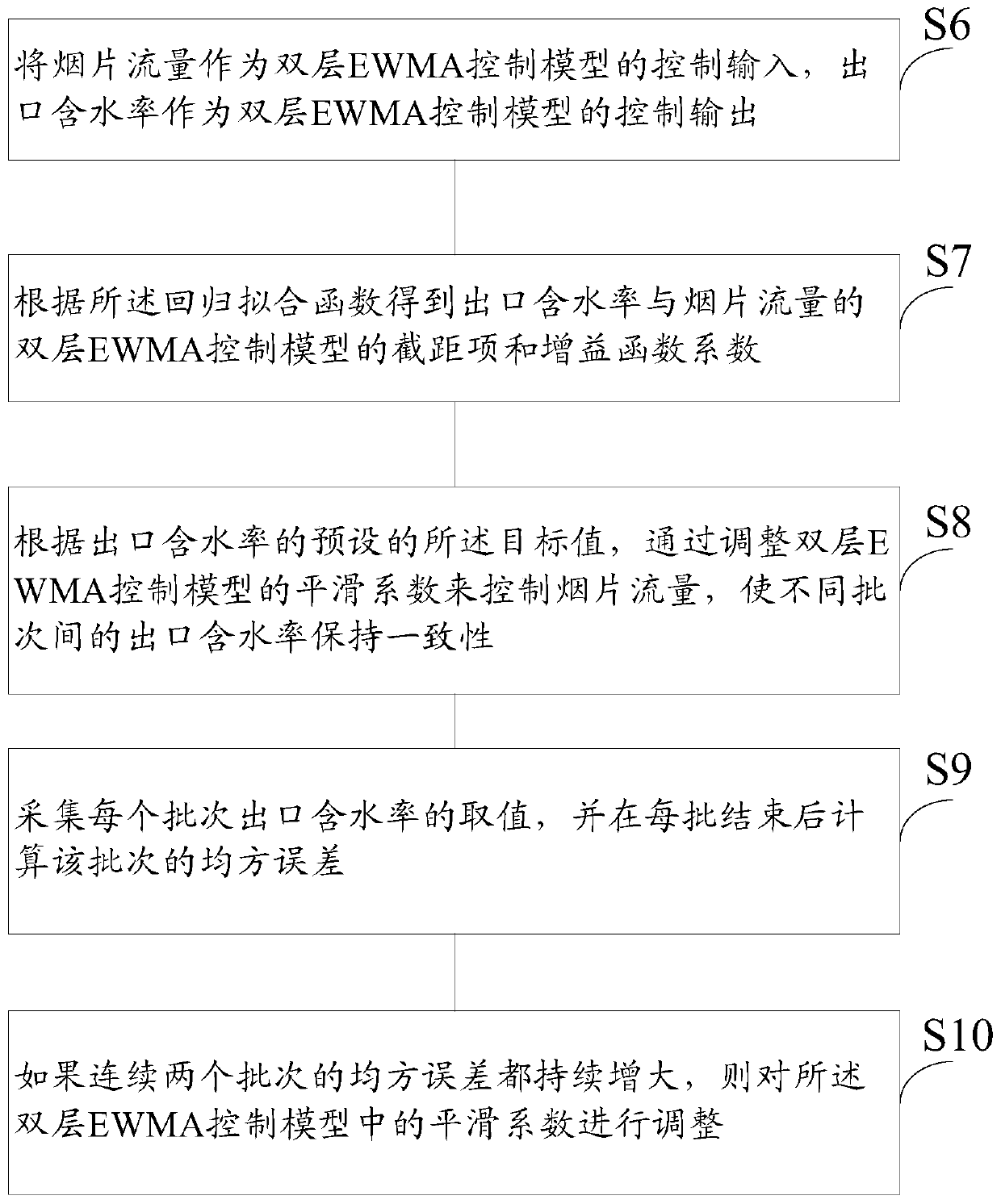

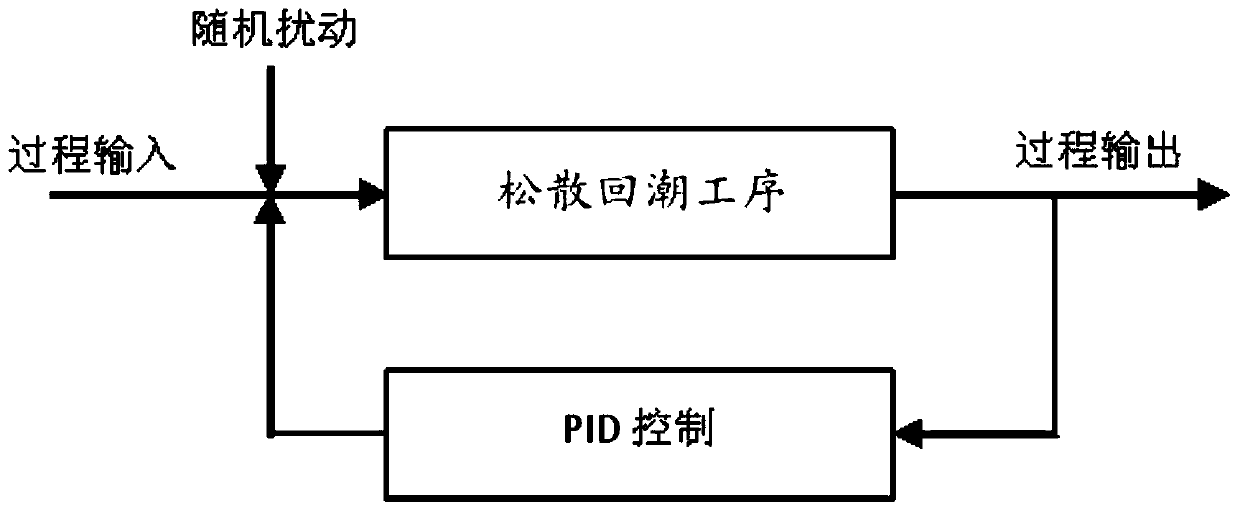

Method and system for controlling outlet moisture content of loosening and dampening process

ActiveCN110893001AResolve accuracyAddressing inhomogeneityTobacco preparationTobacco treatmentProcess engineeringFeedback control

The invention provides a method and a system for controlling the outlet moisture content of a loosening and dampening process, and the method comprises the steps: setting the inlet moisture content and water adding amount of a loosening and dampening machine according to a set value, and setting a target value of the outlet moisture content of the loosening and dampening process; obtaining an actual measurement value of the outlet moisture content of the loosening and dampening process, and obtaining a target deviation value of the outlet moisture content according to the target value and theactual measurement value; and establishing a PID feedback control model for adjusting the flow of the tobacco flakes according to the target deviation value so as to perform feedback control on the outlet moisture content, so that the outlet moisture content of the loosening and dampening process in the batch is controlled according to the target value. The consistency of the loosening and dampening uniformity of all batches can be improved, and the quality control capacity in the production process is improved.

Owner:CHINA TOBACCO HENAN IND

Method for fermenting cigar filling leaves

The invention discloses a method for fermenting cigar filling leaves. The method is characterized by comprising the following steps: controlling the water content of the cigar filling leaves which are subjected to impurity removal and modulation to be 30+ / -2%, and tidying the cigar filling leaves into cigar leaf bundles of which the leaf tips are towards the same direction; stacking the cigar leaf bundles to form a rectangular cigar leaf stack; covering a layer of hessian cloth on the surface of the cigar leaf stack to be used as an air permeable heat-insulating layer; inserting temperature measuring probes into the cigar leaf stack; overturning the stack when the stack filling temperature measured by any temperature measuring probe reaches the alarm upper limit temperature or is in the trend of reducing; after the fermentation is finished, airing the cigar leaves, reducing the moisture of the cigar filling leaves to be 20+ / -2%, and packaging for storage. According to the method, the appearance, the absorbed smell and the quality consistency of the cigar filling leaves can be obviously improved, the content of a harmful ingredient NNK in raw materials can be reduced, and the industrial availability of the cigar leaves can be improved.

Owner:CHINA TOBACCO ANHUI IND CO LTD

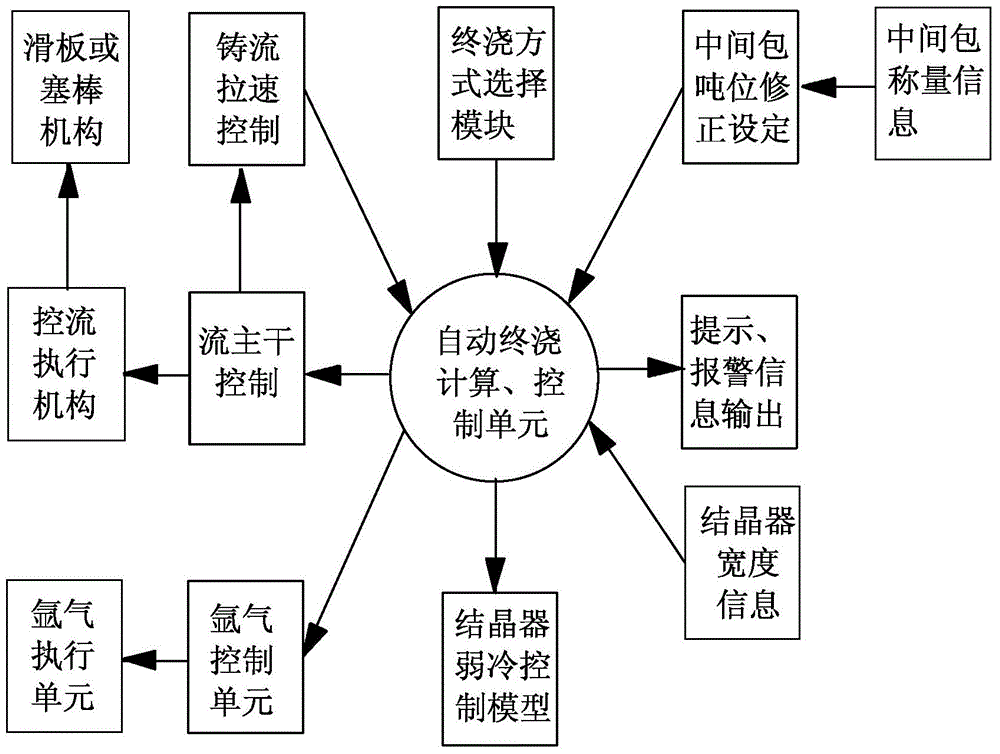

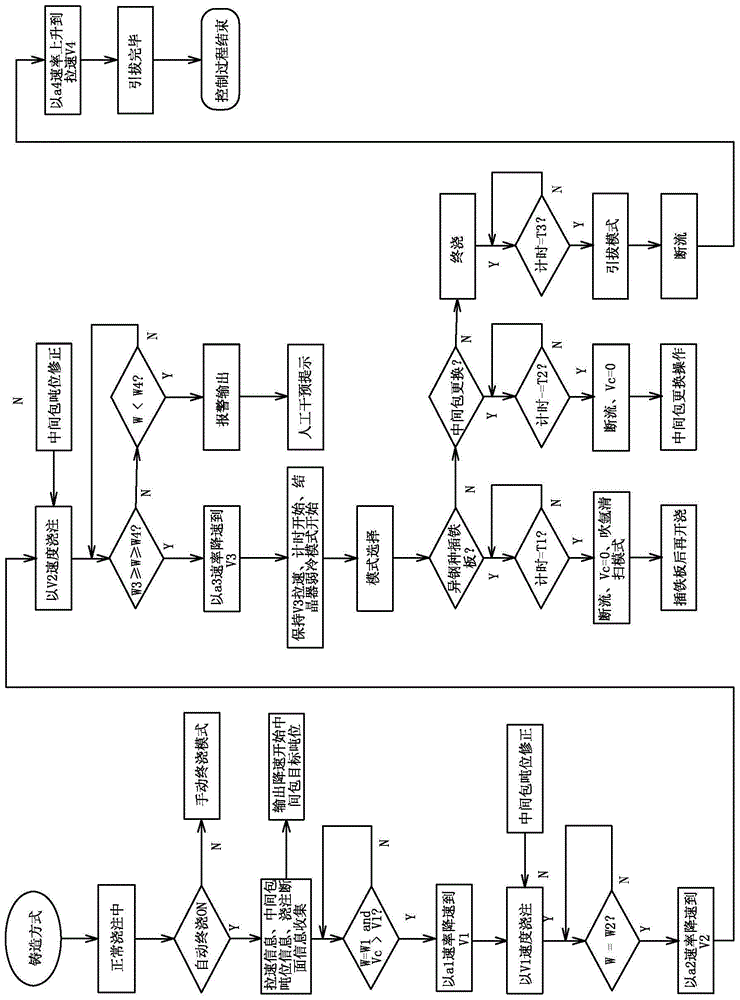

Multifunctional automatic final pouring system of continuous casting machine and process control method

The invention relates to a multifunctional automatic final pouring system of a continuous casting machine and a process control method, and belongs to the field of continuous casting machine equipment and process control. According to the multifunctional automatic final pouring system, a final pouring manner selecting module connected with an automatic final pouring computing control unit is arranged, and a tundish tonnage modification setting module is additionally arranged between the automatic final pouring computing control unit and a tundish weighing information unit; through configuration of related equipment and adjustment of the process control method, the automatic final pouring system of the continuous casting machine is suitable for three working conditions including tundish replacement, different steel type iron plate insertion and final pouring, manual intervention of operation personnel is reduced, the automatic pouring degree is improved, and the tail blank quality control capacity in the final pouring process is improved; and the continuous casting final pouring process is comprehensively combined with the production process, operation, quality control and accident prevention, the input rate of the automatic final pouring system can be greatly improved, and the casting blank quality and the abnormal prevention and control capacity in various final pouring processes are improved. The multifunctional automatic final pouring system can be widely applied to the field of design, manufacturing and production process control of the continuous casting machine equipment.

Owner:BAOSHAN IRON & STEEL CO LTD

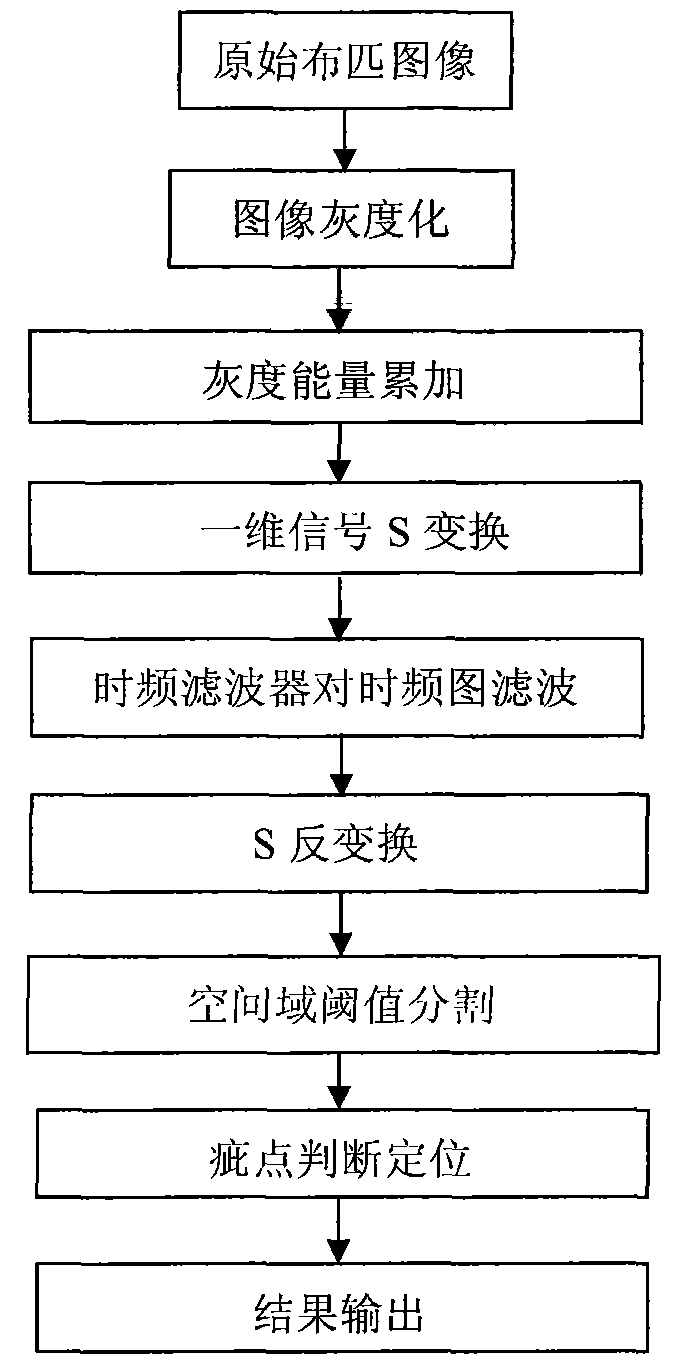

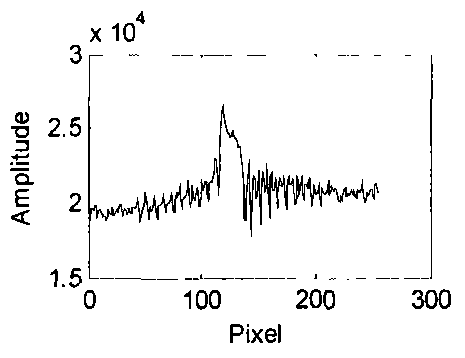

Method for cloth defect detection by utilizing S transformation signal extraction

InactiveCN103729856AImprove cloth quality control abilityReduce labor costsImage analysisQuality controlInversion transformation

The invention relates to a method for cloth defect detection by utilizing S transformation signal extraction and belongs to the field of digital image processing. The method comprises the steps of utilizing a projection method to perform gray energy accumulation, and converting warp knitting cloth images into one-dimensional signals; utilizing an S transformation signal extraction method to retain information of defect signals in an S transformation domain to perform S inversion transformation on the information, and extracting the defect signals; performing threshold segmentation on the extracted defect signals in a spatial domain, and obtaining defects and defect position information. The method for cloth defect detection can replace a manual detection link in the cloth production process, improve cloth quality control capability and reduce labor cost simultaneously; the method is not subject to influences of noise, illumination and texture features simultaneously, and the defect signals are judged more accurately in the spatial domain.

Owner:ZHEJIANG NORMAL UNIVERSITY

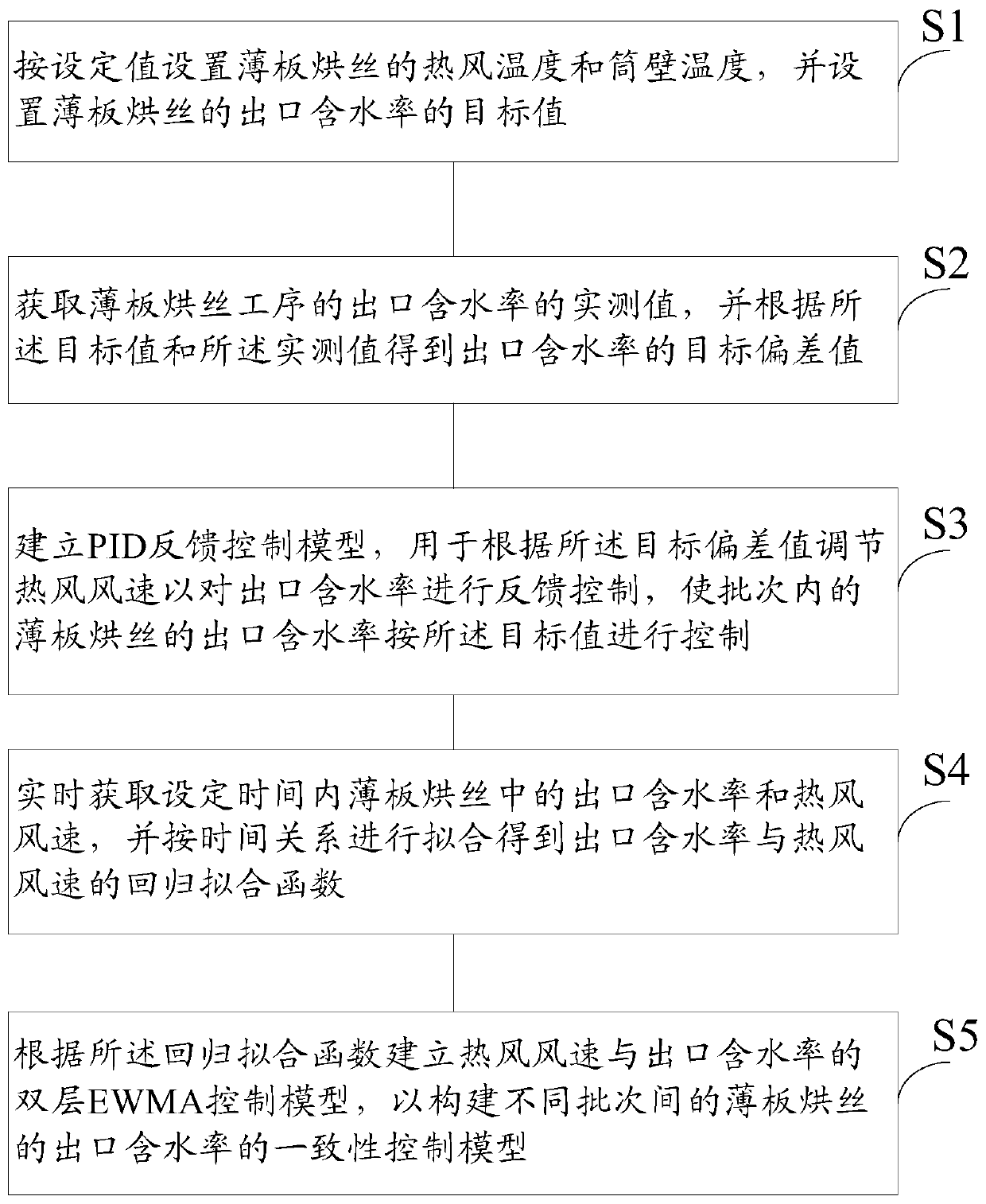

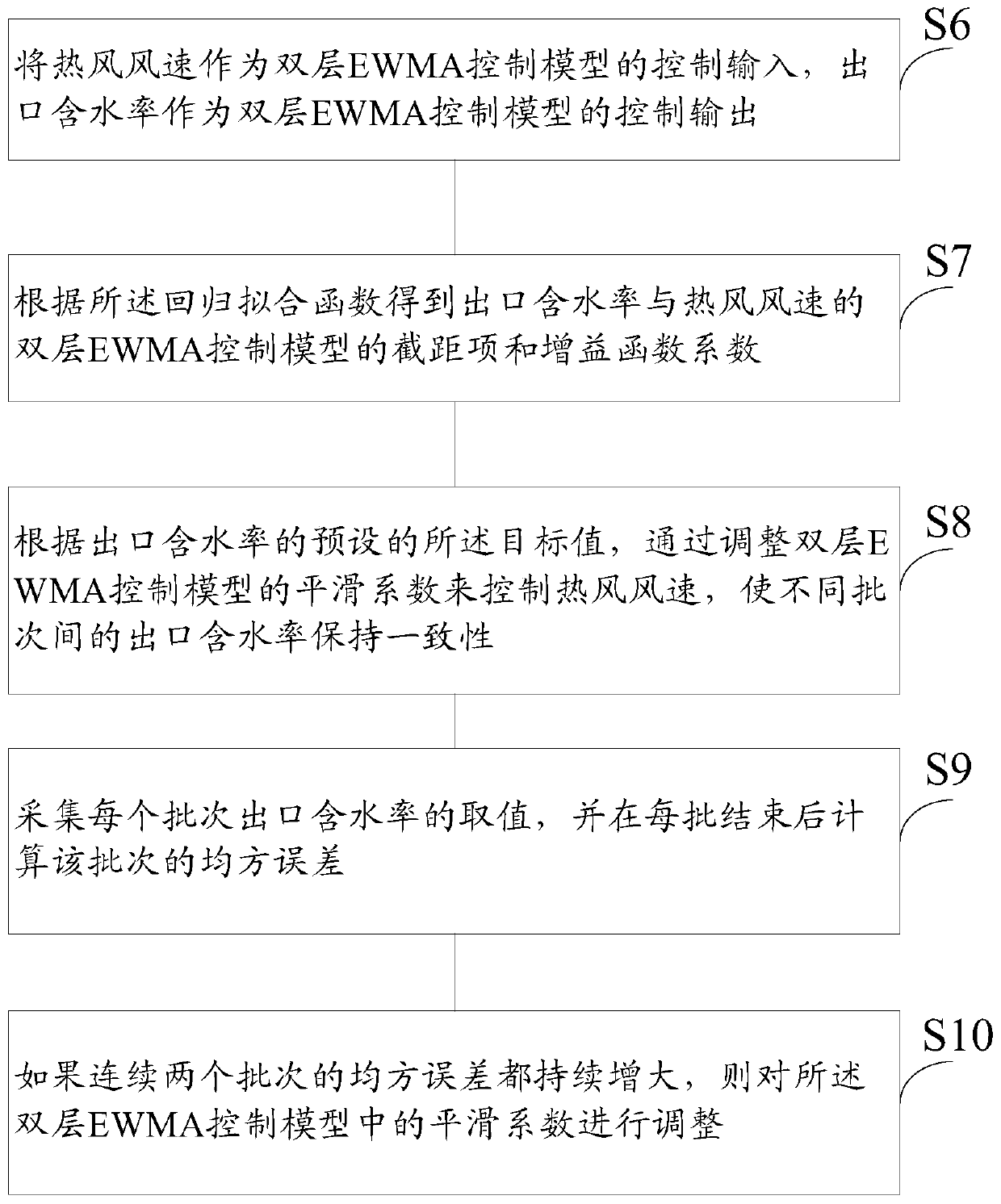

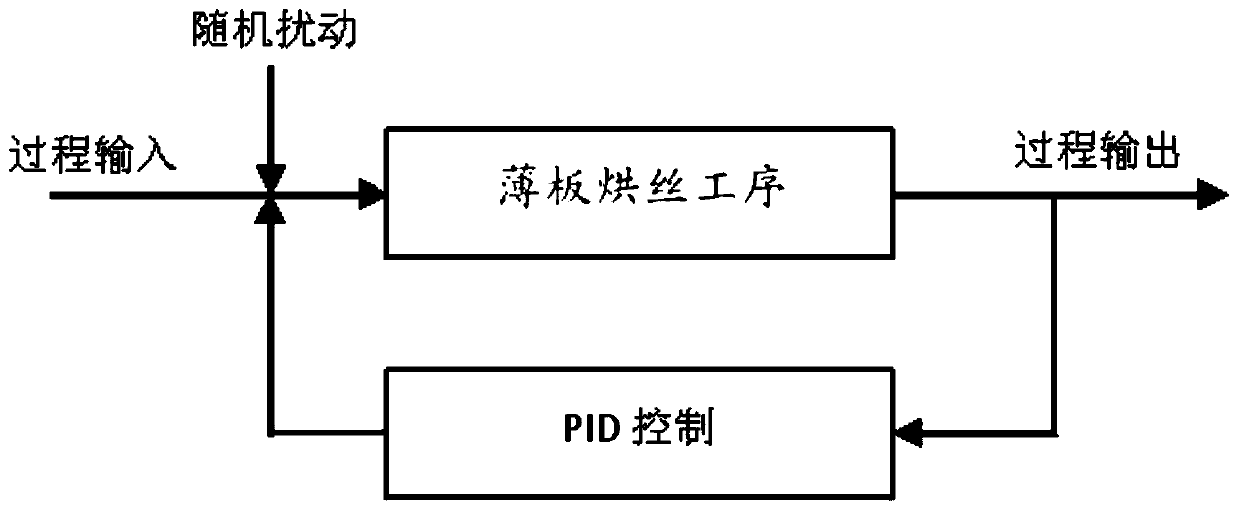

Method and system for controlling tobacco shred water content of sheet tobacco shred drying

ActiveCN111109643AImprove consistencyImprove quality control abilityTobacco preparationTobacco treatmentAgricultural scienceAgricultural engineering

The invention provides a method and a system for controlling tobacco shred water content of sheet cut tobacco drying. The method comprises the following steps: setting hot air temperature of the sheetcut tobacco drying according to a set value, and setting a target value of outlet water content of the sheet cut tobacco drying; obtaining an actual measurement value of the outlet moisture content of the sheet cut tobacco drying process, and obtaining a target deviation value of the outlet moisture content according to the target value and the actual measurement value; and a PID feedback controlmodel is established and used for adjusting the hot air speed according to the target deviation value so as to carry out feedback control over the outlet moisture content, and the outlet moisture content of the thin-plate cut tobaccos in the batch is controlled according to the target value. According to the invention, the uniformity consistency of thin plate cut tobacco drying in each batch canbe improved, and the quality control capability in the production process is improved.

Owner:CHINA TOBACCO HENAN IND

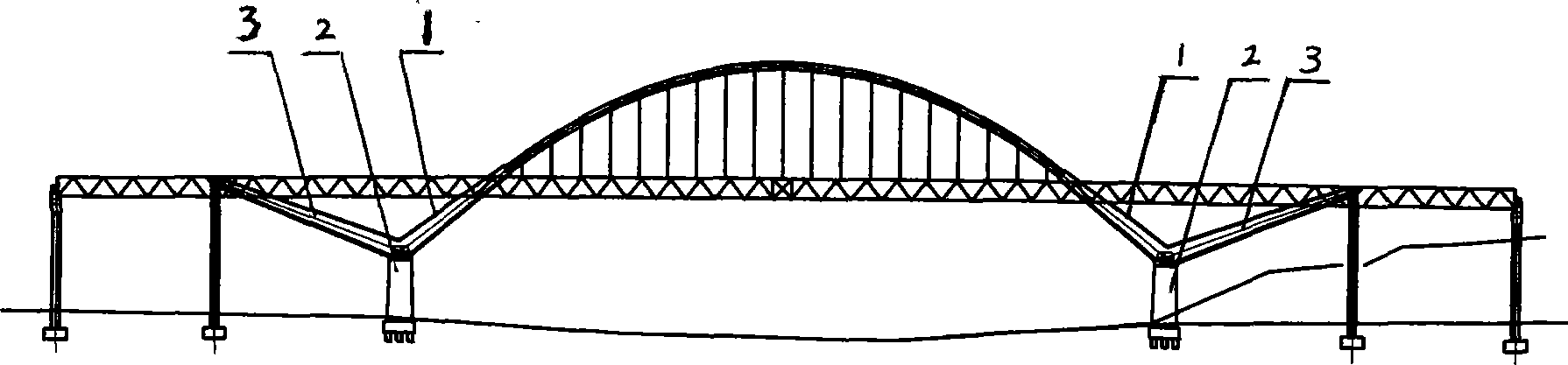

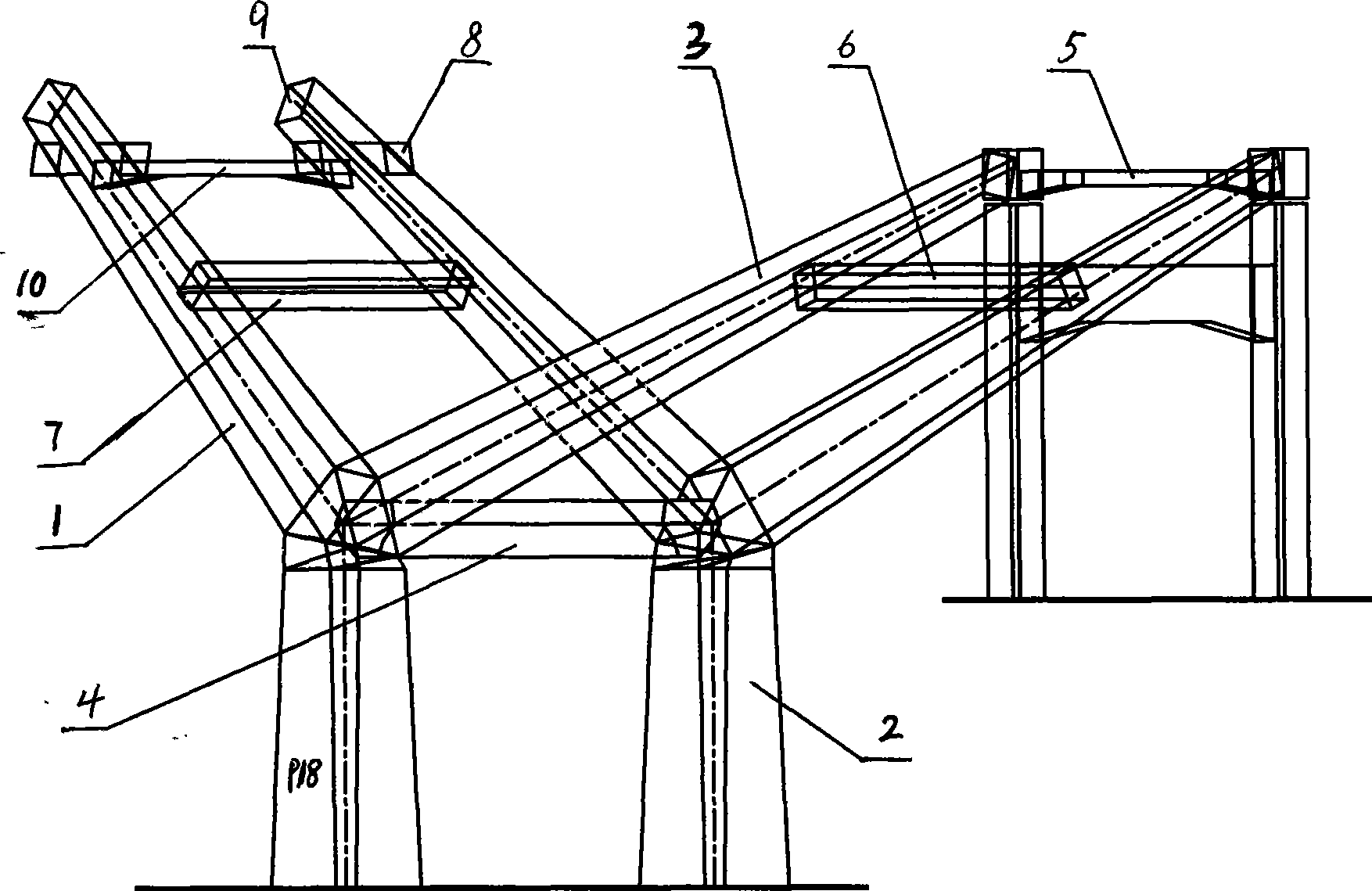

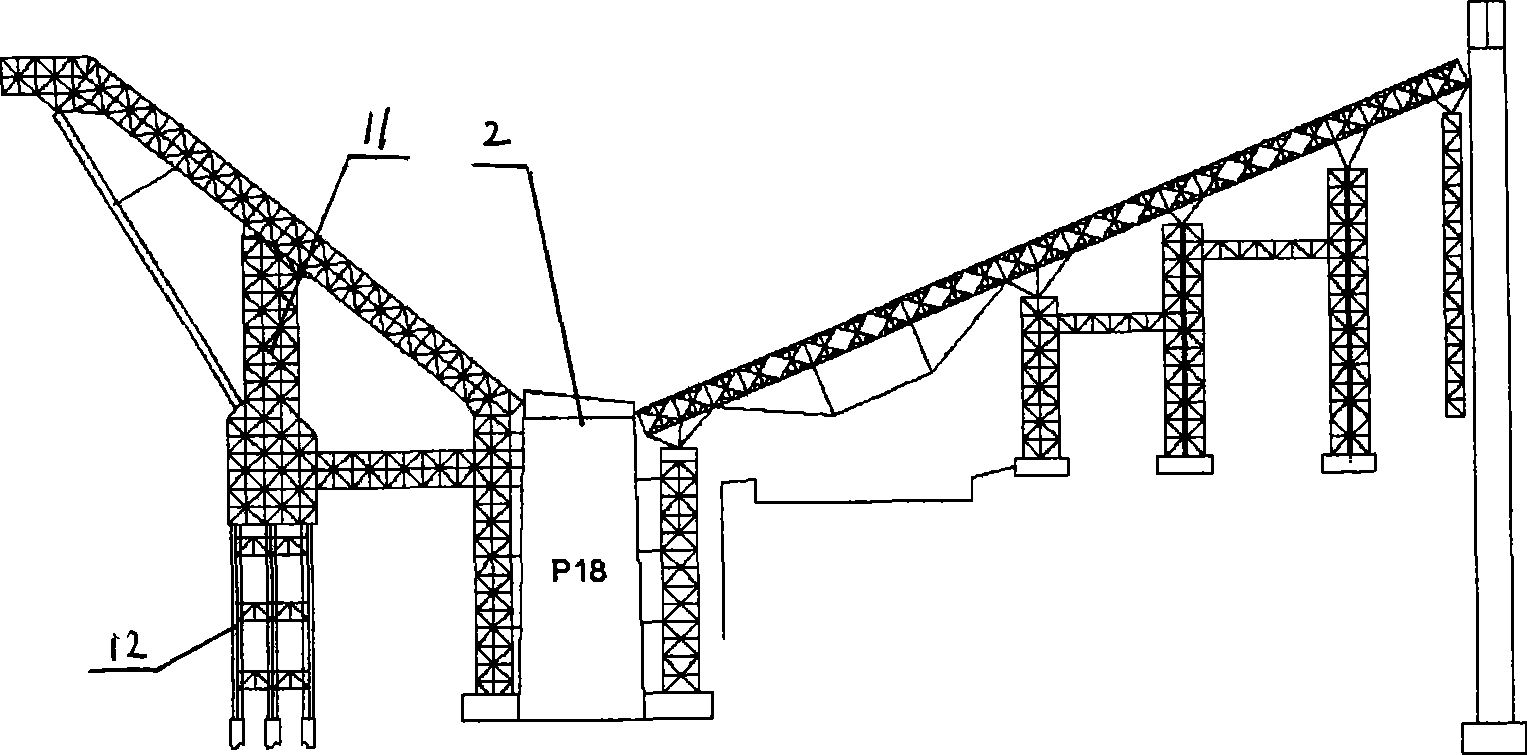

Construction method for Y-shaped frame of large-span steel box basket arch bridge

ActiveCN101446067AEnsure construction safetyEnsure structural safetyBridge erection/assemblyPre stressSpatial structure

The invention discloses a construction method for a Y-shaped frame large-span steel box basket arch bridge. Firstly, the structural style of pre-stressed concrete spatial structure system, the vertical bridge tilt angle and horizontal bridge tilt angle of the fore-and-rear socle beams and the line-type and form of fracture thereof are confirmed and construction blocks are divided; secondly, a full-framing cast-in-place supporting structural style is determined, a formwork system is determined according to the inclined angle of the fore-and-rear socle beams, a line-type control method is determined according to the form of fracture of the fore-and-rear socle beams and concrete blocks are casted in sequence; finally, the pre-stressed concrete spatial structure system is formed. The method not only accords with the Y-shaped frame construction, but also can control the structural line-shape of the Y-shaped frame, thus having the characteristics of improving quality control ability, guaranteeing construction safety, reducing construction cost and enhancing construction progress. The large-scale pre-stressed concrete spatial structure system (Y-shaped frame) of Chongqing Caiyuanba Changjiang River Bridge constructed by the method is completely in accordance with the specification, and all technical and economic indicators meet the design requirements, thus the method has high efficiency.

Owner:THE 5TH ENG MBEC

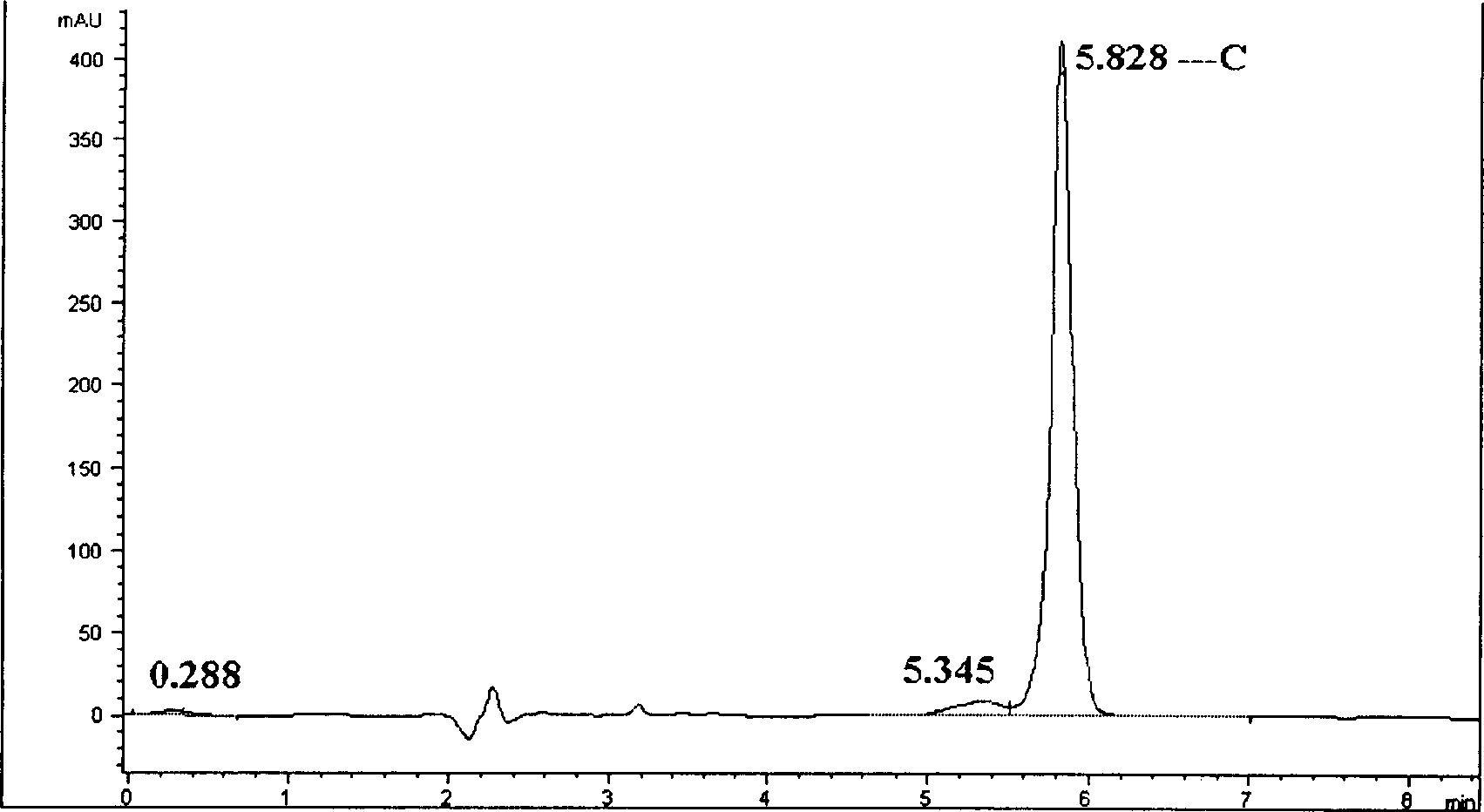

Quality detection method for chinarue cough particle

ActiveCN102133363AImprove quality inspection standardsEasy to operateComponent separationRespiratory disorderAsparagus cochinchinensisLaggera pterodonta

The invention relates to a quality detection method for chinarue cough particles. In the formula, the chinarue cough particles include following materials: 156g of pericarpium citri reticulatae, 96g of rhizoma acori graminei, 312g of polygonum cuspidatum, 188g of asparagus cochinchinensis, 375g of chinarue, 96g of radix stemonae, 750g of marsdenia tenacissima, 375g of laggera pterodonta, 96g of semen armeniacae amarae, 375g of houttuynia cordata and 188g of cortex mori radicis, and the materials are prepared into particles. On the basis of the original standard, the thin-layer chromatography identification of the chrinarue is added, and the chinaure is one of main ingredients. After the thin-layer indentification of the chinaure is added on the basis of the original standard, the scientific basis is provided for qualitative control of the chinaure in the preparation, the quality detection standard of the chinaure cough particles is perfected, and the scientific basis is provided for the judgment of true and false and quality control of the product. In the method, the test and the operation of samples are simple and convenient, and by the continuous verification test of negative interference and the like, free interfered negativeness, good repeatability, and strong specificity are verified and tested. The quality test standard is perfected, and the product quality control capability is promoted.

Owner:唐秋海

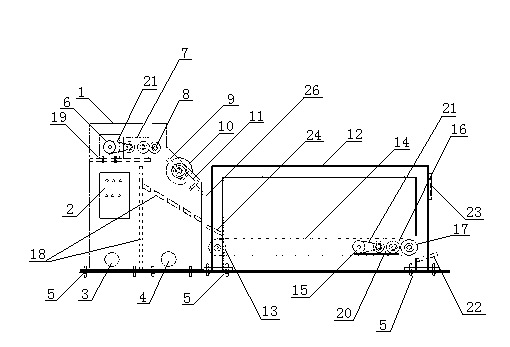

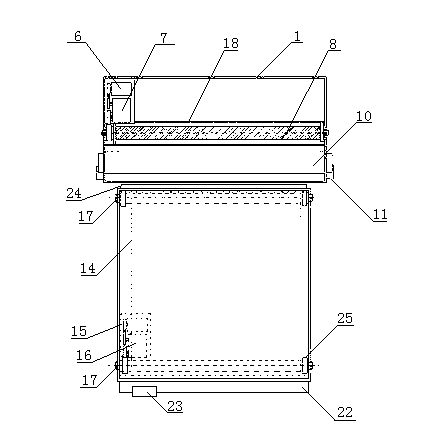

Manual broad tufted carpet cutting machine

ActiveCN103225185AImprove pile cutting efficiencyImprove quality control abilityTufting apparatusMachine controlElectric machinery

The invention discloses a manual broad tufted carpet cutting machine. The machine comprises a cutting machine box, a cutting machine control switch, a cylinder pressure adjusting device, a cutting motor, a cutting gearbox, a carpet cutting support roller, a support roller elevating cylinder, a fluffy separation plate, an anti-fall baffle plate and a cycle conduction band motor switch, and the support roller elevating cylinder is arranged in an oblique mode; the cutting machine control switch controls the rotation speed of the cutting motor and then adjusts the output speed of the cutting gearbox in order to adjust the rotation speed of a cutting hob; and the cutting machine control switch controls the rotation speed of the cycle conduction band motor switch and then adjusts the output speed of a cycle conduction band gearbox in order to adjust the transmission speed of a carpet cycle nylon conduction band. The manual broad tufted carpet cutting machine can adjust the rotation speed of the cutting hob and the transmission speed of the auxiliary conduction band, adjusts the spacing between the carpet support roller and the cutting hob through a pneumatic knob by two operators, obviously improves the tufted carpet cutting efficiency, reduces the labor intensity and improves the product quality control capability.

Owner:NANTONG TEXTILE VOCATIONAL TECH COLLEGE

Method for determining multiple brightening agents in nickel plating solution

InactiveCN1844910AImprove quality control abilityReduce testing investmentComponent separationNickel plateMetallic Nickel

The invention discloses an analyze method used to detect multi brighteners of bright nickel plated liquid, when there are multi organic additives, as brightener, accelerator, restrainer, and smoothen agent, etc. The inventive method is based on the high-efficiency liquid phase spectrum analysis of brightener, with high accuracy and better repeatedly property.

Owner:NINGBO INST OF TECH ZHEJIANG UNIV ZHEJIANG

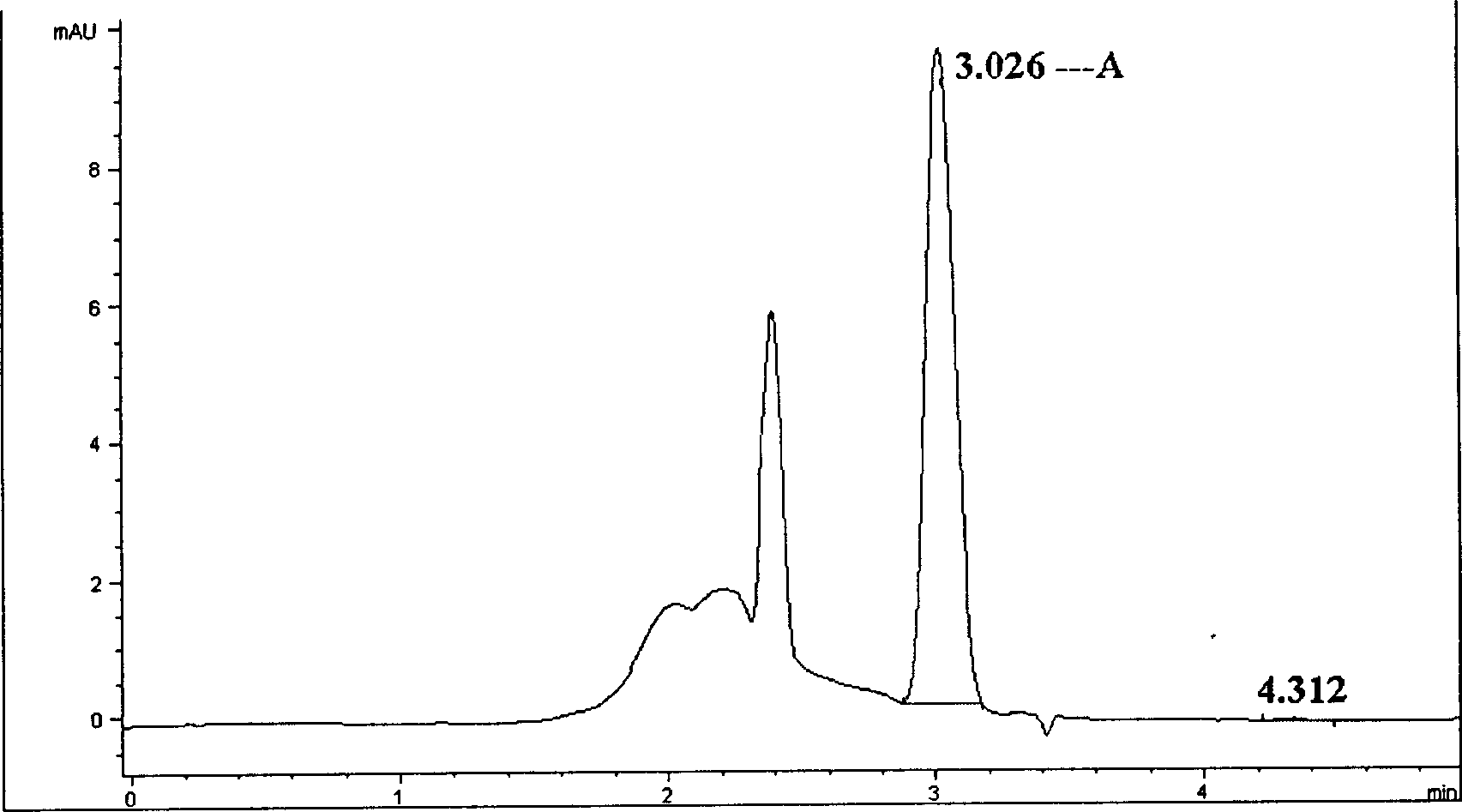

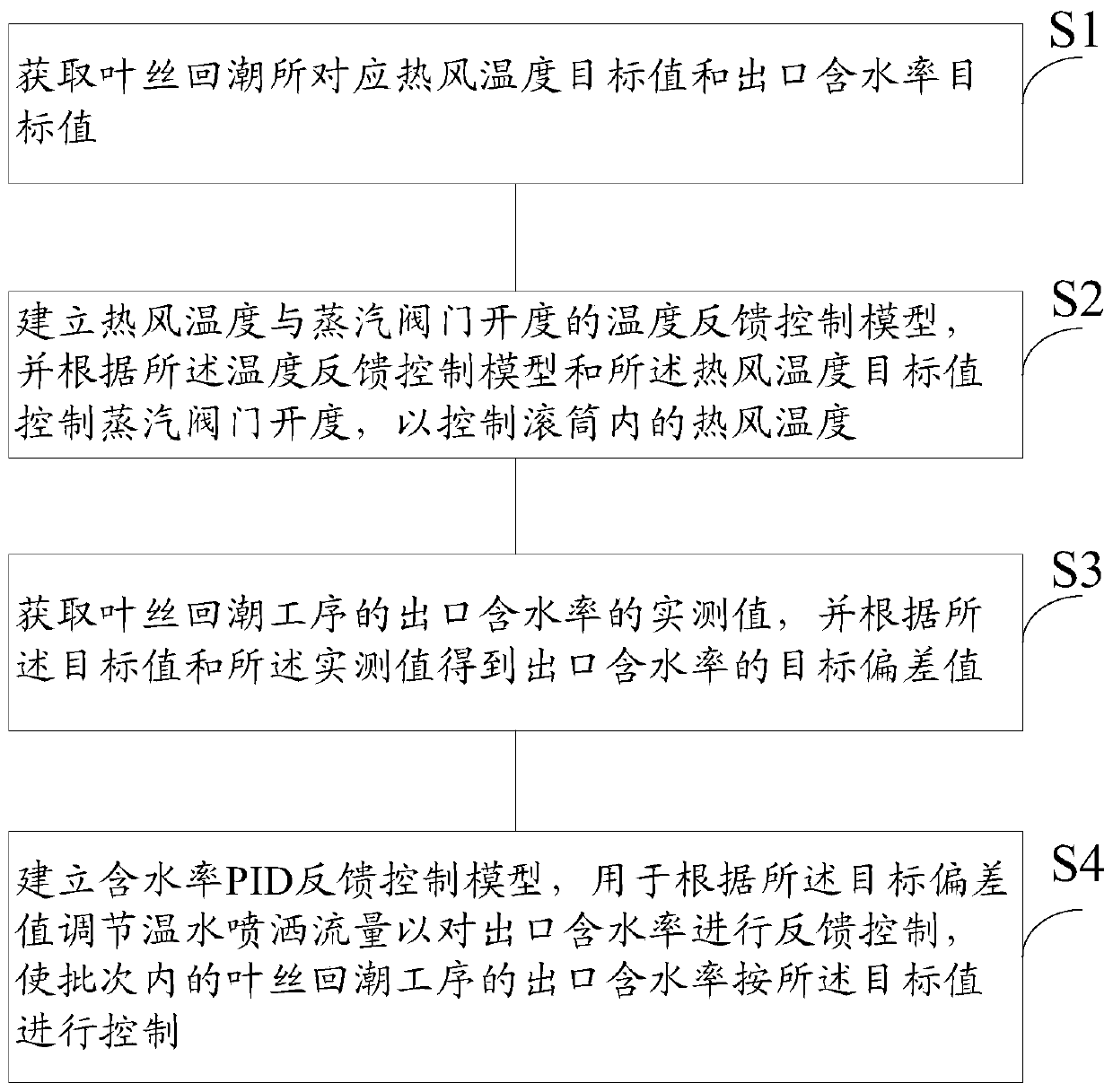

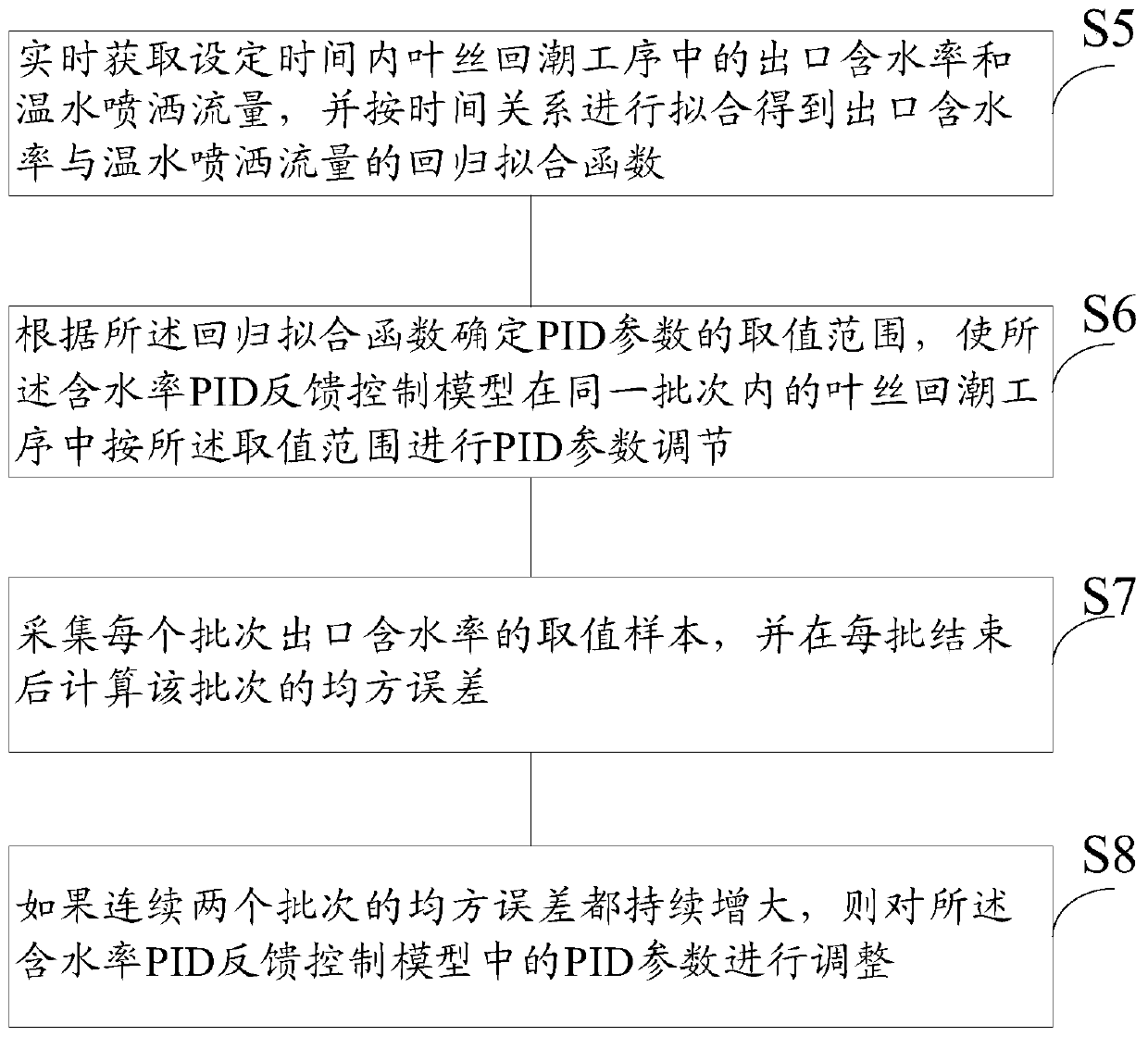

Quality control method and system based on drum-type cut tobacco moisture regaining

ActiveCN110946306AExport moisture content solutionImprove consistencyTobacco preparationTobacco treatmentWarm waterQuality control

The invention provides a quality control method and system based on drum-type cut tobacco moisture regaining. The quality control method comprises the steps of obtaining a hot air temperature target value and an outlet moisture content target value corresponding to cut tobacco moisture regaining; establishing a temperature feedback control model of the hot air temperature and the steam valve opening degree, and controlling the steam valve opening degree according to the temperature feedback control model and the hot air temperature target value so as to control the hot air temperature in a drum; obtaining an actual measurement value of the outlet moisture content of the cut tobacco moisture regaining process, and obtaining a target deviation value of the outlet moisture content according to the target value and the actual measurement value; and establishing a moisture content PID feedback control model for adjusting the warm water spraying flow according to the target deviation value so as to perform feedback control on the outlet moisture content, so that the outlet moisture content of the cut tobacco moisture regaining process in the batch is controlled according to the target value. The method can improve the consistency of moisture contents of moisture regaining outlets of various batches of cut tobaccos, and improves the quality control capability in the production process.

Owner:CHINA TOBACCO HENAN IND +1

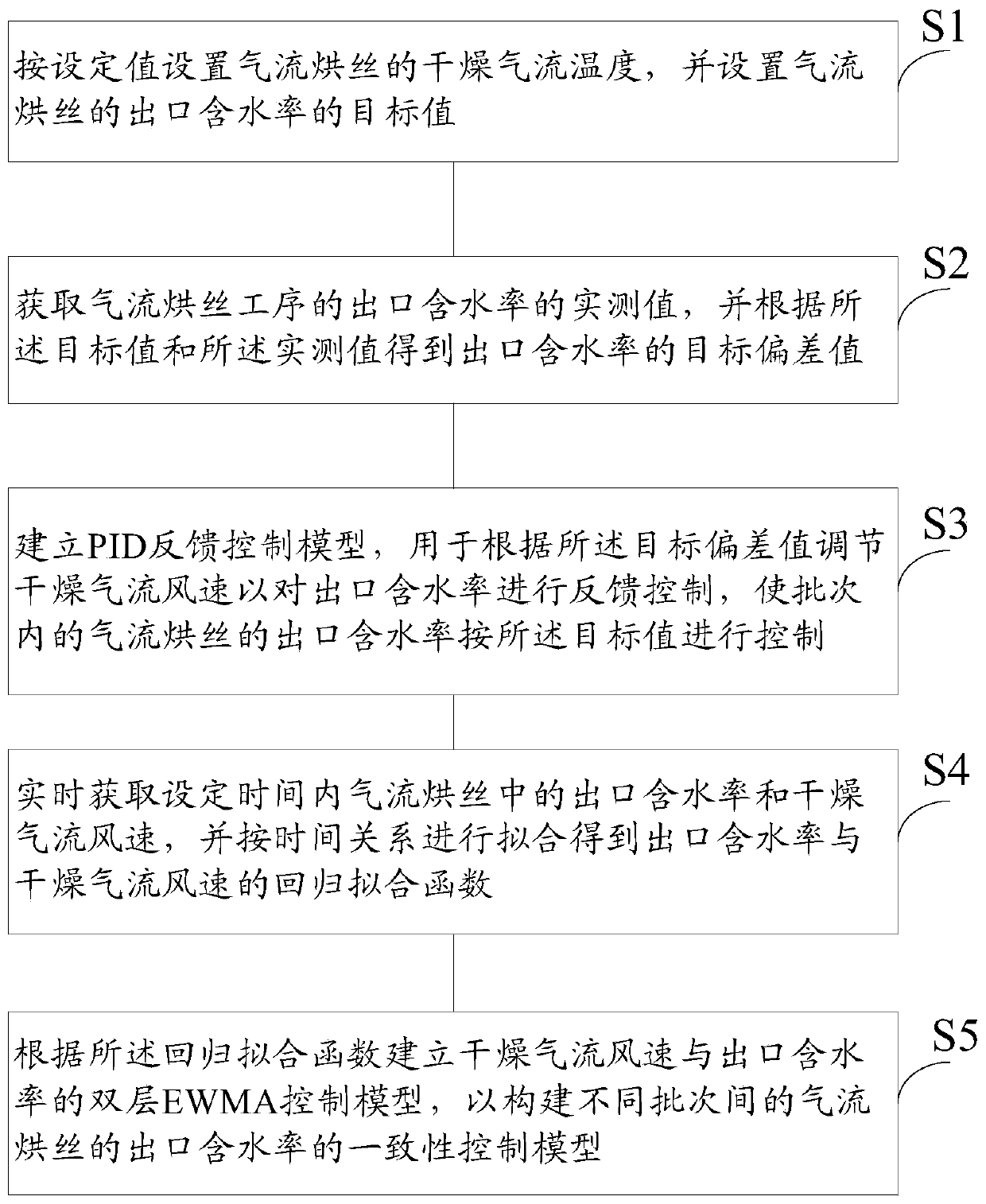

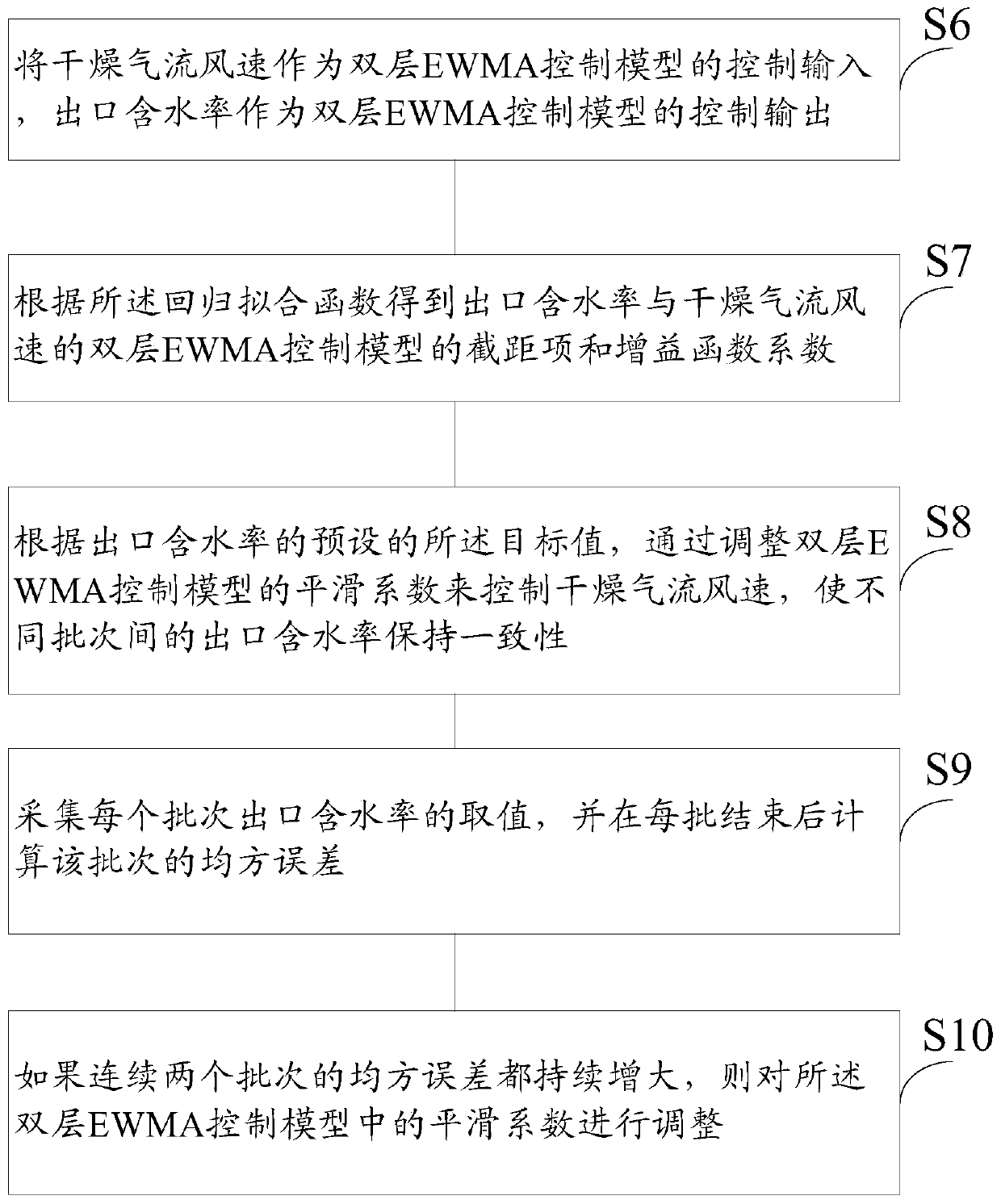

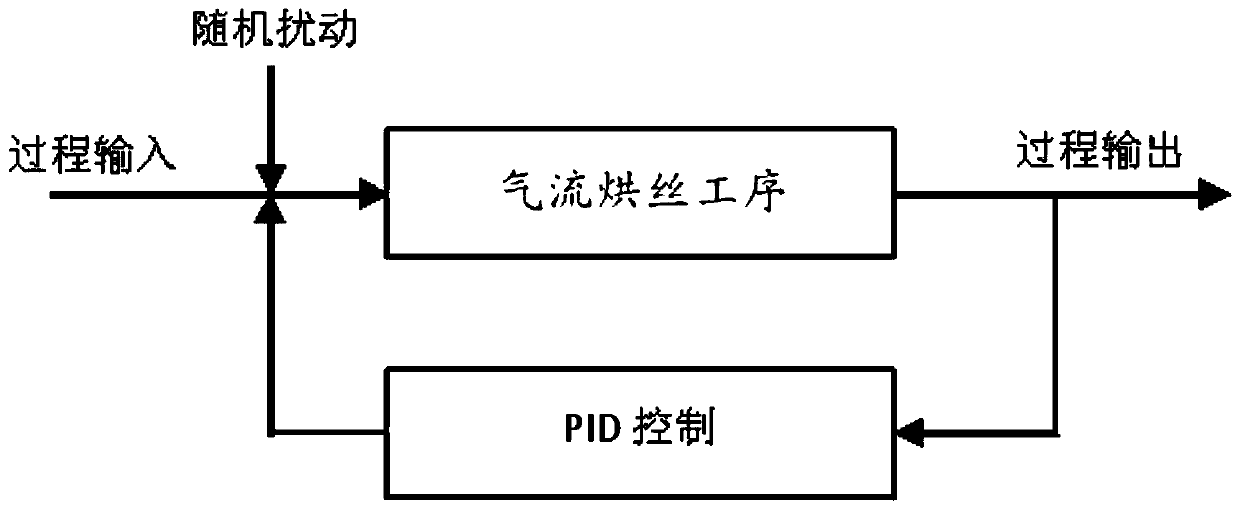

Control method and system for tobacco shred water content of airflow tobacco shred drying

ActiveCN110946314AImprove consistencyImprove the quality control ability of the production processTobacco preparationTobacco treatmentAgricultural engineeringFeedback control

The invention provides a control method and system for the tobacco shred moisture content of airflow tobacco shred drying, and the method comprises the steps: setting the dry airflow temperature of the airflow tobacco shred drying according to a set value, and setting a target value of the moisture content of an outlet of the airflow tobacco shred drying; obtaining an actual measurement value of the outlet moisture content of the airflow tobacco shred drying process, and obtaining a target deviation value of the outlet moisture content according to the target value and the actual measurement value; and establishing a PID feedback control model for adjusting the air speed of the dry airflow according to the target deviation value so as to carry out feedback control on the outlet moisture content, so that the outlet moisture content of the airflow cut tobaccos in the batch is controlled according to the target value. According to the invention, the uniformity consistency of airflow tobacco shred drying in each batch can be improved, and the quality control capability in the production process is improved.

Owner:CHINA TOBACCO HENAN IND

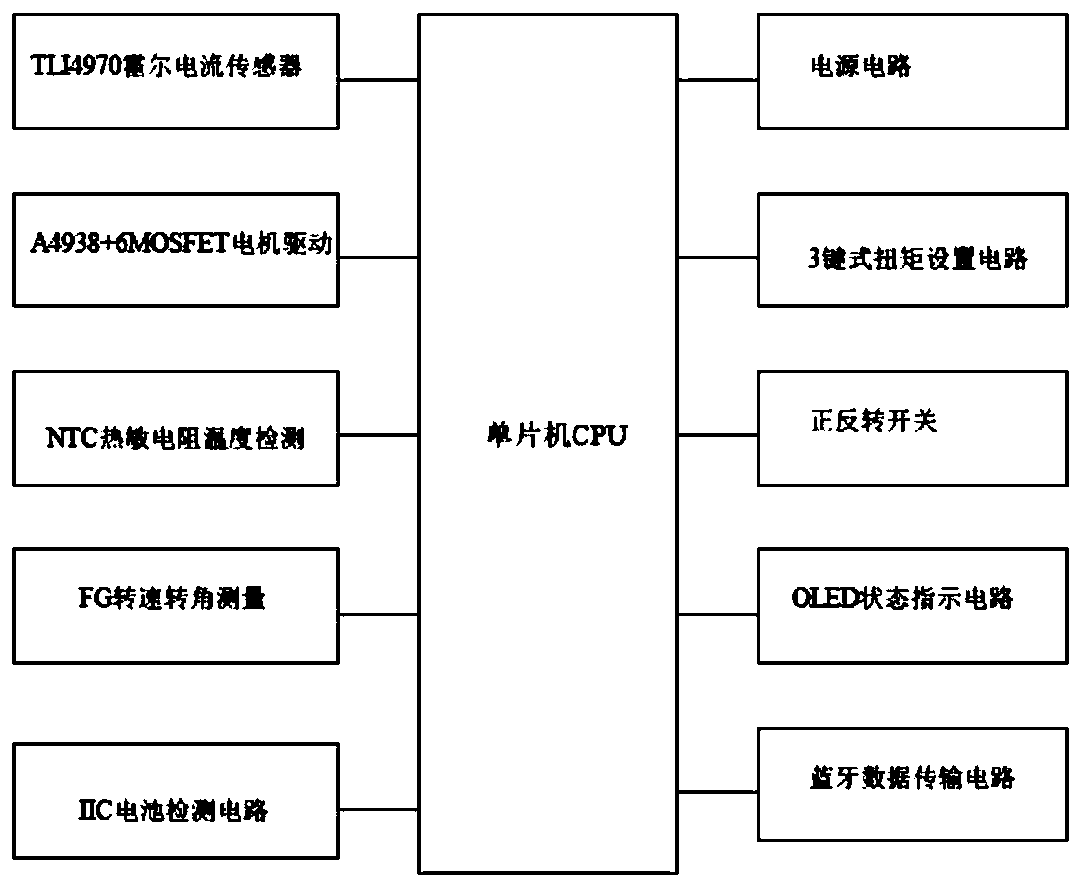

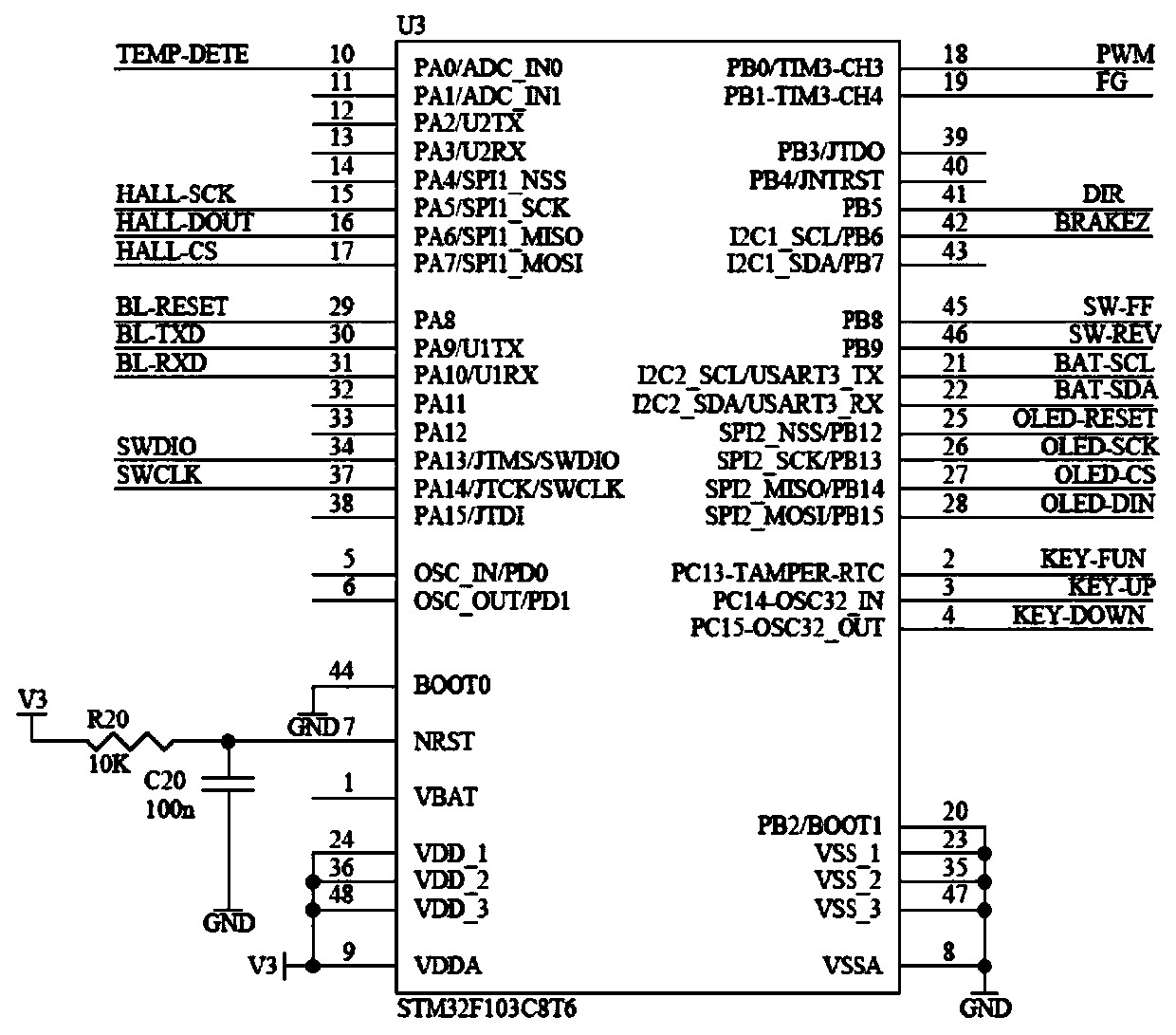

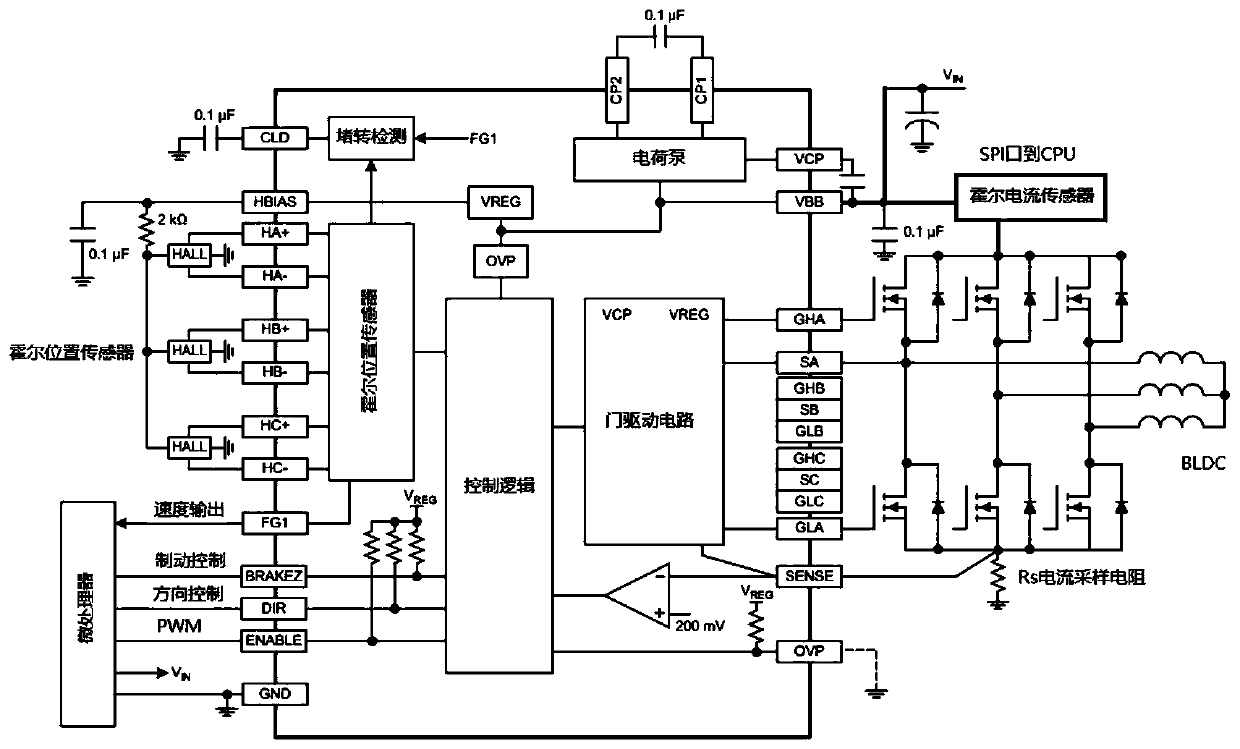

Torque rotating angle multi-dimensional sensing control device and control method for electric wrench

The invention provides a torque rotating angle multi-dimensional sensing control device and control method for an electric wrench and a wrench. The torque rotating angle multi-dimensional sensing control device comprises a processor module, a brushless direct current motor, a servo control module and a current sensing module; the current sensing module is corrrespondingly connected with the brushless direct current motor and the processor module and is used for acquiring the current of the brushless direct current motor in real time and transmitting the current to the processor module; the processor module is in communication connection with the brushless direct current motor through the servo control module, the processor module is used for realizing the self-adaptive control of the rotation speed, the direction, the rotation angle and torque of the brushless direct-current motor, and realizing the control of fixed torque and / or the perception of the torque and the rotation angle during fixed-angle control, accurate control of the fixed torque and the fixed angle is realized, data processing is carried out by adopting a statistical principle, so that the quality control capabilityof the wrench is greatly improved.

Owner:孟朝晖

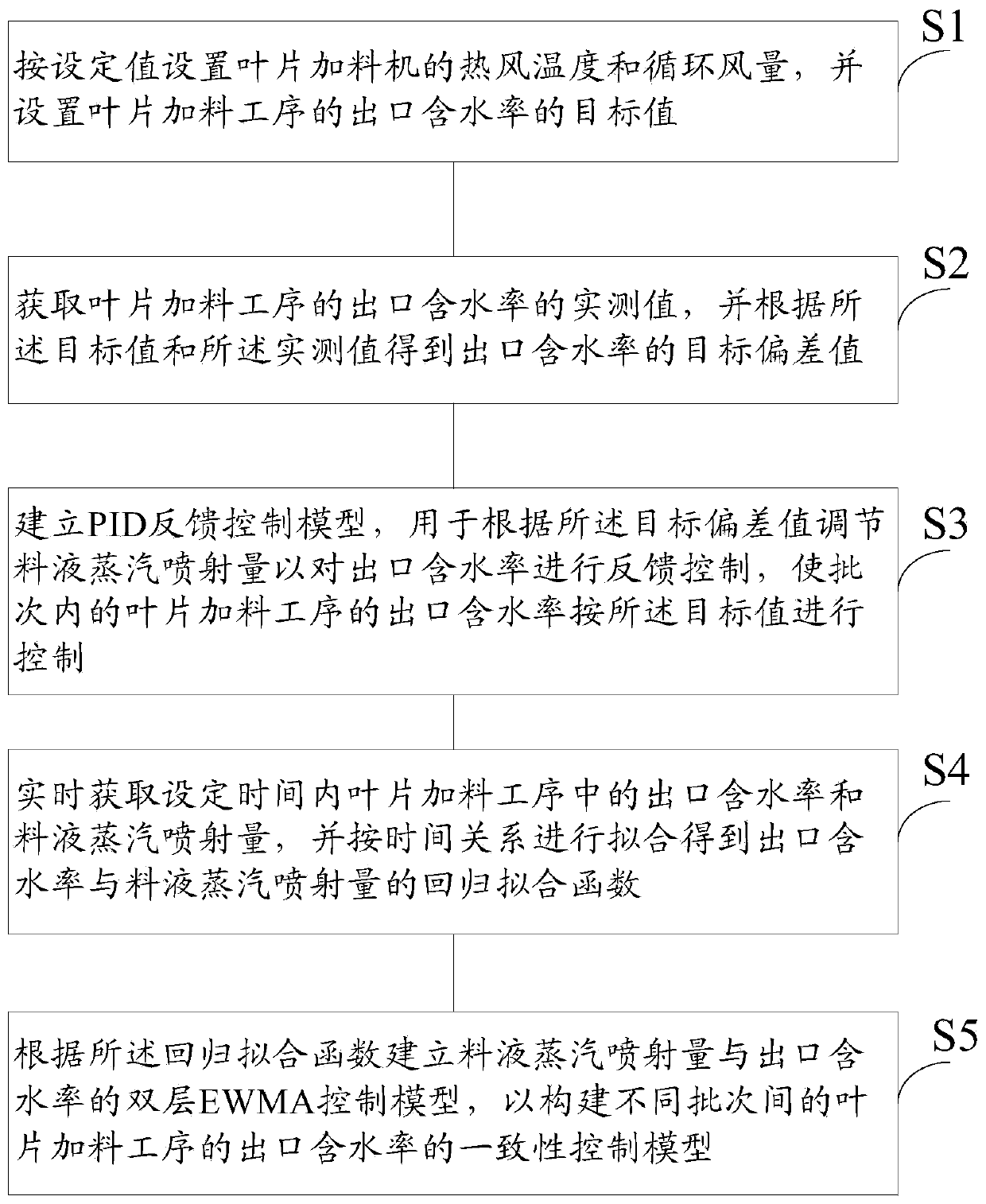

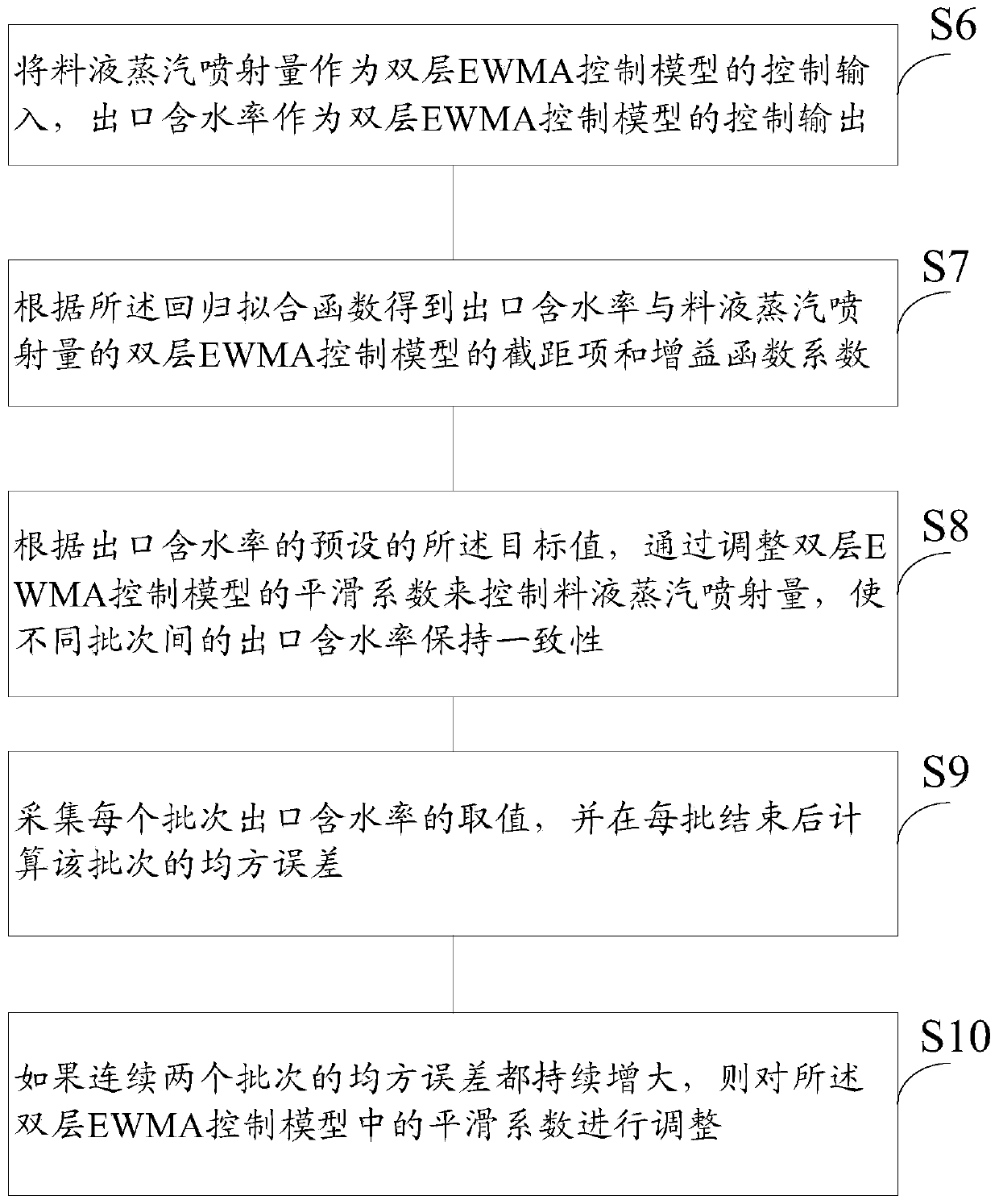

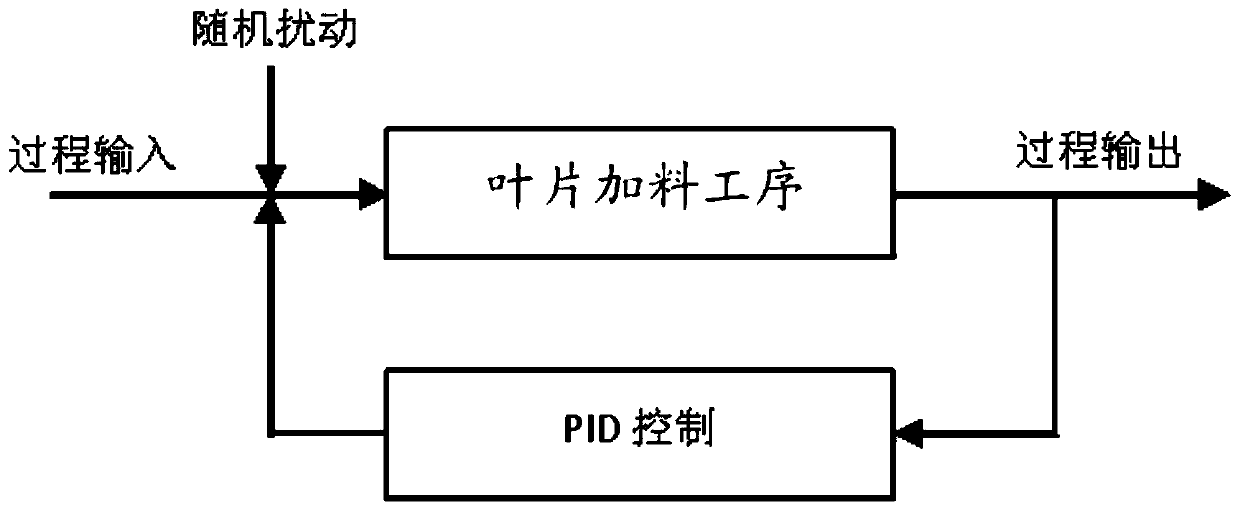

Feed liquid control method and system for blade feeding

ActiveCN110879581AImprove consistencyImprove quality control abilityProgramme total factory controlAir volumeControl engineering

The invention provides a feed liquid control method and system for blade feeding, and the method comprises the steps: setting the hot air temperature and circulating air volume of a blade feeding machine according to a set value, and setting a target value of the outlet moisture content of a blade feeding process; obtaining an actual measurement value of the outlet moisture content of the blade feeding process, and obtaining a target deviation value of the outlet moisture content according to the target value and the actual measurement value; and establishing a PID feedback control model for adjusting the feed liquid steam injection amount according to the target deviation value so as to carry out feedback control on the outlet moisture content, so that the outlet moisture content of the blade feeding process in the batch is controlled according to the target value. The consistency of the charging uniformity of each batch of blades can be improved, and the quality control capability inthe production process is improved.

Owner:CHINA TOBACCO HENAN IND

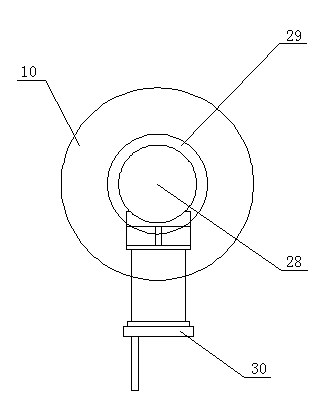

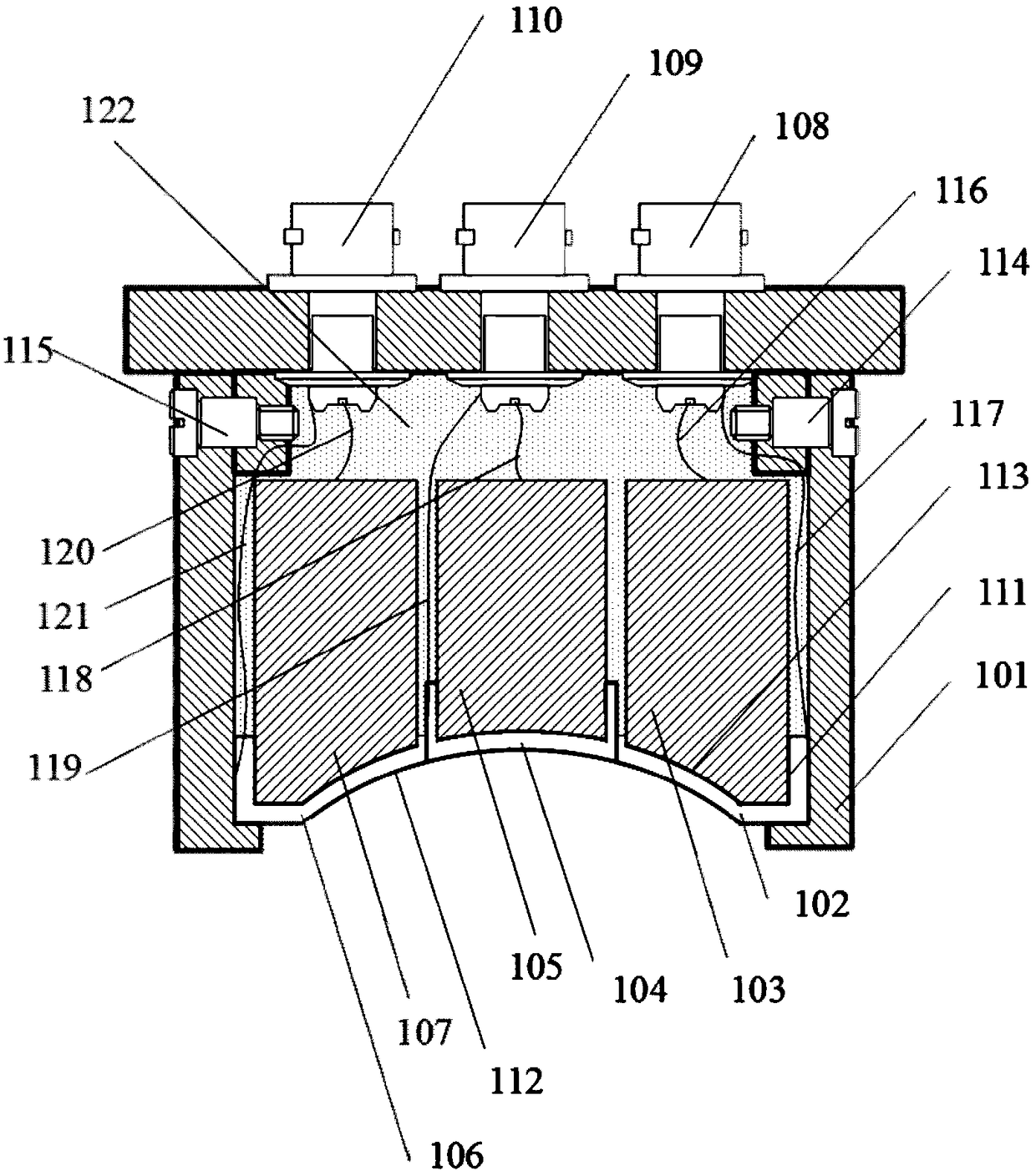

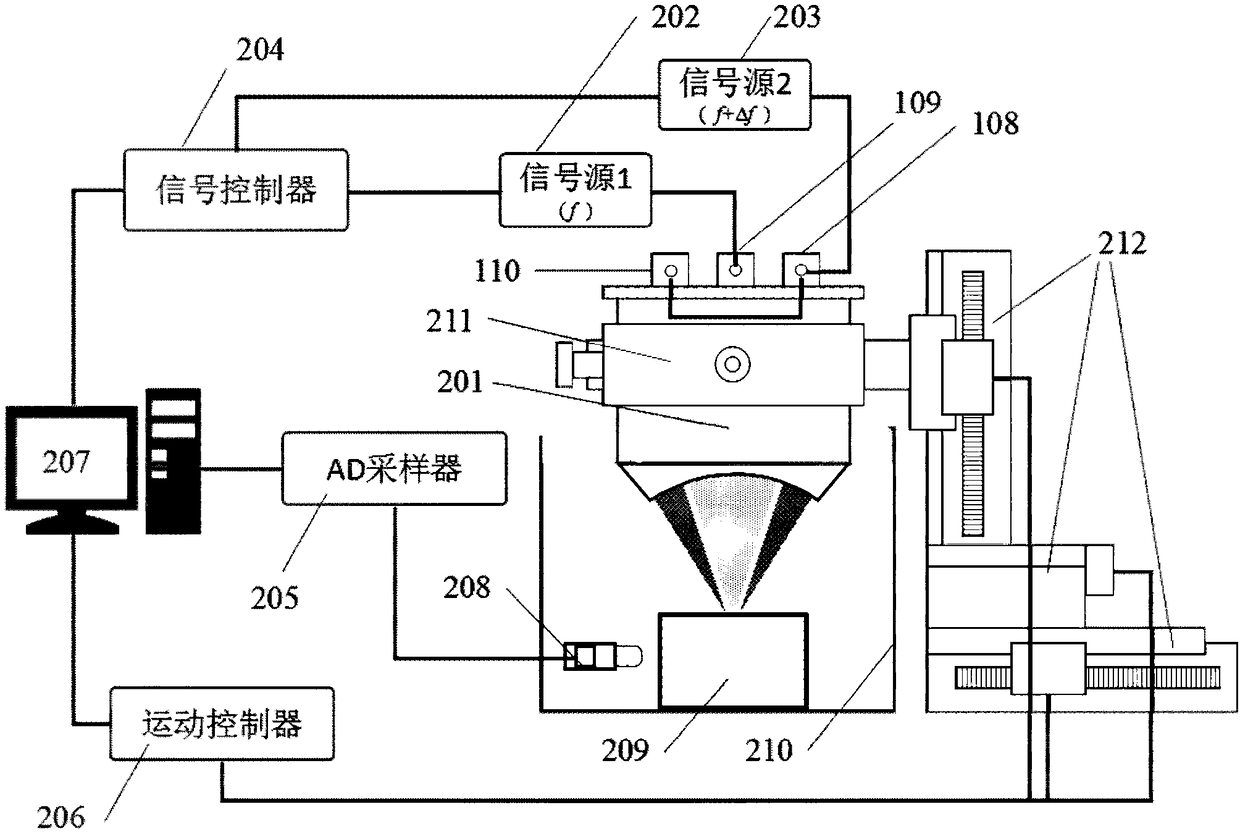

Dual-frequency confocal ultrasonic transducer

ActiveCN108593783AImprove quality control abilityUltrasonic/sonic/infrasonic wave generationUltrasonic sensorRadio frequency

The invention discloses a dual-frequency confocal ultrasonic transducer, which is suitable for the fields of biological tissue characterization, tissue engineering mechanical performance regulation, ultrasonic non-destructive testing and the like. The dual-frequency confocal ultrasonic transducer specifically comprises piezoelectric elements, a back lining layer having a concave cylindrical surface, radio frequency bases and an outer shell, and is specifically characterized in that the dual-frequency confocal ultrasonic transducer has three independent piezoelectric elements and the corresponding radio frequency bases, the piezoelectric element is a piezoelectric film made of a piezoelectric macromolecule polymer, the upper surface of the piezoelectric film is covered with a positive electrode, the lower surface of the piezoelectric film is covered with a negative electrode, the piezoelectric film is closely attached to the concave cylindrical surface of the back lining layer, the positive electrode of the piezoelectric film is connected to the positive electrode of the corresponding radio frequency base through an electrode leading wire, and the positive electrode of the piezoelectric film is connected to the negative electrode of the corresponding radio frequency base through an electrode leading wire. According to the present invention, with the dual-frequency confocal ultrasonic transducer, ultrasonic waves with two different frequencies can be generated, such that the mechanical properties of the biological tissue can be evaluated, and the anisotropy of the material can be analyzed.

Owner:ZHEJIANG UNIV

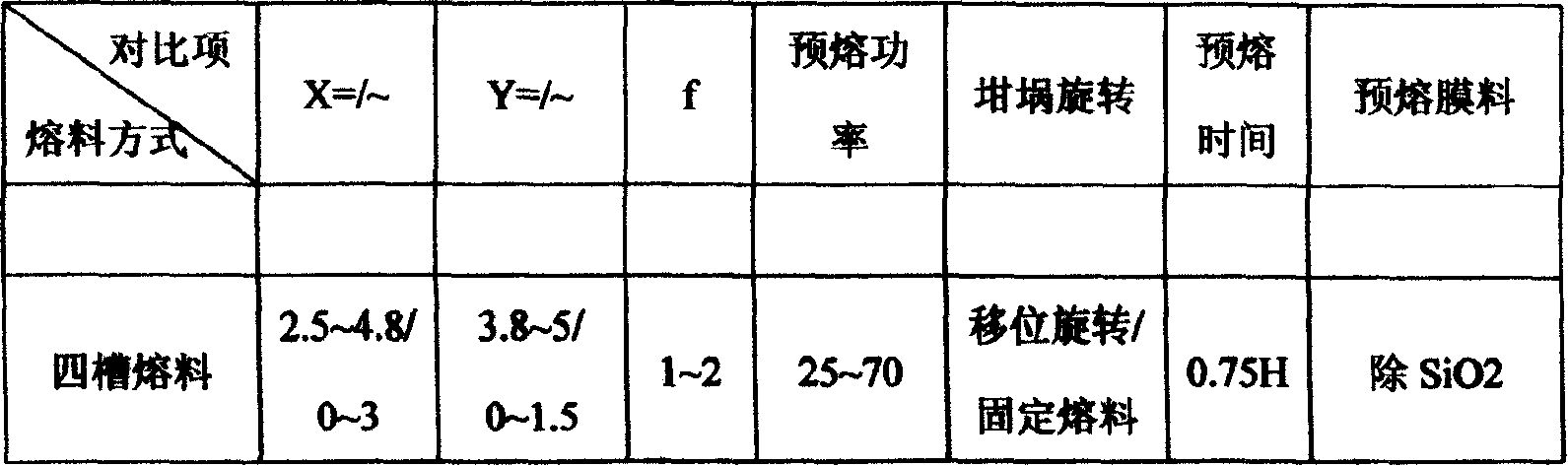

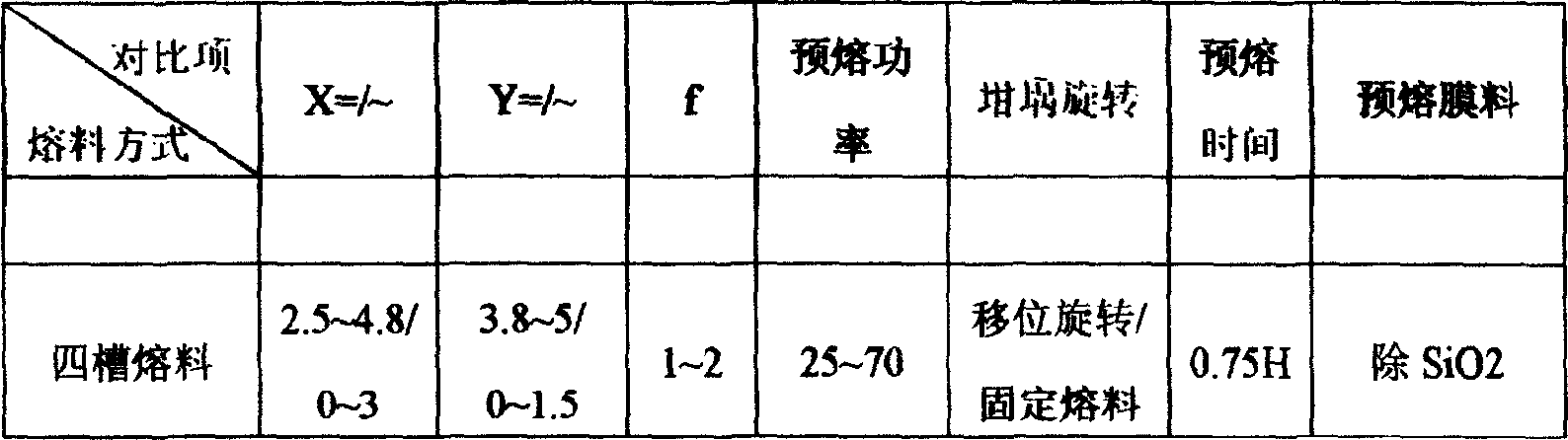

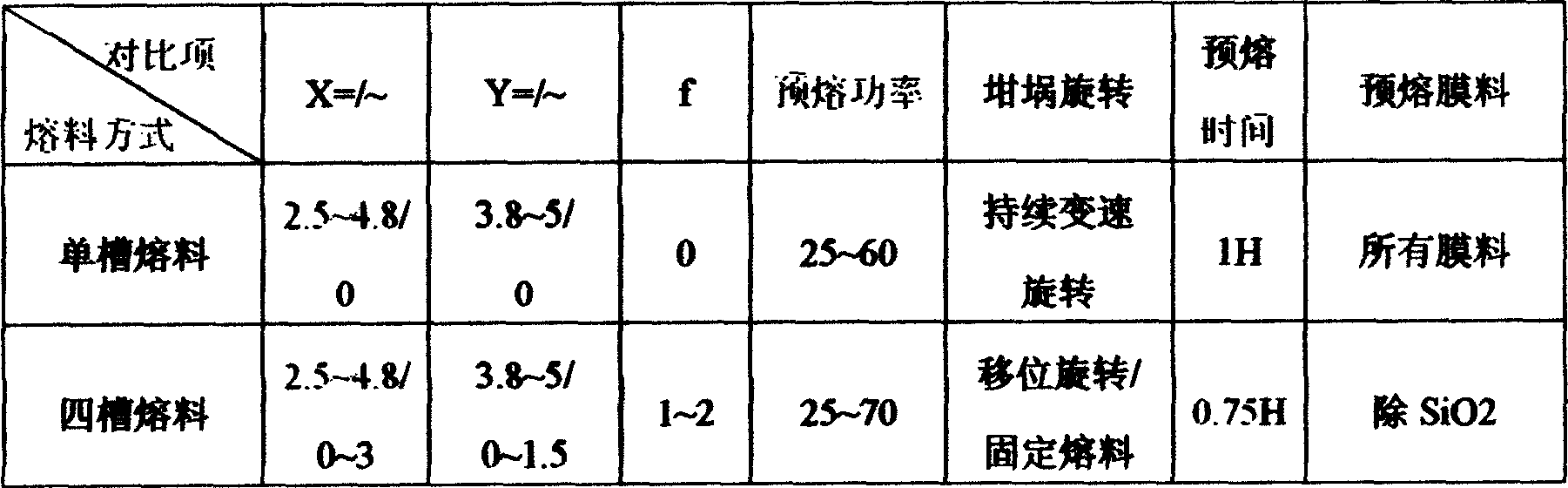

Optical filter coating method

ActiveCN1891849AEasy to cleanImprove efficiencyVacuum evaporation coatingSputtering coatingManufacturing technologyBiochemical engineering

The invention relates to a producing technology process for high performance IR-CUT filter that includes the following steps: cutting basal piece to mold basal piece and removing the silica oxide in polishing process, taking ultrasonic wave cleaning to the basal piece before coating, and taking R film coating, detecting, cutting, ultrasonic cleaning after coating, and detecting processes. The invention could effectively solve the film design and manufacturing technology consistency. It could decrease the coating layers.

Owner:SHENZHEN O FILM TECH

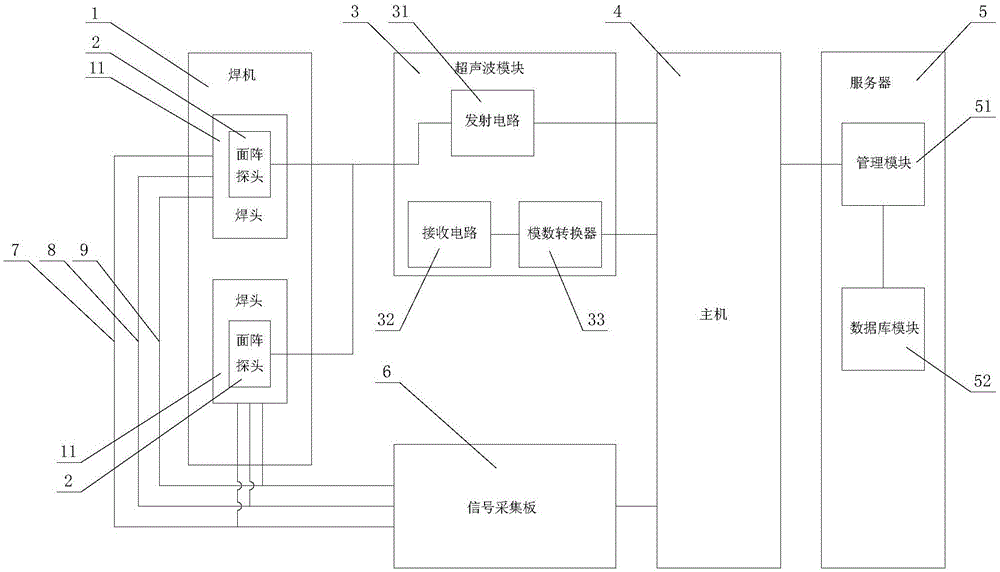

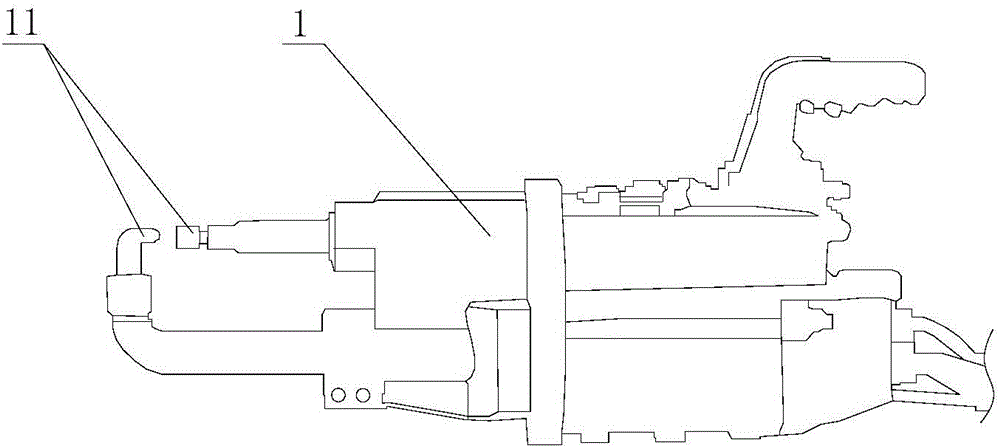

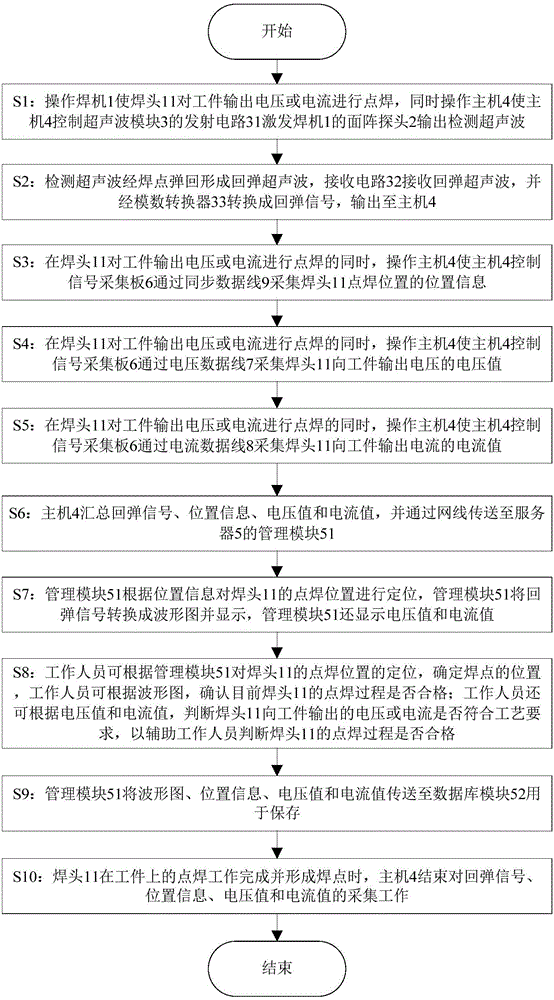

On-line detecting system and method for spot welding

InactiveCN106624313AQuality improvementIncrease productivityAnalysing solids using sonic/ultrasonic/infrasonic wavesWelding monitoring devicesPower flowQuality control

The invention discloses an on-line detecting system and method for spot welding. The system comprises a welding machine, area array probes, a supersonic module, a main engine and a server. The welding machine is provided with welding heads, and the area array probes are arranged in the welding machine in an integrated mode. The supersonic module is connected with the area array probes, the main engine is connected with the supersonic module, and the server is connected with the main engine; the welding heads output a voltage or an electric current to a work piece for spot welding and welding spots are formed, the area array probes are excited by the supersonic module to output detection ultrasonic waves to a spot welding position on the work piece, and the supersonic module further receives rebound ultrasonic waves rebounded from the spot welding position. The on-line detecting system and method for spot welding have the advantages that real-time monitoring to a spot welding process of a welding position is achieved, and the accuracy of detecting the spot welding process of the welding position is improved, so that the real-time monitoring and process management on a welding work of the welding machine are achieved, the ability of quality control over the spot welding process is improved and the detection efficiency and the welding quality of the welding spots are improved.

Owner:NDT TECH SHANGHAI

Quality detection method of capsule for reducing blood fat and activating collaterals

InactiveCN102133377AFor the purpose of qualitative controlTo achieve the purpose of qualitative controlMetabolism disorderComponent separationCassiaThin layer chromatographic

The invention discloses a quality detection method of a capsule for reducing blood fat and activating collaterals. The capsule for reducing blood fat and activating collaterals is prepared from 100g of cassia seed, 1500g of curcuma, 2000g of rhizoma alismatis, 500g of notoginseng and 2000g of bermudagrass herb. The quality detection method of the capsule for reducing blood fat and activating collaterals additionally provides thin-layer chromatography identification of the rhizoma alismatis on the basis of the primary standard, and the rhizoma alismatis is one of main components of the capsule. After the thin-layer chromatography identification of the rhizoma alismatis is additionally provided on the basis of the primary standard, the purpose of qualitatively controlling the rhizoma alismatis in the preparation is achieved, the quality detection standard of the capsule for reducing blood fat and activating collaterals is perfected, and simultaneously, a scientific basis for judging the truth of products and controlling the quality of products is provided. In the method, a sample test is simple and convenient to operate; and proven by negative interference and other continuous verification tests, the method has the advantages of negative non-interference, good reproducibility and strong specificity. The invention perfects the quality detection standard and improves the control capability of the product quality.

Owner:唐秋海

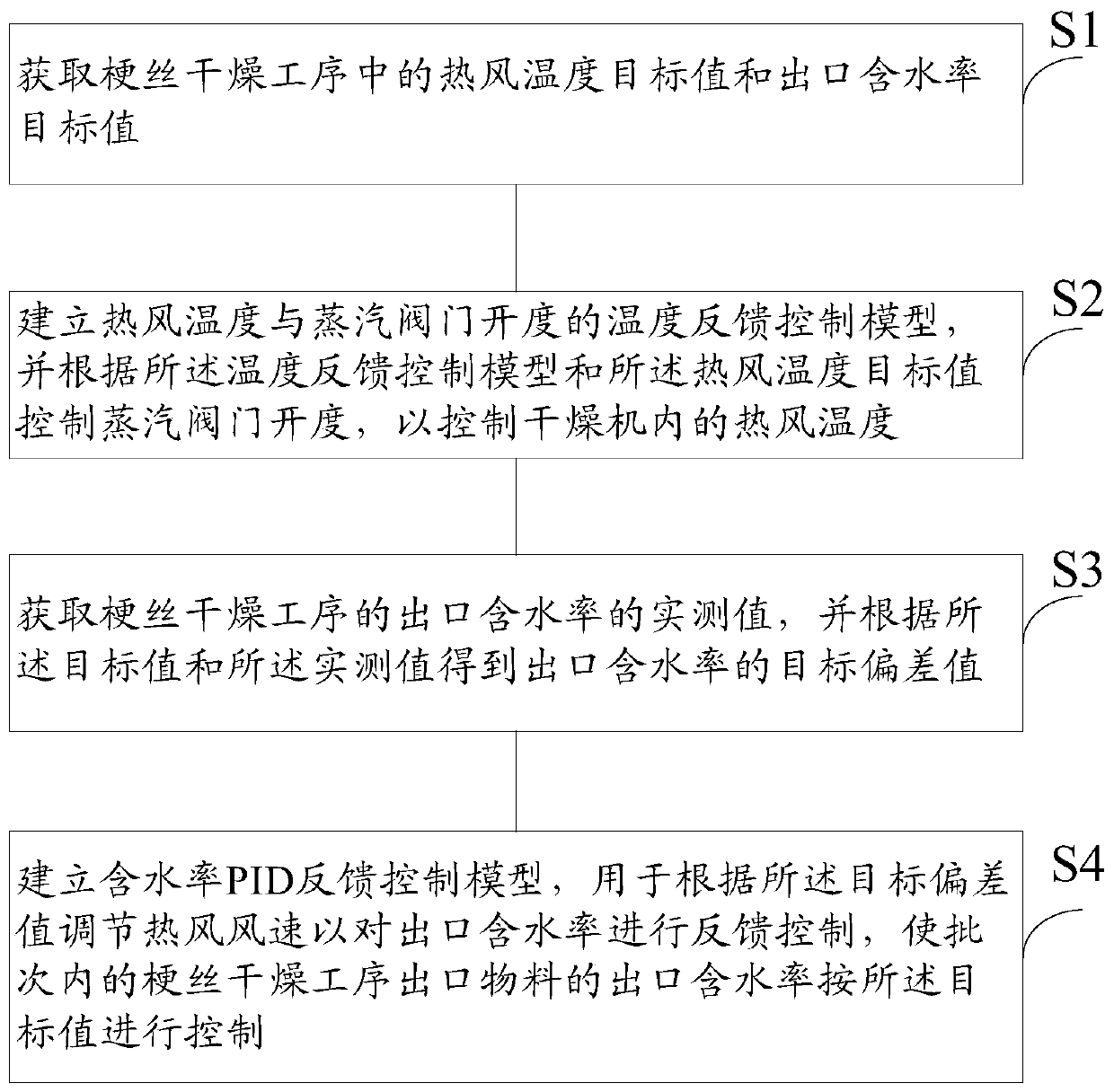

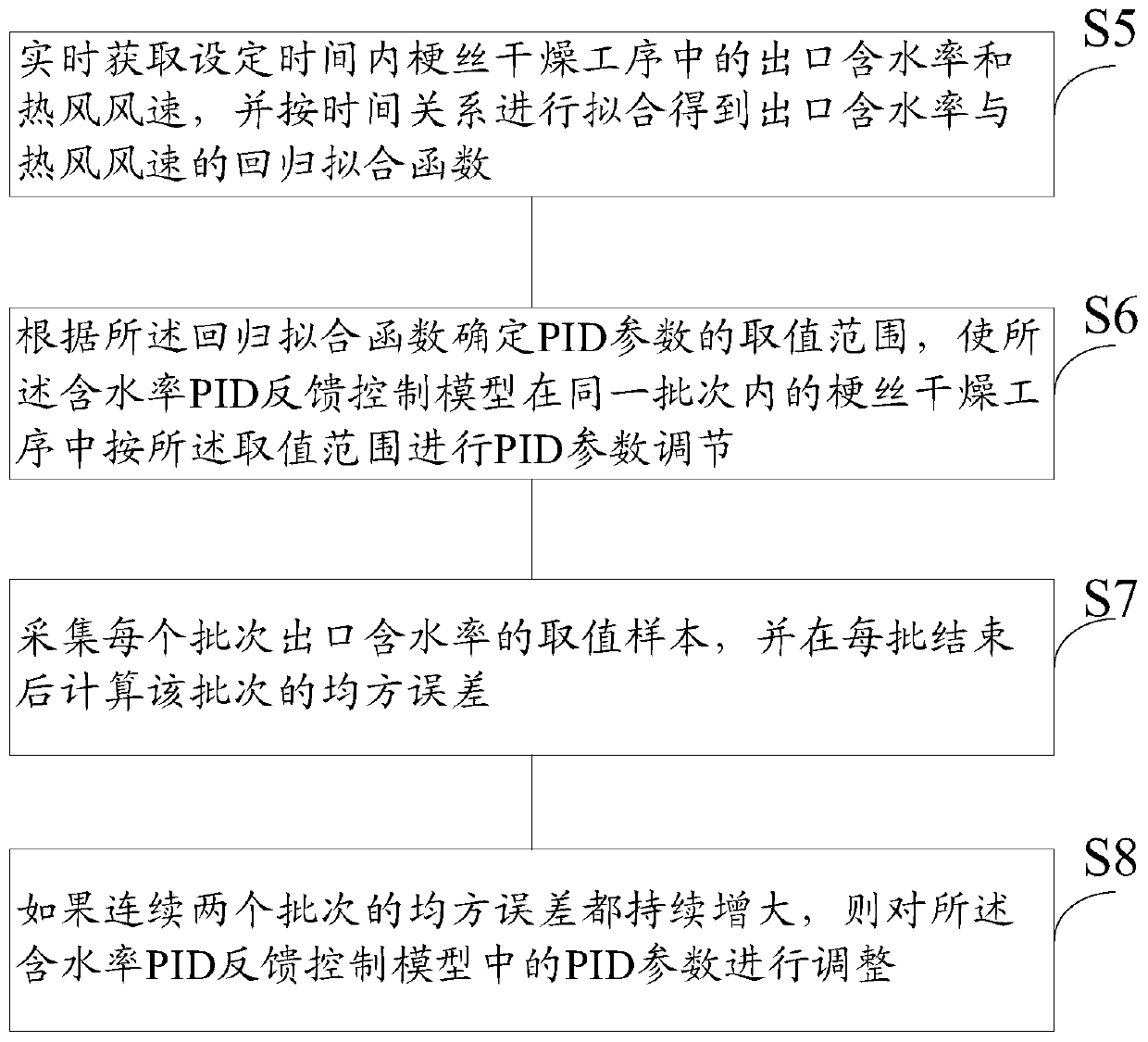

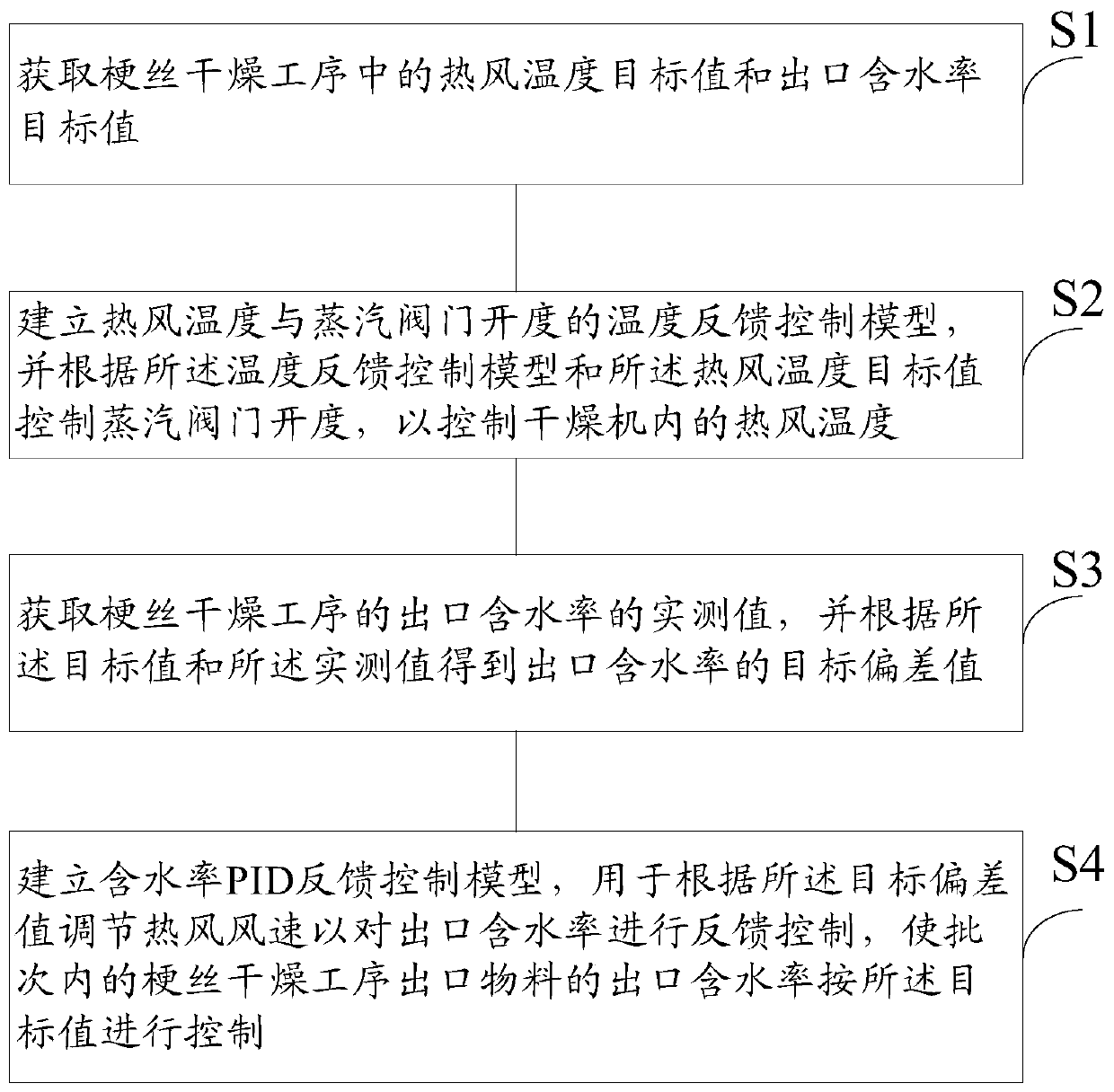

Quality control method and system based on airflow type cut stem drying

PendingCN111165866AImprove batch consistencySolve the problem of uneven moisture content change controlTobacco preparationTobacco treatmentAir velocityQuality control

The invention provides a quality control method and system based on airflow type cut stem drying. The method comprises the steps: acquiring a hot air temperature target value and an outlet moisture content target value in a cut stem drying procedure; establishing a temperature feedback control model of a hot air temperature and a steam valve opening degree, and controlling the steam valve openingdegree according to the temperature feedback control model and the hot air temperature target value so as to control the hot air temperature in a drying machine; acquiring an actual measurement valueof the outlet moisture content of the cut stem drying process, and obtaining a target deviation value of the outlet moisture content according to the target value and the actual measurement value; andestablishing a moisture content PID feedback control model for adjusting the air speed of the hot air according to the target deviation value so as to perform feedback control on the outlet moisturecontent so as to control the outlet moisture content of the outlet material in the cut stem drying process in the batch according to the target value. The batch consistency of the cut stem drying outlet moisture content can be improved, and the quality control capacity in the production process is improved.

Owner:CHINA TOBACCO HENAN IND

Method for determining nickel, chromium, silicon, manganese and phosphor in nickel-containing pig iron

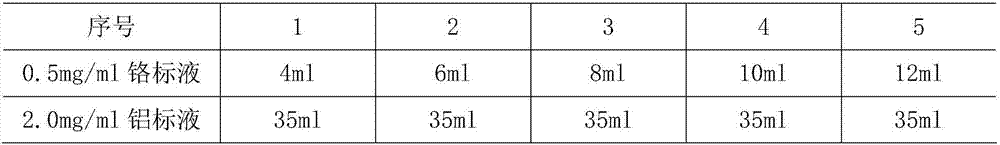

InactiveCN105486677AImprove quality process control abilityImprove detection capabilitiesPreparing sample for investigationAnalysis by thermal excitationScrapMetallic Nickel

The invention relates to a method for determining nickel, chromium, silicon, manganese and phosphor in nickel-containing pig iron. The method is characterized in that five iron samples are taken in each batch of material, one spot is drilled on each iron sample, the drilled iron scraps are ground and pass through a 60-80-mesh target standard sieve; 10 ml of distilled water, 5 ml of concentrated nitric acid (65%) and 5 ml of concentrated hydrochloric acid (37%) are added in order in a 100 ml volumetric flask filled with 0.5000 g of the iron scrap sample for solving the sample, insoluble carbide is filtered and volume is metered to 100 ml; 0.4000 g of a pure iron matrix is added in a standard series solution; an inductively coupled plasma atomic emission spectrometry is used for determining the content of the elements of Ni, Cr, Si, Mn and P in the nickel-containing pig iron for analysis, an optimal analytical line for each element can be selected; spectrum interference of each coexisted element to the analytical line is inspected, and correction of an interference line in the analytical line can be carried out. The method is capable of shortening analysis period, mitigating labor intensity, increasing control capability and detection capability of the analysis result, reducing an application amount of a chemical reagent, reducing the waste liquid discharge, and reducing the analysis cost.

Owner:ANGANG STEEL CO LTD

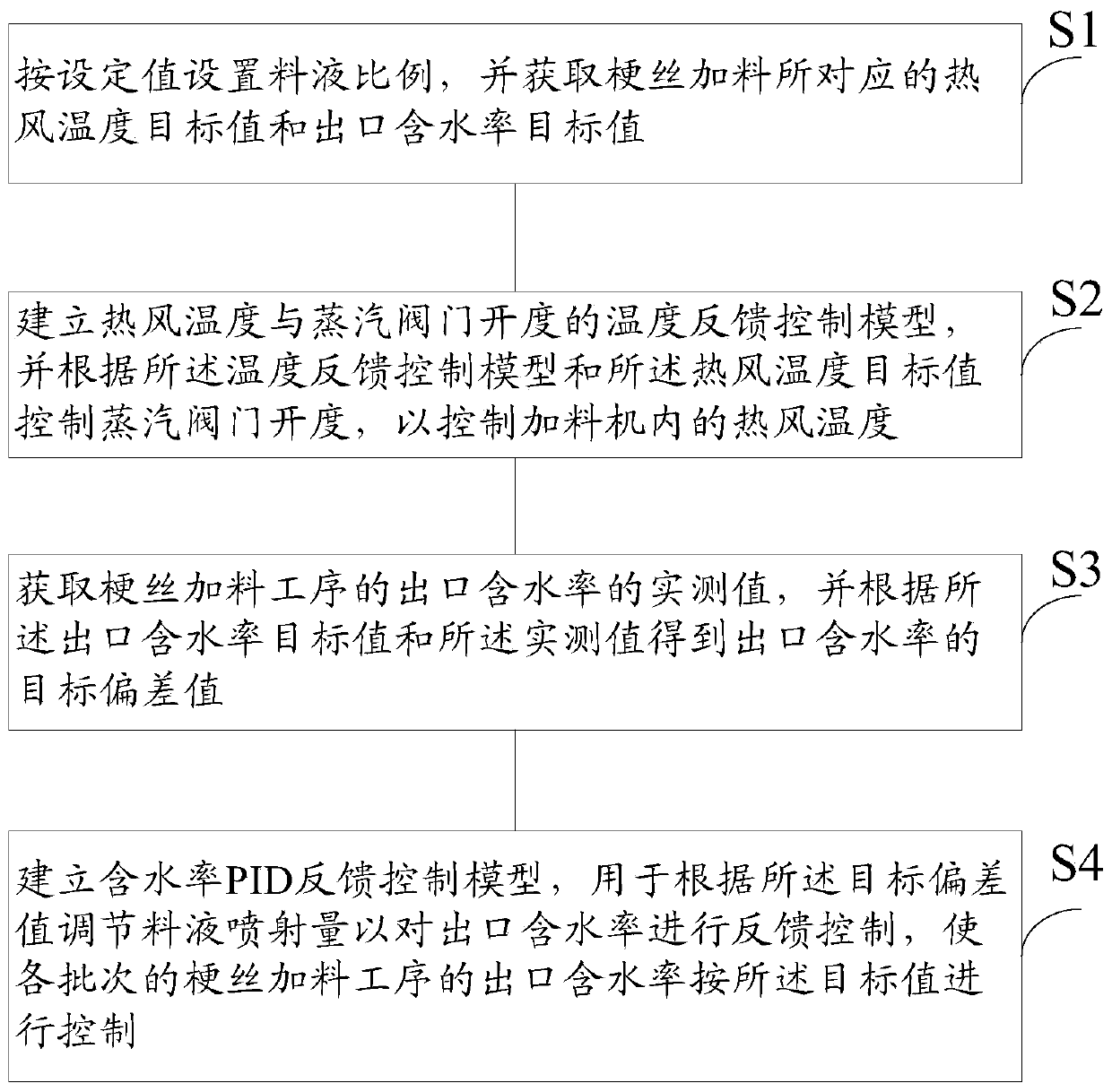

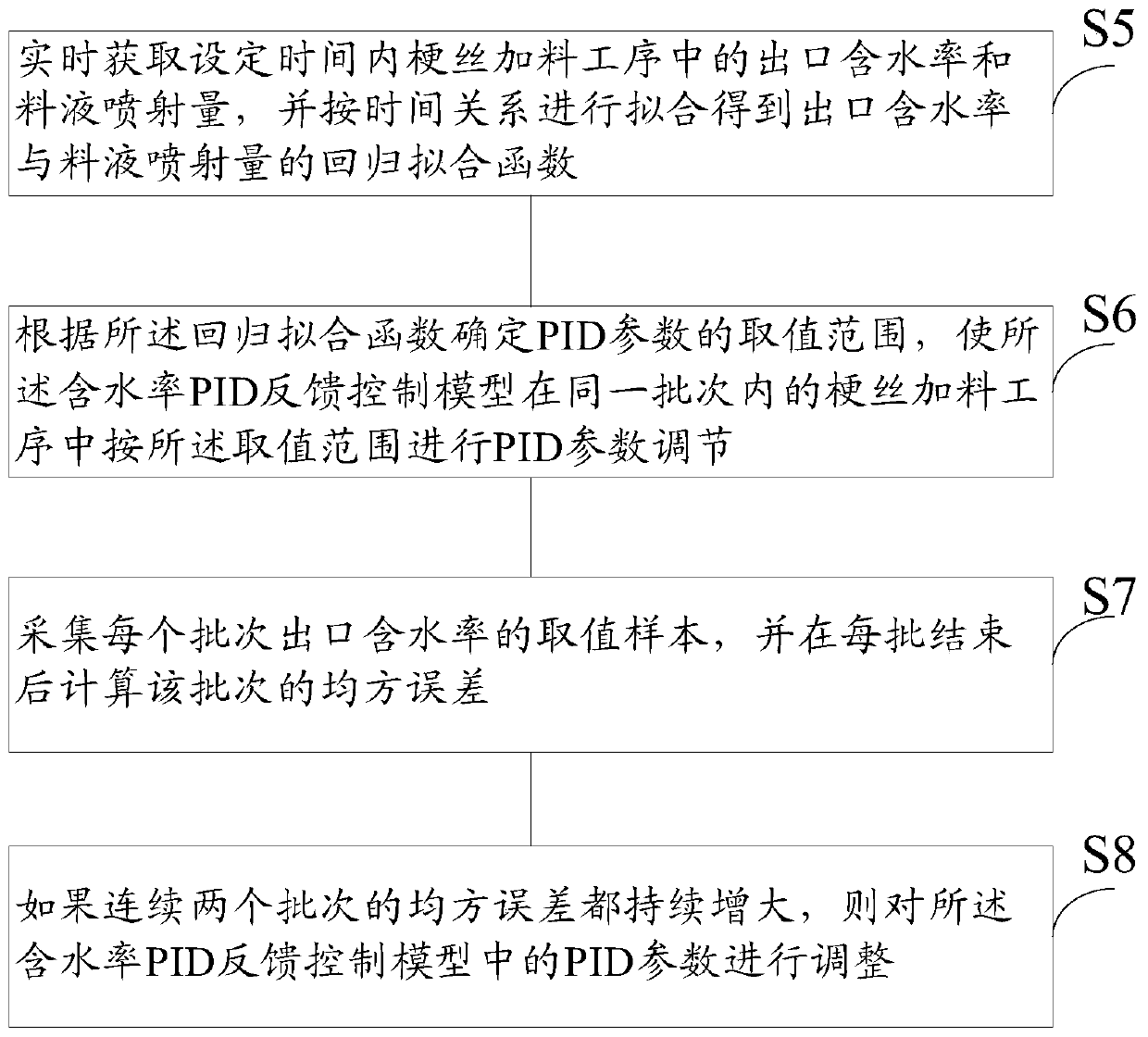

Cut stem feeding quality control method and system

ActiveCN110946311AImprove accuracyImprove stabilityTobacco preparationTobacco treatmentAgricultural scienceAgricultural engineering

The invention provides a cut stem feeding quality control method and system, and the method comprises the steps: setting a feed liquid proportion according to a set value, and obtaining a hot air temperature target value and an outlet moisture content target value corresponding to cut stems; establishing a temperature feedback control model of the hot air temperature and the steam valve opening degree, and controlling the steam valve opening degree according to the temperature feedback control model and the hot air temperature target value so as to control the hot air temperature in the charging machine; obtaining an actual measurement value of the outlet moisture content of the cut stem feeding process, and obtaining a target deviation value of the outlet moisture content according to thetarget value and the actual measurement value; and establishing a moisture content PID feedback control model for adjusting the feed liquid injection amount according to the target deviation value soas to perform feedback control on the outlet moisture content, so that the outlet moisture content of the cut stem feeding process of each batch is controlled according to the target value. The accuracy of the feed liquid proportion of cut stem feeding and the stability of the outlet moisture content can be improved, and the quality control capacity in the production process is improved.

Owner:CHINA TOBACCO HENAN IND

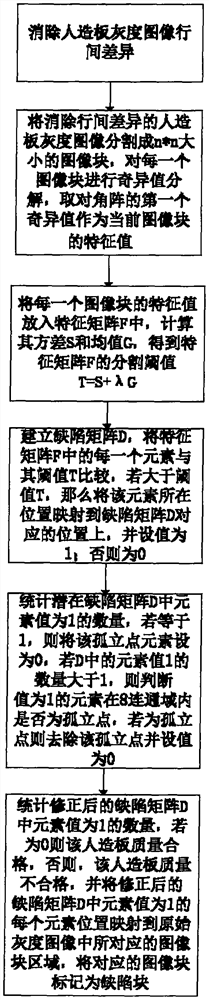

Artificial board surface defect detection method based on singular value decomposition

PendingCN112686890AImprove quality control abilityGuaranteed accuracyImage analysisSingular value decompositionAlgorithm

The invention discloses an artificial board surface defect detection method based on singular value decomposition. The method comprises the following steps: firstly, conducting inter-row difference elimination processing on an original gray image of an artificial board; segmenting the grayscale image with the inter-row difference eliminated into n * n image blocks, carrying out singular value decomposition on each image block, taking a first singular value of the diagonal matrix as a feature value of the selected image block, storing the feature value into a feature matrix F, and carrying out statistics on a variance S and a mean value G of the feature matrix F to obtain a segmentation threshold T of the feature matrix F, T = S + lambda G; establishing a potential defect matrix, comparing each element value in the feature matrix F with a segmentation threshold T, if the element value is greater than the segmentation threshold T, setting the element value at the position corresponding to the potential defect matrix as 1, otherwise, setting the element value as 0; carrying out isolated point correction on the potential defect matrix; and if the number of the corrected element values in the defect matrix is 0, judging that the artificial board is qualified, otherwise, judging that the artificial board is unqualified.

Owner:ZHEJIANG NORMAL UNIVERSITY

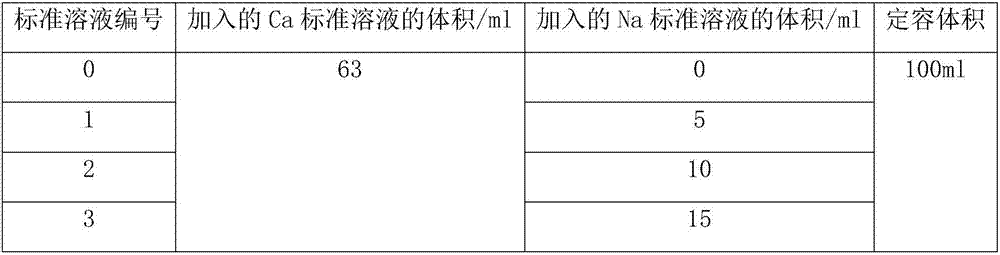

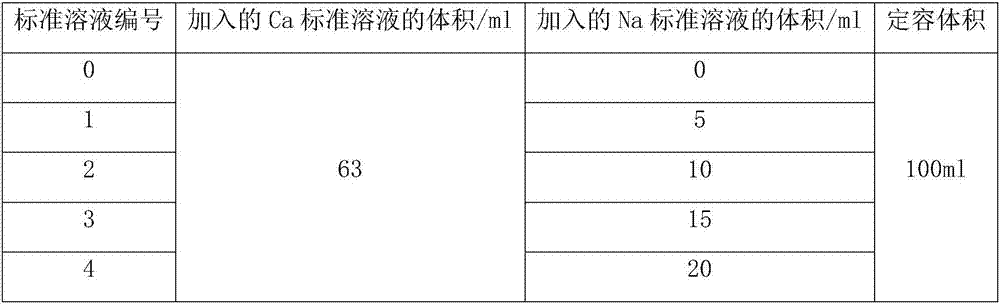

Method for determining sodium chloride in industrial calcium chloride

InactiveCN107367502AShorten the analysis cycleReduce labor intensityPreparing sample for investigationAnalysis by thermal excitationQuality processUltimate tensile strength

The present invention relates to a method for determining sodium chloride in industrial calcium chloride. According to the method, the sodium chloride content in industrial calcium chloride is determined by using an inductively coupled plasma atom emission spectrometer; and the method comprises: 1, drying a crucible, 2, preparing a sample solution, 3, preparing a blank solution, 4, preparing a series of standard sample solutions, 5, drawing a standard working curve, 6, determining the sodium contents in the sample solution and the blank solution, and 7, calculating the sodium chloride content in industrial calcium chloride through the following formula. According to the present invention, with the method, the analysis cycle is shortened, the labor intensity is reduced, the quality process control on the analysis result is improved, the laboratory analysis means is developed, the detection capability is improved, the consumption of chemical reagents is reduced, the waste liquid emission is reduced, the analysis cost is reduced, and other advantages are provided.

Owner:ANGANG STEEL CO LTD

Detection method of lipid-lowering and blood-circulation-promoting capsule

InactiveCN102507837AImprove testing standardsEasy to operateComponent separationBiotechnologyClematis

The invention discloses a detection method of a lipid-lowering and blood-circulation-promoting capsule. The lipid-lowering and blood-circulation-promoting capsule is a capsule preparation prepared from a prescription consisting of 100g of sicklesenna seed, 1,500g of curcuma, 2,000g of oriental water plantain, 500g of radix pseudoginseng and 2,000g of root of cream clematis. According to the detection method of the lipid-lowering and blood-circulation-promoting capsule, disclosed by the invention, a new improvement is carried out on a content determination standard such that science evidence is provided for authenticity judgment and quality control of products when the determination standard of the lipid-lowering and blood-circulation-promoting capsule is improved; furthermore, a sample test through the detection method is simple and convenient to operate based on repeated tests for many times; and based on continuous verification tests such as feminine interference and the like, no feminine interference exists, the reproducibility is excellent, and the exclusivity is strong; and the control capability on quality of the products is improved while the quality detection standard is improved.

Owner:唐秋海

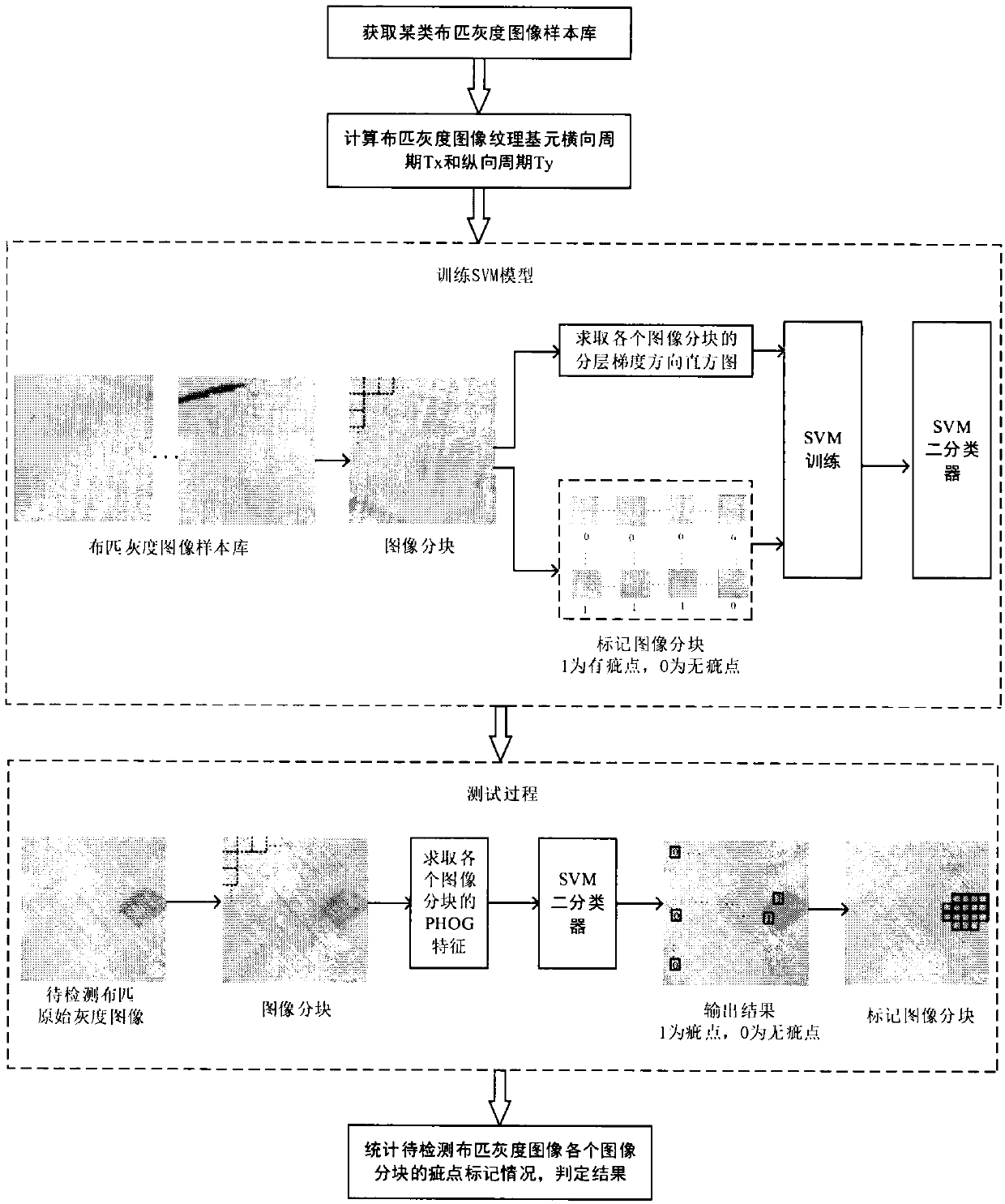

Cloth defect detection method using hierarchical gradient direction histogram and support vector machine

PendingCN110580698AGuaranteed accuracyRobustImage enhancementImage analysisGradient directionHistogram

The invention discloses a cloth defect detection method using a hierarchical gradient direction histogram and a support vector machine, relates to two aspects of feature extraction and learning classification, and belongs to the field of digital image processing application. The method mainly comprises the steps of image blocking, hierarchical gradient direction histogram feature extraction, support vector machine model training, detection classification and the like. The method comprises the following steps: firstly, partitioning a cloth image, then extracting the hierarchical gradient direction histogram characteristics of each block, then inputting the hierarchical gradient direction histogram characteristics into a trained support vector machine classifier, and judging whether each image block contains defects or not according to the output result of the classifier so as to determine whether the whole cloth image contains defects or not. Results show that the detection method has agood classification effect and certain robustness, and can be applied to actual generation.

Owner:ZHEJIANG NORMAL UNIVERSITY

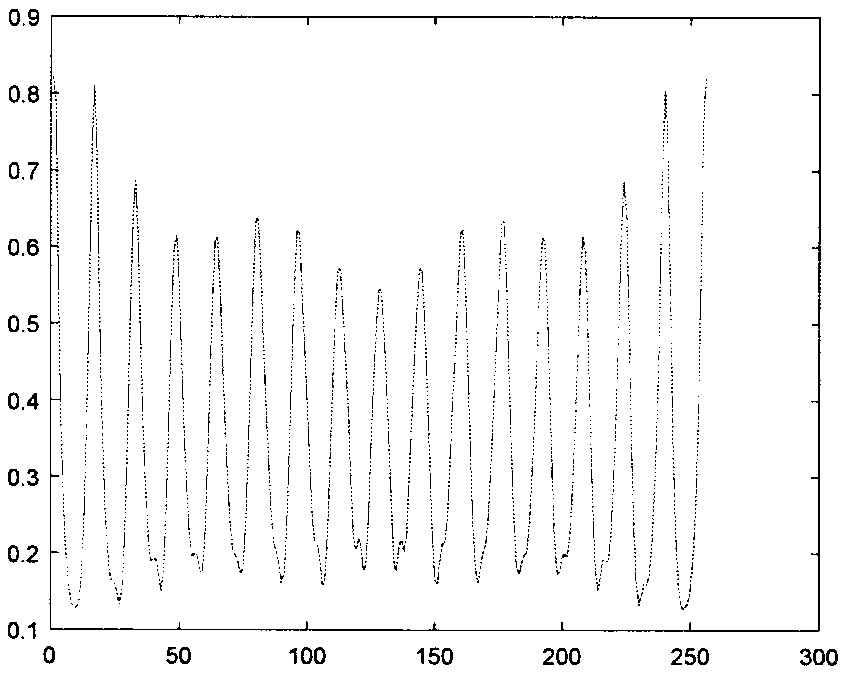

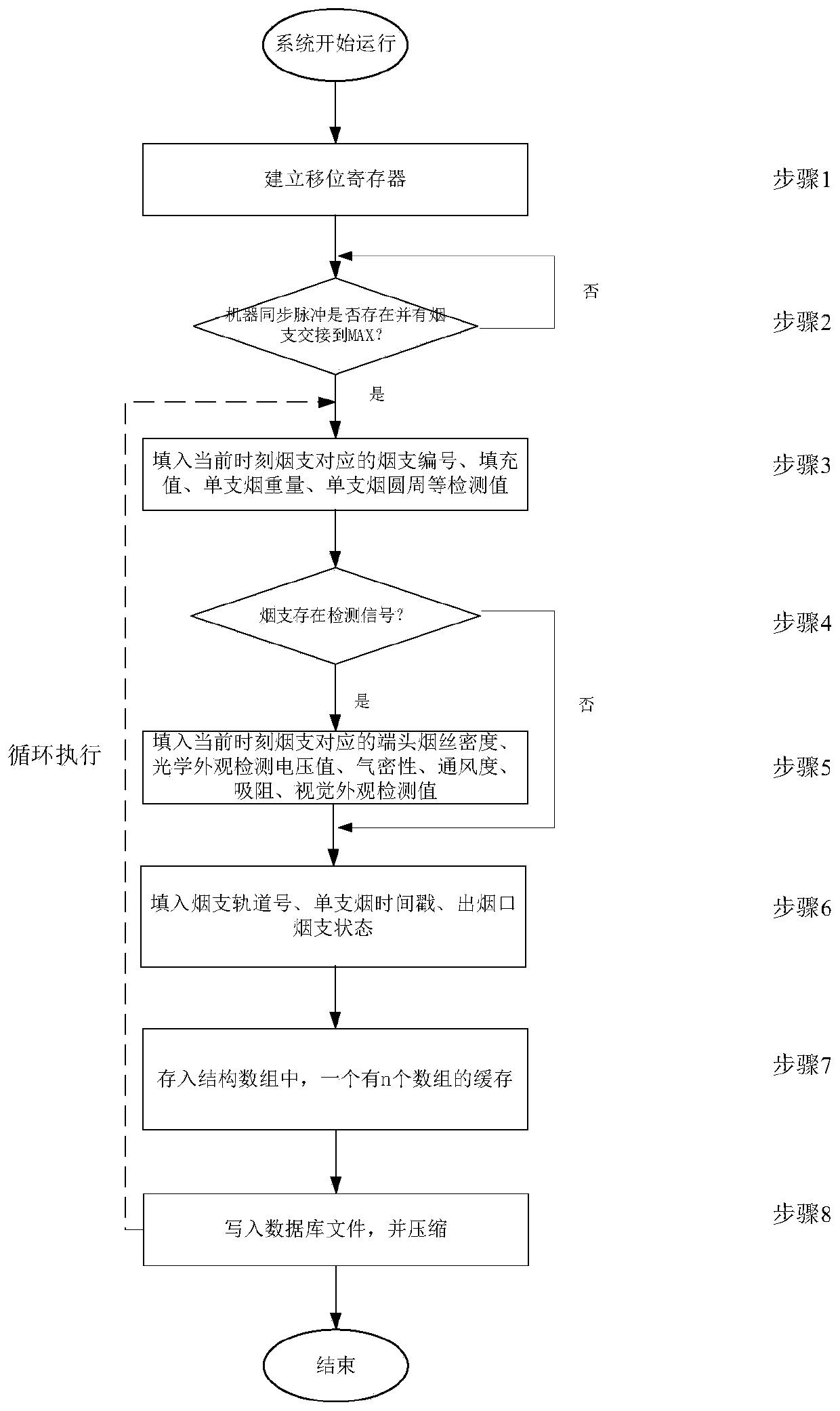

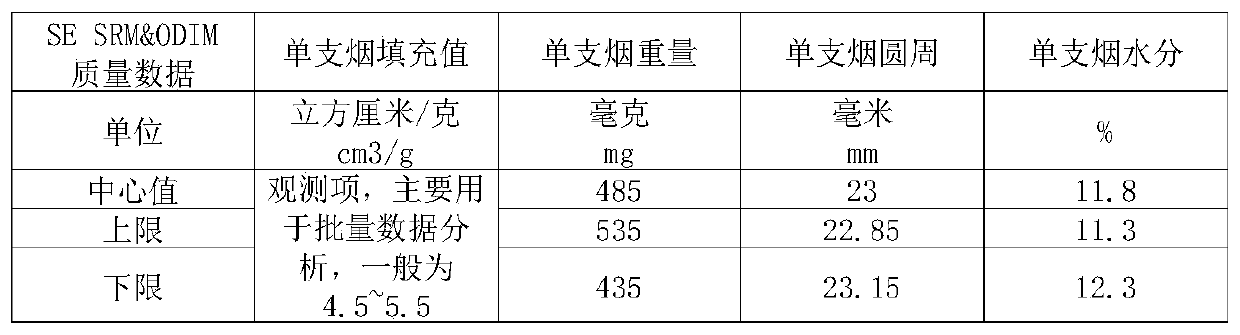

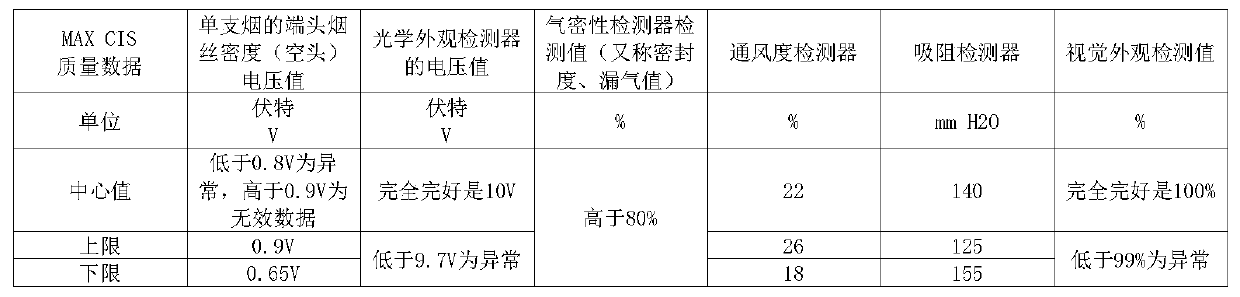

Method for online real-time single cigarette quality data one-by-one synchronization method during cigarette rolling process

ActiveCN109709921AImprove the level of optimizationShorten the design cycleProgramme total factory controlShift registerQuality data

The invention provides a method for online real-time single cigarette quality data one-by-one synchronization method during a cigarette rolling process. The method comprises the following steps: stepone, establishing a shift register; step two, monitoring a machine synchronization pulse and SE-to-MAX cigarette connecting signal continuously; step three, under the condition of existence of the synchronization pulse of the machine and the SE-to-MAX cigarette connecting signal, inputting a detecting value corresponding to the cigarette at a current time in an SE state into the shift register oneby one; step four, monitoring a cigarette existence detector of a MAX cigarette detection system continuously under the condition of continuous relay flowing of the cigarette at a MAX part; step five, representing imminent entrance of a cigarette into the cigarette detection system under the condition of having a rising edge in the cigarette existence detector signal and inputting a detecting value of the MAX cigarette detection system into the shift register one by one; step six, representing a state of arrival of the cigarette at a MAX outlet by a cigarette outlet sensor and inputting a cigarette track number, a time stamp, and a cigarette state one cigarette by one cigarette under the condition of having a rising edge signal by the sensor; step seven, carrying out caching; and step eight, carrying out compression.

Owner:CHINA TOBACCO ZHEJIANG IND

Intelligent quality control method and system

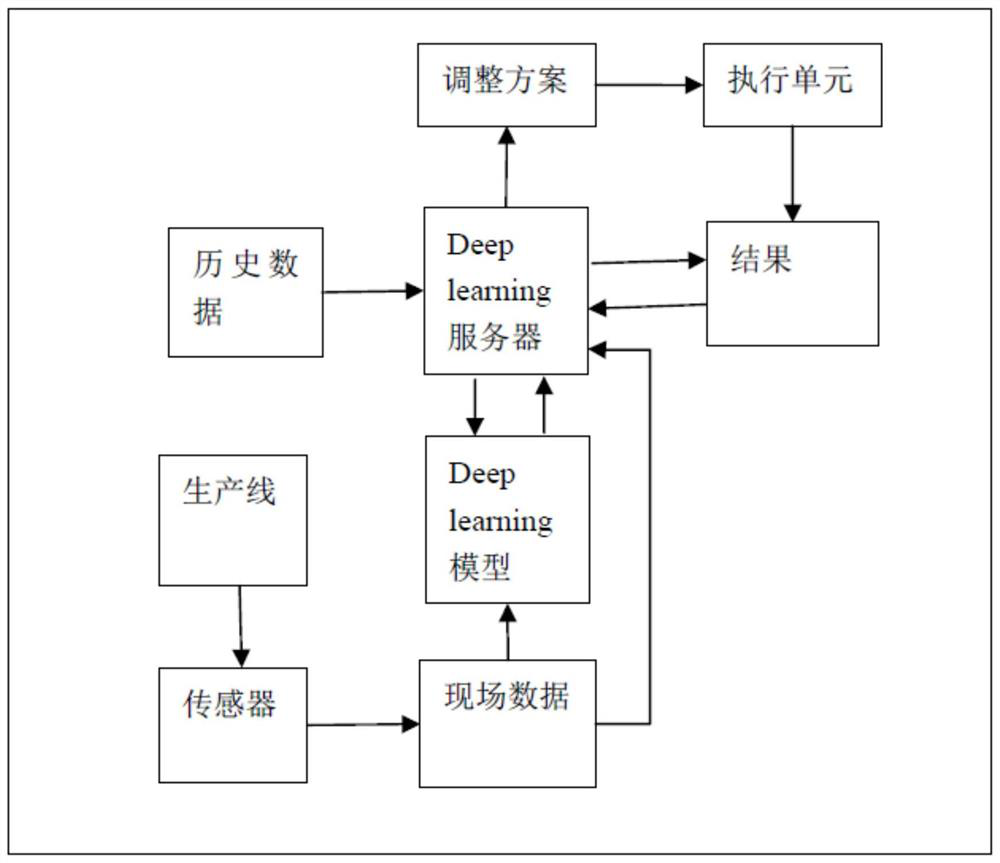

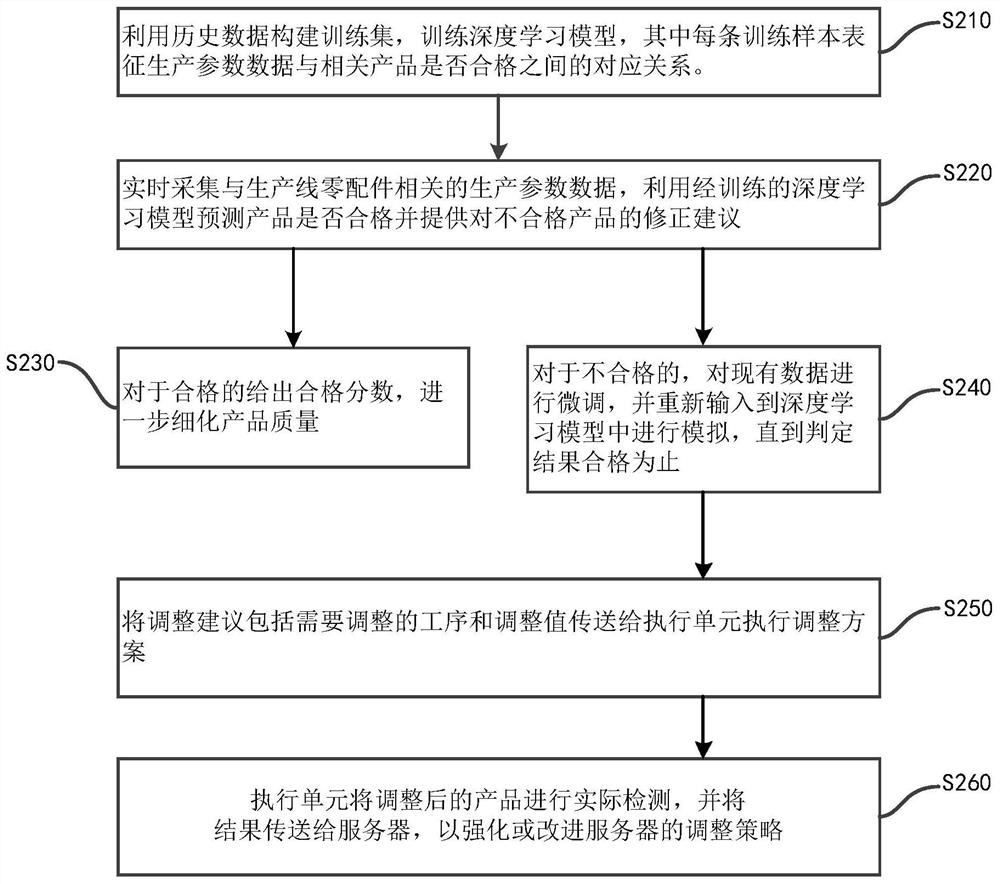

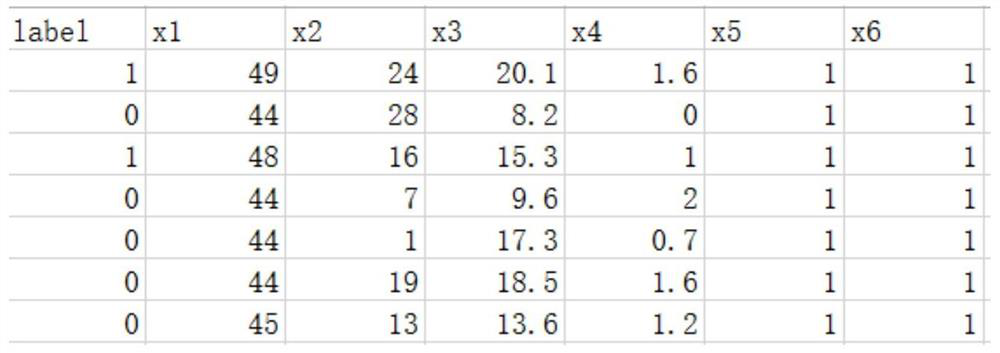

InactiveCN113435699AStrengthen or improve adjustment strategiesImprove quality control abilityForecastingResourcesProduction lineQuality control system

The invention discloses an intelligent quality control method and system. The method comprises the following steps: collecting production parameter data related to parts of a production line; inputting the production parameter data into a deep learning model, predicting whether products produced on site are qualified or not and outputting the result, giving qualified scores for the qualified products, refining the product quality further, giving correction suggestions for the unqualified products and transmitted to an execution unit for execution, conducting actual detection on the corrected products by the execution unit, and transmitting the result to the server so as to strengthen or improve the adjustment strategy of the server, wherein the deep learning model is obtained through training by taking a set loss function as a target, and each training sample represents a corresponding relation between the production parameter data and whether the related product is qualified or not. The method can be applied to actual production, predicts and guides a production result, enables a quality control system to be integrated and intelligent, and solves problems which cannot be solved by manpower.

Owner:SHENZHEN UNIV

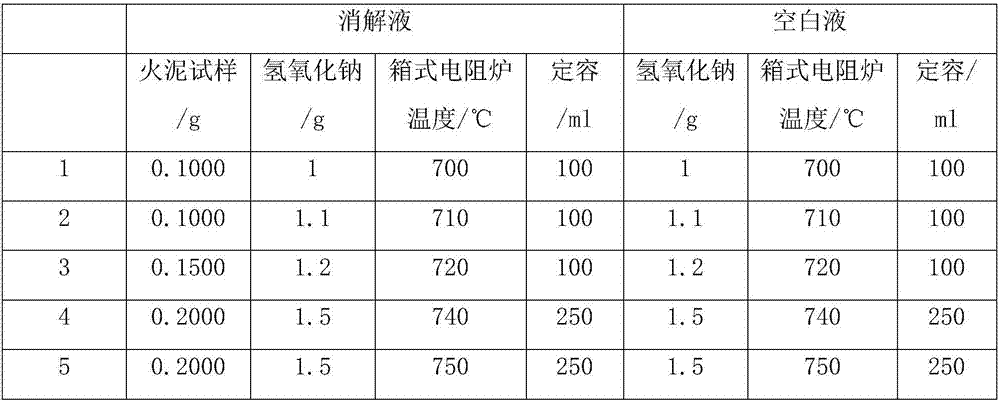

Method for determining chromium oxide in fire clay

ActiveCN107367503AShorten the analysis cycleReduce labor intensityAnalysis by thermal excitationQuality processUltimate tensile strength

The present invention relates to a method for determining chromium oxide in fire clay. The method comprises: digesting chromium oxide in fire clay by using an alkaline fusion method, carrying out a bland test to establish a standard working curve having a certain gradient, and determining the chromium oxide content in fire clay by using an inductively coupled plasma atom emission spectrometer. According to the present invention, with the method, the analysis cycle is shortened, the labor intensity of workers is reduced, the quality process control on the analysis result is improved, the laboratory analysis means is developed, the detection capability is improved, the consumption of chemical reagents is reduced, the waste liquid emission is reduced, and the analysis cost is reduced.

Owner:ANGANG STEEL CO LTD

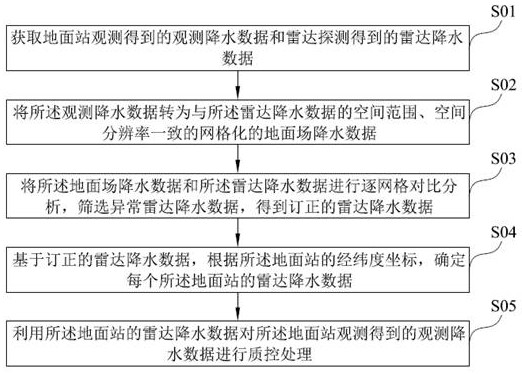

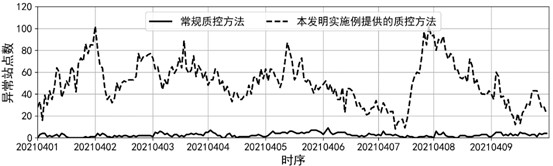

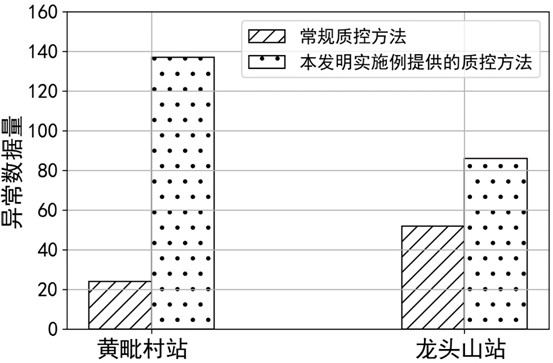

Precipitation data quality control method and device, storage medium and equipment

ActiveCN114114198AResolve uncertaintyImprove quality control abilityRainfall/precipitation gaugesDesign optimisation/simulationRadar rainfallData source

The invention provides a rainfall data quality control method and device, a storage medium and equipment. The method comprises the steps that observation rainfall data obtained through ground station observation and radar rainfall data obtained through radar detection are obtained; performing grid-by-grid comparative analysis on the ground field rainfall data and the radar rainfall data, and screening abnormal radar rainfall data to obtain corrected radar rainfall data; determining radar rainfall data of each ground station based on the corrected radar rainfall data; and performing quality control processing on observation rainfall data obtained by observation of the ground station by using radar rainfall data of the ground station. Through collaborative application of multi-source rainfall data and a space-time multi-scale quality control technology, the problem of uncertainty of a single data source is effectively solved, the rainfall data quality control effect and precision are further improved on the basis of guaranteeing real-time quality control processing time efficiency, a more accurate live rainfall data source is obtained, and the real-time rainfall data quality control method is suitable for popularization and application. And a foundation is laid for subsequent data processing and application analysis.

Owner:江西省气象信息中心

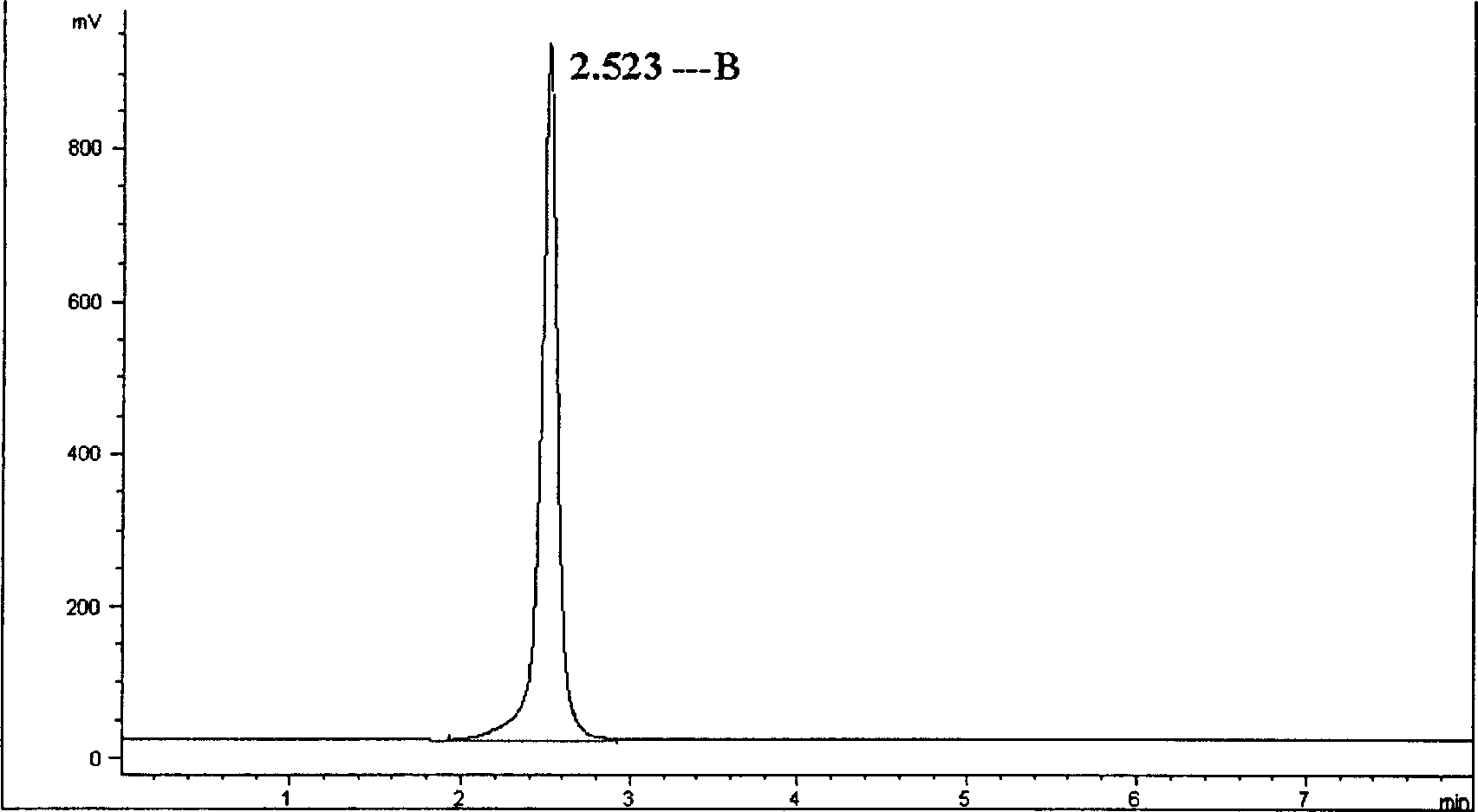

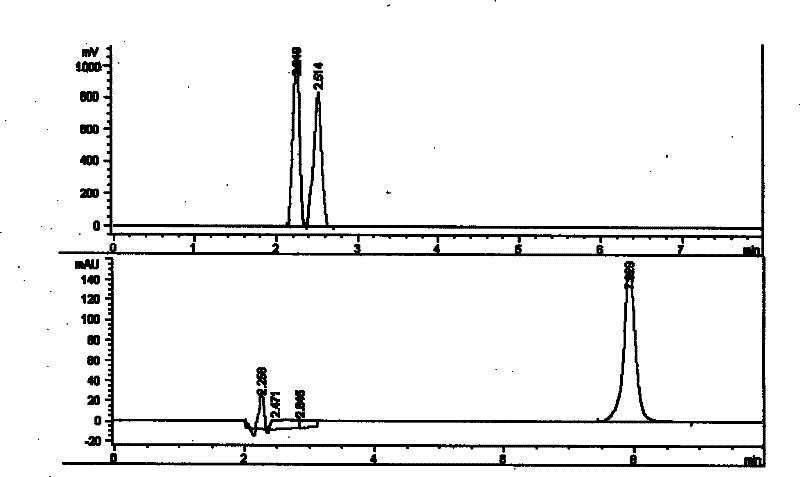

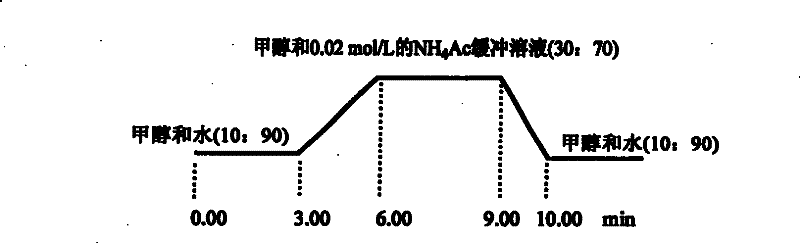

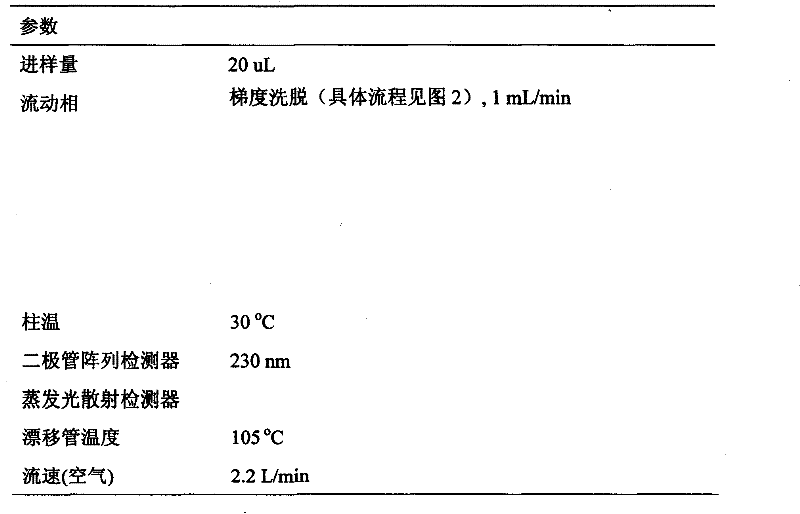

Method for detecting multi-brightener in liquid for brilliantly nickel plating

InactiveCN101363817BImprove quality control abilityAvoid the disadvantages that affect the stability of electroplating qualityComponent separationBiologyLight scattering

Aiming at the deficiency of the prior art, the invention provides an advanced and effective separation method and a detection technology, in particular to a combined detection method by utilizing liquid chromatogram-diode array-evaporative light scattering detector. One-time sample introduction is adopted, and simultaneously various brightener in bright nickel plating solution is detected. The accurate and effective detection for the content of the various brightener is realized, the quality control of the bright nickel plating is realized in the real sense, the method is reliable and rapid, and the operation is simple.

Owner:NINGBO INST OF TECH ZHEJIANG UNIV ZHEJIANG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com